Chlorine bypass system and method for treating extracted gas from chlorine bypass

A bypass system and treatment method technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve problems such as increased heat loss, coating failure, and reduced slag production in cement sintering systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, modes for implementing the present invention will be described with reference to the drawings in the specification.

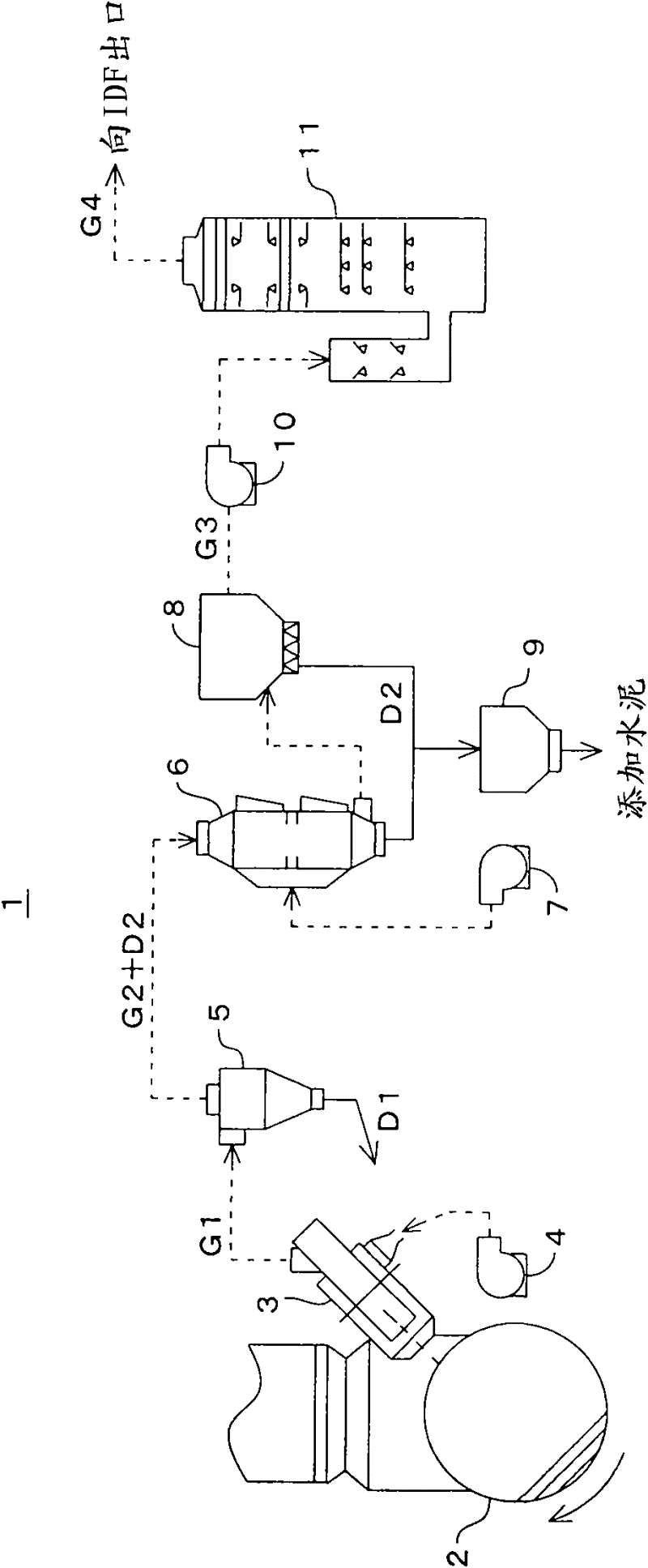

