Patents

Literature

36 results about "Zirconium(IV) hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium (IV) hydroxide, often called hydrous zirconia is an ill-defined material or family of materials variously described as ZrO₂.nH₂O and Zr(OH)₄.nH₂O. All are white solids with low solubility in water. These materials are widely employed in the preparation of solid acid catalysts. These materials are generated by mild base hydrolysis of zirconium halides and nitrates. A typical precursor is zirconium oxychloride.

Coarse-grained sphere-like zirconium hydroxide with large specific surface area and preparation method of zirconium hydroxide

ActiveCN105502490ALow impurity contentUniform particle sizeZirconium compoundsZirconium hydridePotassium hydroxide

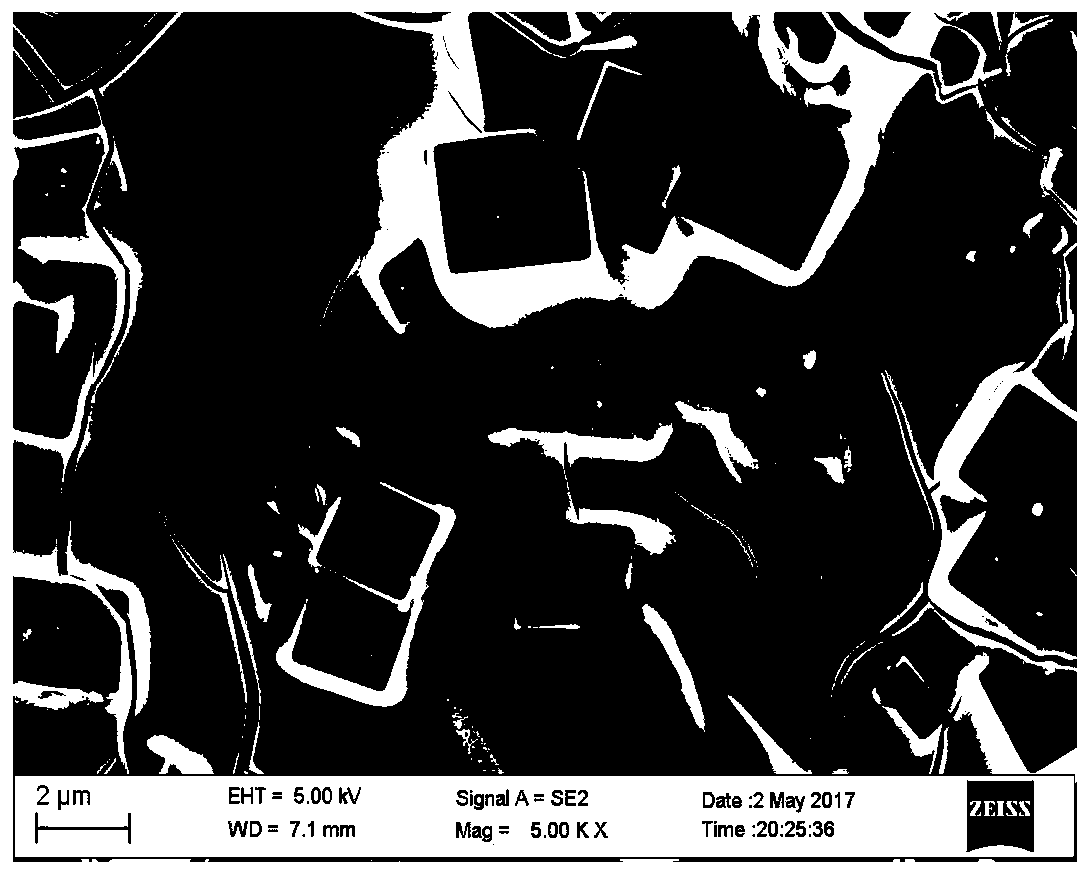

The invention discloses coarse-grained sphere-like zirconium hydroxide with large specific surface area. Zirconium hydroxide adopts a sphere-like structure in shape, the grain size D10 is larger than or equal to 8 mu m, the diameter D50 is larger than or equal to 30 mu m and smaller than or equal to 40 mu m, the diameter D90 is smaller than or equal to 80 mu m, the specific surface area is larger than or equal to 550 m<2> / g, the pore volume is 0.20-0.25 cm<3>, the pore diameter is 2.0-2.4 nm, and the phosphorus / sulfur dynamic adsorption capacity of zirconium hydroxide is larger than 1 mmol / g. The invention further provides a preparation method of coarse-grained sphere-like zirconium hydroxide with the large specific surface area. According to the method, zirconium oxychloride reacts with SO4<2->, a product reacts with potassium hydroxide or sodium hydroxide, and zirconium hydroxide is directly prepared; ammonium ions are avoided effectively, and the prepared product contains few impurities and is uniform in grain size, large in specific surface area and high in activity. With adoption of the coarse-grained sphere-like structure, the product can be applied to phosphorous removal through dynamic adsorption for hemodialysis and can effectively reduce osmotic pressure.

Owner:JIANGXI KINGAN HI TECH

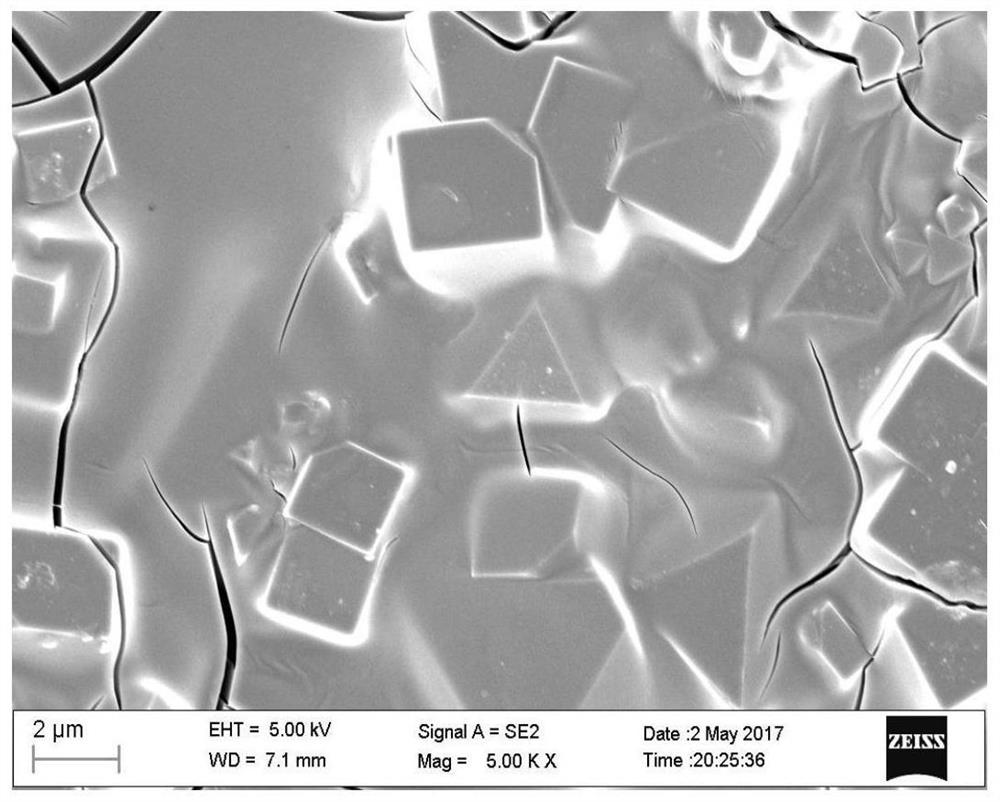

Spray granulation preparation method for zirconium oxide toughened aluminum oxide powder

The invention discloses a spray granulation preparation method for zirconium oxide toughened aluminum oxide powder. The method comprises the following steps of: preparing nano zirconium nitrate and yttrium hydroxide mixed gel by adopting a co-precipitation method, adding nano aluminum oxide, mixing uniformly by using a wet ball milling method to form Zr(OH)4+Y(OH)3 / Al2O3 slurry, performing spray drying granulation and calcination on the slurry, and thus obtaining the zirconium oxide toughened aluminum oxide powder with fine zirconium oxide crystal, uniform distribution of the zirconium oxide crystal in the aluminum oxide, high sintering activity and good forming performance. The method for preparing the zirconium oxide toughened aluminum oxide granulated composite powder overcomes the defects of low uniformity, zirconium oxide agglomeration and the like caused by directly mixing and granulating zirconium oxide powder and aluminum oxide powder in the conventional method, powder making and granulation processes are integrated, the method is simple, and the zirconium oxide is dispersed uniformly and is low in granularity and high in sintering activity.

