Heterojunction thin film composed of same metals and oxygen family elements as well as preparation and application thereof

A technology of oxygen family elements and the same metal, applied in the direction of electrical components, structural parts, chemical instruments and methods, etc., can solve the problems of high requirements for thin film electrodes, limited deposition area, large salt consumption, etc., and achieve a wide range of applications, Simple equipment and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

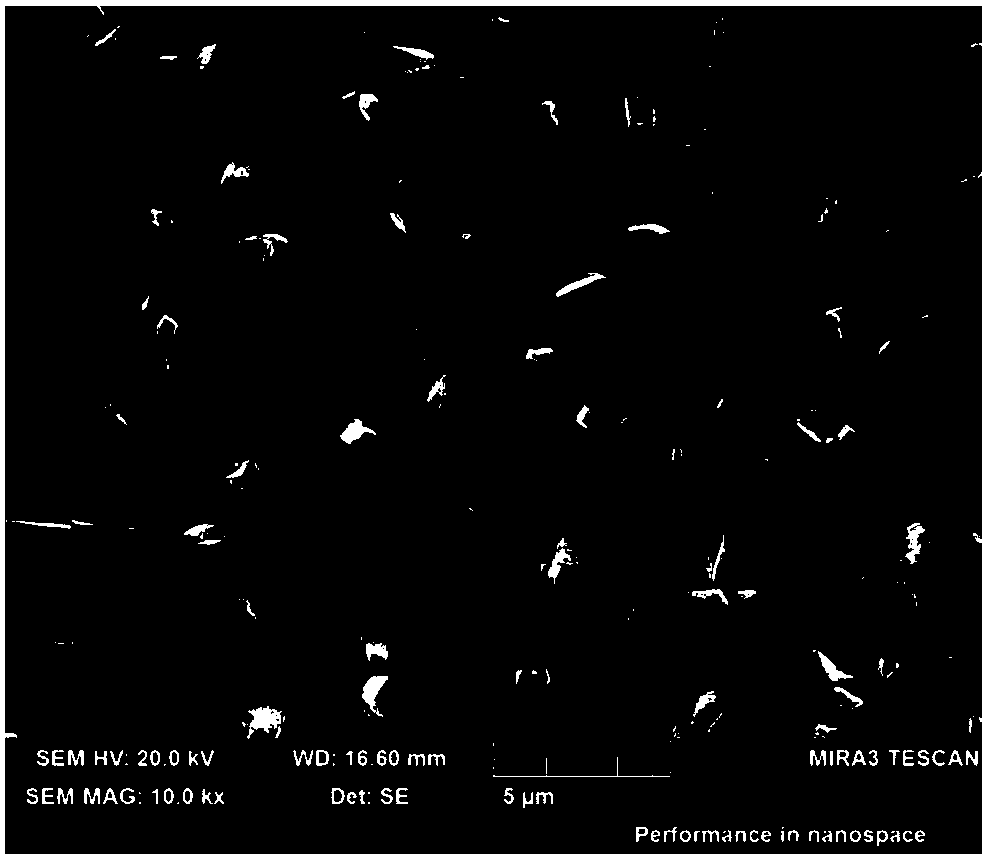

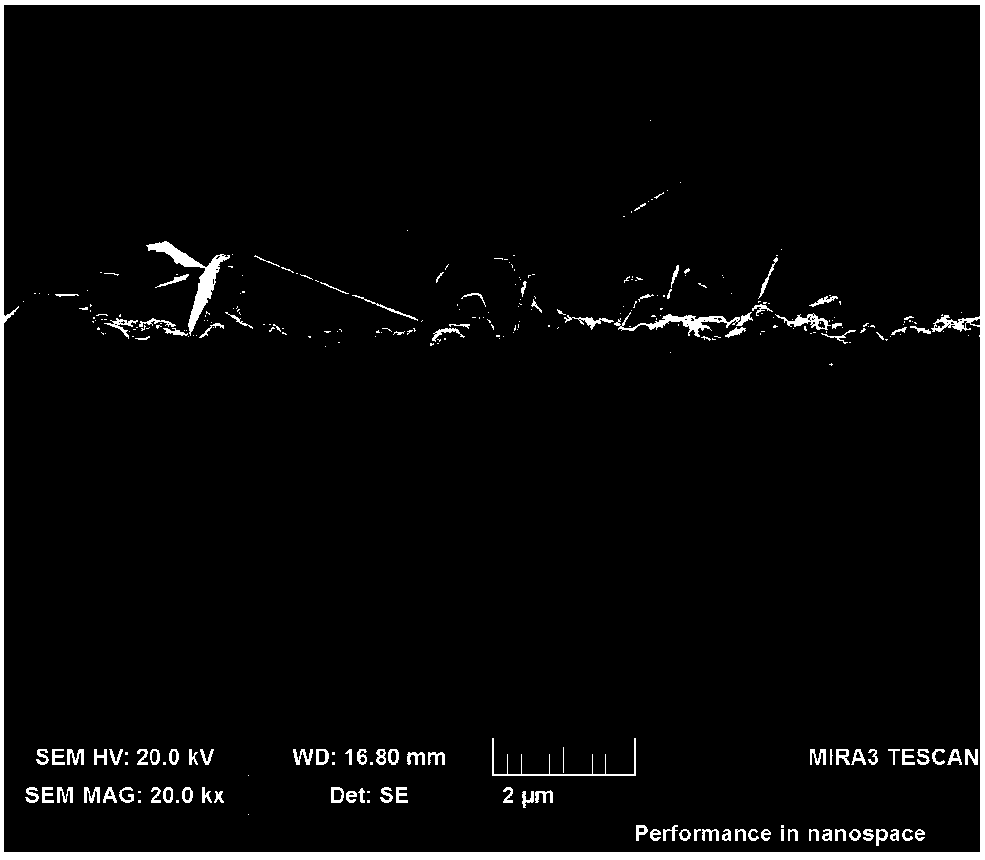

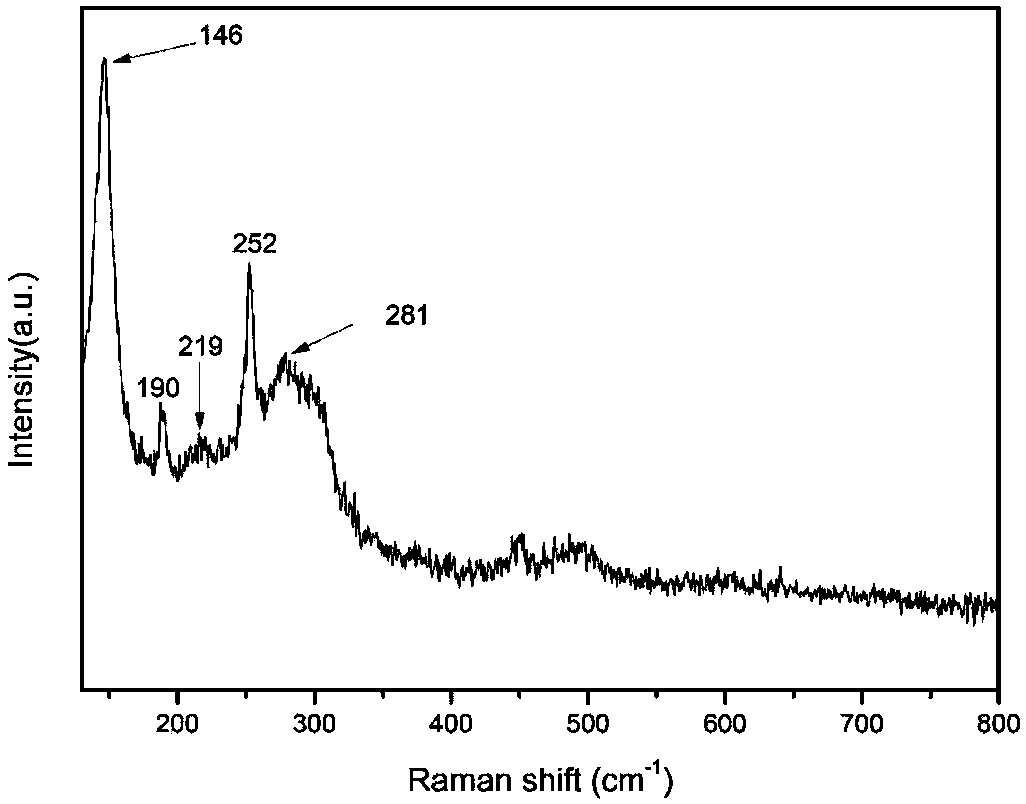

[0098] Antimony oxide (Sb 2 o 3 ) / antimony sulfide (Sb 2 S 3 ) heterojunction preparation

[0099] 1. Pretreatment of deposition substrate

[0100] Choose 30×30×2mm FTO glass as the deposition substrate: a. Degreasing agent cleaning of the substrate: use detergent as the degreasing agent, place the glass substrate in the aqueous solution of detergent, and clean it by ultrasonic vibration at a high temperature of 30°C 60min. b. High-temperature alkali solution cleaning of the substrate: Add 100mL of ammonia water and 100mL of deionized water into a 500mL beaker, place