Patents

Literature

62results about How to "Large heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

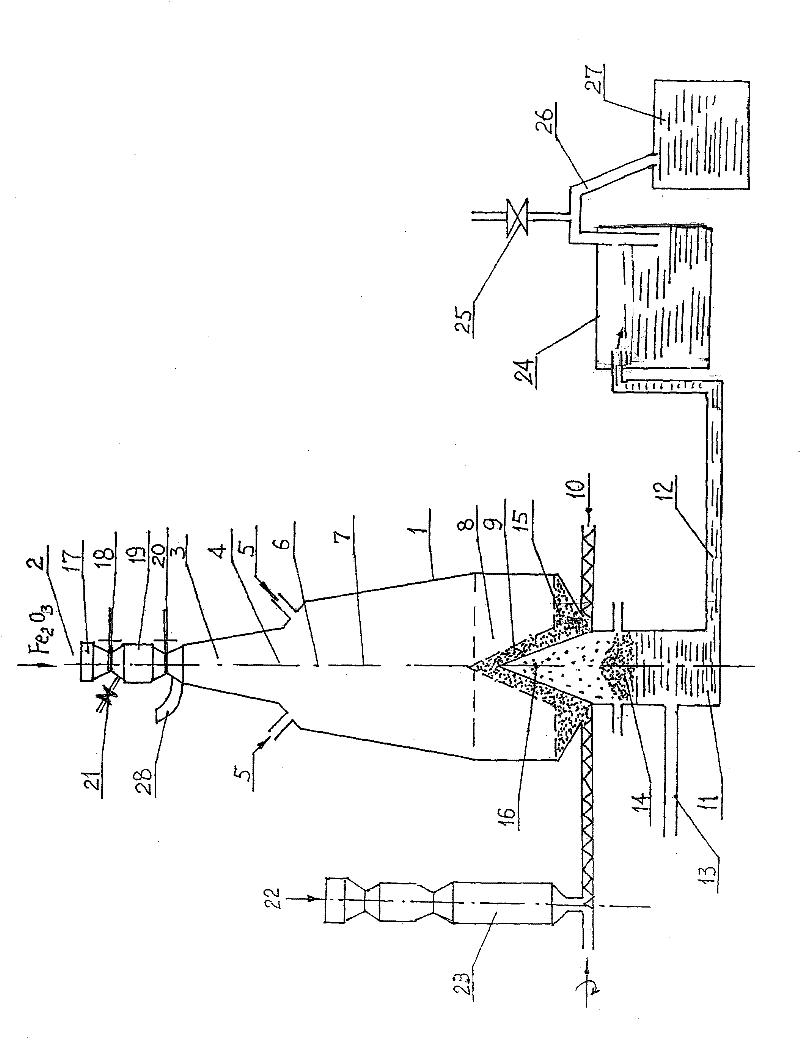

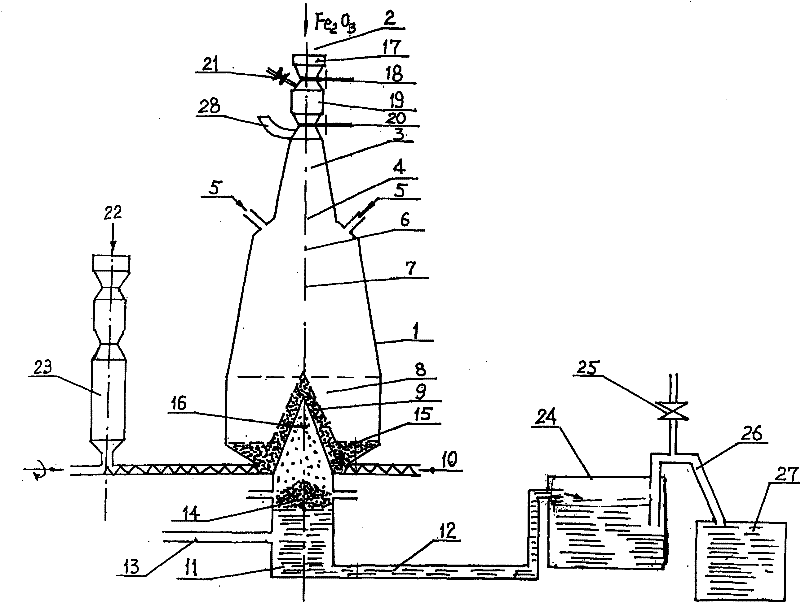

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

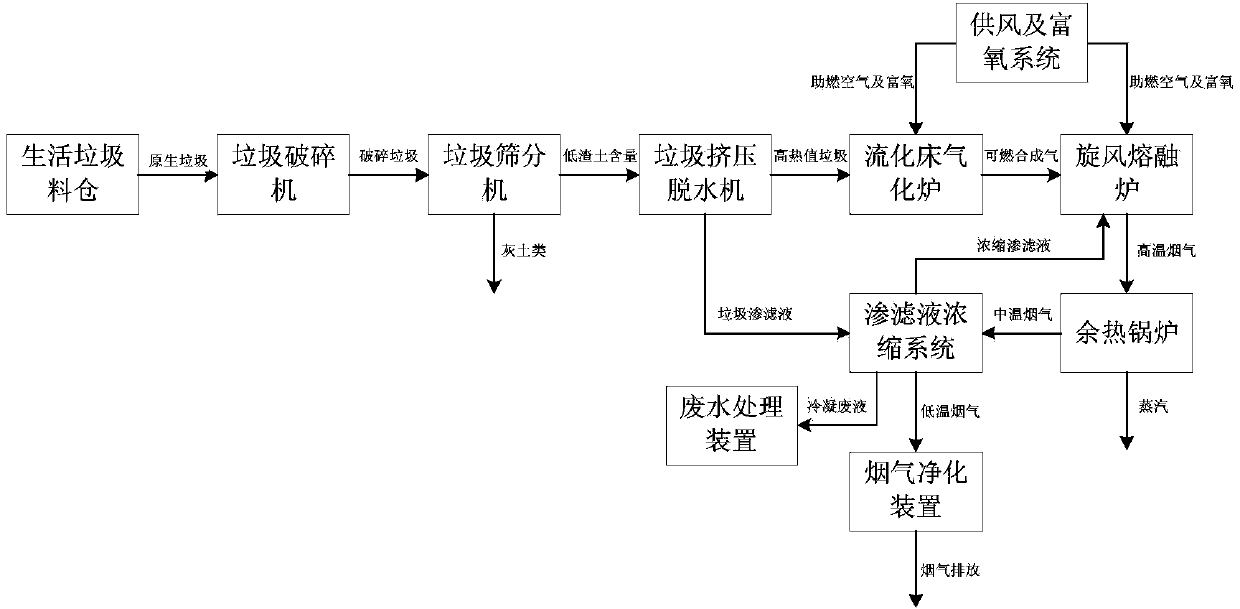

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

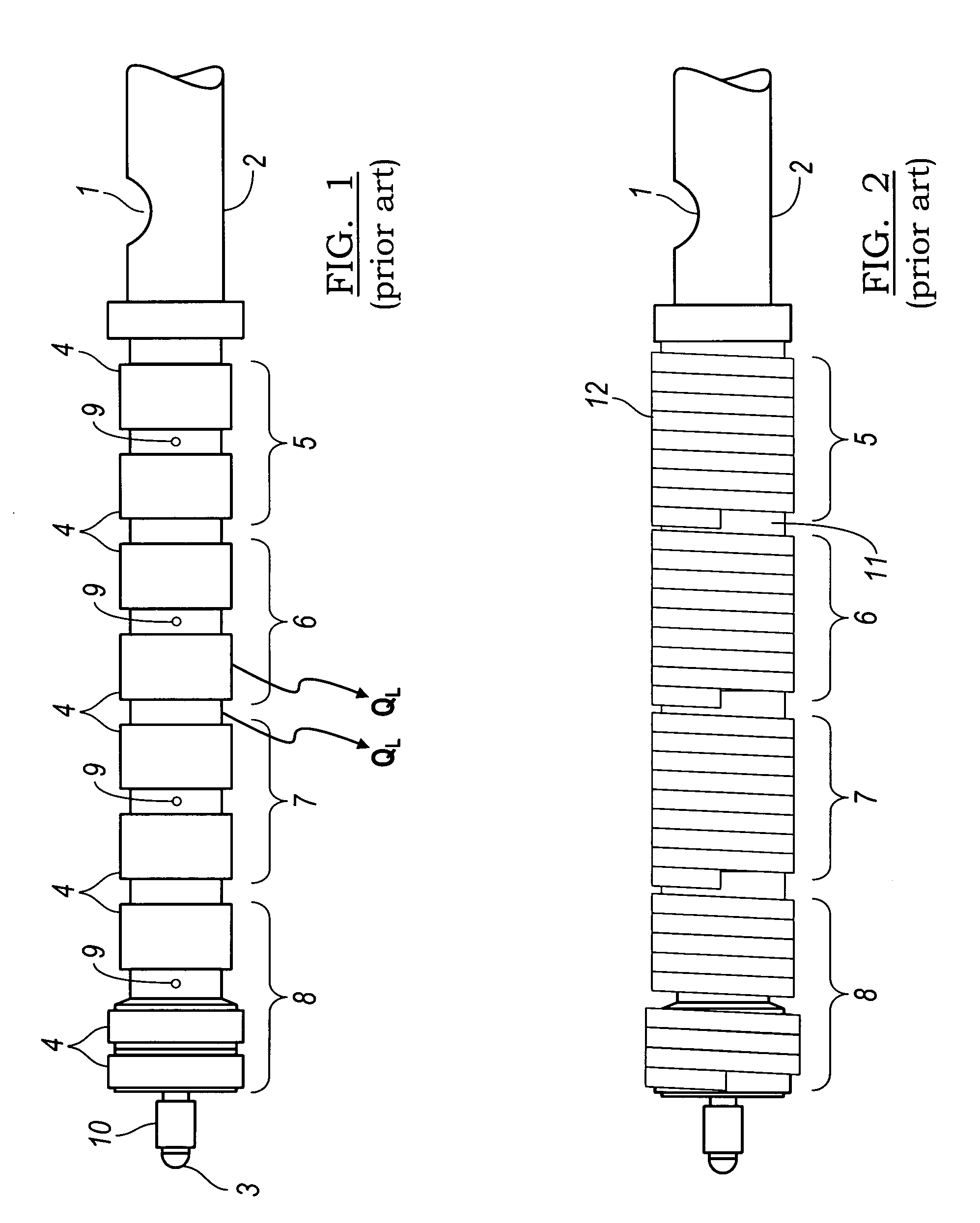

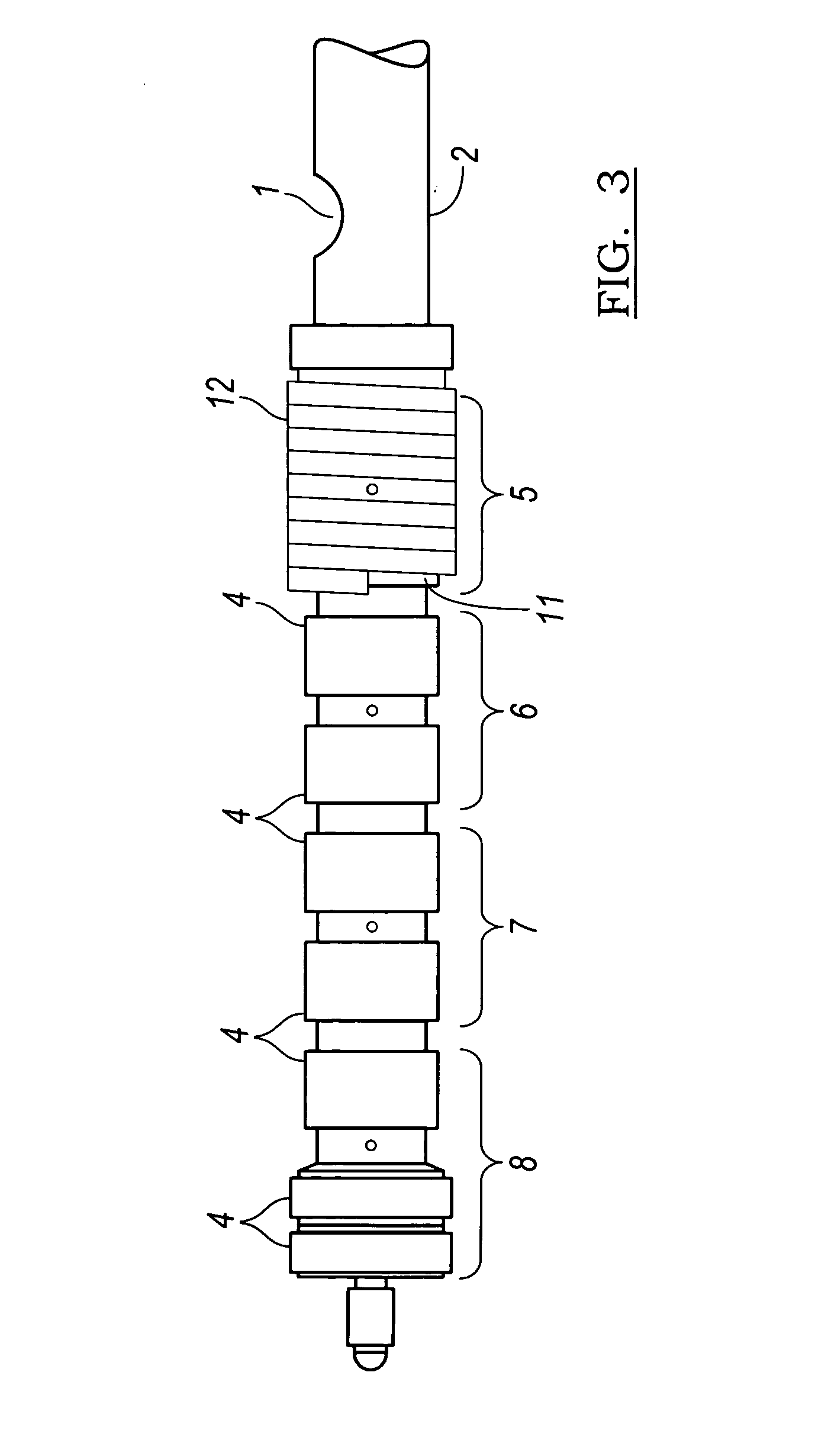

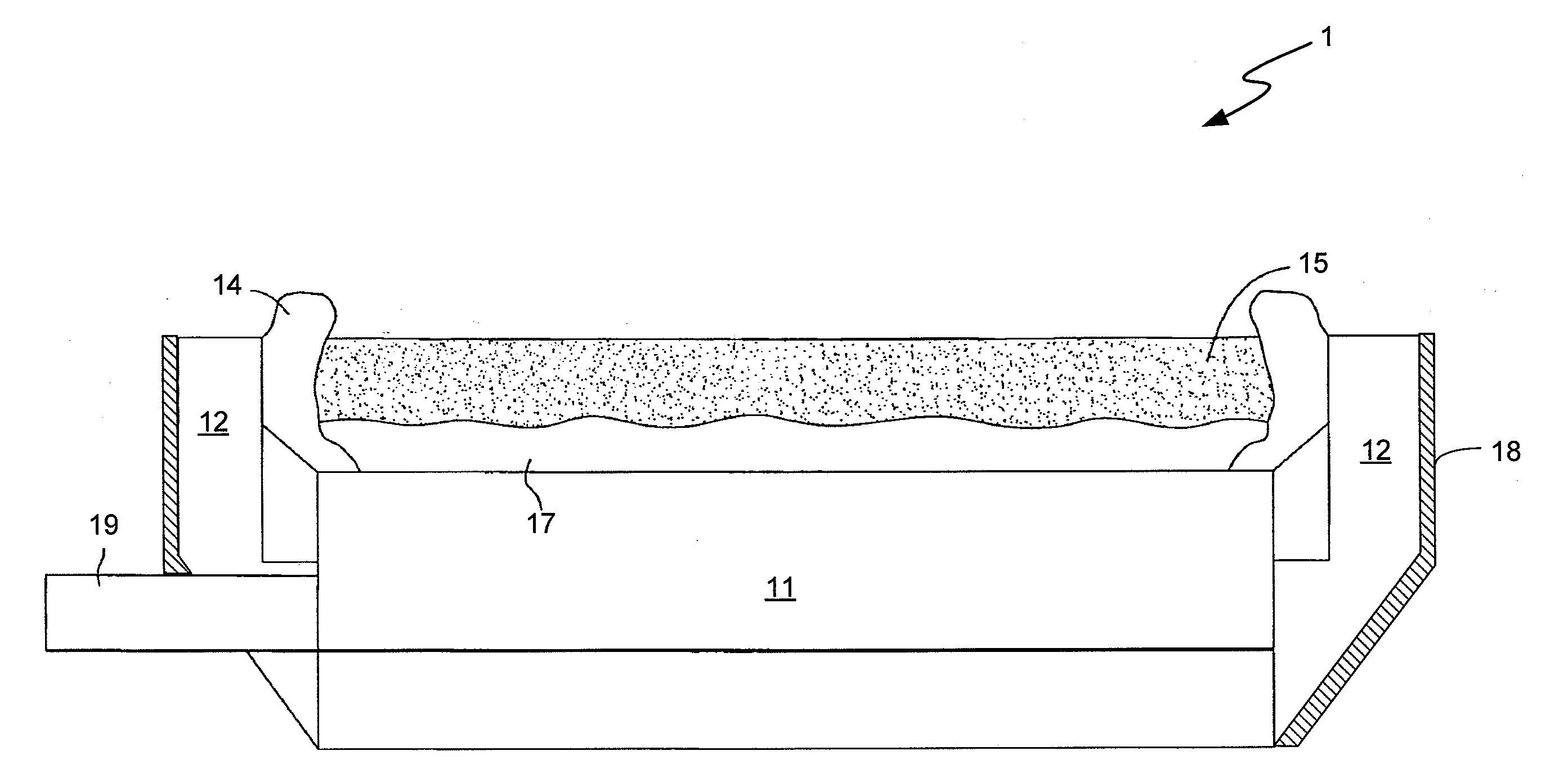

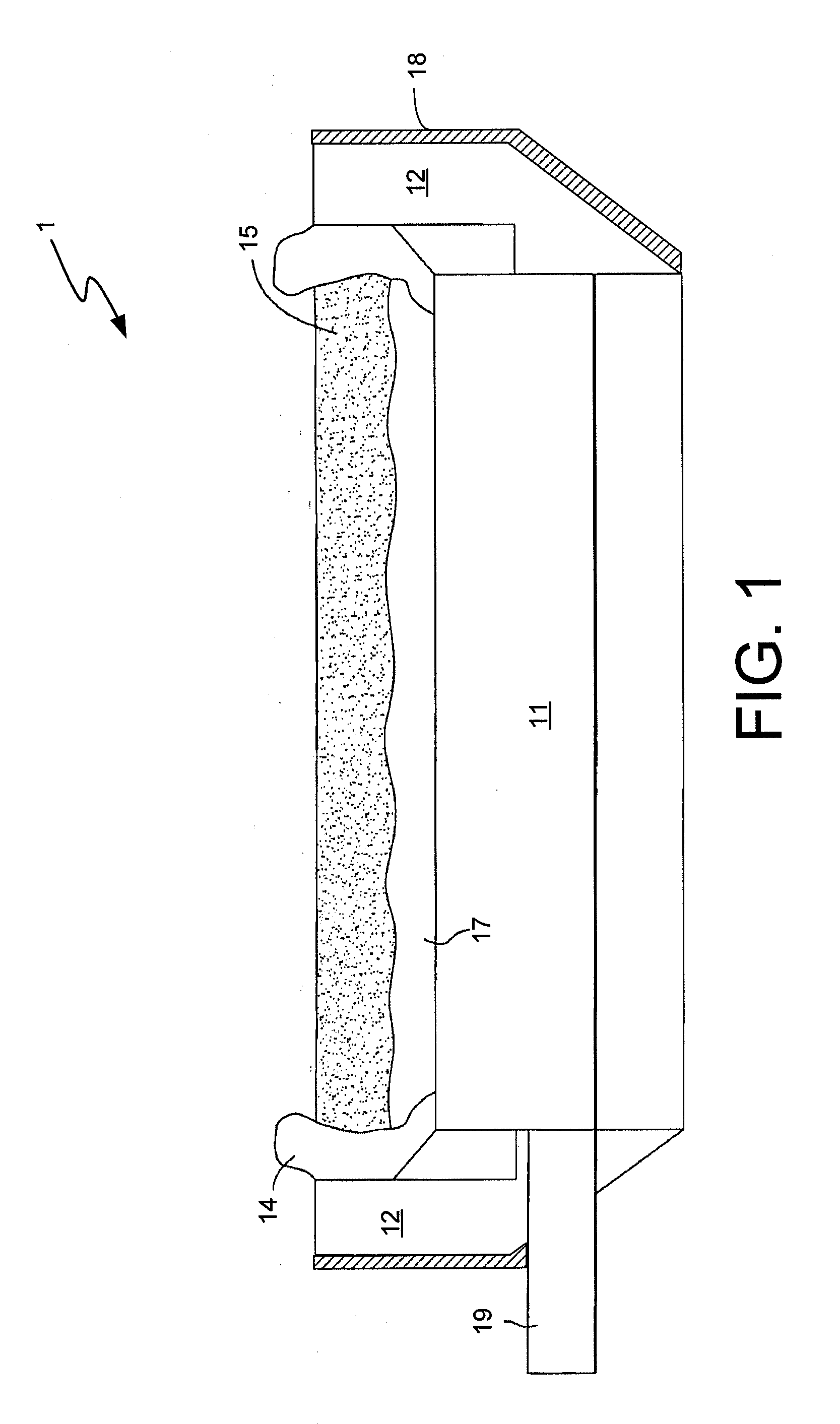

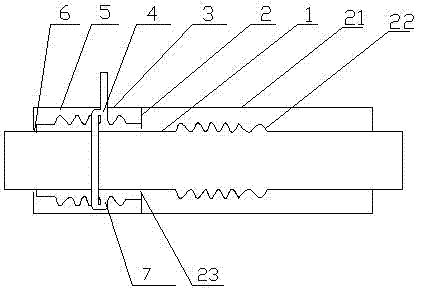

Heating system for plastic processing equipment having a profile gap

InactiveUS20090057300A1Improve returnLarge heat lossInduction heating apparatusHeating systemEngineering

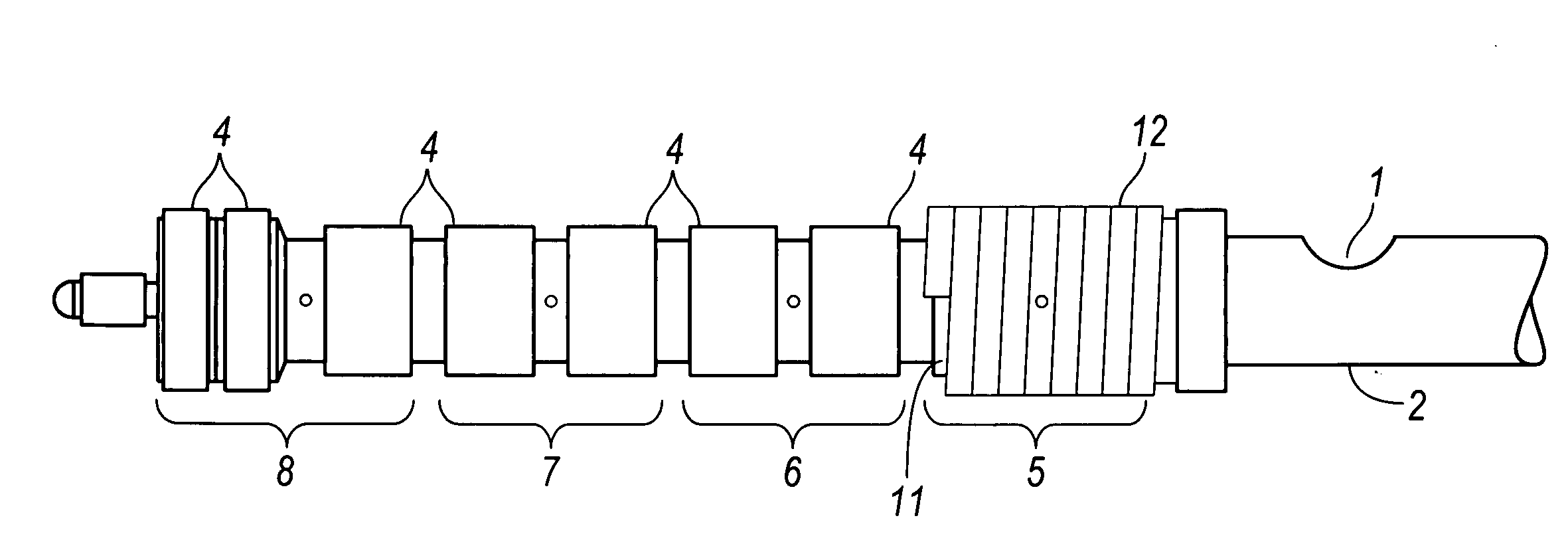

A system for processing plastic feed material includes a barrel having an upstream feed section and a downstream output section. A screw, supported for rotation in the barrel, cooperates with an inner surface of the barrel to form a path in which the feed material moves toward the output section. A heating system includes an induction winding encircling and extending along a portion of an outer surface of the barrel, and a gap interposed between the induction winding and the barrel and having a nonuniform thickness that varies around the periphery and corresponds to a varying wall thickness of the barrel.

