Patents

Literature

1121 results about "Anode catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode catalyst for fuel cells with polymer electrolyte membranes

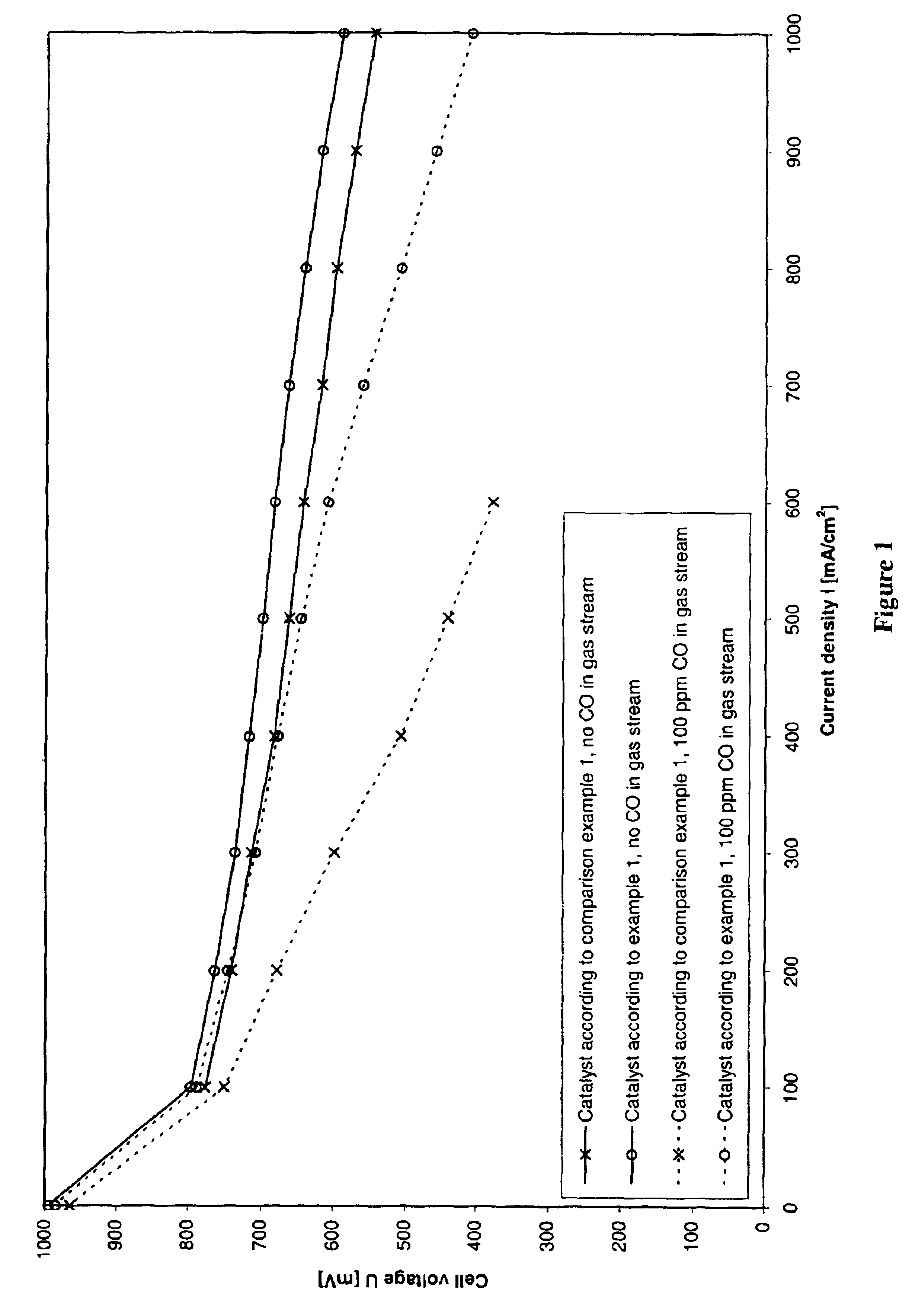

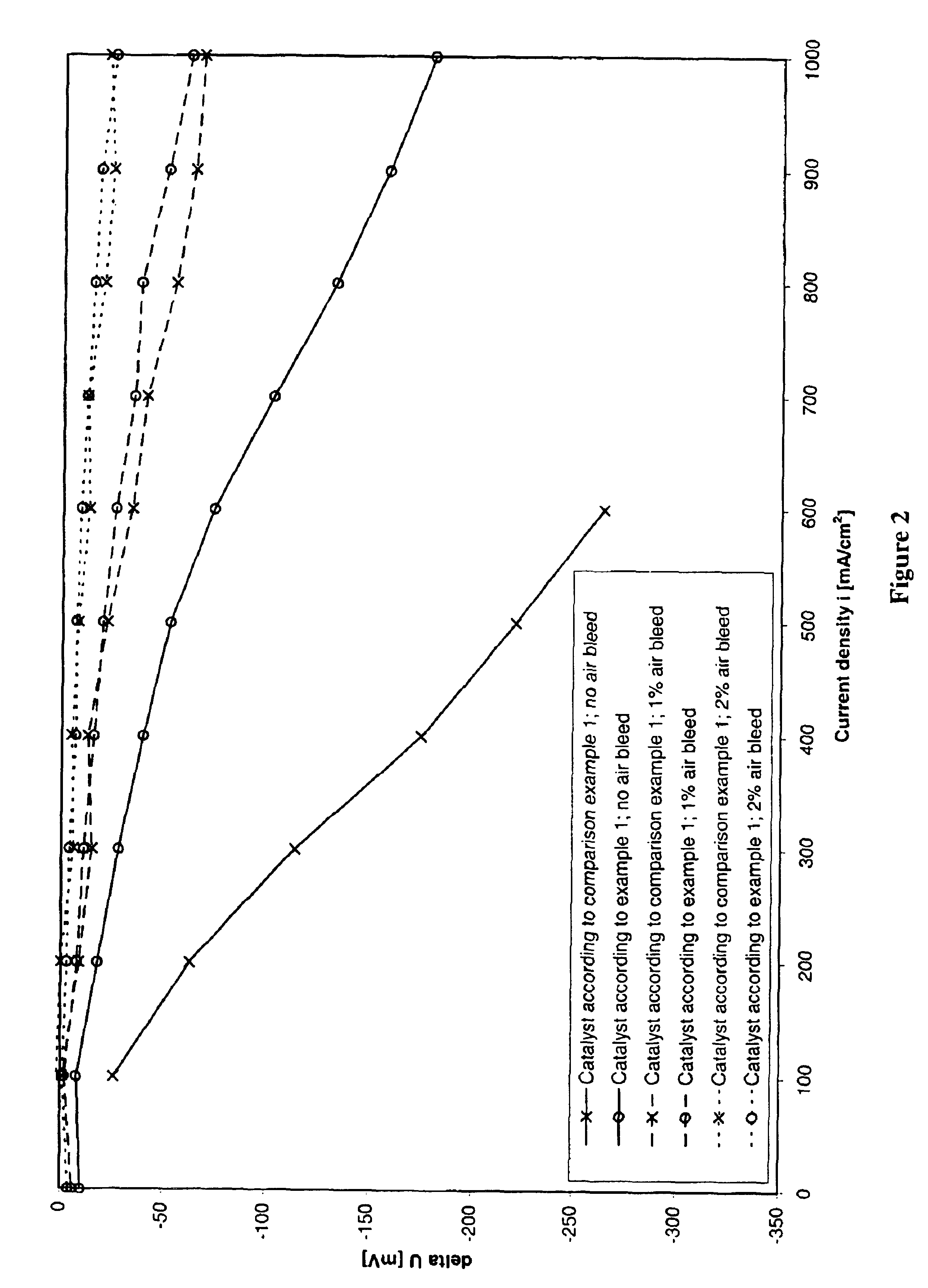

A platinum / ruthenium alloy catalyst that includes finely dispersed alloy particles on a powdery, electrically conductive carrier material. The catalyst is particularly resistant to carbon monoxide poisoning when the alloy particles display mean crystallite sizes of 0.5 to less than 2 nm.

Owner:EVONIK DEGUSSA GMBH

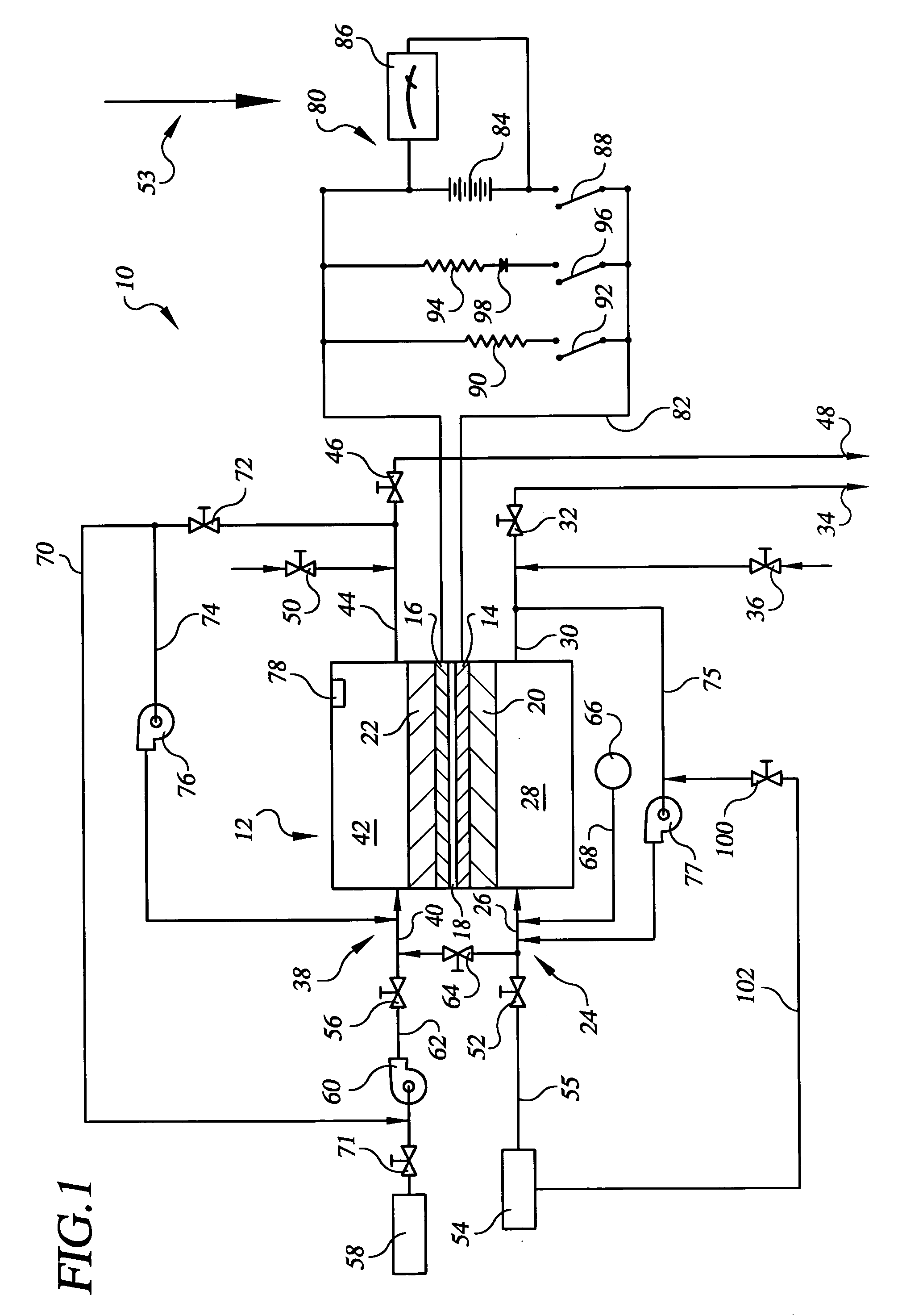

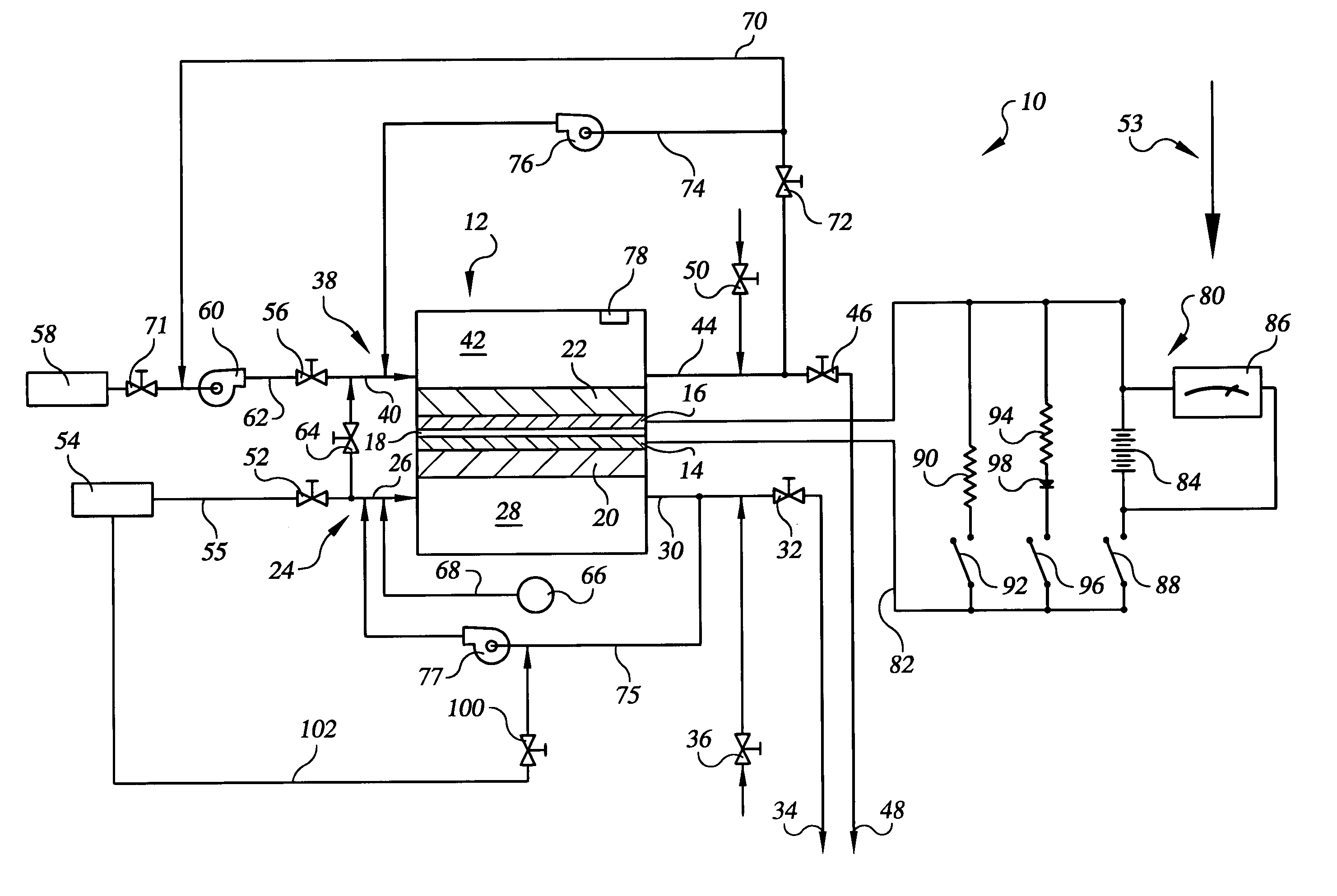

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20050031917A1Move quicklyMinimize oxidation corrosionReactant parameters controlFuel cells groupingPower stationEngineering