Owner:SOUTH CHINA UNIV OF TECH

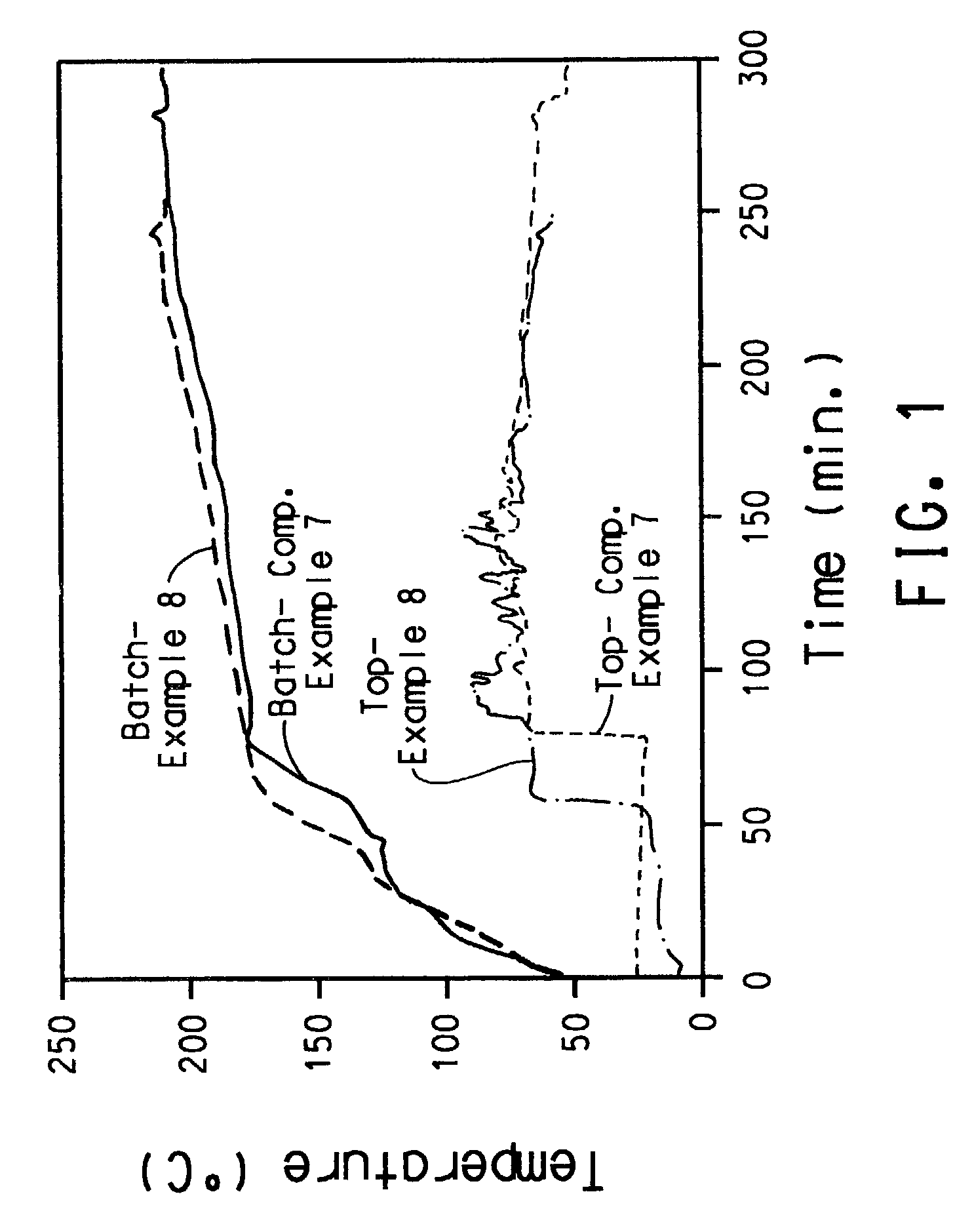

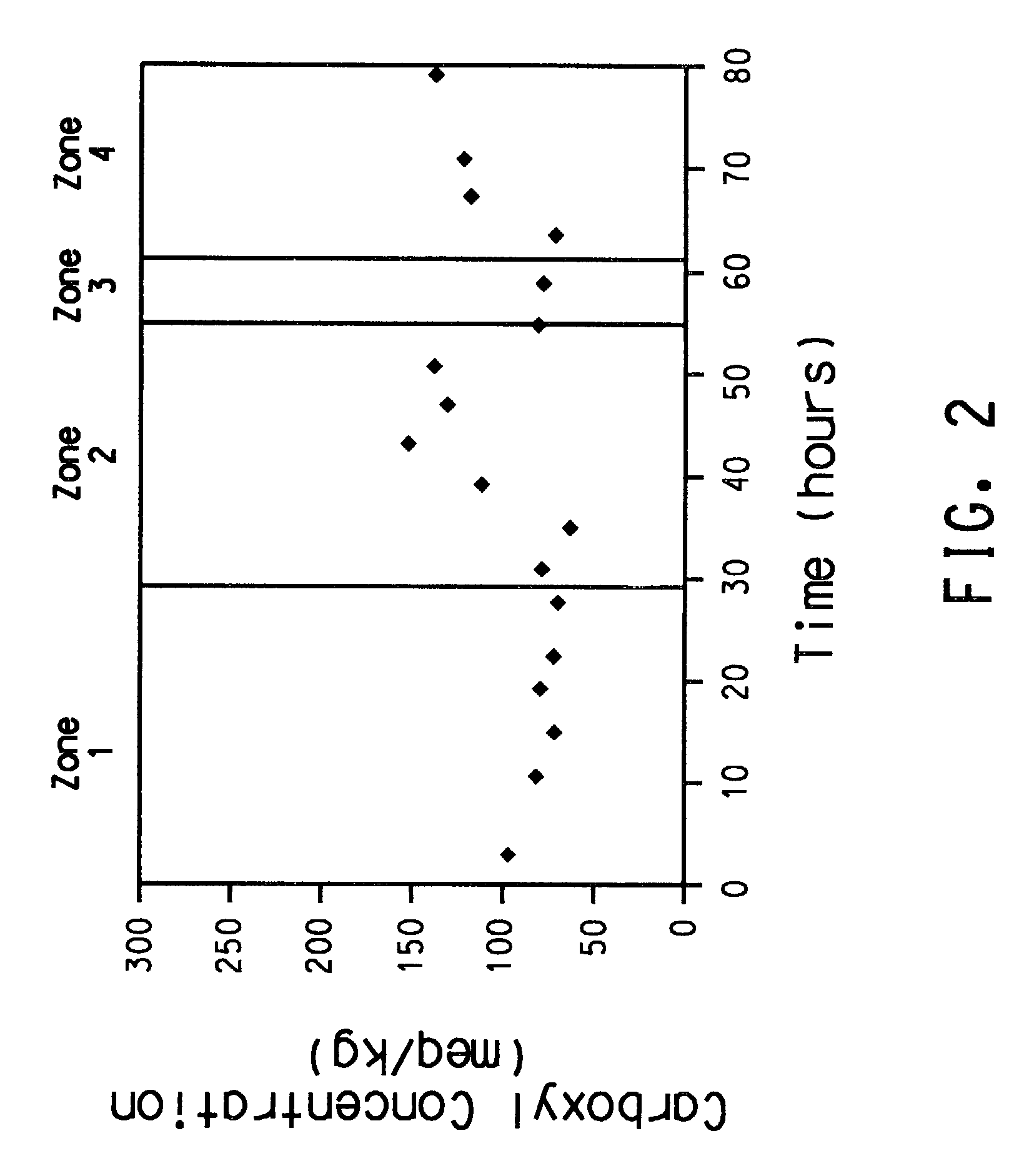

Titanium-zirconium catalyst compositions and use thereof

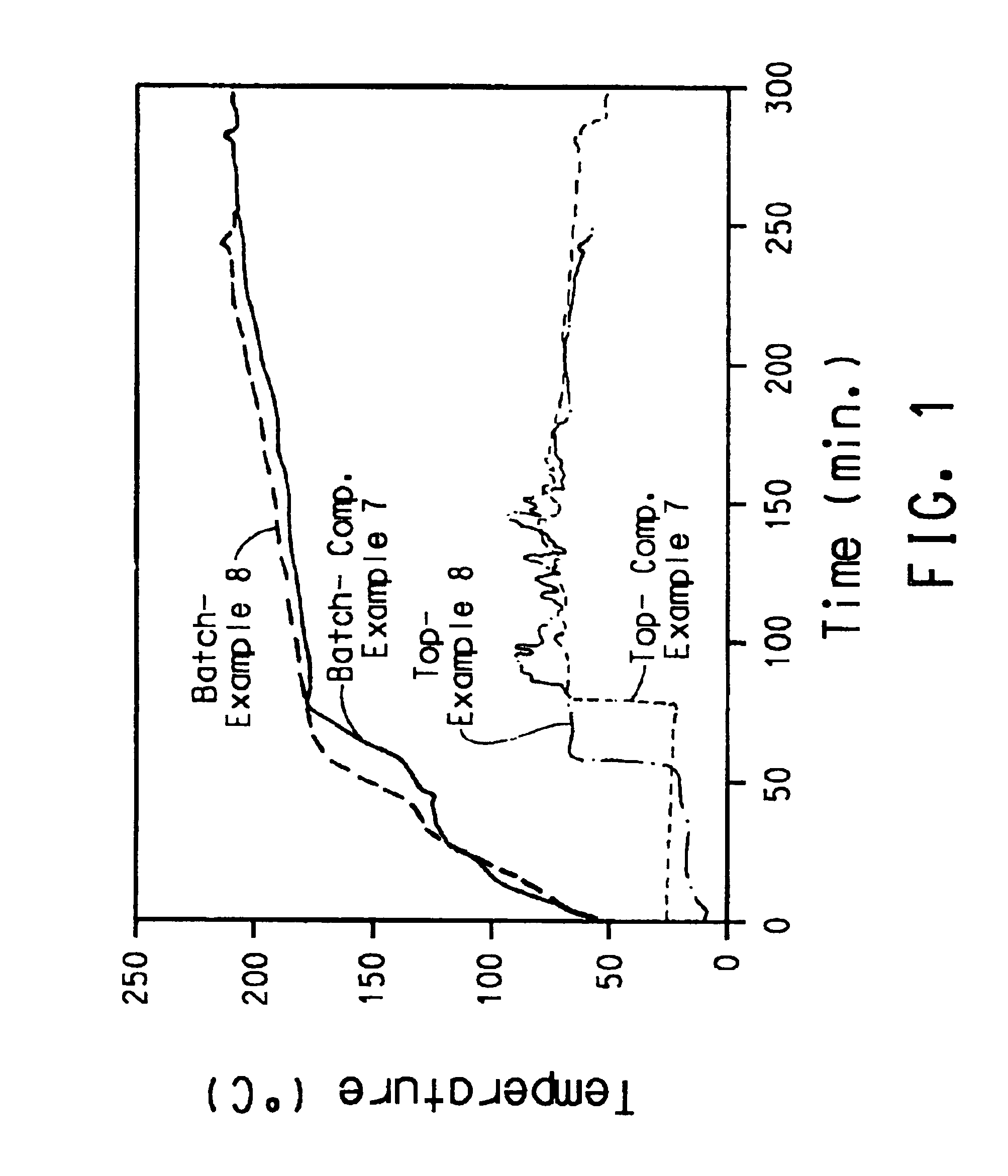

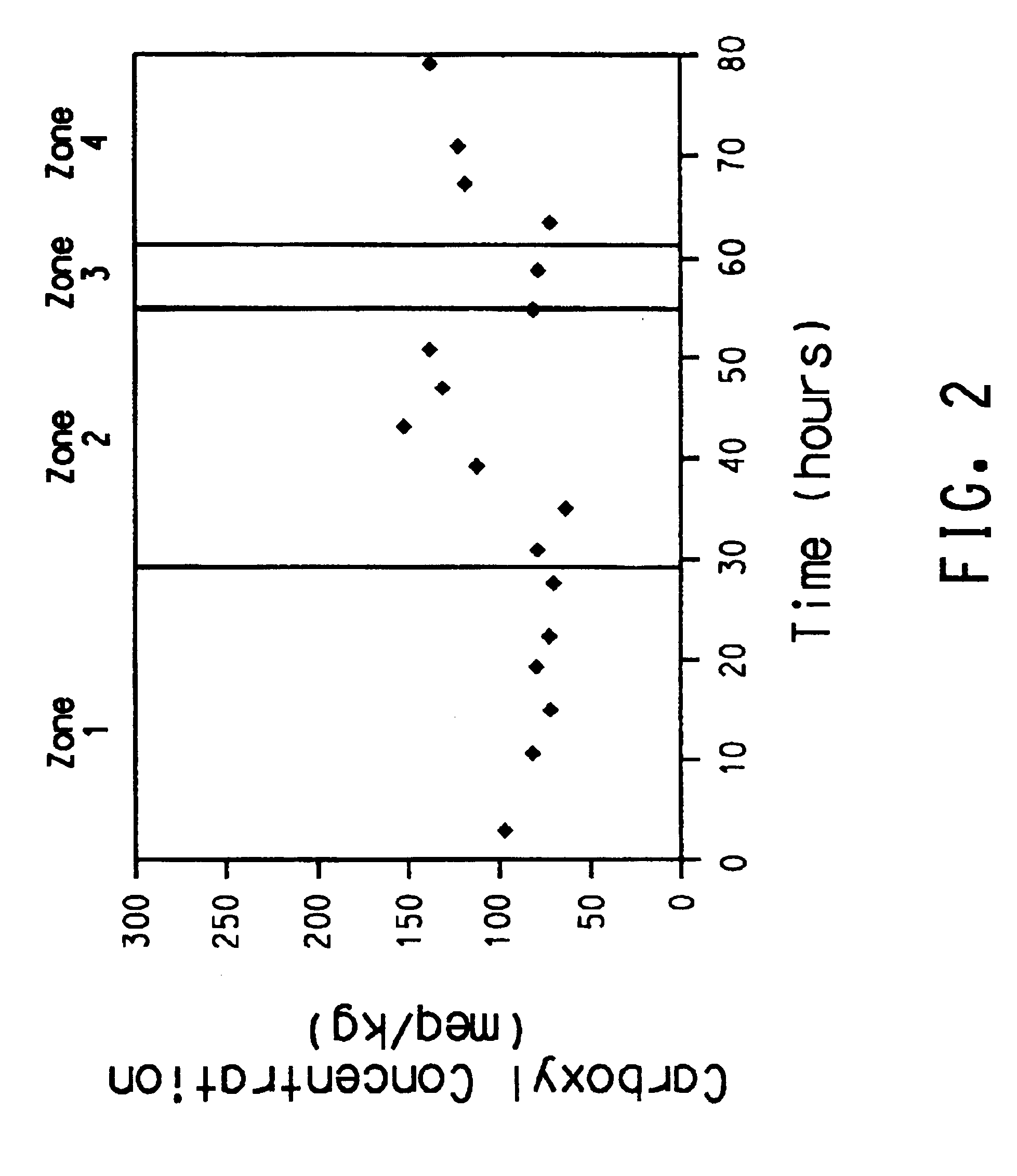

InactiveUS6841505B2Low color requirementReduce colorPreparation from carboxylic acid halidesOrganic compound preparationTitanium zirconiumTitanium