Owner:XALOY INCORPORATED

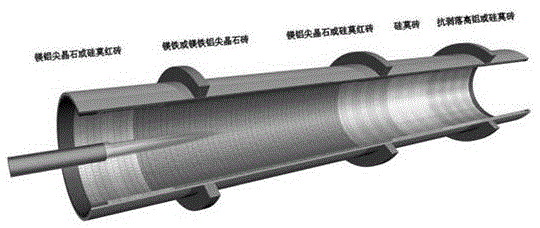

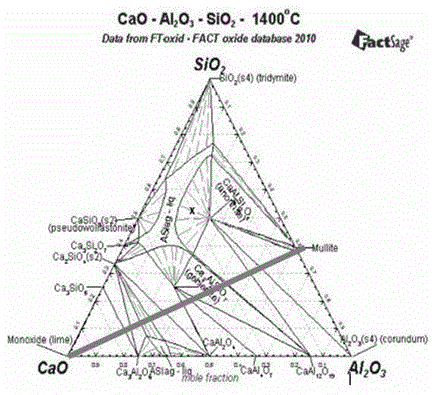

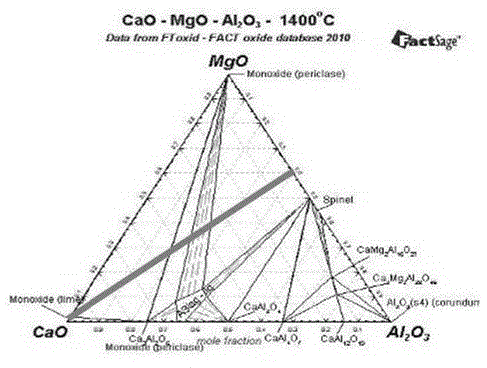

Preparation method of low-heat-conductivity magnesia-alumina spinel brick

ActiveCN105565794AReduced load and mechanical stressEnhanced resistance to peelingCeramic shaping apparatusCeramic layered productsMagnesiumBonding strength

The invention discloses a preparation method of a low-heat-conductivity magnesia-alumina spinel brick. The method is characterized in that the low-heat-conductivity magnesia-alumina spinel brick is prepared from a fire-resistant layer and a heat-insulating layer, and is made by sintering at the temperature of 1,550-1,750 DEG C. The fire-resistant layer of the low-heat-conductivity magnesia-alumina spinel brick prepared by the method is made of high-purity magnesia-alumina spinel, and has excellent high-temperature mechanical properties of erosion resistance, washout resistance, thermal shock resistance and mechanical stress resistance; the heat-insulating layer is made of magnesium-iron composite olivine, and has excellent high-temperature performance and a low heat conductivity coefficient; magnesium olivine and iron olivine are compounded, so that smooth transition of the heat conductivity coefficients of the heat-insulating layer and the fire-resistant layer is realized, high bonding strength is achieved, smooth transition from high heat conductivity to low heat conductivity is also realized, and the heat consumption is lowered.

Owner:ZIBO CITY LUZHONG REFRACTORIES CO LTD

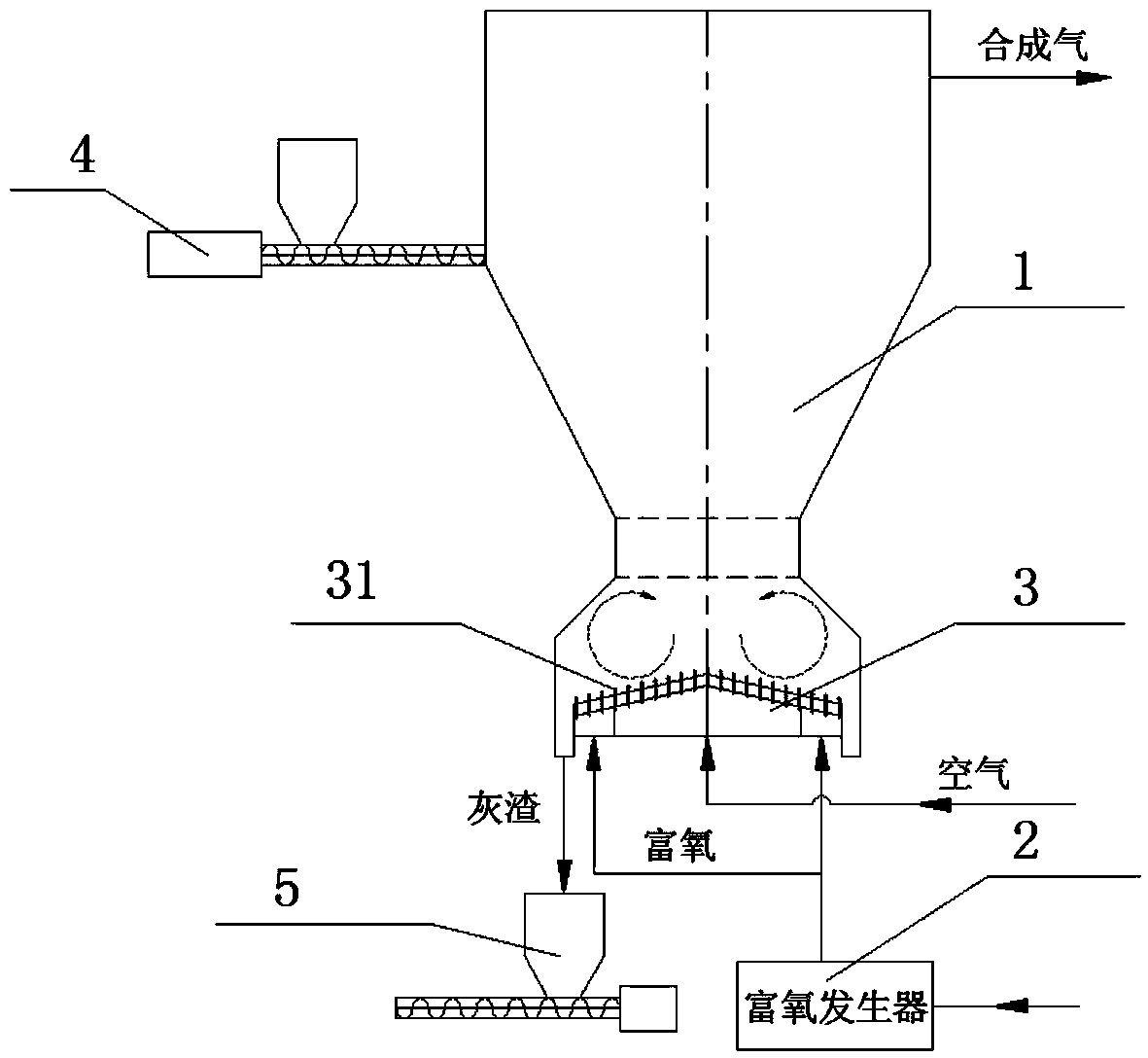

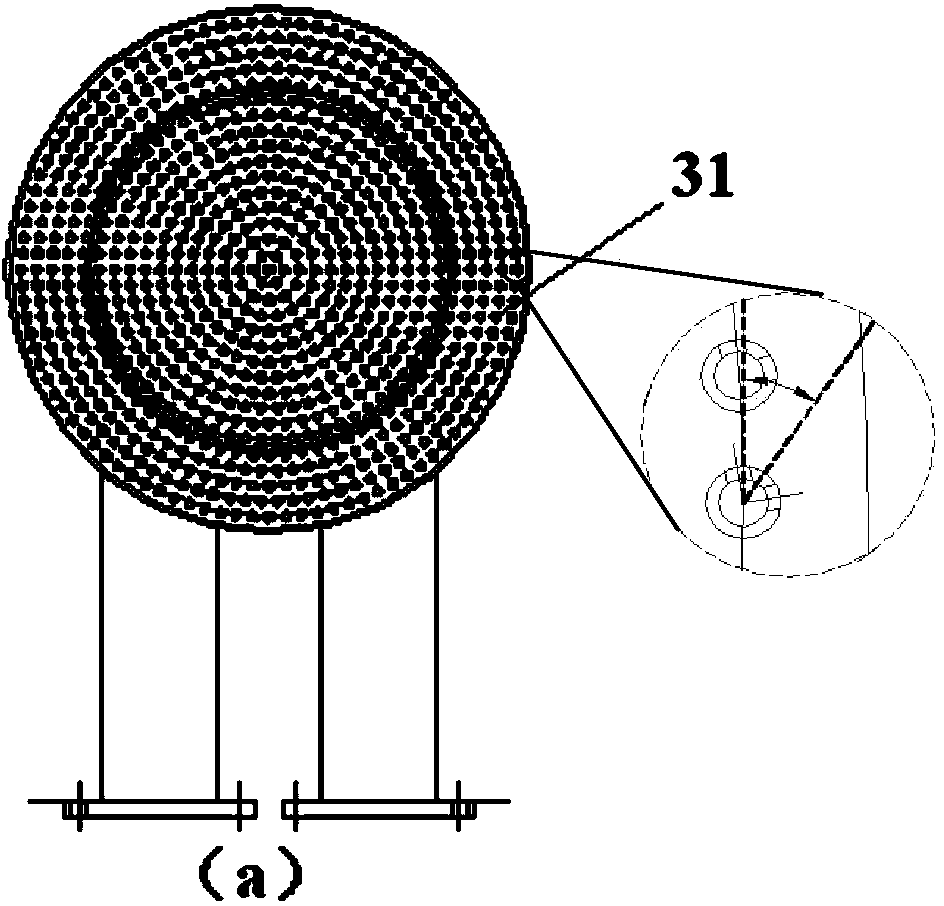

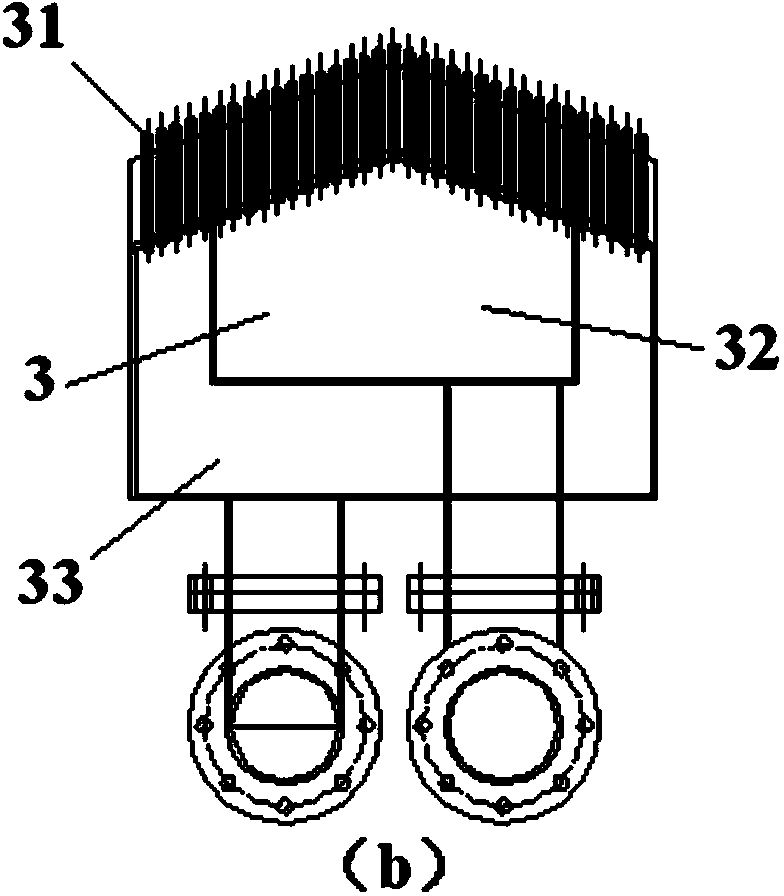

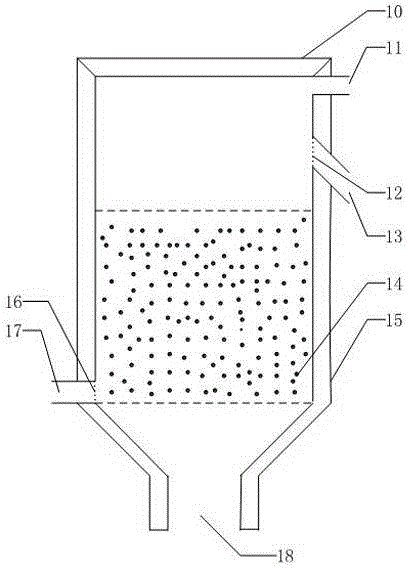

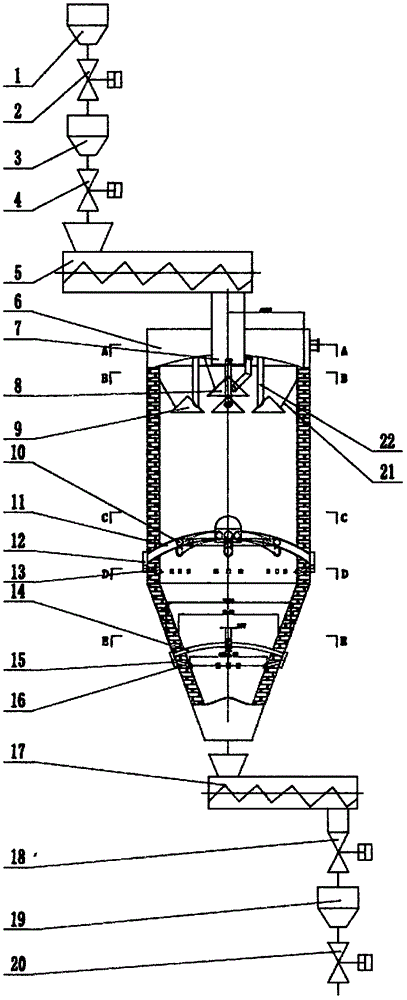

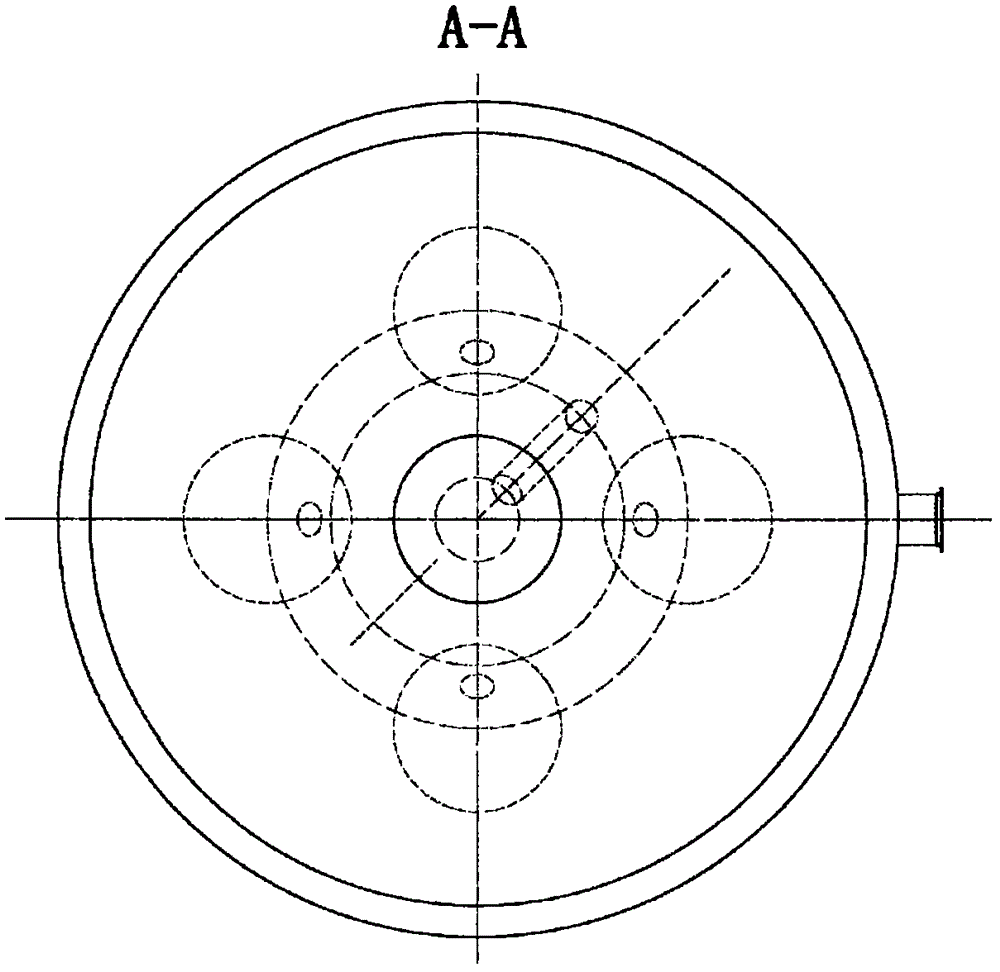

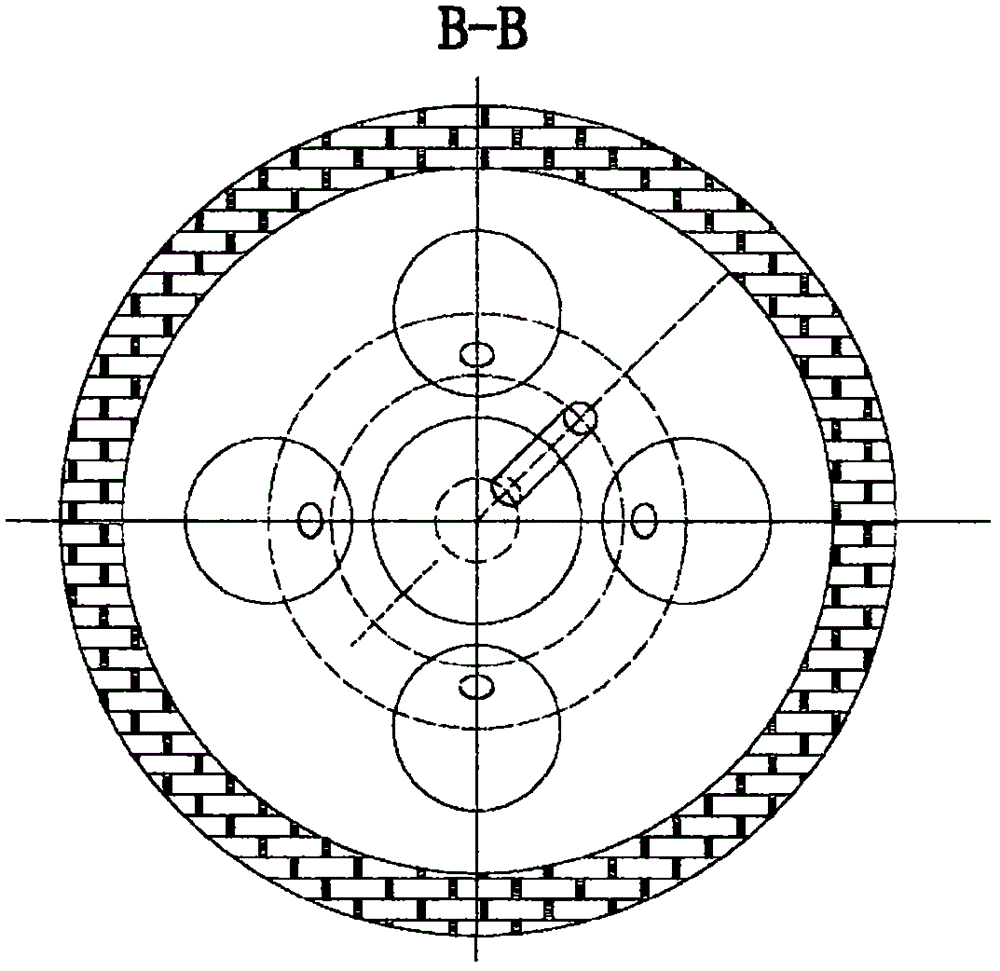

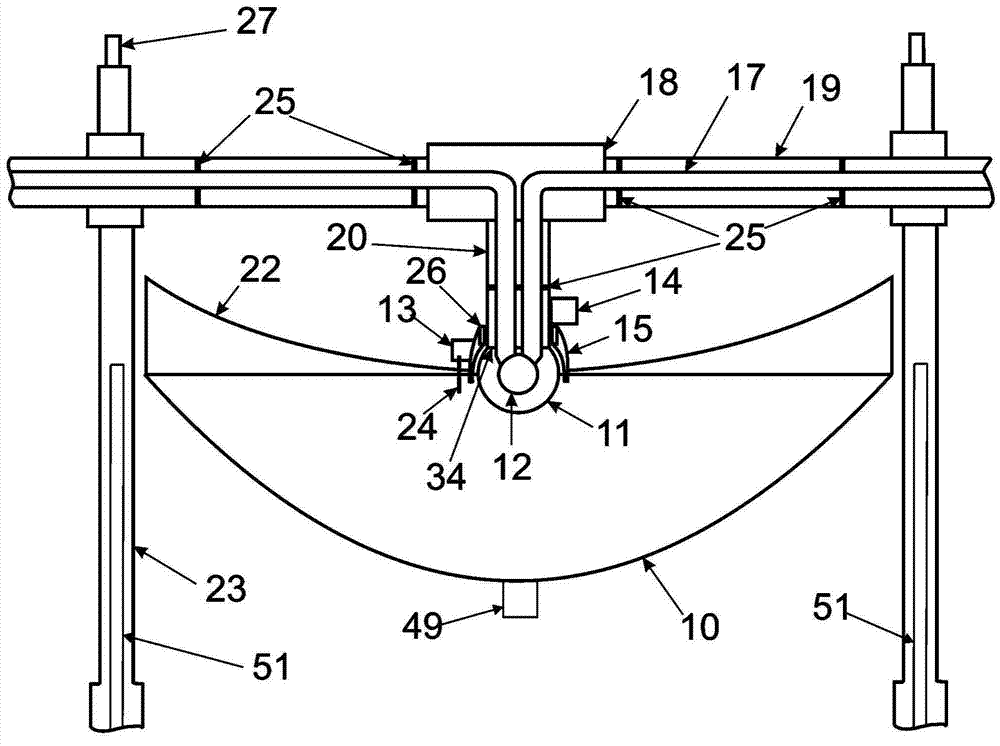

Internal circulating fluidized-bed oxygen-enriched gasification device

ActiveCN103471104AHigh calorific valueGood use effectIndirect carbon-dioxide mitigationIncinerator apparatusFluidized bedSlag

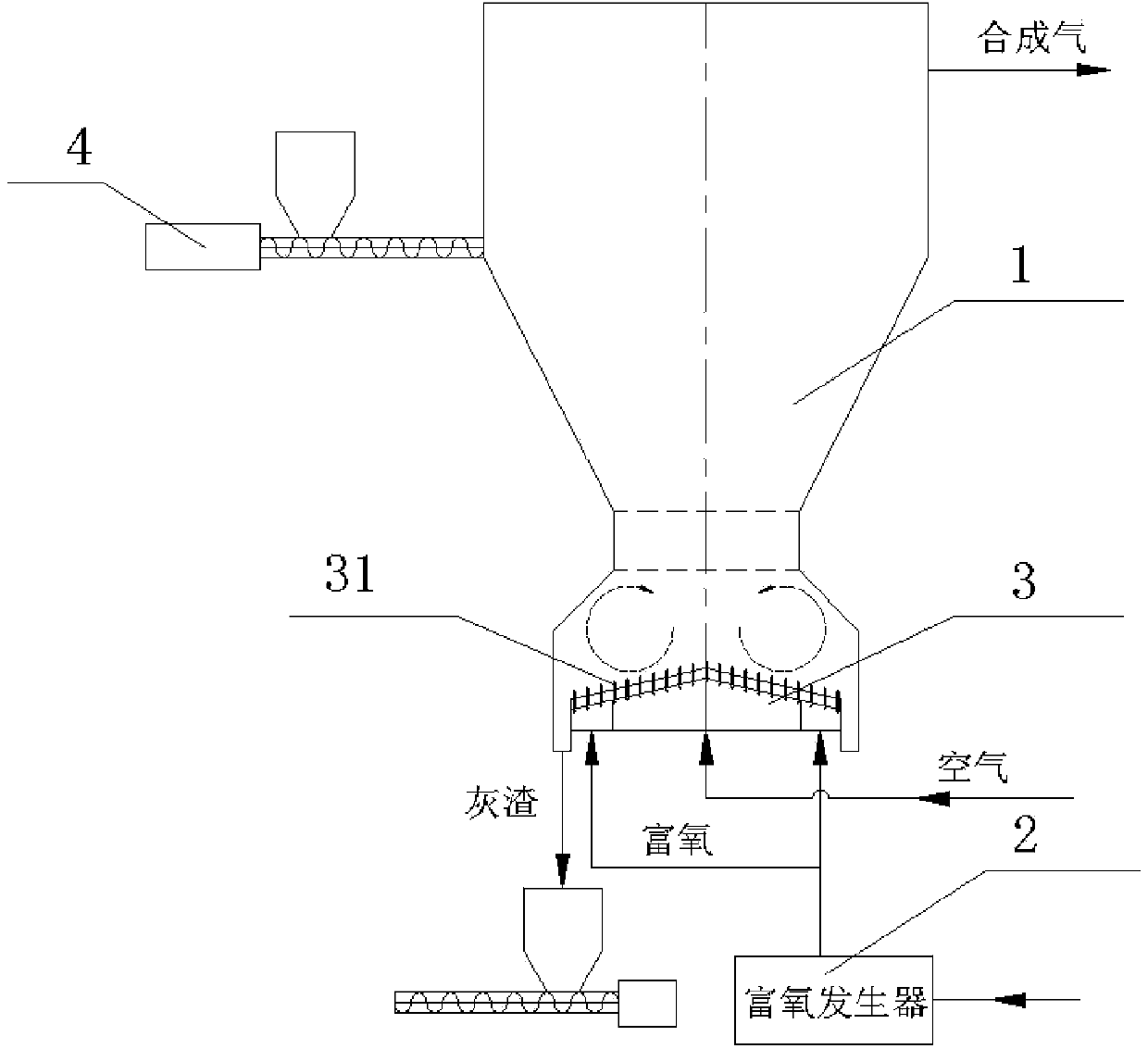

The invention provides an internal circulating fluidized-bed oxygen-enriched gasification device. The device comprises a gasifier body, a rich oxygen generation device, a multi-air-chamber air distribution device, a feeding device and a deslagging device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; the dense-phase region is connected with the dilute-phase region through a throat region; the multi-air-chamber air distribution device which is provided with directional wind caps is arranged at the bottom of the dense-phase region and is connected with the rich oxygen generation device; an outlet of the feeding device is arranged at the junction of the dense-phase section and the dilute-phase section; a slag outlet is arranged at a gap of the multi-air-chamber air distribution device and the gasifier body at the bottom of the dense-phase section; the deslagging device is arranged below the slag outlet. The system can efficiently realize pyrolysis and gasification of waste solid organic matters such as garbage and biomass, and has the advantages of high gasification speed, high conversion efficiency, less deslagging carbon residue, easiness in control over pollutants and the like.