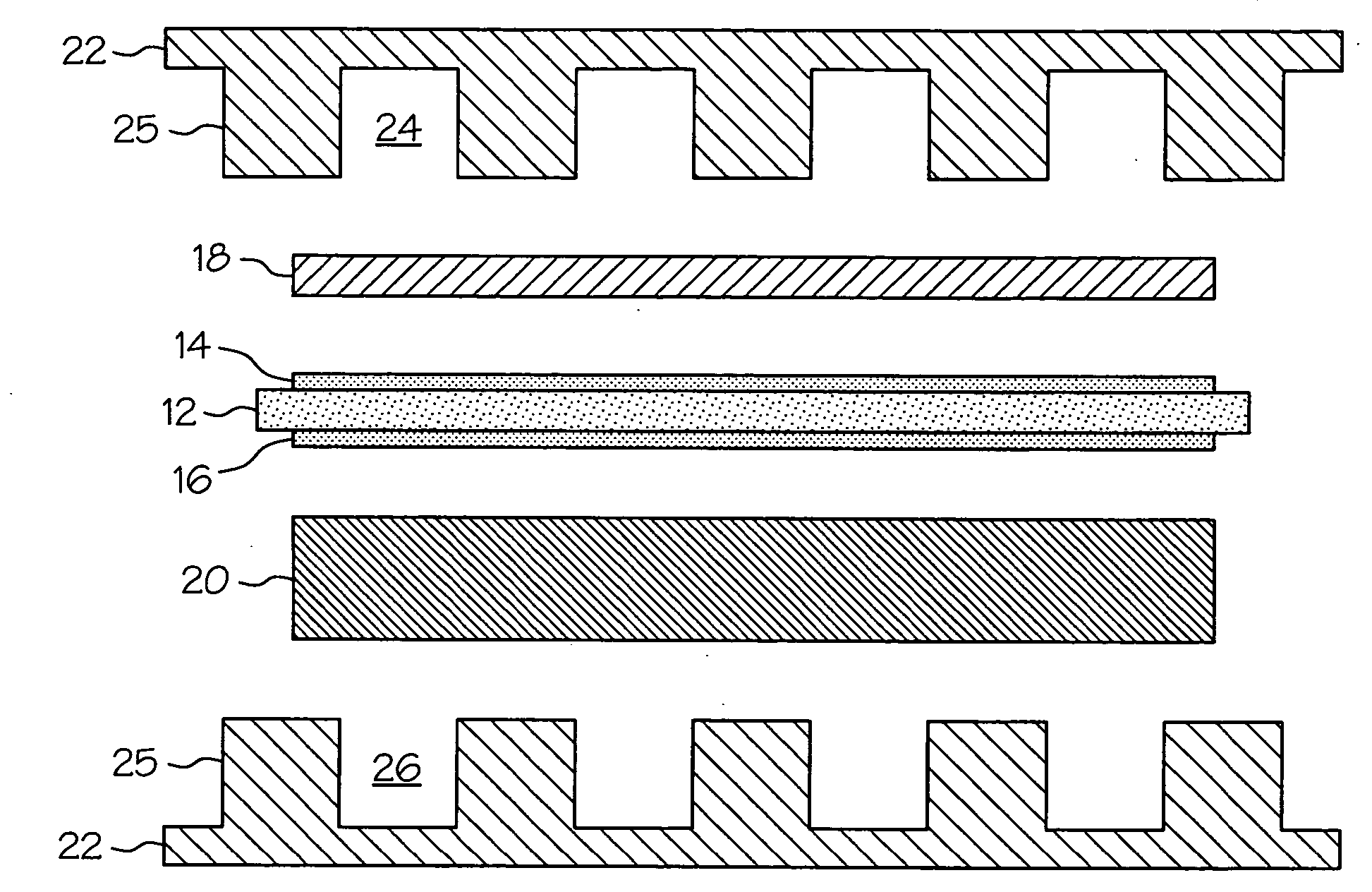

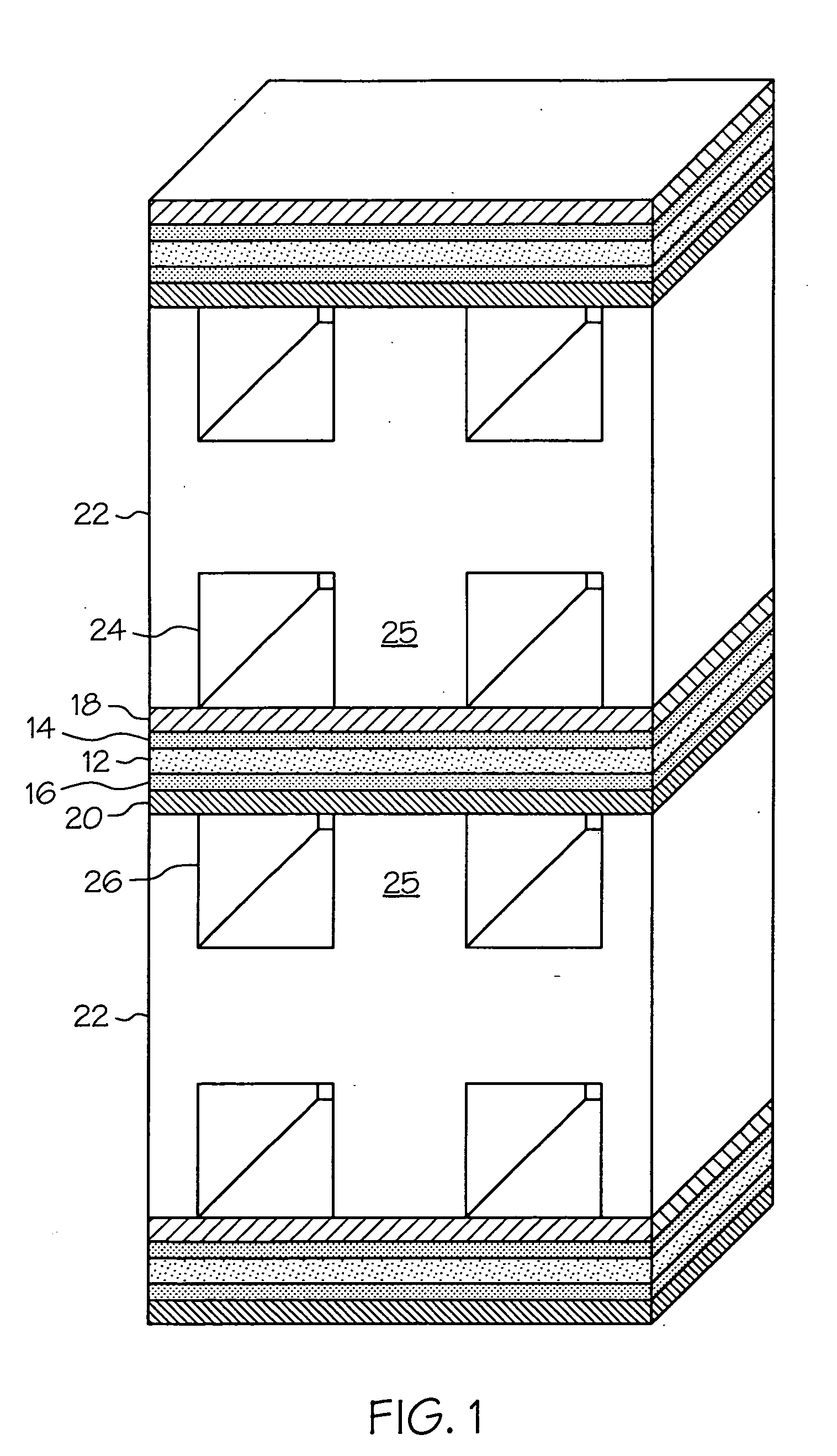

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

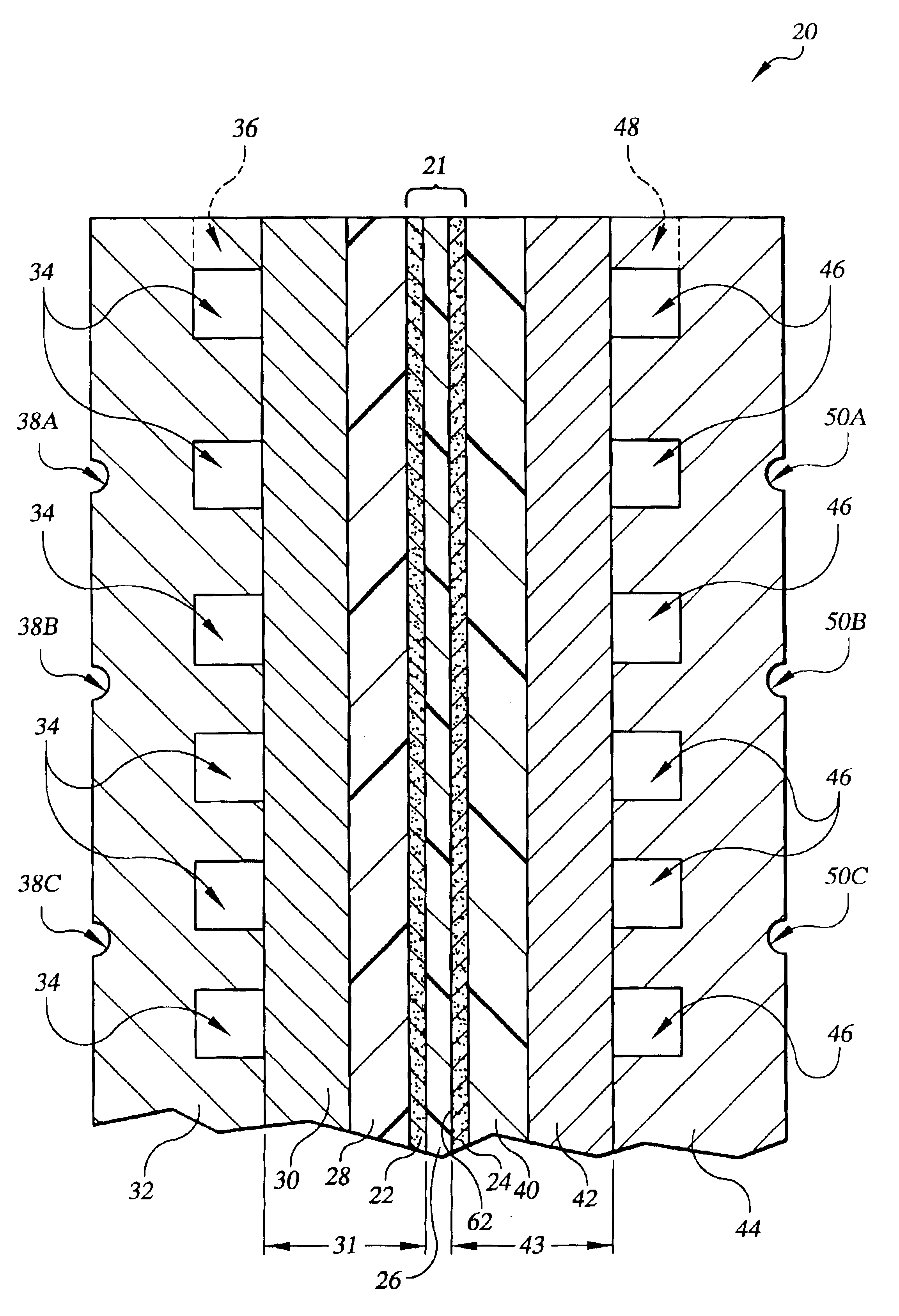

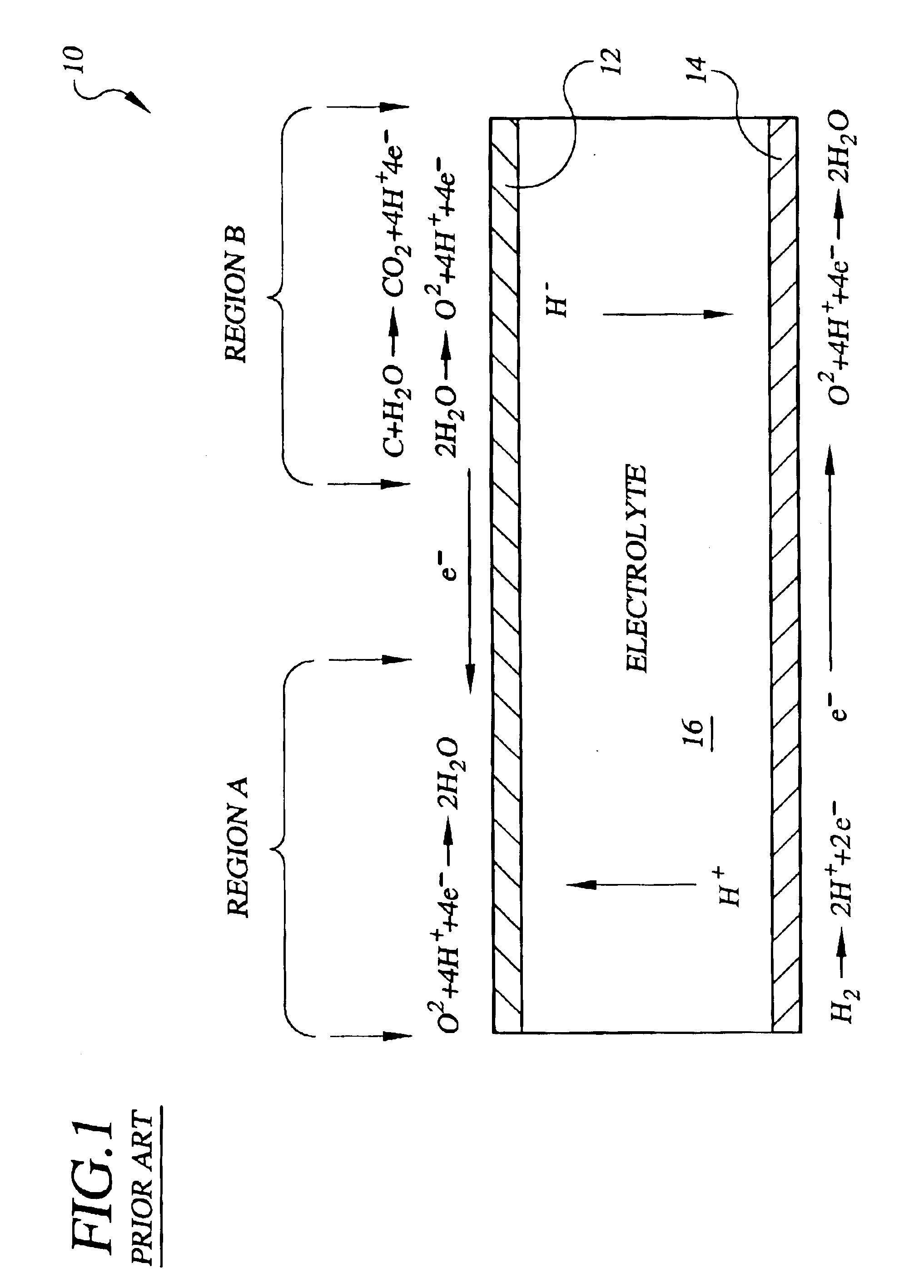

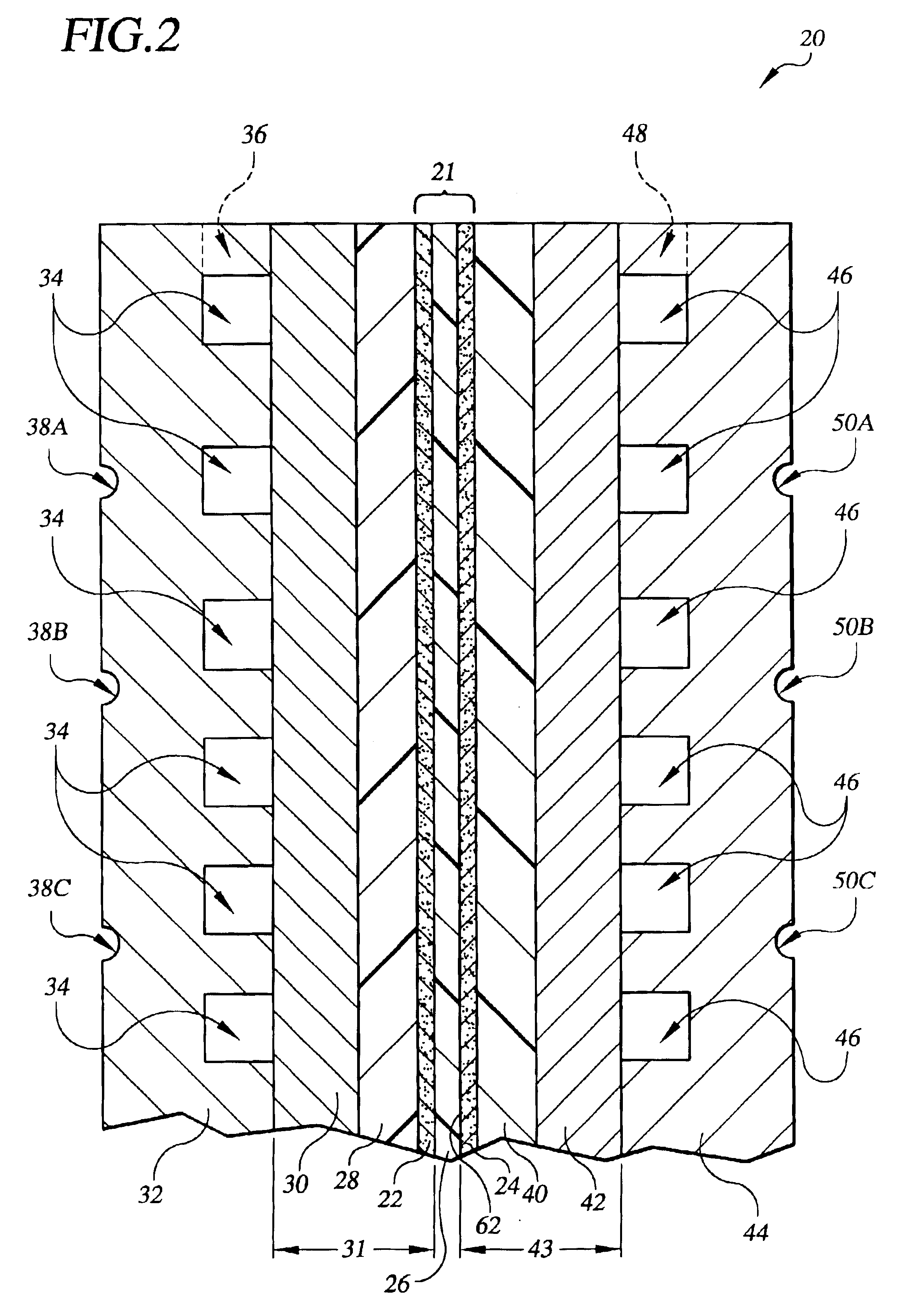

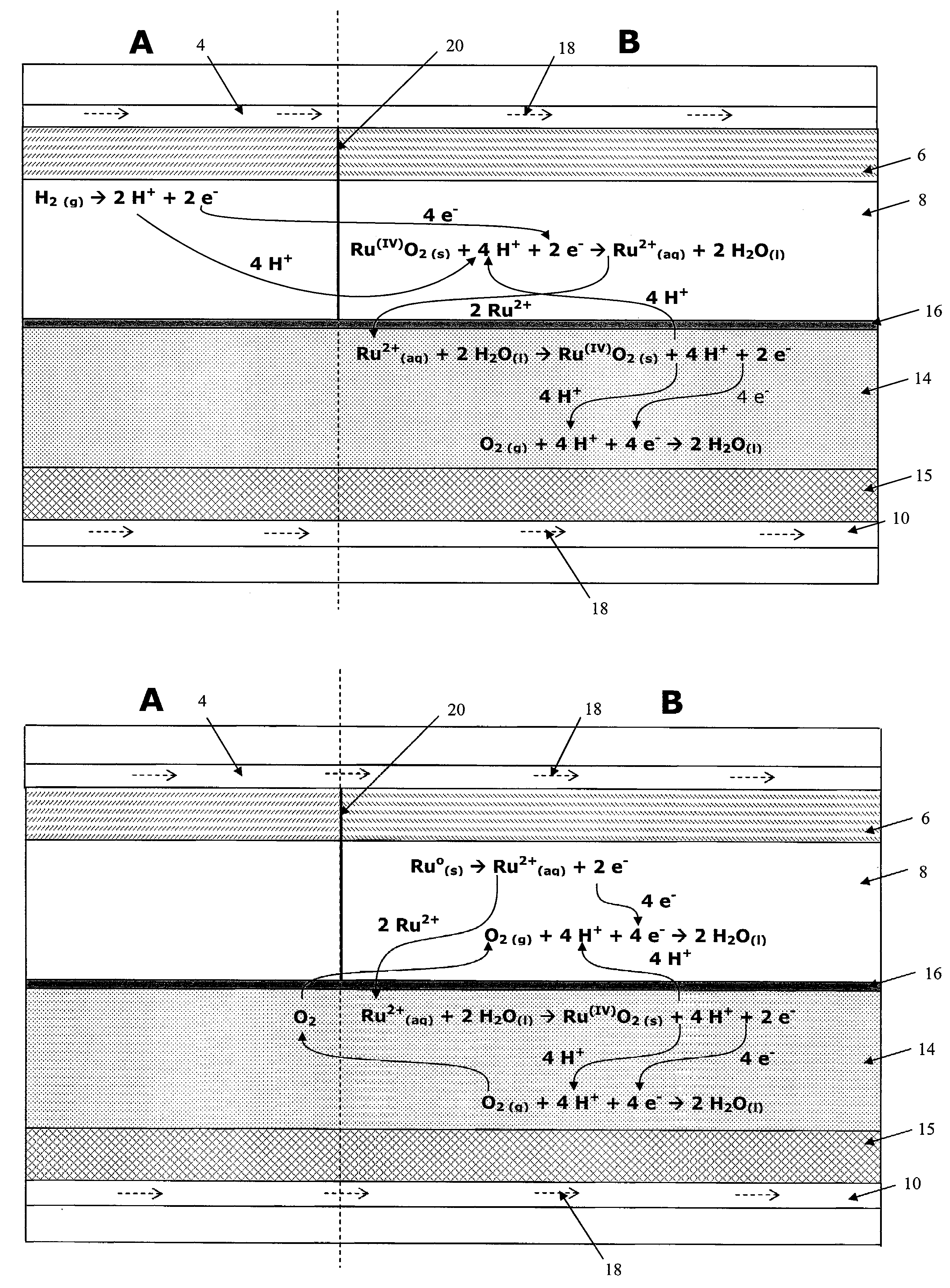

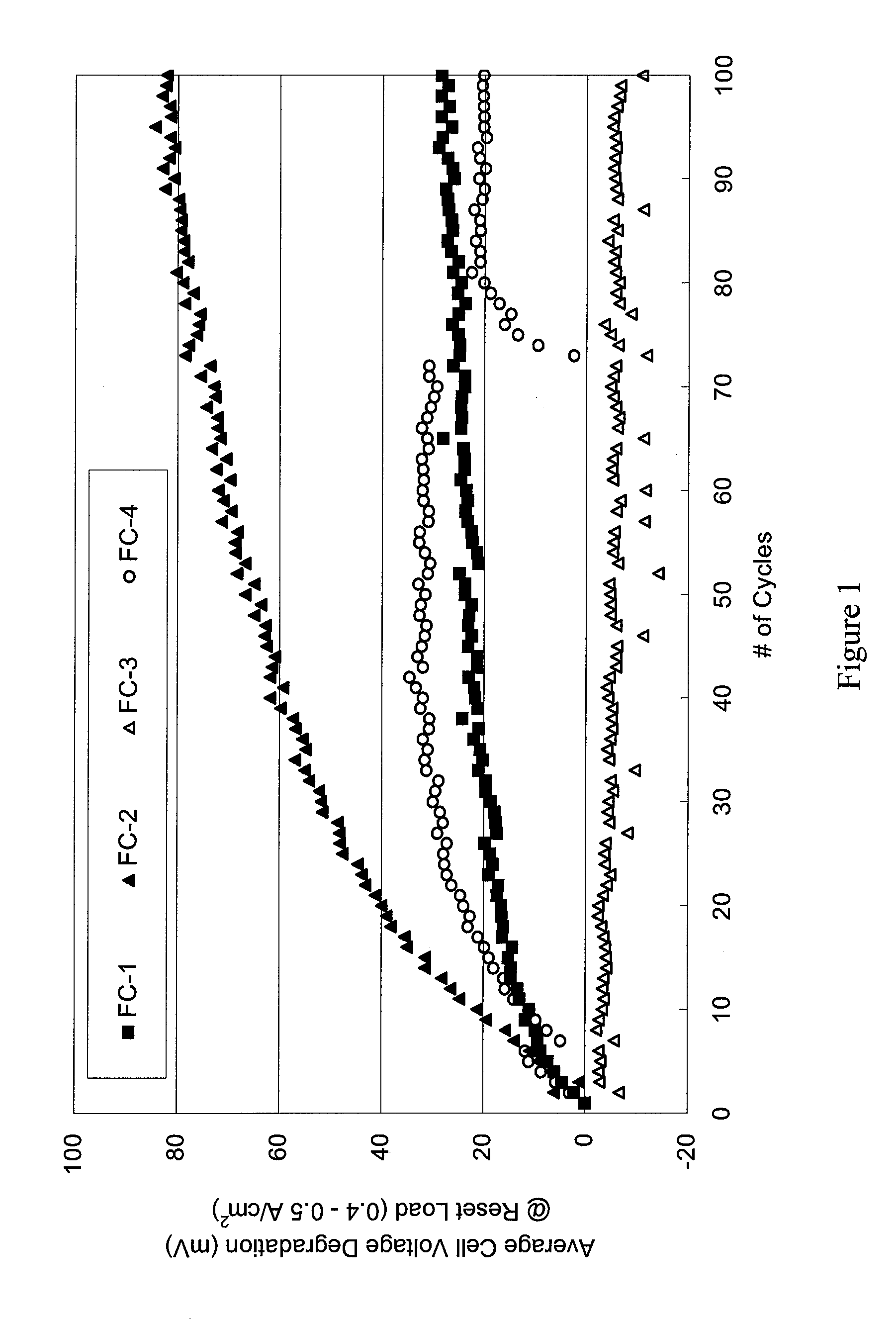

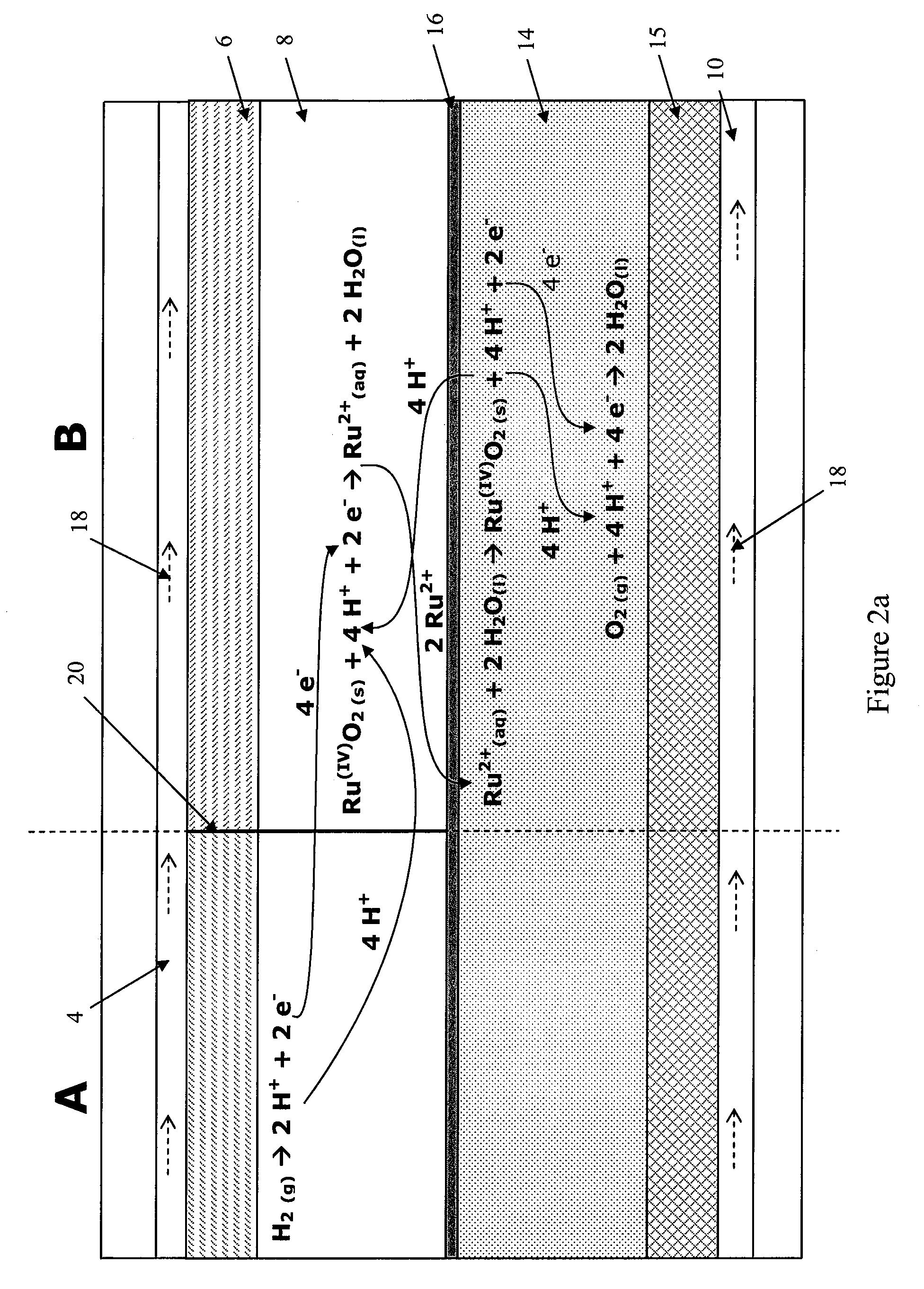

Fuel cell having a corrosion resistant and protected cathode catalyst layer

InactiveUS6855453B2Corrosion minimizationHigh areaActive material electrodesSolid electrolyte fuel cellsOver potentialOxygen evolution

The invention is a fuel cell (20) having a corrosion resistant and protected cathode catalyst layer (24). The cathode catalyst layer (24) includes a platinum oxygen reduction catalyst and an oxygen evolution catalyst selected from the group consisting of catalysts that are more active than platinum for oxygen evolution. The oxygen evolution catalyst may be uniformly applied within the cathode catalyst layer, or non-uniformly applied to identified high corrosion areas (82) (84) of the cathode catalyst layer (24). The cathode catalyst layer (24) may include heat-treated carbon support material, and / or a heat-treated carbon black within a diffusion layer (40) supporting the cathode catalyst layer (24). The fuel cell (20) may also include an anode catalyst layer (22) having a poor oxygen reduction catalyst having a greater oxygen reduction over potential than platinum.

Owner:AUDI AG

Hydrogen passivation shut down system for a fuel cell power plant

InactiveUS6984464B2Minimize oxidation corrosionRapid fuelReactant parameters controlFuel cells groupingPower stationEngineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

