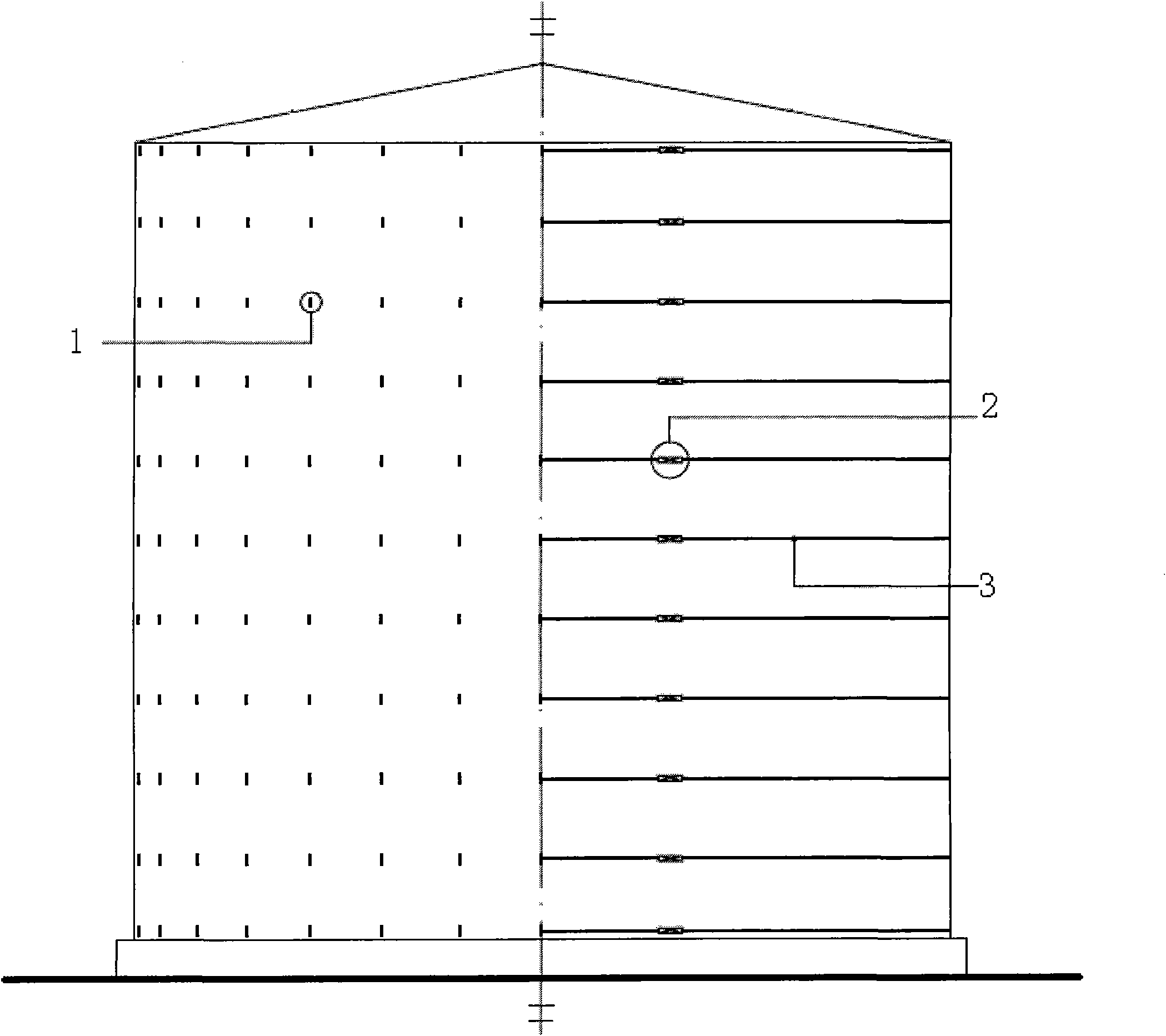

Energy-saving insulation system for storage tank or tower

A heat preservation system and tower technology, applied in the field of energy-saving heat preservation systems, can solve the problems of heat preservation body corrosion, easy loose rivets, difficult construction quality, etc., and achieve the effect of less heat loss and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

