Operation method of ozonizer and ozonizer apparatus used therefor

An ozone generating device and ozone technology, which are applied in the directions of oxygen/ozone/oxide/hydroxide, ozone preparation, chemical instruments and methods, etc., can solve problems such as the reduction of ozone generation capacity, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

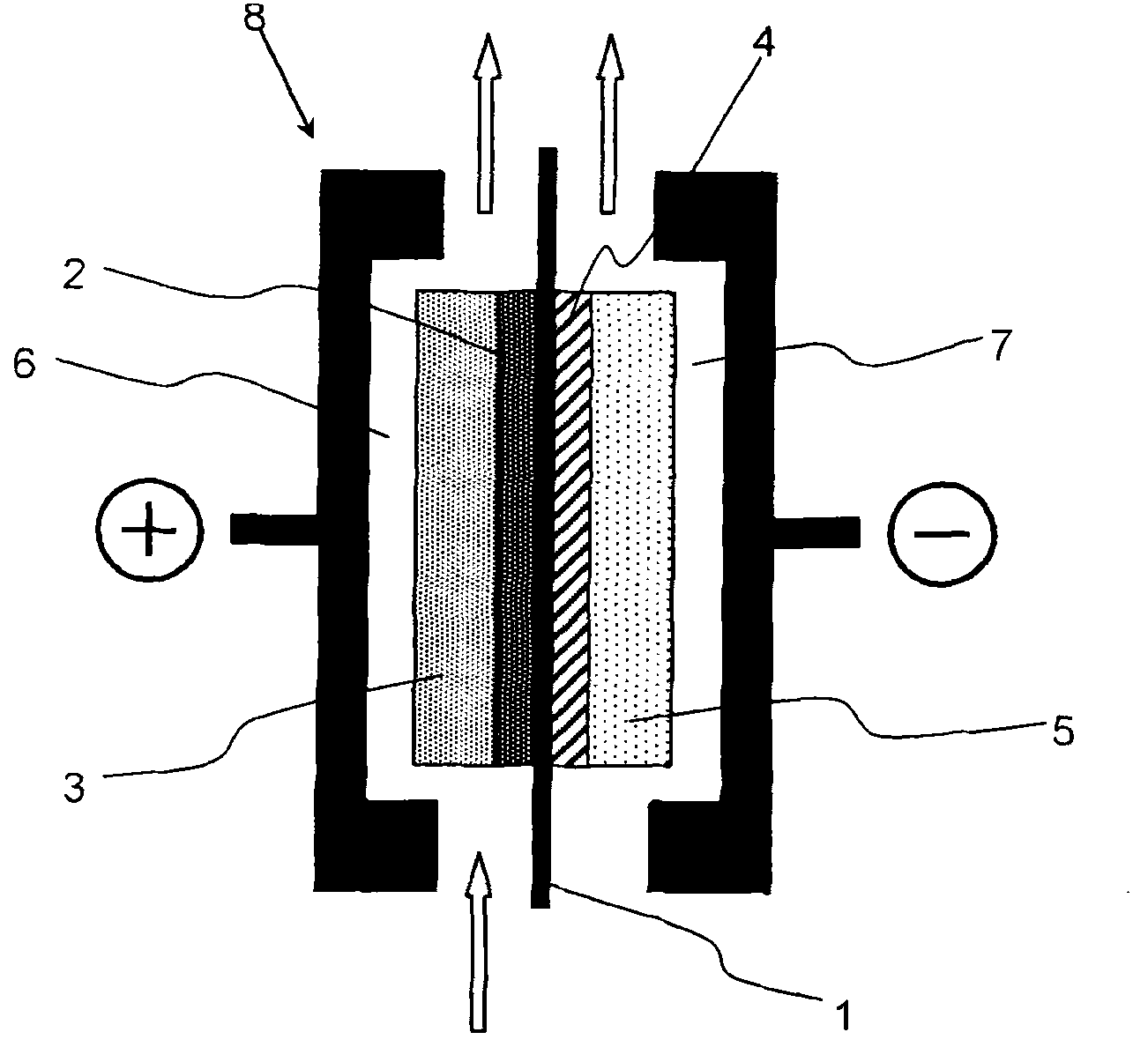

[0092] Use a neutral detergent on a 1mm thick titanium vibrating fiber sintered body (びび made by Chitan 繊 After cleaning and degreasing the junction, Tokyo Steel Co., Ltd., pickled it with 20% by mass, 50°C hydrochloric acid solution for 1 minute to perform pretreatment, and then used the thermal decomposition method on the vibrating fiber made of titanium. A cladding layer containing platinum-titanium-tantalum (25-60-15 mol%) is formed on the sintered body, thereby producing an anode current collector or anode base 3 with an undercoat layer formed on the surface.