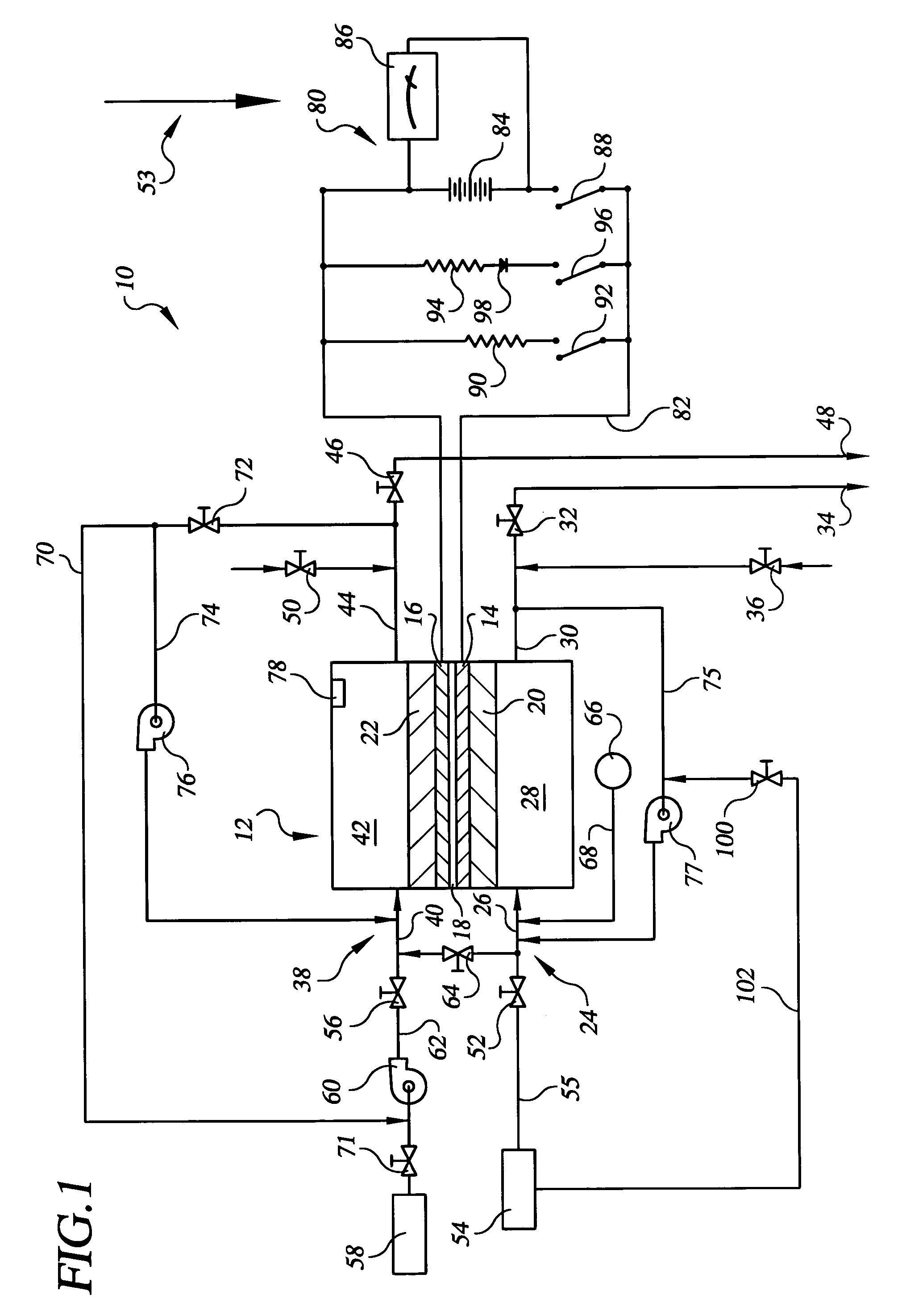

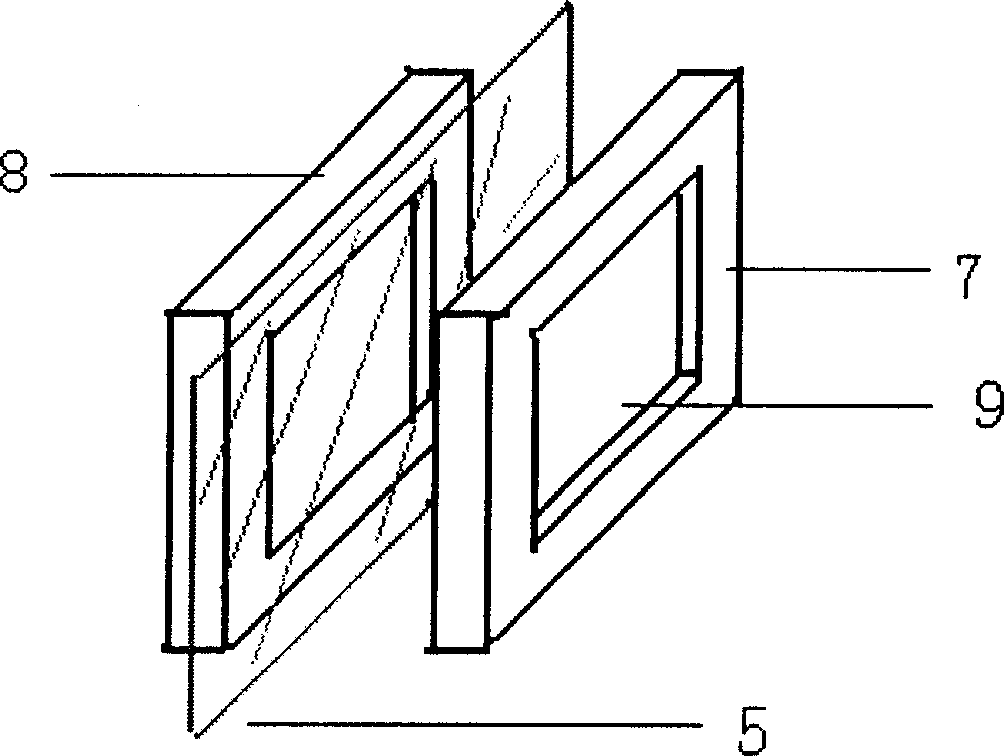

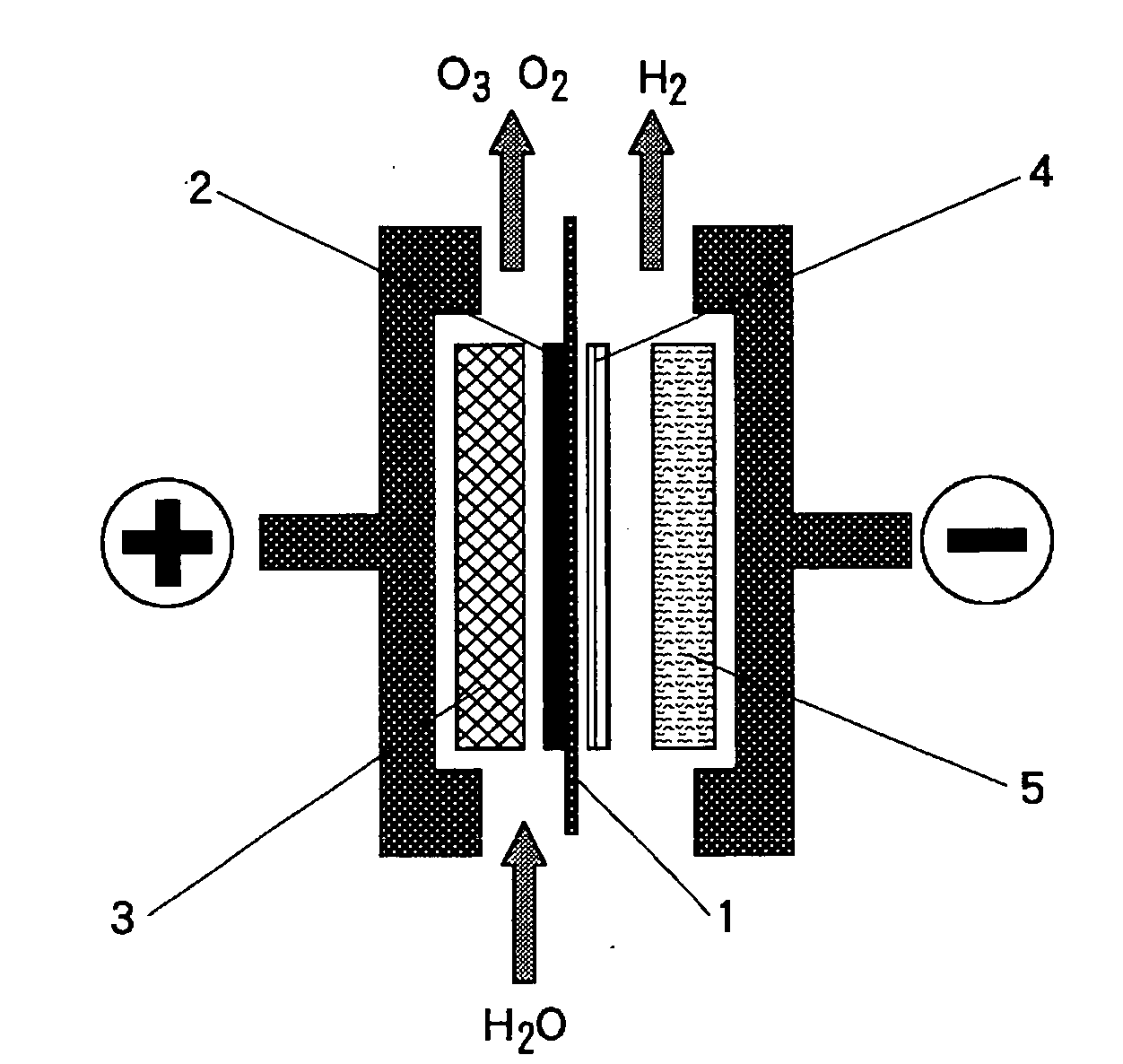

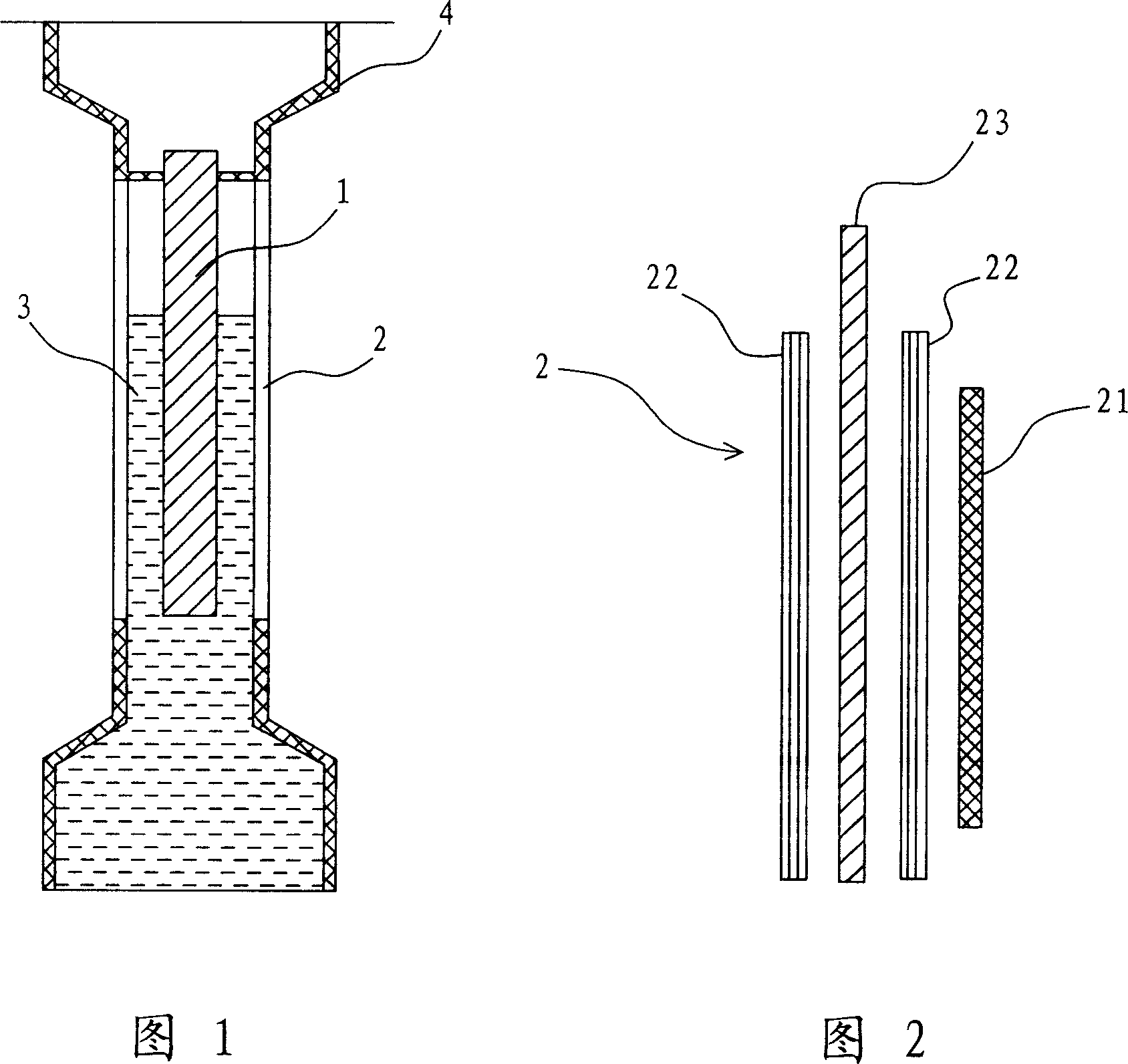

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

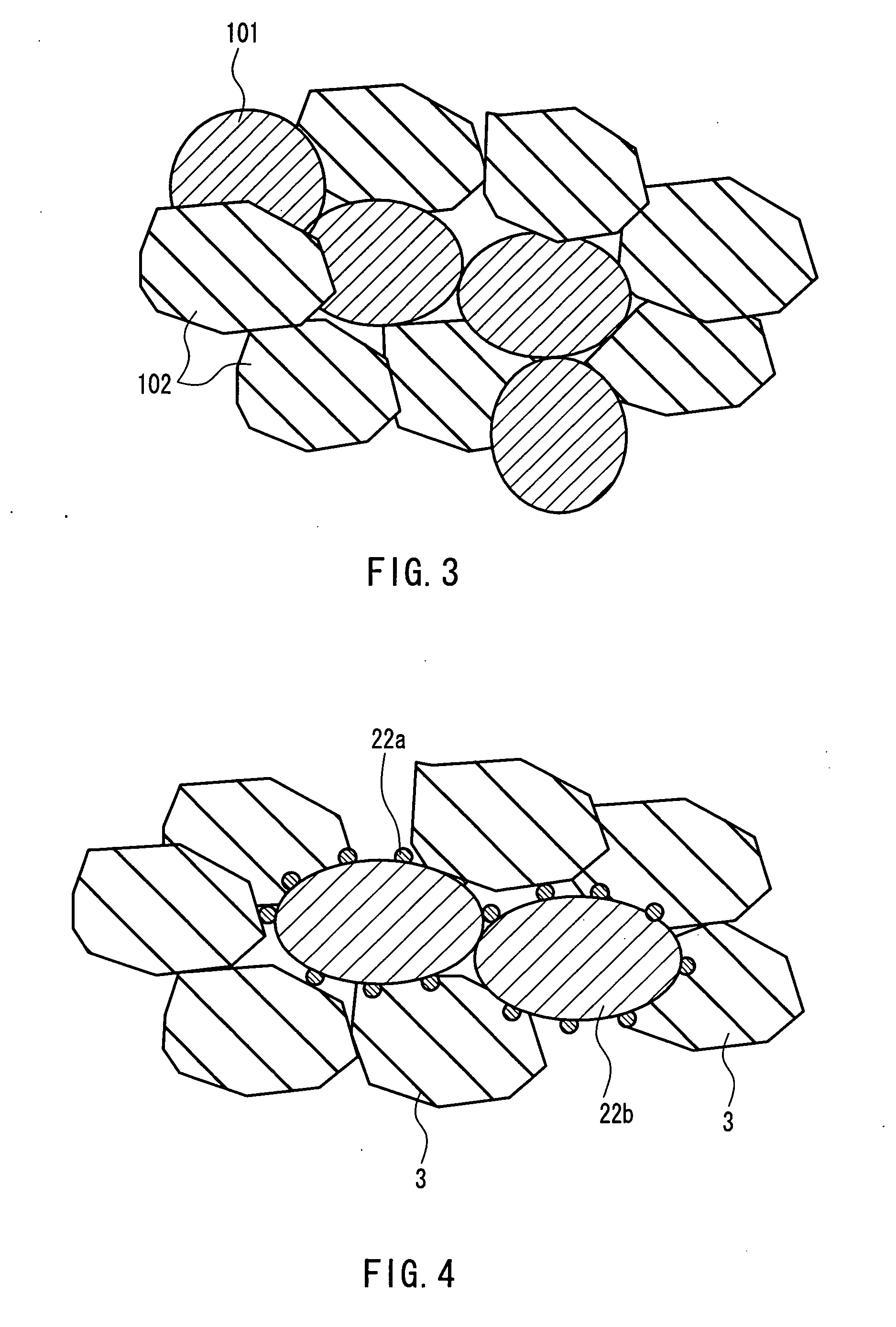

Electrolyte supported cell designed for longer life and higher power

A solid oxide fuel cell (SOFC) includes a cathode electrode, an anode electrode, and a solid oxide electrolyte located between the anode electrode and the cathode electrode. The cathode electrode is a porous ceramic layer infiltrated with a cathode catalyst material, and the anode electrode is a porous ceramic layer infiltrated with an anode catalyst material, and the electrolyte is a ceramic layer having a lower porosity than the anode and the cathode electrodes. A ceramic reinforcing region may be located adjacent to the riser opening in the electrolyte.

Owner:BLOOM ENERGY CORP

Proton exchange membrane fuel cell

A fuel cell system with a proton exchange membrane. There is a cathode catalyst layer overlying the first face of the proton exchange membrane, and a cathode diffusion layer overlying the cathode catalyst layer. There is an anode catalyst layer overlying the second face of the proton exchange membrane, and an anode diffusion layer overlying the anode catalyst layer. The cathode diffusion layer has a water vapor permeance of less than about 3×10−4 g / (Pa s m2) at 80° C. and 1 atmosphere. The invention also relates to cathode diffusion layers for fuel cell systems.