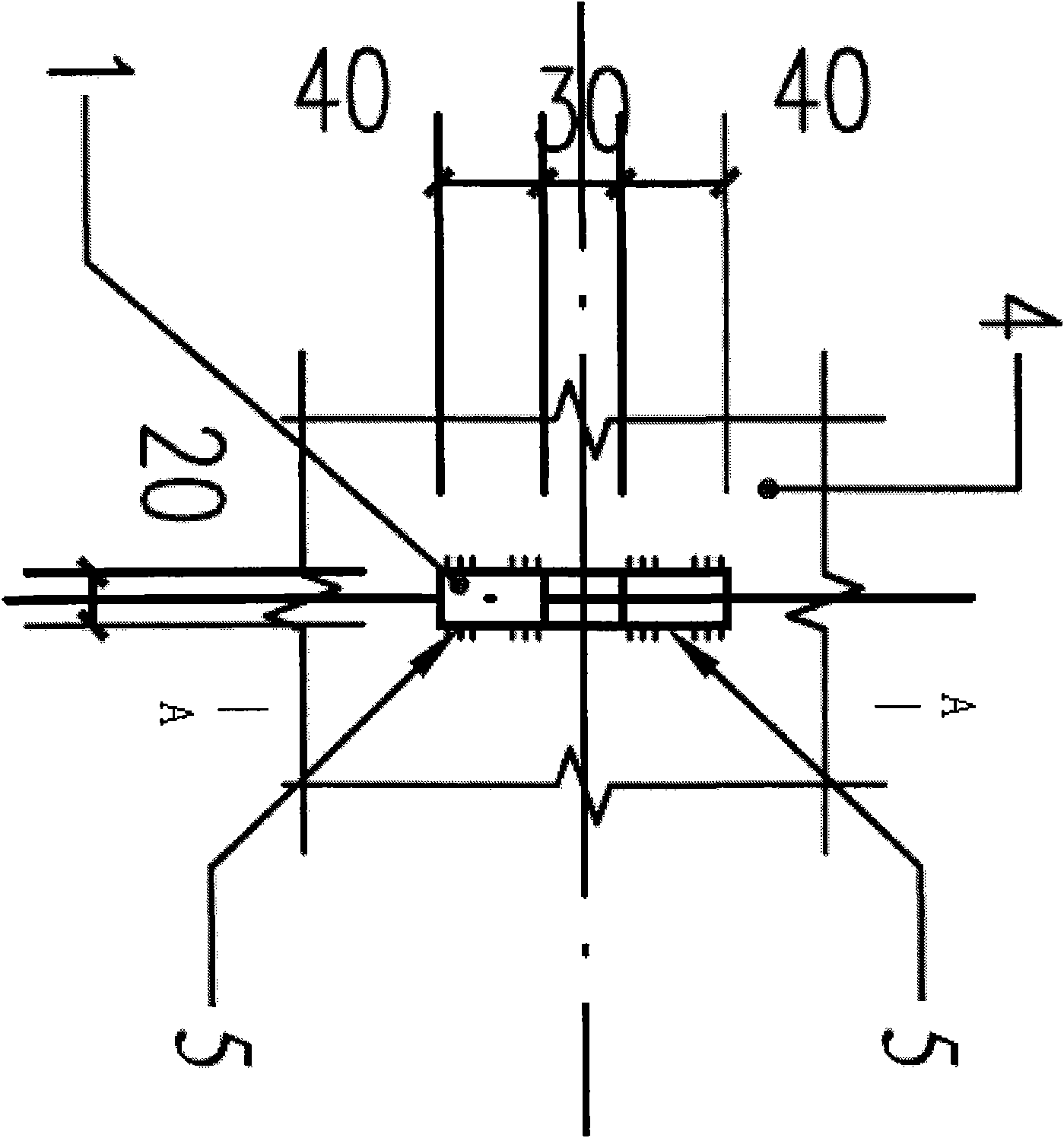

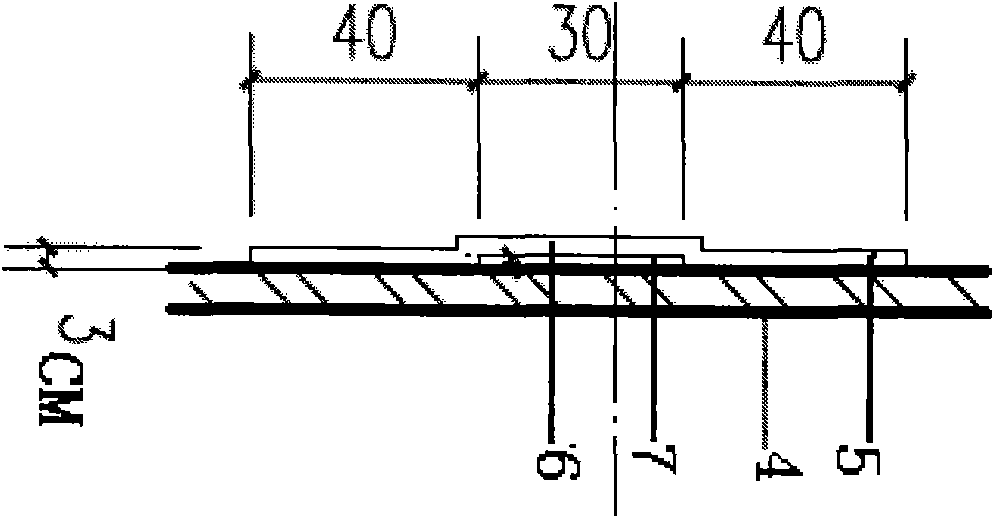

[0023] see Figure 1-8 , an energy-saving heat preservation system for storage tanks or towers, including: a plurality of steel ropes 3 that are tensioned and fixed around the storage tank or tower body 4, and each steel rope 3 is provided with a steel rope tension Adjusting mechanism 2, the plurality of steel ropes 3 are basically arranged in parallel; a plurality of prefabricated profiled thermal insulation panels 9, including thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com