Owner:XI AN JIAOTONG UNIV

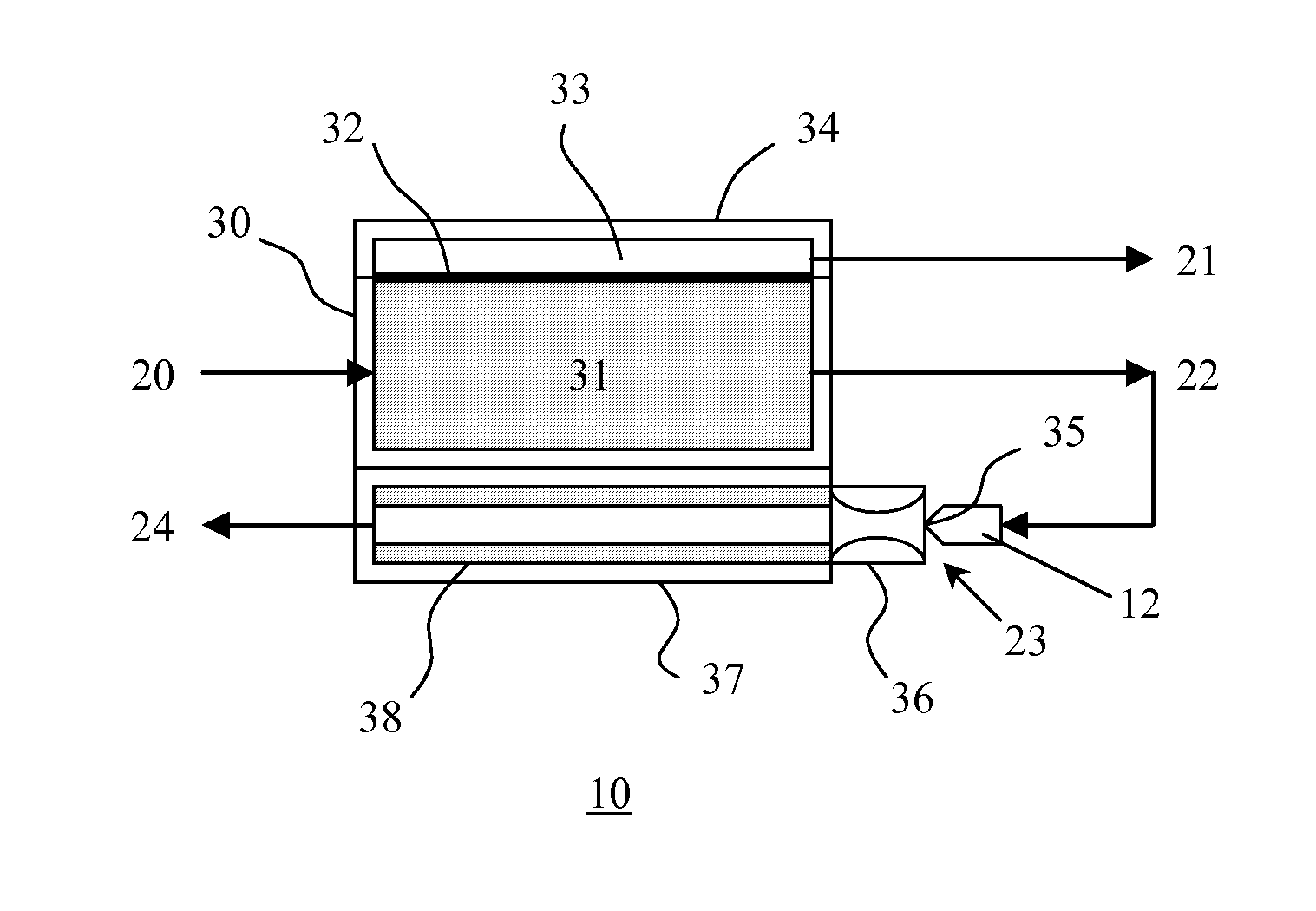

Aluminum electrolysis cell electrolyte containment systems and apparatus and methods relating to the same

InactiveUS20090236233A1Eliminate dependenciesEasy to operateCellsIsotope separationElectrolysisEngineering

Aluminum electrolysis cells and associated system and methods are disclosed. In one embodiment, an aluminum electrolysis cell includes an outer shell, a bottom, a plurality of bath resistant blocks defining a surrounding wall, and at least one spring member coupled to at least one of the plurality of bath resistant blocks and the outer shell, where the at least one spring member is configured to maintain the plurality of bath resistant blocks in a substantially leak-tight configuration.

Owner:ARCONIC INC

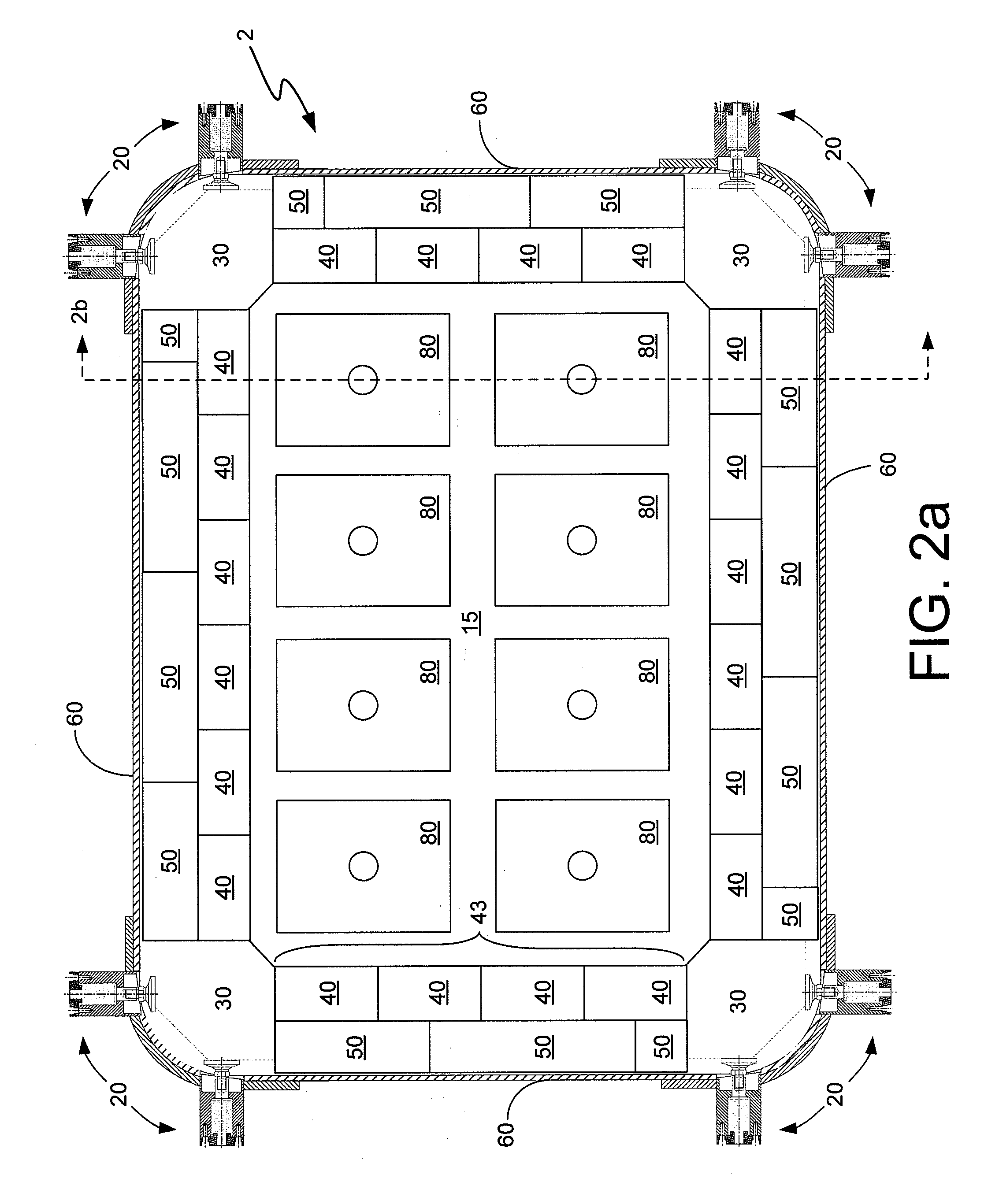

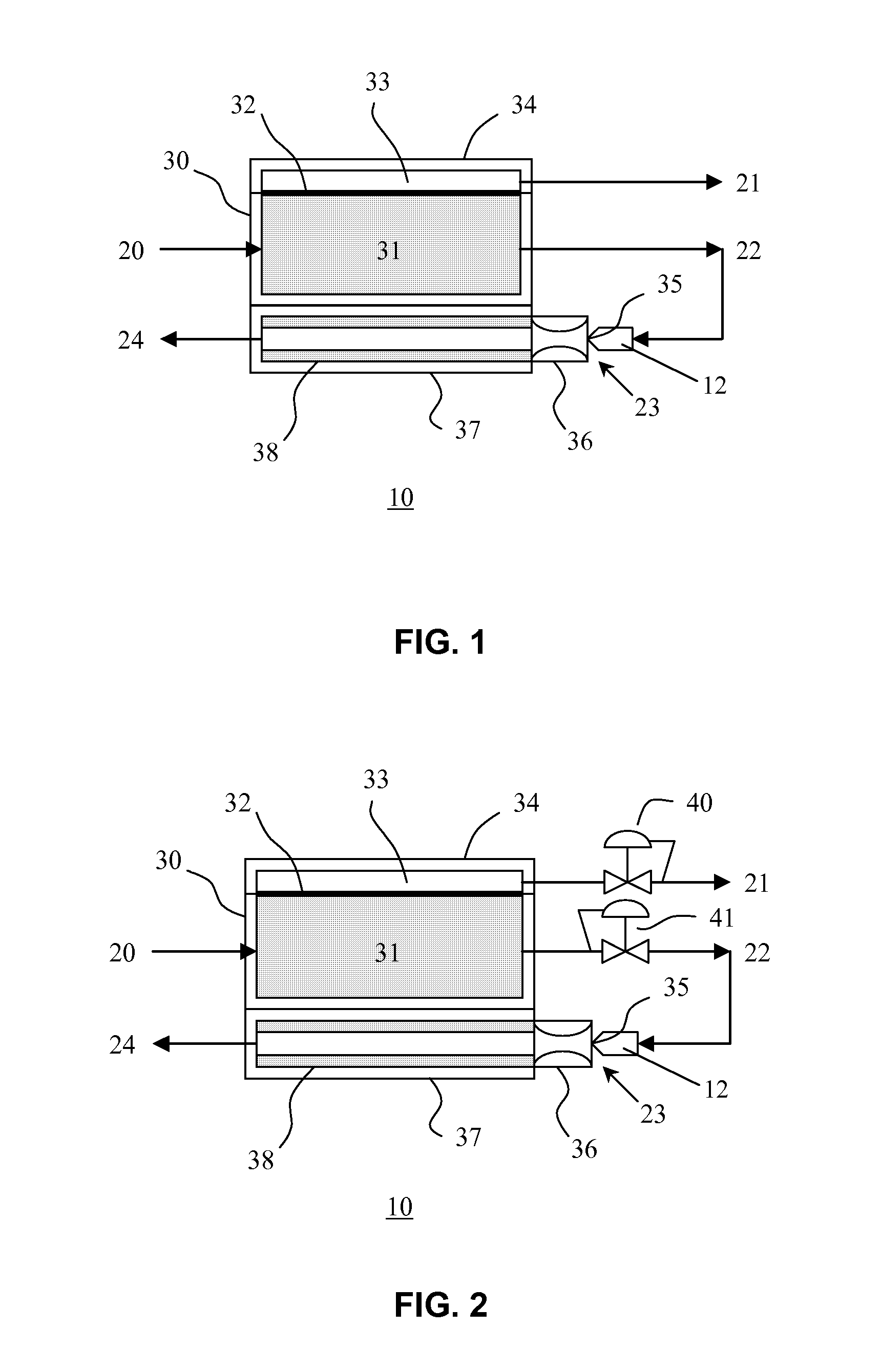

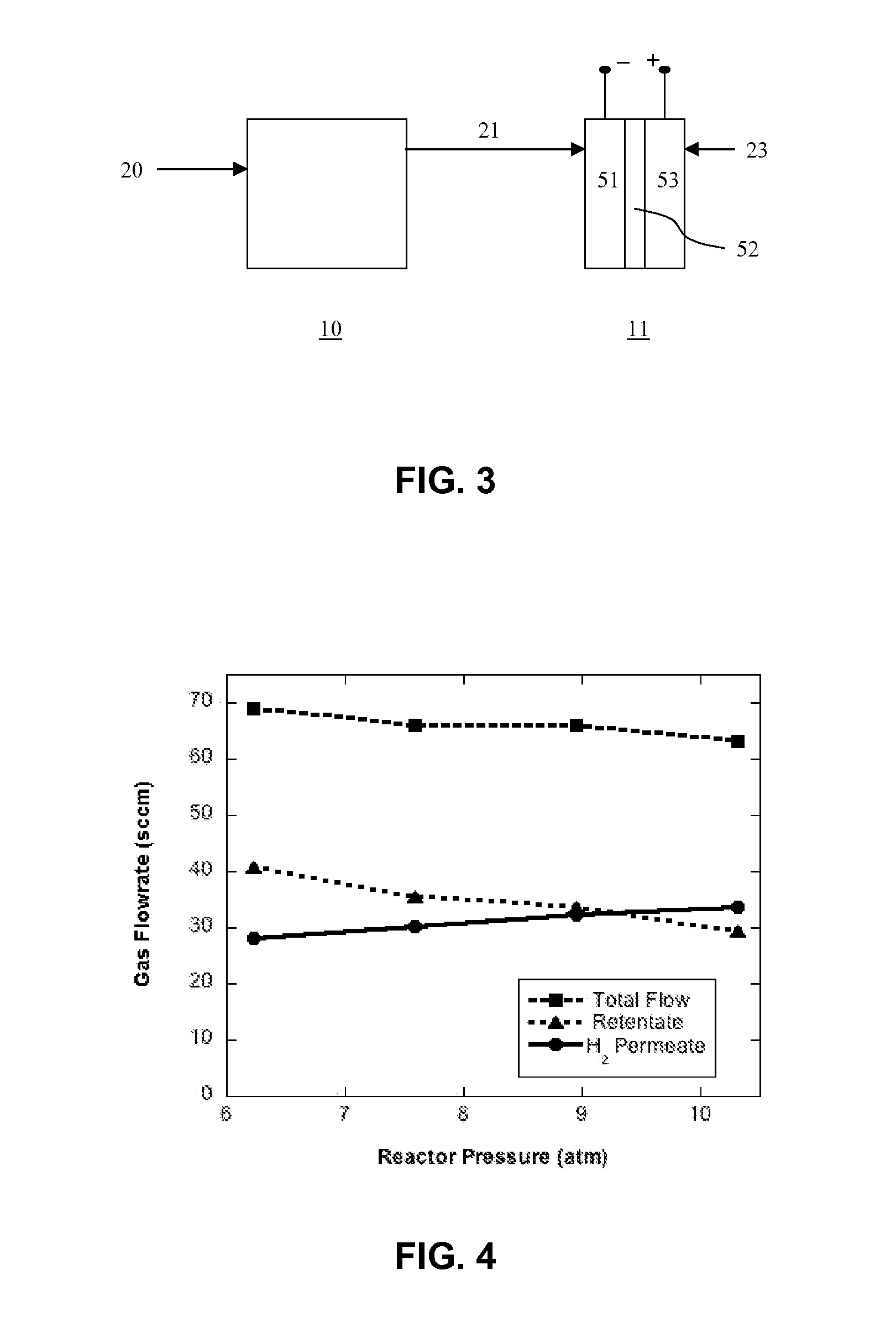

Method and Apparatus for Generating Hydrogen

InactiveUS20070116995A1Eliminate needLarge heat lossChemical industryFuel cell auxillariesChemistryDecomposition

Method and apparatus for generating hydrogen from a fuel comprising an endothermically decomposable compound, preferably methanol, and optionally comprising water. A catalyst is preferably used to decompose the methanol into hydrogen and CO. The catalyst preferably has low selectivity for reacting the CO and water to form CO2 and hydrogen. A permselective membrane, preferably cleaned by the water, is used to separate the hydrogen. The retentate has fuel value and is reacted or otherwise burned in order to provide heat for the decomposition reaction.

Owner:WILSON MAHLON S

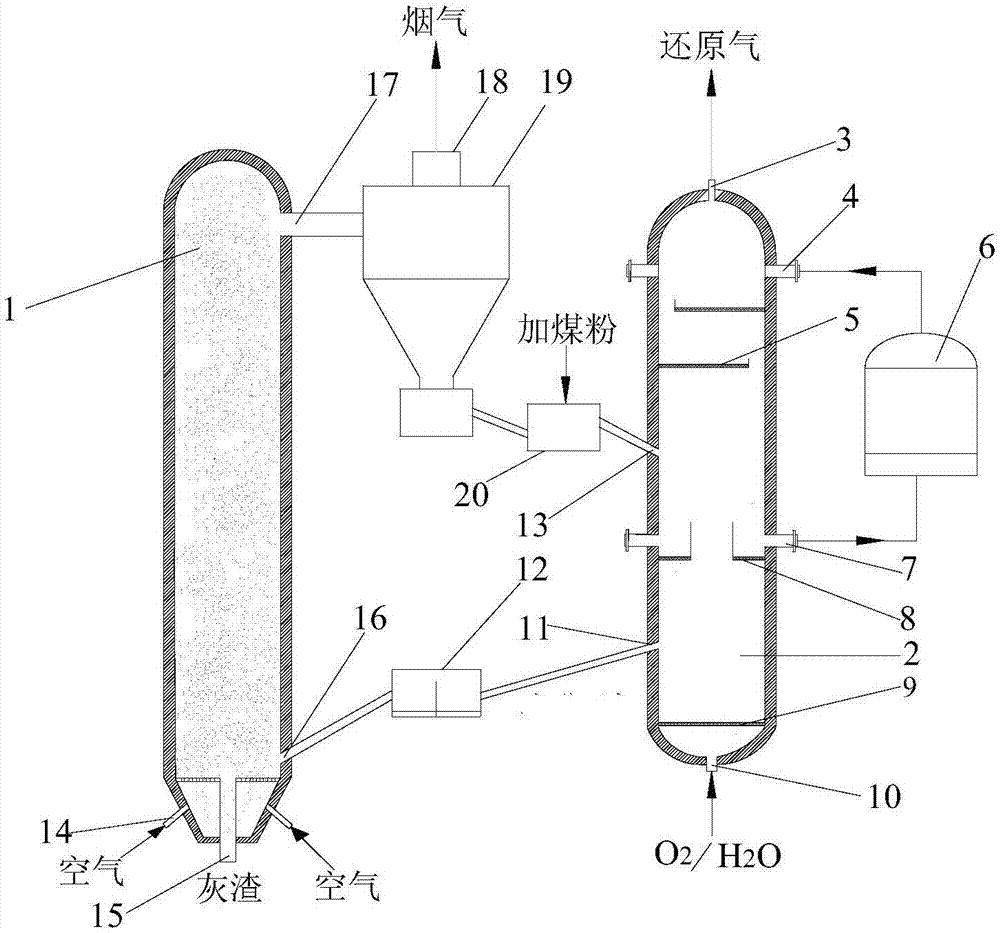

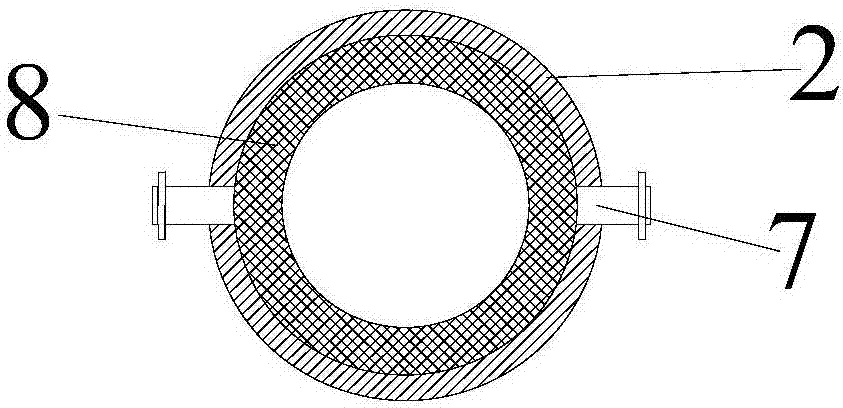

System and method for preparing reducing gas through lignite double-bed gasification

ActiveCN107118807ARich reservesGood catalytic propertiesGasification processes detailsGranular/pulverulent flues gasificationCombustionFlue gas

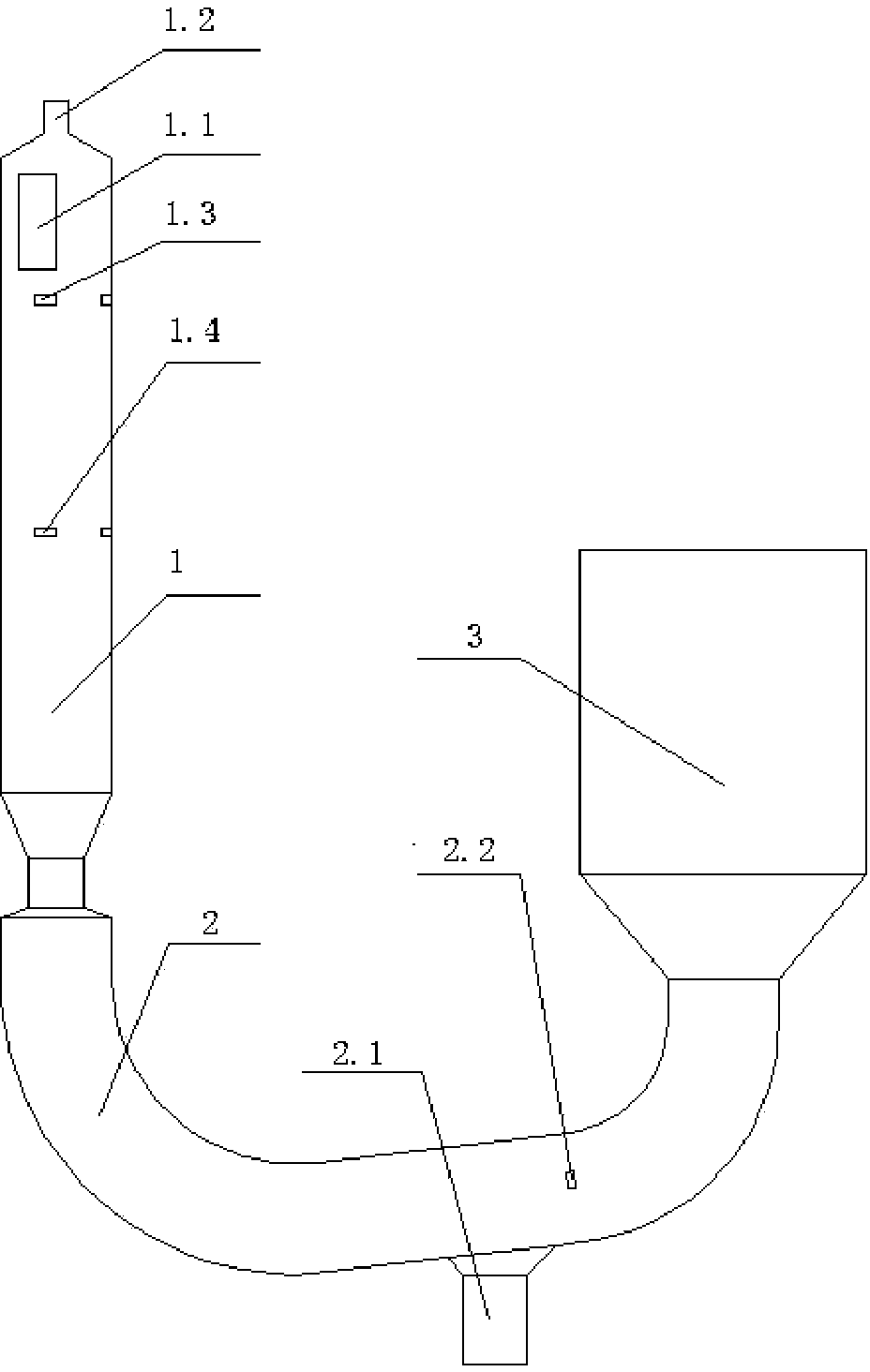

The invention provides a system and a method for preparing reducing gas through lignite double-bed gasification. The system comprises a combustion furnace, a gasification furnace, a gas solid separator, a material return device, a catalyst tank and a pulverized coal mixing device; the combustion furnace is provided with a flue gas outlet, a semi-coke / ash inlet, an ash residue outlet and an air inlet; a gasifying agent distribution plate, a semi-coke collecting plate and a catalyst supporting plate are arranged in the gasification furnace; a semi-coke / ash outlet, a semi-coke outlet, a catalyst inlet and a feeding port are formed in the side wall of the gasification furnace; the semi-coke / ash outlet is connected with the semi-coke / ash inlet through the material return device; the semi-coke outlet is connected with a catalyst inlet of the catalyst tank; the catalyst inlet is connected with a catalyst outlet of the catalyst tank; and the feeding port is connected with a discharging port of the pulverized coal mixing device. By utilization of the system, the reducing gas can be prepared from the lignite, and the reducing gas can be applied to a gas-based shaft furnace to perform direct reduction iron making without needing a conversion device to adjust gas components.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