Owner:GM GLOBAL TECH OPERATIONS LLC

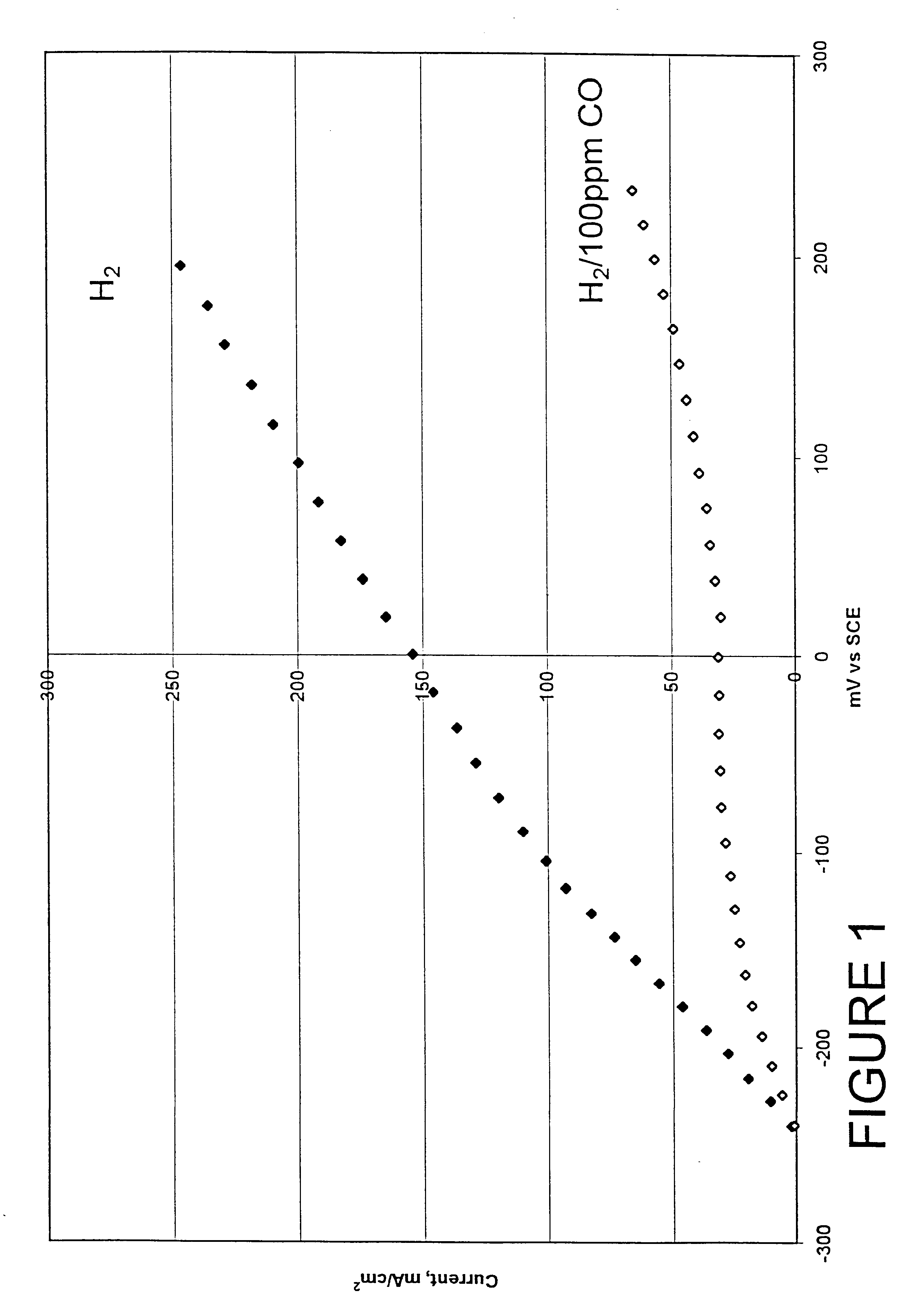

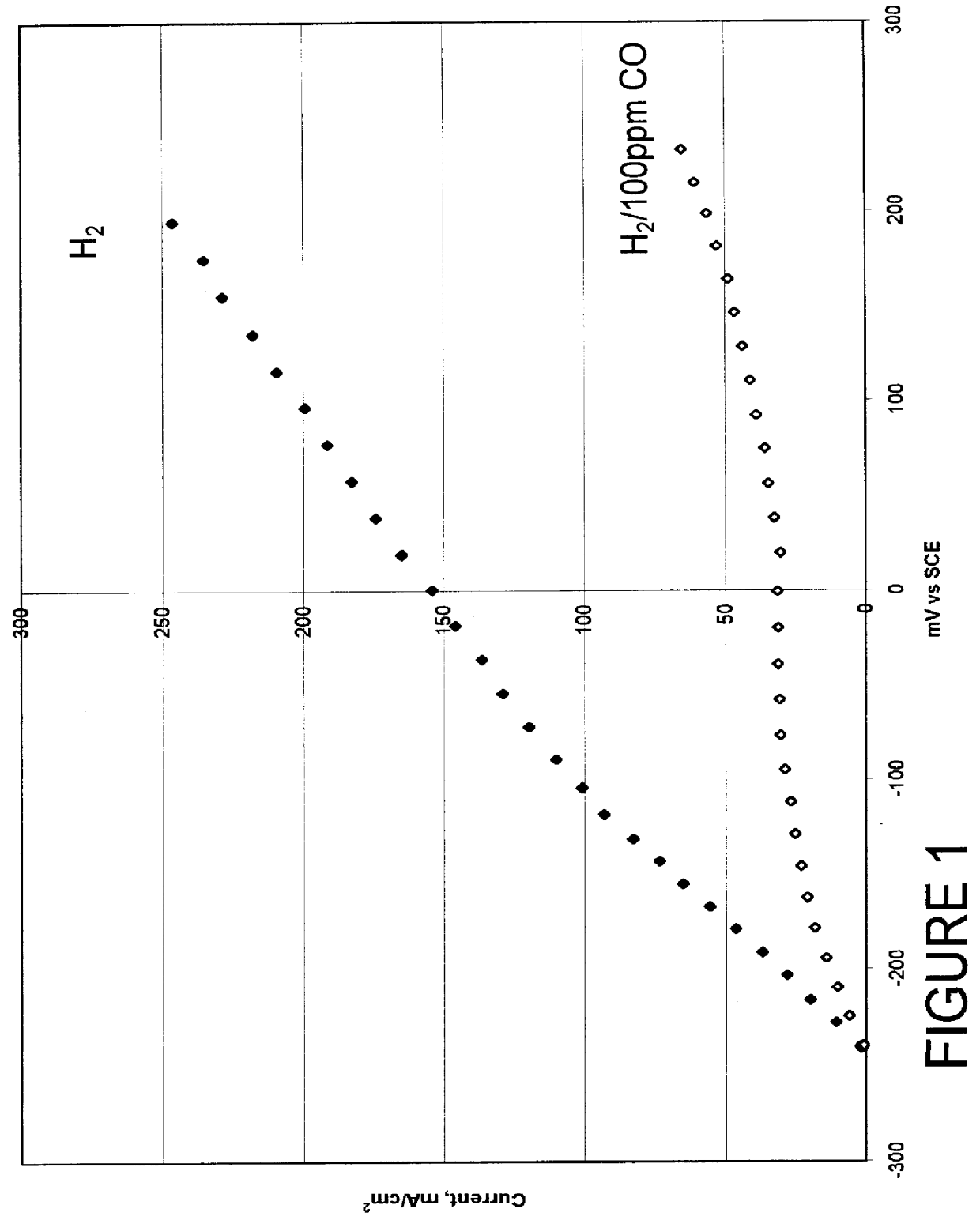

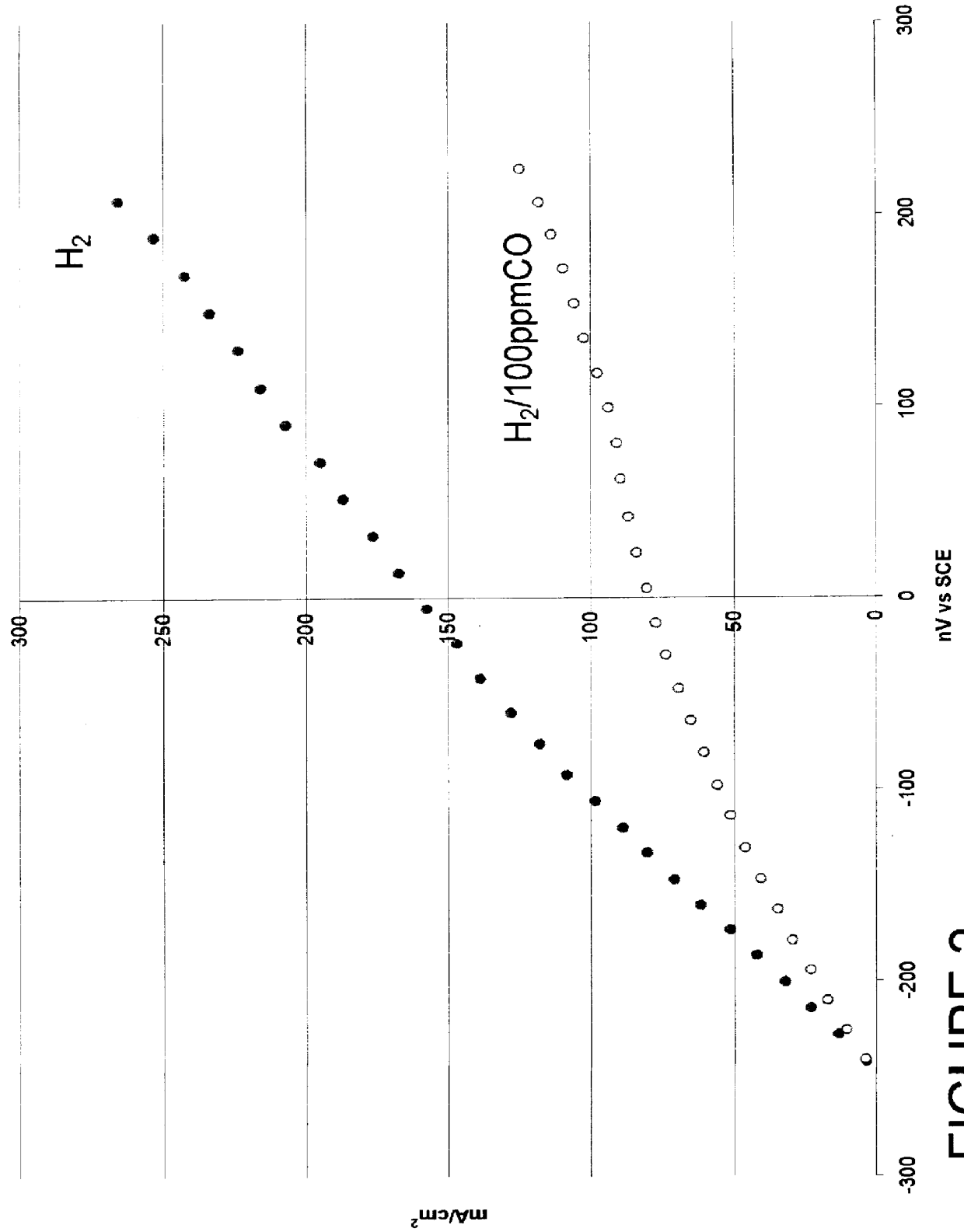

Composition of a selective oxidation catalyst for use in fuel cells

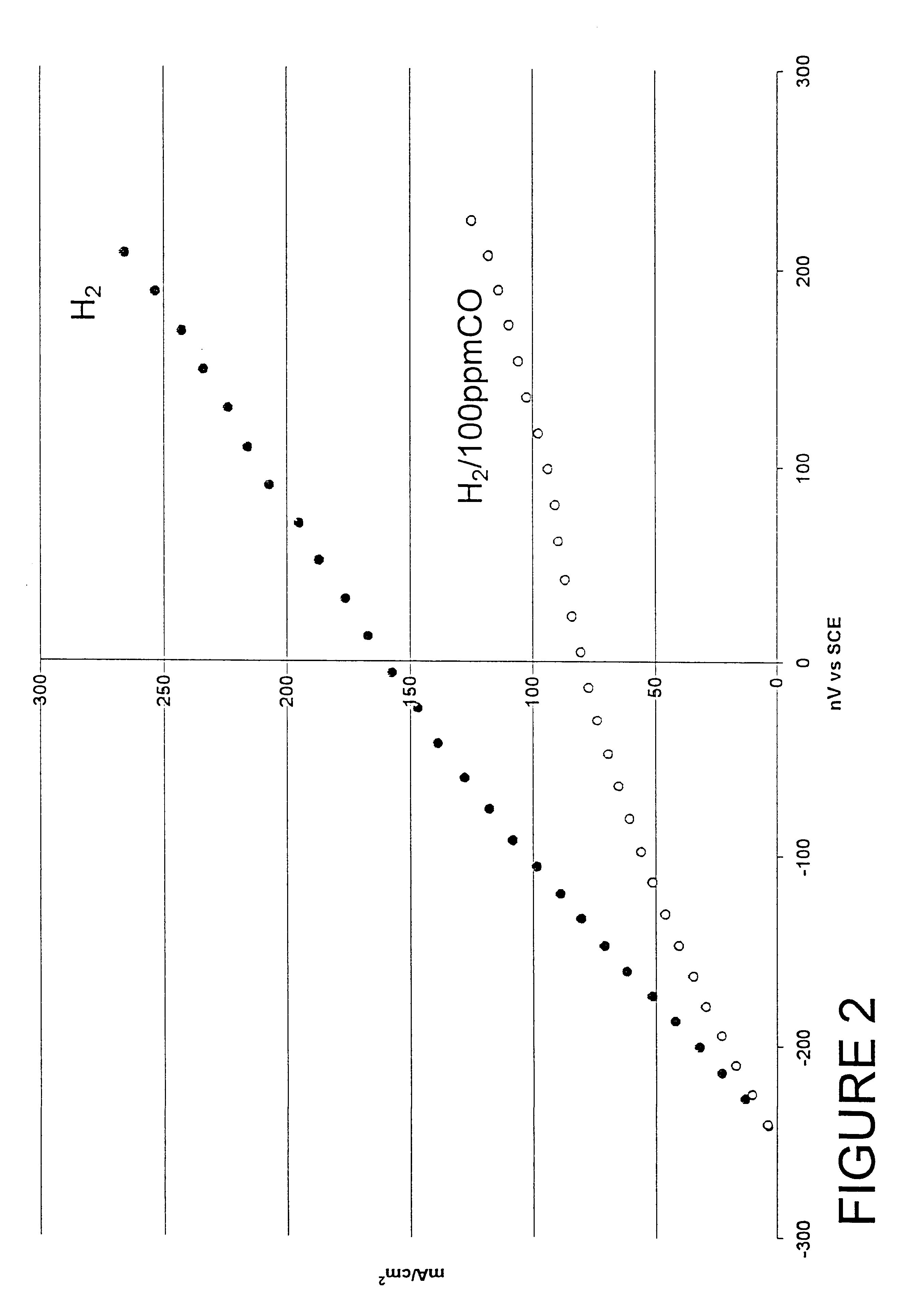

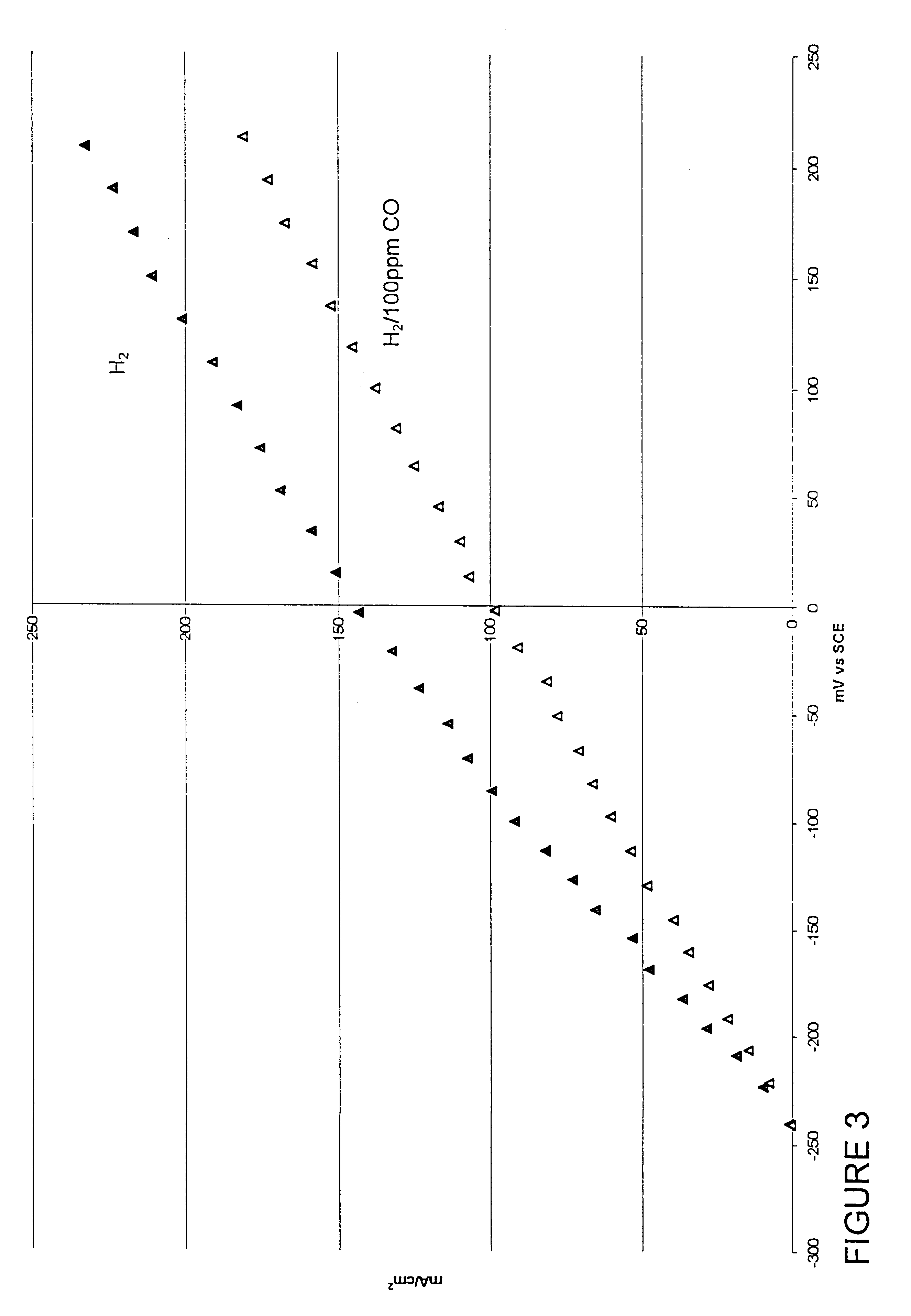

This invention pertains to improved formulations of platinum-molybdenum alloys for use as anode catalysts. These electrocatalysts find utility as a constituent of gas diffusion electrodes for use in fuel cells that operate at less than 180° C. or in applications whereupon hydrogen is oxidized in the presence of carbon monoxide or other platinum inhibiting substances. The new formulations derive unexpected activity through creating highly dispersed alloy particles of up to approximately 300 Å on carbon supports. The desired activity is achieved by carefully controlling the platinum to molybdenum ratio during preparation and judiciously selecting a proper loading of alloy on the carbon support.

