Process for preparing power type lithium-ion battery anode material by using supercritical/subcritcal water thermal process

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as not meeting the requirements of power lithium batteries, restricting development and application, and restricting material development, so as to increase production per unit time and improve Operational efficiency, avoiding inefficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

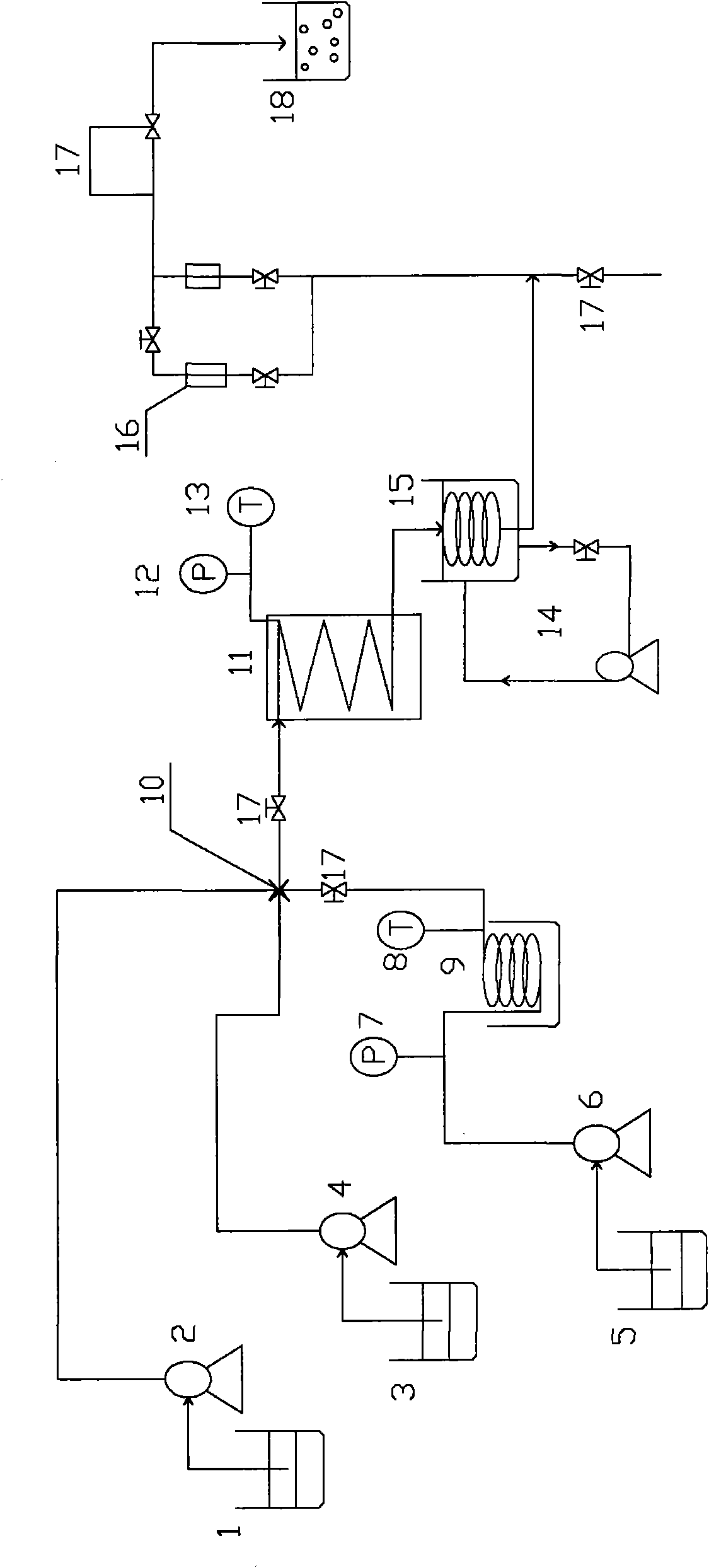

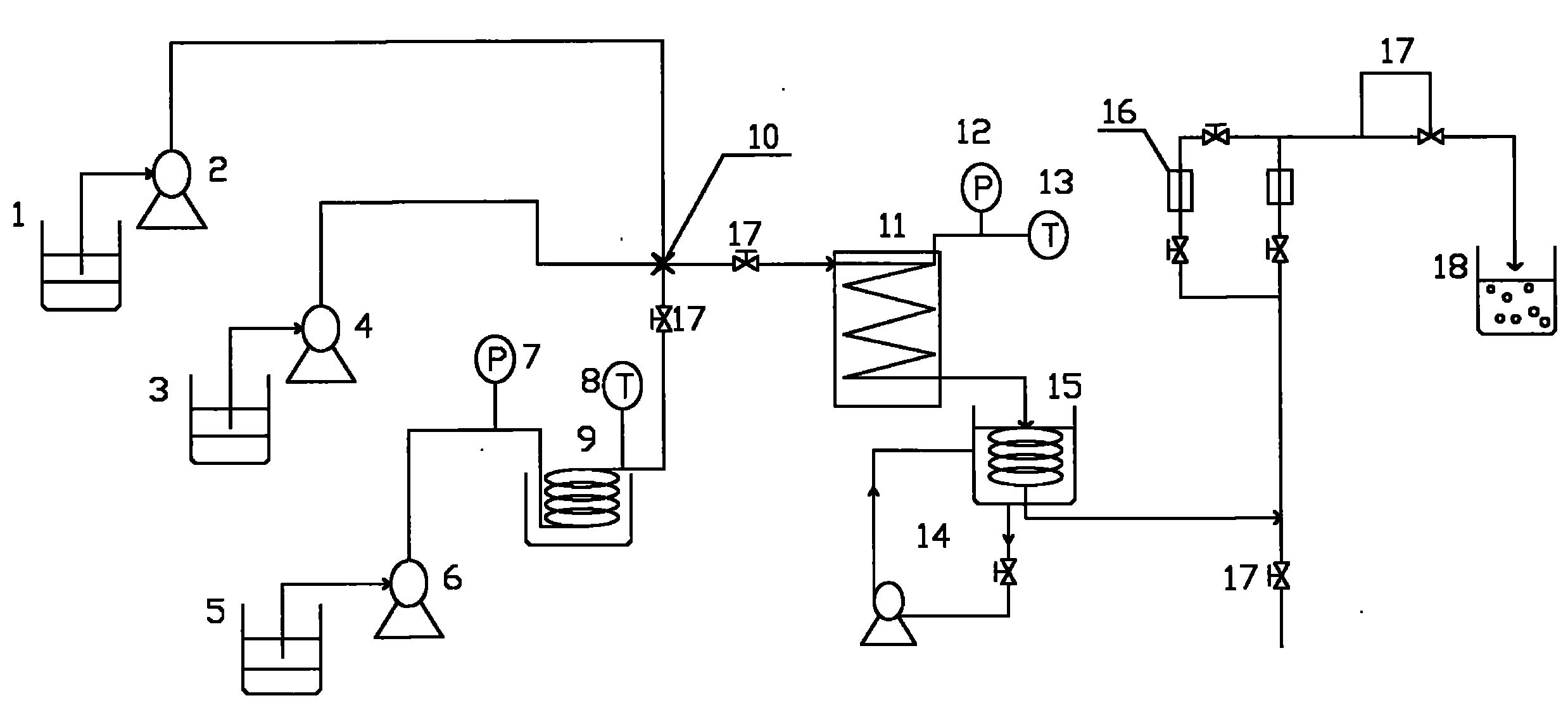

[0039] Preparation of LiFePO cathode material for power lithium-ion batteries by subcritical hydrothermal process 4 basic process flow.

[0040] Prepare 0.3~0.4M LiOH, 0.1M (NH 4 ) 2 Fe(SO 4 ) 2 , 0.1M H 3 PO 4 solution, where (NH 4 ) 2 Fe(SO 4 ) 2 and H 3 PO 4 Dissolved in deionized water and mixed in the storage tank 1, pumped into the mixer 10 through the high-pressure metering pump 2, and the LiOH solution was pumped into the mixer 10 through the high-pressure metering pump 4 in the storage tank 3. The deionized water in the storage tank 3 is pumped into the preheater 9 by the high-pressure metering pump 6 for preheating, and the pressure and temperature are controlled so that the pressure is 5MPa and the temperature is 80°C. The preheater 9 The pressure and temperature in can be read by pressure gauge 7 and temperature gauge 8 respectively. The deionized water preheated by the preheater 9 enters the mixer 10, and is mixed with the raw material liquid lithium ...

Embodiment 2

[0043] Preparation of cathode material LiMnPO for power lithium ion battery by subcritical hydrothermal process 4 basic process flow.