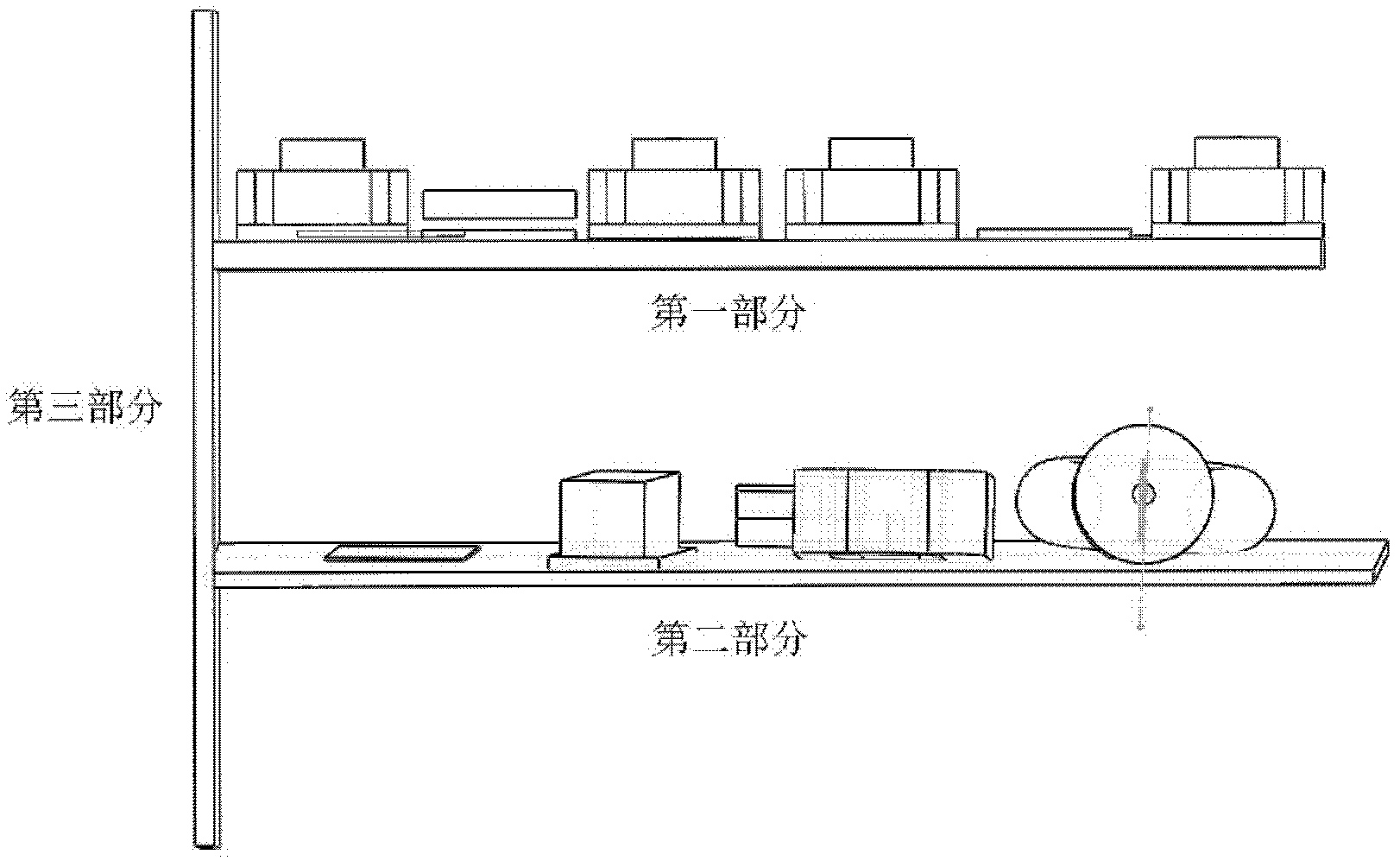

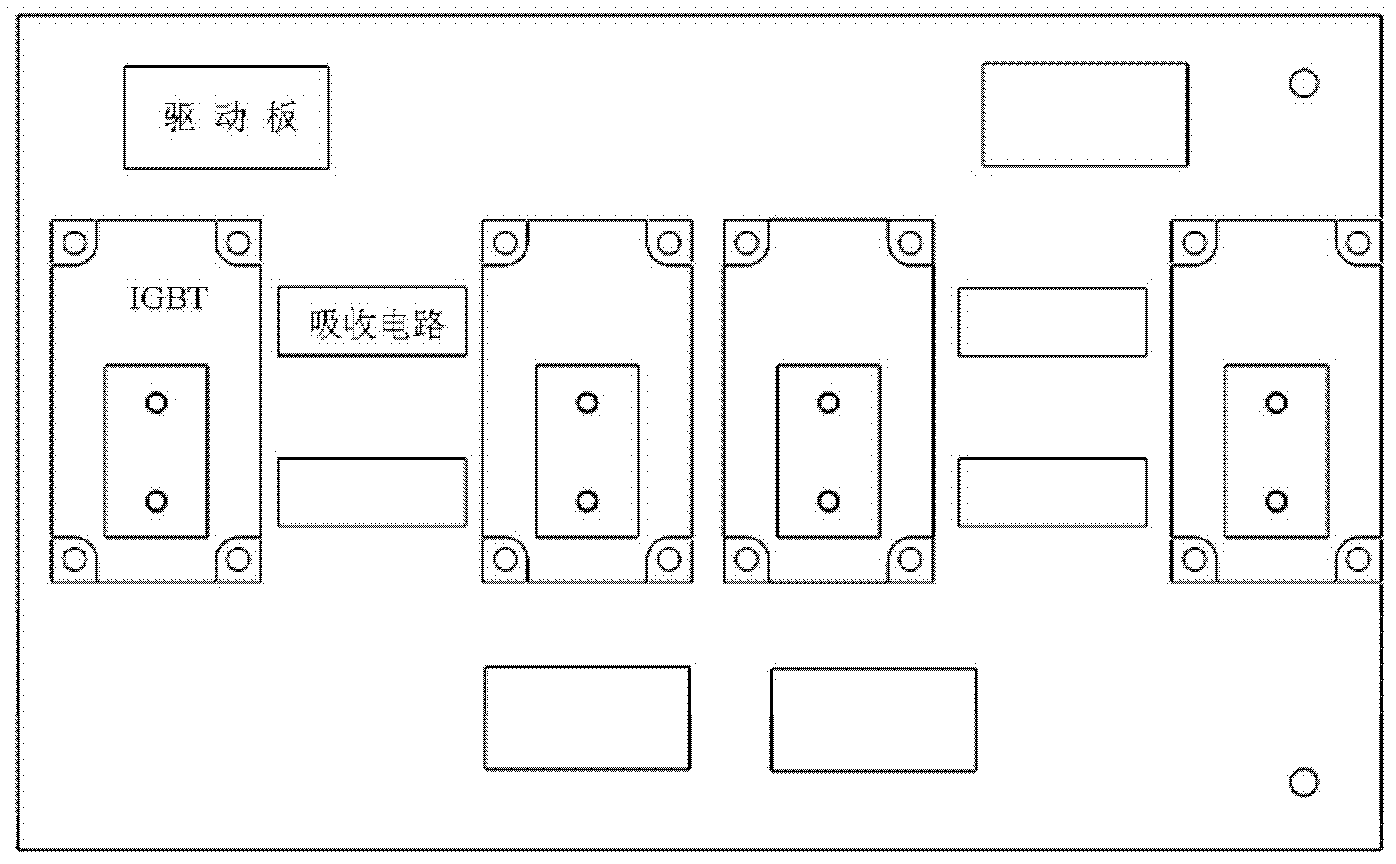

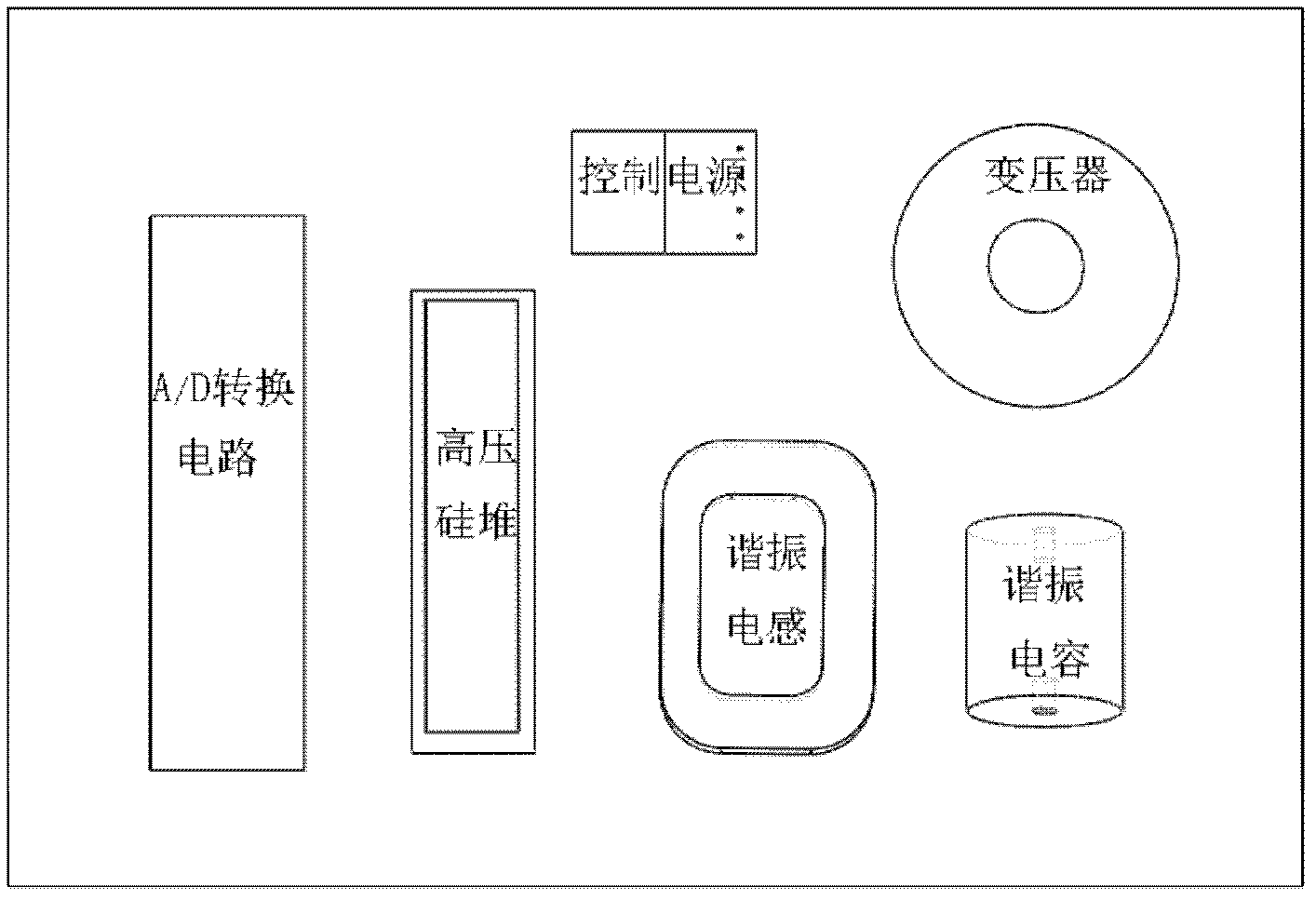

High-frequency high-voltage power supply structure

InactiveCN102223056AImprove power densityLarge heat lossApparatus with intermediate ac conversionEngineeringHigh pressure

The invention discloses a high-frequency high-voltage power supply structure. A cabinet has two layers; the first layer comprises an inverter unit and a driving circuit thereof; the second layer comprises a resonant capacitor, a resonant inductor, a high-frequency high-voltage transformer, a high-frequency high-voltage rectifier circuit and a voltage measurement circuit; the first layer and the second layer are arranged in the power supply cabinet in parallel; and a control circuit is vertically arranged on the left of the first layer and the second layer, and has a 90-DEG inverted n shape. The inverter unit is directly connected with an aluminum plate radiator; one end of the aluminum plate radiator is fixed on the power supply cabinet via a bolt, and the other end of the aluminum plate radiator is fixed on an aluminum shield plate via a bolt; and the bottom end of the aluminum shield plate is connected with a base plate of the power supply cabinet.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

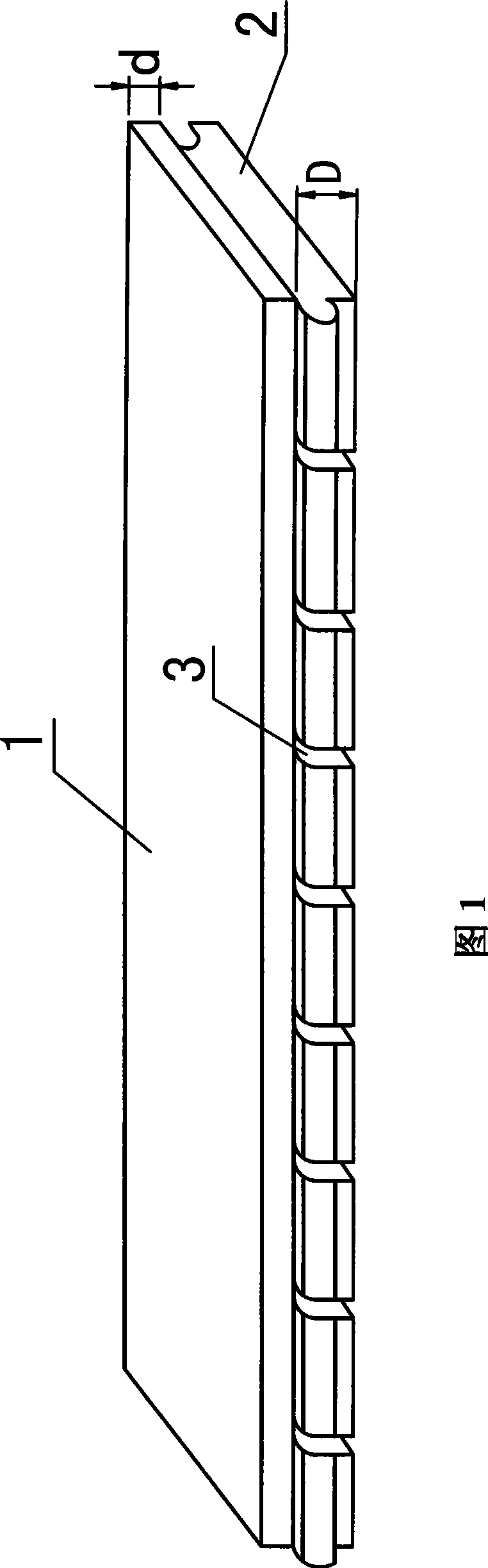

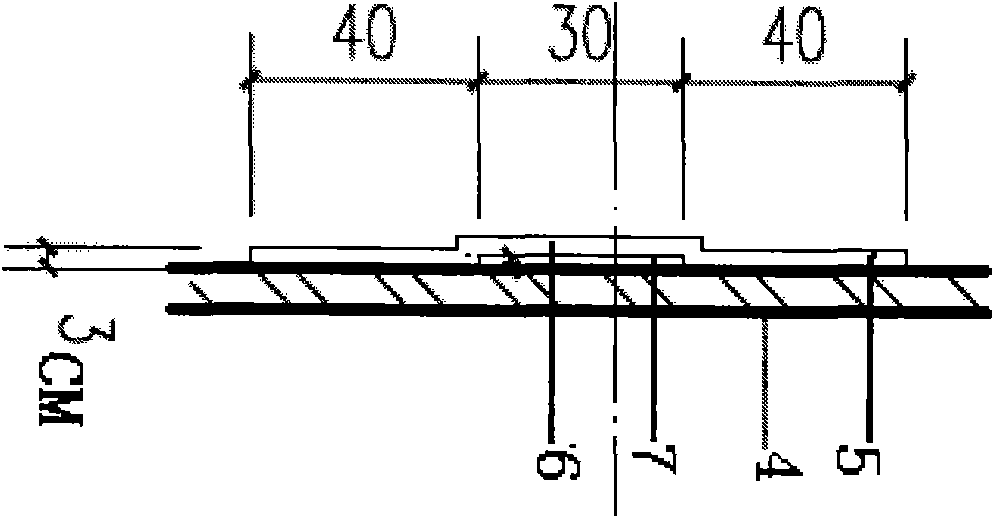

Two-layer charring solid wood terrestrial heat composite floor

InactiveCN101372863AOvercome heat bending deformationOvercome the defects of hygroscopic expansionFlooringSolid woodEngineering

The invention discloses a terrestrial heat compound floor board of two layers charring solid wood, which comprises a surface board (1) and a bottom board (2), wherein the surface board (1) is made of charring wood, the bottom board (2) is made of briar wood, and terrestrial heat grooves (3) are formed on the bottom board (2). The invention has the advantages of less possibility of being heated and bended or deformed, stability, corrosion resistance, durability, high heat transferring speed, high coefficient of heat conductivity, energy conservation and environment protection, by adopting the charring wood as the surface board and the briar wood as the bottom board.

Owner:张勇

Method for extracting zirconium oxide from zirconium-containing solid solution substance

ActiveCN103950977ALarge heat lossDecrease stockZirconium oxidesNatural resourceZirconium oxychloride

The invention relates to a method for extracting zirconium oxide from a zirconium-containing solid solution substance. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance comprises the following steps: mixing zirconium-containing solid solution substance powder with sodium hydroxide and then heating and sintering, so that an acid-soluble sintered material is obtained, carrying out immersion cleaning on the acid-soluble sintered material with a diluted hydrochloric acid aqueous solution, enriching for obtained mixture of sodium zirconate and zirconium hydroxide and a salt solution, carrying out hot dipping on the mixture for obtaining a zirconium oxychloride solution with a hydrochloric acid solution, evaporating, concentrating and cooling the zirconium oxychloride solution for separating out zirconium oxychloride crystals, and purifying the obtained zirconium oxychloride crystals; carrying out neutralizing treatment on the salt solution, extracting useful components, and then concentrating the salt solution for obtaining industrial salt. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance has the advantages of simple technological process, energy conservation, low consumption, high metal recovery rate, less environmental pollution, benefit to harmonious development of natural resources and the ecological environment and obvious resource recycling effect.

Owner:山东鸿远新材料科技股份有限公司

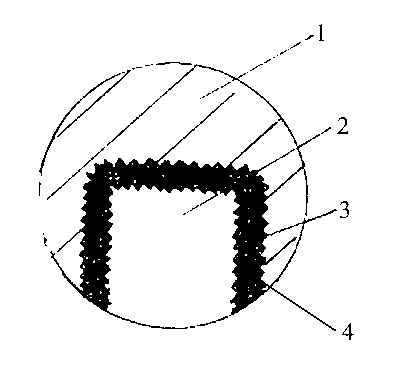

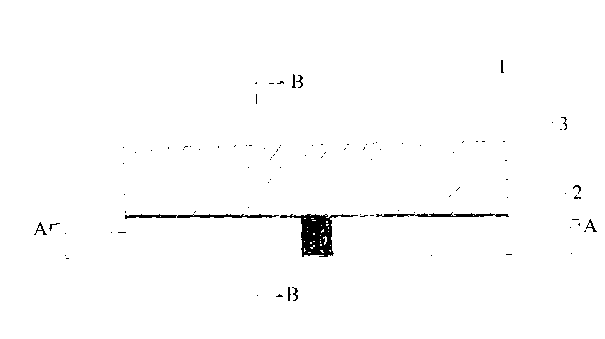

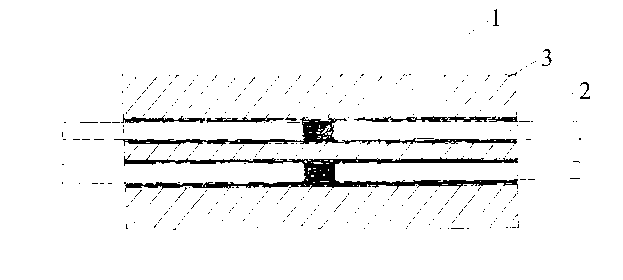

Cathode carbon block and cathode steel bar combined structure of aluminium electrolytic bath

InactiveCN103255436ACathode voltage drop decreasesCathode voltage dropsAluminium electrolysisVoltage drop

The invention belongs to the technical field of aluminium electrolysis and specifically relates to a cathode carbon block and cathode steel bar combined structure of an aluminium electrolytic bath. The technical scheme provided by the invention comprises a cathode carbon block and a cathode steel bar. The bottom of the cathode carbon block is provided with a steel bar groove. The cathode carbon block and cathode steel bar combined structure is characterized in that part of the cathode steel bar along the length direction is positioned inside the steel bar groove and part of the cathode steel bar extends out from the steel bar groove, wherein the part of the cathode steel bar inside the steel bar groove is 30-200mm higher than the part which extends out from the steel bar groove; especially, grooves of 1-5mm depth are also processed on the bottom surface and side surfaces of the steel bar groove; and grooves are processed in the length direction of the cathode steel bar on the top and side surfaces of the cathode steel bar inside the steel bar groove. According to the technical scheme, voltage drop of the cathode steel bar is reduced, electrolytic bath heat loss caused by increasing of cross section of the cathode steel bar is not increased, contact area between the cathode steel bar and cathode carbon paste and contact area between the surface of the cathode steel bar groove and the carbon paste are increased, and contact voltage drop is effectively decreased.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

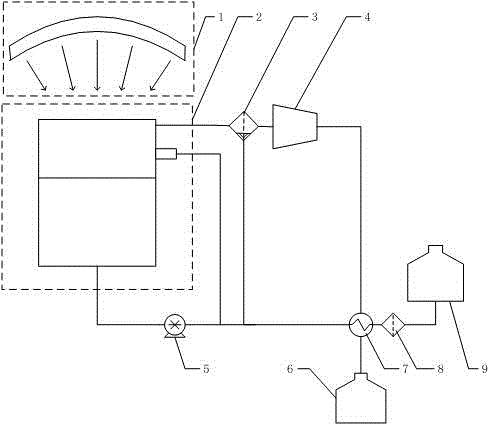

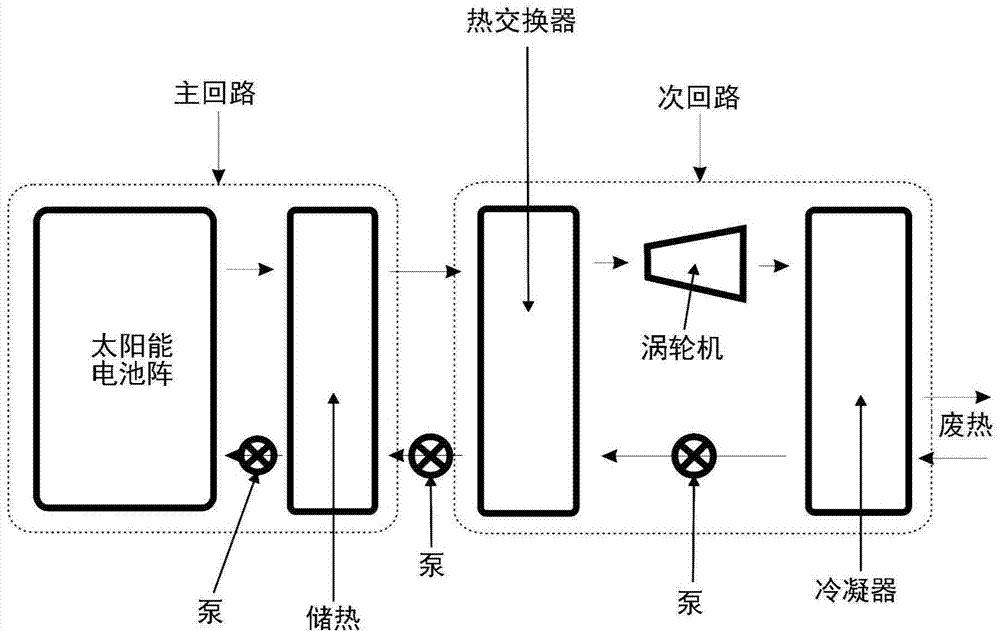

System and method for desalinating seawater through absorbing solar energy via liquid-solid fluidized bed

