Patents

Literature

91 results about "Electrolysis operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

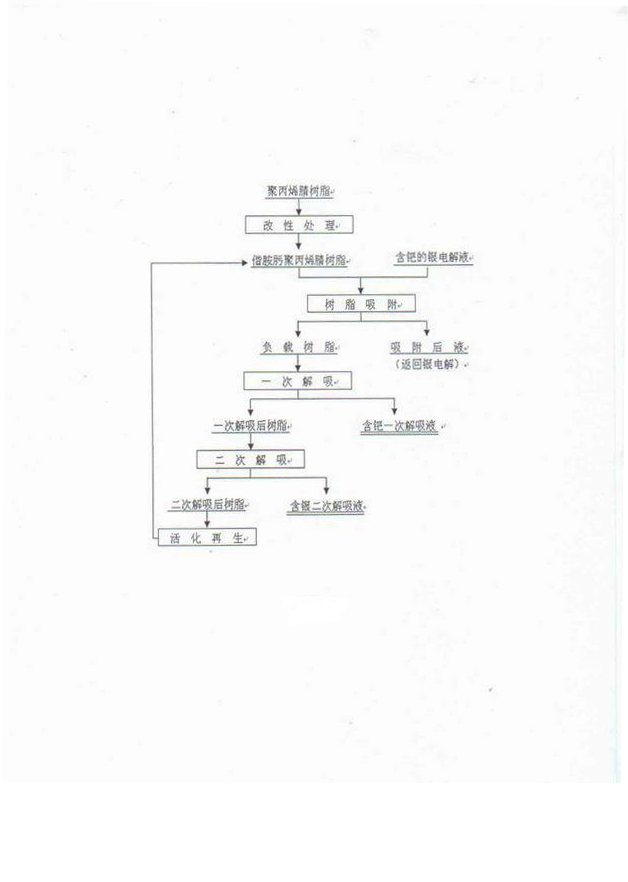

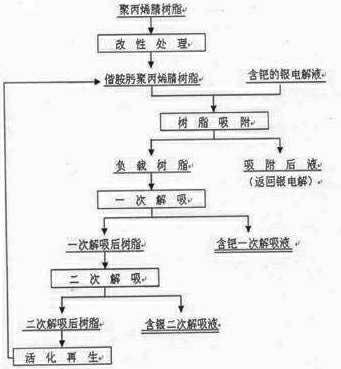

Separation method of palladium from silver electrolyte

InactiveCN102329959AAchieve separationHigh recovery ratePhotography auxillary processesProcess efficiency improvementChelating resinElectrolysis operation

The invention relates to a wet metallurgic method for effectively separating palladium from silver electrolyte by adopting modified polyacrylonitrile resin, and the process is free from pollution. The method adopts a technical scheme that: polyacrylonitrile resin is modified by adopting a hydroxyl amine hydrochloride solution to obtain a novel chelating resin namely amidoxime polyacrylonitrile resin; silver electrolyte which is roughly purified to remove heavy metal impurities is adsorbed by adopting the amidoxime polyacrylonitrile resin, so that palladium in the solution is loaded onto the resin, and the resin is subjected to primary desorption by adopting an acidic thiourea solution to obtain a palladium-containing desorption liquid; the resin is subjected to secondary desorption by adopting a high-concentration hydrochloric acid solution to obtain a silver-containing desorption liquid; and the resin which is subjected to twice desorption is regenerated by adopting a hydroxyl amine hydrochloride solution, and is returned to adsorb the palladium-containing silver electrolyte. According to the method, palladium and silver can be effectively separated, the adsorbed solution can be directly returned to silver electrolysis, the operation is simple, the purification time is short, the recovery rate of noble metals is high, and the practicality is strong.

Owner:CENT SOUTH UNIV

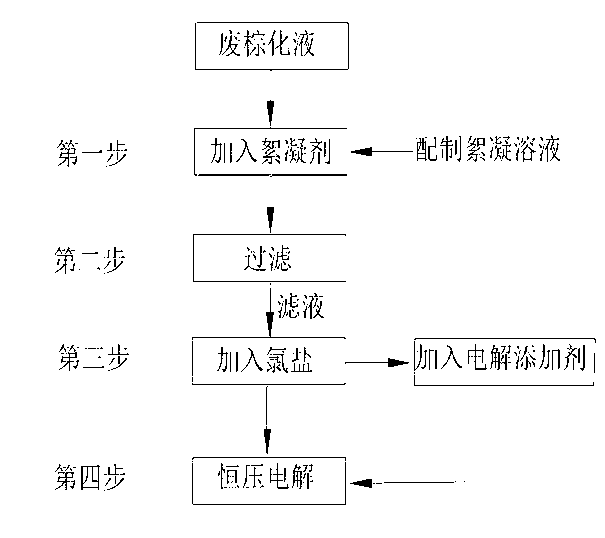

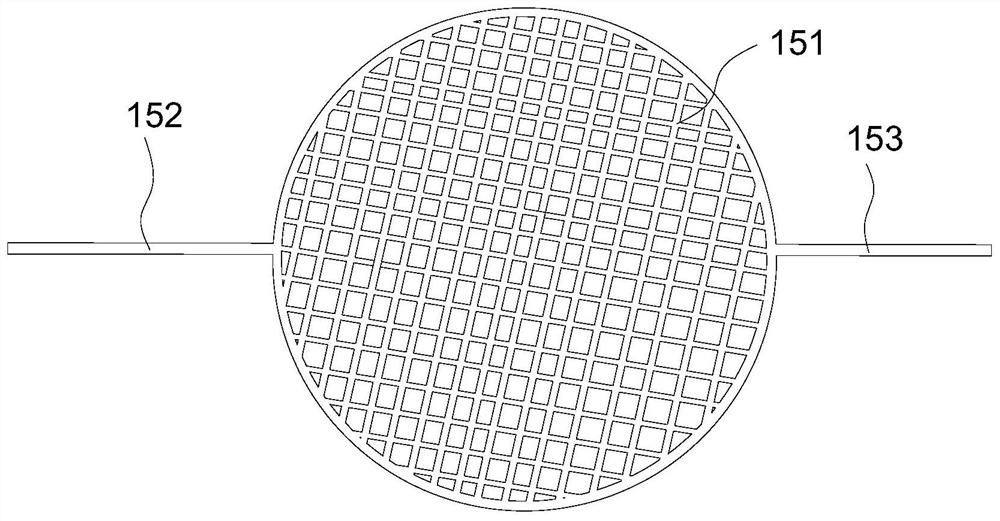

Method for extracting copper by utilizing waste browning liquid

ActiveCN103233244AReduce dosageLow pricePhotography auxillary processesProcess efficiency improvementIndiumThiourea

The invention discloses a method for extracting copper by utilizing waste browning liquid. The method comprises the following steps of: adding flocculating agent to the waste browning liquid, so that large particles and organic substances with multiple potential adsorption points in the waste liquid are preliminarily settled; filtering the treated waste browning liquid to remove filter residues; adding chlorine salt to the filtrate; placing the solution to an electrolytic cell, coating indium oxide on the surface of a titanium mesh as an anode, carrying out electrolysis by using red copper as a cathode to recycle copper; or adding gelatin, thiourea and casein to the solution for electrolysis to recycle block copper. The method for extracting copper by utilizing waste browning liquid can be used for carrying out electrolysis by carrying out simple flocculating settling filter treatment or adding additive, is simple to operate, low in treatment cost and capable of recycling high-quality copper.

Owner:深圳市祺鑫环保科技有限公司

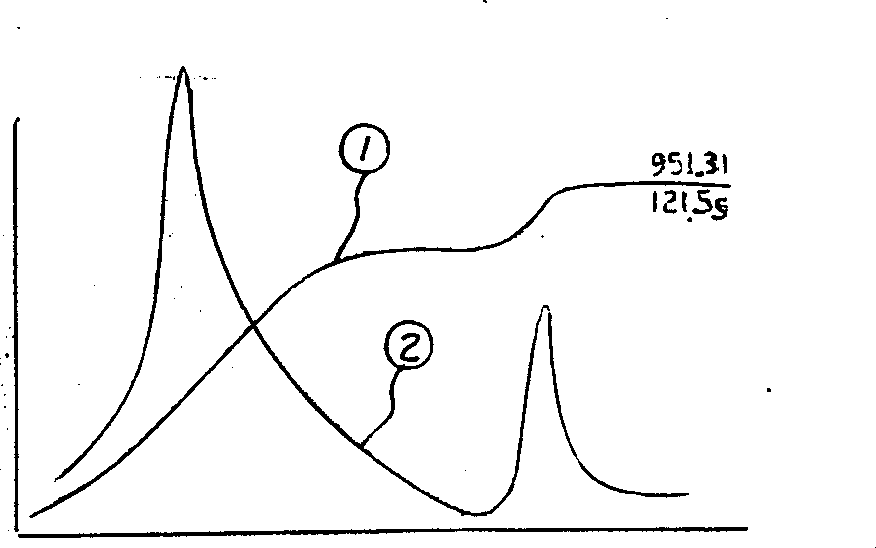

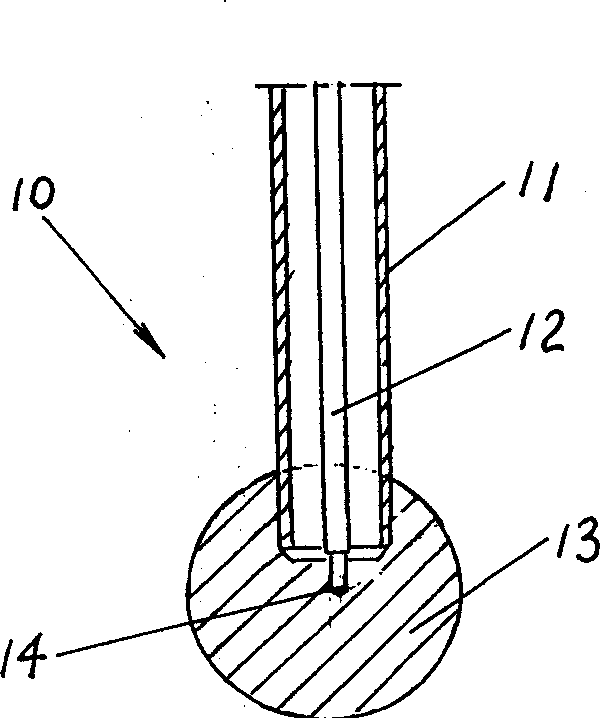

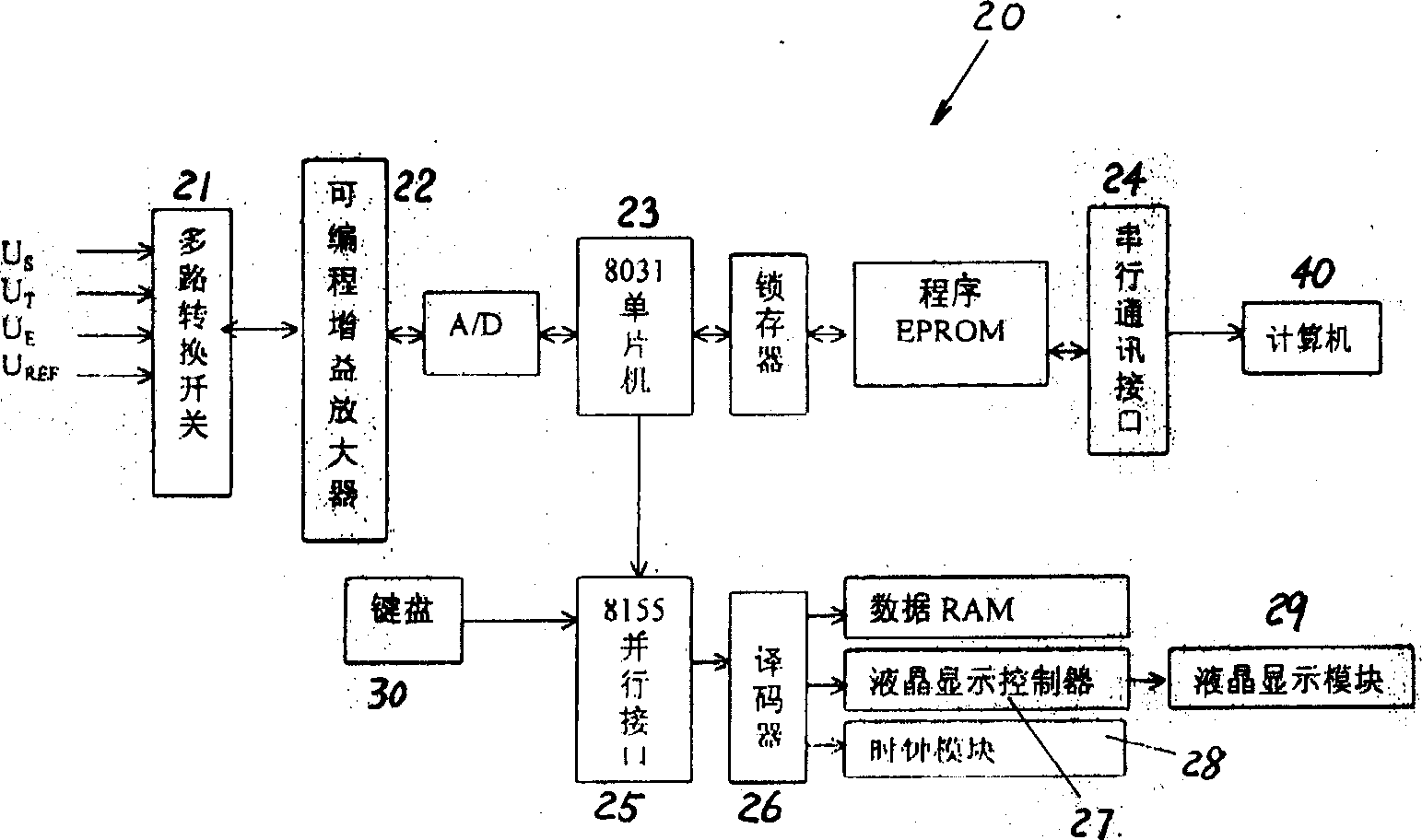

On-line real time measuring method and measurer for aluminium electrolyzing parameters

An on-line real-time aluminium electrolyzing parameters measuring process includes the steps of detecting the primary crystal temperature by inserting the measurer probe into electrolyzer and sendingout the primary crystal temperature signal; and processing the signal and calculating other electrolysis parameters according to the set mathematical model. The probe of the present invention includes thermocouple, metal ball and protecting tube, and the thermocouple inside the protection tube has its end inserted to the geometric center of the metal ball. The present invention can measure and find out important aluminium electrolyzing parameters timely and precisely, and this makes it possible to realize the autocontrol of aluminium electrolyzer for raising its current efficiency, reducing the power consumption and raising the yield.

Owner:程留恩 +1

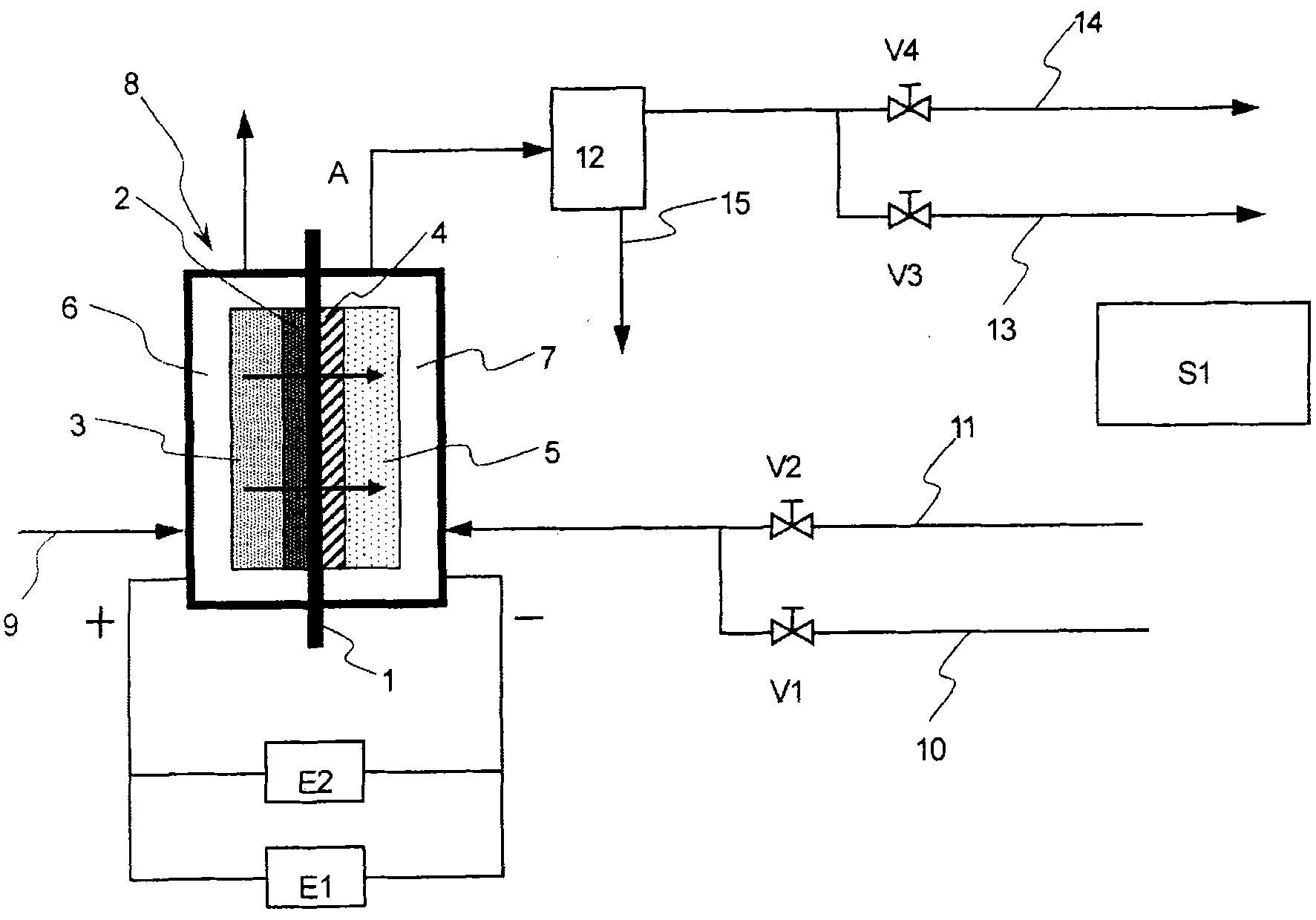

Operation method of ozonizer and ozonizer apparatus used therefor

The present invention offers an operation method of an ozonizer and an ozonizer apparatus to improve ozone gas purity and to achieve long and safety electrolysis operation in such manner that, during normal operation of the ozonizer, ozone gas is generated at the anode in the anode compartment and hydrogen gas is generated at the cathode in the cathode compartment; and only when the ozonizer is stopped and operation is switched to protective current operation during which minute electric current is supplied to protect said anode, oxygen-containing gas is supplied to said cathode compartment after electrolyte and hydrogen gas in said cathode compartment are all drained out, so that said cathode is made function as a gas electrode for oxygen reduction reaction, using said cathode as a reversible electrode with two functions as a gas generation electrode and a gas electrode, thereby during normal operation, ozone is generated efficiently, and during the protective current operation, when safety is a key issue, hydrogen gas is not generated at the cathode and mingling of hydrogen gas into ozone gas generated at the anode is prevented.

Owner:CHLORINE ENGINEERS CORP LTD

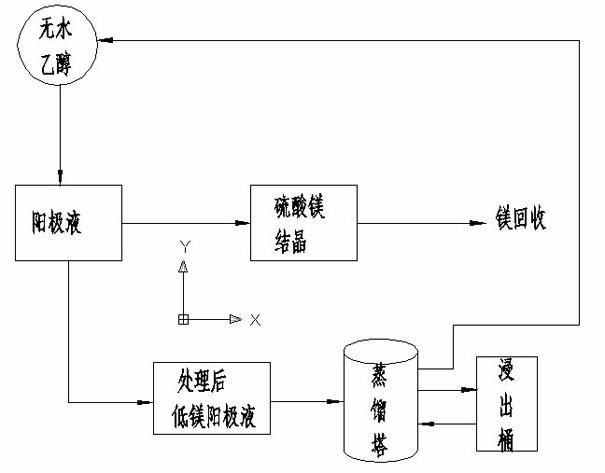

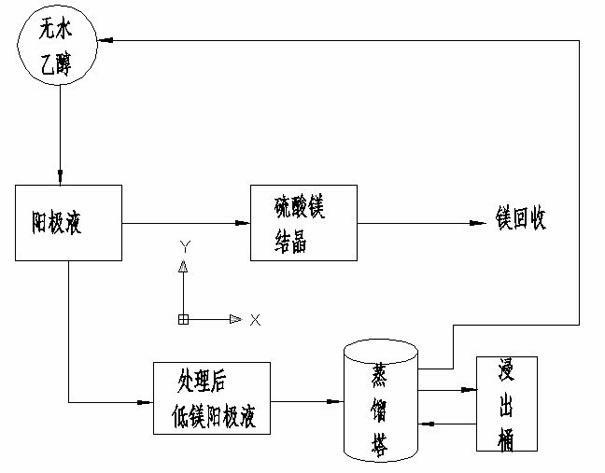

Method for removing magnesium via cycle of ethanol in electrolytic manganese machining process

ActiveCN102134731AEffective destinationEliminates the precipitation of crystalsPhotography auxillary processesElectrolysis componentsElectrolytic agentPhysical chemistry

The invention discloses a method for removing magnesium via cycle of ethanol in an electrolytic manganese machining process, which is characterized by comprising the following steps: adding 80-125g / l of absolute ethanol in anolyte of electrolytic manganese, stirring and adjusting the temperature within 35-55DEG C to ensure that the magnesium sulfate in the anolyte is largely salted out and precipitated; carrying out filtration and impurity removal in the anolyte so as to remove the saturated magnesium sulfate precipitate in the anolyte; and distilling the filtered solution to distill and separate the ethanol so as to realize the recovery and the recycle of the ethanol. Compared with the prior art, the method for removing magnesium via cycle of the invention adopts a process for processingmagnesium sulfate via cycle of ethanol so that the magnesium sulfate can be effectively removed, the precipitation phenomenon of magnesium sulfate crystallization in the production process is eliminated, the electrolytic operation is simpler and easier, the electrolytic environment is improved, the current efficiency is increased, the product quality is improved, the magnesium sulfate is effectively prevented from gradually accumulating in the electrolyte to gradually increase the concentration, the viscosity and the density are reduced, the ions in the electrolyte are normally diffused, the cell voltage is reduced and the like.