Owner:EI DU PONT DE NEMOURS & CO

Method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation

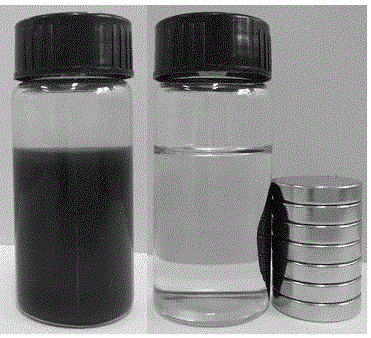

The invention discloses a method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation. The method uses magnetic zirconium hydroxide as a catalyst, uses low carbon alcohol as a reaction solvent and a hydrogen donor, 5-hydroxymethyl furfural is selectively converted into the 2,5-dihydroxymethyl furan through Meerwein-Ponndorf-Verley (MPV) transfer hydrogenation reaction in a high-pressure reaction kettle, and the highest yield is up to 91.5%. The raw materials for the used catalyst are low in price, the preparation process is simple, and the catalytic performance is good. In addition, the 2,5-dihydroxymethyl furan has strong magnetism and is easy to separate, recycle and reuse. Furthermore, the used low carbon alcohol can serve as the in-situ hydrogen donor, hydrogen usage is omitted, and the safety of the reaction process is further improved. Moreover, the 2,5-dihydroxymethyl furan can also serve as a reaction solvent, introduction of exogenous substances is reduced, the production costs are further reduced, and the method has a high application value and a good industrialized prospect.

Owner:HUAIYIN TEACHERS COLLEGE

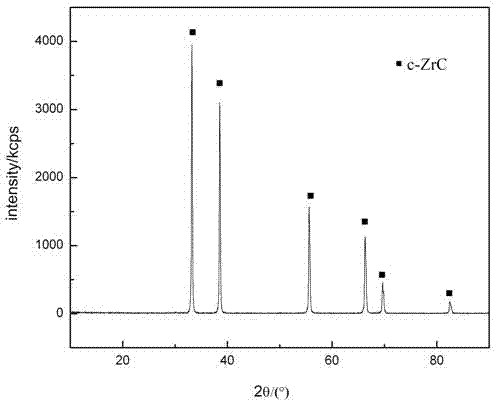

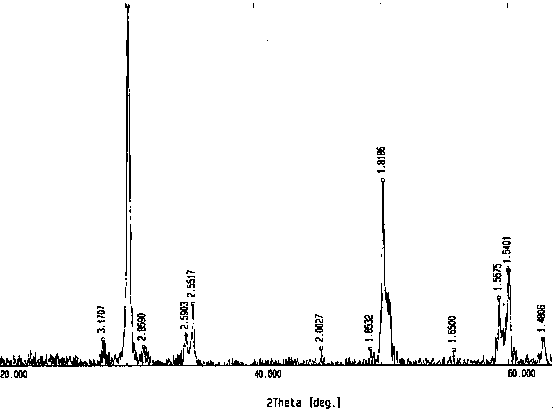

Method for preparing nanocrystalline zirconium carbide powder

The invention relates to a method for preparing nanocrystalline zirconium carbide powder, which comprises the steps that zirconium oxychloride, ammonia water and cane sugar are used as raw materials; the zirconium oxychloride and the cane sugar are dissolved in the mixed solution of absolute ethyl alcohol and water according to a certain proportion; polyethylene glycol 6000 serving as a dispersing agent is added into the mixed solution, and then the ammonia water is dropwise added into the mixed solution for reaction to obtain zirconium hydroxide precipitation; the dried powder is pressed into green bodies; and the green bodies are baked in high-purity argon atmosphere at high temperature of 1500-1650 DEG C and then fully ground to obtain the nanocrystalline zirconium carbide powder. The method for preparing the nanocrystalline zirconium carbide powder has the advantages that the cost of the raw materials is low, the process is simple, the purity of the product is high, and the size of crystalline grains is uniform. The method for preparing the nanocrystalline zirconium carbide powder is favorable to large-scale production.

Owner:SHANGHAI UNIV

Titanium-zirconium catalyst compositions and use thereof

InactiveUS20040018938A1Preparation from carboxylic acid halidesPreparation by ester-hydroxy reactionTitanium zirconiumTitanium

Owner:EI DU PONT DE NEMOURS & CO

Zirconium oxalate sol

ActiveUS20090305878A1Good binderSufficient forceMaterial nanotechnologyTungsten oxides/hydroxidesOxalateOXALIC ACID DIHYDRATE

A sol of the present invention is a sol comprising zirconium oxalate compound as a dispersoid, wherein a mol ratio of oxalic acid to Zr (oxalic acid / Zr) is from 1.2 to 3 and a particle diameter D50 of the dispersoid is from 10 to 100 nm. This sol is produced by adding oxalic acid to a dispersion liquid of zirconium hydroxide, and the addition of oxalic acid is carried out in twice.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

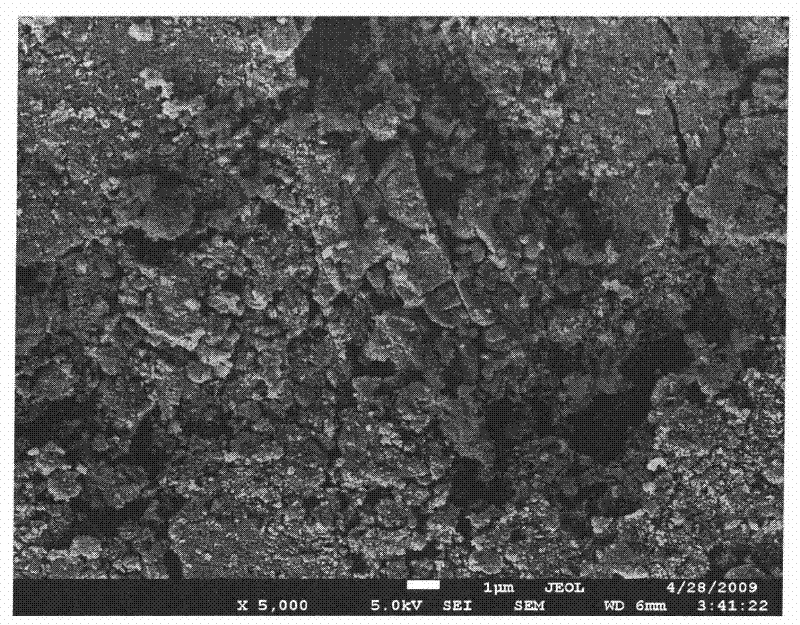

Preparation method and application of WO3/ZrO2 solid super acidic catalyst

InactiveCN101829559ASmall grainHigh catalytic activityHydrocarbon by isomerisationCatalyst activation/preparationIsomerizationTungstate

The invention belongs to the technical field of catalysts, and particularly relates to a preparation method and application of a WO3 / ZrO2 solid super acidic catalyst. The preparation method comprises the following steps of: preparing a zirconium hydroxide precursor by adopting a precipitation method, carrying out hydro-thermal treatment on the precursor, soaking the precursor in ammonium meta-tungstate and roasting at high temperature to obtain the solid super acidic catalyst with larger specific surface. When applying the catalyst to Alpha-pinene isomerization reaction, a favorable effect can be obtained, Alpha-pinene conversion ratio and selectivity to target products of camphene and limonene are high and the catalyst still keeps high activity and high selectivity after multiple regeneration and repeated use.

Owner:FUDAN UNIV

Solid super acidic catalyst and preparation method thereof

The invention discloses a solid super acidic catalyst and a preparation method thereof. The catalyst has an active ingredient of sulfate radical, and carriers of zirconia and alumina, wherein the carriers are obtained by mixing and forming the zirconia and alumina xerogels prepared by a supersolubilizing micelle method. In the method, the final catalyst has bigger orifices on a big-pore external surface, large pore volume, high porosity, high pore penetrability and high suitability for treating macromolecule-containing reactions, so that the catalyst, different from ink bottle-type orifices, avoids inactivation due to orifice blocking to facilitate the increase of impurity deposition and prolong the running period of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

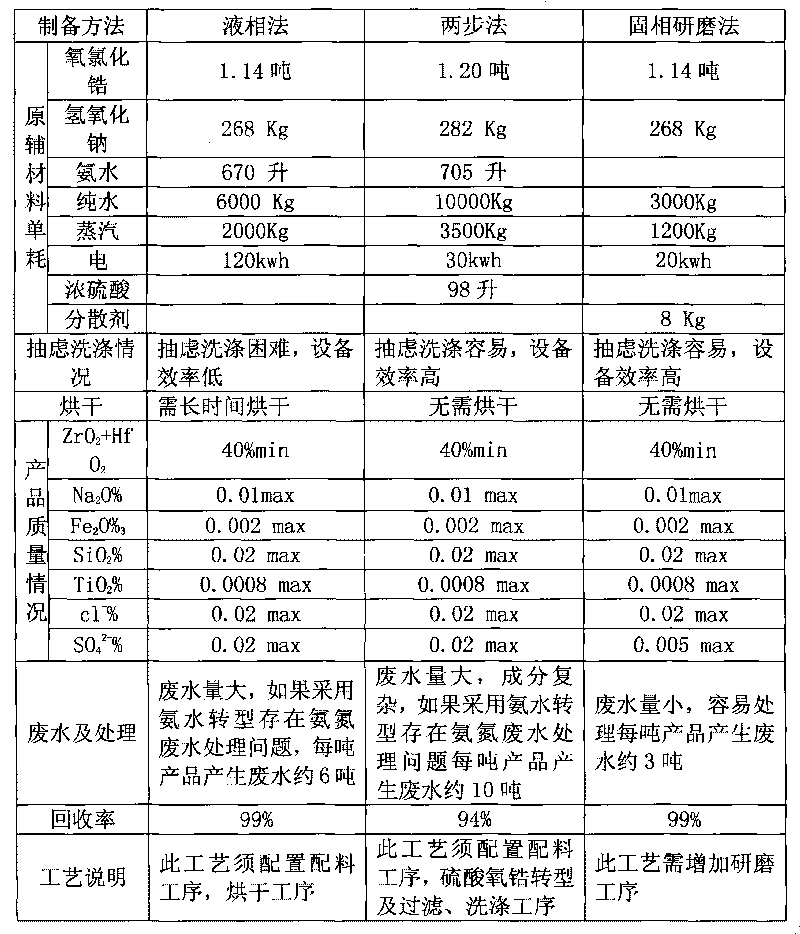

Zirconium hydroxide solid-phase grinding synthesis method

The invention discloses a zirconium hydroxide solid-phase grinding synthesis method. The method of high purity zirconium hydroxide comprises the following steps: adding zirconium hydroxide in a mixing machine, adding dispersant of which weight ratio to zirconium hydroxide is 0.005-0.02; adding solid sodium hydroxide in the mixing machine; starting the mixing machine for mixing and aging, pouring materials in a grinder, transferring the grinded materials into a vacuum suction filtration tank; pumping 40-90 DEG C of pure water of which weight ratio to the materials is 1-10:1 in a suction filtration tank, draw off water after soaking, adding 40-90 DEG C of pure water of which weight ratio to the materials is 1-10:1 again; and rinsing 2-8 times with pure water, transferring the product to a centrifuge to centrifuge for 10-30 minutes, and packaging to obtain the finished product. The method of the invention reduces the flow, simplified devices and reduces the water consumption; in addition, the devices are easy to operate and the production cost is reduced.

