Preparation method of compound zirconium oxide

A technology of zirconia and zirconia oxychloride, which is applied in the field of preparation of chemical materials, can solve the problems of poor mixing uniformity of composite zirconia materials and difficult control of crystal structure, and achieve excellent mechanical properties, controllable crystal structure, and specific surface area. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

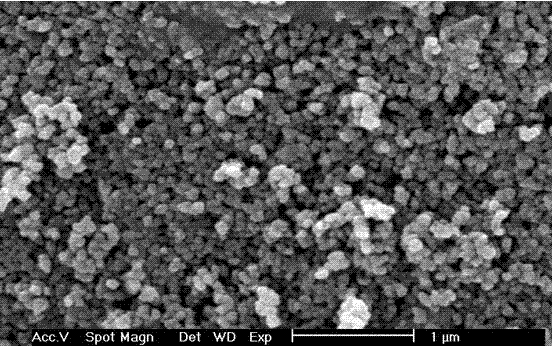

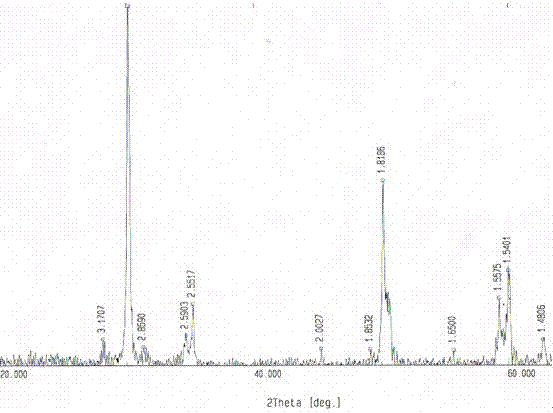

Image

Examples

Embodiment 1

[0010] a. Control the concentration of the zirconium oxychloride solution before feeding to be 0.3mol / L, and the concentration of ammonia water is controlled to be: 1.6mol / L;

[0011] b. Add ammonia water dropwise to the zirconia solution to react, control the molar ratio of ammonia water to zirconia to 2.0:1, control the reaction temperature to 55°C, control the flow rate to 1800L / h, keep the temperature for 1hr after adding the ammonia water dropwise, and react After completion, zirconium hydroxide hydrogel is generated;

[0012] c. washing the zirconium hydroxide hydrogel with deionized water, and obtaining the zirconium hydroxide colloid through pressure filtration;

[0013] d. Dry the zirconium hydroxide gel at 200°C, and then powder it to obtain powdery zirconium oxide;

[0014] e. Mix powdery zirconia, yttrium oxide, and small materials, wherein the addition amount of yttrium oxide is 4.5%, the amount of small materials is 0.2%, and the mixing time is 5h;

[0015] f. ...

Embodiment 2

[0018] a. Control the concentration of zirconium oxychloride solution before feeding to 0.7mol / L, and the concentration of ammonia water to 2.4mol / L

[0019] b. Add ammonia water dropwise to the zirconia solution to react, control the molar ratio of ammonia water to zirconia to 3.0:1, control the reaction temperature to 70°C, control the flow rate to 2500L / h, keep the temperature for 2hr after adding the ammonia water dropwise, and react Zirconium hydroxide hydrogel is generated upon completion;

[0020] c. washing the zirconium hydroxide hydrogel with deionized water, and obtaining the zirconium hydroxide colloid through pressure filtration;

[0021] d. Dry the zirconium hydroxide gel at 500°C, and then powder it to obtain powdered zirconium oxide;

[0022] e. Mix powdery zirconia, yttrium oxide, and small materials, wherein the addition amount of yttrium oxide is 6.5%, the amount of small materials is 0.6%, and the mixing time is 10h;

[0023] f. After the mixing is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com