Owner:贵州武陵锰业有限公司

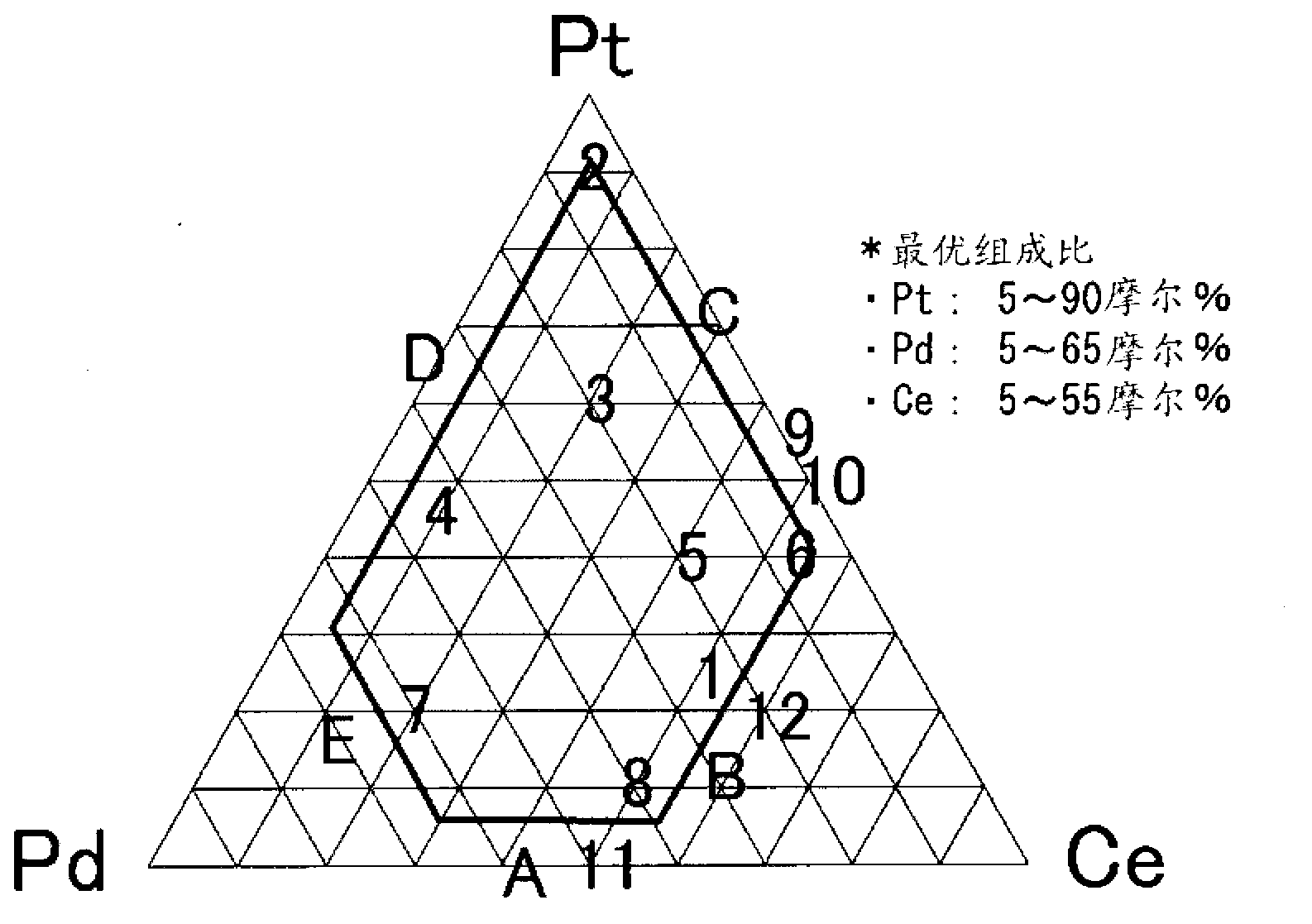

Activated cathode for hydrogen evolution

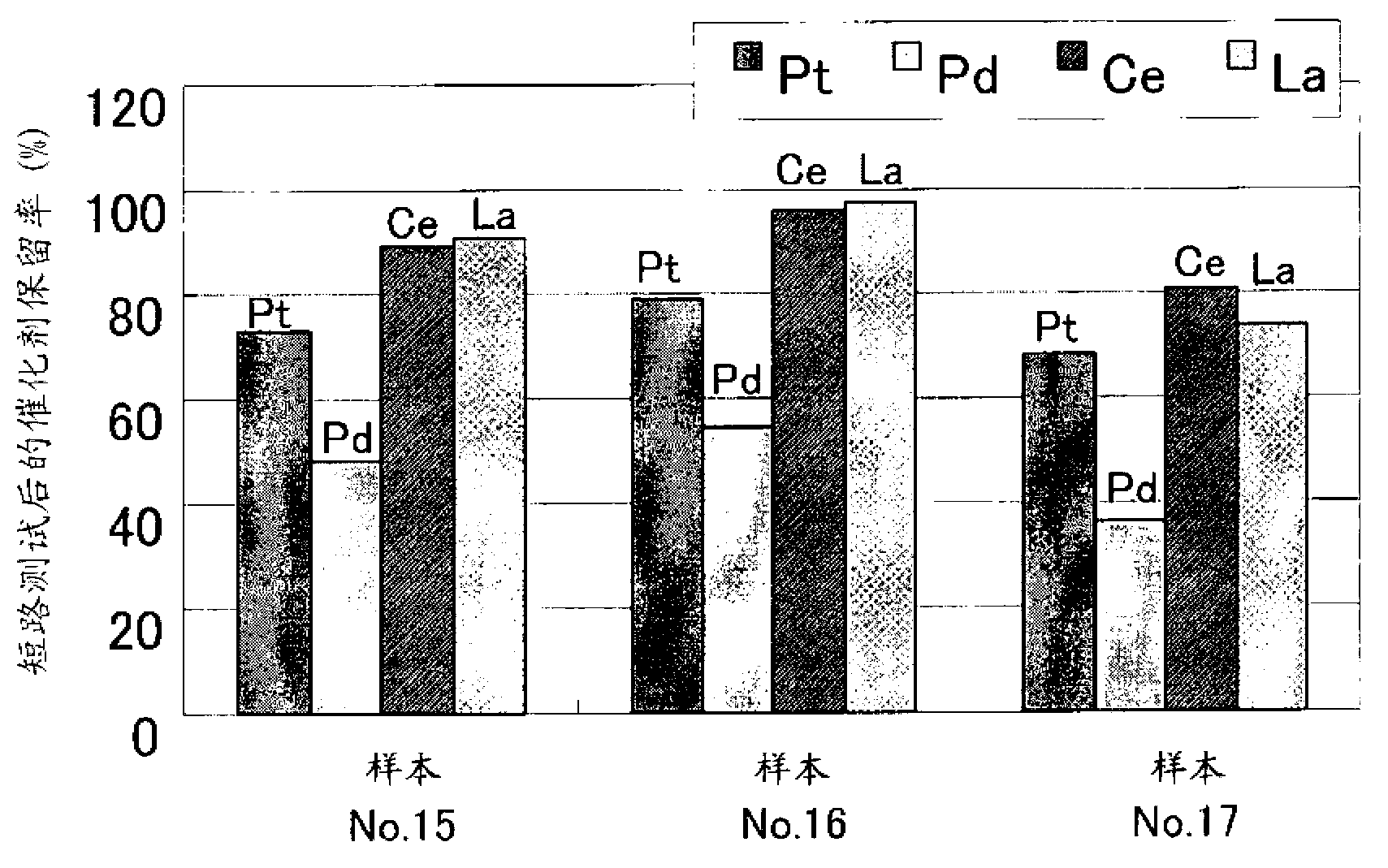

InactiveCN102762776AImprove the effect of electrolysisHigh retention rateMultiple component coatingsHigh current densityOvervoltage

The present invention aims to provide an activated cathode enabling a long-time stable operation with hydrogen overvoltage maintained at a low value, keeping a high remaining rate of the catalyst element after a cease of operation for a short-circuiting and after an electrolysis operation at a high current density, restricting catalyst loss to a little, and having a strong resistance to contamination caused by electrolyte impurity elements. The present invention relates to a cathode for hydrogen evolution with a catalyst layer formed on the cathode substrate, having, at least, three elements comprising platinum, cerium and palladium, as essential element, in a state of metal, metal oxide, or hydroxide, contained, where the mole fraction of respective element being x, y, and z, within a range of 5mol%=x=90mol%, 5mol%=y=55mol%, 5mol%=z=65mol%.

