Preparation method of spherical lithium iron phosphate cathode material

A lithium iron phosphate, spherical technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of carbon doping or uneven coating dispersion, low electrical conductivity, low packing density, etc., to avoid uneven distribution of elements Uniformity, easy doping, and the effect of reducing multiple mixing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

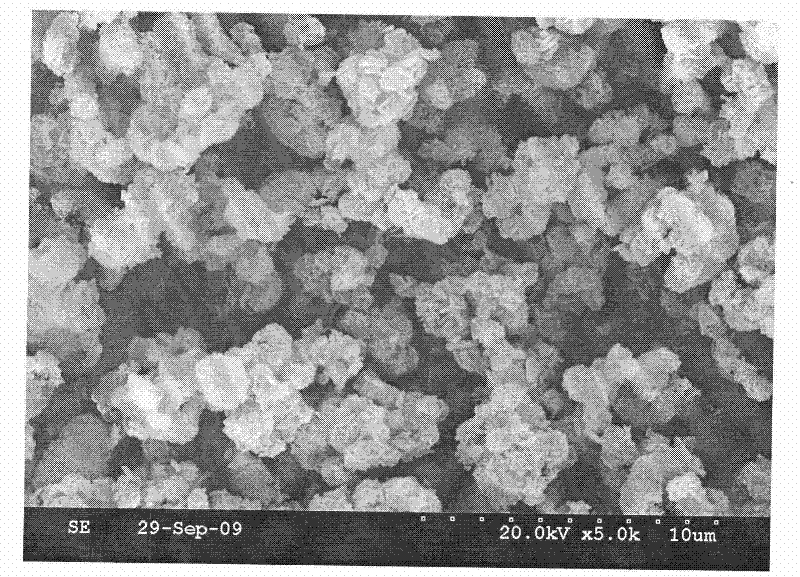

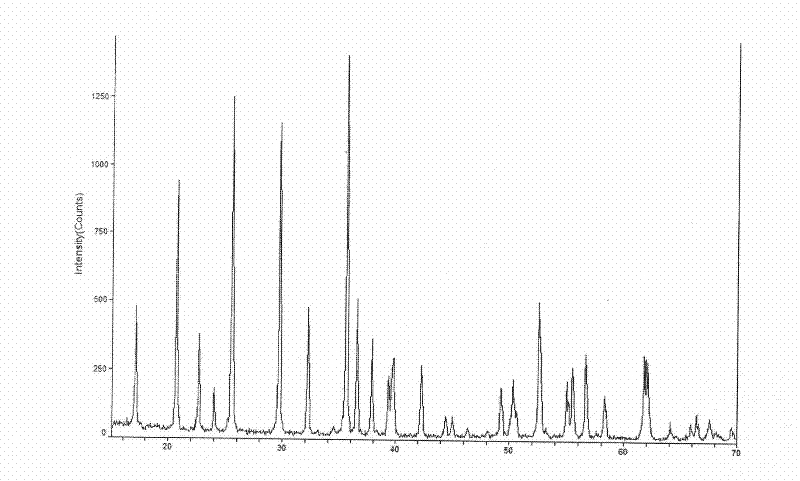

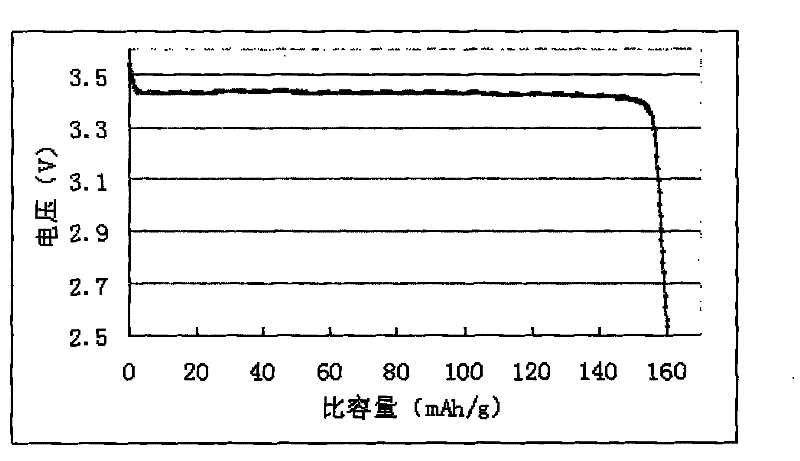

Embodiment 1

[0025] Weigh 1mol FeC 2 o 4 2H 2 O, 1mol H 3 PO 4 , 1mol of LiOH·H 2 O and 0.008mol V 2 o 3 Prepare 1mol / L, 1mol / L, 1mol / L, 0.008mol / L solutions, and add them into a 10L reaction kettle with an overflow port through a metering pump at a flow rate of 15mL / min, and simultaneously add 3mol / L ammonia water and 2mol / L sodium borohydride are added into a 10L reaction kettle with an overflow port at a flow rate of 5-10mL / min and 15mL / min respectively. Adjust the pH value of the reaction solution to 3.5, control the stirrer speed to 220r / min, and keep the temperature in the reactor at 70°C to make it D 50 The suspension of spherical lithium iron phosphate precursor >3 μm flows out from the overflow port.

[0026]Then it is carried out surface coating treatment according to the following scheme: take polytetrafluoroethylene (PTFE) by spherical lithium iron phosphate precursor: polytetrafluoroethylene=15:1 (wt%), add water and be made into 70% floating liquid ( wt%), according ...

Embodiment 2

[0030] Weigh 1molFeO, 1molH 3 PO 4 , 1mol LiOH·H 2 O and 0.01mol Mg(CH 3 COO) 2 9H 2 O is made into solutions of 1mol / L, 1mol / L, 1mol / L, and 0.01mol / L, and are added into a 10L reaction kettle with an overflow port through a metering pump at a flow rate of 15mL / min, and 3mol / L of Add ammonia water and 2mol / L ascorbic acid into a 10L reaction kettle with an overflow port at a flow rate of 5-10mL / min and 15mL / min respectively. Keep the pH value of the reaction solution at 4, control the stirrer speed to 200r / min, and keep the temperature in the reactor at 85°C to make it D 50 The suspension of the spherical lithium iron phosphate precursor >2 μm flows out from the overflow port.

[0031] Then it is carried out surface coating treatment according to the following scheme: take by weighing styrene-butadiene rubber (SBR) by spherical lithium iron phosphate precursor: styrene-butadiene rubber=16: 1wt%, add water and be made into 65% floating liquid (wt%), press Lithium iron ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com