Production method of zirconium hydroxide

A zirconium hydroxide and production method technology, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of slurry viscosity, uneven material content, and low purity, so as to improve the water passing efficiency and reduce the The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

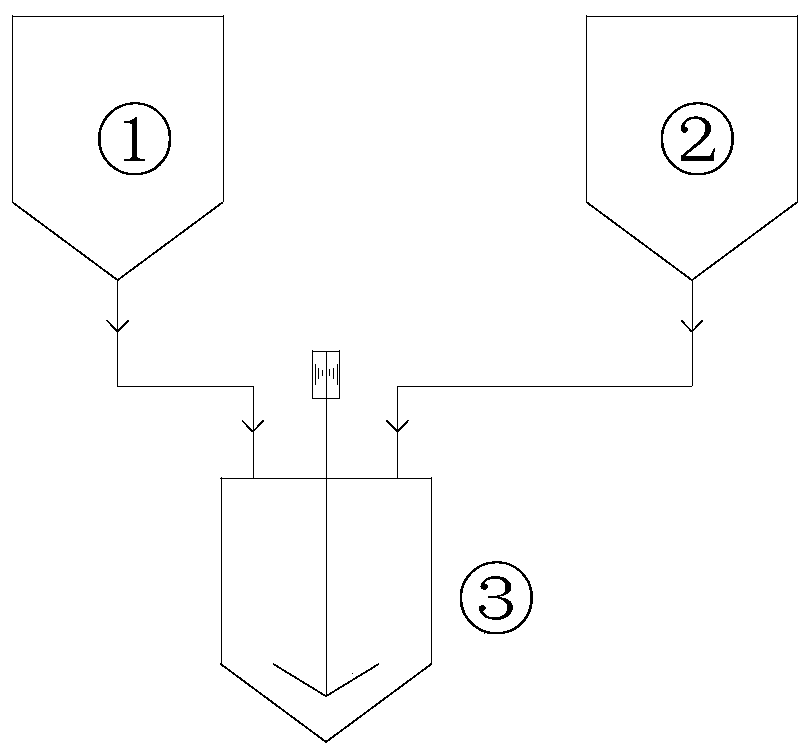

[0024] as attached figure 1 Shown, a kind of production method of zirconium hydroxide comprises the following steps:

[0025] A, prepare zirconium oxychloride solution, dissolve the zirconium oxychloride of 1kg in the demineralized water of 3kg, filter in the storage tank after dissolving;

[0026] B. Stir and mix 10% ammonia water and 30% sodium hydroxide according to the mass ratio of 5:1 to obtain an alkaline precipitant;

[0027] C, the zirconium oxychloride solution of weighing 1kg and the alkaline precipitation agent of 1.8kg enter in the first elevated tank 1 and the second elevated tank 2;

[0028] D, add 0.1kg of demineralized water in the reactor, through the control valve, make the solution in the first elevated tank 1 and the second elevated tank 2 flow into the reactor 3 simultaneously within 2 hours, and age for 6 hours;

[0029] E, supplement the zirconium oxychloride solution of 0.2kg in the first elevated tank 1, by controlling the valve, the zirconium oxych...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is:

[0034] In step B, 10% ammonia water and 30% sodium hydroxide are stirred and mixed according to the mass ratio of 8:1 to obtain an alkaline precipitant.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is:

[0037] In step B, 10% ammonia water and 30% sodium hydroxide are stirred and mixed according to the mass ratio of 6:1 to obtain an alkaline precipitant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com