Porous Co3O4 monodisperse microsphere-loaded Au-Pd alloy nanocatalyst and preparation method thereof

A technology of monodisperse microspheres and alloy nanometers, applied in separation methods, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve simple preparation process, controllable specific surface area, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

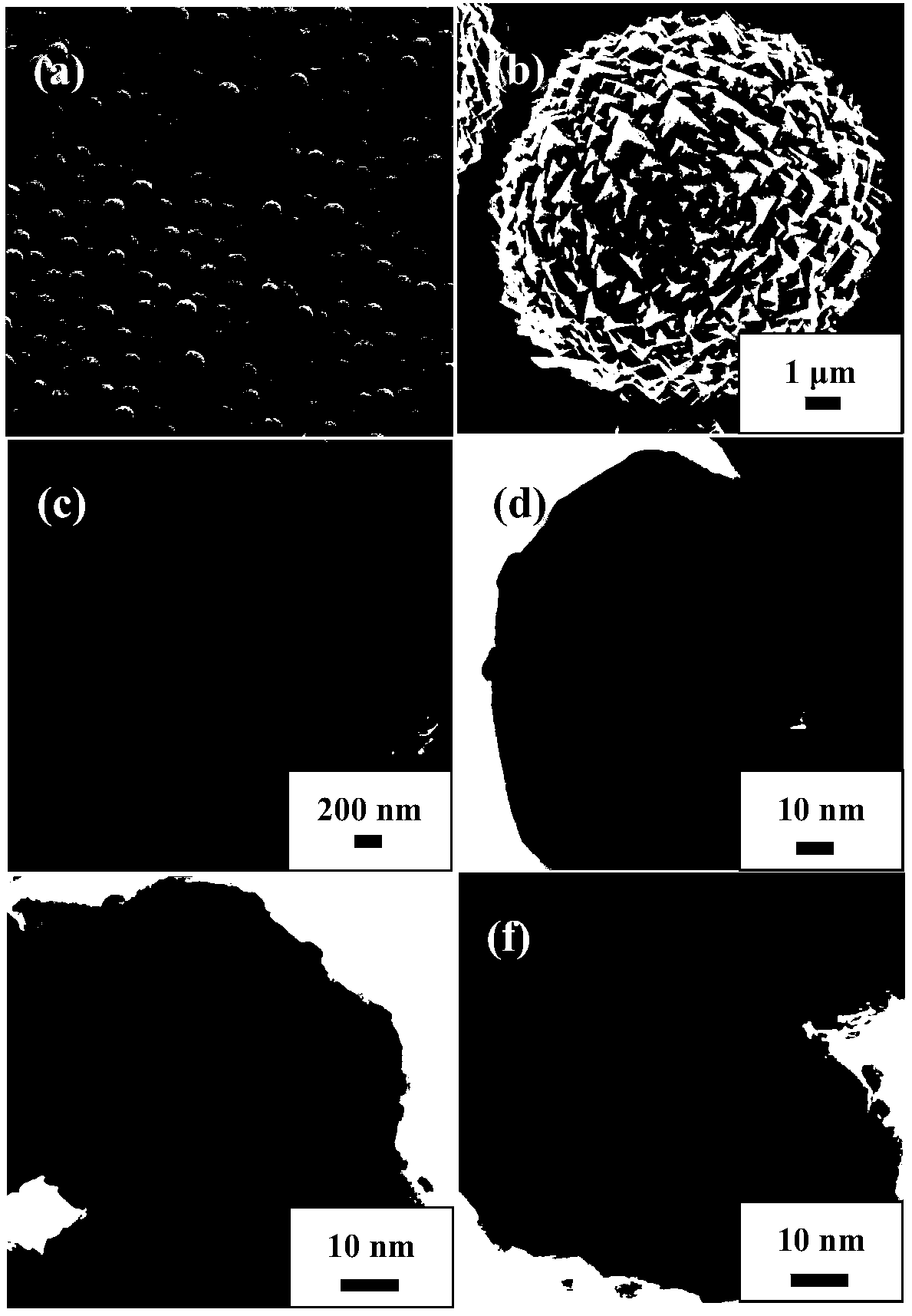

[0041] Porous Co prepared in Example 1 3 o 4 Monodisperse microspheres:

[0042] 1.0g CoCl 2 ·6H 2 Dissolve O in a mixed solution of 20mL deionized water, 60mL glycerol and 1.0g urea, and stir for 1h; transfer the obtained red solution into a 100mL polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal treatment at 120°C for 12h; The precipitate obtained after hydrothermal treatment was centrifuged, washed three times with absolute ethanol and deionized water, and dried in an oven at 80 ° C for 12 h; finally, the obtained magenta powder was roasted in an air atmosphere in a muffle furnace. Raise from room temperature to 500 °C at a rate of 1 °C / min and keep at this temperature for 3 h to obtain porous Co 3 o 4 Monodisperse microsphere carrier.