the glass substrate in the above solution, and clean it with ultrasonic vibration at a high temperature of 50°C for 30min. c. Ultrasonic vibration ethanol cleaning of the substrate: Take 200mL of absolute ethanol and add it to a 500mL beaker, place the glass substrate in ethanol, and clean it by ultrasonic vibration at a high temperature of 40°C for 60min. d. Ultrasonic vibration washing of the substrate: th...

Embodiment 2

[0109] Bismuth oxide (Bi 2 o 3 ) / bismuth sulfide (Bi 2 S 3 ) heterojunction preparation

[0110] 1. Pretreatment of deposition substrate

[0111] The method of Example 1 is used to pretreat the substrate.

[0112] 2. Preparation of metal oxide prefabricated film

[0113] Weigh 1.49g of bismuth nitrate into a beaker, add 10mL of concentrated nitric acid to it, and then add deionized water to prepare 60mL of bismuth nitrate solution. Add saturated sodium hydroxide solution dropwise to the solution, adjust the pH to 10 (temperature lower than 40°C) to obtain a bismuth nitrate precursor solution, put the pretreated deposition substrate into the precursor solution, and deposit at 60°C for 60 minutes , washed several times with deionized water, and dried. The thickness of the oxide layer was 5 μm.

[0114] 3. Vulcanization heat treatment

[0115] Wash and dry the above film prefabricated layer and put it in the reaction equipment, add an appropriate amount of sulfur powder ...

Embodiment 3

[0118] Indium oxide (ln 2 o 3 ) / indium sulfide (ln 2 S 3 ) heterojunction preparation

[0119] 1. Pretreatment of deposition substrate

[0120] The method of Example 1 is used to pretreat the substrate.

[0121] 2. Preparation of metal oxide prefabricated film

[0122] Weigh 0.88g of indium chloride into a beaker, add 10mL of concentrated hydrochloric acid to it, and then add deionized water to prepare 60mL of indium chloride solution. Add saturated sodium hydroxide solution dropwise to the solution, adjust the pH to 8 (temperature lower than 40°C) to obtain an indium chloride precursor solution, put the pretreated deposition substrate into the precursor solution, and deposit at 90°C for 40 minutes Then, it was washed several times with deionized water and dried. The thickness of the oxide layer was 600 nm.

[0123] 3. Vulcanization heat treatment

[0124] Wash and dry the above film prefabricated layer and put it in the reaction equipment, add an appropriate amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com