Two-layer charring solid wood terrestrial heat composite floor

A composite floor, carbonized wood technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of the floor being easily bent and deformed by heat, poor dimensional stability of the floor, low thermal conductivity, etc., to reduce hygroscopicity and low processing costs. , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

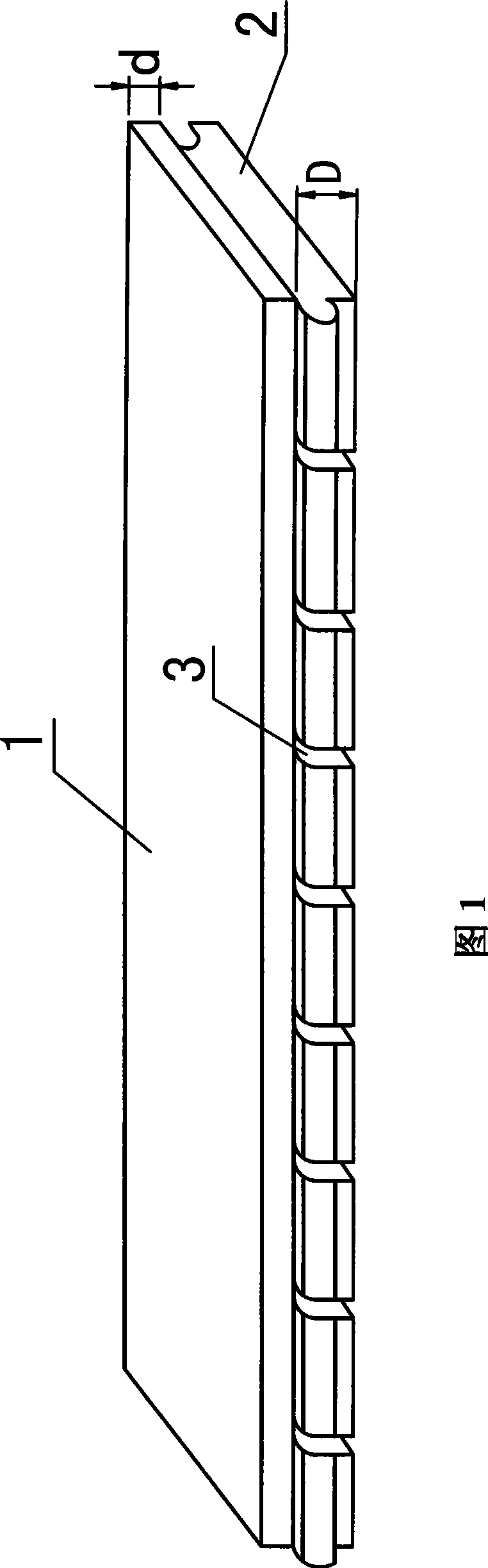

[0013] Example. As shown in Figure 1, it includes a surface plate 1 and a bottom plate 2. The surface plate 1 is made of carbonized wood, and its thickness d is 4mm; the bottom plate 2 is made of birch wood, and its thickness is 6mm. A plurality of geothermal grooves 3 are arranged on the base plate 2, and the geothermal grooves 3 are directly connected with the bottom surface of the surface plate 1, and heat can be directly transferred to the bottom surface of the surface plate 1 through the geothermal grooves 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com