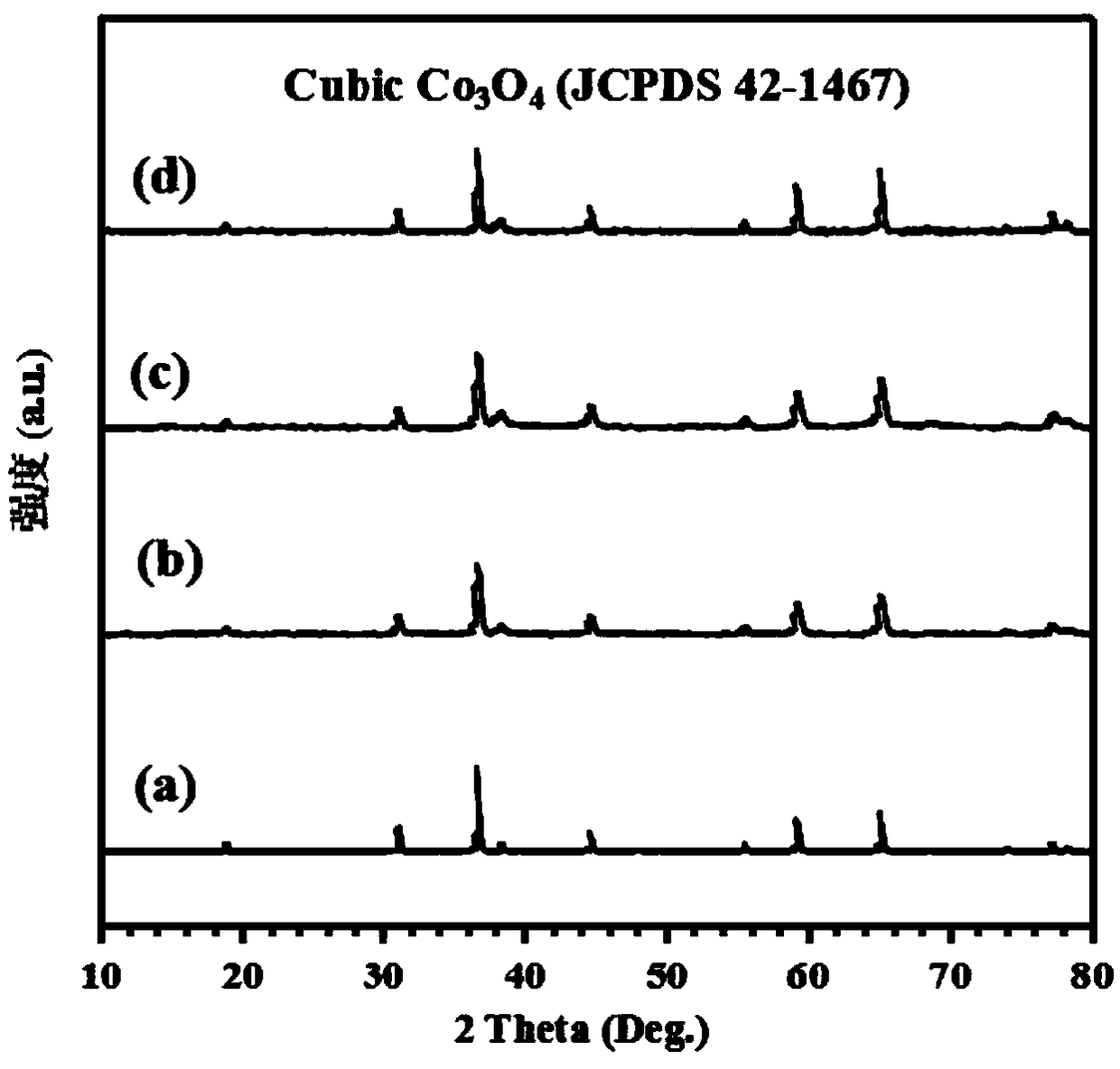

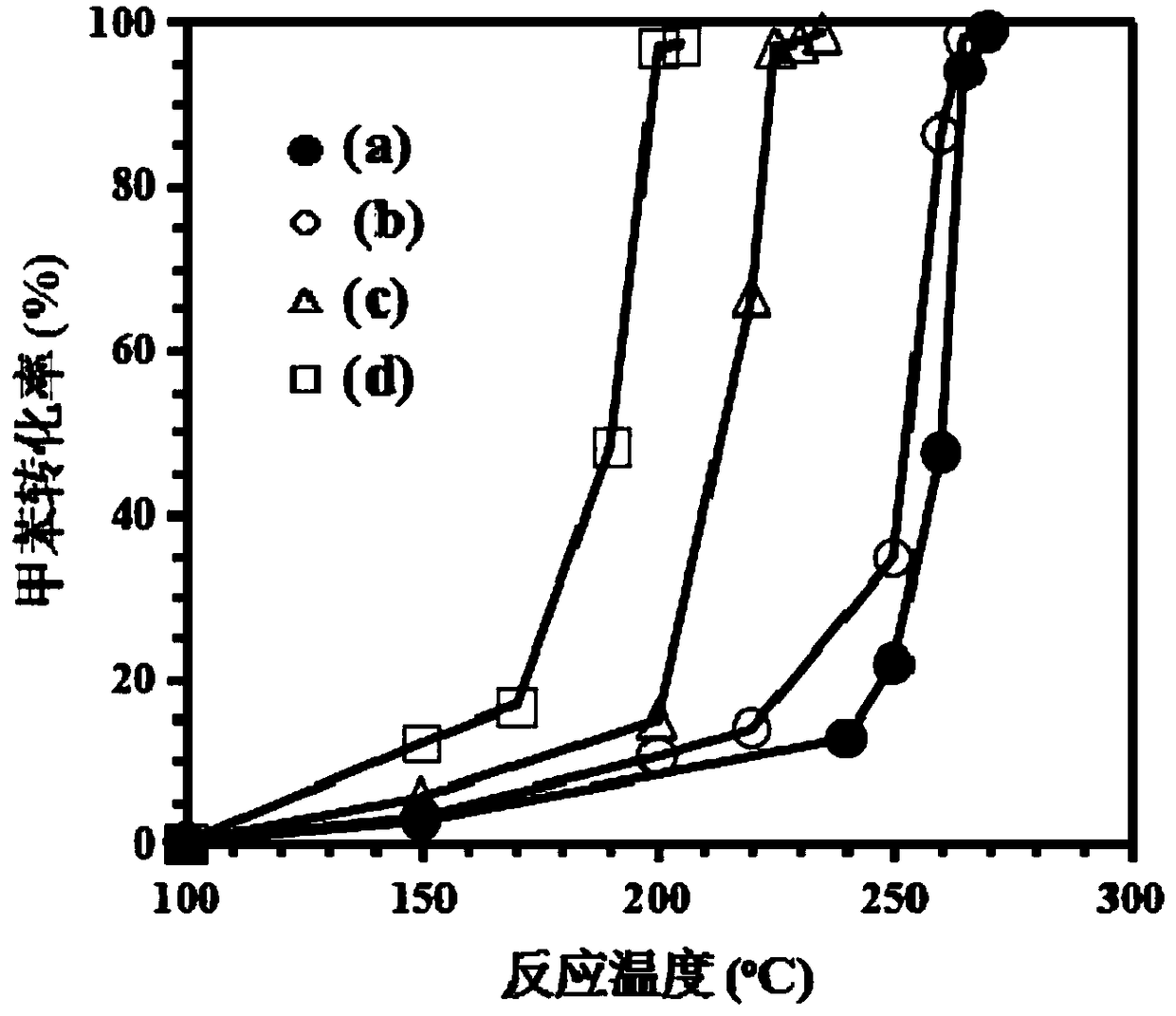

[0043] Wherein, the XRD spectrogram of the prepared sample is detailed in figure 1 Curve (a) in, after comparison with the standard XRD pattern of cobalt oxide sample, it can be known that the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com