Method for preparing air electrode

An air electrode and electrospinning technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of diffusion and transfer of unfavorable reaction products, increase the electrochemical polarization of air batteries, and hinder the diffusion of oxygen in catalysts, etc., to achieve The effect of slowing down the polarization phenomenon, reducing concentration polarization, good hydrophobicity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing an air electrode, comprising:

[0030] (1) A first diffusion layer and a second diffusion layer are formed on both sides of the current collector. Wherein, the first diffusion layer and the second diffusion layer are prepared by mixing activated carbon and polytetrafluoroethylene, which are permeated on both sides of the current collector. The current collector can be made of conductive materials with a honeycomb structure such as copper mesh and nickel mesh.

[0031] (2) The catalyst and the polymer solution are formulated into a spinning solution. Among them, the catalyst is selected from one or more of carbon-supported platinum, carbon-supported silver and carbon-supported manganese dioxide, and the polymer solution is selected from PVA or PVP, with a medium viscosity, a content of 10%, and an average molecular weight of 110,000 to 130,000 polymer, and the mass ratio of the catalyst to the polymer solution is 1:1-10.

...

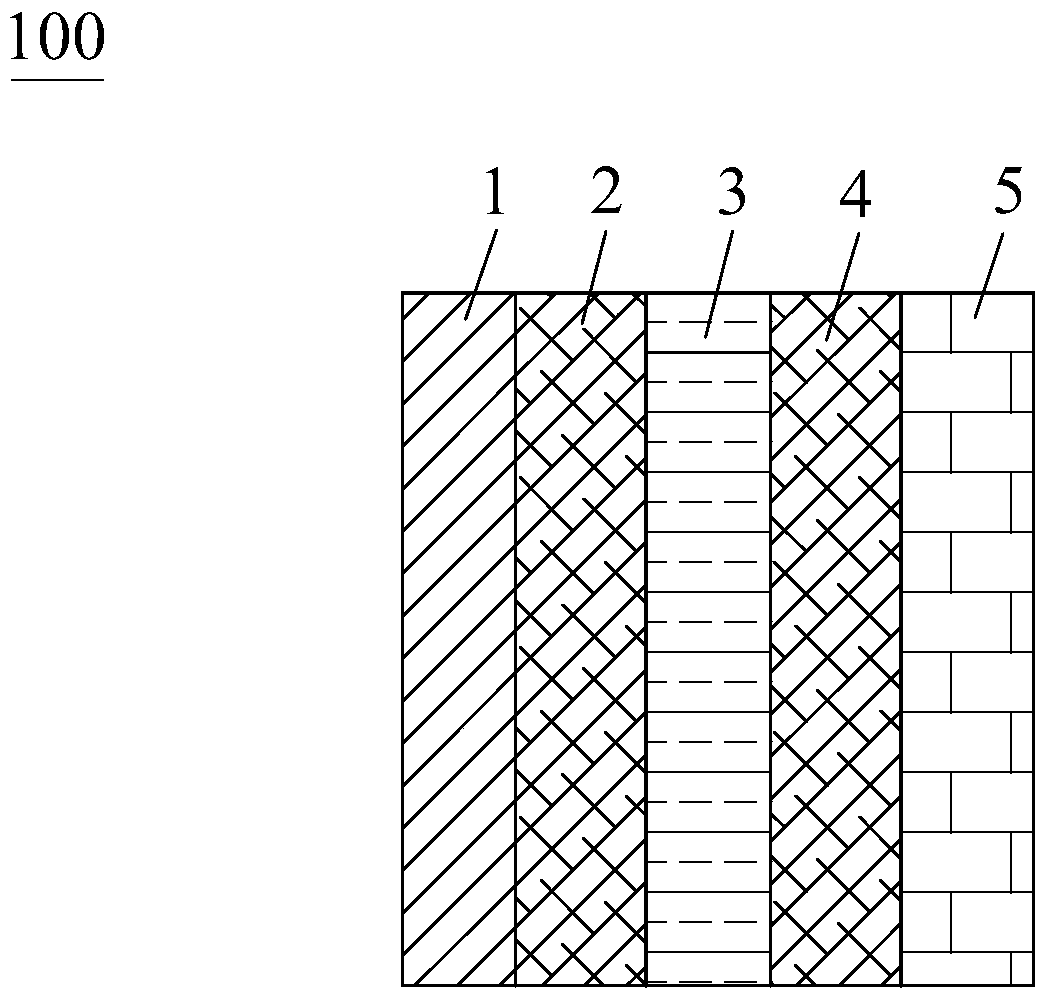

Embodiment 1

[0037] See figure 1 , the activated carbon and polytetrafluoroethylene are mixed and arranged, and permeated on both sides of the current collector 3 to form the first diffusion layer 2 and the second diffusion layer 4 . Weigh 5g of carbon-supported manganese dioxide and 50g of PVA solution, mix and magnetically stir for 4 hours to obtain the required spinning solution. Aspirate the spinning solution into a 5 mL glass syringe equipped with a 9# stainless steel needle and fix it on the syringe pump. The spray needle is connected to the positive pole of the high voltage power supply, and the collector is connected to the negative pole of the power supply. The flow rate of the spinning solution is controlled by a syringe pump, and the flow rate is 0.5 mL / h. When droplets appear at the needle, turn on the high-voltage power supply, set the injection voltage to 15kV, set the distance between the injection needle and the first diffusion layer 4 to 15cm, adjust the drum speed to 12...