InactiveCN103910398AGood absorptionReduce heat lossGeneral water supply conservationSeawater treatmentSeawaterLiquid storage tank

The invention discloses a system and a method for desalting seawater through absorbing solar energy via a liquid-solid fluidized bed, belonging to the field of solar-powered seawater desalination technologies. The system comprises a solar spotlighting device, the liquid-solid fluidized bed, a pump, a compressor, a preheater, a filter, a gas-liquid separator and a liquid storage tank, wherein the solar spotlighting device is used for and directly irradiating the sunlight into the liquid-solid fluidized bed after focusing the sunlight, absorbing the solar thermal radiation by utilizing solid particles and heating the seawater in the liquid-solid fluidized bed; after being compressed, the pressure and the temperature of the water vapor generated in the liquid-solid fluidized bed rise, and the water vapor enters into the preheater to preheat the seawater which is about to enter into the liquid-solid fluidized bed; and after condensation, fresh water is obtained. The system provided by the invention is operated at normal pressure; and according to the system, the solar thermal radiation is absorbed by utilizing the solid particles with high absorptivity in the liquid-solid fluidized bed, and the evaporation efficiency of the seawater is improved at the same time by utilizing the efficient heat exchange between the liquid and the solid in the liquid-solid fluidized bed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

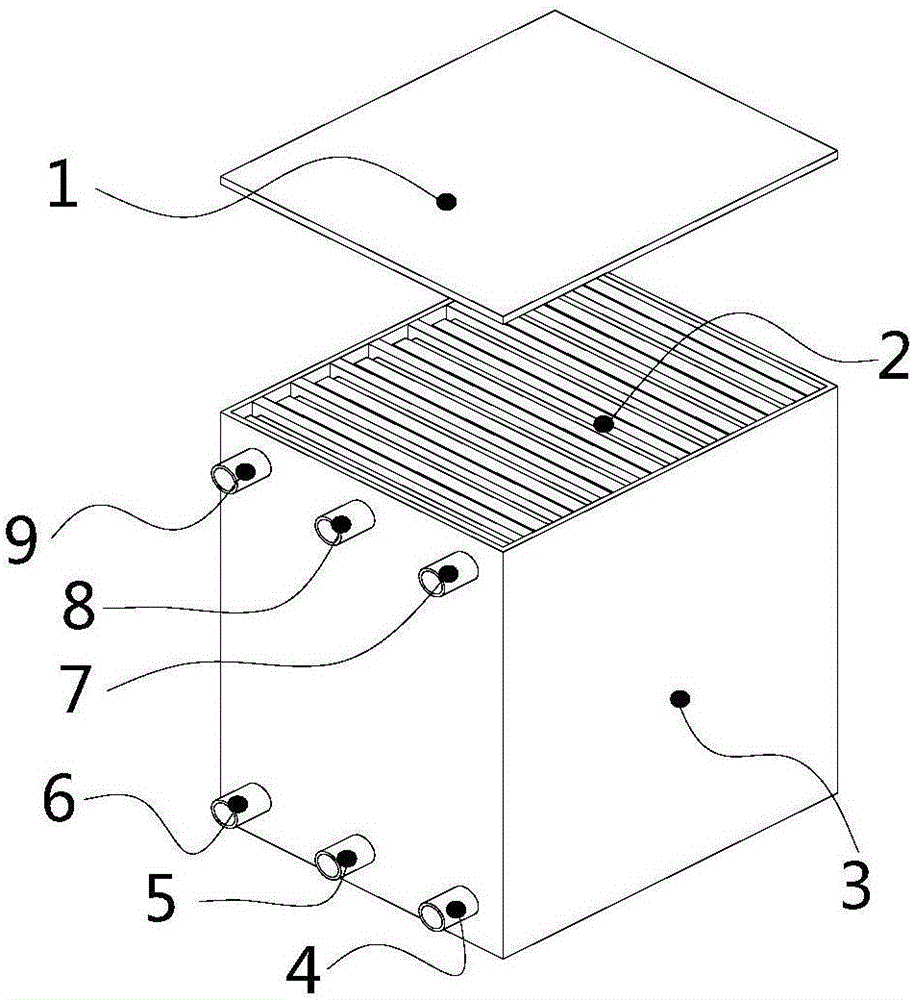

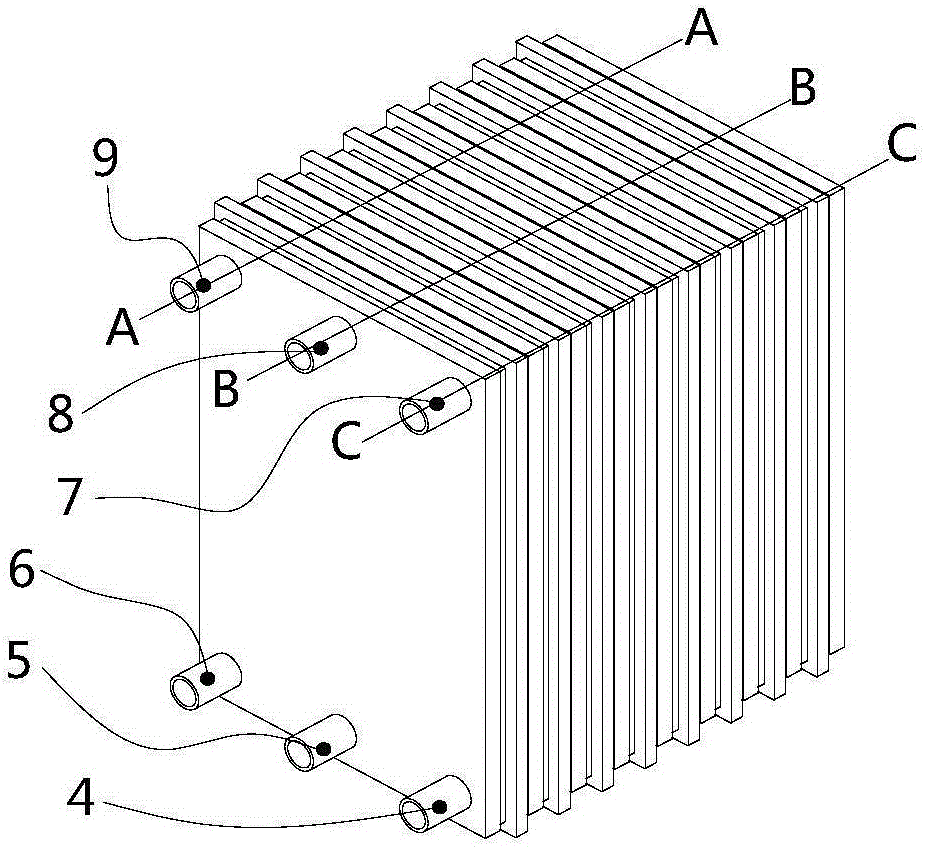

Fuel cell reaction device

InactiveCN106252687AIncrease the reaction areaImprove reaction efficiencyFuel cell heat exchangeChemical reactionFuel cells

The invention discloses a fuel cell reaction device. The fuel cell reaction device comprises a fuel cell reaction body and a box body, wherein the fuel cell reaction body is placed in the box body and is formed by sequentially splicing a cooling plate, a positive electrode chamber, a proton exchange membrane and a negative electrode chamber, a negative electrode fuel inlet passage, a cooling fluid inlet passage and a positive electrode fuel inlet passage are arranged at an upper end of the fuel cell reaction body at intervals, and a positive electrode fuel outlet passage, a cooling fluid outlet passage and a negative electrode fuel outlet passage are arranged at a lower end of the fuel cell reaction body at intervals. The fuel cell reaction device is used as the fuel cell reaction body and simultaneously used as a fuel cell heat sink, the reaction device and the heat sink are integrated, a negative electrode fuel and a positive electrode fuel perform chemical reaction through various passages, the fuel reaction area is expanded due to the narrow and zigzag passages, and the fuel reaction efficiency is improved; and the fuel cell reaction device is compact in structure and small in occupancy area, and the power of the fuel cell is improved.

Owner:GUANGDONG UNIV OF TECH

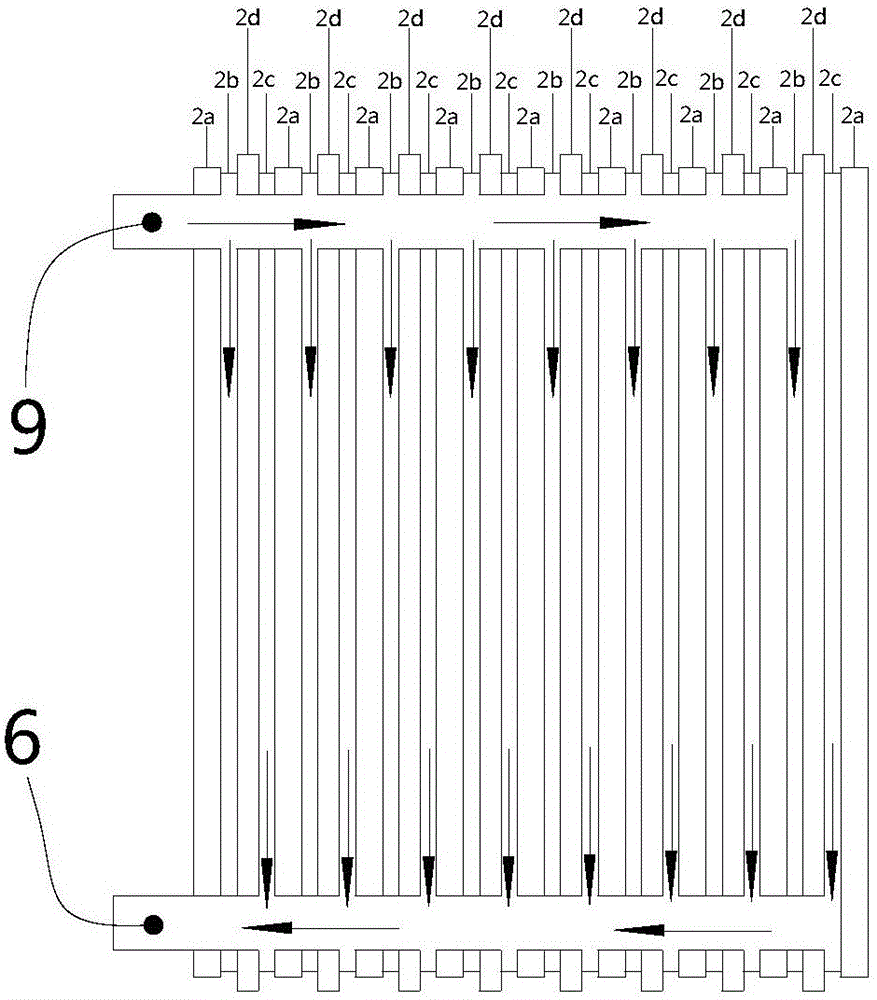

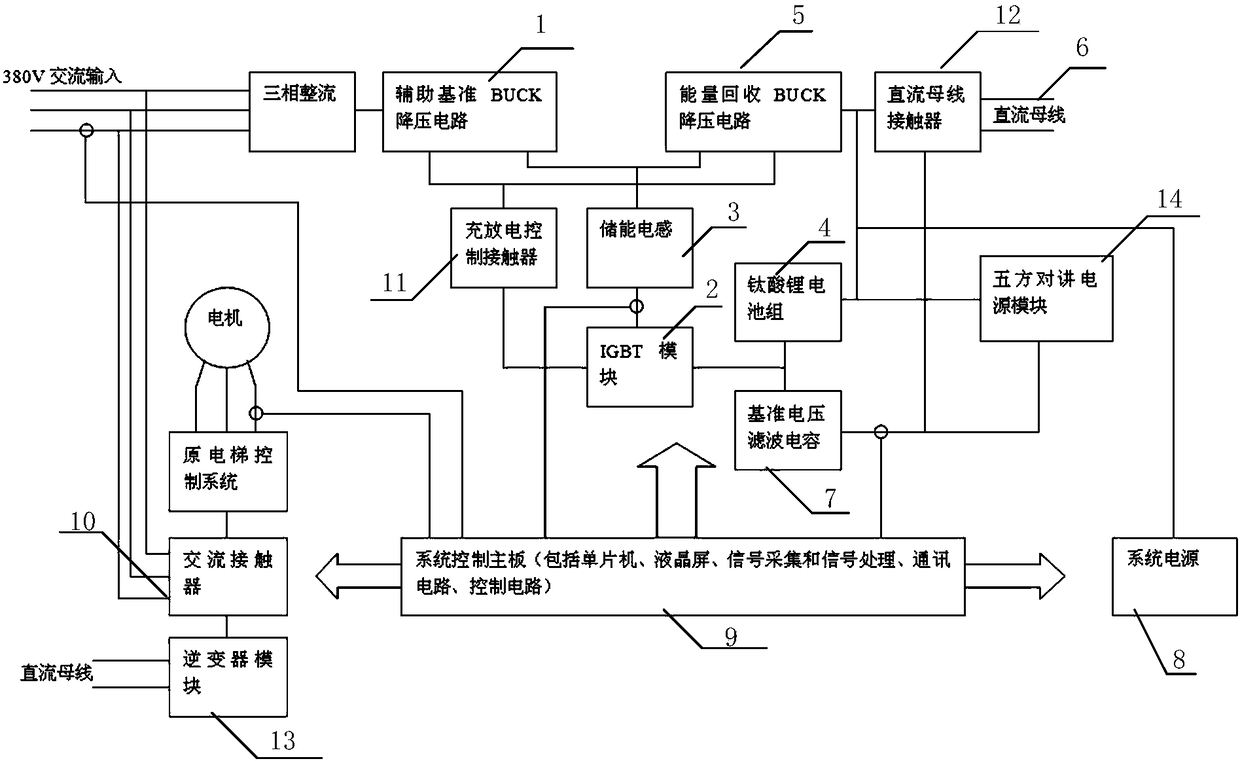

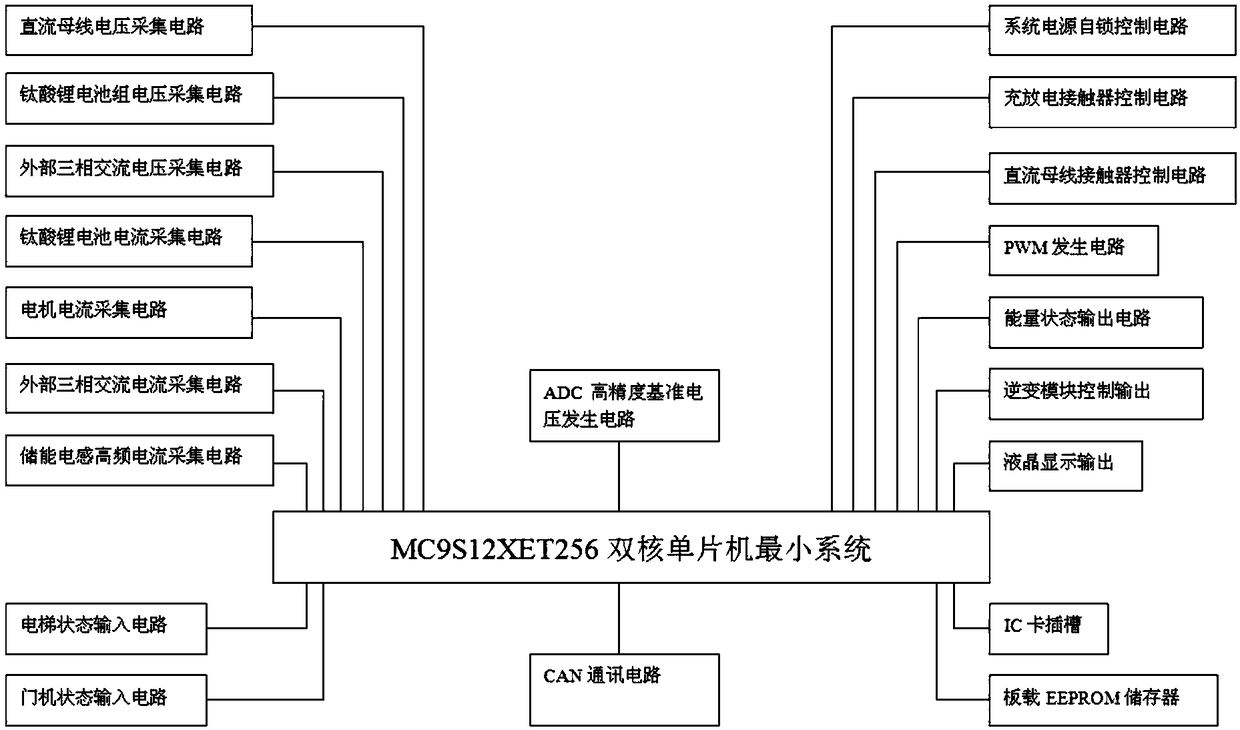

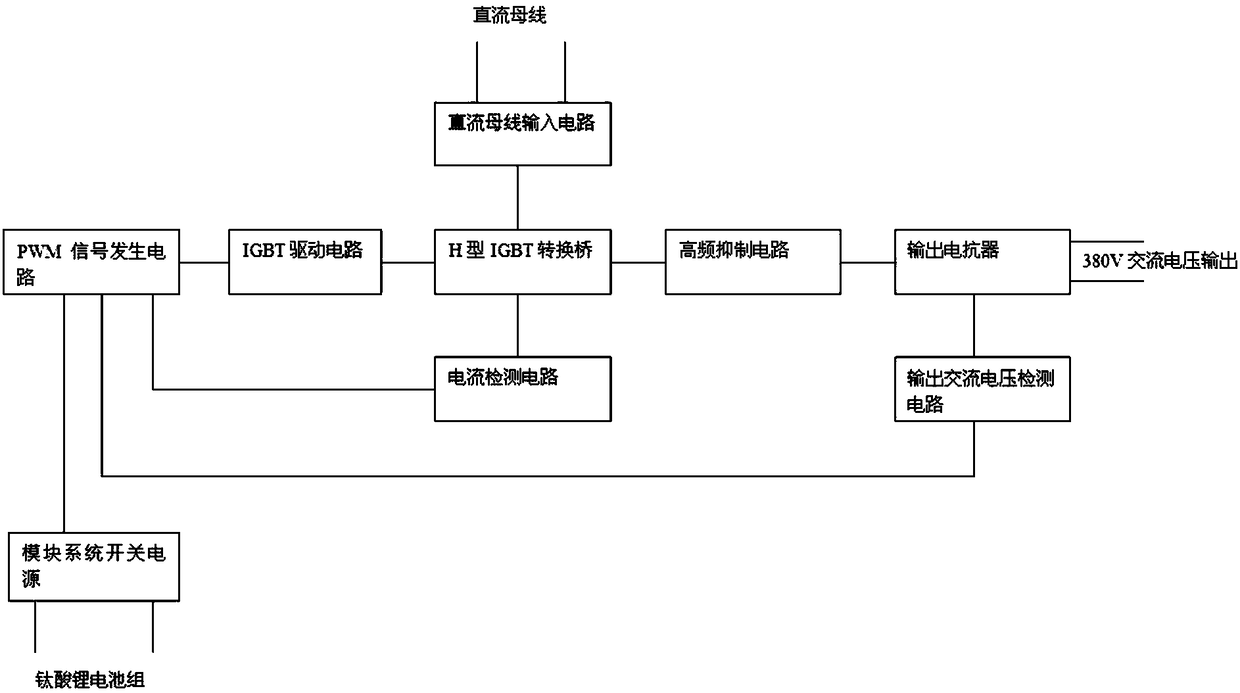

Elevator energy recovery system based on lithium carbonate batteries

PendingCN108110781ALarge capacityAdd five-party intercom power moduleAc network load balancingLithium carbonateEnergy recovery

The invention discloses an elevator energy recovery system based on lithium carbonate batteries, comprising a first buck circuit which is in communication connection with a system control motherboardto realize energy recovery, a lithium carbonate battery pack S1 which is connected in series to the output end of the first buck circuit and used for storing energy, and a second buck circuit which assists in adjusting a reference voltage output by S1. In the second buck circuit, the reference voltage is stabilized by a capacitor C1 connected in series with one end of the lithium carbonate batterypack so that the voltage of a DC bus connected with the lithium carbonate battery pack is raised and stabilized within a predetermined voltage value range. The invention provides an elevator energy recovery system based on lithium carbonate batteries. The cost of the system is reduced by reducing the string number of the energy storage devices of the energy storage unit to less than half of thatin the existing elevator energy recovery system scheme.

Owner:SICHUAN CLIMB ELEVATOR +1

Solid heat storage material, and preparation method and application thereof

The invention belongs to the field of high temperature materials, and in particular, relates to a solid heat storage material, and a preparation method and an application thereof. The solid heat storage material comprises the following raw materials in parts by weight: 5-95 parts of iron ore, 5-50 parts of magnesium iron bricks, 5-20 parts of iron scales, 5-20 parts of a silicon carbide dedusting powder, 1-20 parts of aluminum nitride, 1-5 parts of beryllium nitride, 0.5-5 parts of boron mud, 1-2.5 parts of sodium hexametaphosphate, 1-2 parts of a magnesium aluminum high temperature cementing agent and 1-4 parts of water. The material is low in cost and high in specific heat; and the value of the thermal conductivity coefficient is adjusted according to different ingredient ratios, so as to meet the requirements of different heat storage devices.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

