Fuel cell reaction device

A fuel cell and reaction device technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of poor operation stability, high cost investment, low reaction efficiency, etc., and achieve small heat loss and protection safety , high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

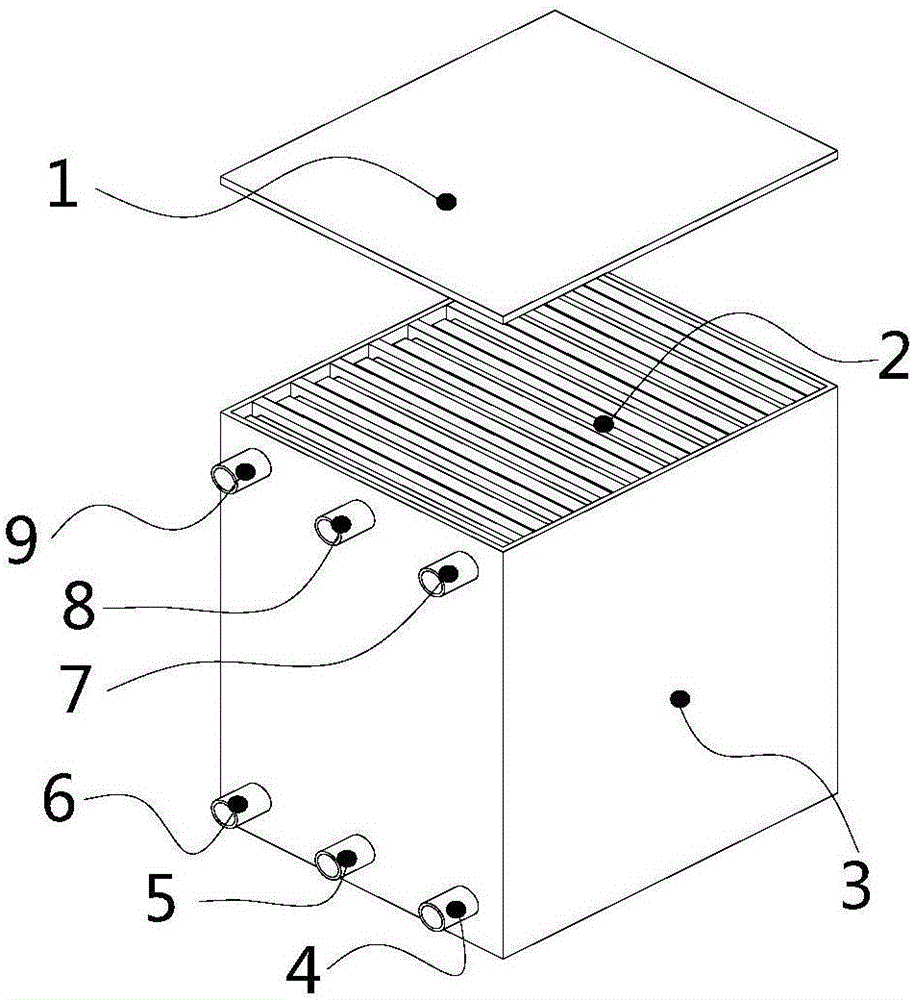

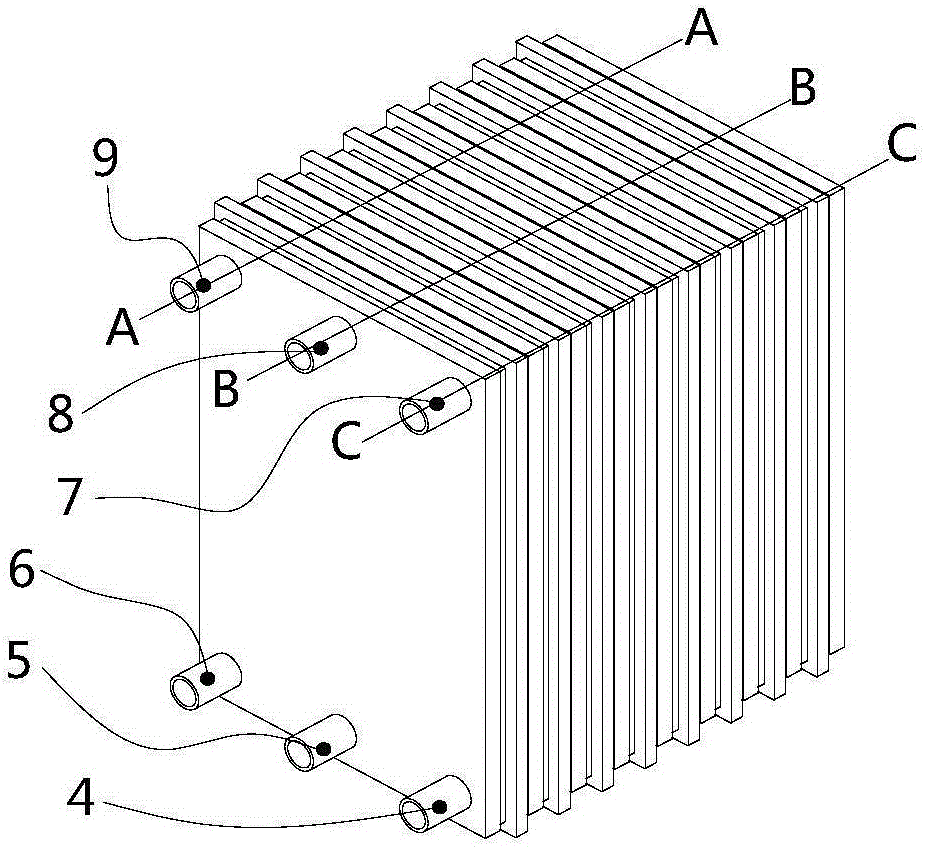

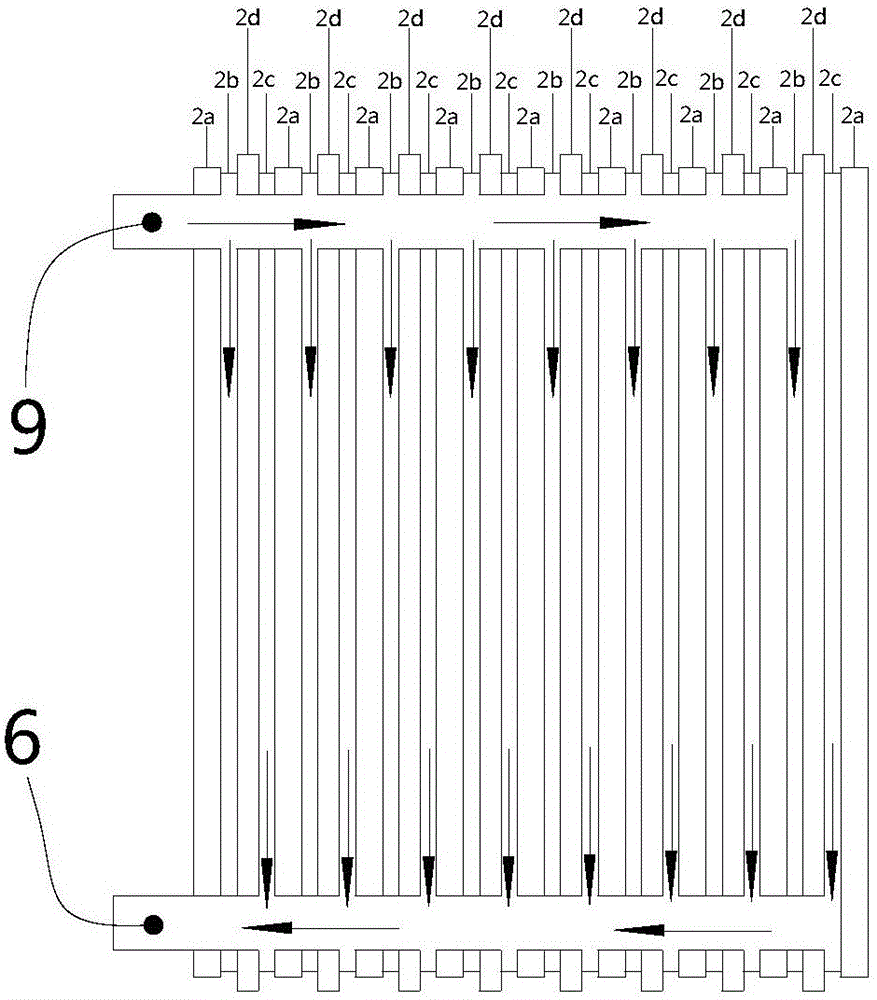

[0023] refer to Figure 1-5 , the present embodiment relates to a fuel cell reaction device, in specific use; the cathode fuel enters the cathode chamber 2c from the cathode fuel inlet channel 7 (see Figure 5 ), the anode material enters the anode chamber 2b from the anode fuel inlet channel 9 (see image 3 ); After fully reacting, the cathode fuel flows out from the cathode fuel outlet channel 6 (see image 3 ), the anode material flows out from the anode fuel outlet channel 4 (see Figure 5 ); Simultaneously, the cooling fluid flows through the cooling plate 2a from the cooling fluid inlet passage 8, and flows out from the cooling fluid outlet passage 5 after cooling the cathode chamber 2c and the anode chamber 2b (see Figure 4 ).

[0024] The fuel cell reaction body 2 is "cooling plate 2a—anode chamber 2b—proton exchange membrane 2d—cathode chamber 2c—cooling plate 2a—anode chamber 2b—proton exchange membrane 2d—cathode chamber 2c..." Plate heat exchanger structure; h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com