Owner:DE NORA PERMELEC LTD

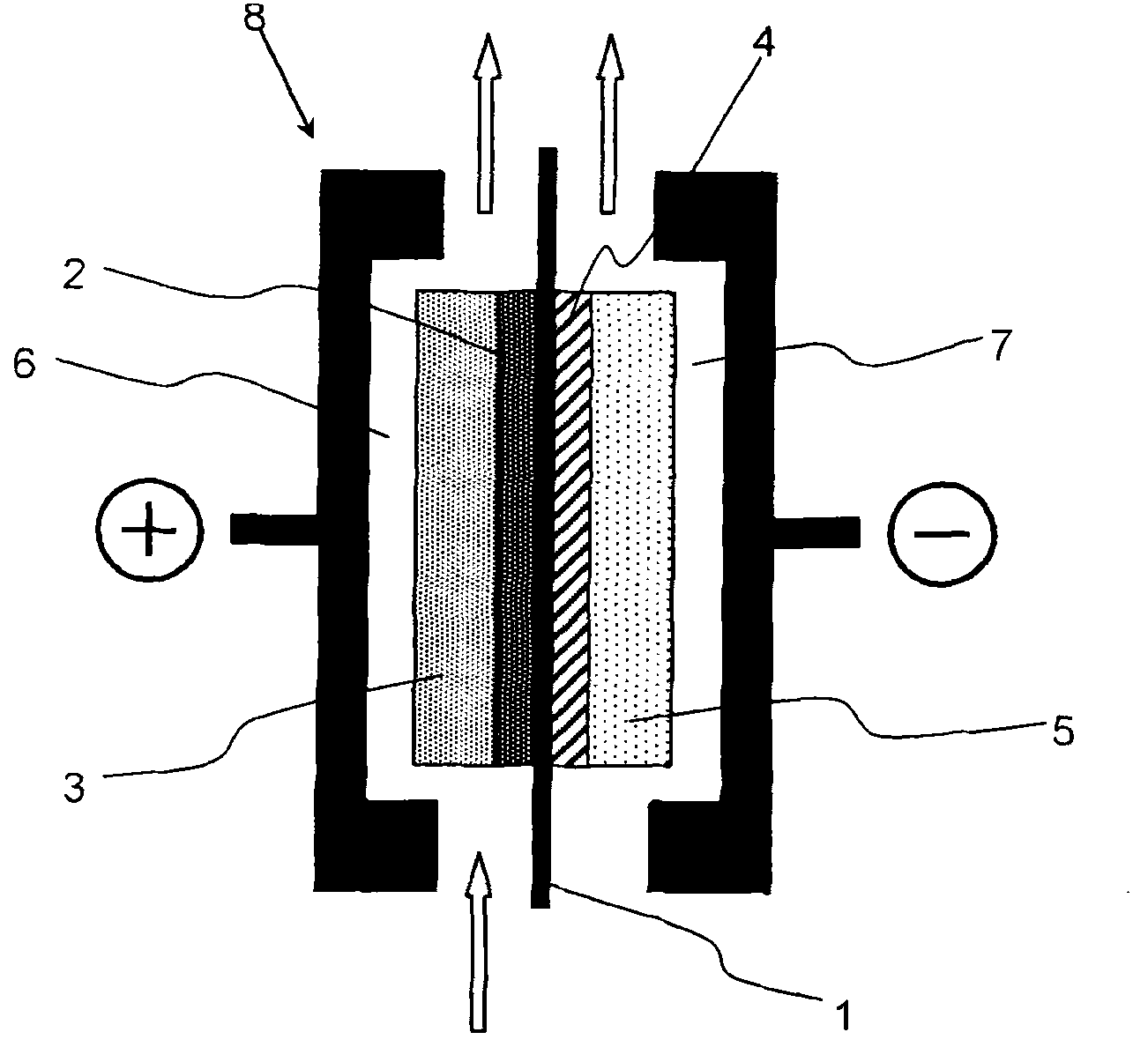

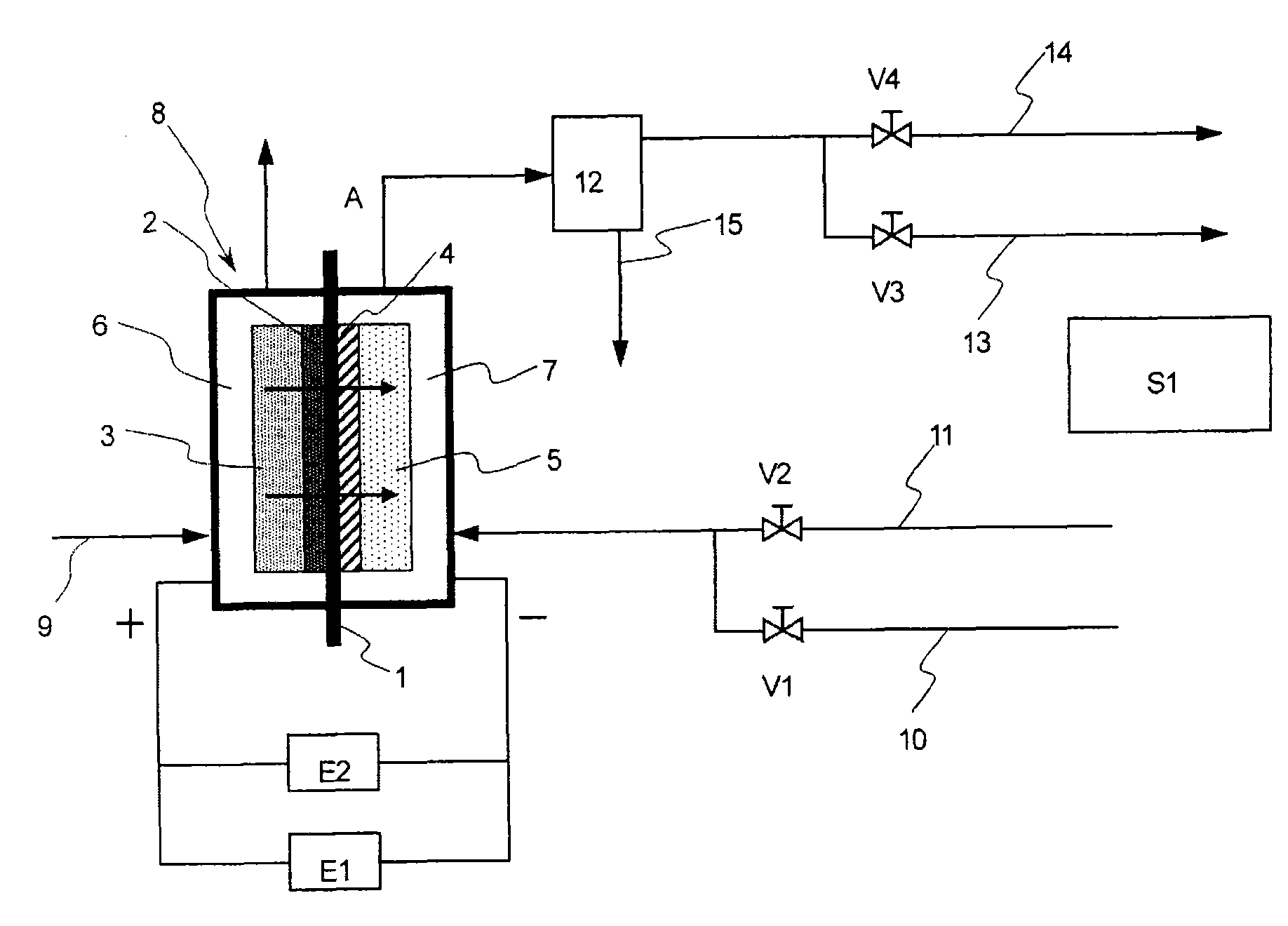

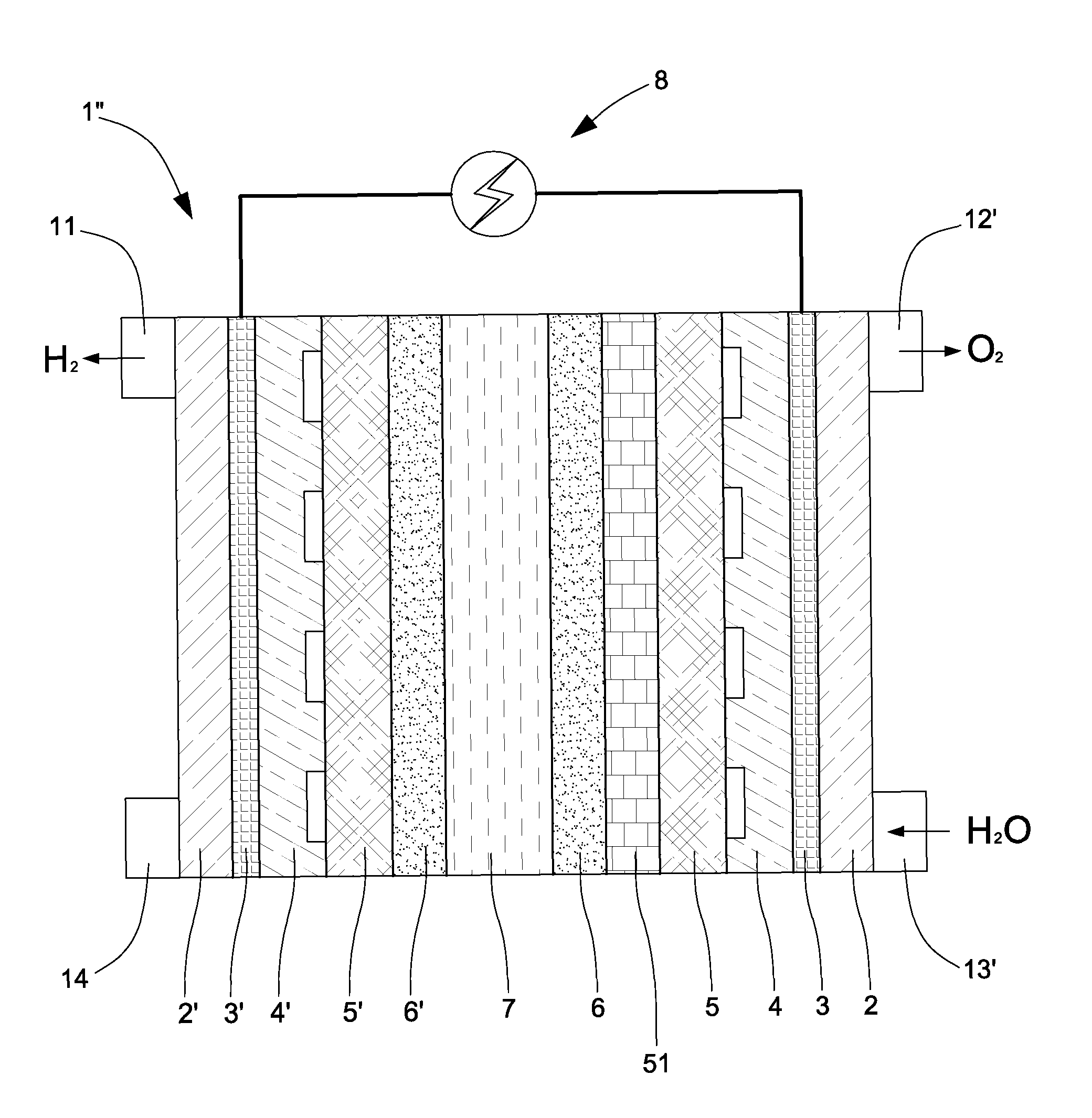

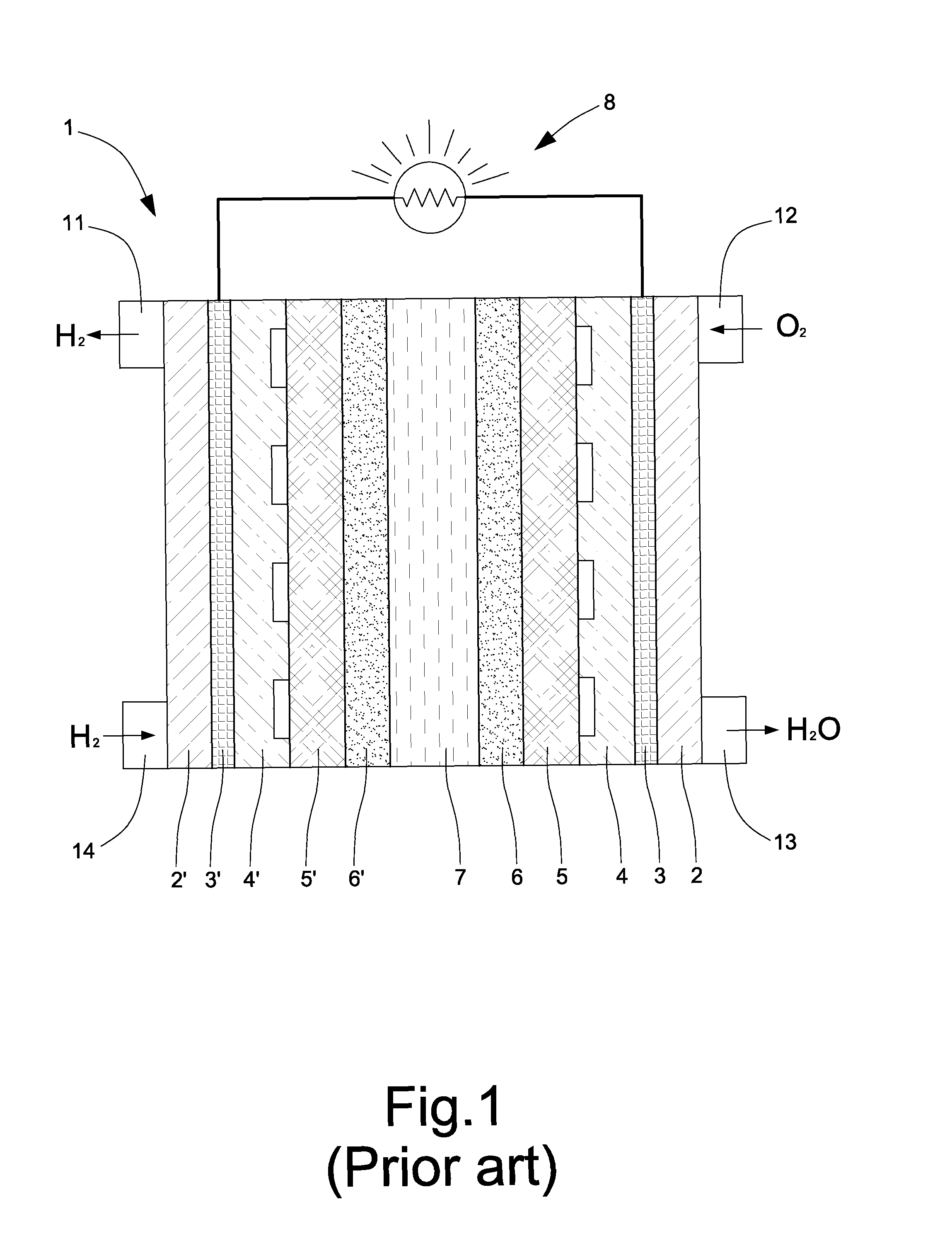

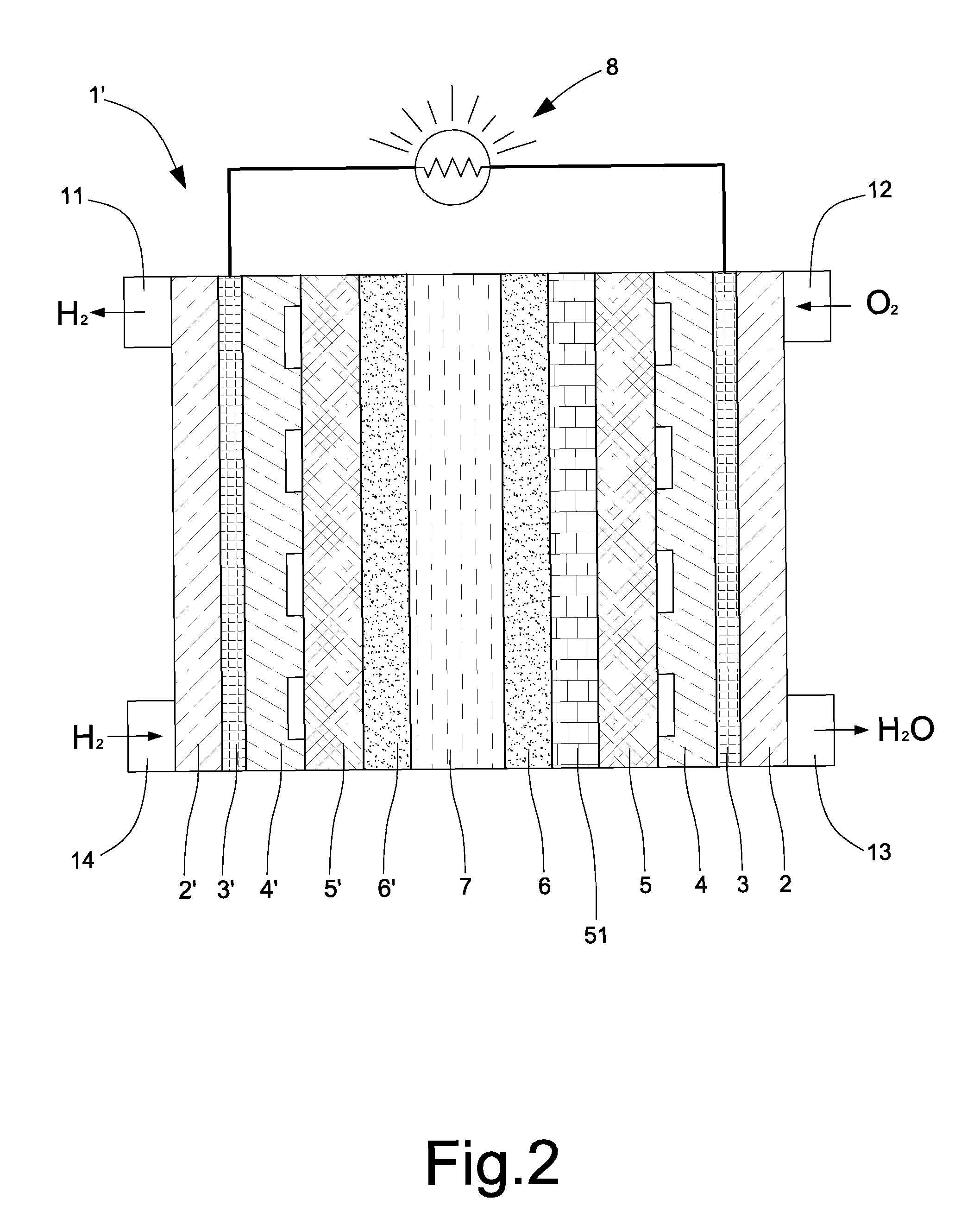

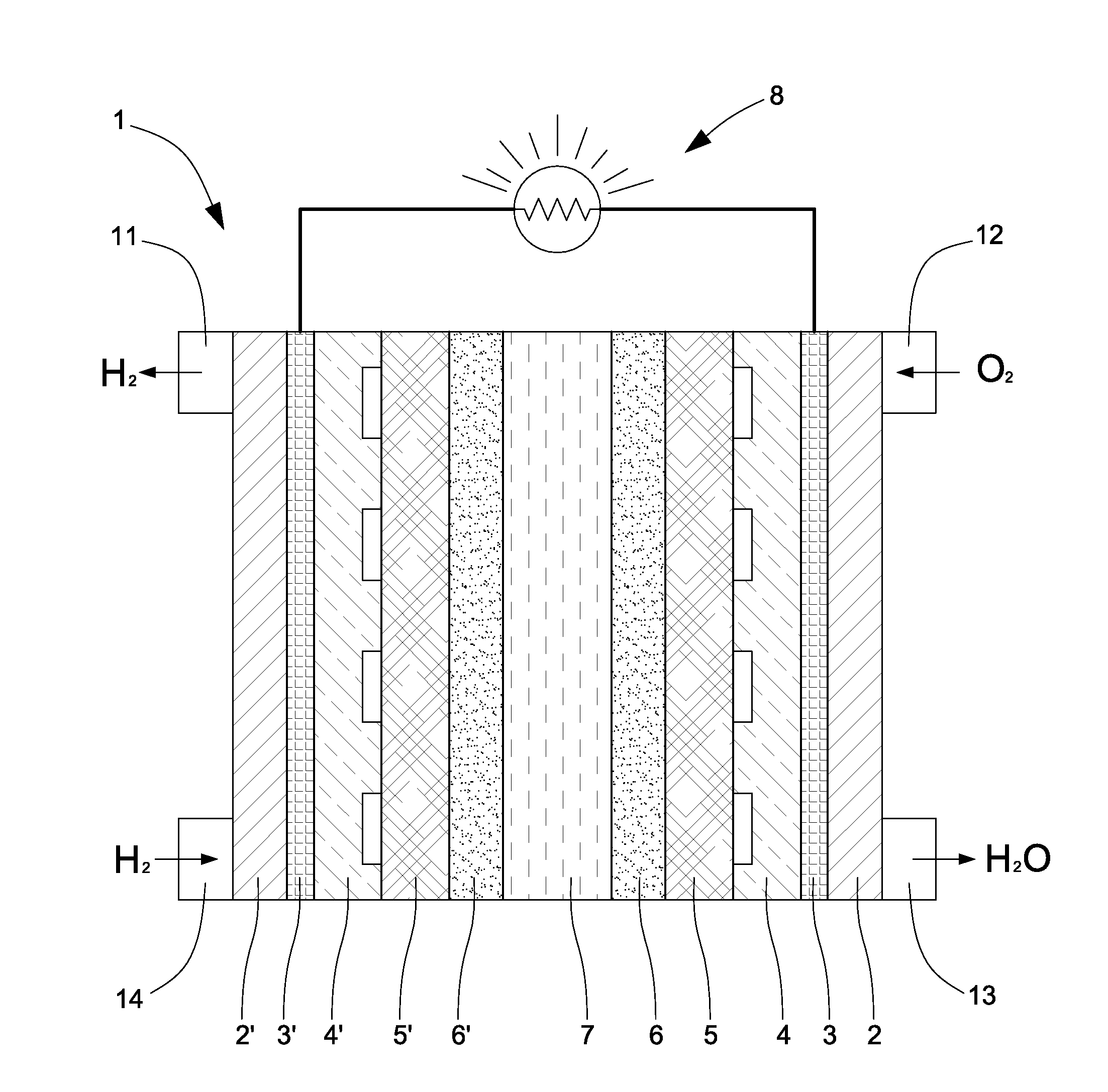

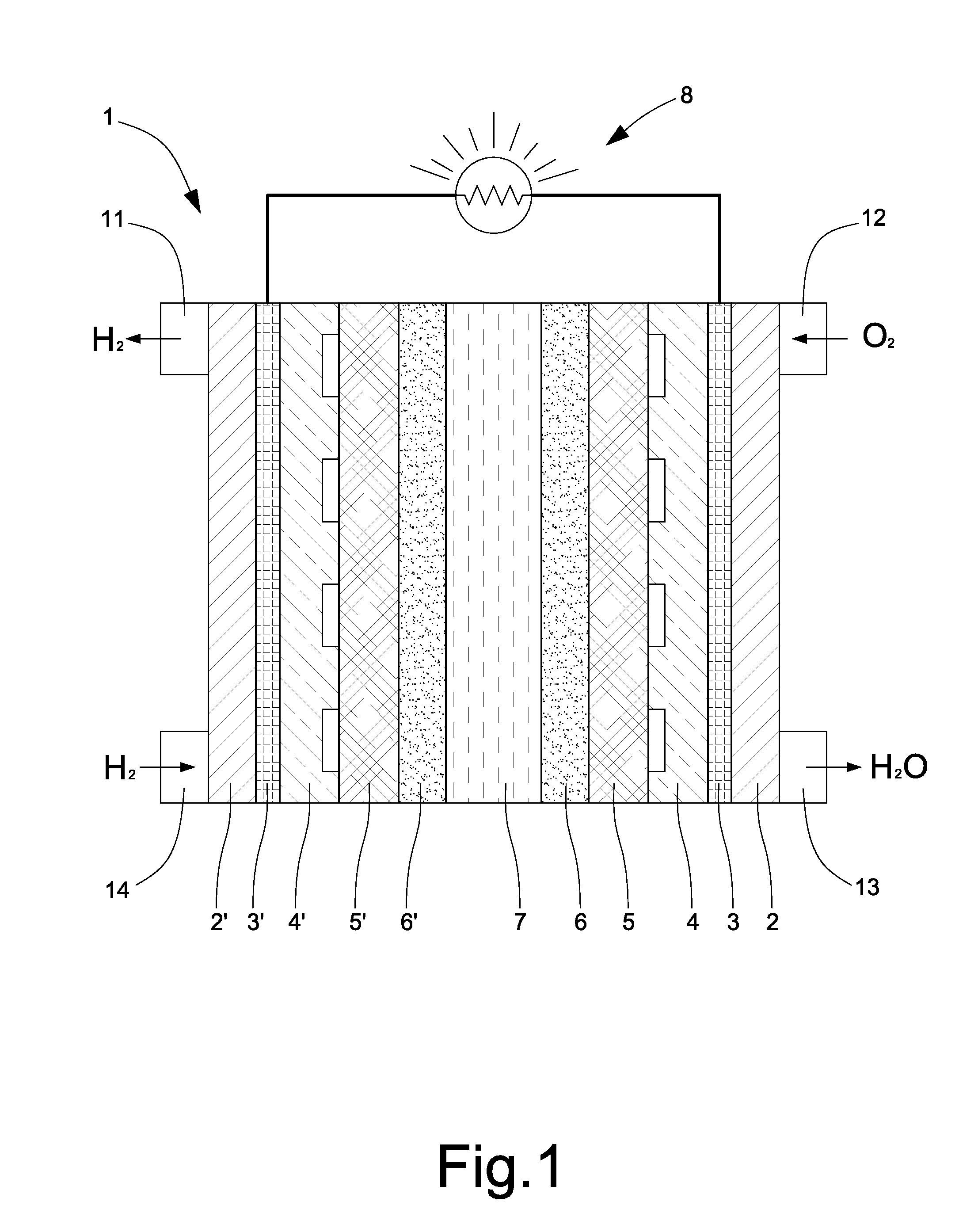

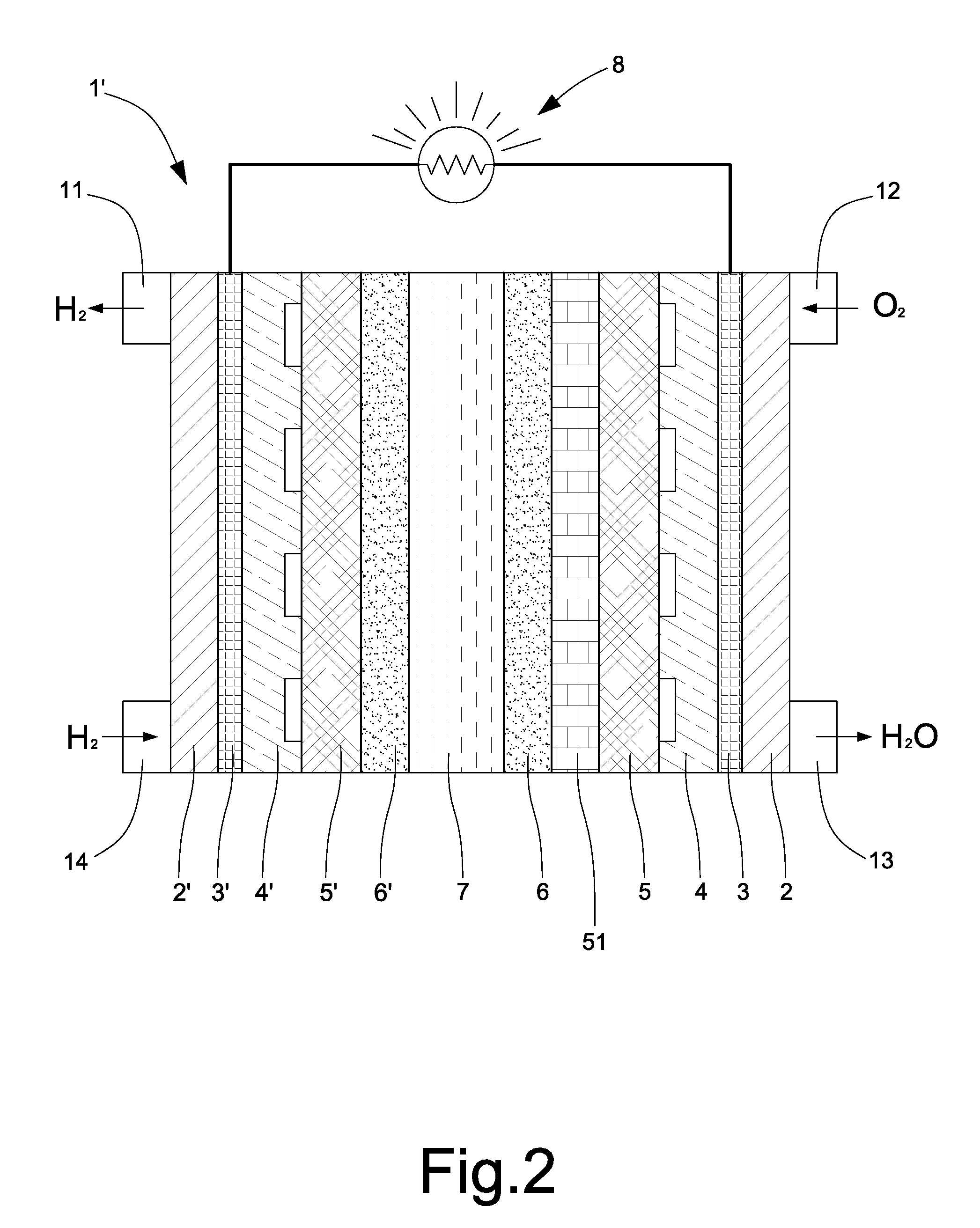

Corrosion resistant gas diffusion layer with a micro protective layer for electrochemical cells

ActiveUS7909969B2Simple methodAvoid layeringCellsActive material electrodesElectrolysis of waterActive oxygen

A gas diffusion layer with a micro protective layer is utilized in the electrochemical cells. The cell mainly includes end plates, current collectors, flow field plates, gas diffusion layers, catalyst layers, a proton exchange membrane and a circuit unit. When the cell functions as a fuel cell, hydrogen reacts with oxygen to generate electricity and water. Reversely, when the cell functions as a water electrolysis cell, water was decomposed electrolytically to produce hydrogen and oxygen gases. In this manner, the present invention particularly has the gas diffusion layer to be coated with a micro protective layer so as to prevent the gas diffusion layer from being corroded by active oxygen species generated within the oxygen electrode under the catalysis during water electrolysis operation.