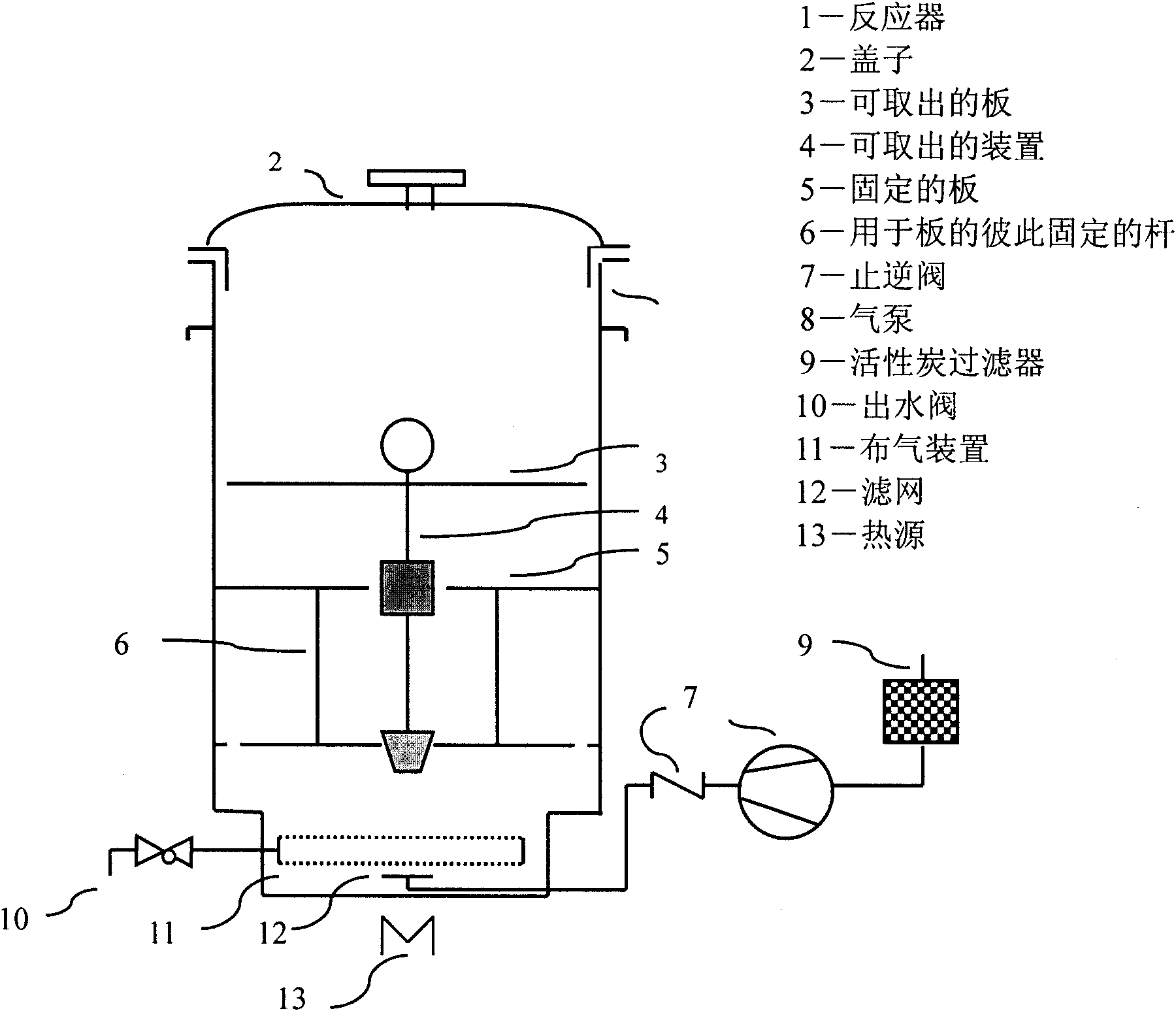

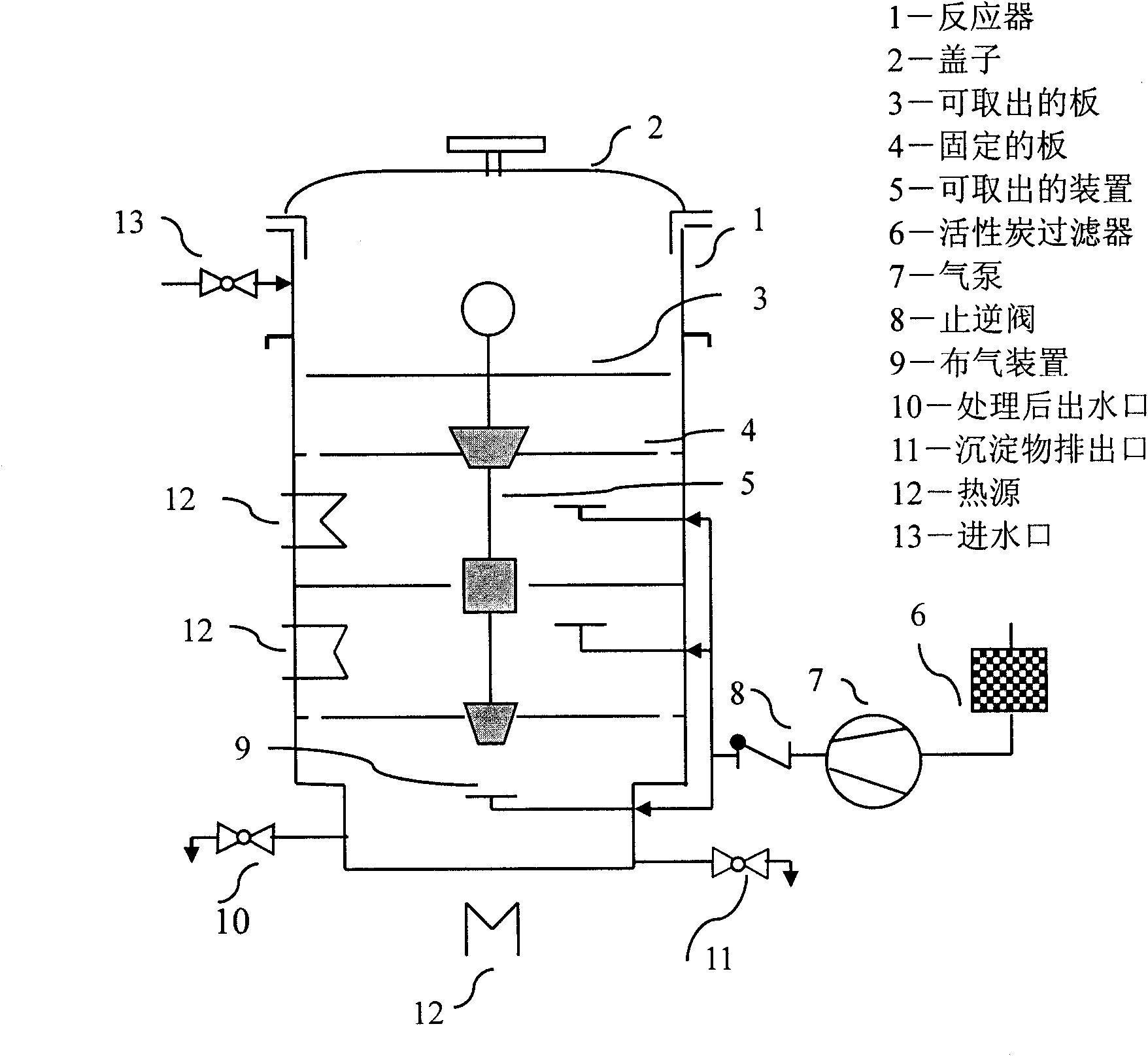

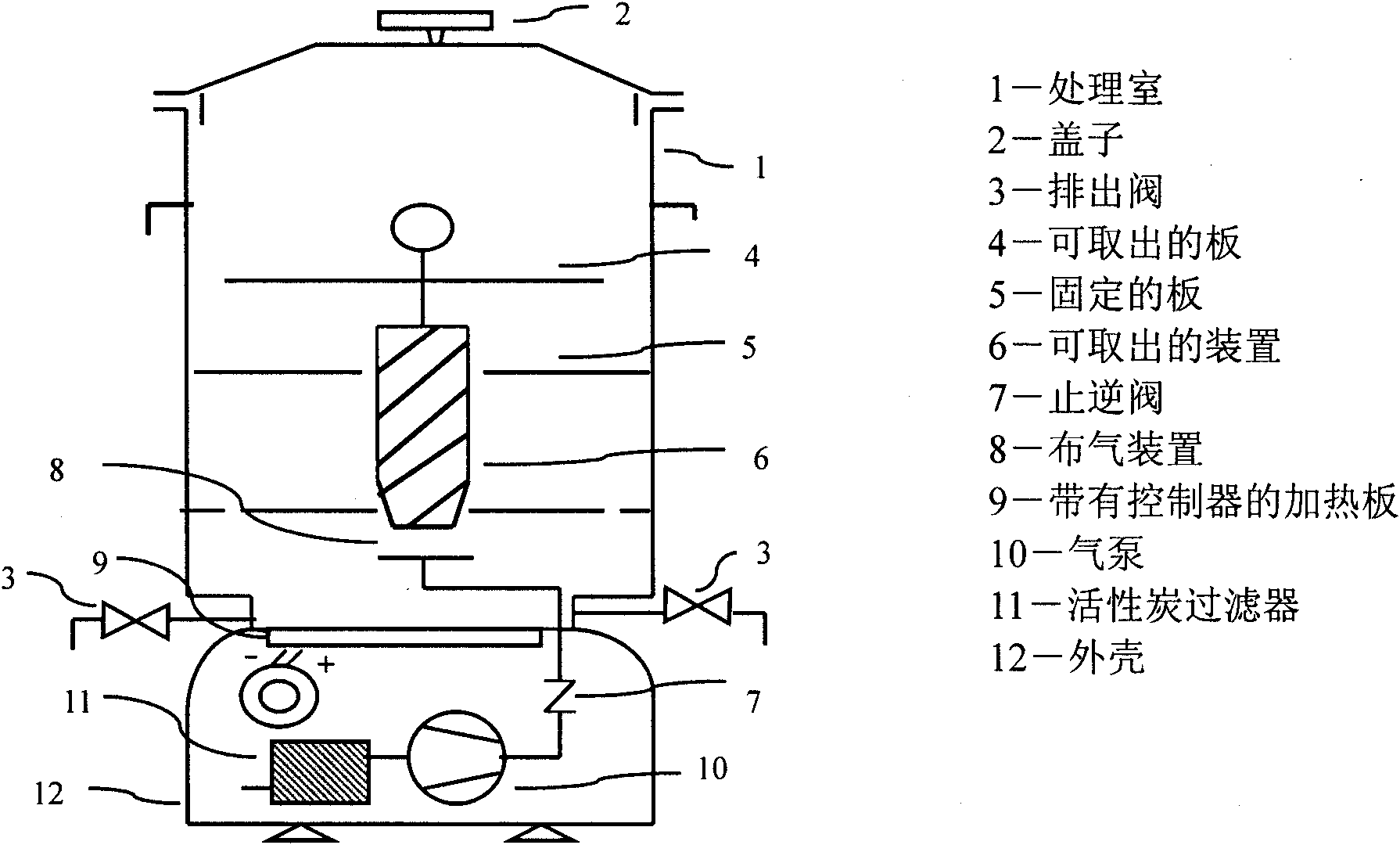

Reactor and method for decalcifying water and simultaneous removal of pollutants

InactiveCN101626981ALarge heat lossExtend the blowing timeSpecific water treatment objectivesWater softeningTurbidityEngineering

The invention relates to a reactor and to a method for decalcifying water and simultaneously removing pollutants, in addition to reducing the turbidity and disinfection which enables the largest possible variation in relation to carrying out the method and the amount of water which is to be treated. The reactor is characterised in that the fixed plates respectively comprise a bore in their centrethrough which a device for opening and closing the bores by means of conical and / or cylindrical-shaped closing elements extends. The upper ends of the device do not comprise plates and / or is connected to one or more non-fixed plate(s) and comprises a holding device. One or more of the fixed plates comprise peripheral openings in the edge area and the one or more additional fixed plate(s) do not have peripheral openings. The direct heating devices and aeration pipes are arranged in sections of the reactor at a distance from each other. The water inlet and the outlet are arranged in the upper and lower area of the reactor. One plate provided with only one large bore in the centre is placed over a plate comprising small holes on the edge. The inventive reactor can also comprise a discharge tap for removing residues.

Owner:马舒特·卡利姆尼亚

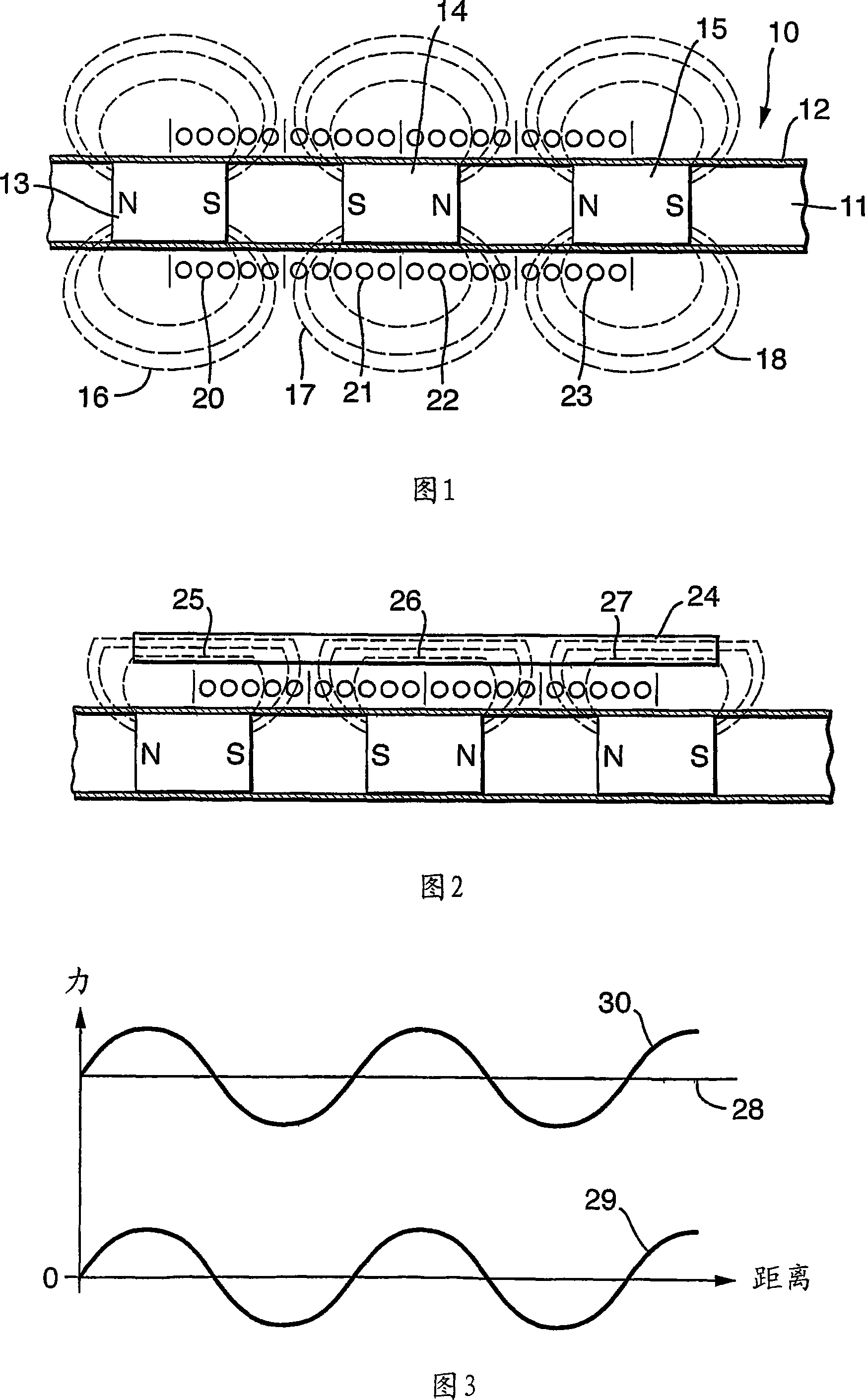

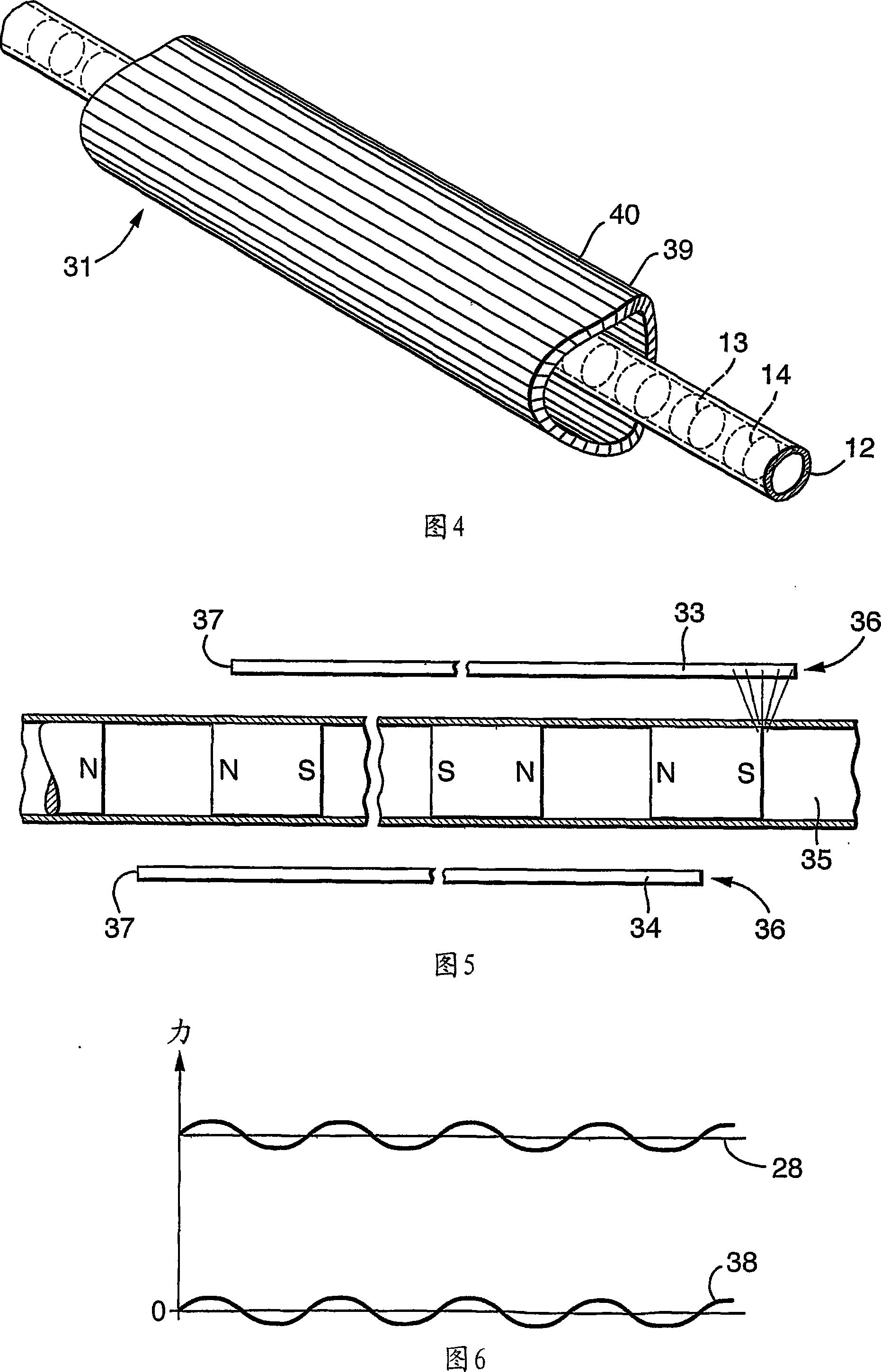

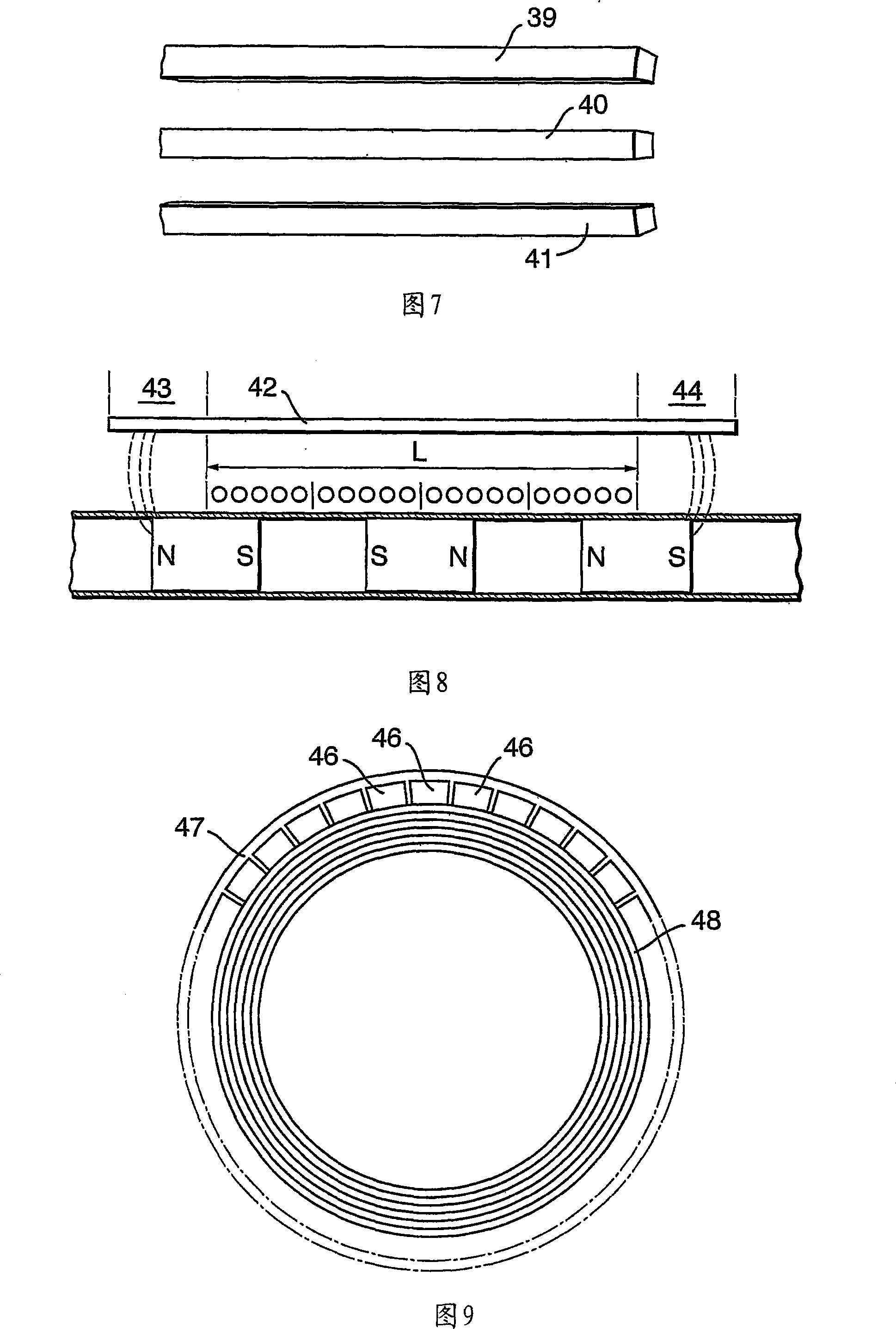

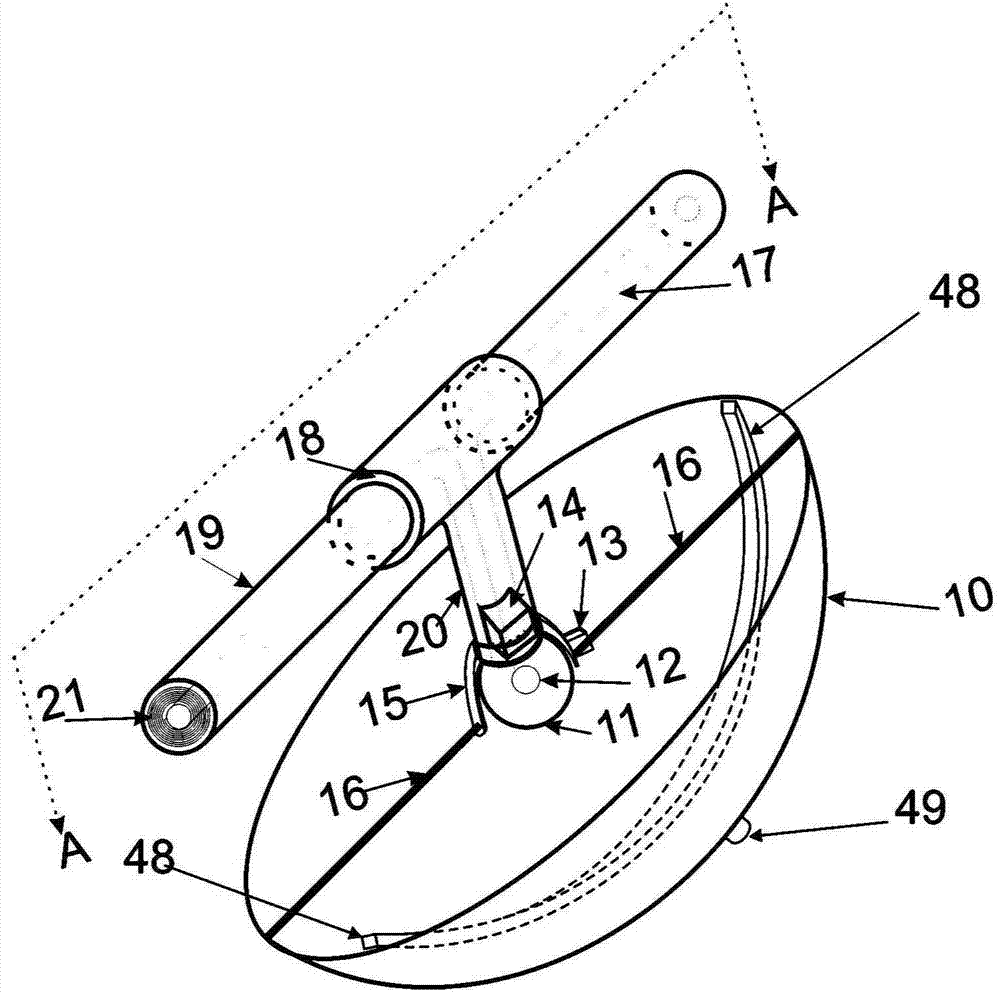

Improvements to tubular electrical generators

ActiveCN101107770AWeakened net attractionImprove magnetic fluxMagnetic circuitPermanent-magnet clutches/brakesElectricityRelative motion

A tubular linear generator comprises an elongate translator (12), containing a series of permanent magnets (13, 14....) and one or more annular coils (not shown) contained within and affixed to a ferromagnetic sleeve (31). Relative movement between the translator and armature causes the generation of electricity in the coils. The sleeve is contoured in terms of permeability around its circumference at one or both its ends, as shown at (32), in order to reduce cogging forces between the sleeve and the permanent magnets along the translator.