Embodiment 8

[0039] In Example 8, except that the data shown in Table 1 are different from Example 1, the injection voltage is set to 5kV, the distance between the spray needle and the first diffusion layer is 10cm, the rotating speed of the drum is adjusted to 80rpm, and the spinning time is 20min.

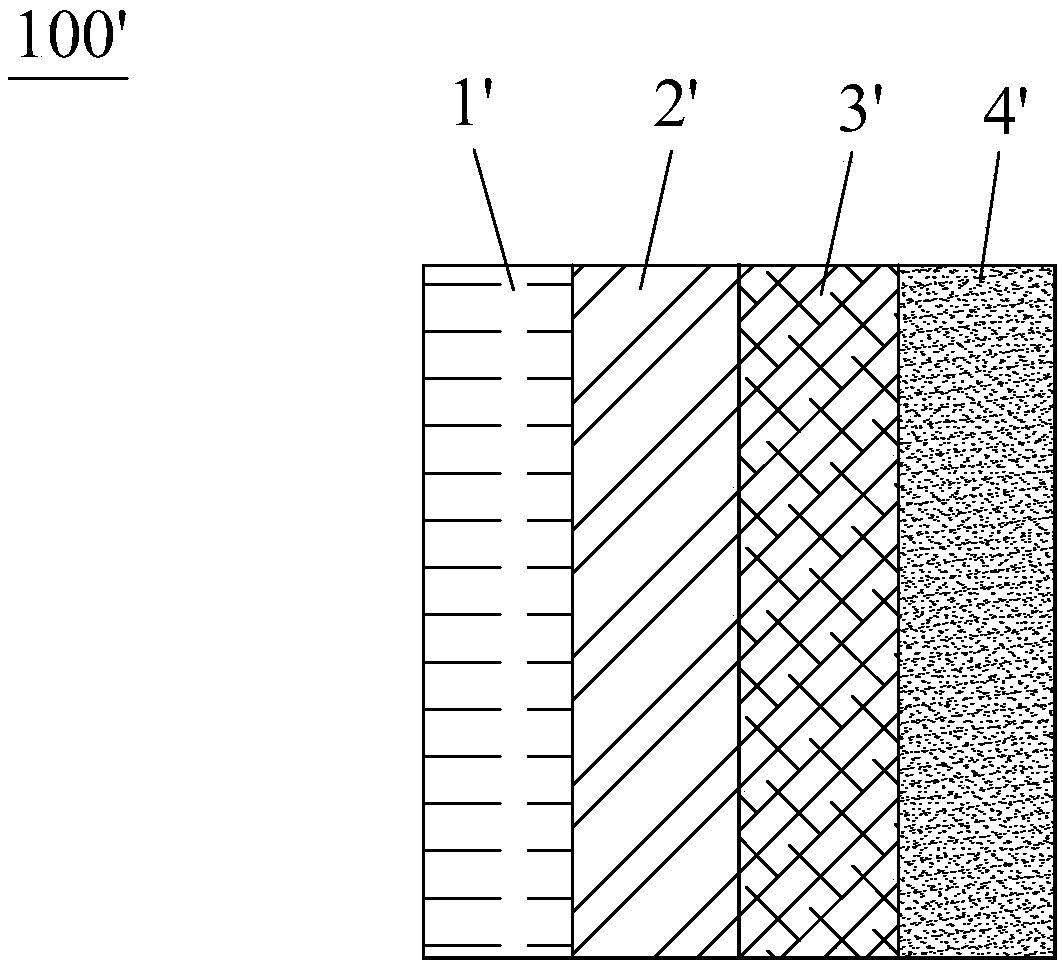

[0040] See figure 2 , in Comparative Example 1, a diffusion layer 2' is provided on one side of the current collector 3', and the catalyst carbon-supported platinum is mixed with the polymer solution at a mass ratio of 1:5 to prepare a spinning solution, which is then sprayed on the diffusion layer. Catalytic layer 1' is formed on layer 2', the injection voltage is set to 15kV, the distance between the spray needle and the first diffusion layer is 15cm, the rotating speed of the drum is adjusted to 120rpm, the spinning time is 40min, and the waterproof and breathable membrane is 4' placed on the side of the current collector 3', and rolled to obtain an air electrode 100'.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com