Owner:GOC INT TECH CORP

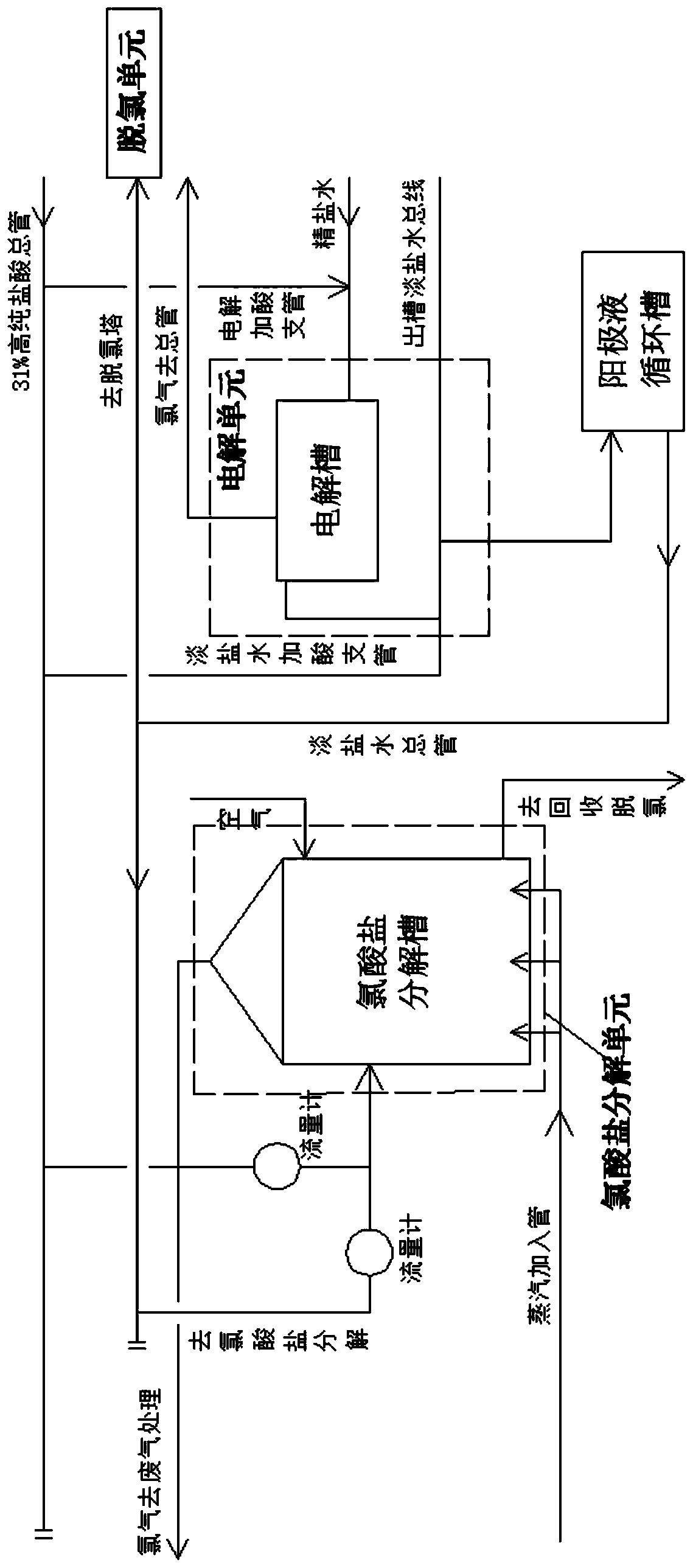

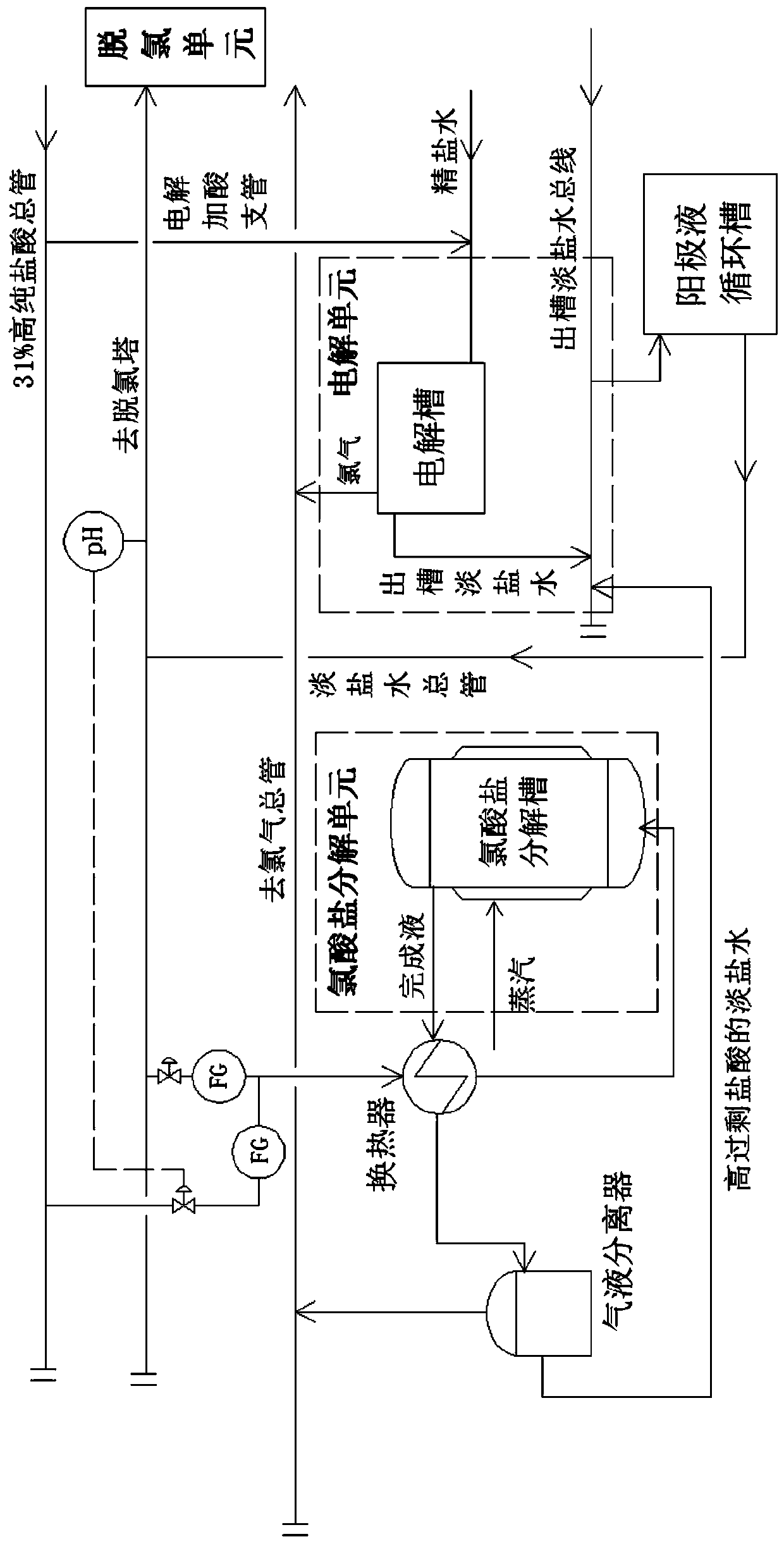

Device and method for decomposing chlorate generated by side reaction of anode chamber of electrolytic cell in chlor-alkali production and related acid adding process

ActiveCN111254455ASpeed up decompositionImprove decomposition rateChlorine/hydrogen-chlorideElectrolysis componentsElectrode potentialPerchlorate

The invention provides a device and method for decomposing chlorate generated by side reaction of an anode chamber of an electrolytic cell in chlor-alkali production and a related acid adding process.According to the method, an acid process for an electrolysis system is creatively improved, and the high peracid content is utilized to enhance the chlorate oxidation electrode potential and enhancethe reaction temperature, thereby greatly enhancing the decomposition speed and decomposition efficiency of the chlorate, completely decomposing the chlorate in the light salt brine into Cl2, Cl <-> and H2O at one time, avoiding the unstable gas ClO2 in the gas phase, and directly merging the pure wet Cl2 into a main pipe. The peracid content in the light salt brine after chlorate decomposition isutilized to replace light salt brine for dechlorination and acidification, thereby saving the self-used hydrochloric acid and caustic soda for electrolytic production. In the actual electrolysis operation, the decomposed chlorate can be balanced with the byproduct chlorate of the electrolytic bath at any time, so that the chlorate enriched in the electrolysis system can be quickly reduced, the problems of chlorate enrichment in the electrolysis system, influence on caustic soda quality, strong corrosion to solid caustic soda equipment and the like are solved, and the technical progress of chlor-alkali electrolysis production is greatly promoted.

Owner:吕子红

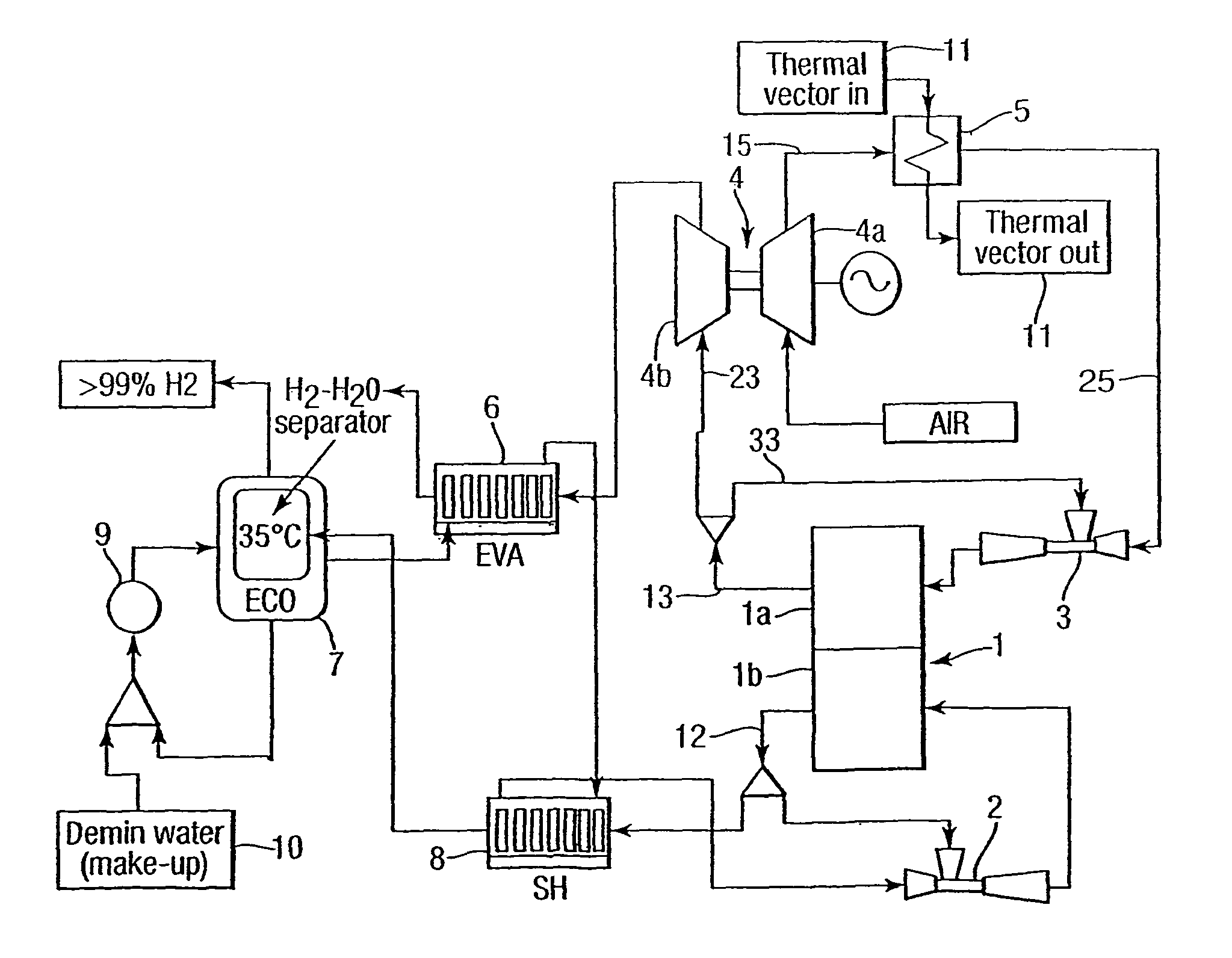

Electrolysis apparatus

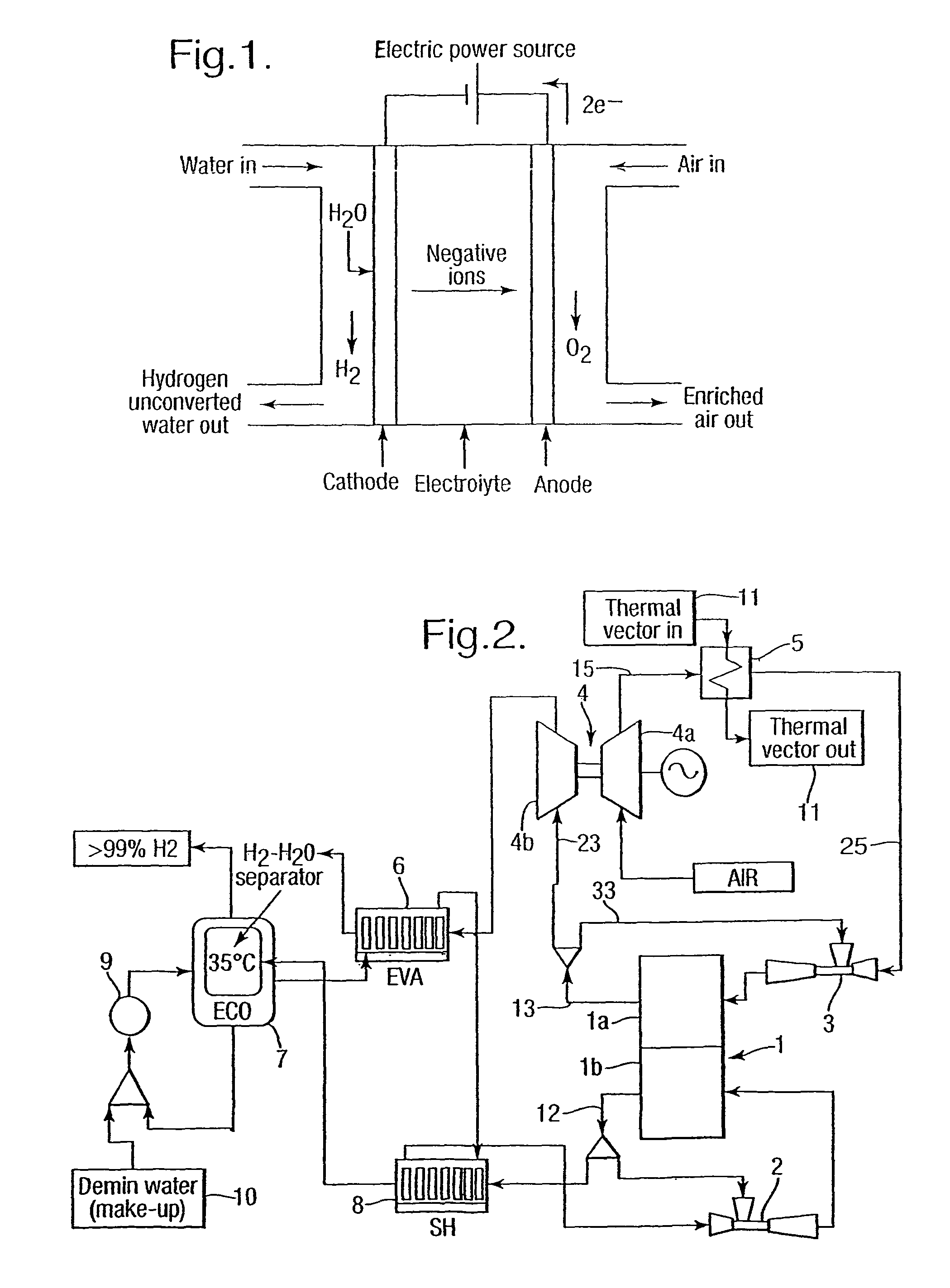

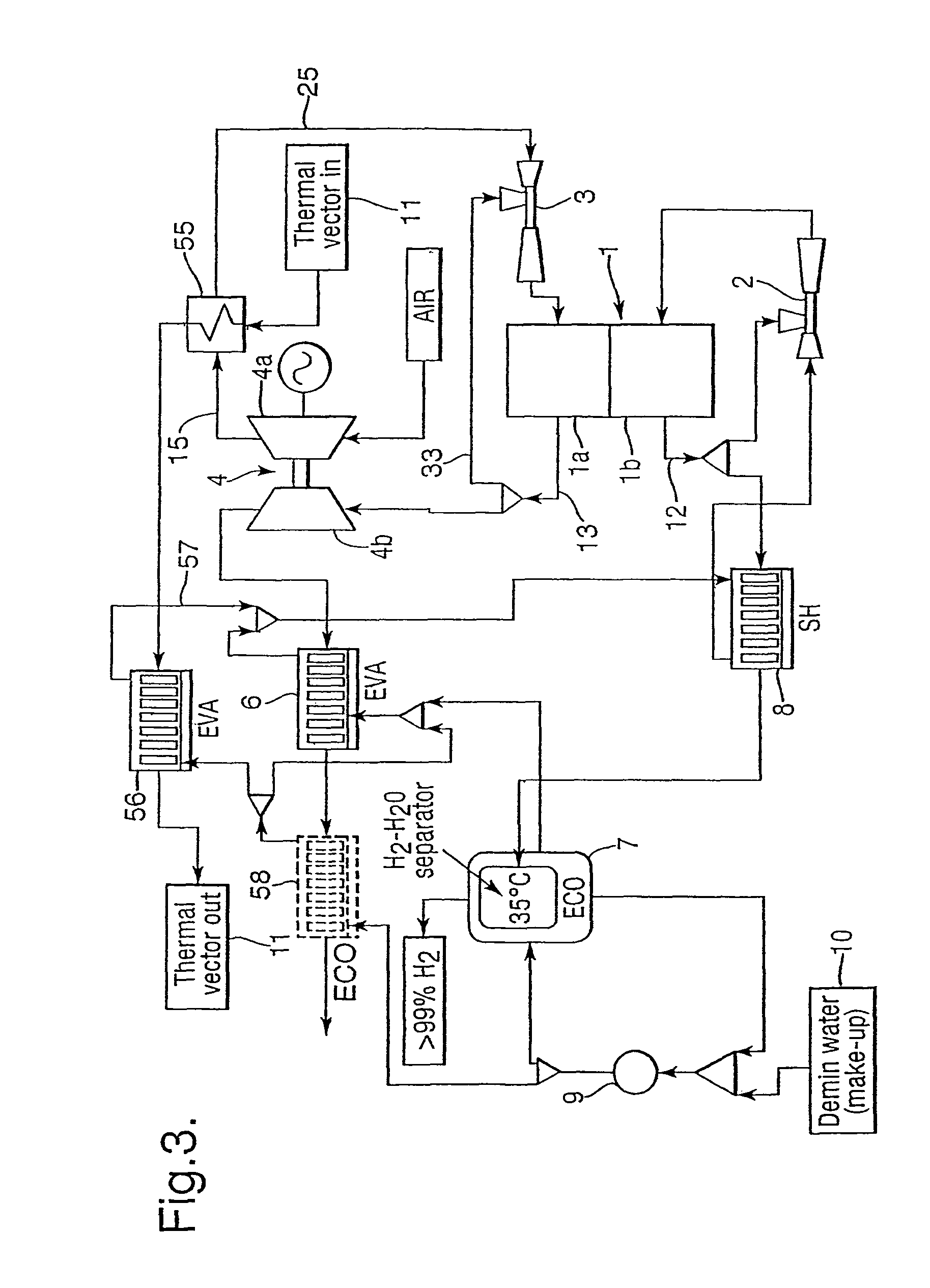

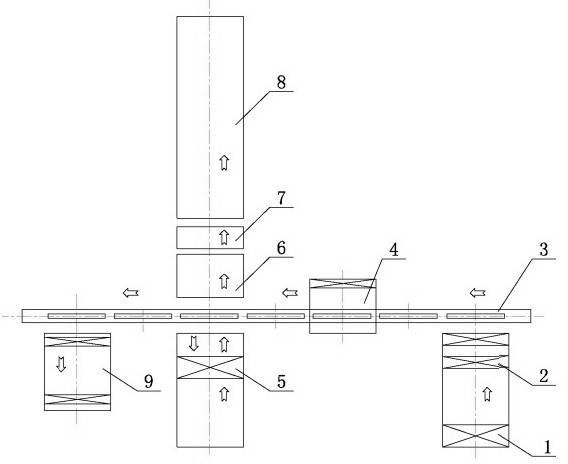

Solid oxide stacks used as fuel cells generate electricity from hydrogen or other sources. By an electrolysis process such standard fuel cells can be operated in order to create hydrogen or other electro chemical by-products. Unfortunately stacks generally operate at relatively high temperatures which will be difficult to sustain purely on economic grounds. In such circumstances less efficient operation can be achieved at lower temperatures where the air-specific resistance is higher by balancing with the electrical power input in order to cause the disassociation required. In such circumstances by provision of an incident heat source, whether that be through a heat exchanger heating the compressed air flow, or recycling of a proportion of exhaust from the stack, or combustion of a product from stack disassociation the result will be a sustaining electrolysis operation reducing the amount of expensive electrical supply required to achieve dissociation.

