Three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst and preparation method thereof

A composite oxide, mesoporous structure technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve cheap and easily available raw materials, controllable specific surface area, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

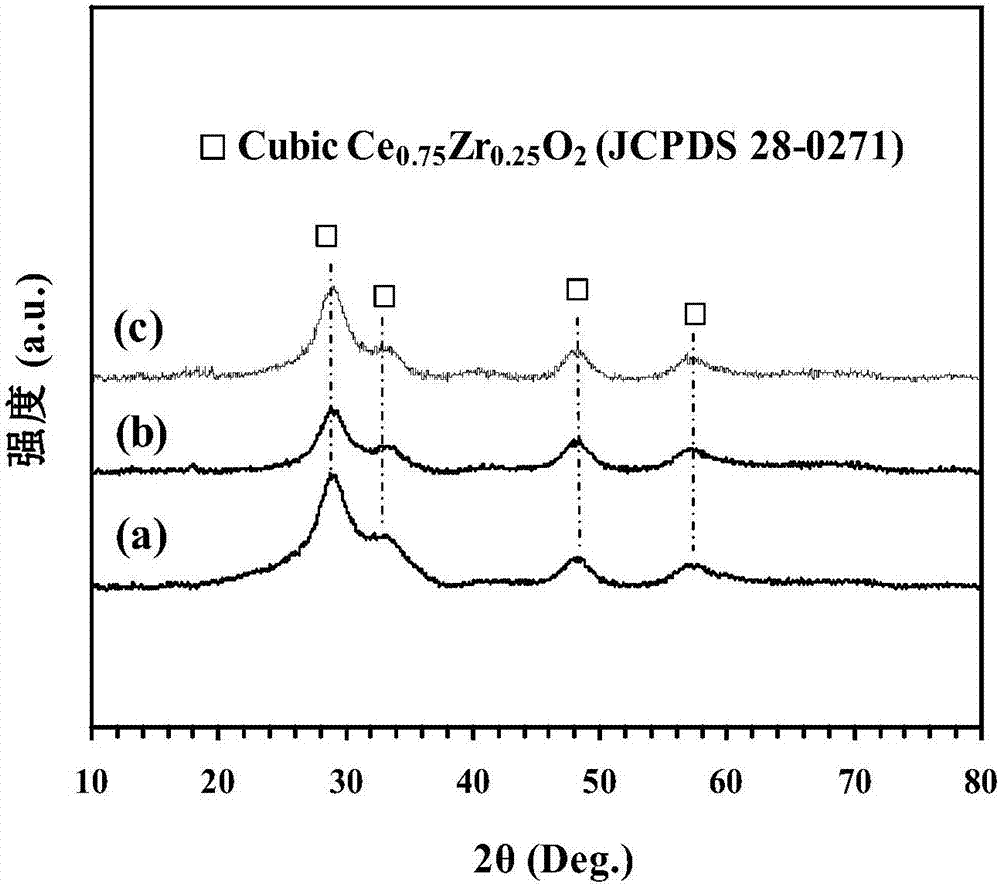

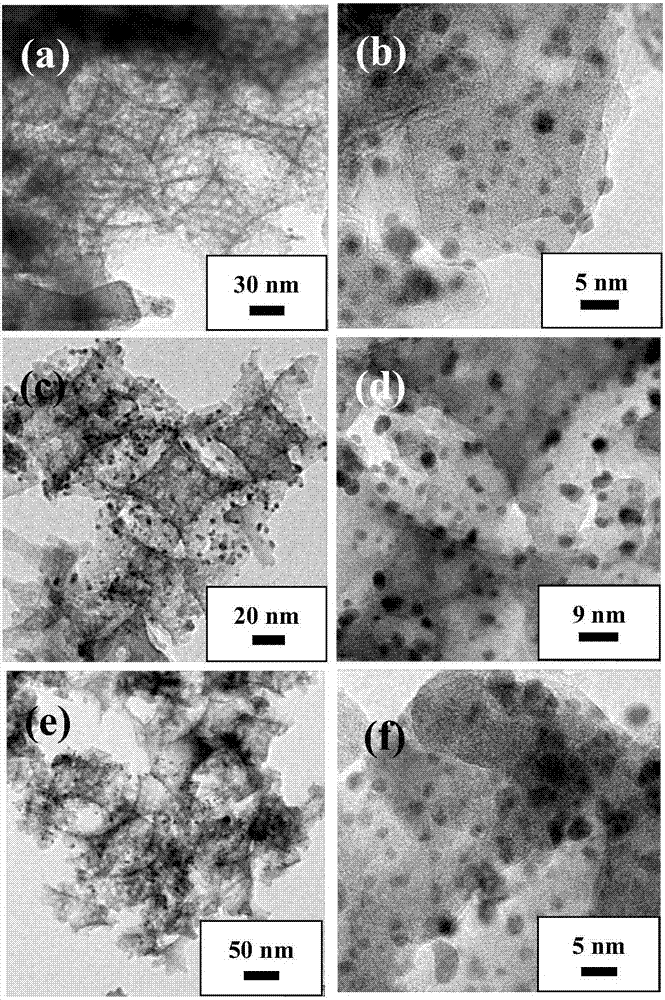

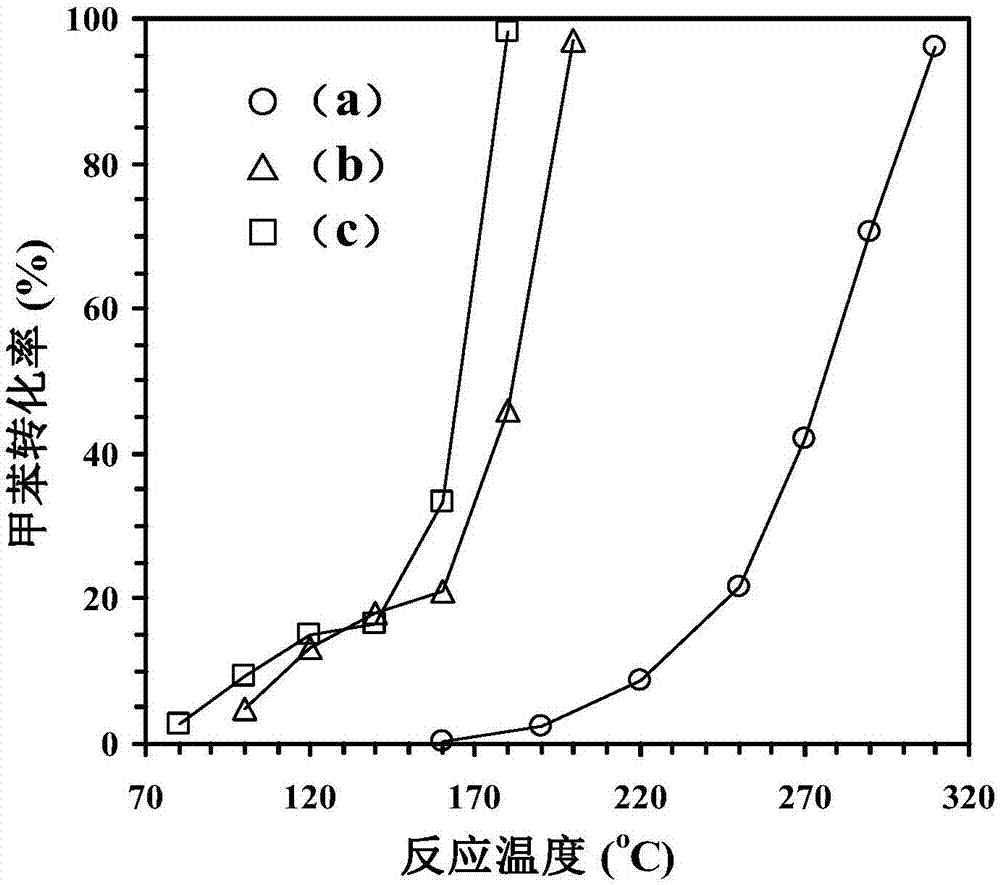

[0045] Preparation of Au / 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 :

[0046] (i) with HAuCl 4 Prepare a 0.01mol / L precious metal solution for the precious metal source;

[0047] (ii) Dilute a certain stoichiometric noble metal solution with deionized water to 2.0×10-4 mol / L concentration, add a certain amount of PVA to the above precious metal solution in an ice-water bath, the Au / PVA mass ratio is 1.0:1.5, and stir vigorously for 10 minutes;

[0048] (iii) Quickly inject 0.1mol / L NaBH 4 Aqueous solution, Au / NaBH 4 The molar ratio was 1.0:5.0, and the sol was obtained after continuous stirring for 20 min;

[0049] (iv) According to the theoretical Au loading of 0.5wt%, a certain amount of 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 The composite oxide carrier was added to the sol, and the obtained suspension was treated with ultrasonic waves (60kHz) for 30s, and the N 2 The bubbling operation stirred the suspension system for 10 hours until the colloidal gold ...

Embodiment 2

[0052] Preparation of Pt / 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 :

[0053] (i) with H 2 PtCl 6 Prepare a 0.01mol / L precious metal solution for the precious metal source;

