Cathode carbon block and cathode steel bar combined structure of aluminium electrolytic bath

A cathode steel rod and cathode carbon block technology, which is applied in the field of aluminum electrolysis, can solve the problem of high cathode voltage drop, achieve the effect of reducing cathode voltage drop and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

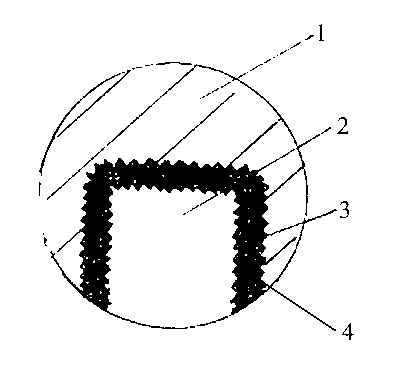

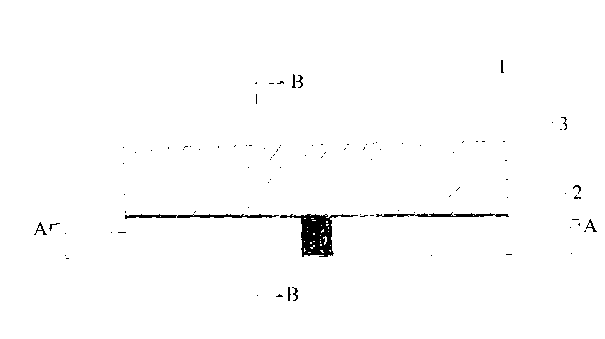

[0033] like figure 1 , figure 2 and image 3 As shown, the combined structure of the aluminum electrolytic cell cathode carbon block and the cathode steel rod that can reduce the cathode voltage drop of the aluminum electrolytic cell of the present invention includes a cathode carbon block 1 and a cathode steel rod 2, and the bottom of the cathode carbon block 1 has a A steel rod groove, a part of the cathode steel rod 2 is in the steel rod groove along the length direction, and a part extends out of the steel rod groove, wherein the part of the cathode steel rod 2 in the steel rod groove is 30-150mm higher than the part extending out of the steel rod groove; The carbon paste 3 is between the cathode steel rod 2 and the steel rod groove, filling the gap between the cathode steel rod 2 and the steel rod groove, each cathode carbon block has 2 steel rod grooves, and 2 pairs of cathode steel Great.

[0034] Grooves 4 with a depth of 1-5 mm are processed on the bottom and sides ...

Embodiment 2

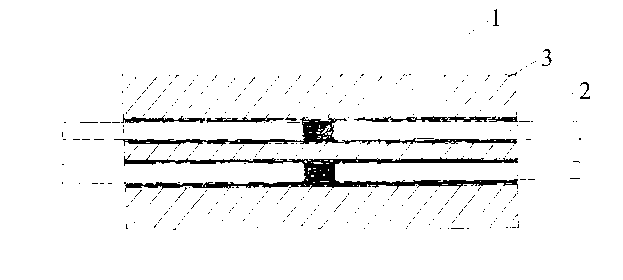

[0037] like figure 1 , figure 2 and Figure 5 As shown, the combined structure of the aluminum electrolytic cell cathode carbon block and the cathode steel rod that can reduce the cathode voltage drop of the aluminum electrolytic cell of the present invention includes a cathode carbon block 1 and a cathode steel rod 2, and the bottom of the cathode carbon block 1 has a A steel rod groove, a part of the cathode steel rod 2 is in the steel rod groove along the length direction, and a part extends out of the steel rod groove, wherein the part of the cathode steel rod 2 in the steel rod groove is 30-150mm higher than the part extending out of the steel rod groove; The carbon paste 3 is between the cathode steel rod 2 and the steel rod groove, filling the gap between the cathode steel rod 2 and the steel rod groove, each cathode carbon block has 2 steel rod grooves, and 2 pairs of cathode steel Rod, when the thickness of the cathode steel rod is less than 70mm, the thickness of ...

Embodiment 3

[0039] like Image 6 , Figure 7 As shown, the combined structure of the aluminum electrolytic cell cathode carbon block and the cathode steel rod that can reduce the cathode voltage drop of the aluminum electrolytic cell of the present invention includes a cathode carbon block 1 and a cathode steel rod 2, and the bottom of the cathode carbon block 1 has a A steel rod groove, a part of the cathode steel rod 2 is in the steel rod groove along the length direction, and a part extends out of the steel rod groove, wherein the part of the cathode steel rod 2 in the steel rod groove is 20-150mm higher than the part extending out of the steel rod groove; The difference between Embodiment 3 and Embodiment 1 and Embodiment 2 is that the cathode steel rod extending into the steel rod groove in this embodiment is relatively higher than the cathode steel rod protruding from the steel rod groove, and the downward extension height is 20- 150mm, the carbon paste 3 is between the cathode ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com