Owner:PEMEAS

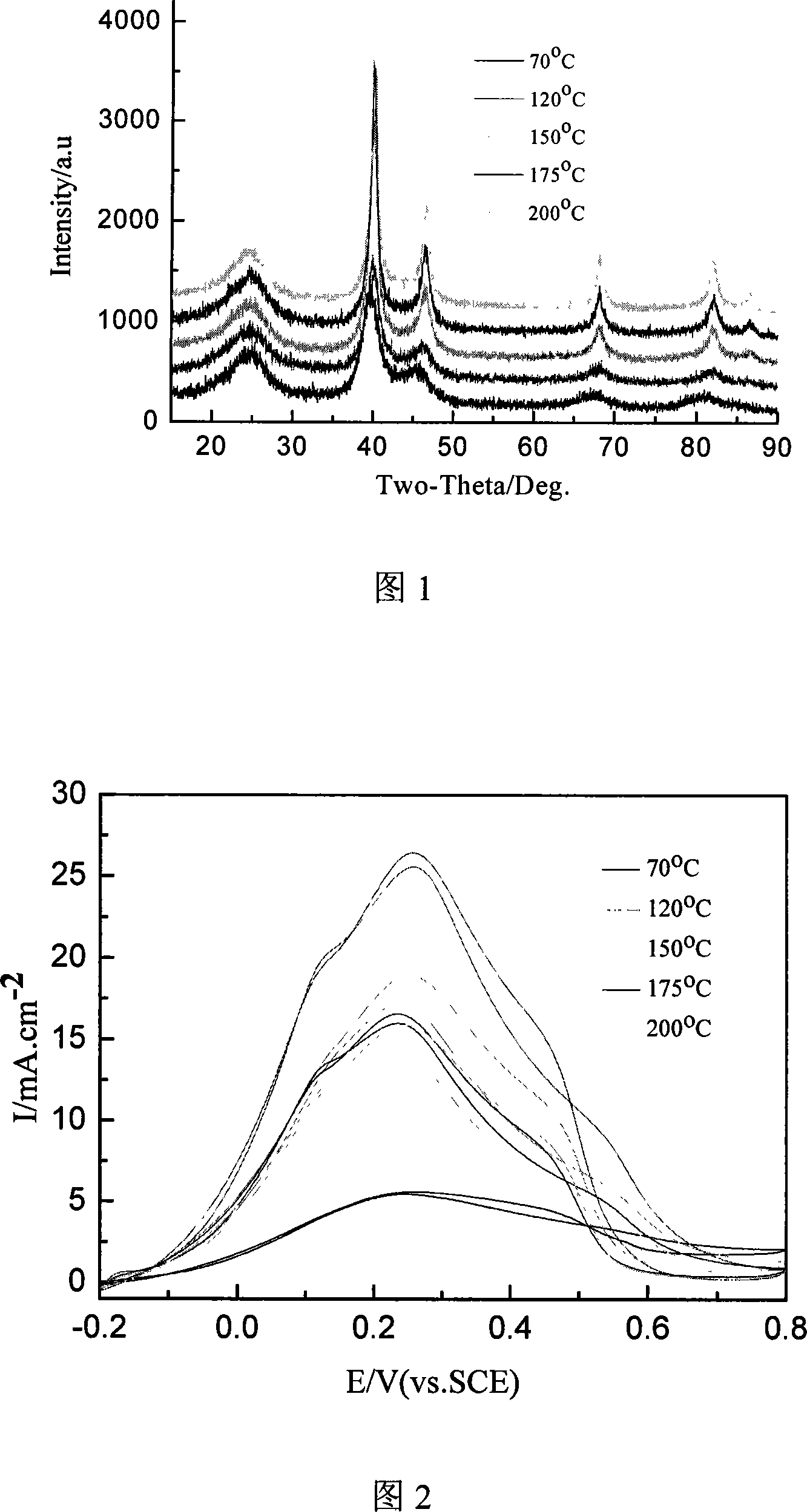

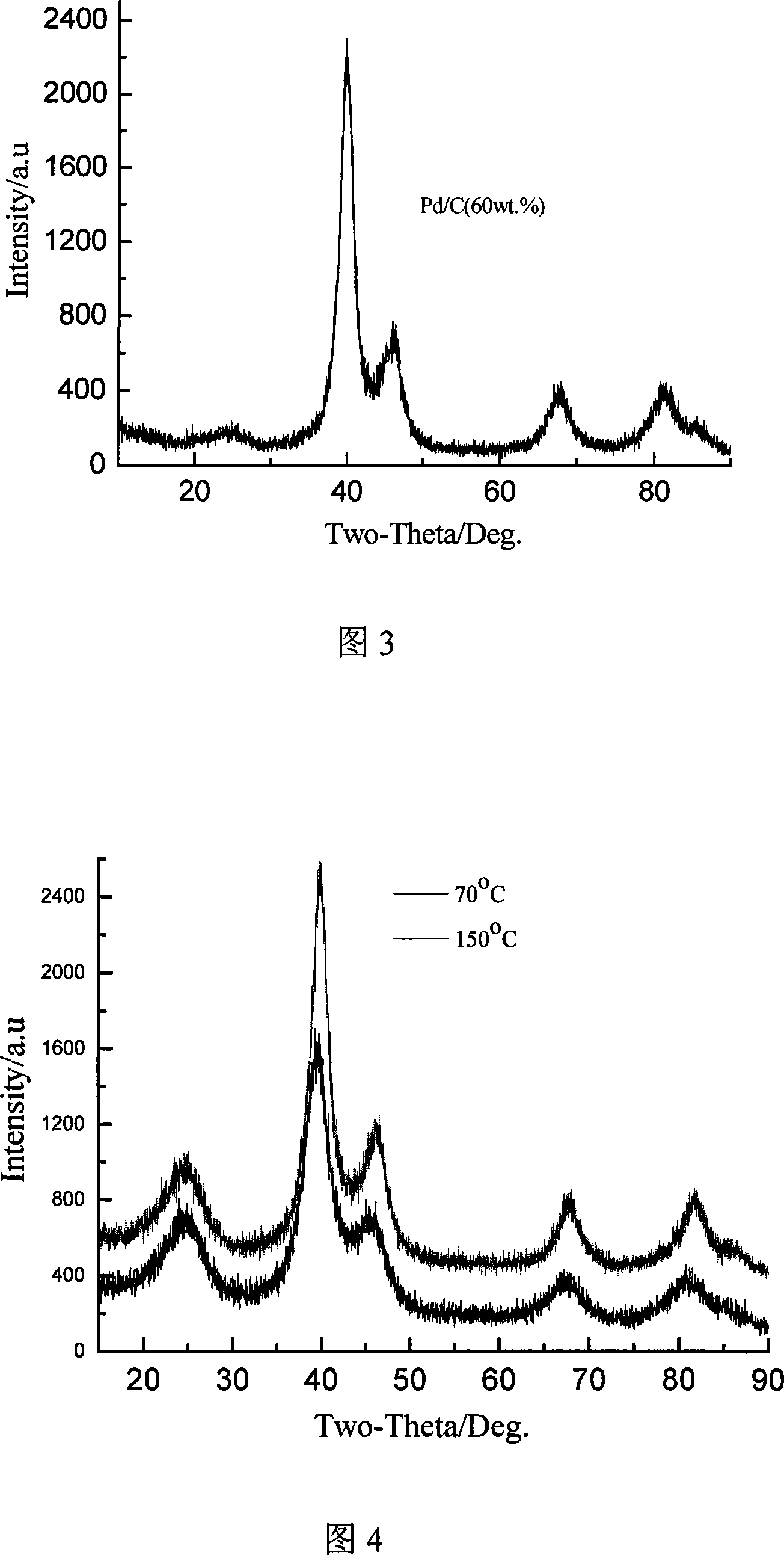

Method for preparing nano-Pd or Pd platinum alloy electrocatalyst for fuel cell

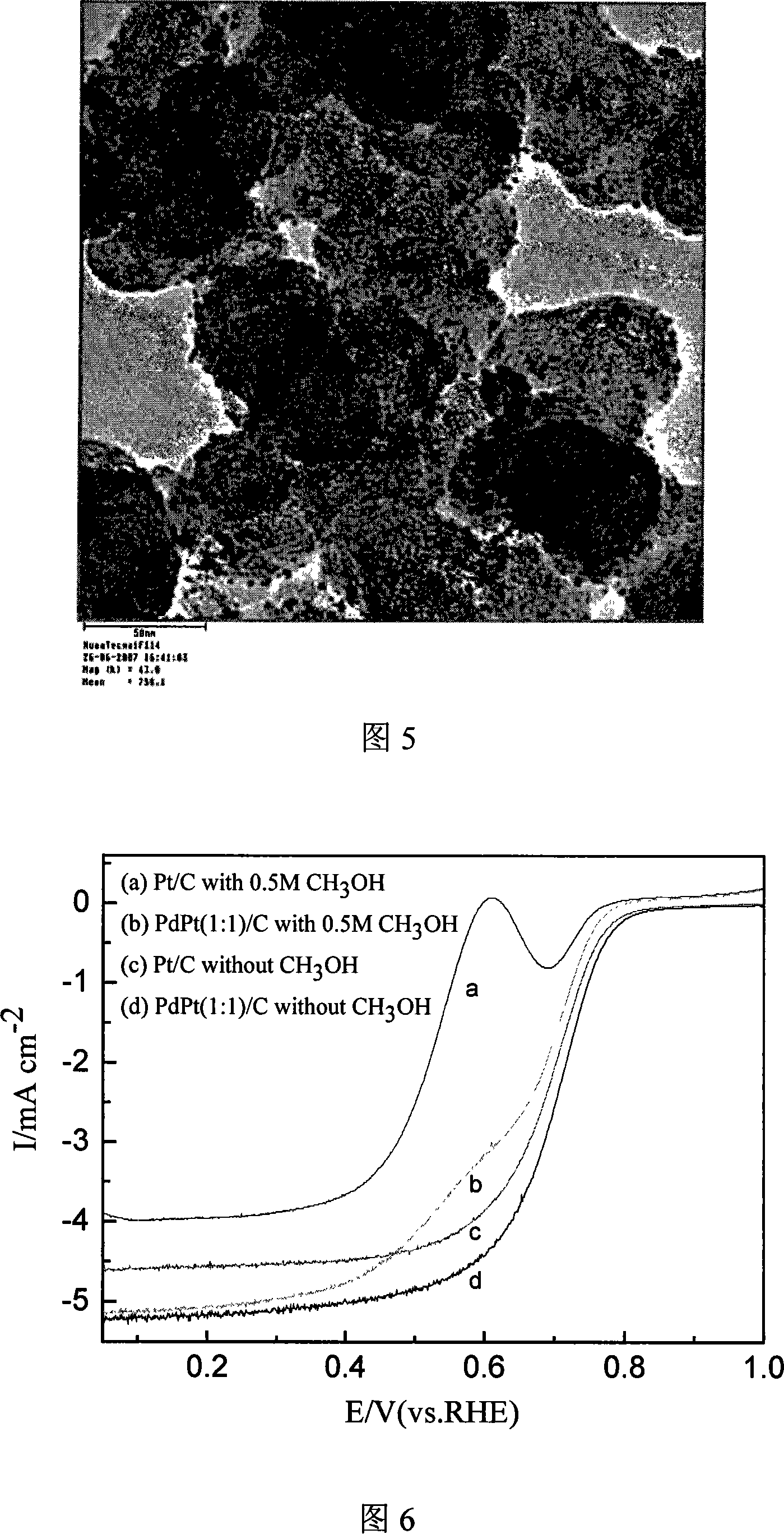

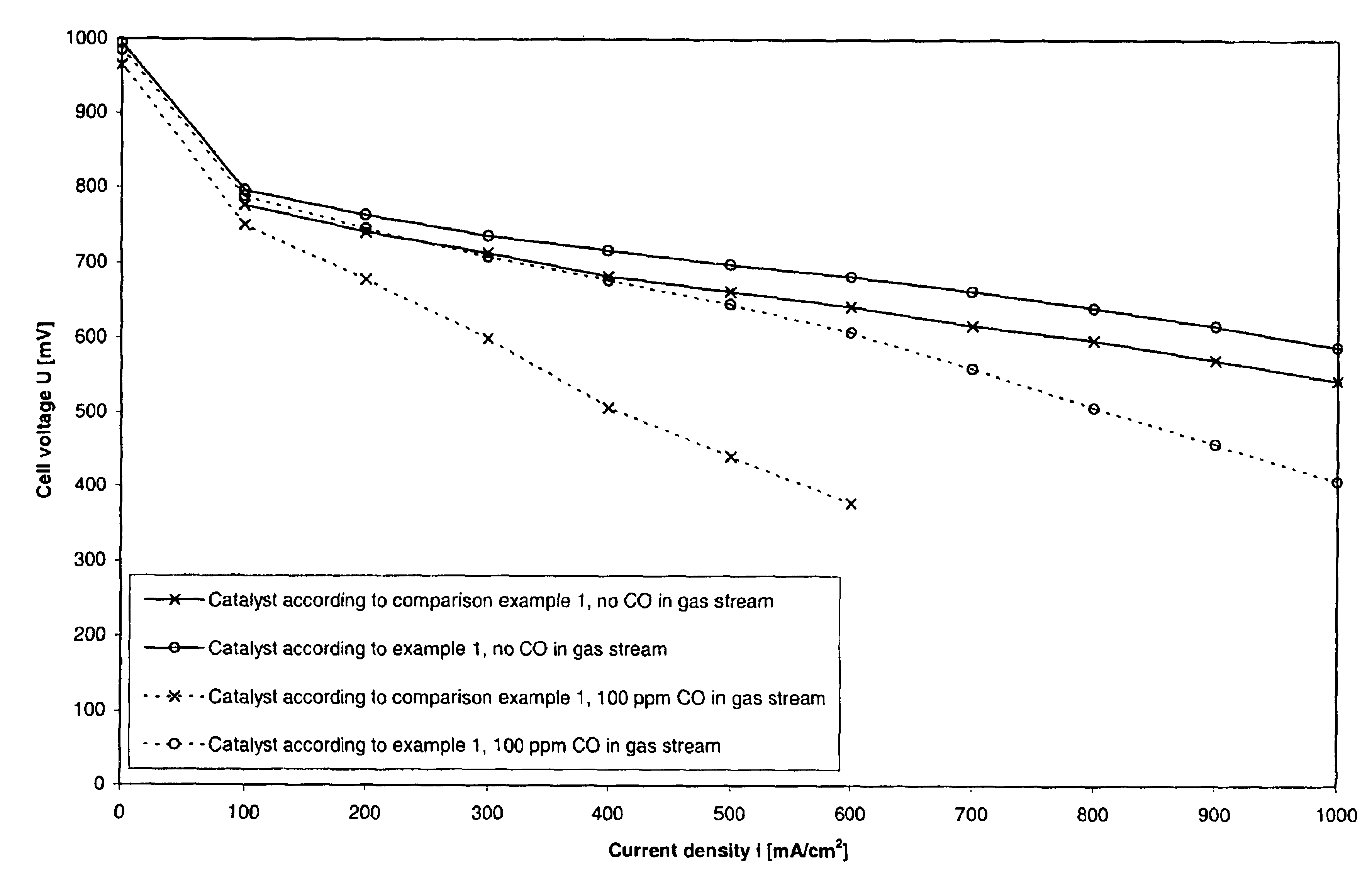

InactiveCN101083325ANarrow particle size distributionSimple methodCell electrodesCatalyst activation/preparationPlatinum saltsHydrazine compound

The invention relates to a preparation method of a nanometer Pd or the Pd platinum gold electrocatalysis catalyzer which is used in a kind of fuel cell, whose characteristic lies in that dissolve the mixture of the ration Pd salt or the Pd salt and the platinum salt (in which the Pd atomic ratio accounts for metal quantity 10-100%) in the water, after joining the right amount complexing agent solution, elevates temperature to 0-80deg.C and keeps the temperature 5 minutes to 8 hours, then cooling to the room temperature, adjusts the pH value to 5 to 12 and adds the carbon carrier, then adds the solution of hydroboration sodium, hydrazine or formic acid and so on reducing agent under the 0 to 80deg.C , and maintains 10 minutes to 10 hours, then filtrating, laundering, dry, finally in inert atmosphere or reducing atmosphere through 100 to 300deg.C heat treatment in 0.5 to 10h, namely carries the carbon Pd or the Pd platinum electrocatalysis. The particle size of catalyst is controllable, adjustable, the composition is controllable, regards the heat treatment temperature to be different, the particle size which obtains is relatively 1.8nm to 20nm above, and the granule distribution is narrow, is suitable to serve as the direct formic acid fuel cell anode catalyst as well as the direct methanol fuel cell anti-methyl alcohol negative pole catalyst.

Owner:上海新微科技集团有限公司 +1

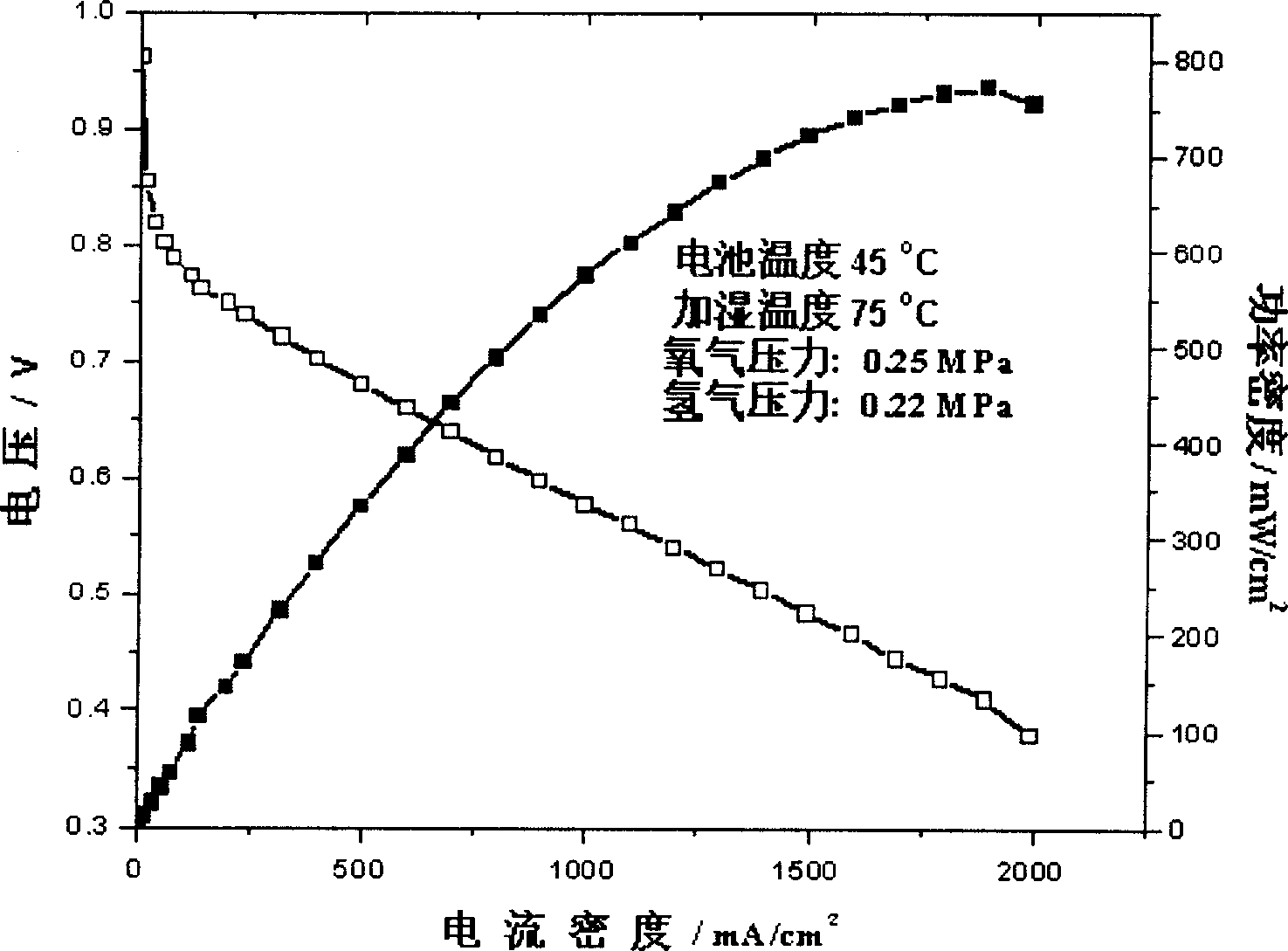

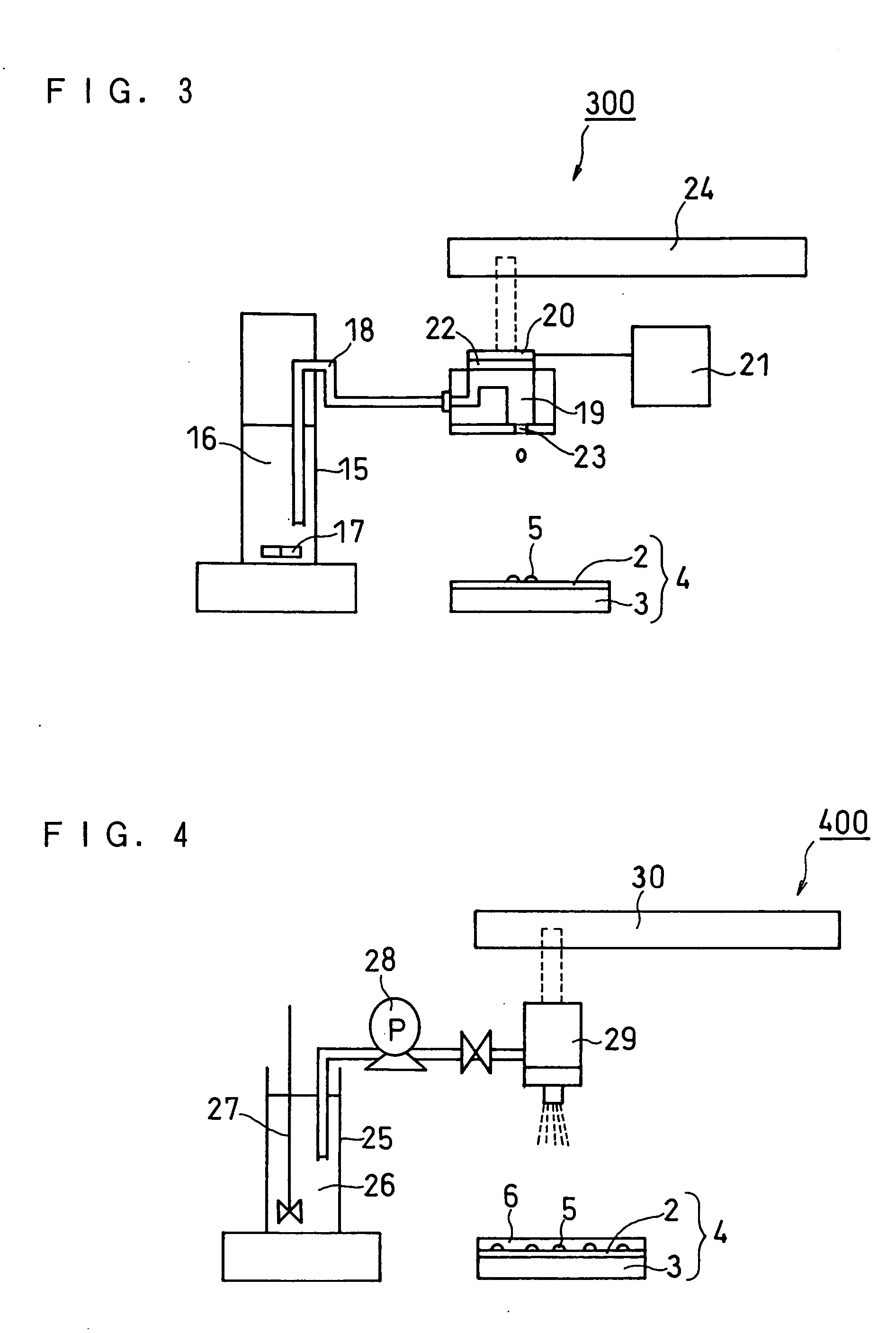

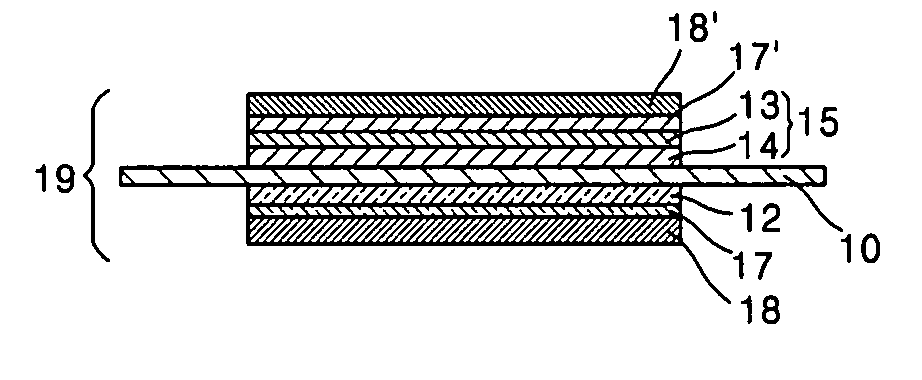

Process for preparing an anode catalyst for fuel cells and the anode catalyst prepared therewith

InactiveUS6797667B2High activityHigh oxidation stateActive material electrodesCatalyst activation/preparationCarboxylic acidRuthenium chloride

The invention provides a process for preparing a platinum-ruthenium catalyst and the catalyst prepared therewith. The catalyst can be supported on a support material in powder form or may also be unsupported. To prepare the supported catalyst, the support material is suspended in water and the suspension is heated to at most the boiling point. While keeping the temperature of the suspension the same, solutions of hexachloroplatinic acid and ruthenium chloride are then added to the suspension, then the pH of the suspension is increased to a value between 6.5 and 10 by adding an alkaline solution and the noble metals are thus precipitated onto the support material. Afterwards, one or more organic carboxylic acids and / or their salts are added to the suspension and the catalyst is chemically reduced, washed, dried and optionally subsequently calcined under an inert or reducing atmosphere at a temperature between 300 und 1000° C. The catalyst is characterised by a high tolerance to carbon monoxide poisoning in the fuel cell.