Owner:TRIDENT ENERGY

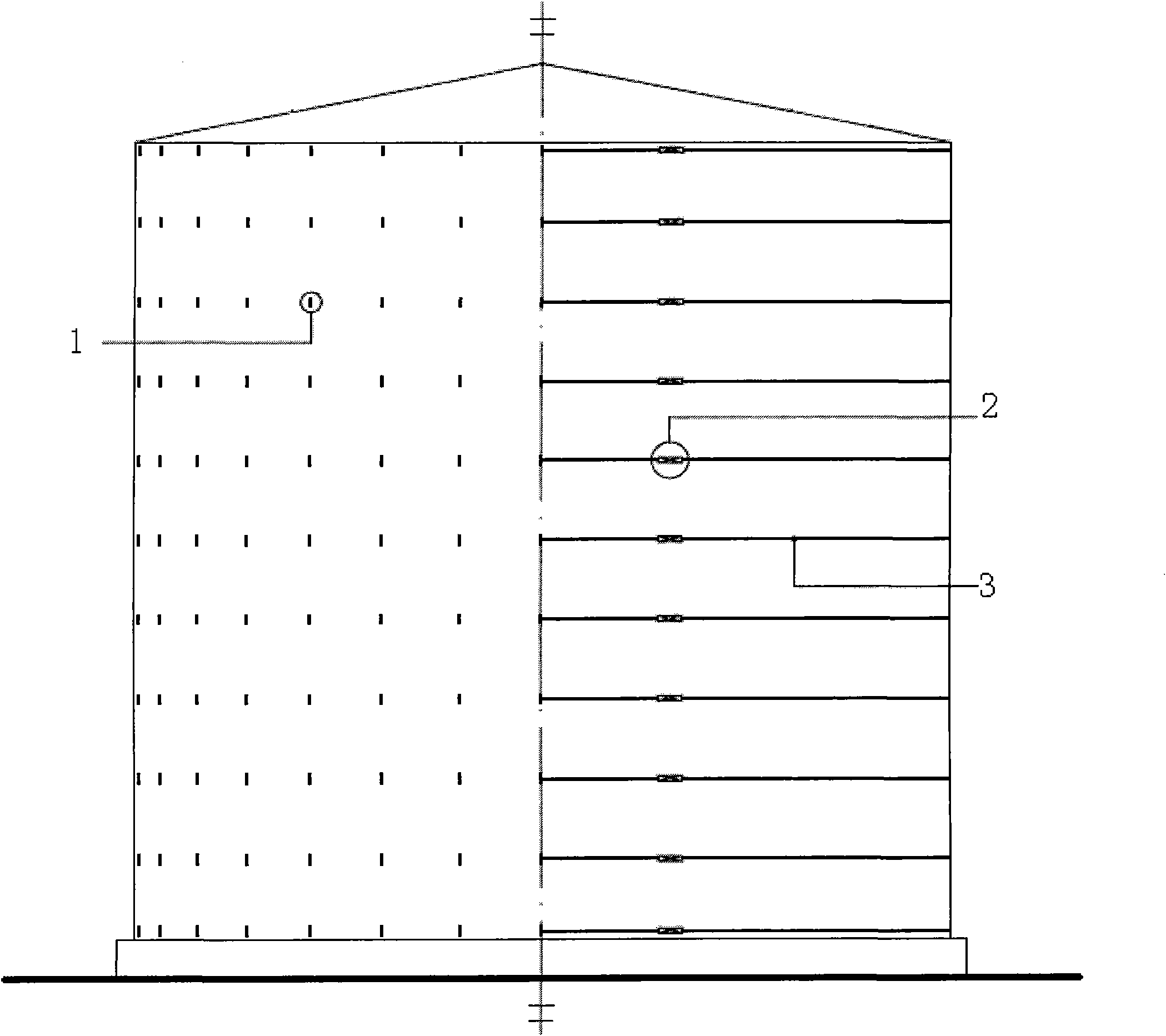

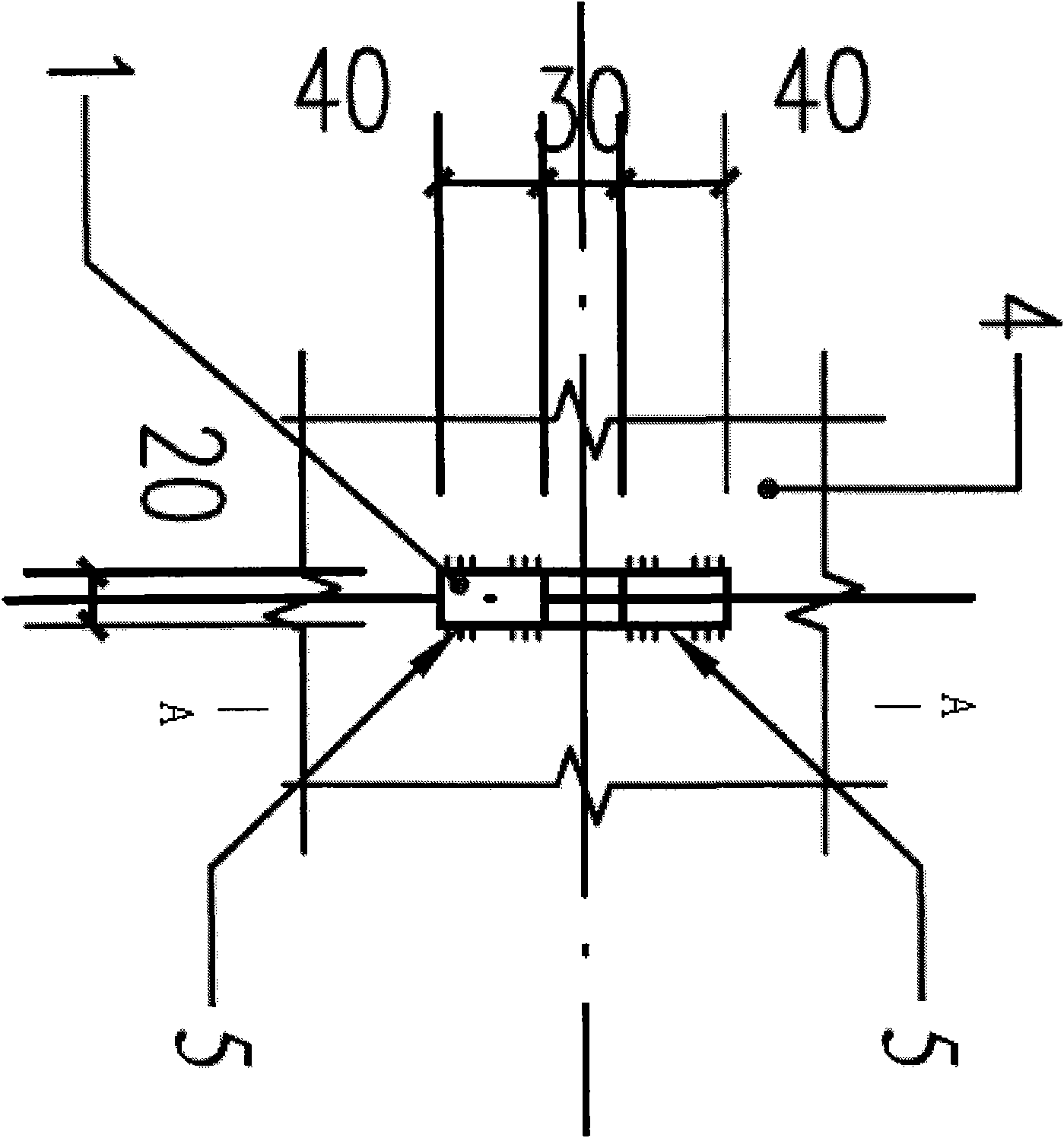

Energy-saving insulation system for storage tank or tower

InactiveCN102249058AImprove sealingLarge heat lossLarge containersArchitectural engineeringInsulation system

The invention discloses an energy-saving insulation system for a storage tank or a tower, comprising a plurality of steel ropes, a plurality of prefabricated profiling insulation boards and clamping belts. The steel ropes are fixed around a storage tank body or a tower body flexibly. Each steel rope is provided with a steel rope tension adjusting mechanism. The steel ropes are arranged in a basically parallel manner. The prefabricated profiling insulation boards comprise insulation materials and insulation protecting boards. The profiling insulation boards are provided with reinforcing ribs. The clamping belts are buckled and sleeved on the steel ropes and used for connecting and tying the profiling insulation boards. The clamping belts are drawn into a seam between the profiling insulation boards while the profiling insulation boards are connected. The system has the advantages of good insulation effect and easiness in construction.

Owner:孙逸宸

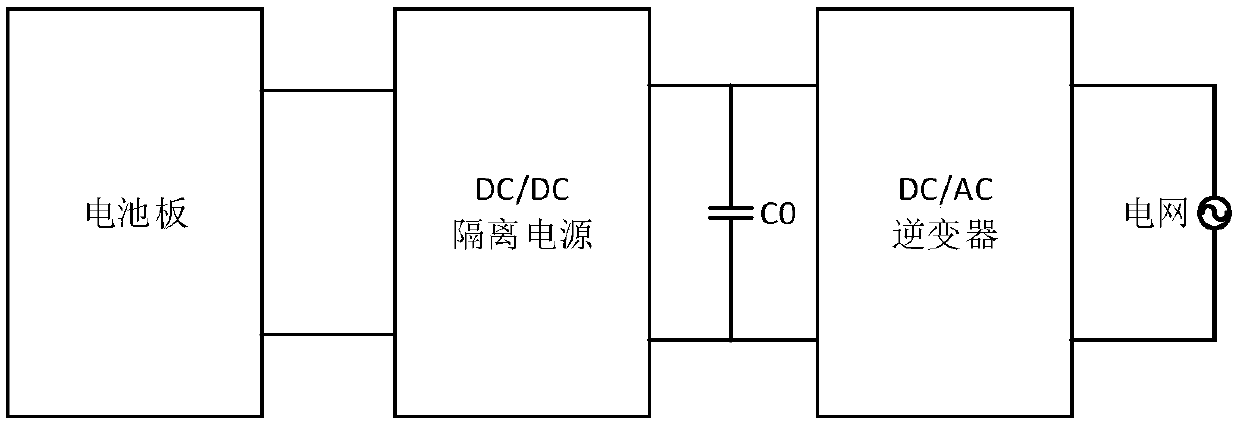

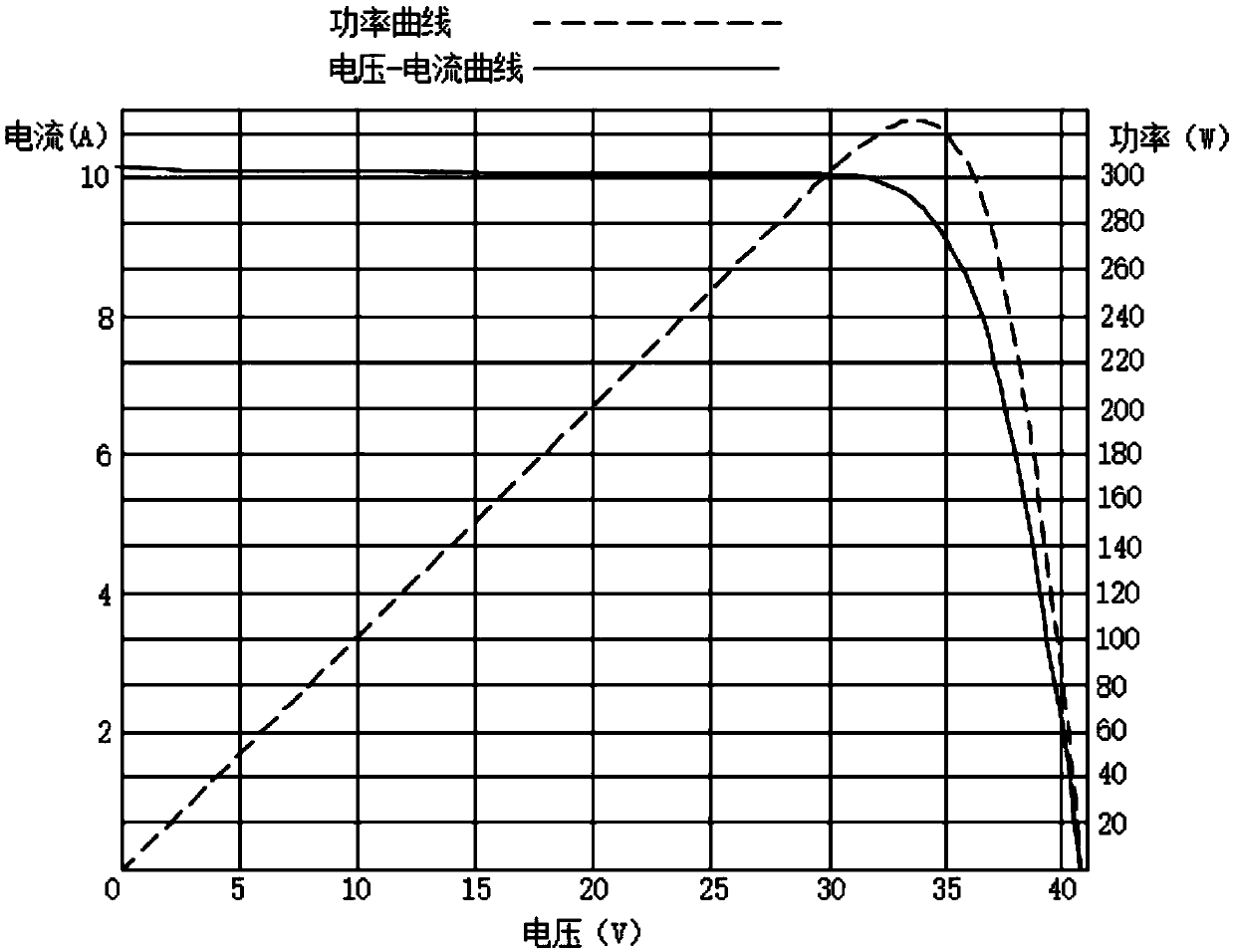

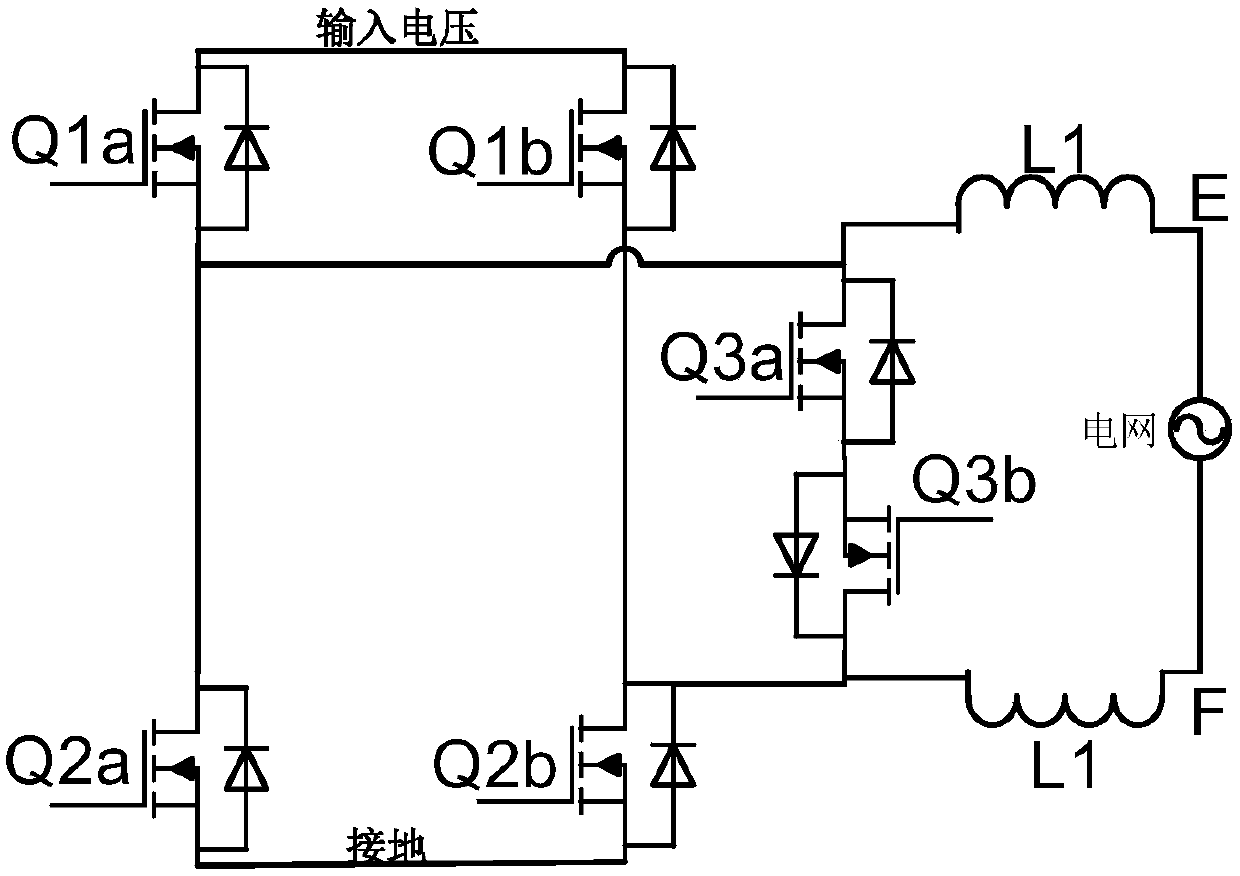

Voltage regulating circuit and inverter system

ActiveCN109728739AReduce spike voltageReduce heat lossSingle network parallel feeding arrangementsDc-ac conversion without reversalCapacitanceVoltage regulation

The application provides a voltage regulating circuit and an inverter system. The voltage regulating circuit includes a first voltage-regulator tube, a second voltage-regulator tube, a voltage stabilizing resistor, a circuit switch, a first capacitor and a second capacitor, wherein the first voltage-regulator tube and the first capacitor are connected in parallel between a first node and a secondnode; the voltage stabilizing resistor and the second capacitor are connected in parallel between the second node and a third node; the second voltage-regulator tube and the circuit switch are connected in series between the first node and the second node; the voltage regulation value of the first voltage-regulator tube is different from the voltage regulation value of the second voltage-regulatortube; and the voltage between the first node and the third node is the bus voltage. The voltage regulating circuit provided by the present application can be applied to a photovoltaic power generation system, and the driving voltage of an inverter switching tube can be adjusted through the voltage regulating circuit. Specifically, when the inverter is started, the inverter switching tube is provided with a low driving voltage such that the peak voltage of the switching tube is reduced. A high driving voltage is provided for the switching tube during the high-power operation of the power generation system, thereby reducing heat loss.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Method for preparing environmentally-friendly chlorinated plasticizer from waste grease, and product produced therethrough

ActiveCN109971551AGood compatibilityHigh plasticizing efficiencyFatty oils/acids recovery from wasteFatty acid esterificationPlasticizerEthyl Chloride

The invention discloses a method for preparing an environmentally-friendly chlorinated plasticizer from waste grease. The method comprises the following steps: the waste grease, used as a raw material, and methanol undergo esterification and ester exchange to obtain a high-condensation point fatty acid methyl ester mainly containing saturated fatty acid methyl ester; and the high-condensation point saturated fatty acid methyl ester is post-treated under the action of a catalyst in the presence of introduced chlorine to obtain chloro fatty acid methyl ester. The environmentally-friendly chlorofatty acid methyl ester plasticizer prepared by the method of the invention has a good plasticizing effect, and makes PVC products have the advantages of difficult oil effusion, low condensation point, low price and good quality. The method has the advantages of simple preparation process, and suitableness for industrial production.