[0093] With the anode current collector or anode substrate 3 as the anode and 400g / l lead nitrate aqueous solution as the electrolyte, at 60°C, 1A / dm 2 The electrolysis was carried out for 60 minutes under certain conditions, thereby forming the anode 2 on the surface of the anode current collector or the anode substrate 3, the anode 2 comprising a coating layer of the anode catalyst, ie, β-lead dioxide.

[009...

Embodiment 2

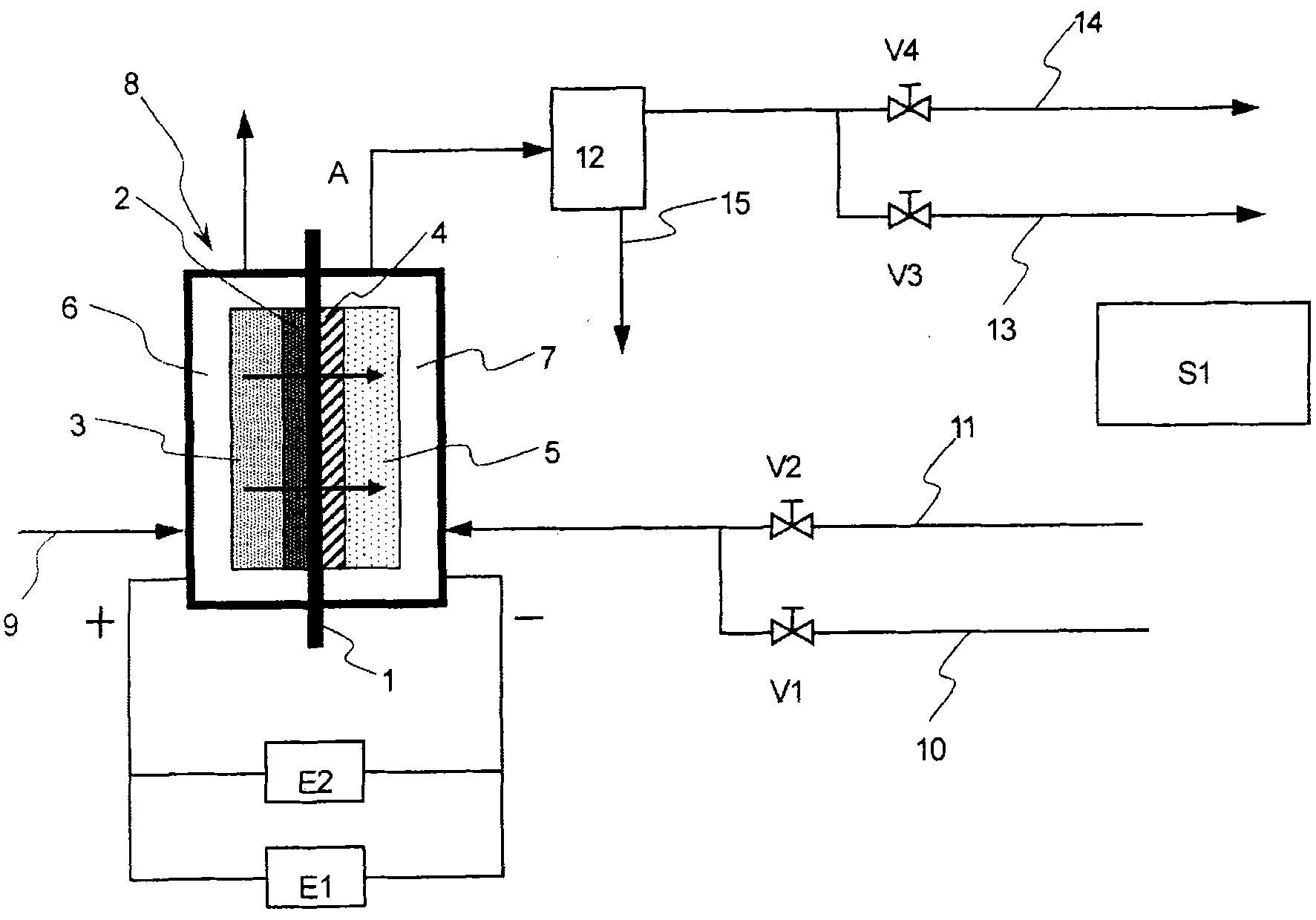

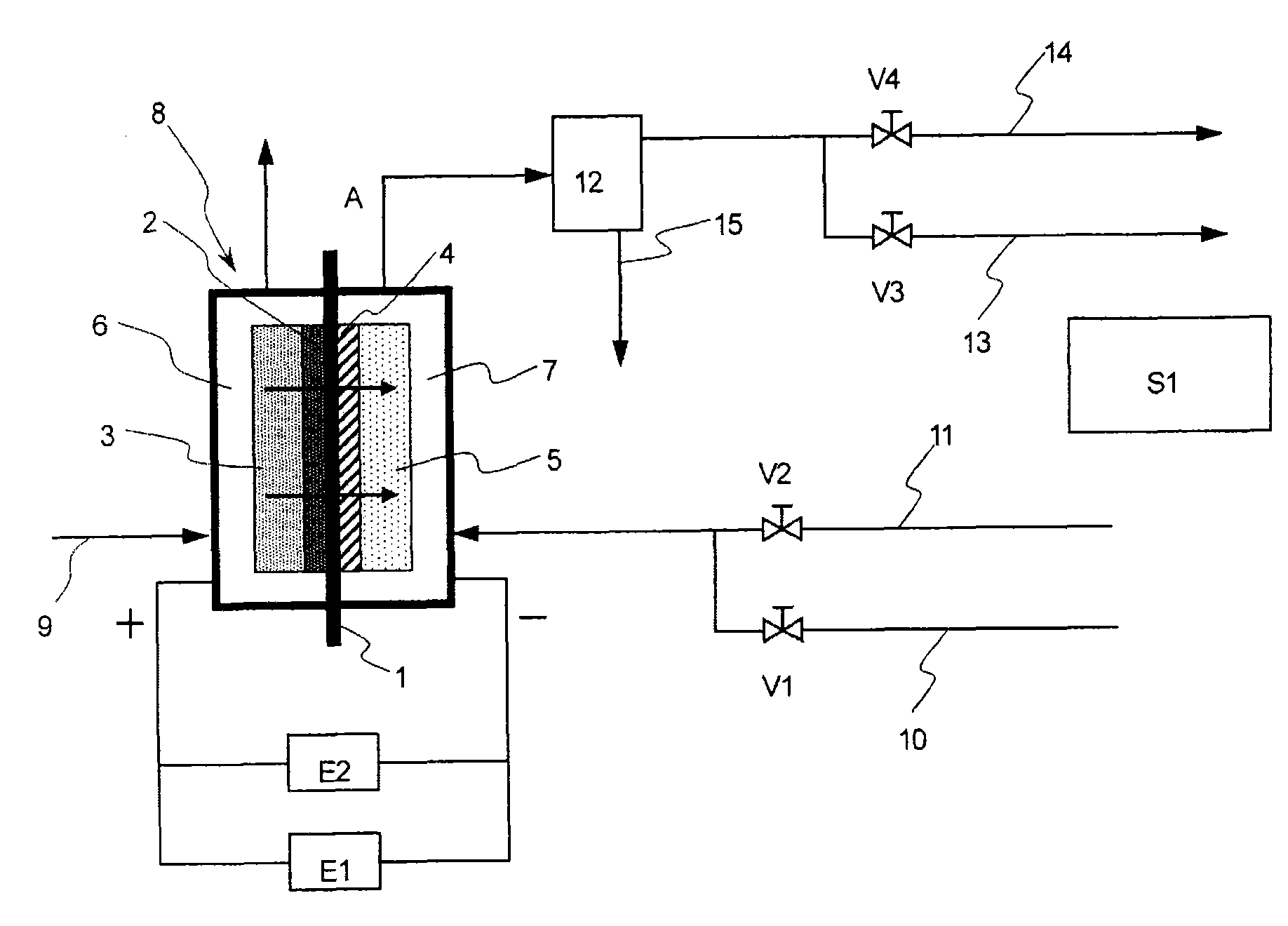

[0100] After carrying out normal electrolysis according to the same operation as in Example 1, switch to the protection current, replace the electrolyzed water and gas in the cathode chamber with pure water, and after the replacement, supply oxygen concentrated through PSA to the cathode chamber at a speed of 0.3 L / min ( When the oxygen concentration was 96%), no hydrogen concentration was detected in the anode generated gas, and no hydrogen concentration was detected in the cathode chamber exhaust gas. The battery voltage is 0.4V.

Embodiment 3

[0102] After carrying out normal electrolysis according to the same operation as in Example 1, switch to the protection current, and use an air pump to supply air to the cathode chamber at a speed of 0.5 L / min. At this time, the water in the cathode chamber is discharged, and there is no Hydrogen concentration was detected and was not detected in the cathode chamber exhaust gas. The battery voltage is 0.5V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com