Owner:LG FUEL CELL SYST

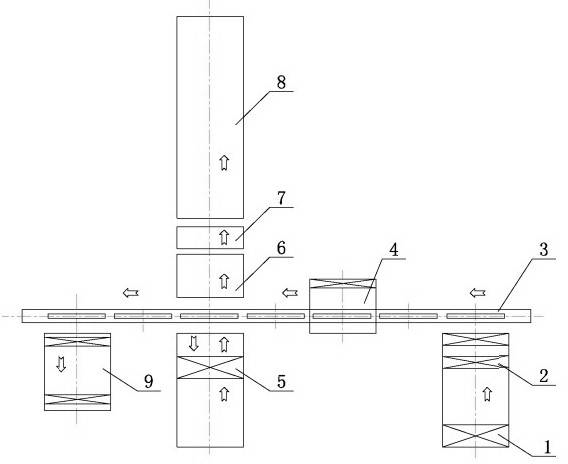

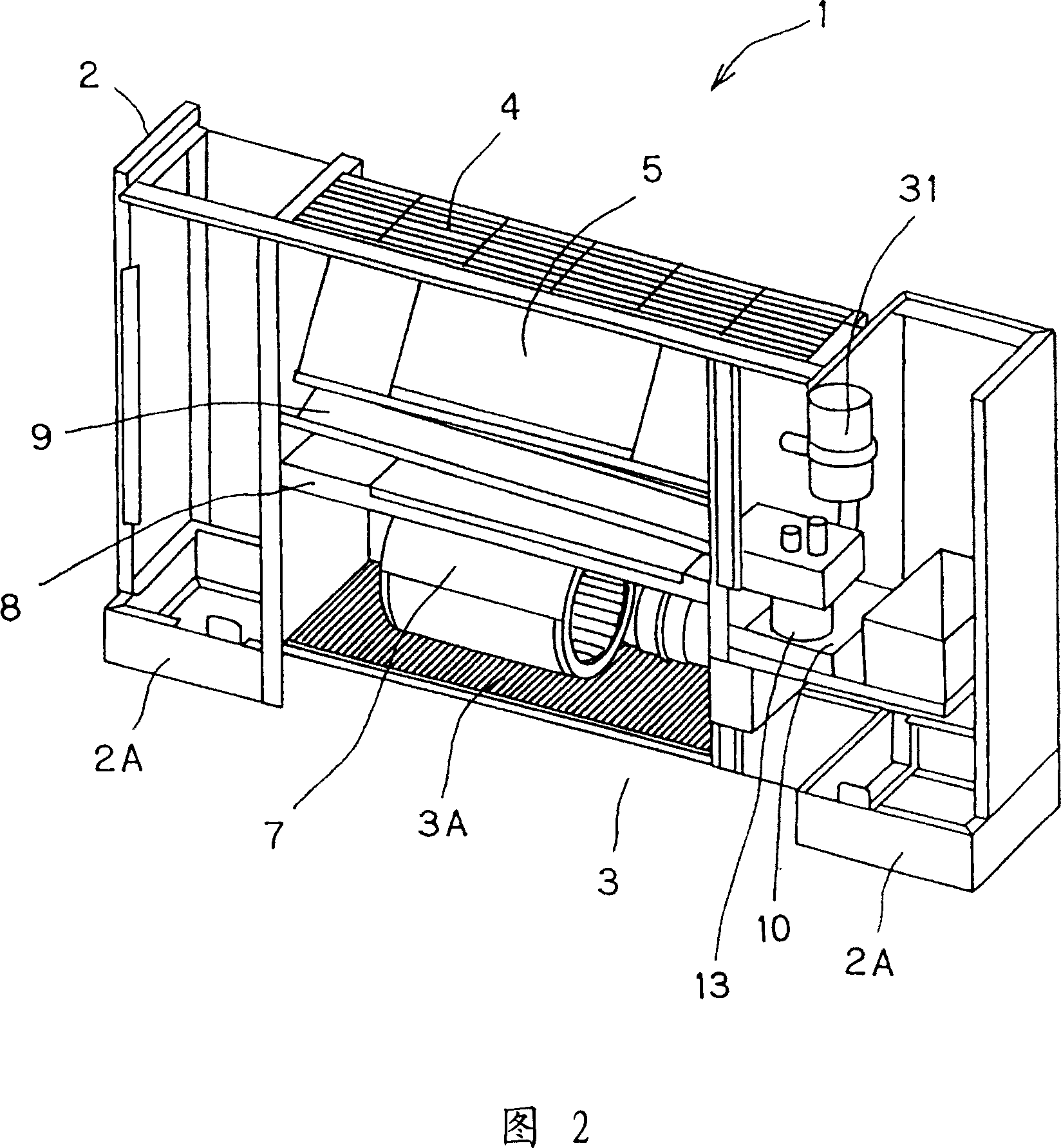

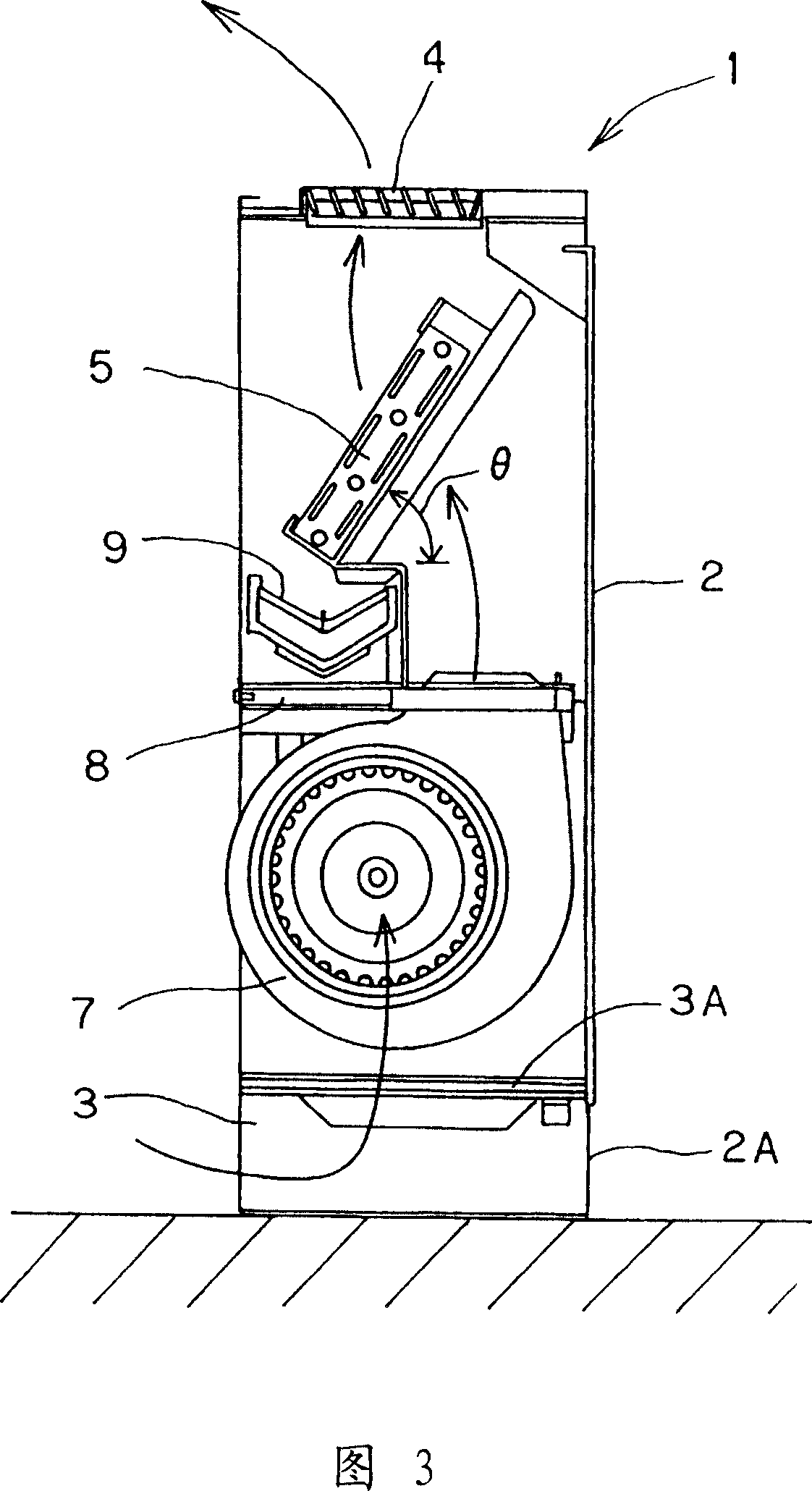

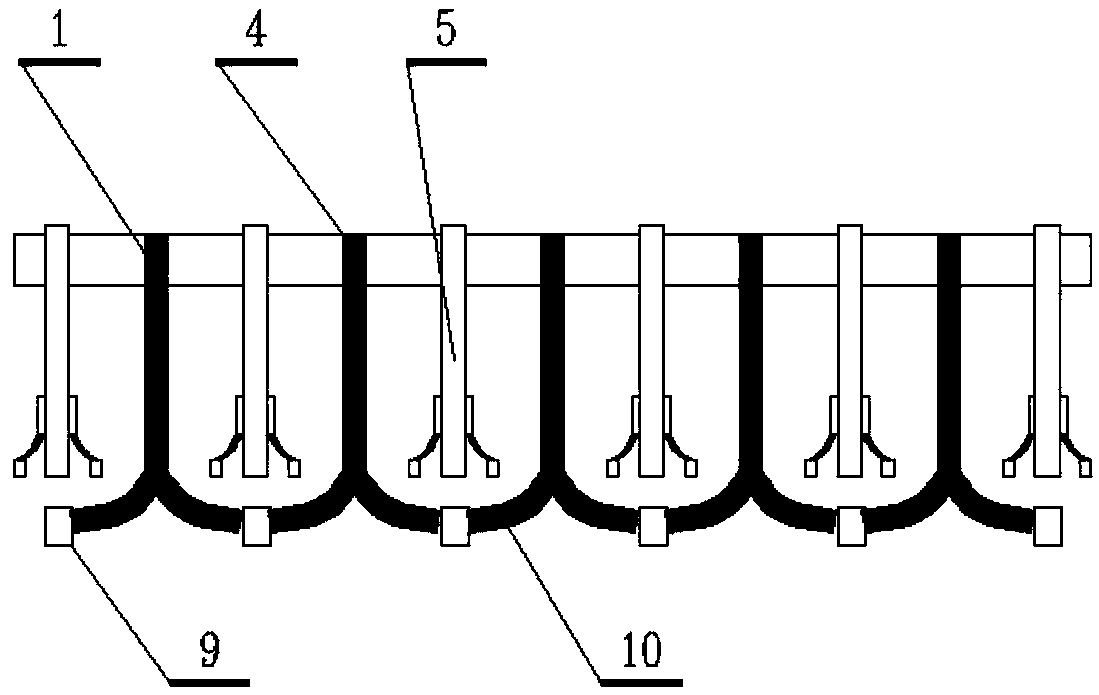

Arrangement method for anode unit for electrolysis

ActiveCN102424981AReduce production capacityShorten speedPhotography auxillary processesOther manufacturing equipments/toolsUnit systemEngineering

The present invention discloses an arrangement method for an anode unit for electrolysis. Equipment of the method comprises: an acceptance plate apparatus capable of reception of the anode, an acceptance plate chain conveyor and separation piece, a vertical correction ear, a weighing mechanism, a traversing chain conveyor, a plate surface shaping pressure machine and thickness measuring device, a side lug milling device, a bottom lug milling device, an oblique lifting device, and a plate arrangement chain conveyor and plate arrangement frame. The arrangement method of the present invention has the following advantages that: the side lug milling function forms an open circuit or a parallel connection in the unit system, such that the side lug milling device can work separately, the work of the anode unit system is not affected, the production capacity of the anode unit is not reduced substantially in spite of increase of the anode lug thickness, the reduction of the production capacity is proportional to the number of the anode requiring lug milling, the unit can meet the requirements of the electrolysis operation rate; meanwhile the speed of the side lug milling can be properly reduced, such that the milling force can be reduced so as to prolong the service life of the mill, and reduce the production cost.

Owner:JIANGXI NERIN EQUIP

Corrosion resistant gas diffusion layer with a micro protective layer for electrochemical cells

ActiveUS20090272645A1Simple methodAvoid layeringCellsActive material electrodesElectrolysis of waterActive oxygen

A gas diffusion layer with a micro protective layer is utilized in the electrochemical cells. The cell mainly includes end plates, current collectors, flow field plates, gas diffusion layers, catalyst layers, a proton exchange membrane and a circuit unit. When the cell functions as a fuel cell, hydrogen reacts with oxygen to generate electricity and water. Reversely, when the cell functions as a water electrolysis cell, water was decomposed electrolytically to produce hydrogen and oxygen gases. In this manner, the present invention particularly has the gas diffusion layer to be coated with a micro protective layer so as to prevent the gas diffusion layer from being corroded by active oxygen species generated within the oxygen electrode under the catalysis during water electrolysis operation.

Owner:GOC INT TECH CORP

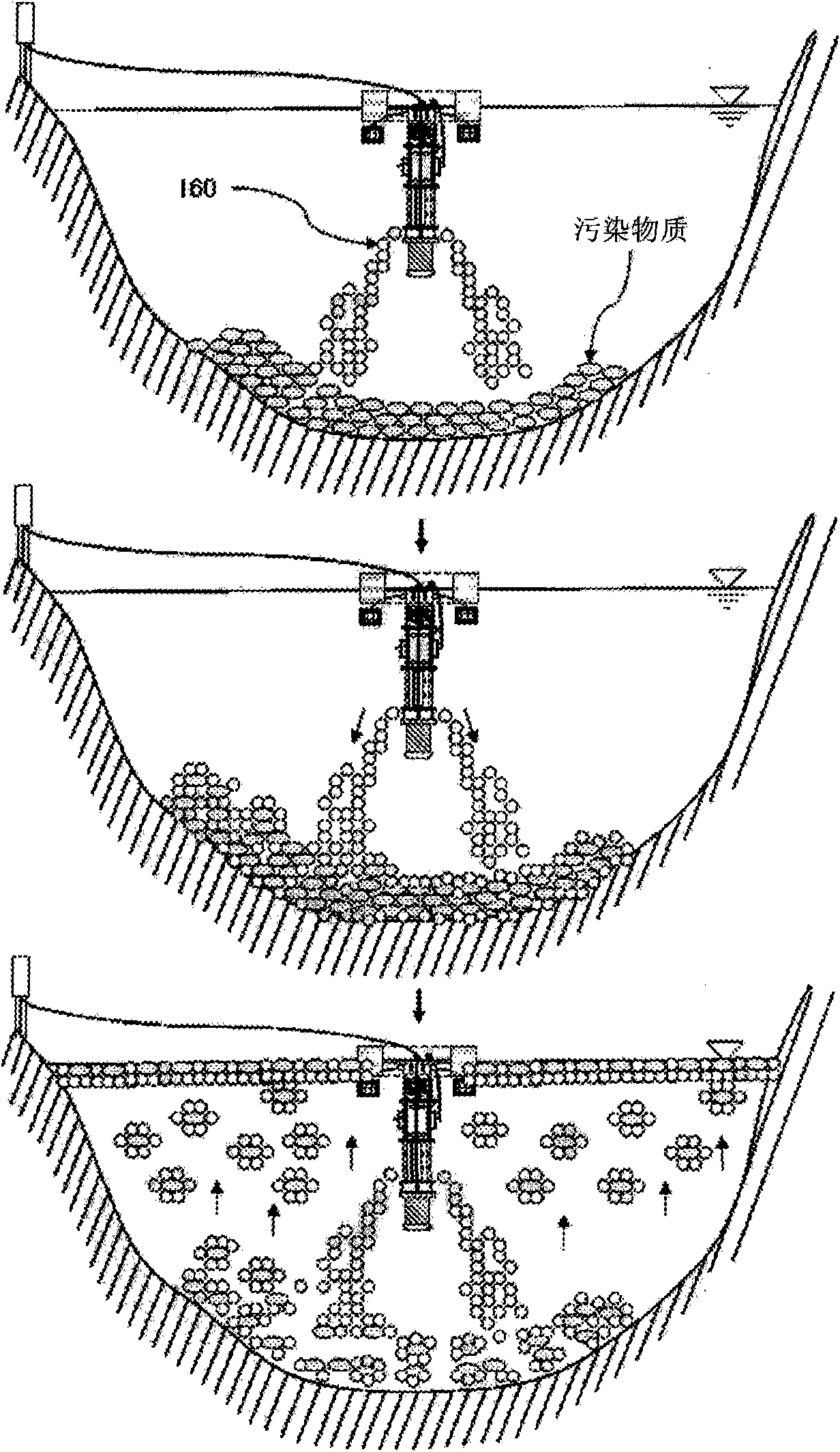

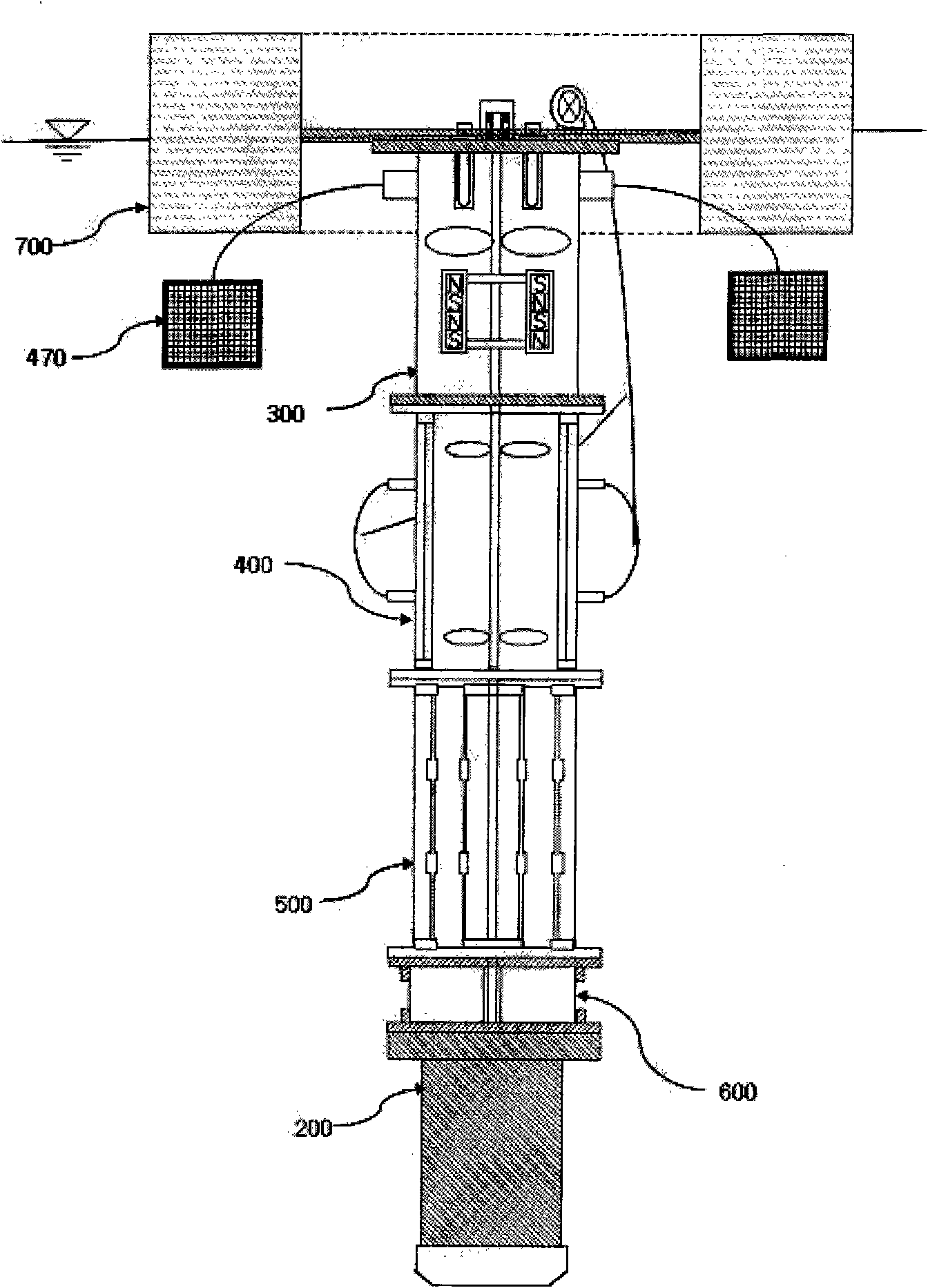

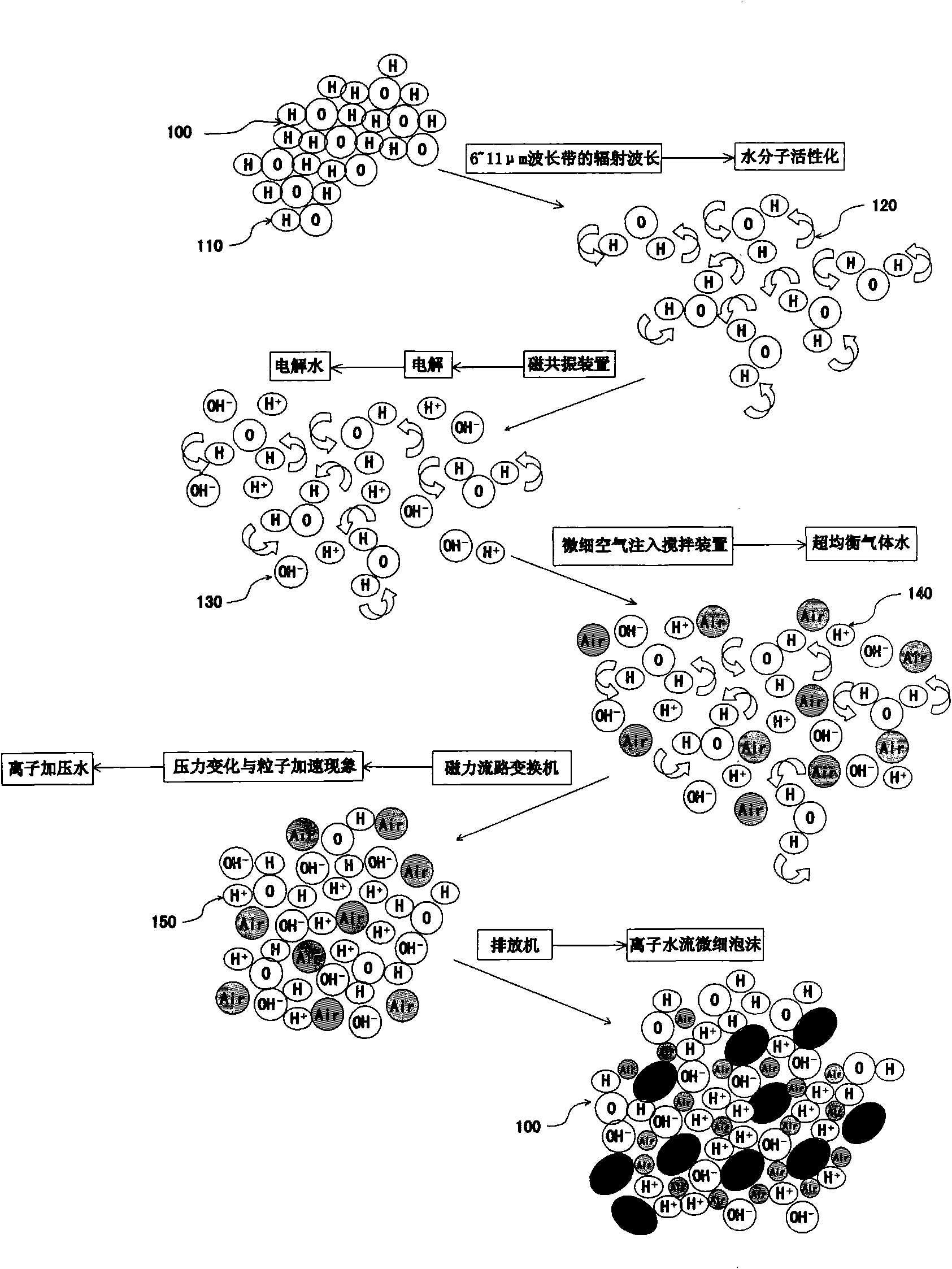

Ionized current superfine foam generating device and ionized current superfine foam generating method using device

InactiveCN101643257AEasy to eluteEasy to removeWater/sewage treatment by flotationFiltrationMolecular cluster

The invention relates to an efficient ionized current superfine foam generating device and an ionized current superfine foam generating method using the device, which can purify the water quality of polluted water. The system and the method are characterized in that inflow water in a molecular cluster state is naturally absorbed and then stirred, and the active motion of water molecules is activated by radiation wavelengths which are emitted from a far infrared lamp and have water molecule resonance absorption wavelengths; by means of the self-heating and resonance phenomenon produced by high-speed rotation of the water molecules, the electrolysis operation is carried out without an electrode, and then superfine foams sheared when flowing through a micro-pore filtration core collide with the electrolyzed water; the foams are effectively dissolved and stored by using a flow path and pressure change caused by sectional area change of the flow path and generate ion pressurized water; theion pressurized water is prayed to the water in an atmospheric pressure state to generate ionized current superfine foams; and then the superfine foams and polluted substances float up the water together so as to effectively purify the polluted water.