Owner:JIANGXI KINGAN HI TECH

High-phosphate-adsorption-activity large-particle-size zirconium hydroxide, and preparation and use methods and application thereof

InactiveCN105435733AGood biological adaptabilitySo as not to damageOther chemical processesWater contaminantsHigh phosphateImpurity ions

The invention discloses a high-phosphate-adsorption-activity large-particle-size zirconium hydroxide. The specific area is 300-700 m<2> / g; the pore volume is 0.15-0.3 cm<3> / g; the pore size is 1.5-3.0nm; and the particle size D10 is greater than or equal to 5 mu m and smaller than or equal to 15 mu m, the particle size D50 is greater than or equal to 20 mu m and smaller than or equal to 30 mu m, and the particle size D90 is greater than or equal to 40 mu m and smaller than or equal to 90 mu m. The invention also discloses preparation and use methods and application of the zirconium hydroxide. The prepared zirconium hydroxide has favorable selective adsorption effects on H2PO4<->, HPO4<2-> and PO4<3-> in the water body, and is free from the influence of other impurity ions; and the adsorption capacity can reach 0.7 mmol / g or above. The zirconium hydroxide has the advantages of favorable biocompatibility, no toxicity and no harm, can lower the dialysis pressure and energy consumption when being mixed with large-particle-size SiO2, and can be used as a medical dialysis material to regulate the phosphorus content in blood.

Owner:JIANGXI KINGAN HI TECH

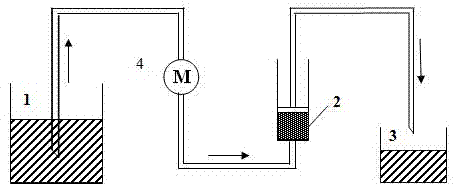

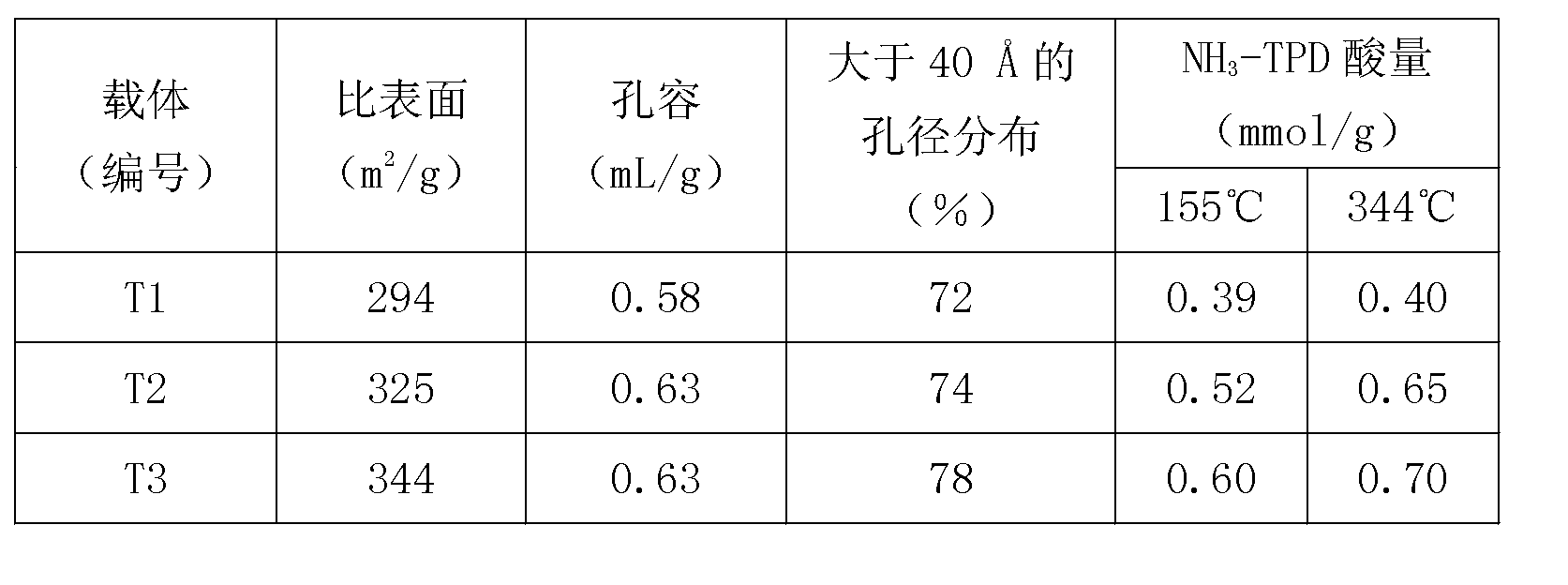

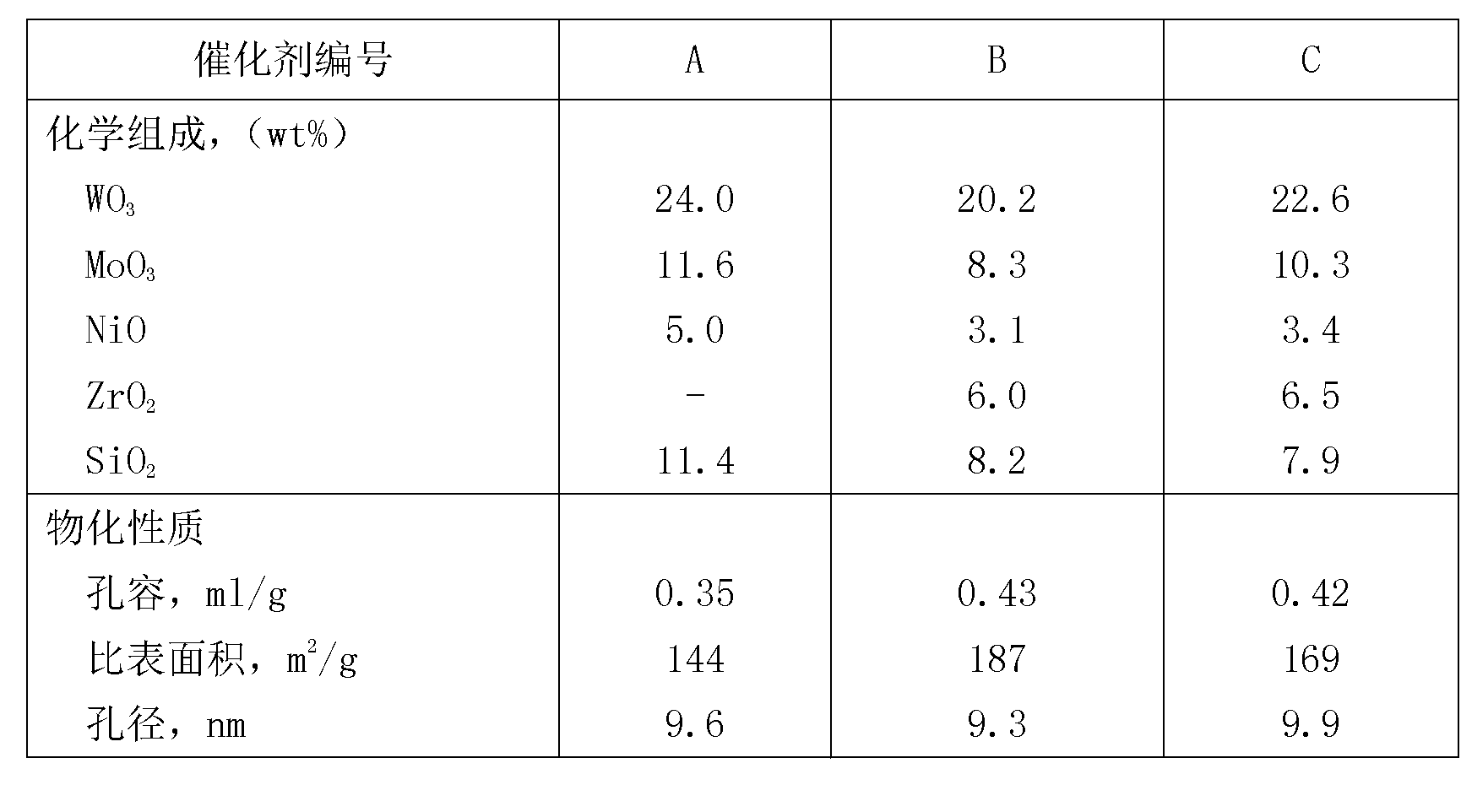

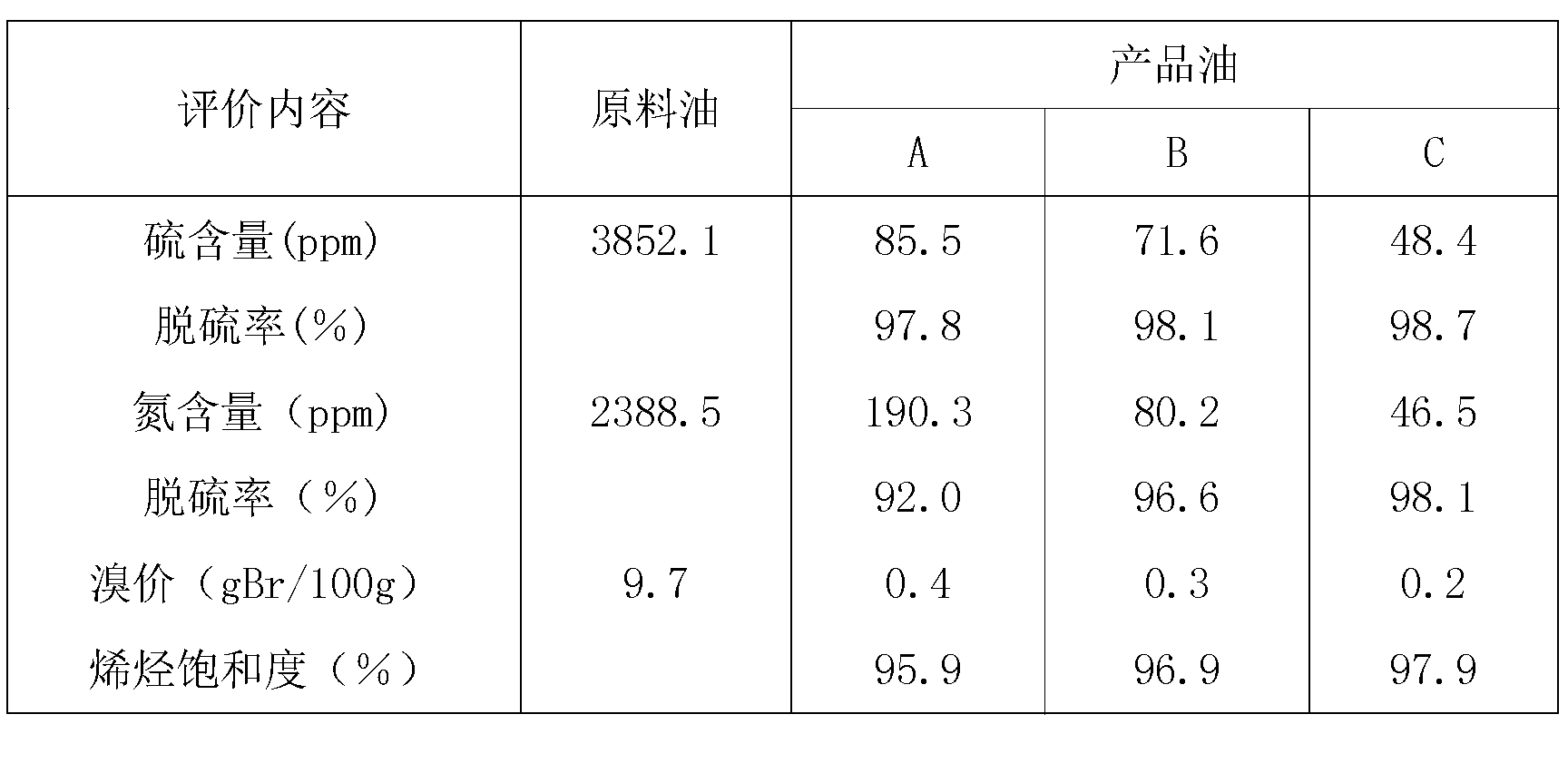

Preparation method of wax oil hydrogenation pretreatment refining agent

InactiveCN103240106AIncrease profitIncrease medium to strong acidityPhysical/chemical process catalystsRefining to eliminate hetero atomsSilica gelCobalt