[0044] Prepare 0.11~0.2M LiOH, 0.1M MnSO 4 , 0.1M H 3 PO 4 solution, where MnSO 4 and H 3 PO 4 Dissolved in deionized water and mixed in the storage tank 1, pumped into the mixer 10 through the high-pressure metering pump 2, and the LiOH solution was pumped into the mixer 10 through the high-pressure metering pump 4 in the storage tank 3. The deionized water in the storage tank 3 is pumped into the preheater 9 by the high-pressure metering liquid pump 6 for preheating, and the pressure and temperature are controlled so that the pressure is 10 MPa and the temperature is 80 ° C. The preheater 9 The pressure and temperature in can be read by pressure gauge 7 and temperature gauge 8 respectively. The deionized water preheated by the preheater 9 enters the mixer 10, and is mixed with the raw material liquid lithium source and the mixed liqui...

Embodiment 3

[0047] The basic process flow of supercritical hydrothermal process for the preparation of positive electrode materials for power lithium-ion batteries.

[0048] Prepare 0.3~0.4M LiOH, 0.1M (NH 4 ) 2 Fe(SO 4 ) 2 , 0.1M H 3 PO 4 Solution, wherein the molar ratio to iron ions is 1-10% Mg 2+ with (NH 4 ) 2 Fe(SO 4 ) 2 and H 3 PO 4 Dissolve together in deionized water and mix in the storage tank 1, and pump into the mixer 10 through the high-pressure metering pump 2, and the LiOH solution is pumped into the mixer 10 through the high-pressure metering pump 4 in the storage tank 3. The deionized water in the storage tank 3 is pumped into the preheater 9 by the high-pressure metering pump 6 for preheating, and the pressure and temperature are controlled so that the pressure is 5 MPa and the temperature is 160 ° C. The preheater 9 The pressure and temperature in can be read by pressure gauge 7 and temperature gauge 8 respectively. The deionized water preheated by the preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com