Owner:郑浩荣

Electric current control method and apparatus for use in gas generators

InactiveCN100513649CReduce capacityElectrolysis componentsFluoride preparationEngineeringSteady state

The present invention provides a current control method and a current control device of a gas generating device capable of maintaining an optimal electrolysis state and stably operating, and generating fluorine or fluoride gas without manual labor. The present invention is a kind of electric current control method that makes the electrolytic bath (5) that is made of mixed molten salt containing hydrogen fluoride, use carbon electrode as anode (4a) to electrolyze and generate fluorine or the gas generator of fluoride gas, measure in gas The range of voltage variation between the cathode (4b) and the anode (4a) after a certain current is applied to the generating device, and the current is applied while changing the amount of input current according to the range of voltage fluctuation.

Owner:TOYO TANSO KK

Protection method for separating electrode guide rod from corrosion caused by electrolyte melt

ActiveCN104480494AImprove reliabilityImprove long-term stabilityProtection layerElectrochemical corrosion

The invention discloses a protection method for separating an electrode guide rod from corrosion caused by electrolyte melt and in particular relates to a protection method of a noble electrode aluminium cell electrode guide rod. The method is characterized in that fire-resistant powder is prepared from sodium carbonate, calcium carbonate, calcium oxide, boric oxide, sodium fluoride, and industrial aluminium oxide which are used as raw materials, and can react with the electrolyte melt fast to generate a solid crusting with the high melting point; the fire-resistant powder is fed between the electrode guide rod and a compound anti-corrosion ceramic protection sleeving tube; when an electrode is in normal electrolysis operation, the electrolyte melt permeating from gaps or micropores can react with the fire-resistant powder to form the compact crusting to obtain an electrode guide rod protection layer for separating the corrosion caused by the electrolyte melt; the further permeating of the electrolyte melt and the electrochemical corrosion of the electrolyte melt to the guide rod can be blocked by the protection layer; the compound anti-corrosion ceramic protection sleeving tube can be used for resisting the dissolving corrosion caused by the electrolyte melt. In the method, the fire-resistant powder can be used for enabling the electrolyte permeating process to be changed to the protection layer forming process, the compound anti-corrosion ceramic protection sleeving tube is adopted, the practicality and the long-time stability of the compound anti-corrosion ceramic protection sleeving tube are greatly improved, and a general assembly scheme is simple and easy to implement.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

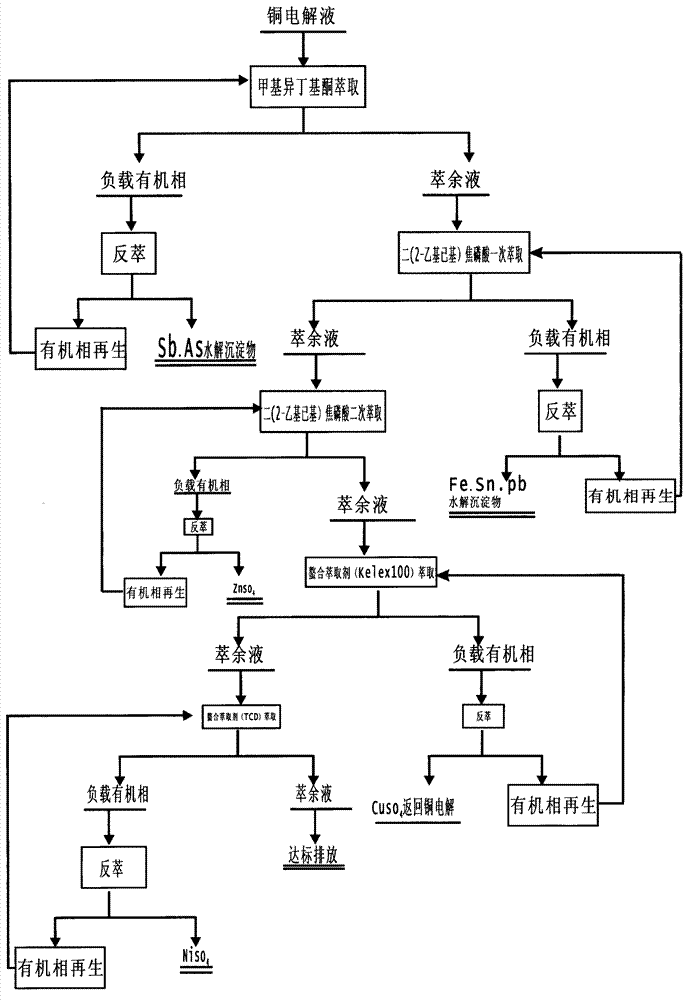

Copper electrolyte extracting and purifying process technology

InactiveCN102925920ASimple processReasonable configurationElectrolysis componentsPhotography auxillary processesMethyl isobutyl ketonePhysical chemistry

The invention discloses a copper electrolyte extracting and purifying process technology which is characterized in that an extracting and purifying technique process is composed of methyl isobutyl ketone, bis(2-ethylhexyl) pyrophosphoric acid and a chelate extraction agent, according to the theory that Sb3+, As3+, Fe3+, Sn2+, Pb2+, cd2+, Zn2+, cu2+ and Ni2+ can be extracted respectively through extractants according to different acidity, the acidity and the extractants can be adjusted step by step, impurities in the copper electrolyte can be separated and removed in sequence, and the aim of purifying the electrolyte can be achieved. The copper electrolyte extracting and purifying process technology has the advantages of being high in extraction rate, complete in impurity separation, thorough in impurity removing, capable of effectively removing the impurities in the copper electrolyte, accordingly, current efficiency of the copper electrolysis is high, negative plates are good in quality, the phenomena of passivation, polarization, short circuit, resistance increasing and the like cannot occur easily, labor intensity of electrolysis operation workers is reduced, and the copper electrolyte extracting and purifying process technology is suitable for popularization and application in copper electrolysis enterprises.

Owner:崖巨钊

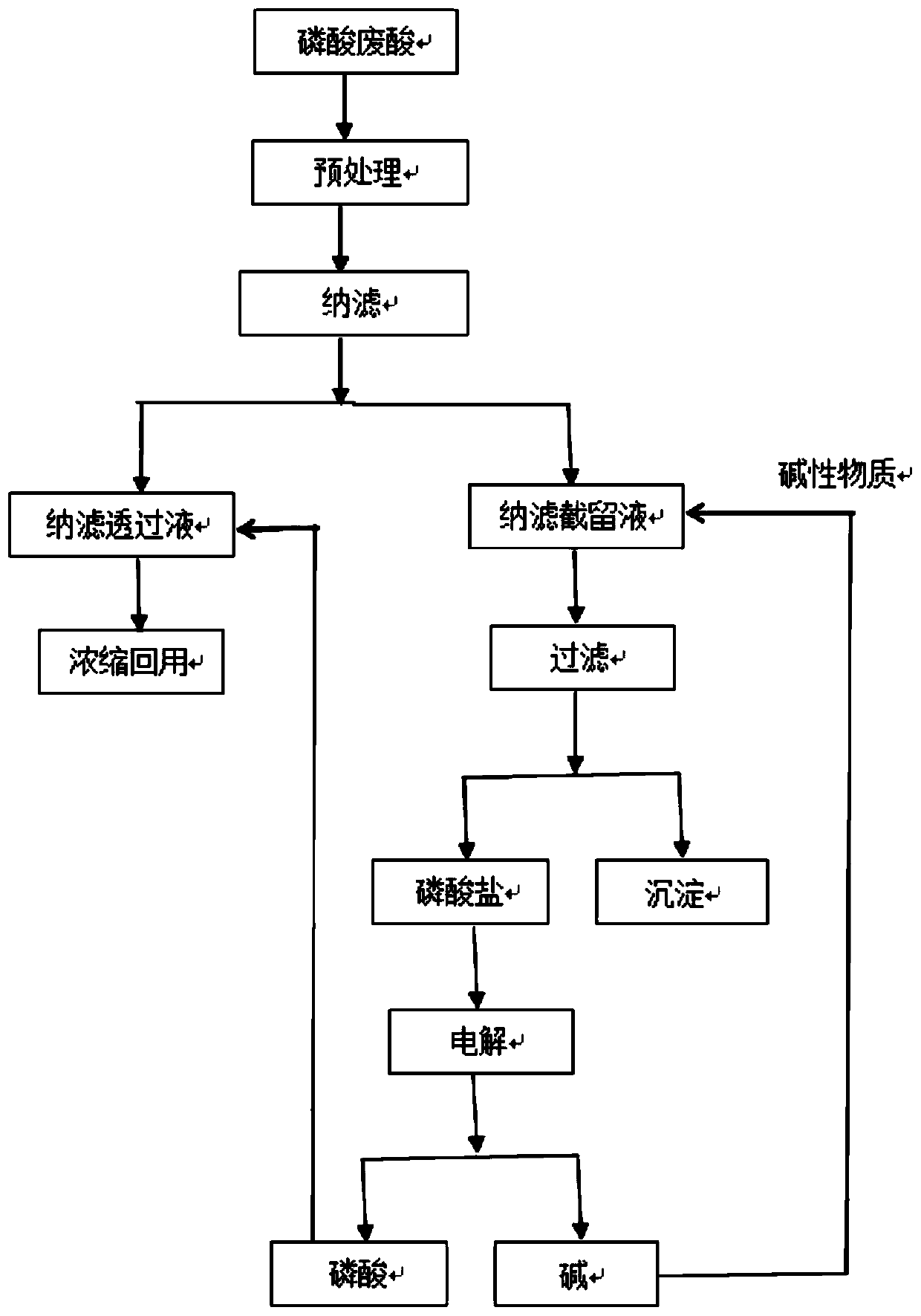

Recovery treatment method for waste phosphoric acid

InactiveCN111591967ARealize enrichment recoveryHigh recovery rateElectrolysis componentsPhosphorus compoundsO-Phosphoric AcidPhosphate

The invention provides a recovery treatment method for waste phosphoric acid. The method comprises the following steps: pretreating waste phosphoric acid, and carrying out nanofiltration treatment toobtain a nanofiltration permeate and a nanofiltration trapped fluid; adding an alkaline substance into the nanofiltration trapped fluid to remove impurities, and carrying out solid-liquid separation to obtain a phosphate solution; and electrolyzing the phosphate solution to obtain phosphoric acid and alkali, and returning the alkali for recycling. According to the method, the waste phosphoric acidis sequentially subjected to nanofiltration, neutralization, precipitation and electrolysis operation, impurities in the waste phosphoric acid are separated, enrichment and recovery of phosphoric acid are achieved, and the recovery rate of phosphoric acid is high; the recovered phosphoric acid is high in purity and excellent in performance, and can meet the requirements of industries such as semiconductors; the method is simple to operate and relatively low in cost, and resource utilization of the waste acid solution is realized.

Owner:盛隆资源再生(无锡)有限公司

Potassium aurous cyanide production technology

PendingCN109518210AHigh production process efficiencyGet the most out of your burn rateElectrolysis componentsElectrolytic organic productionPotassium cyanidePotassium

Owner:泰州市欣港电子材料有限公司

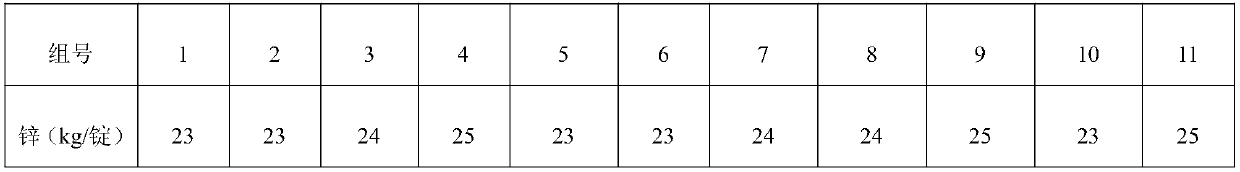

Electrolytic additive formula for improving zinc sulfate solution electrolyzed zinc quality and production environment and application method

InactiveCN107858703AImprove concentration polarizationDispersedElectrolysis componentsPhotography auxillary processesPolyethylene glycolAlloy

The invention belongs to the technical field of electrolytic zinc optimization, and provides an electrolytic additive formula for improving zinc sulfate solution electrolyzed zinc quality and the production environment and an application method. The method comprises the steps that a zinc sulfate solution is adopted as an electrolyte, a lead-silver alloy plate is used as an anode plate, and a calendered aluminum plate is used as a cathode plate; when the density of zinc on the calendered aluminum plate is reduced, a bone glue solution is added into the electrolyte; and polyacrylamide, polyethylene glycol, sodium methylene dinnaphthalene sulfonate are prepared to be a polyacrylamide solution, a polyethylene glycol solution and a sodium methylene dinnaphthalene sulfonate solution respectively, and the prepared solutions are added into the electrolyte correspondingly. By adopting the formula, the technical problems that the zinc sulfate solution electrolyzed zinc produced by a common cobalt removal process adopting reagents is poor in quality, high in lead and iron content and low in ingot casting recovery rate are solved; meanwhile, the field environment is improved, and the environment pollution is reduced; and adverse factors influencing the quality of zinc electrolyzing and electric energy consumption in the electrolysis operation can be eliminated by adopting the using method,so that the quality of the electrolytic zinc and the operating environment are greatly improved.

Owner:四川四环锌锗科技有限公司

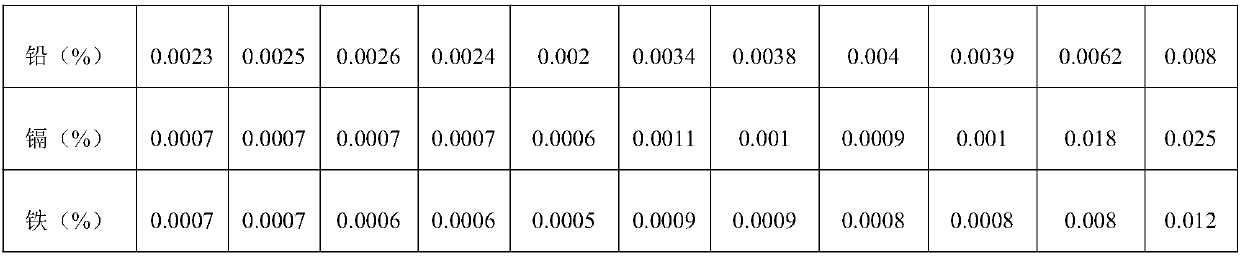

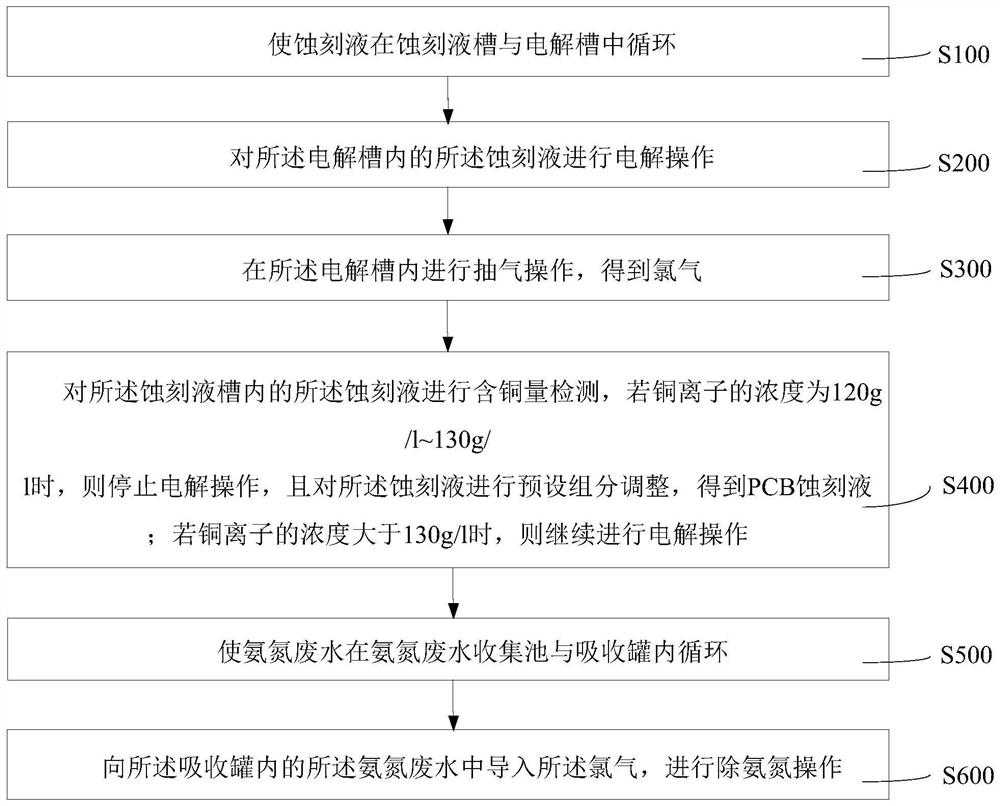

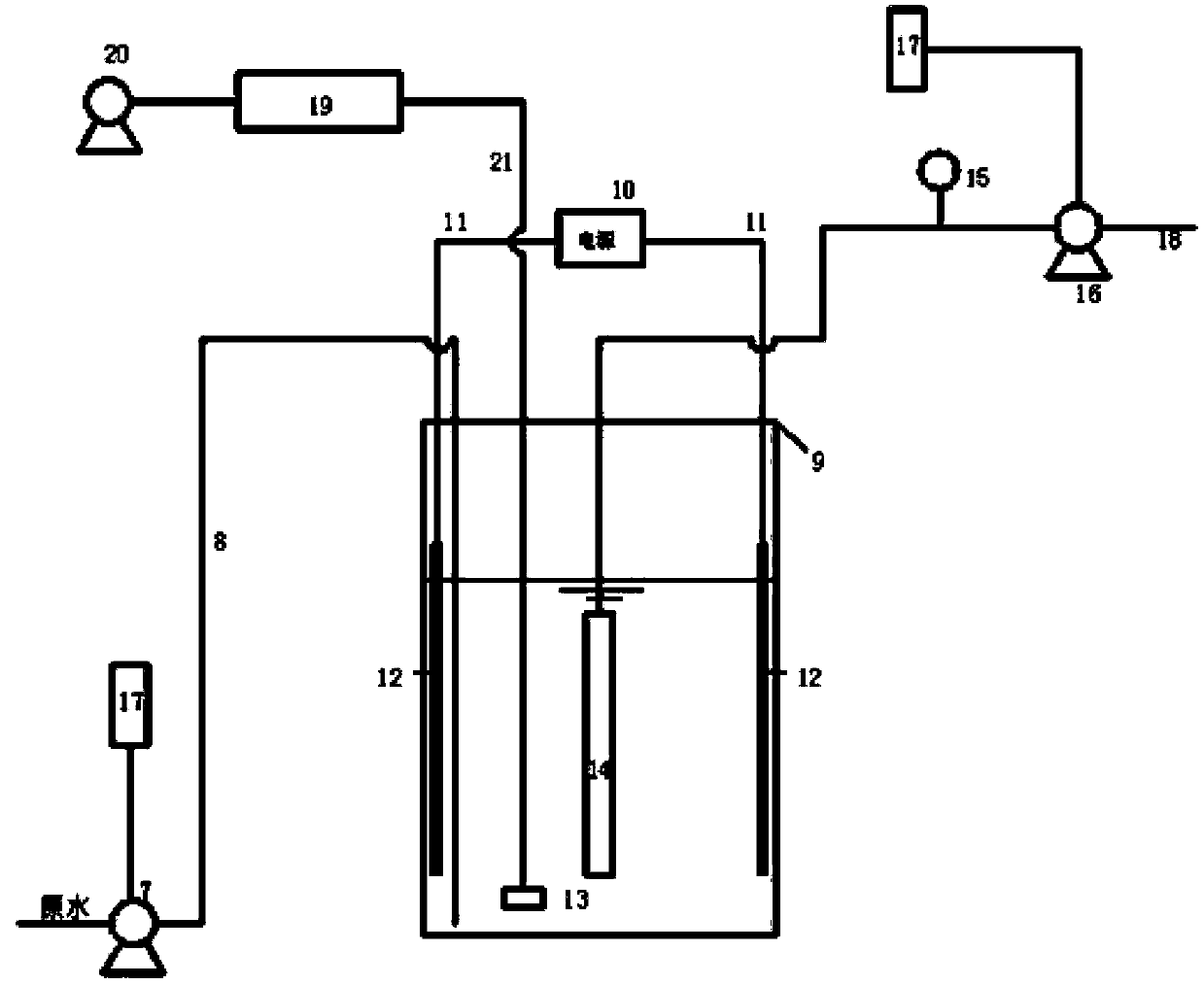

Ammonia-nitrogen wastewater treatment method and system

PendingCN112225302AAchieve recyclingReduce processing costsCellsPhotography auxillary processesAmmoniacal nitrogenNitrogen removal

The invention provides an ammonia nitrogen wastewater treatment method and system. The ammonia-nitrogen wastewater treatment method comprises the following steps: circulating an etching solution in anetching solution tank and an electrolytic tank; carrying out electrolysis operation on the etching solution in the electrolytic tank; carrying out gas extraction operation in the electrolytic tank toobtain chlorine gas; detecting the copper content of the etching solution in the etching solution tank, stopping the electrolysis operation if the concentration of copper ions is 120-130g / l, and adjusting preset components of the etching solution to obtain a PCB etching solution; if the concentration of copper ions is greater than 130g / l, continuing the electrolysis operation; circulating ammonia-nitrogen wastewater in an ammonia-nitrogen wastewater collection tank and an absorption tank; and introducing chlorine into the ammonia-nitrogen wastewater in the absorption tank, and performing ammonia-nitrogen removal operation. According to the ammonia-nitrogen wastewater treatment method, the ammonia-nitrogen wastewater treatment cost is reduced, the ammonia-nitrogen wastewater treatment effect is improved, and ammonia-nitrogen wastewater treatment can be completed only by using equipment with a relatively small volume.