The invention relates to a preparation method of a wax oil hydrogenation pretreatment refining agent; and the preparation method is characterized by comprising the steps of: adding zirconium hydroxide and silica sol into macroporous aluminum hydroxide dry gel powder; drying and carrying out high-temperature roasting to obtain silicon-zirconium modified aluminum oxide gamma-Al2O3 as carrier; and loading active hydrogenated metal oxide components such as tungsten, molybdenum, cobalt and nickel as well as auxiliary agents containing components such as phosphorus and fluorine by using an impregnation method.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for extracting zirconium oxide from zirconium-containing solid solution substance

ActiveCN103950977ALarge heat lossDecrease stockZirconium oxidesNatural resourceZirconium oxychloride

The invention relates to a method for extracting zirconium oxide from a zirconium-containing solid solution substance. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance comprises the following steps: mixing zirconium-containing solid solution substance powder with sodium hydroxide and then heating and sintering, so that an acid-soluble sintered material is obtained, carrying out immersion cleaning on the acid-soluble sintered material with a diluted hydrochloric acid aqueous solution, enriching for obtained mixture of sodium zirconate and zirconium hydroxide and a salt solution, carrying out hot dipping on the mixture for obtaining a zirconium oxychloride solution with a hydrochloric acid solution, evaporating, concentrating and cooling the zirconium oxychloride solution for separating out zirconium oxychloride crystals, and purifying the obtained zirconium oxychloride crystals; carrying out neutralizing treatment on the salt solution, extracting useful components, and then concentrating the salt solution for obtaining industrial salt. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance has the advantages of simple technological process, energy conservation, low consumption, high metal recovery rate, less environmental pollution, benefit to harmonious development of natural resources and the ecological environment and obvious resource recycling effect.

Owner:山东鸿远新材料科技股份有限公司

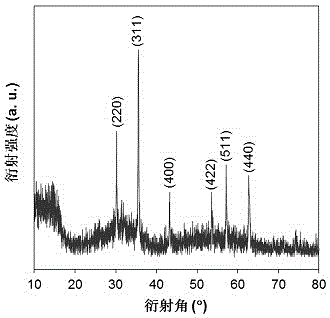

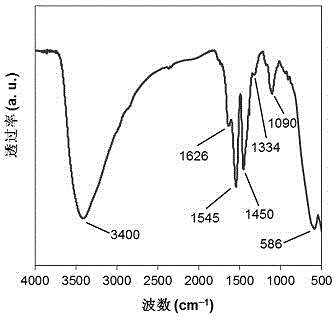

Preparation method and application of zirconium hydroxide modified magnetic biochar adsorption material

InactiveCN111804276AHigh affinityGood choiceOther chemical processesWater contaminantsPhysical chemistryZirconium(IV) hydroxide

The invention discloses a preparation method and application of a zirconium hydroxide modified magnetic biochar adsorption material, and belongs to the technical field of water treatment. The preparation method of the adsorption material comprises the following steps: carbonizing pineapple peel, and modifying with a ferric salt solution to prepare magnetic biochar; loading zirconium hydroxide on the magnetic biochar through an impregnation method to prepare the zirconium hydroxide modified magnetic biochar adsorption material. The defects in the prior art are overcome, the pineapple peel is turned into treasure through the prepared adsorption material, and the adsorption material has advantages of high phosphorus adsorption capacity, easy recovery, good selectivity, good stability and cyclic utilization.

Owner:安徽汇泽通环境技术有限公司

Preparation method of compound zirconium oxide

ActiveCN102503415AGood particle mixing uniformityControl feed flow rateAqueous dropletMixed materials

The invention relates to a preparation method of compound zirconium oxide. The method comprises the following steps that: A, ammonia water is dripped into zirconium oxychloride solution for reaction, and zirconium hydroxide water sol is generated after the reaction completion; B, deionized water is used for washing the zirconium hydroxide water sol, and zirconium hydroxide colloid is obtained after press filtering; C, the zirconium hydroxide colloid is dried, and then, powdery zirconium hydroxide is obtained through powdery processing; D, yttrium oxide and auxiliary materials (one kind of materials or several kinds of materials from aluminum oxide, magnesium oxide and calcium oxide) are added into the powdery zirconium oxide to be mixed (through ball mill or stirring tank mixing), and after the mixing completion, the mixed materials are roasted for 2 to 3 hours at 950 to 1050 DEG C, and compound zirconium oxide powder is obtained. The method has the advantages that the scaled production method of high-performance compound zirconium oxide materials is obtained, the produced compound zirconium oxide materials have good uniformity, the specific surface area of products is controllable, and the crystal phase structure is controllable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

