Improvements to tubular electrical generators

A linear generator and armature technology, applied in ocean energy power generation, propulsion systems, electric components, etc., can solve problems such as damage and mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

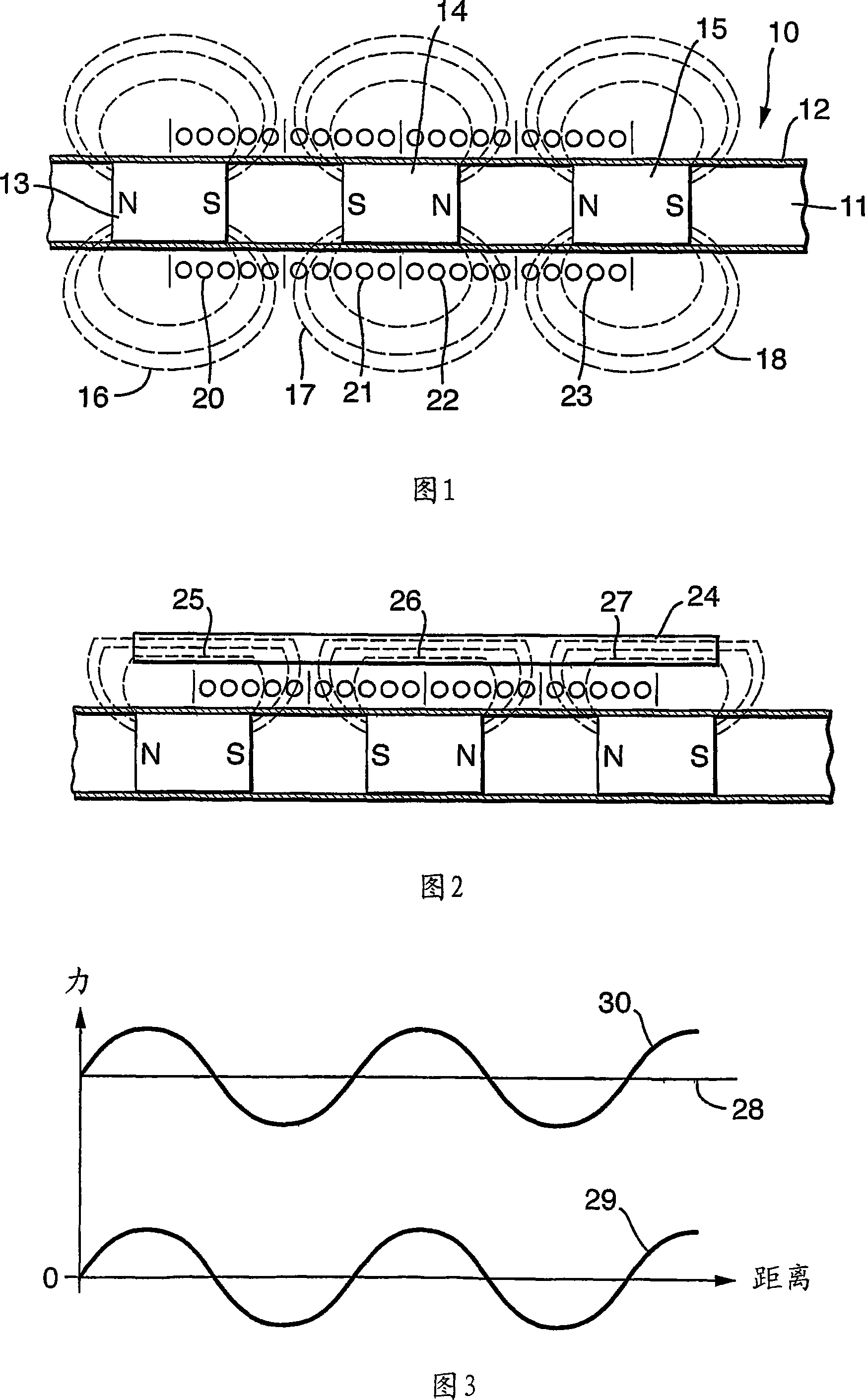

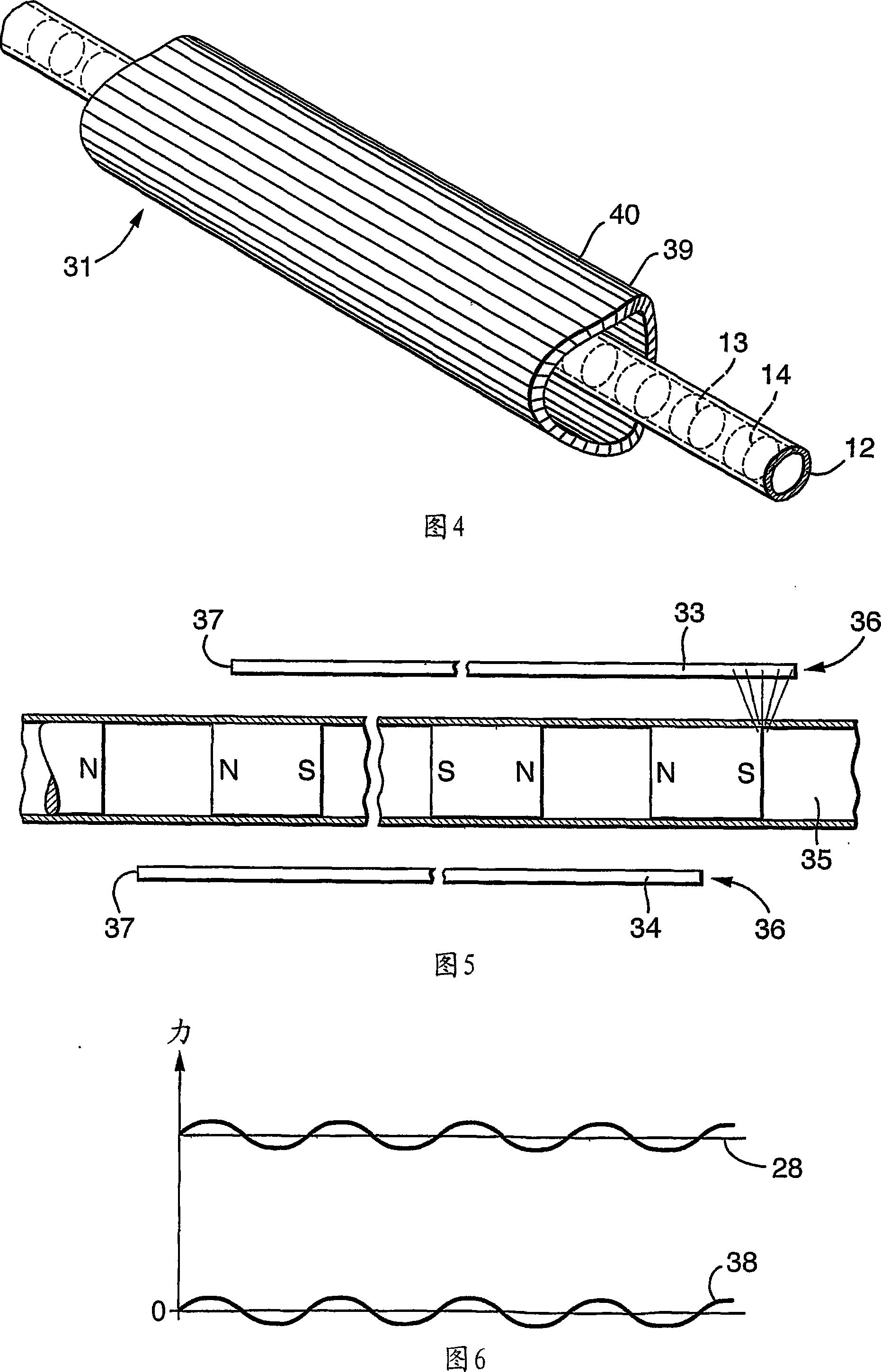

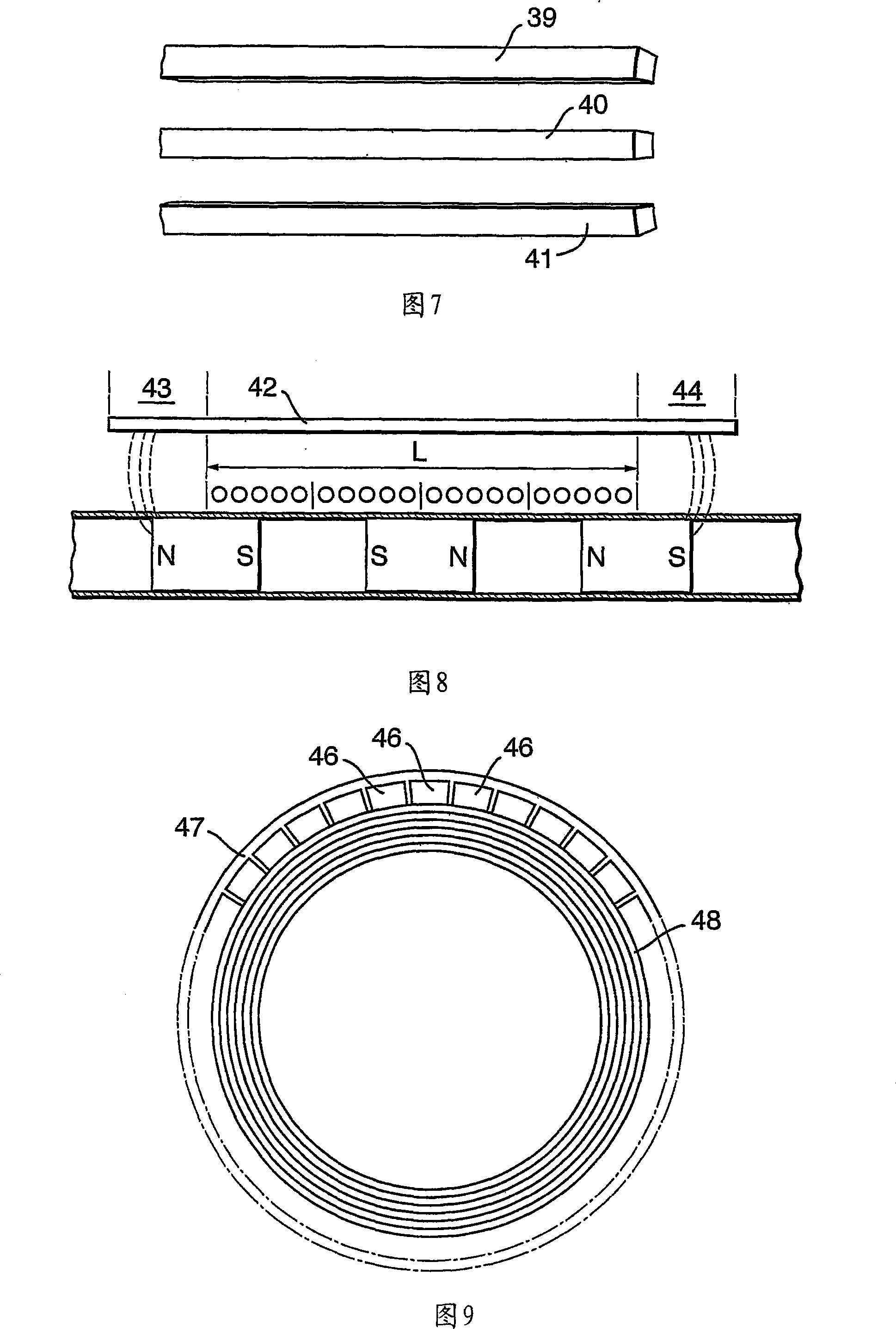

[0034] Figures 1, 2 and their descriptions provide a generally relevant background to aid in the understanding of the present invention.

[0035]Referring now to FIG. 1 , an improved typical tubular linear generator disclosed herein is indicated generally at 10 . The converter 11 comprises a non-ferromagnetic tube 12 in which a series of magnetized permanent magnets 13, 14, 15 etc. are arranged axially at intervals. It can be seen that the like-named poles of the magnets face each other. The result is magnetic teeth as shown in 16, 17 and 18, which emanate radially from the tube supporting the permanent magnet, and the rotation of the coaxial armature coils shown can cut the magnetic teeth, here the same Shaft armature coils are indicated at 20 , 21 , 22 and 23 . (Note that these coils are fixed inside another tube, not shown here for clarity.) Forcing relative motion between the armature and converter results in sinusoidal AC power in the armature coils. (This arrangement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com