Owner:UMICORE AG & CO KG

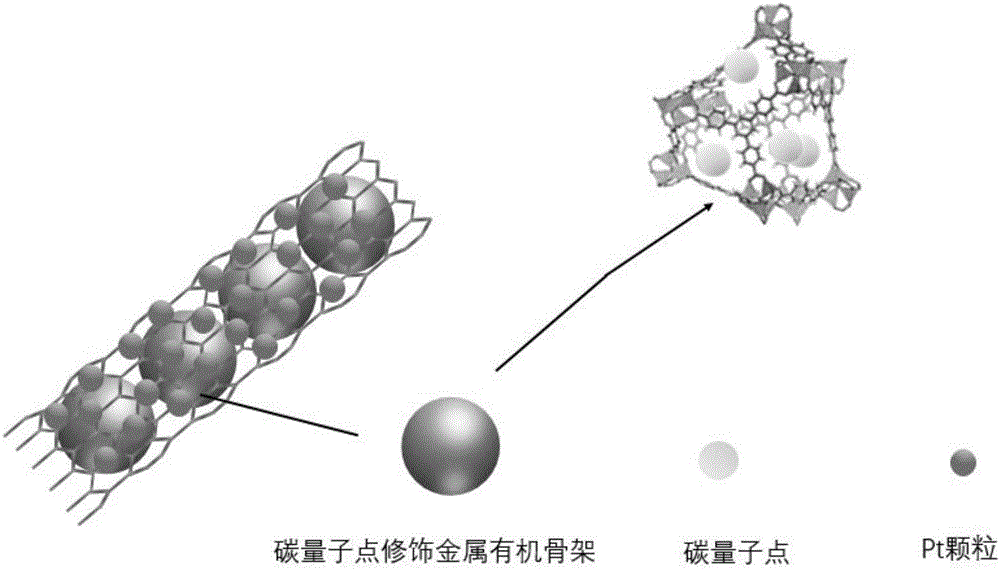

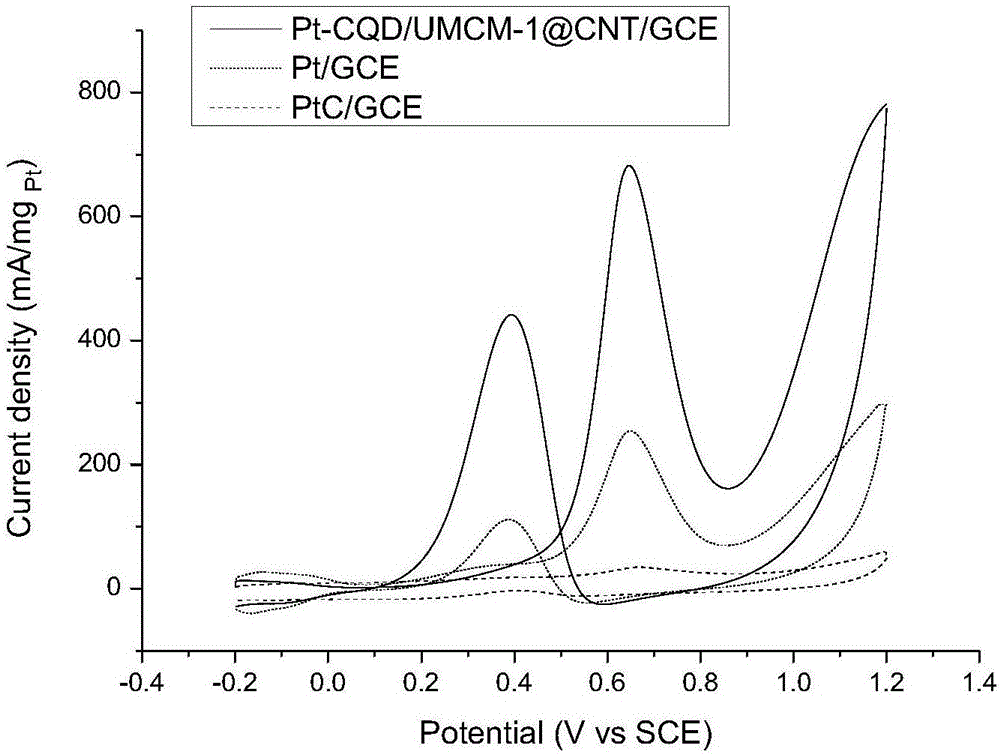

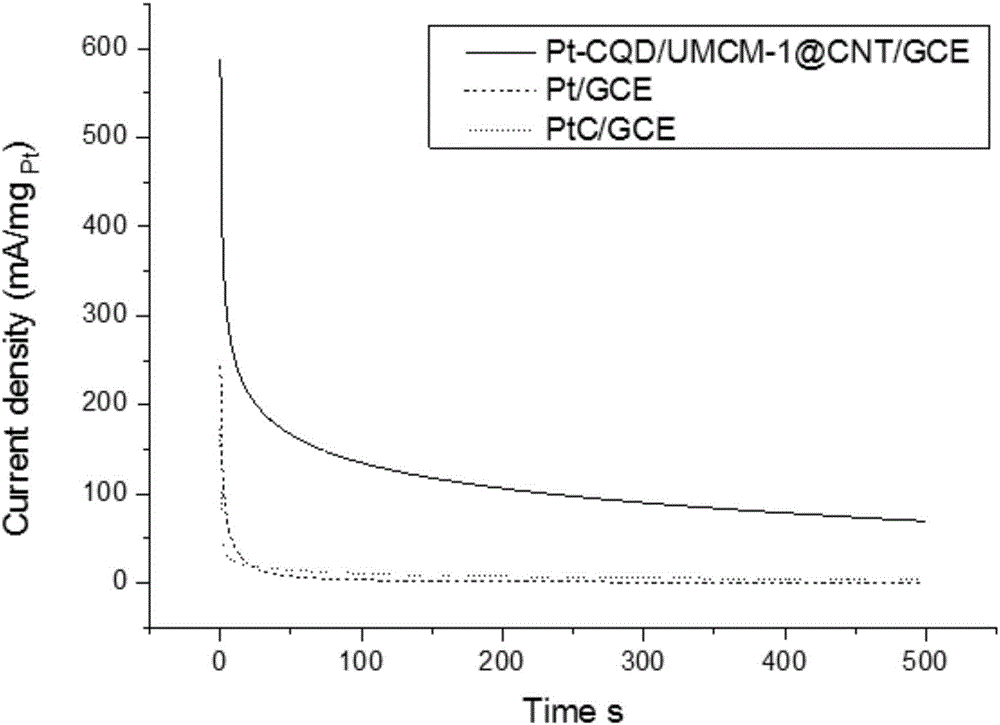

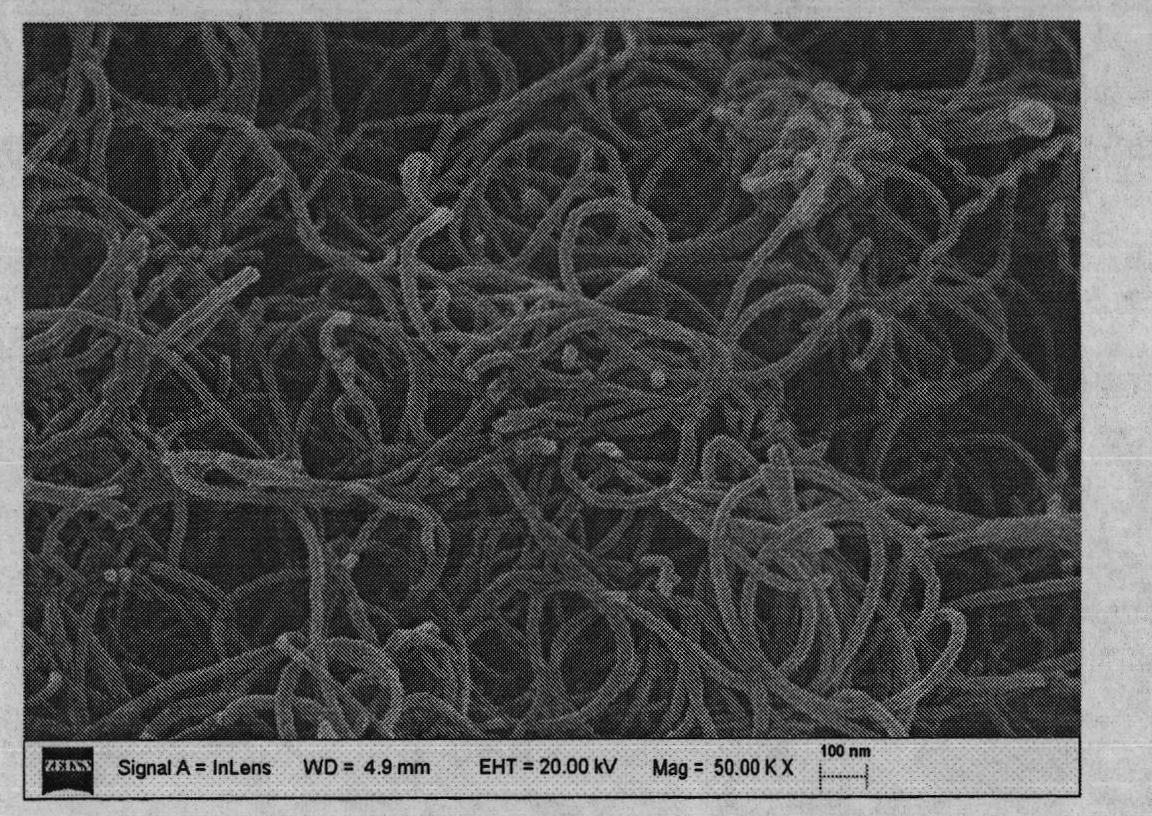

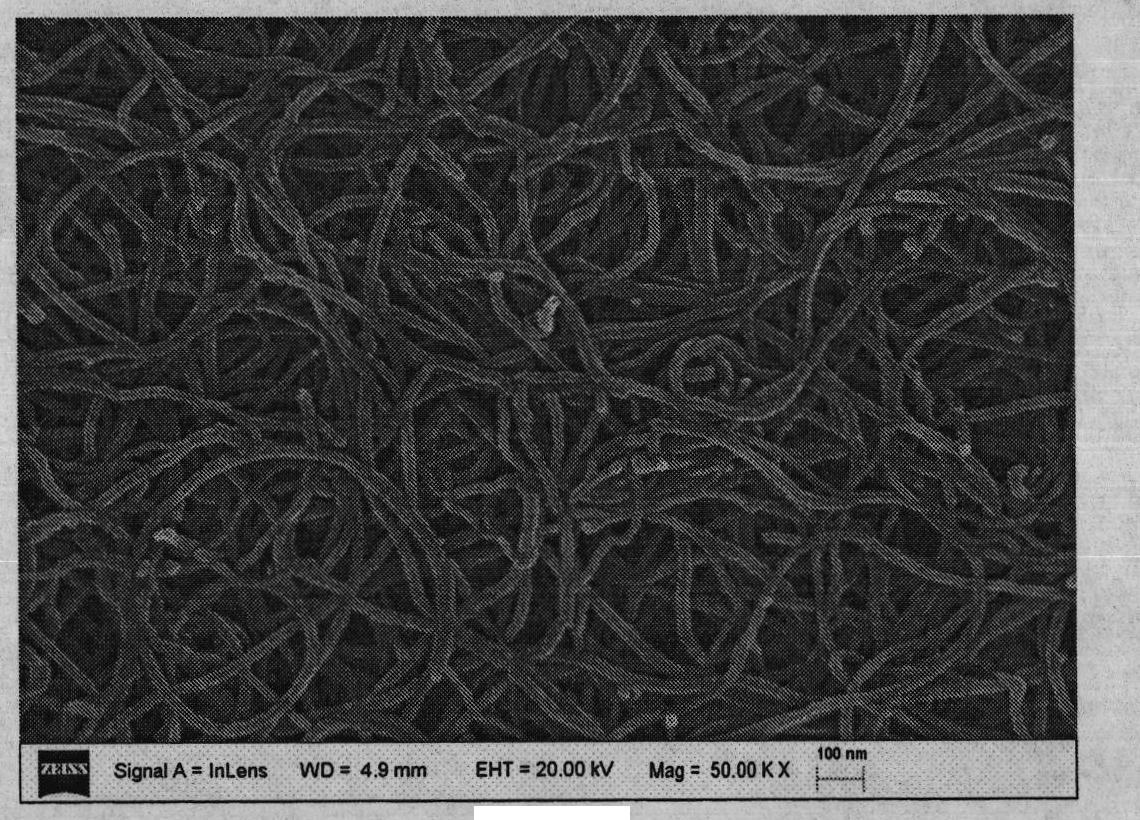

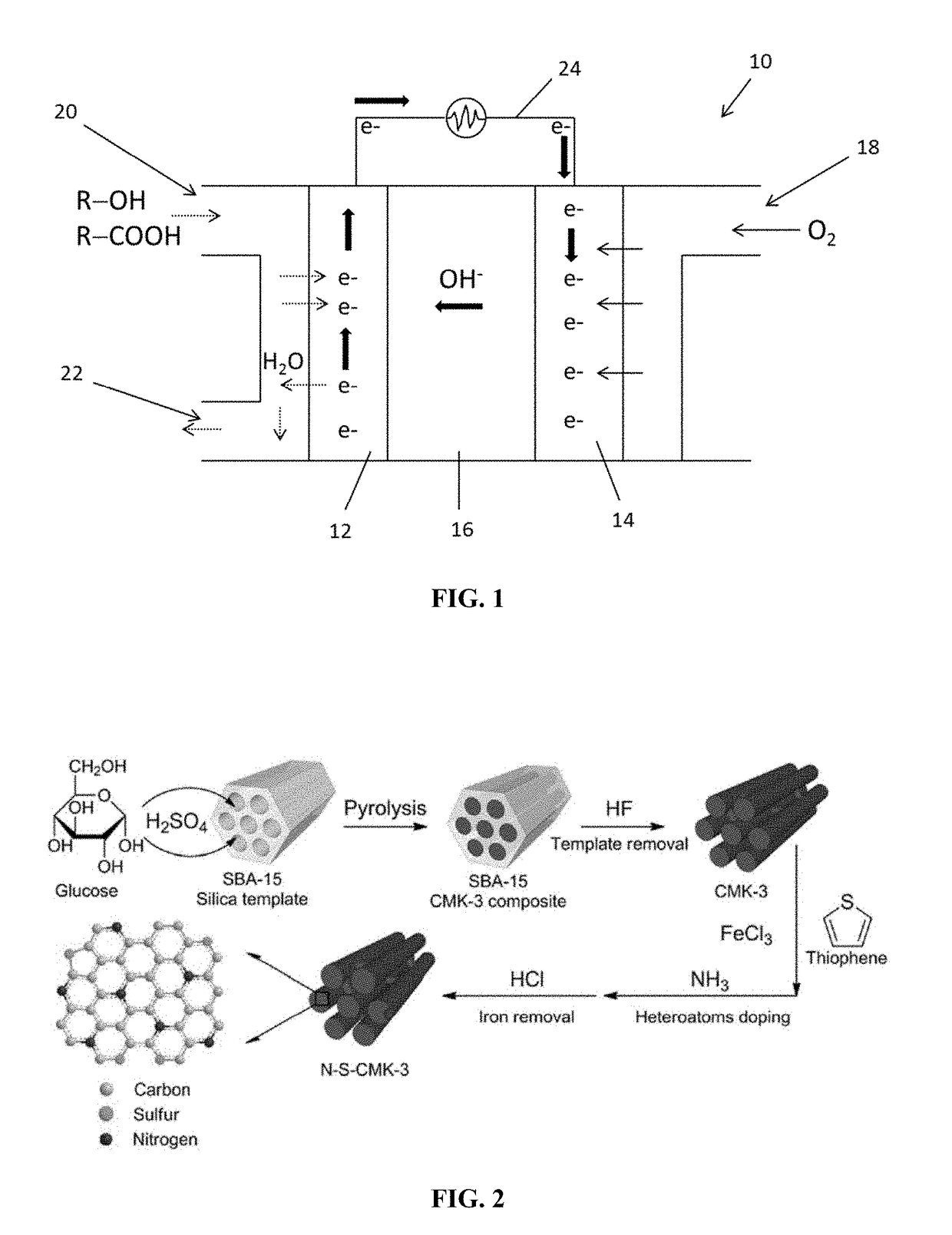

Preparation of carbon nanotube material embedded with quantum-dot modified metal organic framework

The invention provides preparation of a carbon nanotube material embedded with a quantum-dot modified metal organic framework. The preparation comprises the following steps of firstly, adding a certain amount of powder quantum dots to a formed metal organic framework precursor solvent so that the quantum dots of which the diameters are matched with the sizes of pore passages are embedded into the pore passages of the formed metal organic framework; secondly, uniformly mixing the obtained quantum-dot modified metal organic framework and melamine powder, and performing high-temperature processing to obtain a composite material (QD / UMCM-1@CNT) in a carbon nanotube embedded with the quantum-dot modified metal organic framework; and finally, enabling Pt to be loaded on a surface of the composite material carbon nanotube (Pt / QD / UMCM-1@CNT) by microwave radiation heating to be used as a positive electrode catalyst of a methanol fuel cell. Compared with a traditional hydrothermal method for synthesis of the carbon nanotube, the quantum-dot modified metal organic framework obtained by high-temperature processing is embedded into the composite material in the carbon nanotube, the structural aspects such as the length and the diameter of the carbon nanotube are more consistent, and a catalyst substrate with a unified structure is easier to form.

Owner:QINGDAO UNIV

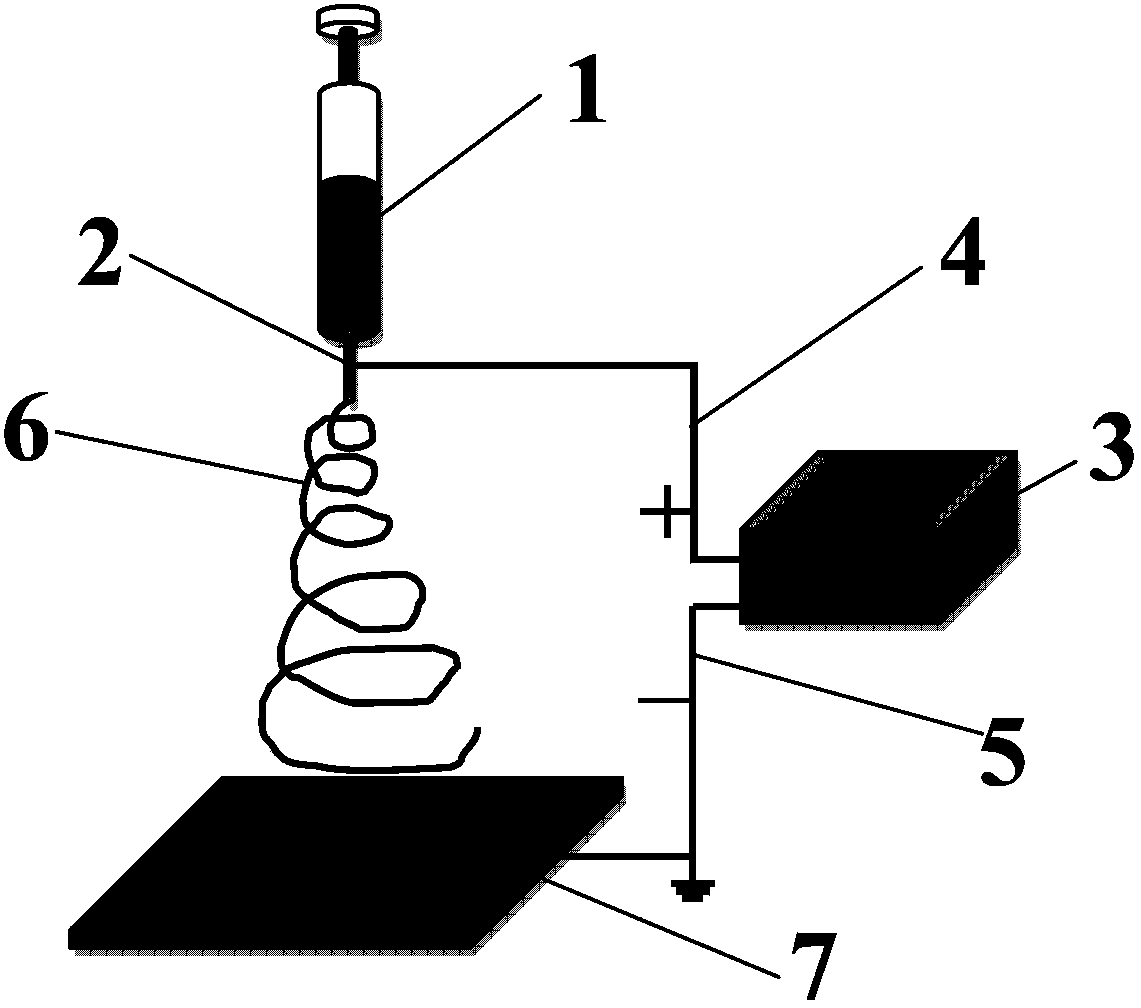

Direct spraying method for preparing fuel cell membrane electrode

InactiveCN1838456AEasy to operateEasy to storeLiquid surface applicatorsCell electrodesPhysical chemistryIon-exchange membranes

This invention discloses a directly spraying to make fuel cell film electrode method, which mainly provides a film electrode method in which the electrode is unknit, catalyst layer is uniform, no swelling deforming, and the electrode output energy density is high. The method includes the following steps: preprocessing the ion exchange membrane firstly, then fixing it in a film fixing equipment, and then spraying cathodic and anodic catalyst paste onto the two sides of the ion exchange membrane, at last drying under lower temperature in vacuum. This invention is fit for the membrane electrode of the ion exchange membrane preparation filed.

Owner:SOUTH CHINA UNIV OF TECH

Composition of a selective oxidation catalyst for use in fuel cells

This invention pertains to improved formulations of platinum-molybdenum alloys for use as anode catalysts. These electrocatalysts find utility as a constituent of gas diffusion electrodes for use in fuel cells that operate at less than 180 DEG C. or in applications whereupon hydrogen is oxidized in the presence of carbon monoxide or other platinum inhibiting substances. The new formulations derive unexpected activity through creating highly dispersed alloy particles of up to approximately 300 ANGSTROM on carbon supports. The desired activity is achieved by carefully controlling the platinum to molybdenum ratio during preparation and judiciously selecting a proper loading of alloy on the carbon support.