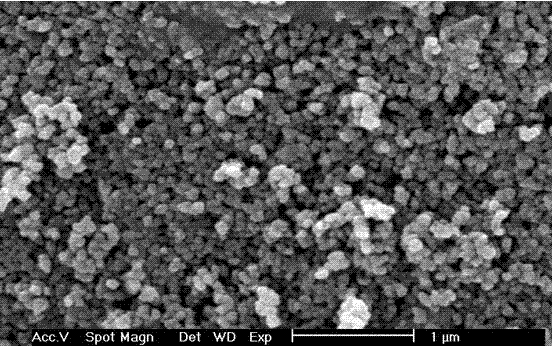

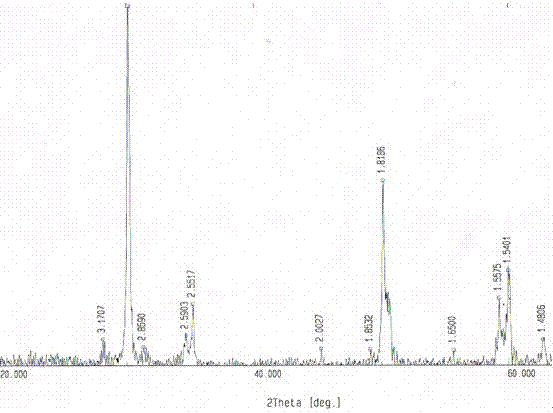

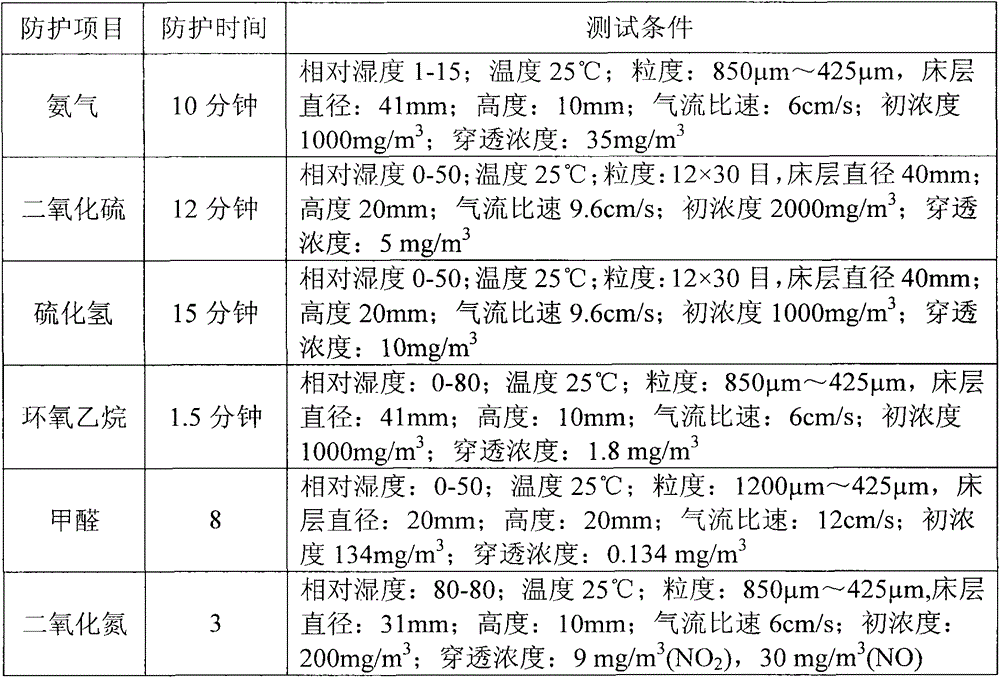

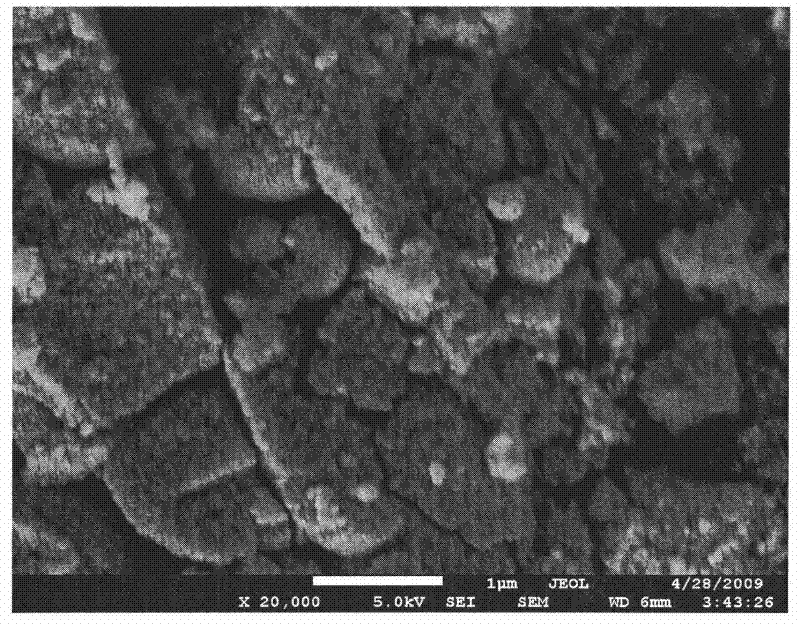

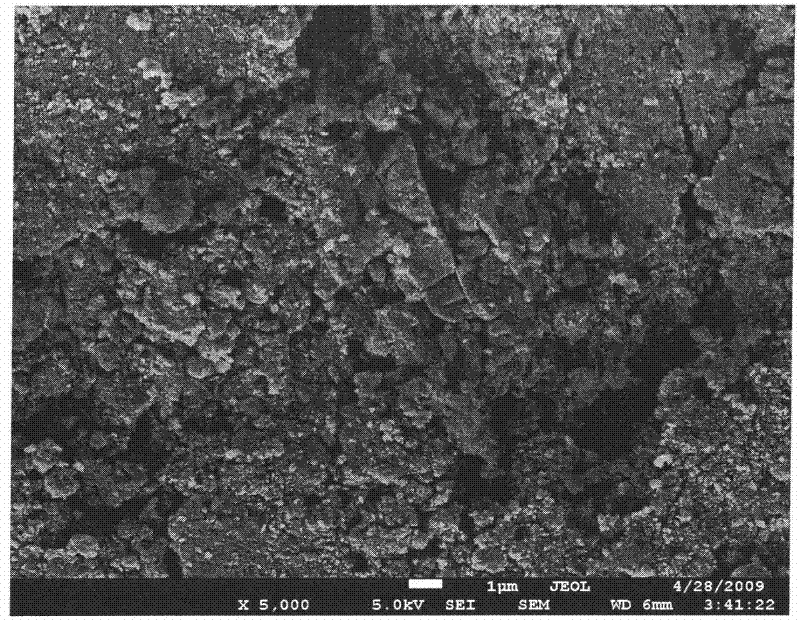

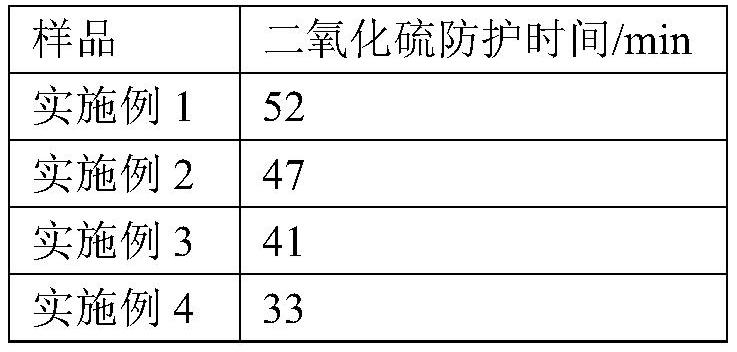

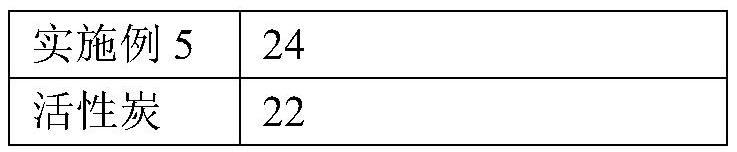

Novel zirconium-loading chemical protective material and preparation method thereof

InactiveCN104415742ALarge specific surface areaStrong physical adsorption capacityMolecular sieve catalystsMolecular sieveActivated carbon

The invention discloses a novel zirconium-based chemical protective material which takes activated carbon or a molecular sieve and other adsorbing materials as a carrier. The material is produced by dipping a zircon salt and then an ammonium hydroxide buffer solution in pores to carry out in situ synthesis to produce zirconium nitrate and then drying and activating in air. The material has excellent protection capacity on chemical toxic agents and acid poisonous and harmful industrial chemicals, and can be widely applied to the fields of military, air purification and room temperature catalysis.

Owner:NO 63971 TROOPS PLA

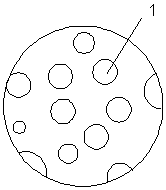

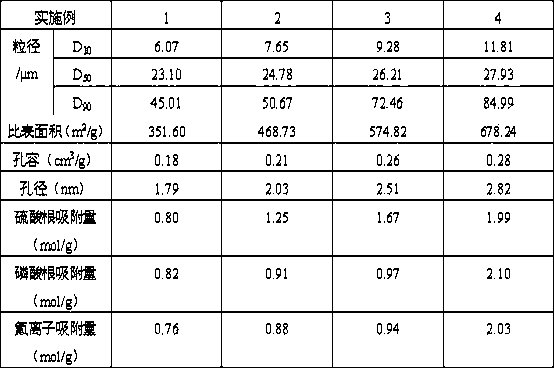

Micron-scale zirconium hydroxide, preparation method and applications thereof

InactiveCN107758739AImprove adsorption capacityGood biological adaptabilityOther chemical processesWater contaminantsMicron scaleZirconium hydride

The invention discloses a micron-scale zirconium hydroxide, with a pore size of 1.8-2.8 nm; a pore volume of 0.18-0.28 cm3 / g; ~680m2 / g, the zirconium hydroxide has a hollow structure. The invention also discloses the preparation method of the zirconium hydroxide, its application in purified water and its adsorption in hemodialysis. The micron scale of the present invention can adsorb phosphate, sulfate and fluoride ions in water, and can also adsorb phosphate in hemodialysis.

Owner:董思言

Production method of zirconium hydroxide

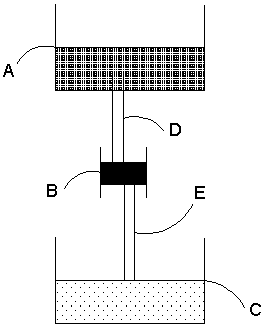

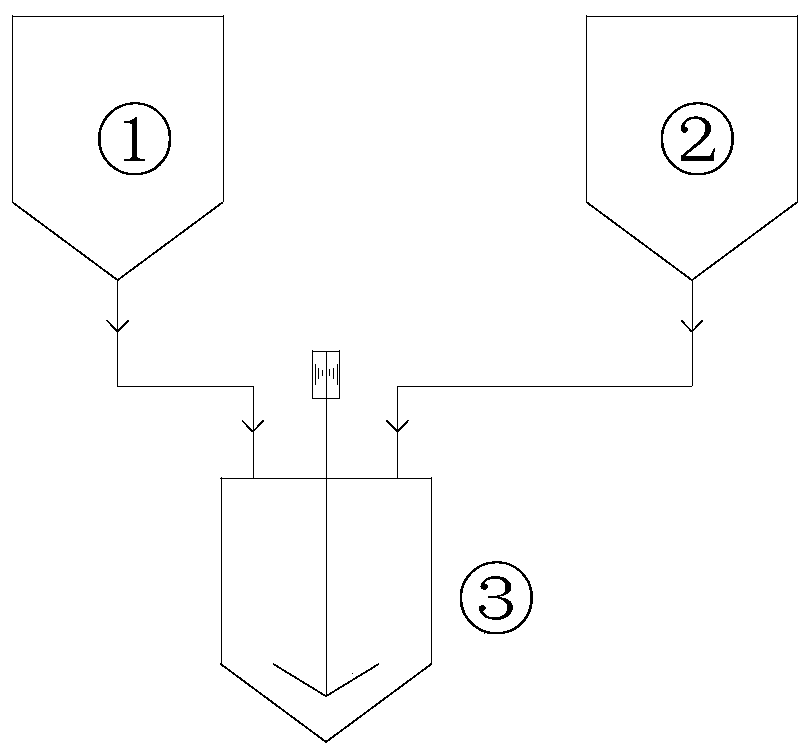

PendingCN111422904AChange gel stateImprove water efficiencyZirconium compoundsCentrifugationPhysical chemistry

The invention relates to the technical field of zirconium hydroxide production processes, in particular to a production method of zirconium hydroxide. The method comprises the steps of zirconium oxychloride solution preparation, weighing and proportioning, flow control reaction, aging, zirconium oxychloride solution weight supplement, water washing and centrifugation. The proper reaction speed isdesigned by adjusting the use ratio of zirconium oxychloride and ammonia water / sodium hydroxide. Zirconium hydroxide particles are generated through a batch reaction, loose powdery zirconium hydroxidewith Cl<-> sizes of smaller than 200 ppm is obtained through washing with 3 times of deionized water, and the content of zirconium oxide can reach 40%.

Owner:青岛天尧新材料有限公司

Wear-resistant heat-resistant tire tread rubber

InactiveCN110746664AImprove mechanical propertiesImprove wear resistanceSpecial tyresSODIUM METAPHOSPHATESodium phosphates

The invention discloses wear-resistant heat-resistant tire tread rubber. The prepared tire tread rubber has relatively good mechanical properties, wear resistance and heat resistance and is outstanding in quality and long in service life; carbon black has relatively high surface activity, is difficult to disperse during milling of rubber and is prone to aggregation to form an aggregate, and thus,comprehensive properties of a composite are weakened; and the carbon black is firstly treated with sodium hydroxide to form micro-etched dots on the surface of the carbon black, then, zirconium oxychloride, sodium metaphosphate and Span are added, then, ammonia water is dropwise added and reacts with the zirconium oxychloride to produce zirconium hydroxide, the sodium metaphosphate and the Span are adsorbed to the micro-etched dots, the attachment of the zirconium hydroxide to the micro-etched dots is promoted, and zirconium dioxide is produced on the surface of the carbon black after roasting, so that the probability of contact among homogeneous filler granules of the carbon black is lowered, the dispersion of fillers is improved, uniform stress concentration points are formed in a rubbermatrix, and mechanical properties of the composite are obviously improved.

Owner:界首市鸿鑫塑业有限公司

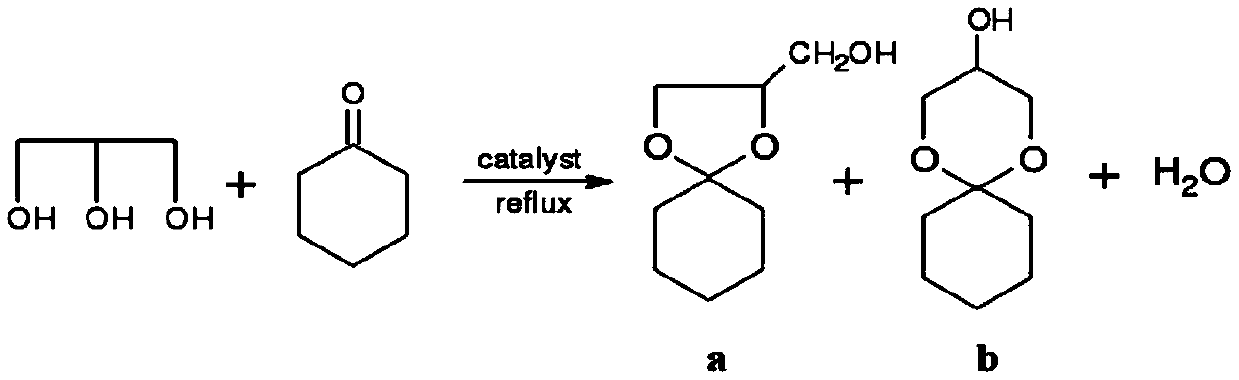

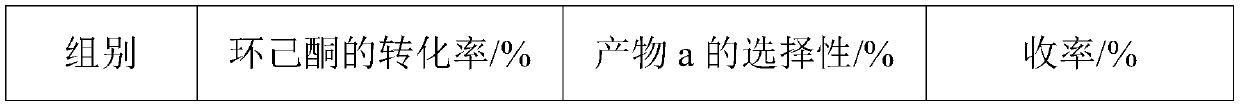

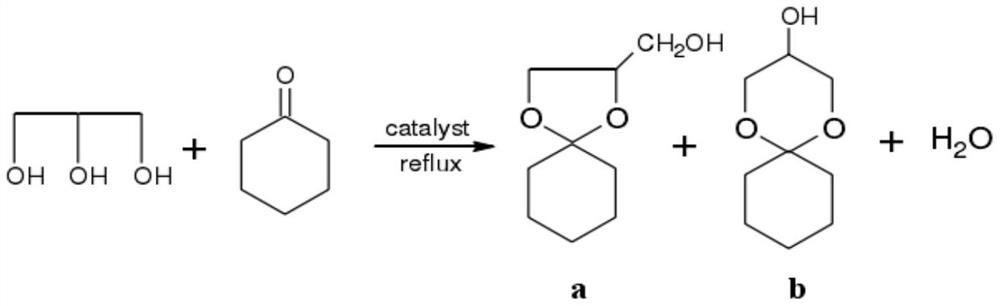

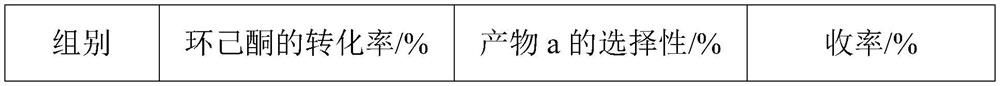

Solid superacid, preparation method of solid superacid, glycerinum cyclohexanone ketal and preparation method of glycerinum cyclohexanone ketal

The invention relates to a solid superacid and a preparation method thereof, and a glycerin cyclohexanone ketal and a preparation method thereof. The preparation method of the solid superacid catalystcomprises the following steps: soaking zirconium hydroxide in a 0.4mol / L-0.6mol / L ammonium persulfate aqueous solution, and filtering to obtain a filter cake; drying and roasting the filter cake to obtain the solid superacid catalyst, wherein the mass volume ratio of zirconium hydroxide to the ammonium persulfate aqueous solution is (0.114-16.6): 1 g / mL. The preparation method of the solid superacid catalyst is simple, only zirconium hydroxide and the ammonium persulfate aqueous solution need to be mixed according to the proportion and filtered to obtain the filter cake, then the filter cakeis dried and roasted to activate the catalyst, and finally the prepared solid superacid catalyst containing S2O8<2-> / ZrO2 is good in catalytic activity and high in product selectivity.

