System and method for preparing reducing gas through lignite double-bed gasification

A technology for lignite and gasifier, which is applied to the system of synthesis gas, coal gas, high-efficiency production of metallurgical reducing gas, and double bed gasification of lignite, can solve the problem of high pressure, high energy consumption and high cost of gas production in the gasifier. problems, to achieve the effect of good product gas quality, low energy consumption and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

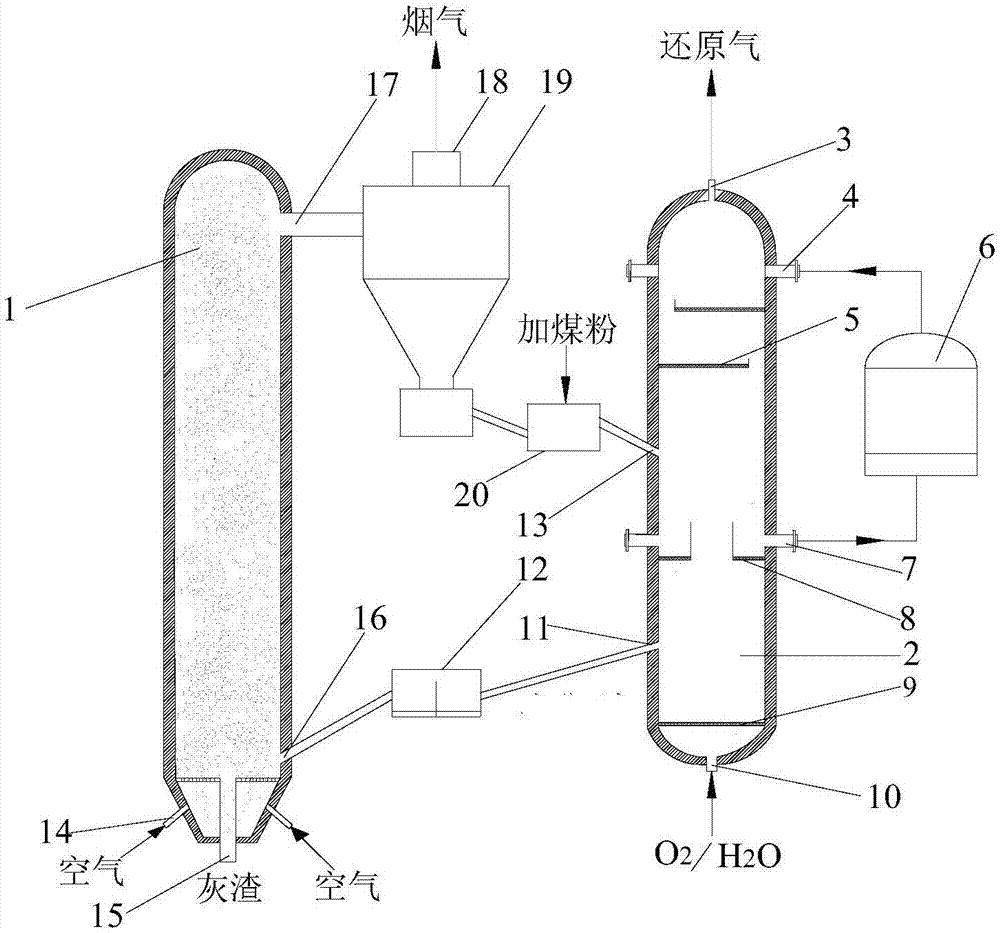

[0055] See figure 1 , which is a schematic diagram of the system for producing reducing gas by double-bed gasification of lignite in this embodiment, and the in-out situation of materials is marked in the schematic diagram. The system for producing reducing gas by double-bed lignite gasification provided in this embodiment includes a combustion furnace 1, a gasification furnace 2, a gas-solid separator 19, a feeding device 12, a catalyst tank 6 and a pulverized coal mixing device 20;

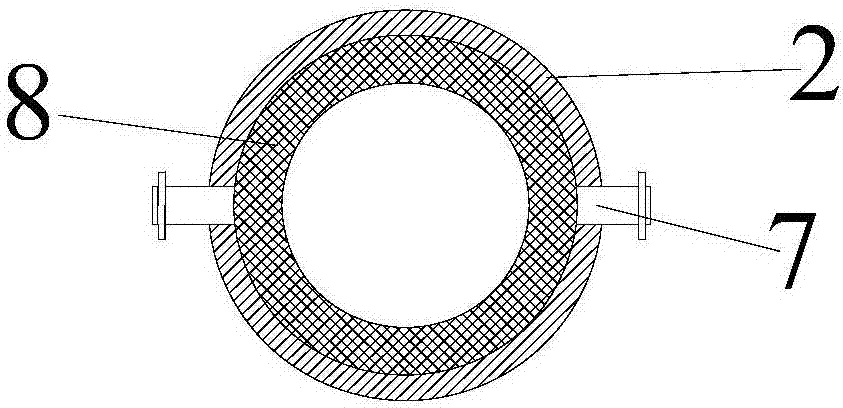

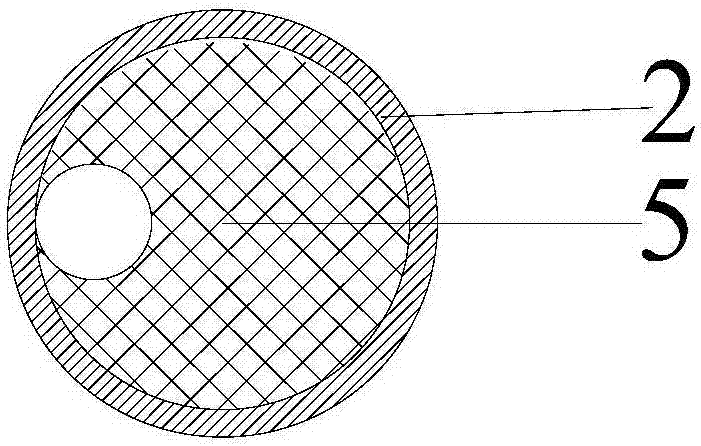

[0056] The combustion furnace 1 is provided with a flue gas outlet 17, a semi-coke / ash inlet 16, an ash outlet 15, an air distribution plate and an air inlet 14; The air is evenly distributed, the flue gas outlet is close to the top of the combustion furnace, the semi-coke / ash inlet is located at the lower part of the combustion furnace, the ash outlet is located at the bottom of the combustion furnace, and the air inlet is located at the lower part of the combustion furnace. The side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com