Owner:FUJIAN MINGZHOU ENVIRONMENTAL PROTECTION DEV

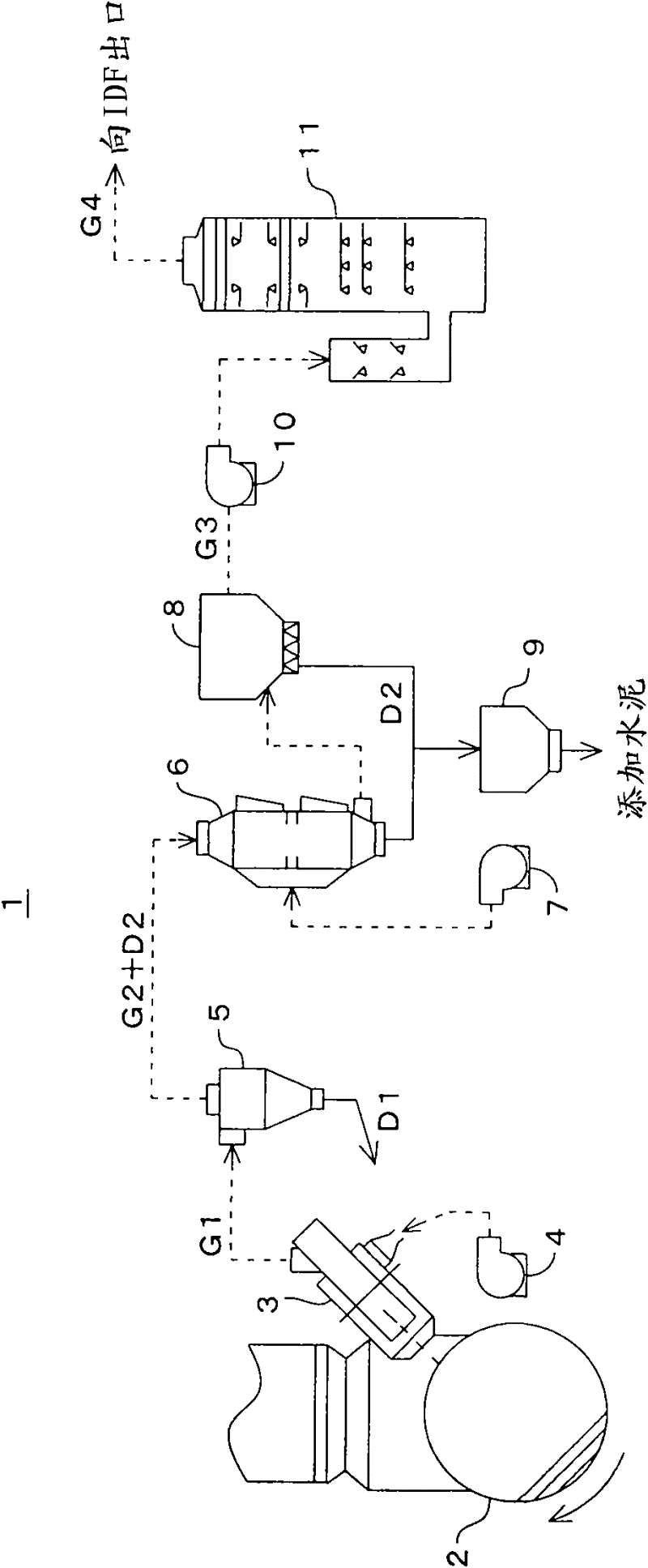

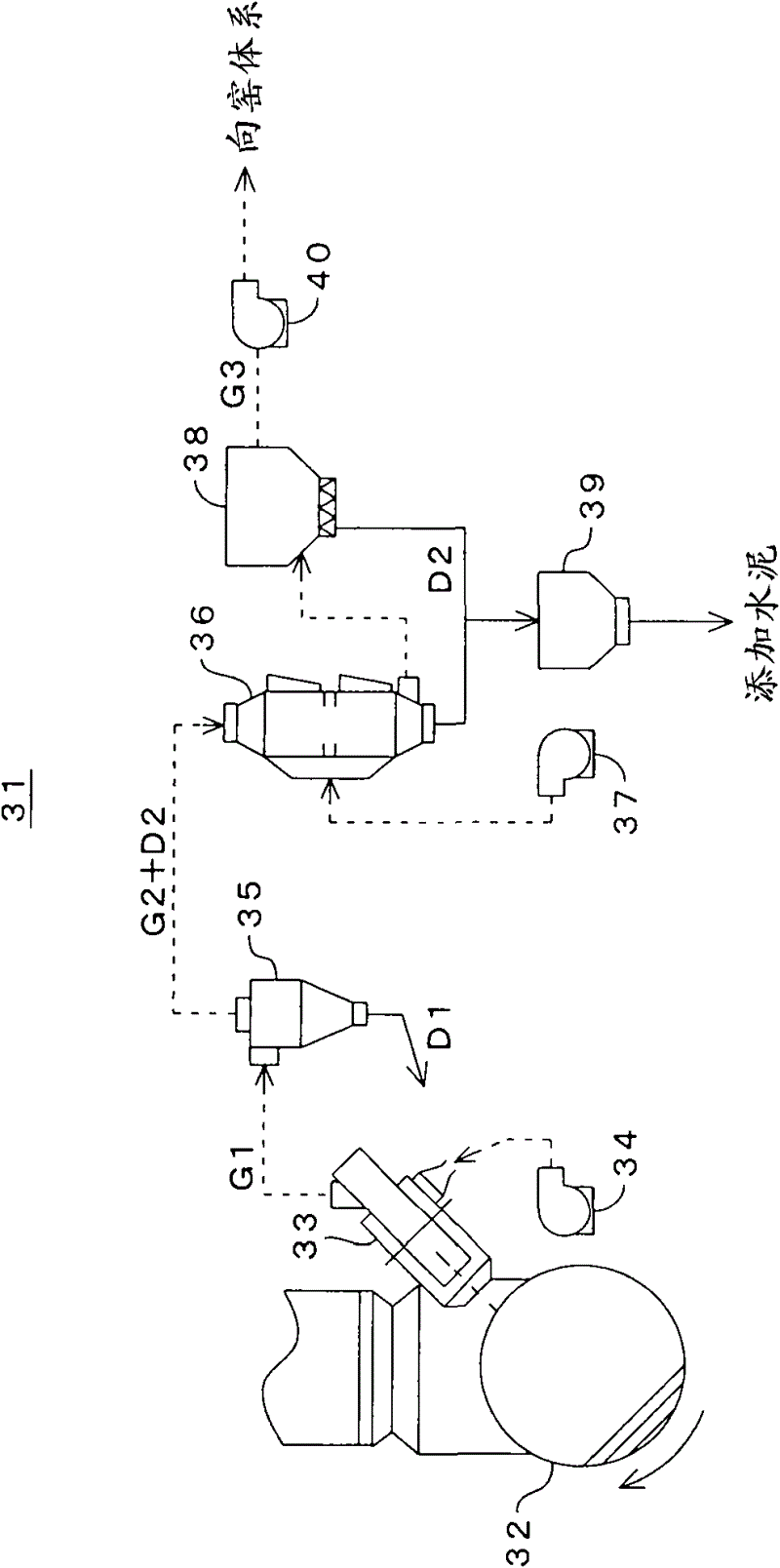

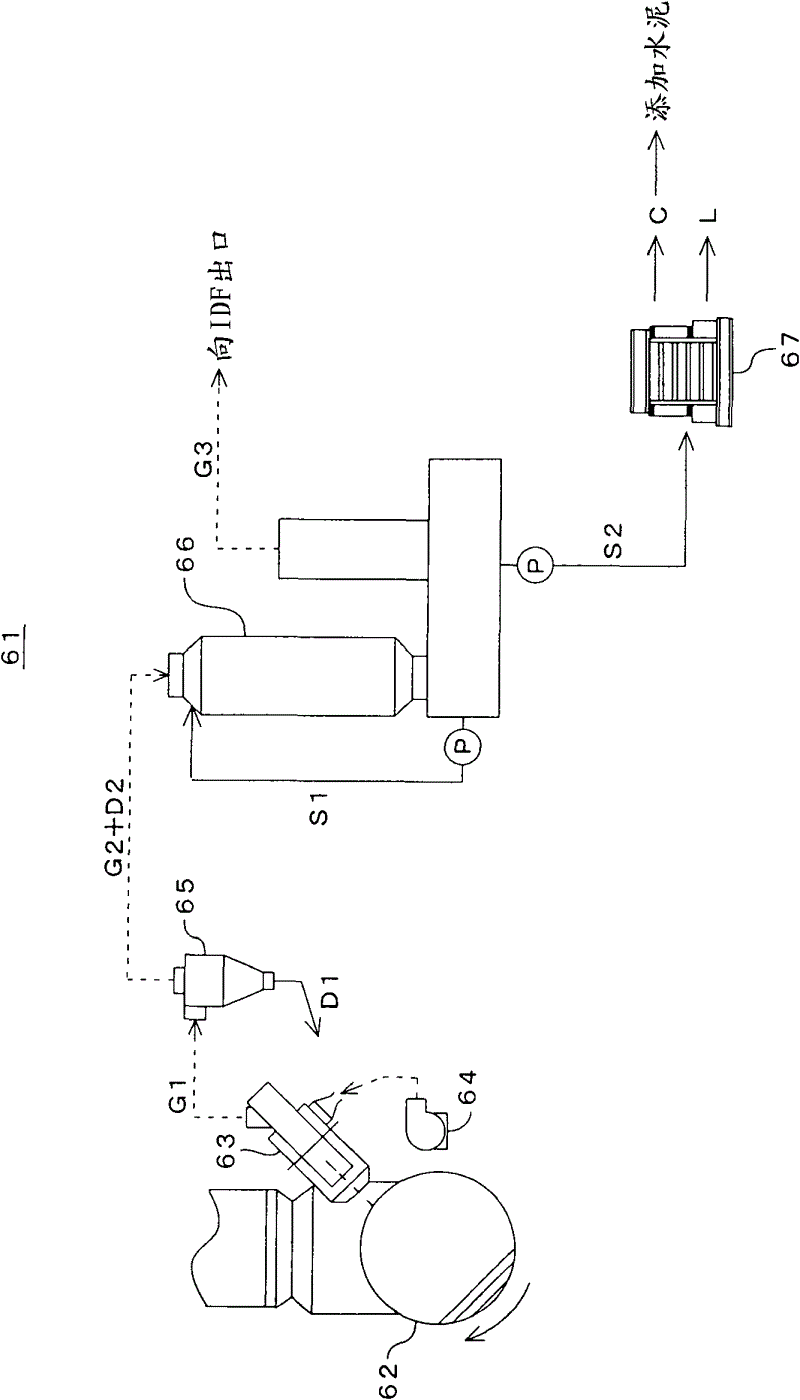

Chlorine bypass system and method for treating extracted gas from chlorine bypass

The invention provides a chlorine bypass system and a method for treating extracted gas from a chlorine bypass and is used for fulfilling the aims of reducing cost, avoiding increase of heat loss of a cement sintering system and decrease of slag yield, suppressing concentration of a sulfur component, an organic component and a chlorine component and exhausting of the sulfur component, the organic component and the chlorine component from a chimney to the outside of the system, and treating exhausted gas from the chlorine bypass. The chlorine bypass system (1) comprises a sampler (3), a dried dust collector (8) and a device (11), wherein the sampler (3) is used for extracting a part of combustion gas from a kiln gas exhaust flow passage between the tail of a cement kiln (2) and a lowermost cyclone; the dried dust collector (8) is used for collecting dust (D2) contained in the extracted gas (G1) which is extracted by using the sampler; and the device (11) is used for removing and recovering harmful components contained in exhausted gas (G3) which is subjected to dust collection. By supplying the purified extracted gas, namely exhausted gas (G4), to an outlet of a guide fan which is arranged at the outlet of a pre-heater attached to the cement kiln, chlorine bypass rate can be improved.

Owner:TAIHEIYO CEMENT CORP

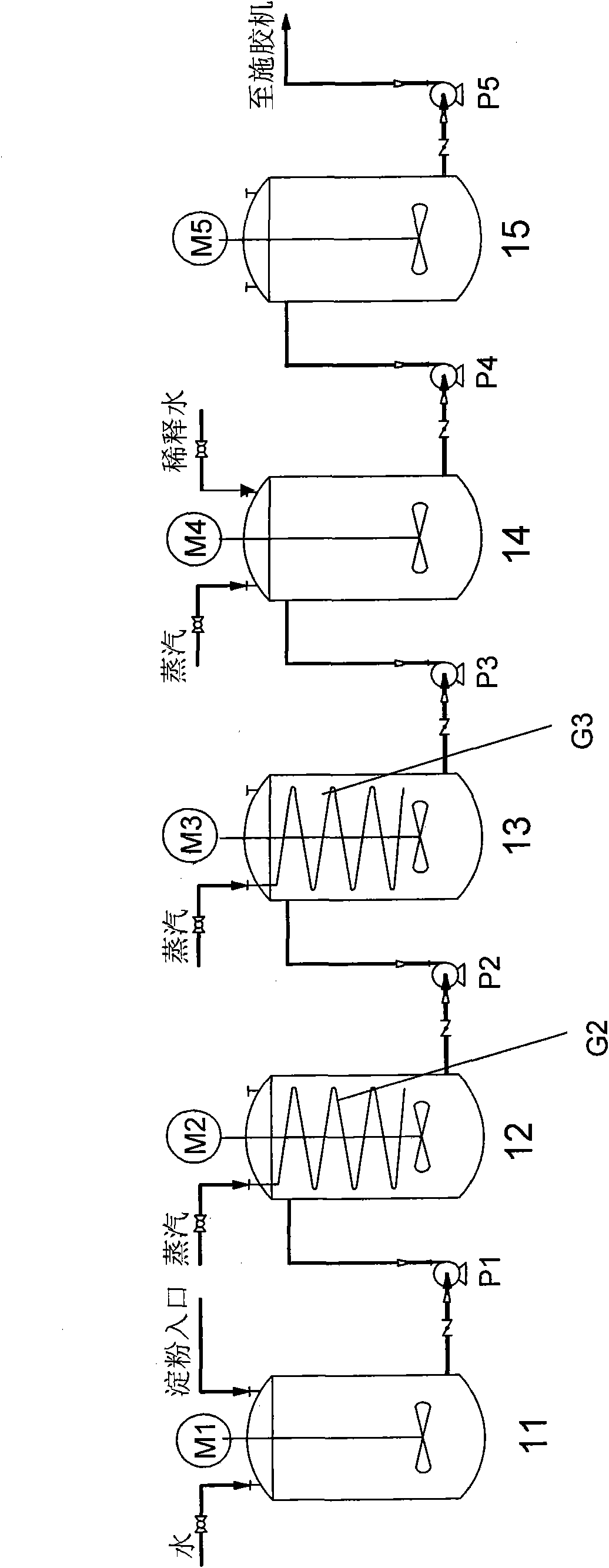

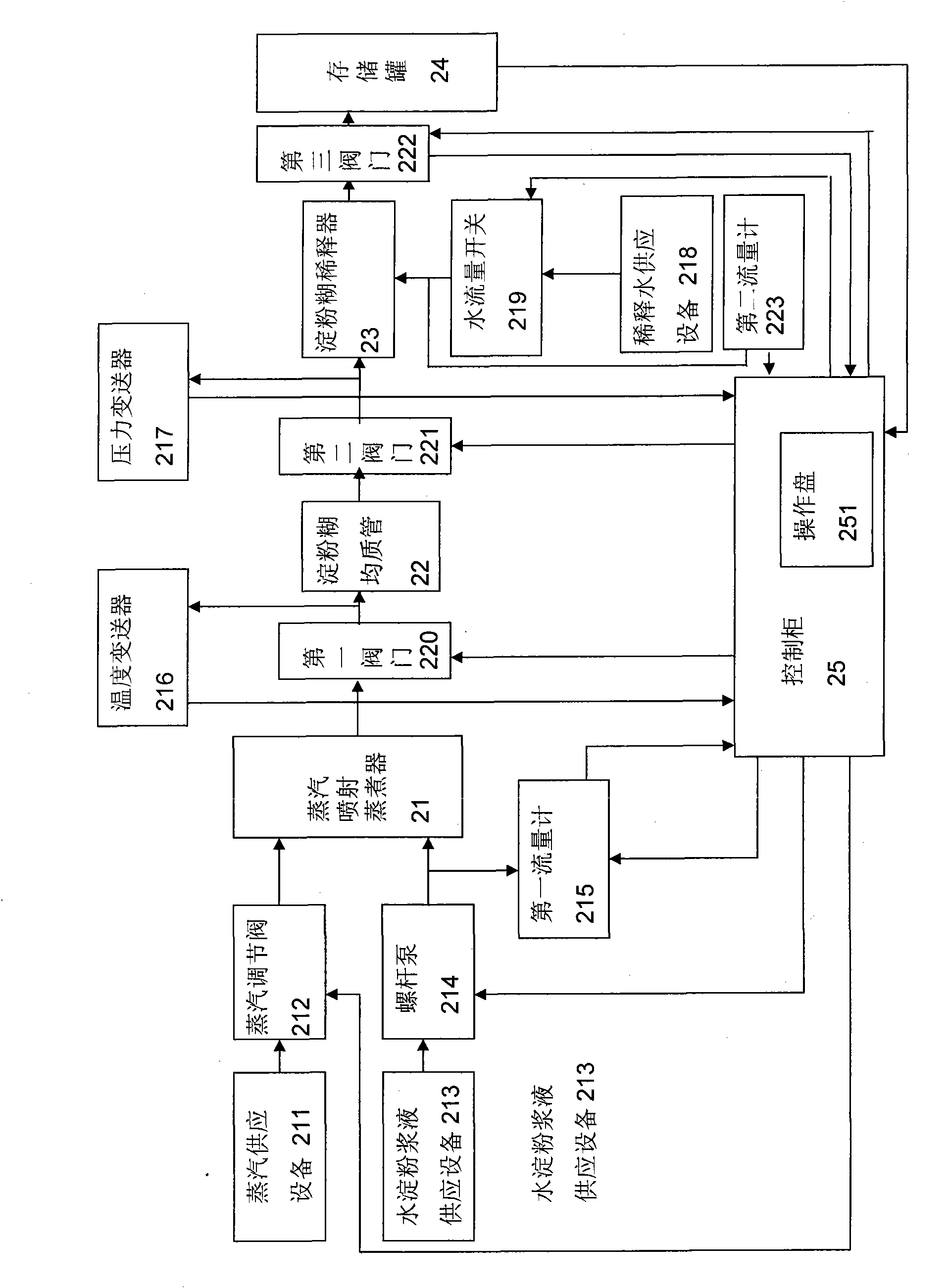

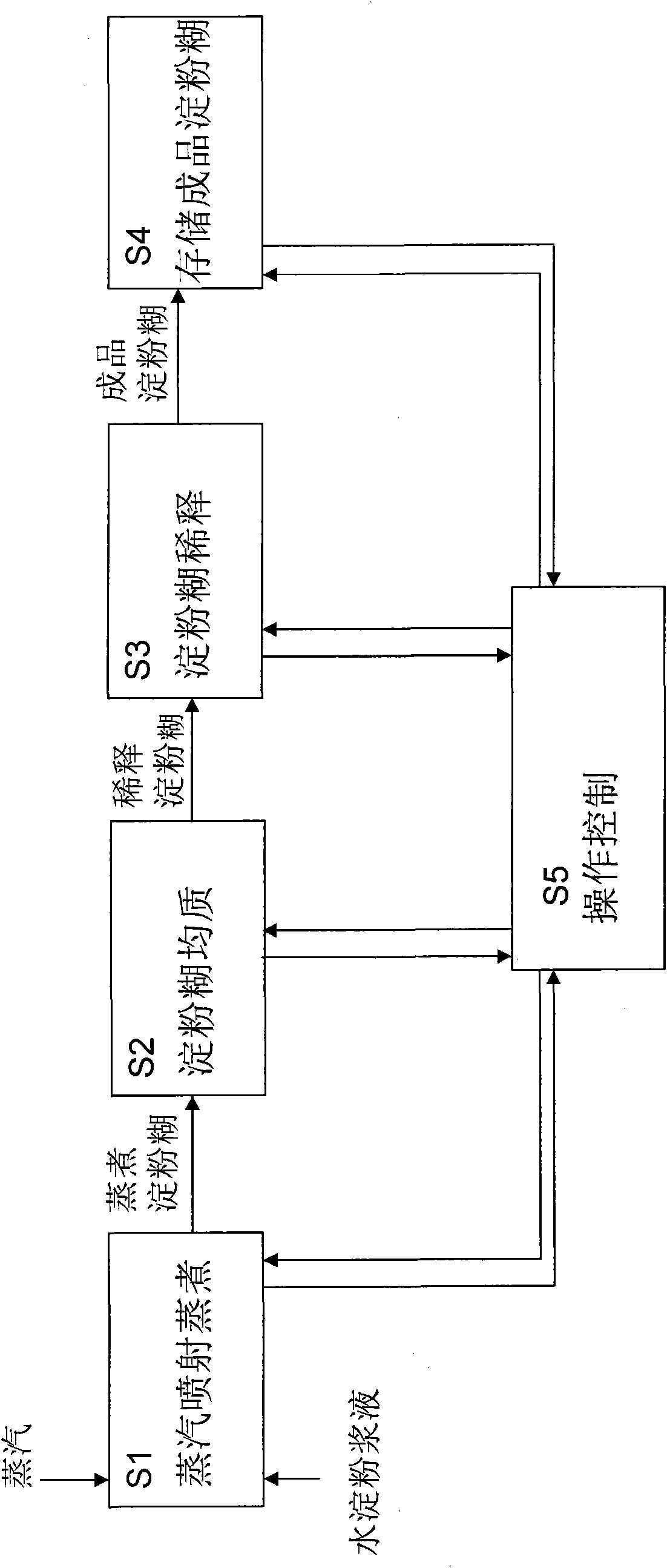

Farina online digestor and digestion method thereof

ActiveCN102312387AReduce volumeLess investmentDigestersPaper material treatmentControl systemProcess engineering

A farina online digesting method belongs to the field of farinaceous size digestion, and solves the problems that the existing pot-type digestor has a large volume, low automation degree and energy consumption and cannot be continuously produced. The inventive method comprises a steam injection digesting step in which the high temperature steam is used to digest water farinaceous size, and the digested farina paste is output; a farina paste homogeneous step in which the digested farina past is homogenized, and the homogeneous farina paste is output; a farina paste diluting step in which the homogeneous farina paste is diluted, and the finished farina paste is output; a finished product farina paste storage step in which the finished product farina paste is stored in a storage tank; and an operation control method in which the above each step is controlled by a control cabinet and the operation control includes automatic and manual operation control. In the online digesting method the steam injection heating is used to complete the farina digestion, the volume of the digestor is greatly reduced, and the cost is lowered; the water farinaceous size is directly contacted with the steam, can be used during the digestion, continuous production is realized, the thermal conversion rate is high, and the energy is saved; and the operation control is provided with a PLC control system, so the automation degree is high.

Owner:上海昂莱机电东台有限公司

Leakage remedying device of steam straight buried pipe compensator

The invention provides a leakage remedying device of a steam straight buried pipe compensator, which comprises a core pipe arranged outside an external protective pipe; and a remedying device is sleeved centrically on the core pipe on one end of the core pipe, where a gap is formed between the protective sleeve and the core pipe. The remedying device comprises a protective cover and a corrugated pipe orderly arranged from outside to inside, wherein the same ends of the protective cover and the corrugated pipe are hermetically connected to the protective sleeve; a gap is arranged between the other end of the protective cover and the core pipe. A steam discharge pipe is communicated to the corrugated pipe and penetrates to a hole arranged by the protective cover and the external protective pipe outwards. The leakage remedying device has the following advantages: avoiding the steam in the damaged compensator impacting and destroying a heat insulation layer, and the leaked steam condensate water soaking heat insulation cotton; avoiding the steam that the compensator leaks accumulating in the external protective pipe and reducing the useful life of the pipeline; ensuring normal flexibility and deformation of the core pipe; being convenient to maintain specifically; reducing maintenance time and reducing earth excavating volume.

Owner:淮安四方保温管有限公司

High-capacity oil shale dry distillation cylindrical furnace with star-shaped arch style gas distribution device

ActiveCN106085483ALarge heat lossUse energyCombustible gas coke oven heatingDirect heating destructive distillationCombustionEngineering

The invention discloses a high-capacity oil shale dry distillation cylindrical furnace with a star-shaped arch style gas distribution device. The furnace comprises a furnace body, wherein an oil gas outlet header, a compound array umbrella material distribution device, a hot gas distribution pipe and a cold gas distribution pipe are arranged in the furnace body from top to bottom in sequence, the compound array umbrella material distribution device comprises a feeding pipe, and the feeding pipe penetrates through the oil gas outlet header to be connected with the discharging end of a spiral feeder; a center array umbrella is installed below the feeding pipe through a suspension rod, a plurality of surrounding array umbrellas are installed around the center array umbrella through suspension rods, and the center array umbrella and the surrounding array umbrellas are communicated with the oil gas outlet header through air guiding pipes respectively; the two ends of the hot gas distribution pipe penetrate through the two sides of the furnace body to be connected with hot gas inlet headers, and the two ends of the cold gas distribution pipe penetrate through the two sides of the furnace body to be connected with cold gas inlet headers. According to the furnace, oil yield is about 85-95%, discharged semicoke heats circulating gas through combustion of a circulating fluidized bedboiler, energy is utilized, and gas is distributed more uniformly.

Owner:NORTHEAST DIANLI UNIVERSITY

A kind of solid heat storage material and its preparation method and application

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Novel energy-saving and environment-friendly technology for making iron and making iron alloy by using lamp-shaped furnace

The invention relates to a novel energy-saving and environment-friendly method for making iron and making an iron alloy by using a lamp-shaped furnace. Large-air hole pressure-proof type ore is loaded from the top of the furnace by using the lamp-shaped furnace with a small furnace hearth and a hot furnace core, coal oxygen or coal power is jetted from the furnace hearth, high-temperature reduction gas is generated and rises to reduce the type ore, reduced furnace gas is combusted again to preheat the descended type ore, and the utilization rate of CO in the furnace is approximate to 100 percent. The furnace has a small amount of coke, low air displacement, a high material temperature and high smelting speed and does not have nitrogen, so that the utilization coefficient of furnace capacity is improved by more than 10 times compared with that of a blast furnace. The standard coal consumption in each ton of iron is less than 400kg and oxygen consumption is less than 320NM<3>, or coal consumption is less than 270kg, power consumption is less than 1,000 degrees and the oxygen consumption is less than 25NM<3>. The occupied area, investment and employees of a lamp furnace ton iron factory cannot reach one fifth of those of a blast furnace process. The energy consumption of the iron alloy reduced by coal electric furnace charcoal is lowered to a great extent, and the novel method is suitable for updating and leading the conventional energy-saving and emission-reduction technology of large and medium blast furnaces or submerged arc furnaces.

Owner:丁公权 +2

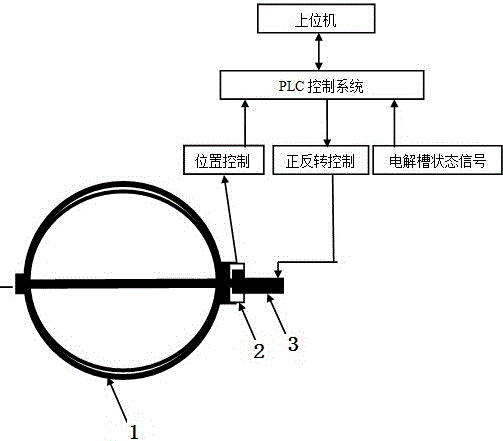

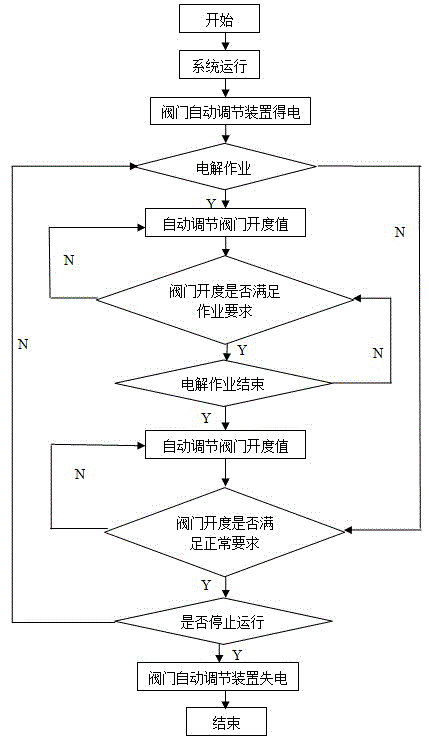

Exhaust gas trapping device of aluminum electrolysis cell and control method thereof

The invention relates to an exhaust gas tapping device of an aluminum electrolysis cell and a control method thereof, belonging to the technical field of aluminum electrolysis. An automatic regulating device and a positioner are additionally arranged on a smoking tube control valve, a control program control is written to connect with a monitoring system; according to the operation of opening a slot cover according to the conditions whether the electrode change, aluminum discharging and the like exist in electrolysis production or not, the opening of the smoking tube control valve is timely regulated according to the needs, the air drafting quantity of the electrolysis cell is controlled according to the practical operation condition of the electrolysis cell, so that not only can the direct-current power consumption of the aluminum electrolysis production be lowered, but also the energy consumption can be lowered on the premise of exhausting the exhaust gas trapping rate; meanwhile, the working environment of normally opening the slot to operate by the electrolysis operation further can be improved.

Owner:云南云铝海鑫铝业有限公司

Method for producing heat-resisting oil-resisting cable sheath

InactiveCN105086188AAvoid poisoningGuaranteed oil resistancePlastic/resin/waxes insulatorsEnvironmental resistanceHeat resistance

The invention discloses a method for producing a heat-resisting oil-resisting cable sheath, which belongs to the technical field of cable line, the method comprises the following steps: 1) preparing materials, taking the following raw materials by weight: 80-90 parts of a SG-1 type resin, 10-15 parts of a plasticizer, 4-6 parts of a compound stabilizer and 2-3 parts of an antioxidant, carrying out material preparing grinding, fully mixing, grinding until fineness is less than or equal to 80 [mu]m, and obtaining a main material after grinding; 2) adding 20-30 parts of a filler in the main material, uniformly stirring and regrinding until the fineness is less than or equal to 65 [mu]m, and obtaining the main material after regrinding; 3) controlling the temperature at 60-75 DEG C and kneading the regrinded main material for 5-10 minutes; 4) carrying out plastic extruding, wherein the temperature is controlled at 150-160 DEG C; and 5) carrying out plastication to obtain the finished product, wherein the temperature is controlled at 165-175 DEG C. The method can keep heat-resisting and oil-resisting performances of the cable sheath, heavy metal poisoning can be prevented when the cable sheath is heated due to no lead and cadmium in the formula,, and the cable sheath has the advantages of environment protection and durability.

Owner:张凌

Method for making oil-resistivity red cable sheath by double rollers

InactiveCN105086191AInhibition of thermal oxidative degradationExcellent heat and oil resistanceRubber insulatorsPlastic/resin/waxes insulatorsSteam pressureHeat resistance

The method discloses a method for making an oil-resistivity red cable sheath by double rollers, which belongs to the technical field of cable line, the method comprises the following steps: 1)preparing the raw materials for standby; 2) kneading; 3) mixing, placing the powder in a mixing chamber; 4) milling by two rollers, discharging to a two-roller mill, under steam pressure being 0.4-0.5 MPa, heating to the roll temperature at 160-170 DEG C until the materials are completely and uniformly plasticized, and obtaining sheet with thickness being 3 mm as a material sheet; and 5) cooling, granulating and packaging. The method has the advantages of simple operation, work efficiency of milling by two rollers is high, product quality is good, through combinations of various raw materials, heat-resisting and oil-resisting performances of the cable sheath can be ensured, no lead and cadmium is generated in the formula, heavy metal poisoning can be prevented when the cable sheath is heated, and the cable sheath has the advantages of environment protection and durability.

Owner:张凌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com