[0054] (ii) Dilute a certain stoichiometric noble metal solution with deionized water to 2.0×10 -4 mol / L concentration, add a certain amount of PVA to the above precious metal solution in an ice-water bath, the mass ratio of Pt / PVA is 1.0:1.5, and stir vigorously for 10 minutes;

[0055] (iii) Quickly inject 0.1mol / L NaBH 4 Aqueous solution, Pt / NaBH 4 The molar ratio was 1.0:5.0, and the sol was obtained after continuous stirring for 20 min;

[0056] (iv) According to the theoretical Pt loading of 0.5wt%, a certain amount of 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 The composite oxide carrier was added to the sol, and the obtained suspension was treated with ultrasonic waves (60kHz) for 30s, and the N 2 The bubbling operation stirred the suspension system for 10 hours until the colloi...

Embodiment 3

[0059] Preparation of AuPt 2 / 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 :

[0060] (i) with HAuCl 4 、H 2 PtCl 6 Prepare a 0.01mol / L precious metal solution for the precious metal source;

[0061] (ii) Dilute a certain stoichiometric noble metal solution with deionized water to 2.0×10 -4 mol / L concentration, add a certain amount of PVA to the above precious metal solution in an ice-water bath, AuPt 2 / PVA mass ratio is 1.0:1.5, stir vigorously for 10min;

[0062] (iii) Quickly inject 0.1mol / L NaBH 4 Aqueous solution, AuPt 2 / NaBH 4 The molar ratio was 1.0:5.0, and the sol was obtained after continuous stirring for 20 min;

[0063] (iv) According to theory AuPt 2 The loading amount is 0.5wt%, and a certain amount of 3DOMacro-meso Ce 0.75 Zr 0.25 o 2 -Al 2 o 3 The composite oxide carrier was added to the sol, and the obtained suspension was treated with ultrasonic waves (60kHz) for 30s, and the N 2 The bubbling operation stirred the suspension system for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com