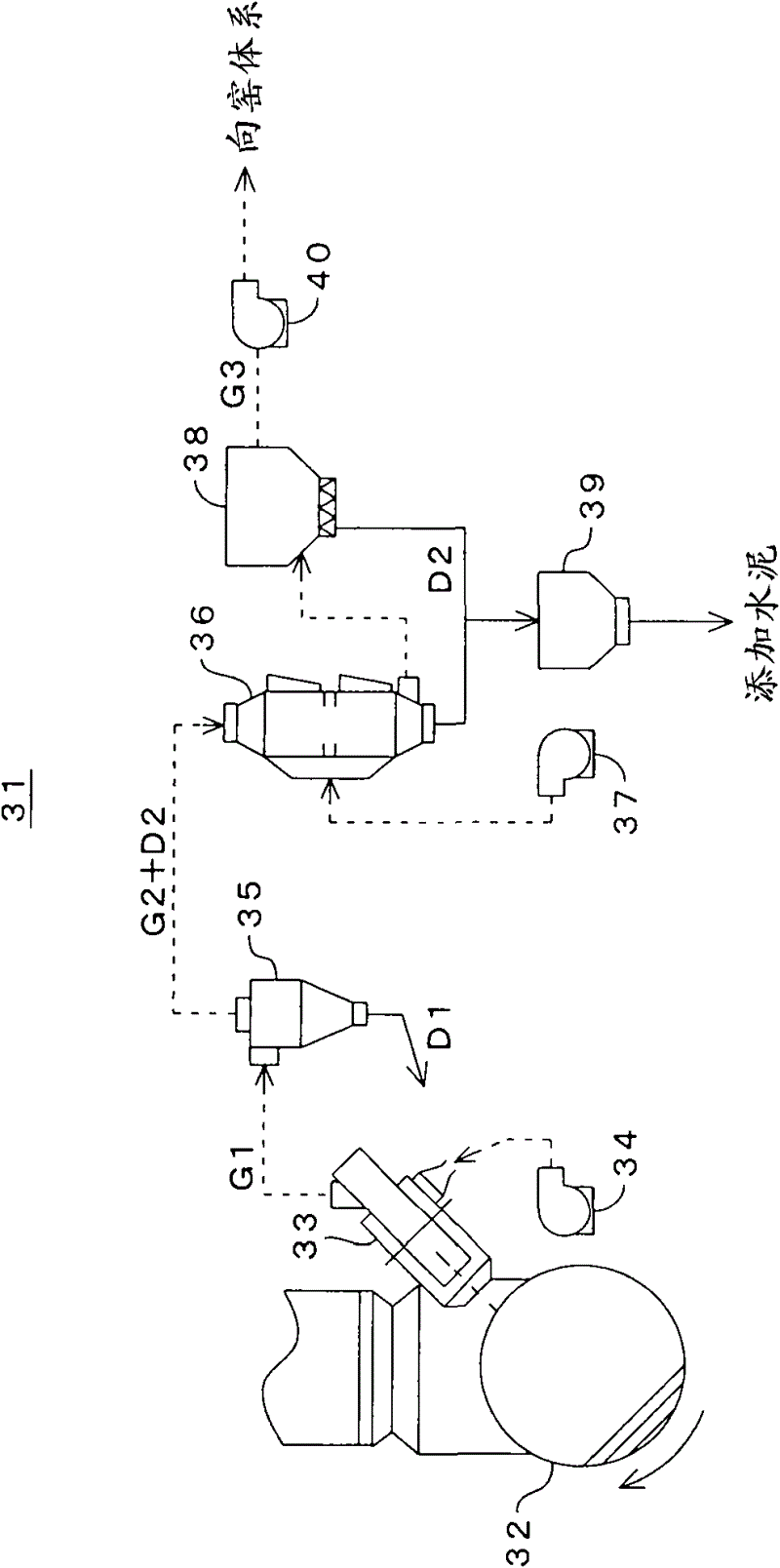

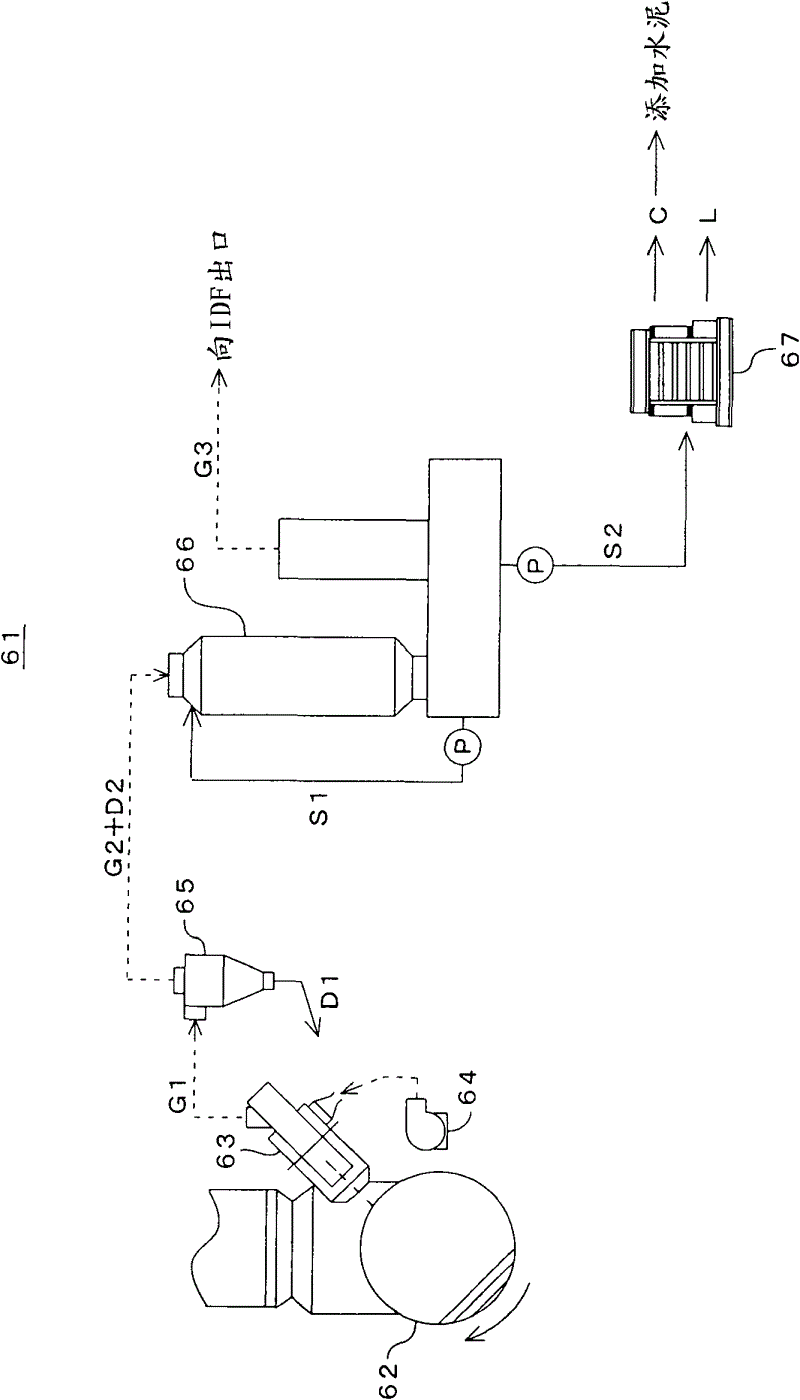

[0049] figure 1 Showing one embodiment of the chlorine bypass system of the present invention, the chlorine bypass system 1 is characterized in that it includes a kiln exhaust flow path from the kiln tail of the cement kiln 2 to the lowest stage cyclone (not shown). A sampler 3 that extracts part of the combustion gas, a cooling fan 4 that supplies cold air into the sampler 3 to quench the extraction gas G1, and a cyclone that serves as a classifier for separating the coarse powder D1 of dust contained in the extraction gas G1 5. Cool the cooler 6 of the exhaust gas G2 containing the fine powder D2 discharged from the cyclone 5, the cooling fan 7 supplying cold wind to the cooler 6, and the fine powder D2 in the exhaust gas G2 cooled by the cooler 6. The bag dust collector 8 for dust collection, the dust tank 9 for recovering the fine powder D2 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com