Semi-dry circulating cyclone bed desulfurizing tower

A technology of desulfurization tower and swirling bed, which is applied in the field of circulating swirling bed semi-dry flue gas desulfurization, which can solve the problems of small flow field shear force, low air turbulence intensity, and low utilization rate of desulfurization agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

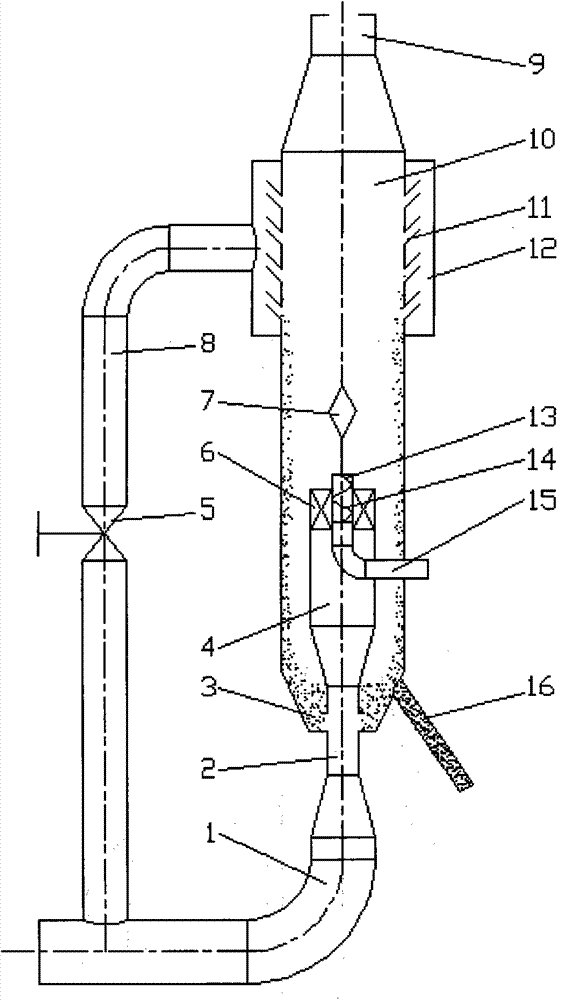

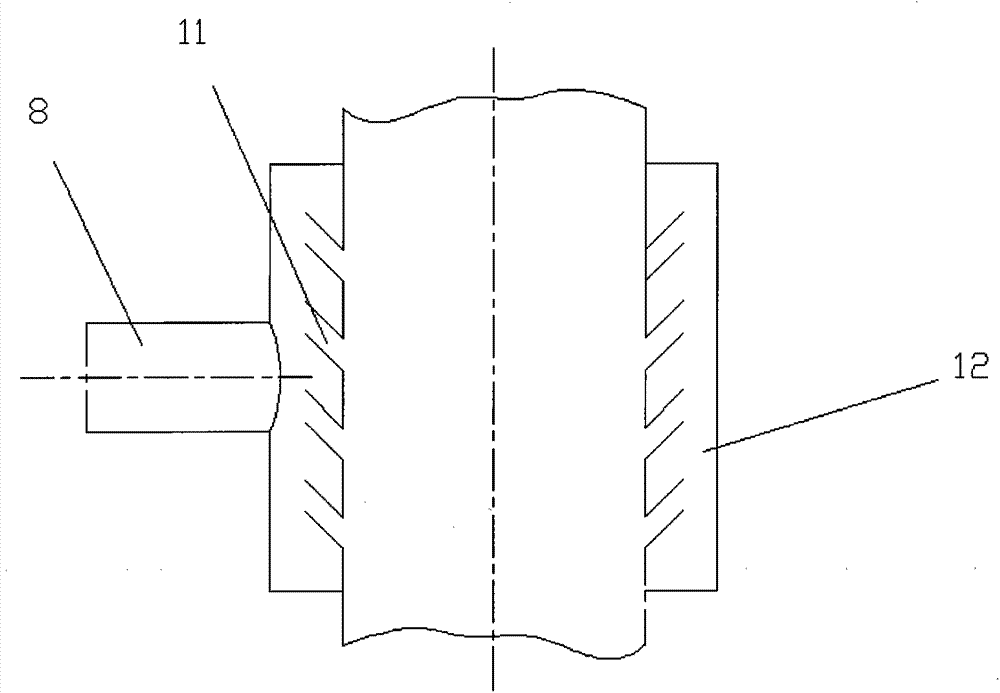

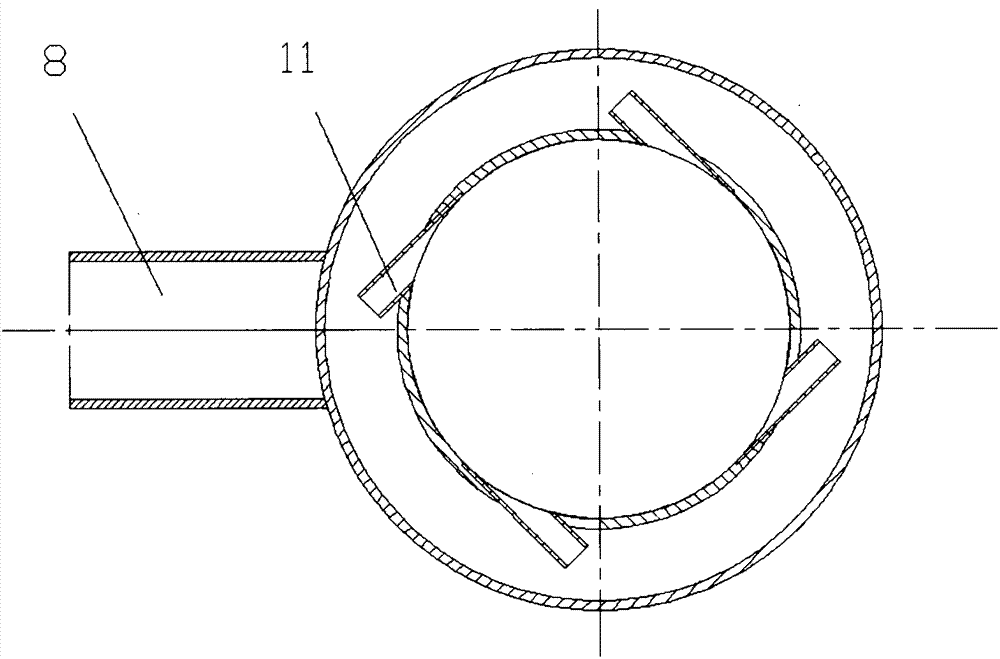

[0031] figure 1 It is the structural diagram of the circulating swirl bed desulfurization tower. When a semi-dry circulating swirling bed desulfurization tower of the present invention is used, the flue gas enters the circulating desulfurization reactor (4) from the flue gas inlet pipe (1) through the Venturi tube (2). Due to the suction effect of the Venturi tube (2), the absorbent particles in the dust chamber are drawn into the circulating desulfurization reactor (4). A guide vane (6) is arranged at the outlet of the circulating desulfurization reactor (4) to form a rotation when the flue gas flows out, so that a strong rotating flow field is formed in the circulating fluidized bed desulfurization tower. The fresh desulfurization absorbent is ejected from the desulfurization absorbent outlet pipe (13) in the center of the circulating desulfurization reactor (4) located at the center of the bottom of the desulfurization tower, and shoots to the distributor (7). The materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com