Owner:HUAIHUA UNIV

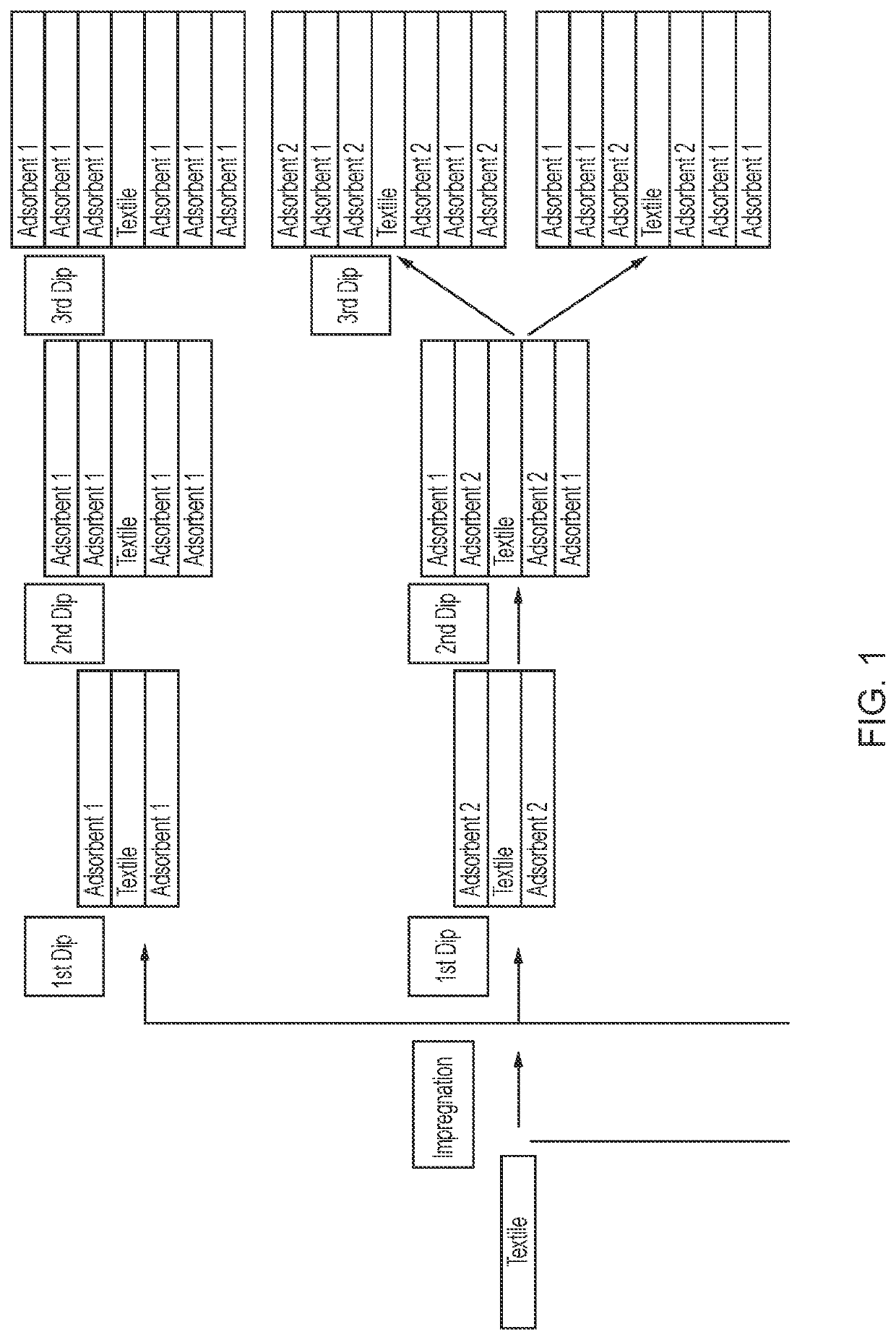

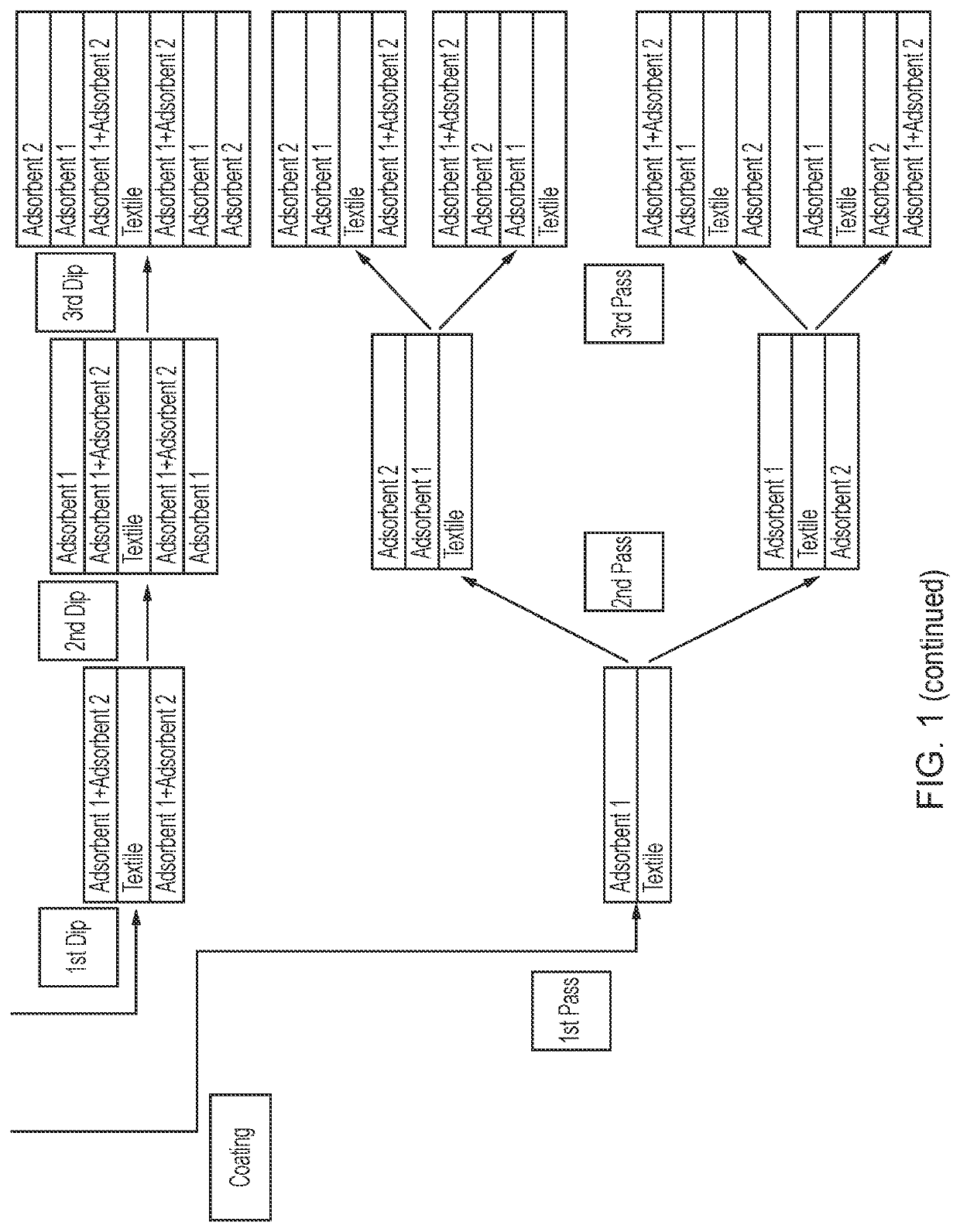

Adsorbent material

PendingUS20220362738A1Increase volumeGood conformabilitySolvent-treatmentPersonal careZirconium oxideZirconium(IV) hydroxide

A flexible material is disclosed comprising a flexible substrate, a sorbent comprising zirconium hydroxide and a binder, wherein the solids weight ratio of the binder to the zirconium hydroxide is in the range 1:1 to 1:120. Also disclosed is a process for production of a fabric, comprising: providing a flexible material, providing at least one sorbent dispersion comprising zirconium hydroxide and a binder, applying the sorbent dispersion to the flexible material to produce a treated flexible material, squeezing the treated flexible material under pressure, and passing the pressed treated flexible material through a stenter.

Owner:HEATHCOAT FABRICS LTD

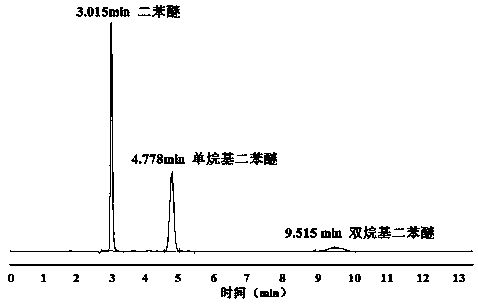

Process for preparing alkyl diphenyl ether by catalyzing reaction of olefin and diphenyl ether with solid acid

PendingCN111454130ASimple preparation processNothing producedPhysical/chemical process catalystsOrganic chemistryPtru catalystDistillation

The invention discloses a process for preparing alkyl diphenyl ether by catalyzing a reaction of olefin and diphenyl ether with solid acid. The method comprises the following steps: (1) preparation ofa solid acid catalyst: adding sulfate and zirconium hydroxide into a reactor, carrying out mechanical stirring for uniform mixing, and performing calcining to obtain the solid acid catalyst, whereinthe sulfate is ammonium sulfate or a mixture of ammonium sulfate and aluminum sulfate; and (2) preparation of alkyl diphenyl ether through an alkylation reaction: adding diphenyl ether and the solid acid catalyst into a reaction kettle, carrying out heating to a reaction temperature of 100-180 DEG C, slowly adding olefin into the reaction kettle, continuing reacting after the addition of the olefin is finished, filtering reaction liquid to remove the catalyst, and carrying out reduced-pressure distillation to remove the diphenyl ether and the olefin so as to obtain the alkyl diphenyl ether. The preparation process of the solid acid catalyst is simple, and no wastewater is generated in the preparation process; and the preparation process of the alkyl diphenyl ether is a heterogeneous reaction, post-treatment is simple, and the catalyst can be recycled.