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

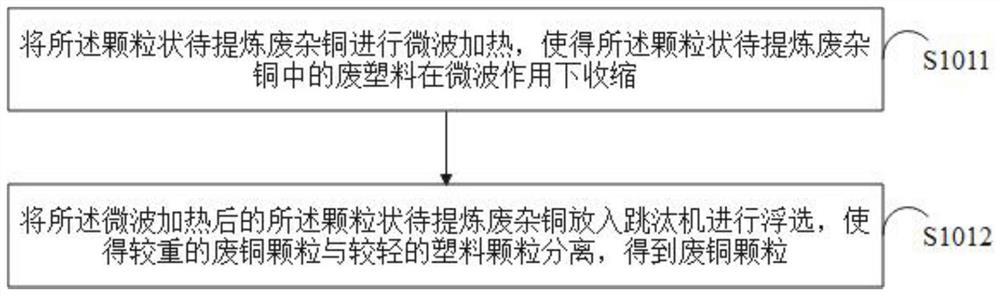

Clean production technology of electrolytic copper by directly electrolyzing and refining waste impure copper

InactiveCN104630823AElectrolysis operation improvementAbsence of anode buttsPhotography auxillary processesProcess efficiency improvementCopper sulfateCleaner production

The invention discloses a clean production technology of electrolytic copper by directly electrolyzing and refining waste impure copper. In the provided technology, waste impure copper is taken as the raw material and then placed in an anodic framework, the raw material is taken as the anode, a permanently-stainless cathode plate or pure copper sheet is taken as the cathode, and finally an acidic copper sulfate solution is taken as the electrolyte to carry out direct electrolysis and refining on the waste impure copper. The framework-type anode is different from the integral anode, and if electrolysis is carried out in a framework type anode, new waste copper particles can be added into the framework after the waste copper particles in the framework are dissolved, so the electrolysis operation does not need to be stopped, and the electrolysis production can be continuously operated. Moreover, the situation of residual anode will not happen when electrolysis is carried out in a framework type anode. The refining process is eliminated, and the electrolysis operation on casted anode is improved at the same time.

Owner:QINGDAO HONGTAI COPPER IND

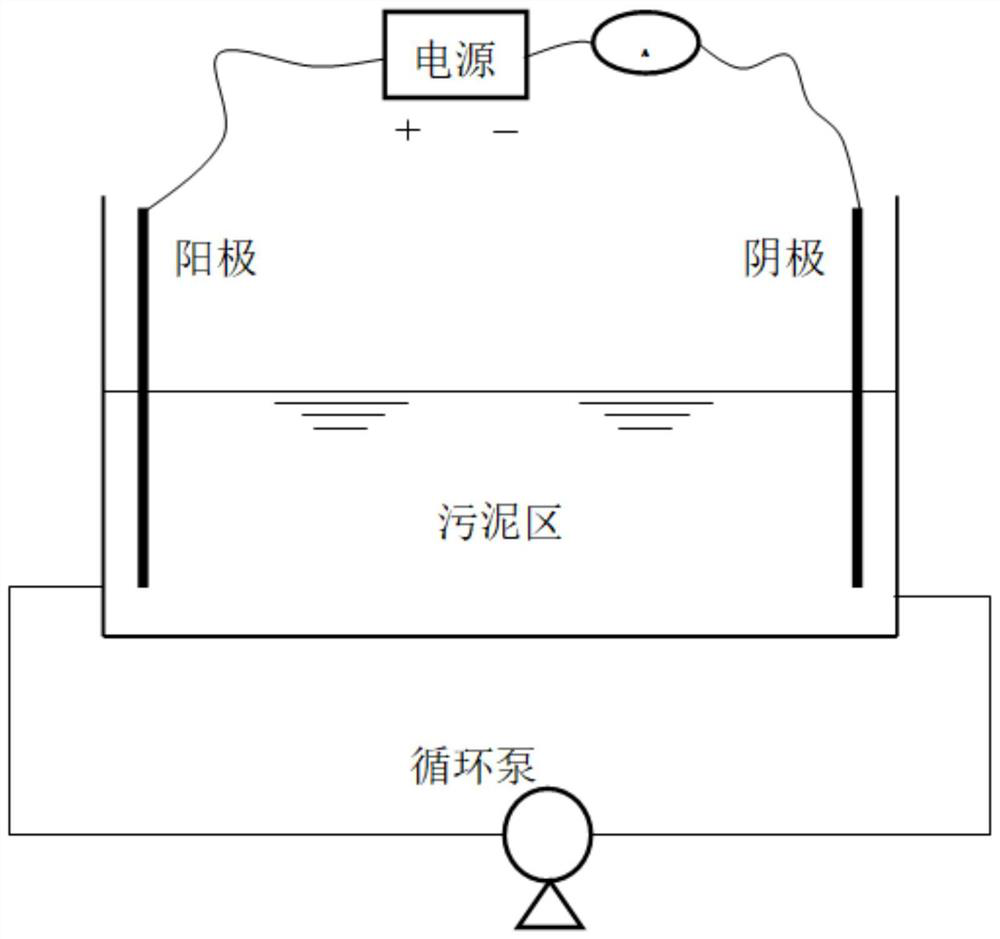

Method for degrading heavy metals in sludge through alkaline hydrolysis-electrolysis combination

InactiveCN112939384AShort degradation cycleReduce energy consumptionWater contaminantsElectrochemical sludge treatmentElectrolytic agentMicroorganism

The invention provides a method for degrading heavy metals in sludge through alkaline hydrolysis-electrolysis combination, and belongs to the technical field of sludge resource utilization. Sludge in a secondary sedimentation tank of a sewage treatment plant is sieved and settled, supernate is removed, microorganisms in the sludge are subjected to cell breaking by adopting a hot-alkali combined method, internal dissolved substances in the microorganisms are released, and a sludge lysate is prepared. An electrolyte is added into the sludge lysate solution in which the heavy metals in the microbial cells are released, and an electric field and a circulating device are externally added. According to the method, microbial cells are broken through the heat-alkali combined method, intracellular heavy metals are released, and then the concentration of the heavy metals in the sludge hydrolysate is effectively degraded through electrolysis. The electrochemical method is short in degradation period, simple in equipment, low in energy consumption and free of secondary pollution, subsequent sludge resource reutilization is facilitated, the cost can be controlled by controlling electrolysis operation parameters, and the disclosed method is economical, stable and reliable.

Owner:DALIAN UNIV OF TECH

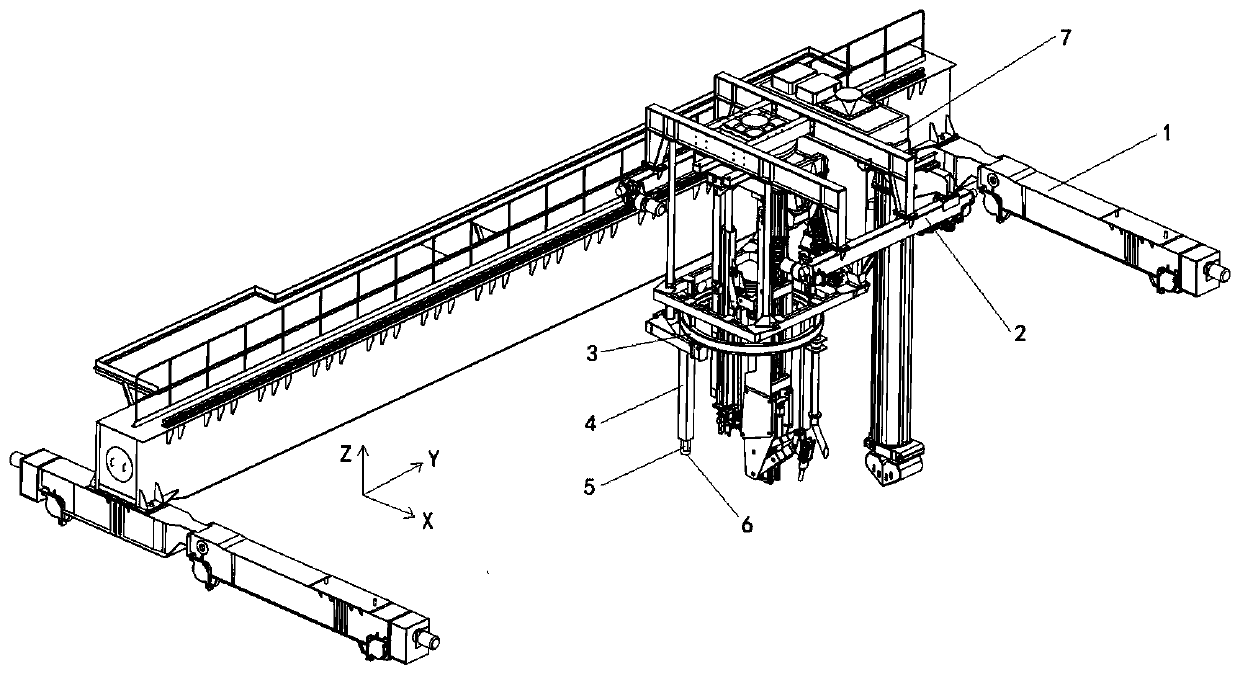

Intelligent visual positioning device and method for multifunctional aluminum electrolysis unit

PendingCN111503468AAchieve precise positioningHigh precisionStands/trestlesAluminium electrolysisEngineering

The invention discloses an intelligent visual positioning device and method for a multifunctional aluminum electrolysis unit. The device comprises a cart device running on workshop rails of an aluminum electrolysis workshop, rails are arranged on two main beams of the cart device, a trolley device is arranged on the rails, and the cart device and the trolley device are each provided with an automatic positioning system. The trolley device is provided with a rotary bracket and an industrial personal computer. A lifting bracket runs on a rotary rail of the rotary bracket, and the lifting supportcan achieve any rotation around the Z-axis direction along the rotary bracket. According to the technical scheme, the defects of high time consumption, large errors and the like of manual naked-eye positioning in the prior art are overcome, accurate positioning of workpieces in the aluminum electrolysis workshop is achieved, and the precision and speed of each electrolysis operation are improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

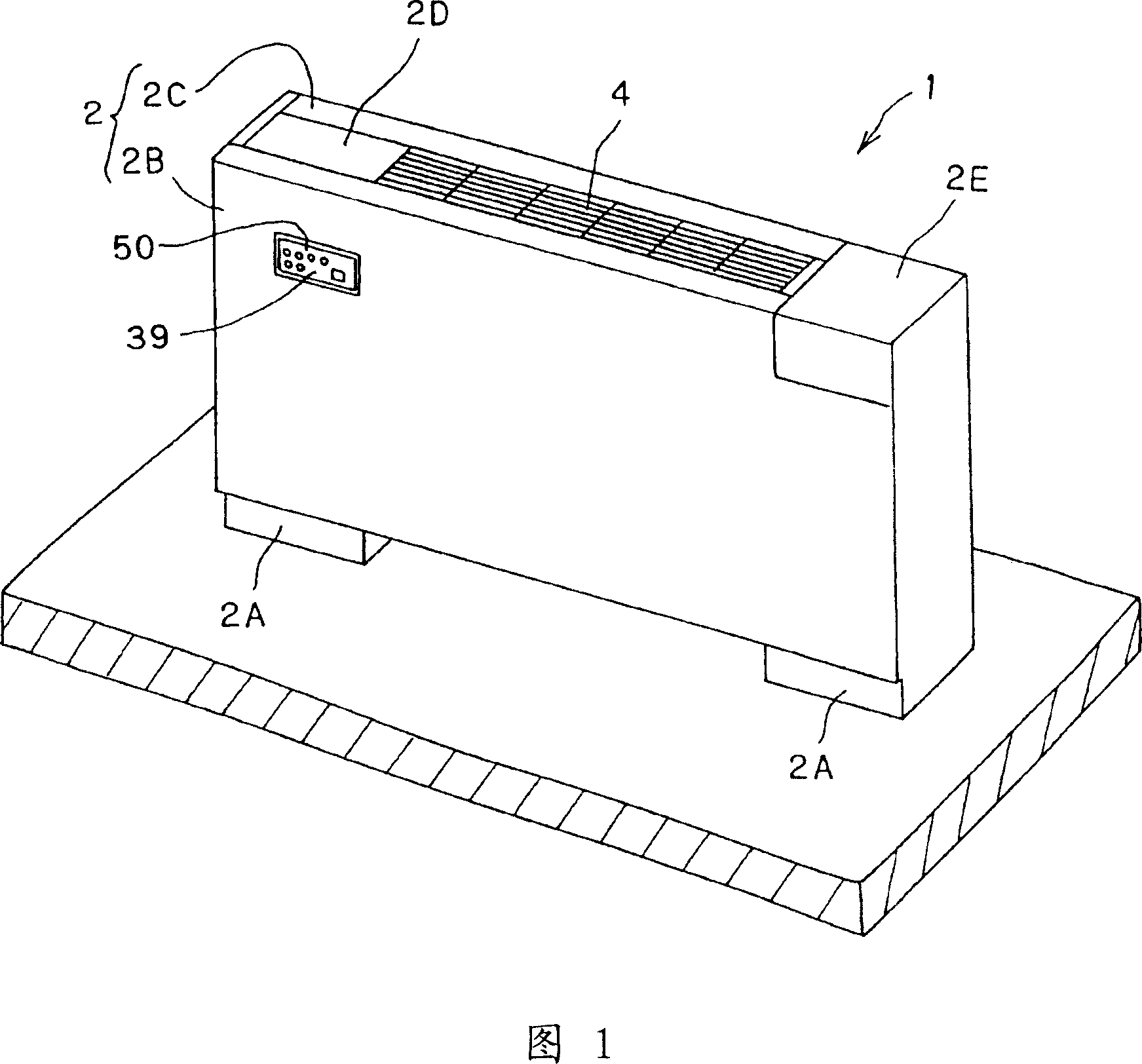

Air filtering apparatus and control method therefor

The invention provides a removing air bacteria device and the controlling method of the removing air bacteria device which can precisely control the reactive oxygen series concentration in the electrolysis water to be a target concentration. When the water is replaced and the time after the last time electrolysis operation is longer, a forward operating mode of electrolysis suitable for electrolyzing water before electrolyzed operates (from step Sa3 to step Sa7); when time after the last time electrolysis operation is shorter, a formal operating mode of electrolysis suitable for electrolyzing water after electrolyzed operates (from step Sa8 to step Sa12).

Owner:SANYO ELECTRIC CO LTD

Steel plate surface electrolysis descaling process

InactiveCN105671625AImprove continuityShort processing timeElectrolysis componentsMetallurgyWastewater

The invention relates to a steel plate surface electrolysis descaling process which has the advantages that the steel plate surface electrolysis descaling process is good in continuity, short in treatment time, environment-friendly in treatment process and free of wastewater, waste gas or waste liquid, the surface of a treated steel plate is bright, and quality requirements of a product can be completely met. The steel plate surface electrolysis descaling process comprises the following steps: conveying a steel strip to an uncoiler by a coil feeding trolley for uncoiling, and uncoiling and tracking the steel strip to a peeling machine by a pressing roller, peeling the steel strip, and treating most oxide skin on the steel strip; implementing leveling treatment on the steel strip; flattening the heads of two ends of a steel plate; polishing defects of the steel strip by steel grits; washing with clean water for a first time so as to remove stain left on the polished steel strip; feeding the steel strip into an electrolytic bath for corresponding electrolysis operation; after electrolysis, washing with clean water for a second time so as to remove stain left on the steel strip after electrolysis; after washing, drying the steel strip, tracking and conveying the steel strip to a coiler by a S-shaped tension roller, and coiling the steel strip by the coiler.

Owner:焦保强

Emergency device and method applicable to aluminum electrolysis head cell and tail cell

PendingCN108677217ASolve difficult-to-emergency problemsFirmly connectedElectricityEmergency treatment

The invention discloses an emergency device and method applicable to an aluminum electrolysis head cell and a tail cell. The device comprises a secondary emergency bus, wherein one end of the secondary emergency bus is connected to a big anode bus of an electrolysis cell at the electricity output end of each electrolysis operation area or a big anode bus of the electrolysis cell at the electricityinput end of each electrolysis operation area, and the other end of the secondary emergency bus is connected to a bus at the electricity output side or a bus in a channel at the electricity input end. According to the device, the big anode bus of the electrolysis cell at the electricity output end of the aluminum electrolysis series communicates with the bus at the electricity output side throughthe secondary emergency bus, and thus a current running loop is formed; and the structure of the device is completely applicable to a head cell in the electricity input end and a tail cell in the electricity output end of each operation area of the aluminum electrolysis series; and the problems that the current in the tail cell without downstream is hardly bridged and emergency treatment is hardly carried out in case of accident in a short circuit port of the head cell in the electricity input end without upstream can be effectively solved.