Owner:CHINA RES INST OF DAILY CHEM IND

Solid super acid and preparation method, glycerol cyclohexanone ketal and preparation method

The invention relates to a solid super acid and a preparation method, a glycerol cyclohexanone ketal compound and a preparation method. Wherein, the preparation method of the solid superacid catalyst comprises the following steps: immersing zirconium hydroxide in 0.4mol / L-0.6mol / L ammonium persulfate aqueous solution, filtering to obtain a filter cake; drying and roasting the filter cake The solid superacid catalyst is obtained, wherein the mass volume ratio of the zirconium hydroxide and the aqueous ammonium persulfate solution is (0.114-16.6): 1 g / mL. The preparation method of the above-mentioned solid superacid catalyst is simple. It only needs to mix the zirconium hydroxide and the aqueous ammonium persulfate solution according to the above ratio, filter to obtain a filter cake, then dry and roast the filter cake to activate the catalyst, and finally obtain the S-containing 2 O 8 2‑ / ZrO 2 The solid superacid catalyst has good catalytic activity and high product selectivity.

Owner:HUAIHUA UNIV

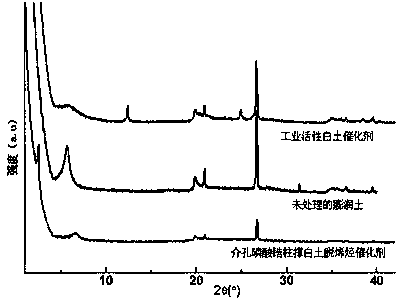

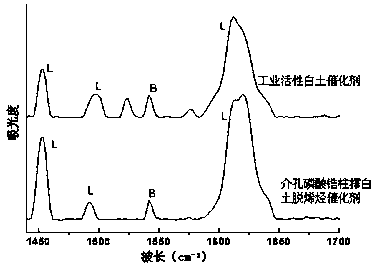

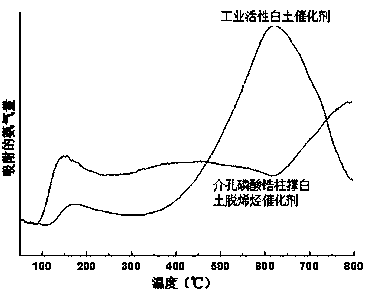

Acidic Mesoporous Zirconium Phosphate Pillared Activated Clay Deolefination Catalyst

ActiveCN107876070BRich mesostructureIncrease the areaCatalyst activation/preparationPtru catalystPhosphoric acid

The invention relates to the technical field of aromatic oil catalysis, and discloses an acidic mesoporous zirconium phosphate pillared activated clay deolefining catalyst, which is composed of mesoporous zirconium phosphate and activated bentonite, and the mesoporous zirconium phosphate is pillared between the activated bentonite layers. , and the proportion of the mesoporous zirconium phosphate is 12.5%wt~25%wt. The preparation method is as follows: S1: Add sulfuric acid solution to zirconium hydroxide, then add mesoporous template agent and the activated bentonite, stir and react, transfer to a reaction kettle for crystallization, and obtain crystallized material; S2: Centrifuge, wash, Dry the crystallized material and then treat it with phosphoric acid; S3: Wash, filter, and dry the phosphoric acid-treated crystallized material and then calcine it to prepare the mesoporous zirconium phosphate pillared activated clay deolefin catalyst. The catalytic activity of the activated clay catalyst supported by mesoporous zirconium phosphate pillars of the present invention has been significantly improved; at the same time, this catalyst has relatively high stability and a relatively long life.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Preparation method of sulfated zirconia

PendingCN111097453AIncrease the areaHigh sulfur contentCatalyst activation/preparationBiodieselIsomerization

The invention relates to a preparation method of sulfated zirconia. The method comprises the following steps: preparing a zirconium oxychloride aqueous solution with a certain concentration, adjustingthe pH value to 10-11 with concentrated ammonia water to obtain a zirconium hydroxide precipitate, repeatedly washing until no chloride ion is detected, drying, impregnating with a dilute sulfuric acid solution with a certain concentration, filtering, drying, and roasting to obtain sulfated zirconia. Sulfated zirconia belongs to solid superacid and has excellent catalytic performance in the aspects of conversion and utilization of biodiesel, isomerization of n-butane and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of compound zirconium oxide

ActiveCN102503415BGood particle mixing uniformityControl feed flow rateAqueous dropletMixed materials

The invention relates to a preparation method of compound zirconium oxide. The method comprises the following steps that: A, ammonia water is dripped into zirconium oxychloride solution for reaction, and zirconium hydroxide water sol is generated after the reaction completion; B, deionized water is used for washing the zirconium hydroxide water sol, and zirconium hydroxide colloid is obtained after press filtering; C, the zirconium hydroxide colloid is dried, and then, powdery zirconium hydroxide is obtained through powdery processing; D, yttrium oxide and auxiliary materials (one kind of materials or several kinds of materials from aluminum oxide, magnesium oxide and calcium oxide) are added into the powdery zirconium oxide to be mixed (through ball mill or stirring tank mixing), and after the mixing completion, the mixed materials are roasted for 2 to 3 hours at 950 to 1050 DEG C, and compound zirconium oxide powder is obtained. The method has the advantages that the scaled production method of high-performance compound zirconium oxide materials is obtained, the produced compound zirconium oxide materials have good uniformity, the specific surface area of products is controllable, and the crystal phase structure is controllable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Solid super acidic catalyst and preparation method thereof

The invention discloses a solid super acidic catalyst and a preparation method thereof. The catalyst has an active ingredient of sulfate radical, and carriers of zirconia and alumina, wherein the carriers are obtained by mixing and forming the zirconia and alumina xerogels prepared by a supersolubilizing micelle method. In the method, the final catalyst has bigger orifices on a big-pore external surface, large pore volume, high porosity, high pore penetrability and high suitability for treating macromolecule-containing reactions, so that the catalyst, different from ink bottle-type orifices, avoids inactivation due to orifice blocking to facilitate the increase of impurity deposition and prolong the running period of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of zirconia trifluoromethanesulfonate

A preparation method of zirconia trifluoromethanesulfonate. The method comprises the following steps: preparing a certain concentration of zirconium oxychloride aqueous solution, adjusting the pH value to 8-10 with concentrated ammonia water, obtaining zirconium hydroxide precipitate, washing repeatedly until no chloride ion is detected, filtering, and trifluoromethanesulfonic acid The aqueous solution and the obtained zirconium hydroxide precipitate are mixed, stirred, an appropriate amount of water is added, and filtered, and the solvent in the filtrate evaporates to obtain zirconium oxide trifluoromethanesulfonate. Zirconia trifluoromethanesulfonate has excellent catalytic performance in chemical synthesis such as silyl etherification of alcohols and ring opening of epoxy compounds.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

A kind of preparation method of high-strength pectin zirconium hydroxide microsphere adsorbent

ActiveCN110508254BUniform particle sizeSignificant biosafetyOther chemical processesAlkali metal oxides/hydroxidesMicrosphereSorbent

The invention relates to the field of preparation of zirconium hydroxide adsorbent, in particular to a preparation method of high-strength pectin zirconium hydroxide microsphere adsorbent. It includes the following steps: 1) mixing zirconium hydroxide powder, diammonium bicarbonate, and polyethylene glycol, adding deionized water, and ultrasonically making the mixed solution form a uniformly dispersed suspension; 2) adding deionized water to the pectin, stirring Until the pectin is completely dissolved; 3) Add the suspension obtained in step 1) to the pectin solution in step 2), and stir evenly to obtain a white gel liquid; 4) Put the white gel liquid obtained in step 3) through drops The tube was added dropwise into simethicone, and the white particles under the simethicone were filtered, washed, and vacuum-dried to obtain pectin zirconium hydroxide microsphere adsorbent. The pectin zirconium hydroxide microsphere adsorbent, its one-step hot-melt / condensation preparation method also avoids the loss and pollution problems caused by the crushing and screening operation of the traditional process, and is convenient for the industrial production and application of zirconium hydroxide.

Owner:SHANXI XINHUA CHEM

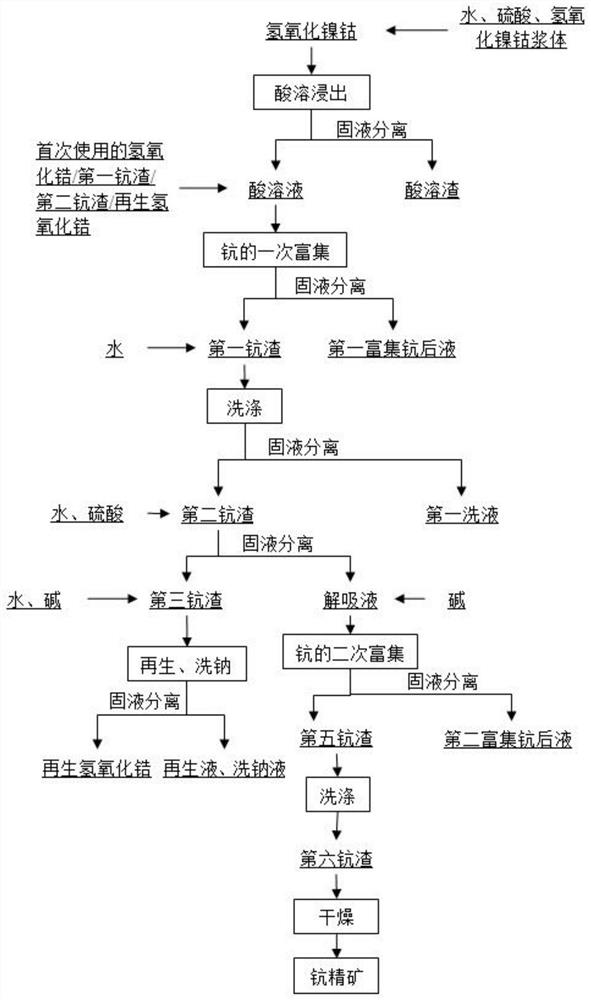

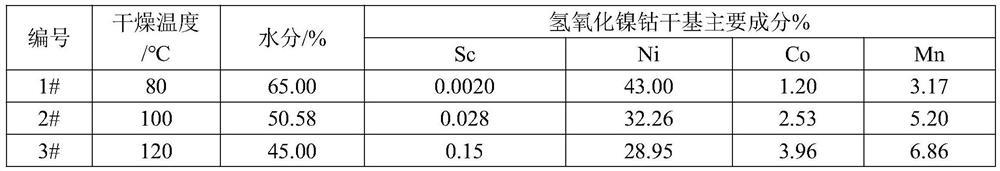

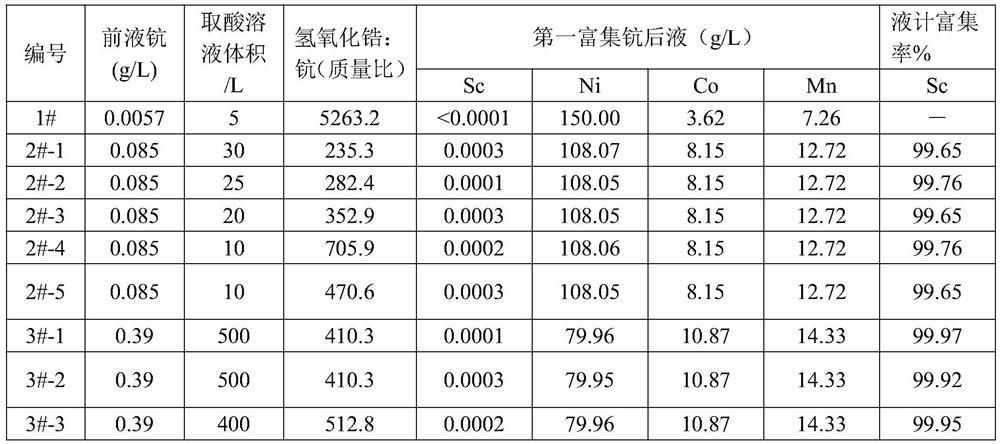

A kind of method for recovering scandium from scandium-containing nickel-cobalt hydroxide

ActiveCN113355540BDoes not affect productionScandium content is highProcess efficiency improvementPhysical chemistryImpurity ions

Owner:广西银亿新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com