Owner:贵州创新轻金属工艺装备工程技术研究中心有限公司 +1

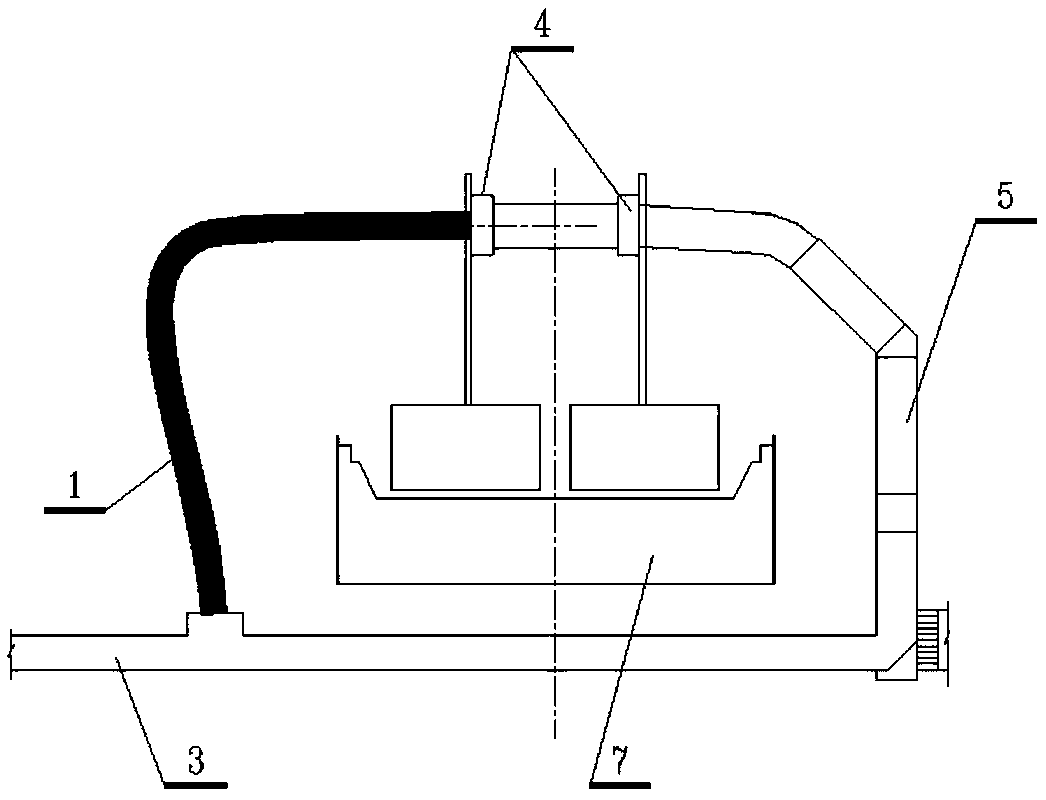

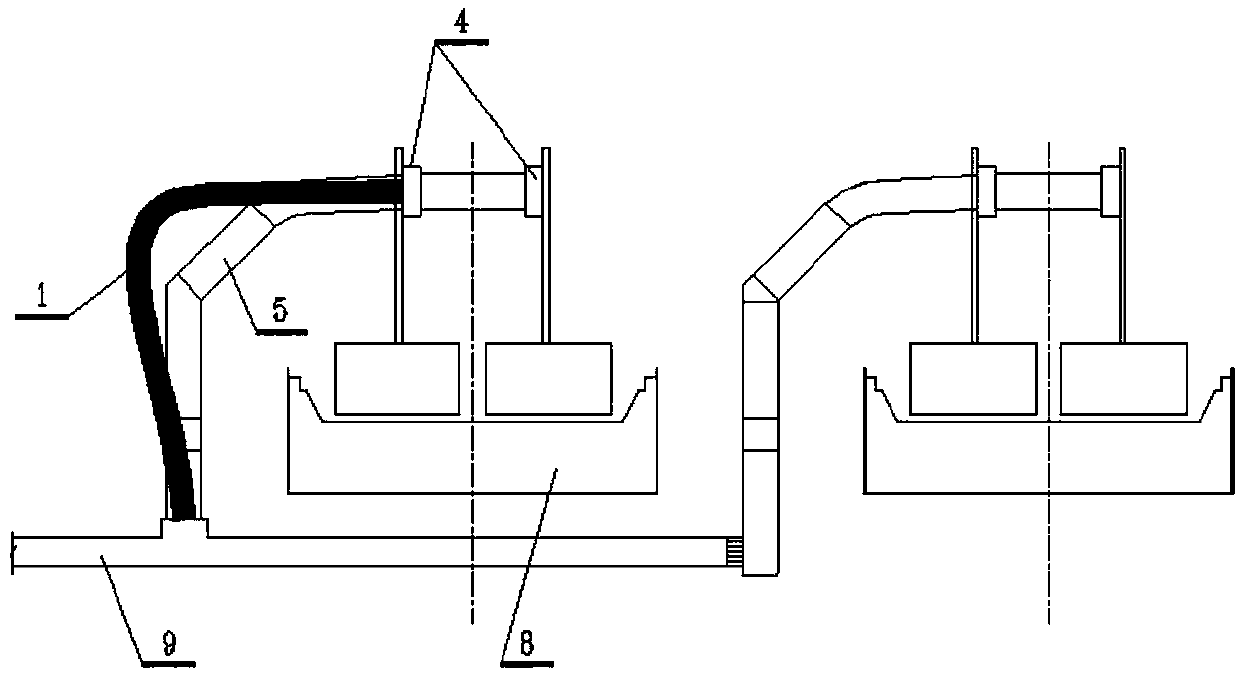

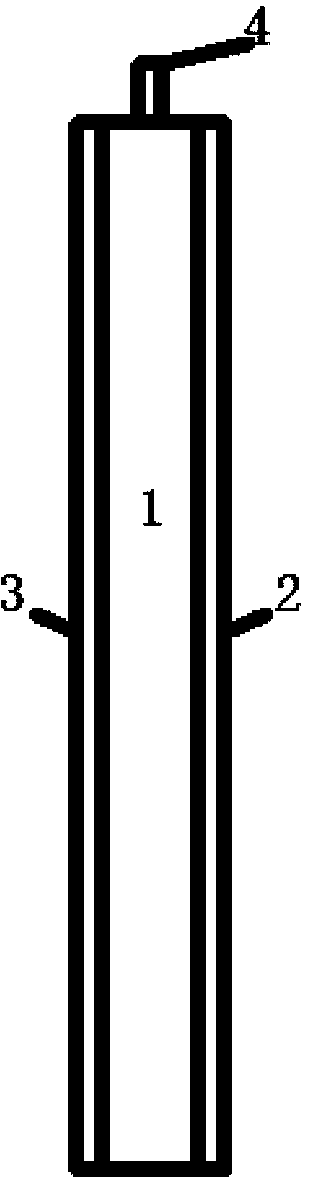

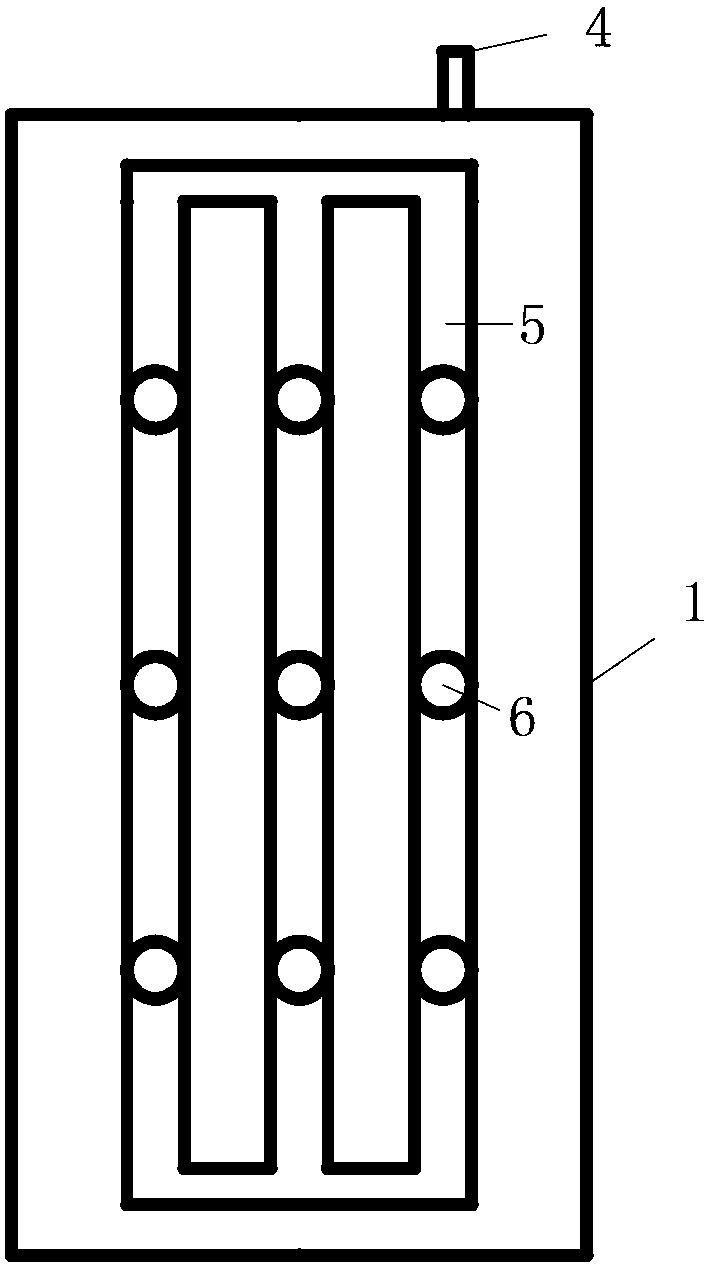

Membrane module

ActiveCN103418244ALow running costSelectively permeableSemi-permeable membranesWater/sewage treatment by ion-exchangeFiltration membraneIon-exchange membranes

The invention relates to a membrane module A which can be used for dialysis, electrolysis operation and enrichment of specific cations in water, and provides the membrane module A which is easy to operate, convenient to maintain and low in energy consumption, has certain specific cation enrichment capability and allows water to seep into. The membrane module A comprises a cation exchange membrane, an ultrafiltration membrane or micro-filtration membrane and a supporting plate with a diversion trench and a hole, and is characterized in that the cation exchange membrane and the ultrafiltration membrane or the micro-filtration membrane are respectively fixed on two sides of the supporting plate.

Owner:北京北华中清环境工程技术有限公司

Preparing method of novel Ce-La co-doped high-catalytic-activity Ti/Ce-Lanano-TiO2 modified electrode and method for electrocatalytic reduction of L-cystine through modified electrode

InactiveCN105274560ASmall surface particlesFine and uniform particlesElectrolytic organic productionElectrodesElectricityRare earth

The invention discloses a preparing method of a novel Ce-La co-doped high-catalytic-activity Ti / Ce-Lanano-TiO2 modified electrode and a method for electrocatalytic reduction of L-cystine through the modified electrode, and belongs to the technical field of organic electricity synthesis. The method comprises the specific steps that the rare earth Ce-La co-doped Ti / Ce-Lanano-TiO2 modified electrode is prepared; organic electricity synthesis is carried out, electrocatalytic reduction of L-cystine is carried out, L-cysteine is prepared, a self-assembled diaphragm plate frame type electrolytic cell is included, an electrolyte is prepared, and electrolysis operation is carried out; and product extraction is carried out, the electrolyzed electrolyte is extracted and purified, and then the L-cysteine product is obtained. The high-catalytic-activity Ti / Ce-Lanano-TiO2 modified electrode prepared through co-doped modification of rare earth Ce and rare earth La serves as a cathode, electrode crystal particles are fine and even, and the catalytic activity and stability of a TiO2 electrode are improved; and the electro-catalytic property, the corrosion resistance and selectivity of the electrode are greatly improved.

Owner:HUAINAN NORMAL UNIV

Lead recovery method and device for perovskite battery

ActiveCN107513618BEfficient recyclingAvoid pollutionPhotography auxillary processesWaste accumulators reclaimingOrganic solventWaste material

The invention relates to a lead recycling method for a perovskite battery. The lead recycling method comprises the following steps that the perovskite battery is smashed to form fragments; the fragments are soaked in a soaking solution and subjected to solid-liquid separation, and thus a leady separation solution is obtained; the soaking solution comprises an organic solvent which can dissolve perovskite materials; and chemical precipitation operation or electrolysis operation is conducted on the leady separation solution so as to obtain a leady solid body. According to the lead recycling method for the perovskite battery, on one hand, lead is recycled, therefore lead pollution is avoided, and the environment is protected; on the other hand, the recycled lead can be changed into valuable matter from a waste material, and thus the effective utilization of resources is improved. In addition, the lead recycling method for the perovskite battery is simple and practicable, and beneficial for application to a mass industry. The invention further provides a lead recycling device for the perovskite battery.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

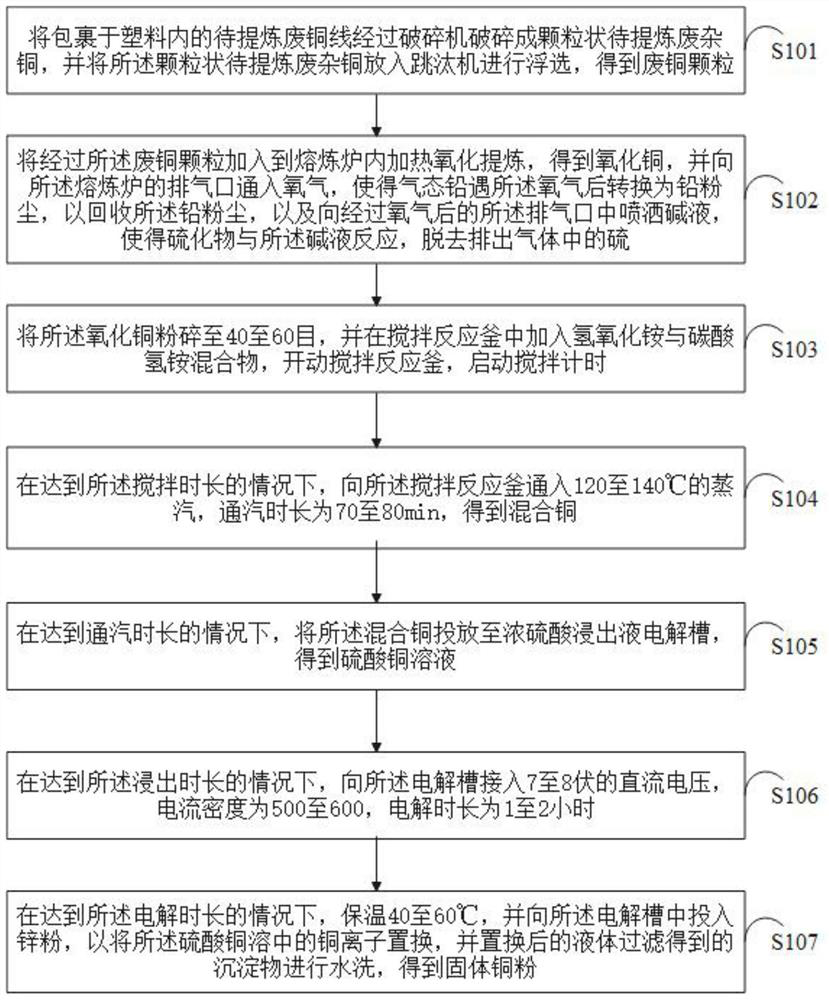

Scrap copper refining process

InactiveCN113005291AHigh purityHigh reuse ratePhotography auxillary processesProcess efficiency improvementPhysical chemistryExhaust fumes

The invention relates to a scrap copper refining process, and relates to the technical field of metal recycle. The scrap copper refining process aims to solve the problems of low purity of recycled copper and air pollution caused by waste gas in the recycle process in the related art. The scrap copper refining process comprises the steps that gaseous lead is converted into lead dust after encountering oxygen through oxygen in the waste gas so as to recycle the lead dust, and an alkali liquor is sprayed into an exhaust port passing through the oxygen, so that sulfide reacts with the alkali liquor to remove sulfur in the exhausted gas; and copper oxide passes through a mixture of ammonium hydroxide and ammonium bicarbonate to be mixed, a mixed liquid is electrolyzed, and electrolyzed copper is subjected to zinc replacement so as to obtain high-purity recycled copper. The pollution of lead and sulfide in the waste gas to air is reduced on the basis of the introduction of oxygen into the waste gas and the spraying of the alkali liquor, and the purity of the recycled copper is improved on the basis of the mixture of ammonium hydroxide and ammonium bicarbonate, electrolysis operation, replacement operation and the like.

Owner:邱小华

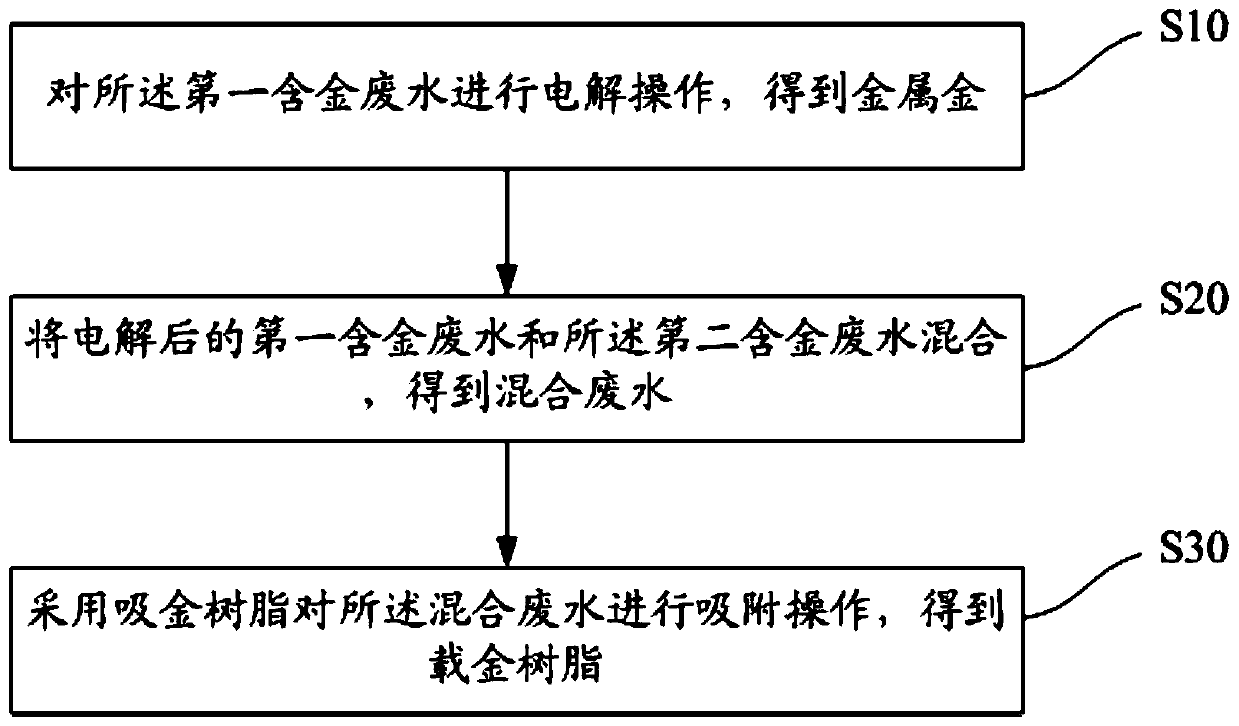

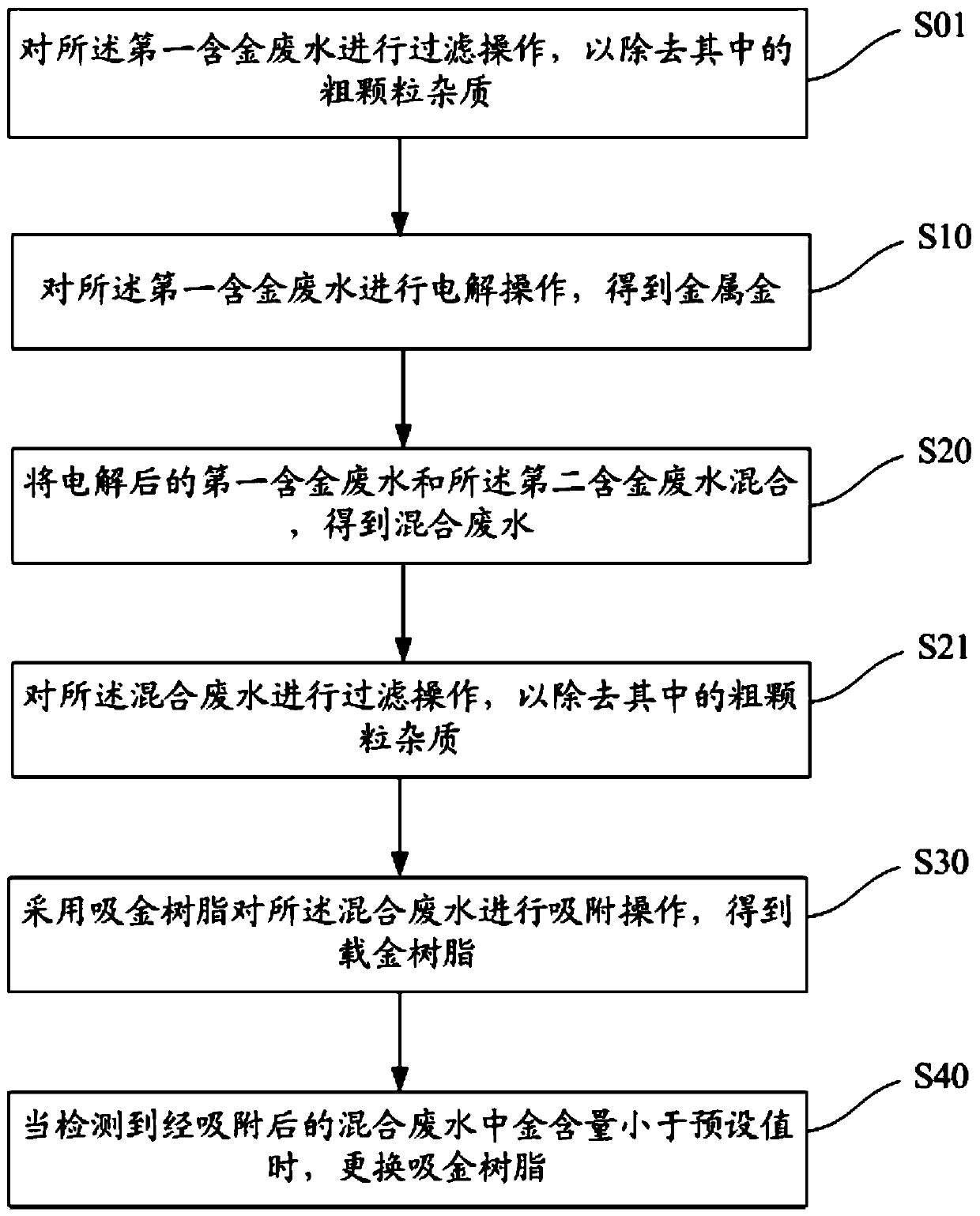

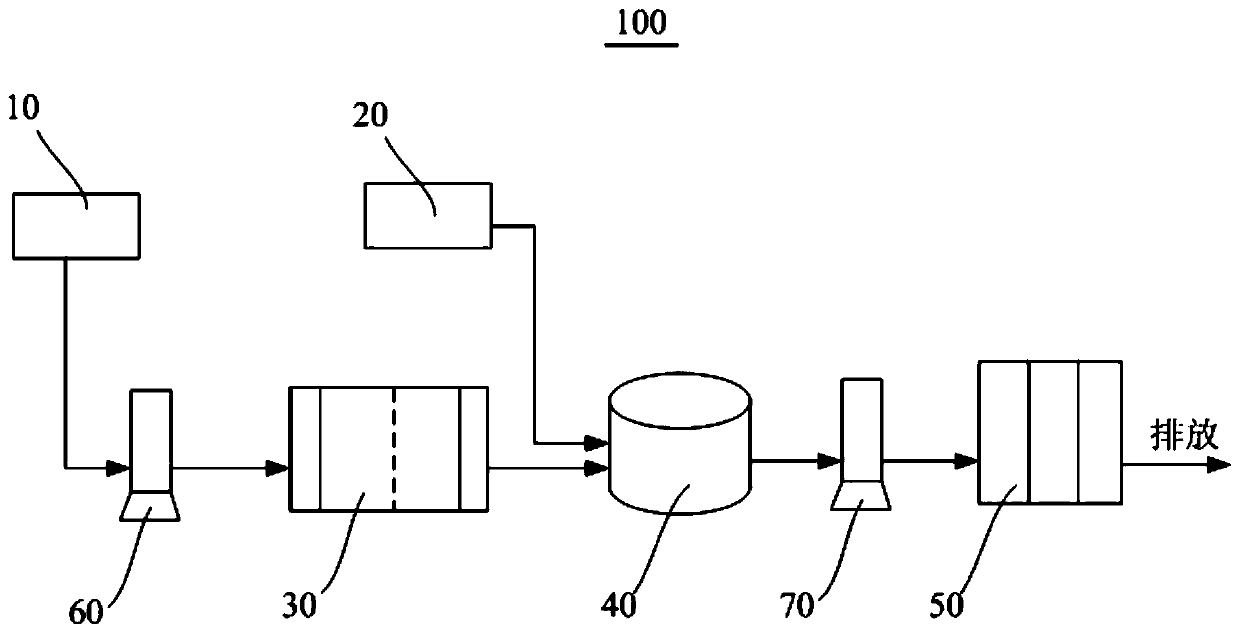

Recovery method and recovery system for gold-containing wastewater

InactiveCN111074301AReduce contentHigh purityPhotography auxillary processesProcess efficiency improvementWastewaterProcess engineering

The invention discloses a recovery method and a recovery system for gold-containing wastewater. Wherein the gold-containing wastewater comprises first gold-containing wastewater and second gold-containing wastewater, the content of gold in the first gold-containing wastewater is higher than the content of gold in the second gold-containing wastewater, and the recovery method of the gold-containingwastewater comprises the following steps of carrying out electrolysis operation on the first gold-containing wastewater to obtain metal gold; mixing the electrolyzed first gold-containing wastewaterwith the electrolyzed second gold-containing wastewater to obtain mixed wastewater; and carrying out adsorption operation on the mixed wastewater by adopting gold adsorption resin to obtain gold-loaded resin. According to the technical scheme, efficient recovery of gold in the gold-containing wastewater can be achieved.

Owner:深圳市祺鑫环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com