Owner:PEMEAS +1

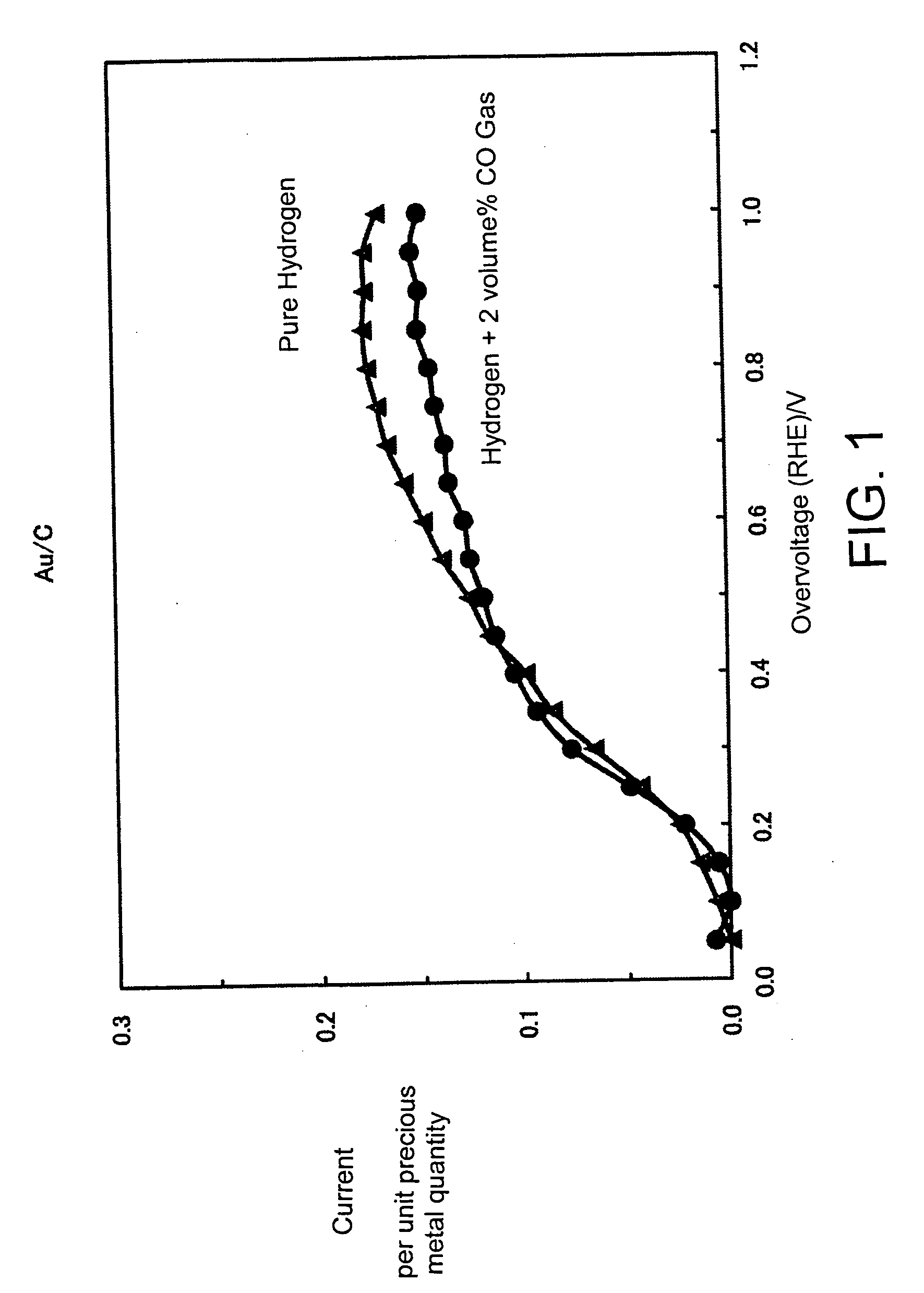

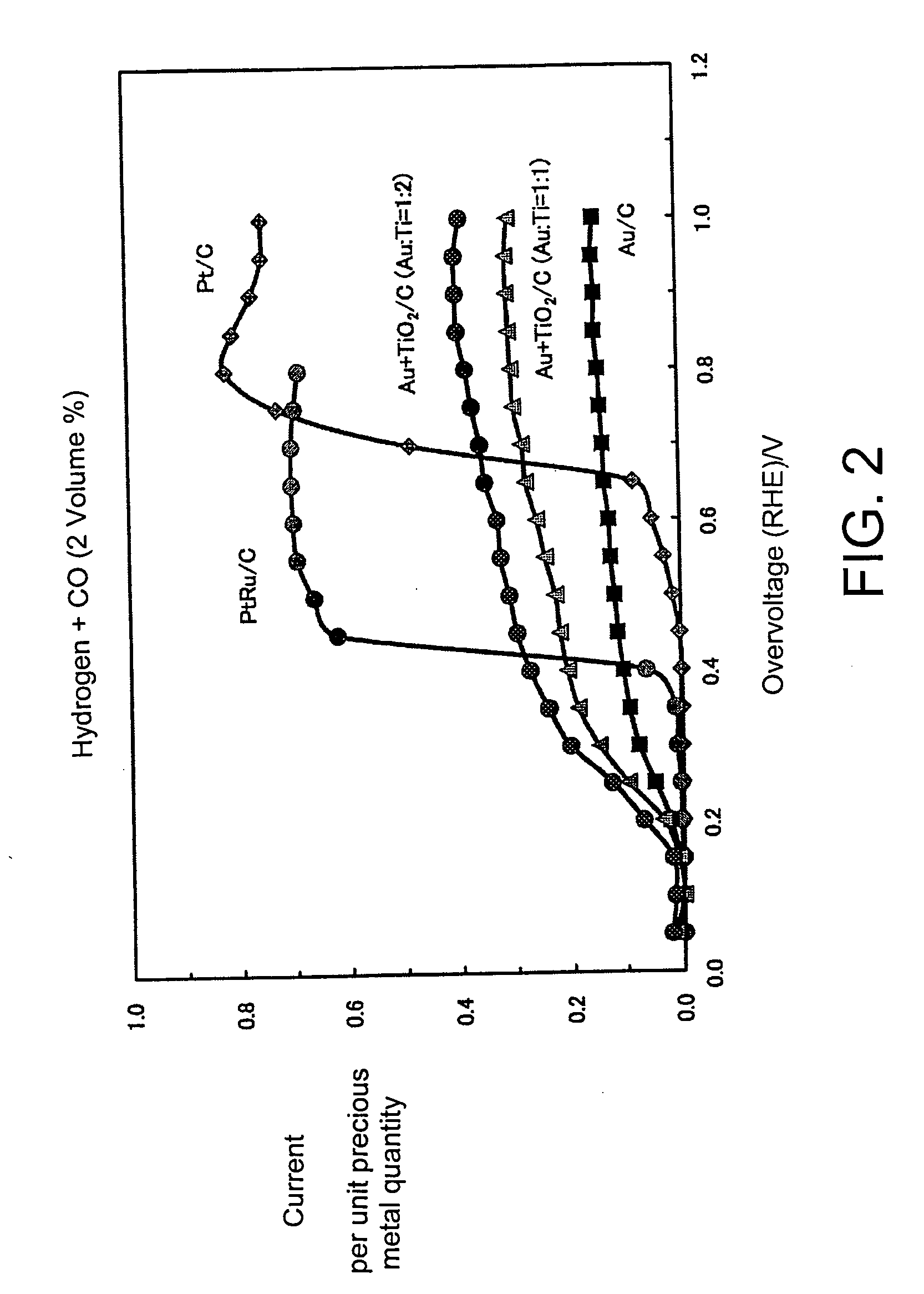

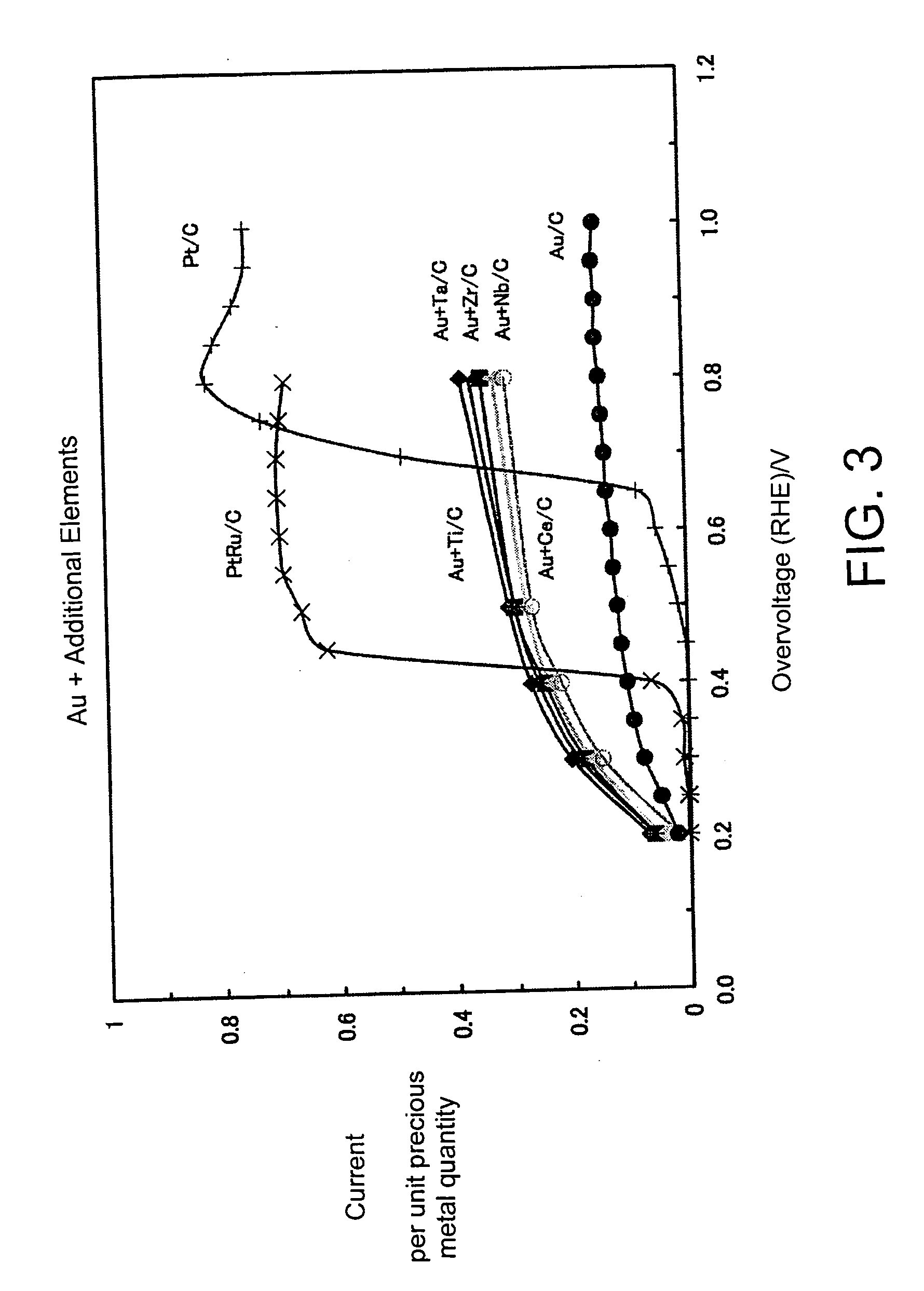

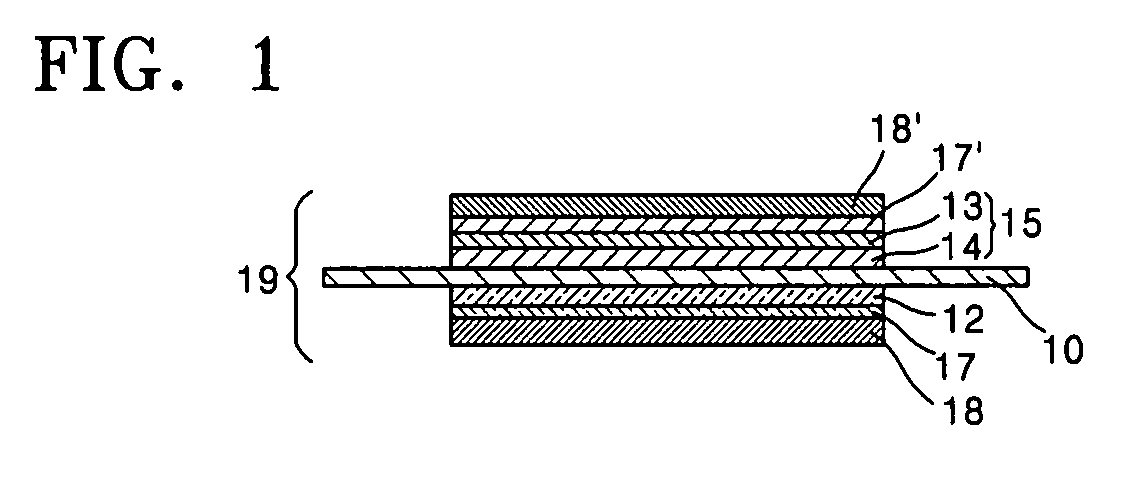

Fuel cell and anode catalyst therefor

InactiveUS20040115515A1High catalytic activityLess expensiveActive material electrodesCatalyst activation/preparationPtru catalystIndium

An anode catalyst contains gold fine particles, and / or at least one member selected from the group consisting of titanium, vanadium, gallium, zirconium, niobium, cerium, tantalum, indium, and the oxides of these metals, and / or at least one member selected from the group consisting of platinum, ruthenium, and ruthenium oxides are coated on a conductive support.

Owner:NAT INST OF ADVANCED IND SCI & TECH

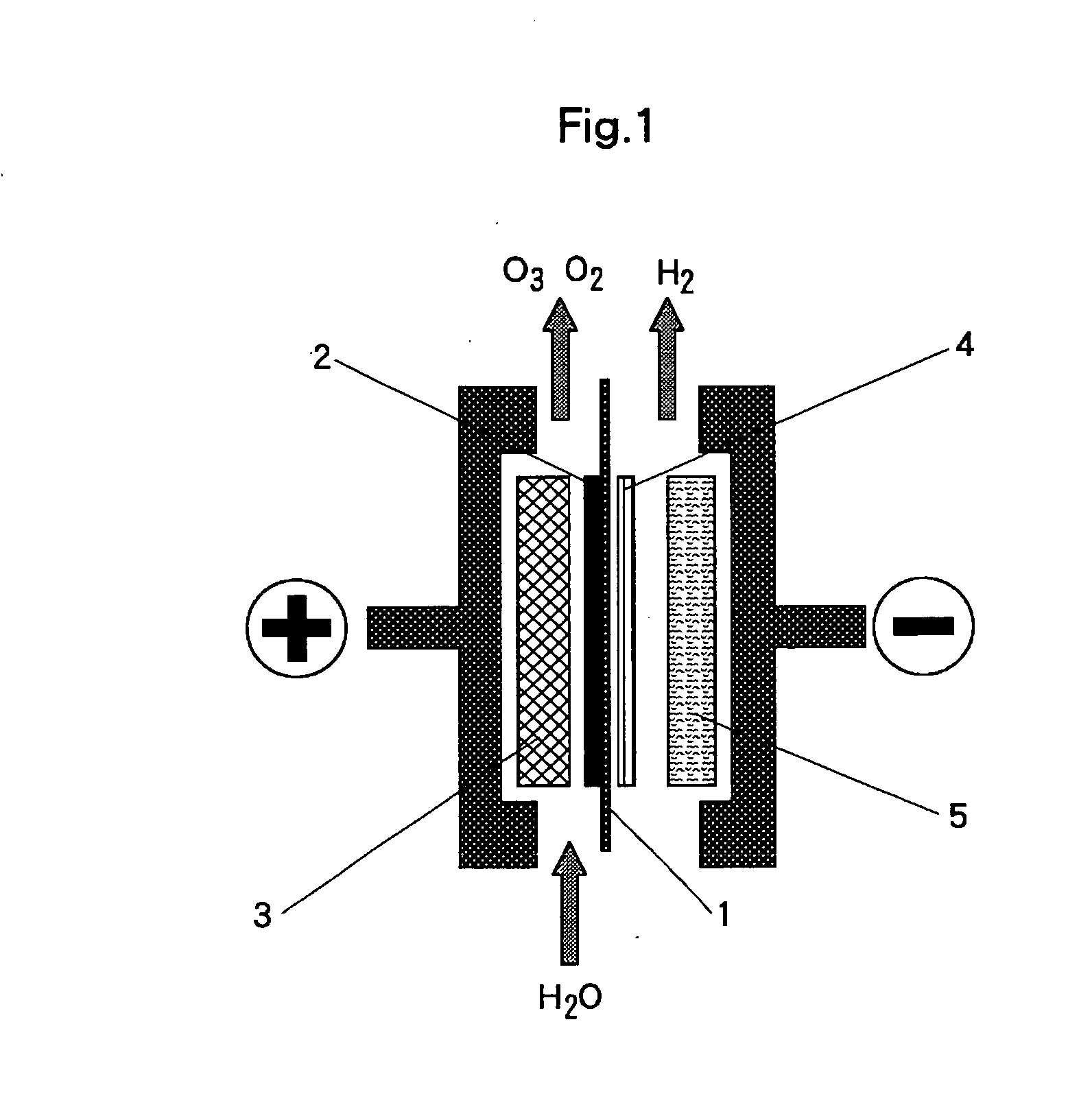

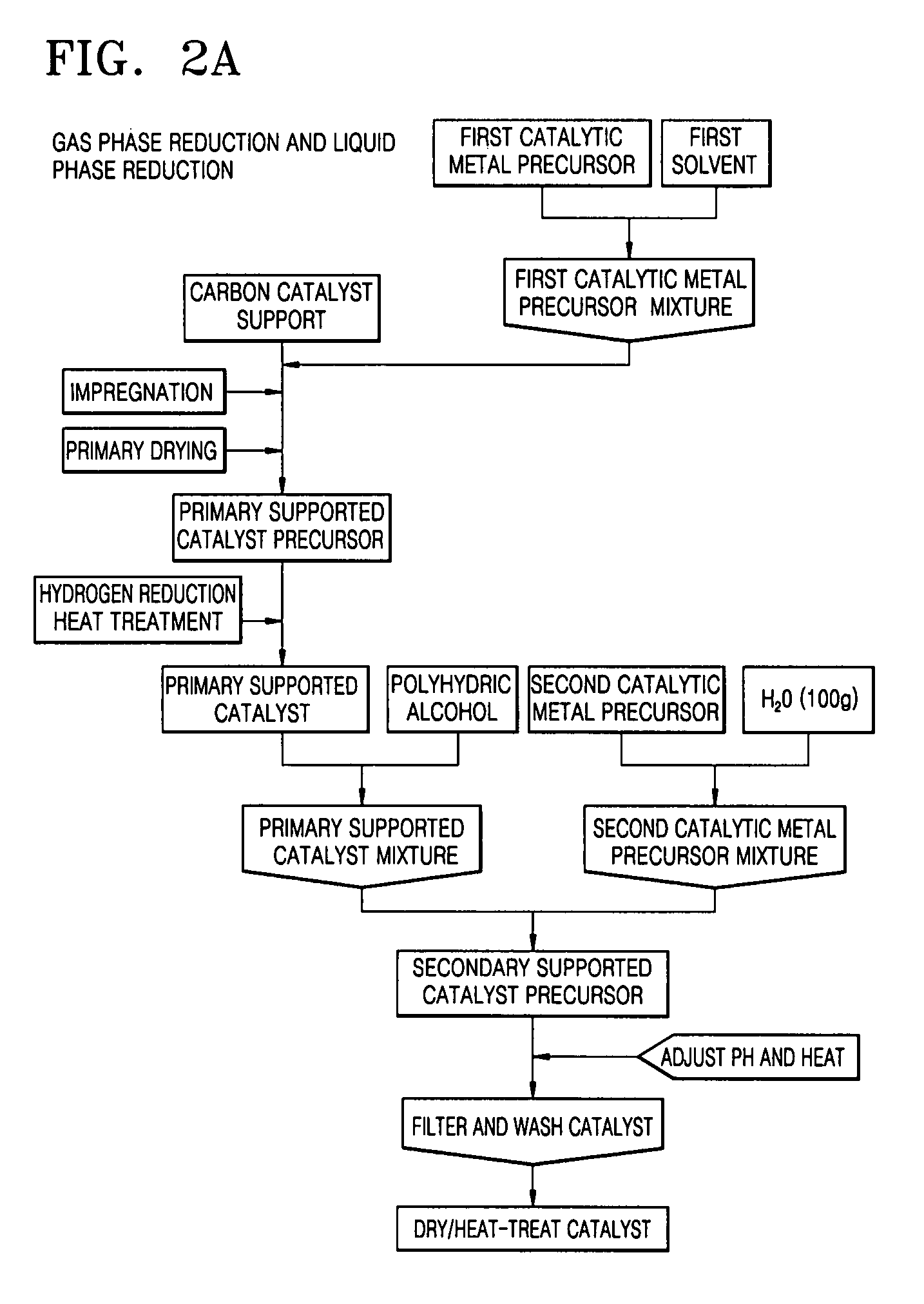

Water electrolysis system

In a water electrolysis system having an anode catalyst layer containing anode catalyst and a cathode catalyst layer containing cathode catalyst tightly attached, respectively, to each surface of a solid polymer electrolyte membrane comprising a cation exchange membrane, wherein at least one catalyst layer of said anode catalyst layer and cathode catalyst layer comprises a porous structure of anode catalyst or cathode catalyst dispersed in fluorine resin containing resin, featuring the surface of the anode catalyst layer or the cathode catalyst layer being hydrophobized and the water contact angle with the surface of the anode catalyst layer or the cathode catalyst layer of said porous structure being 90 degrees or more, whereby the transfer of gas to the counter electrode can be significantly suppressed, gas purity and current efficiency be improved, and safety operation of the electrolysis system be secured, without a major change in configuration of the water electrolysis system.

Owner:CHLORINE ENGINEERS CORP LTD

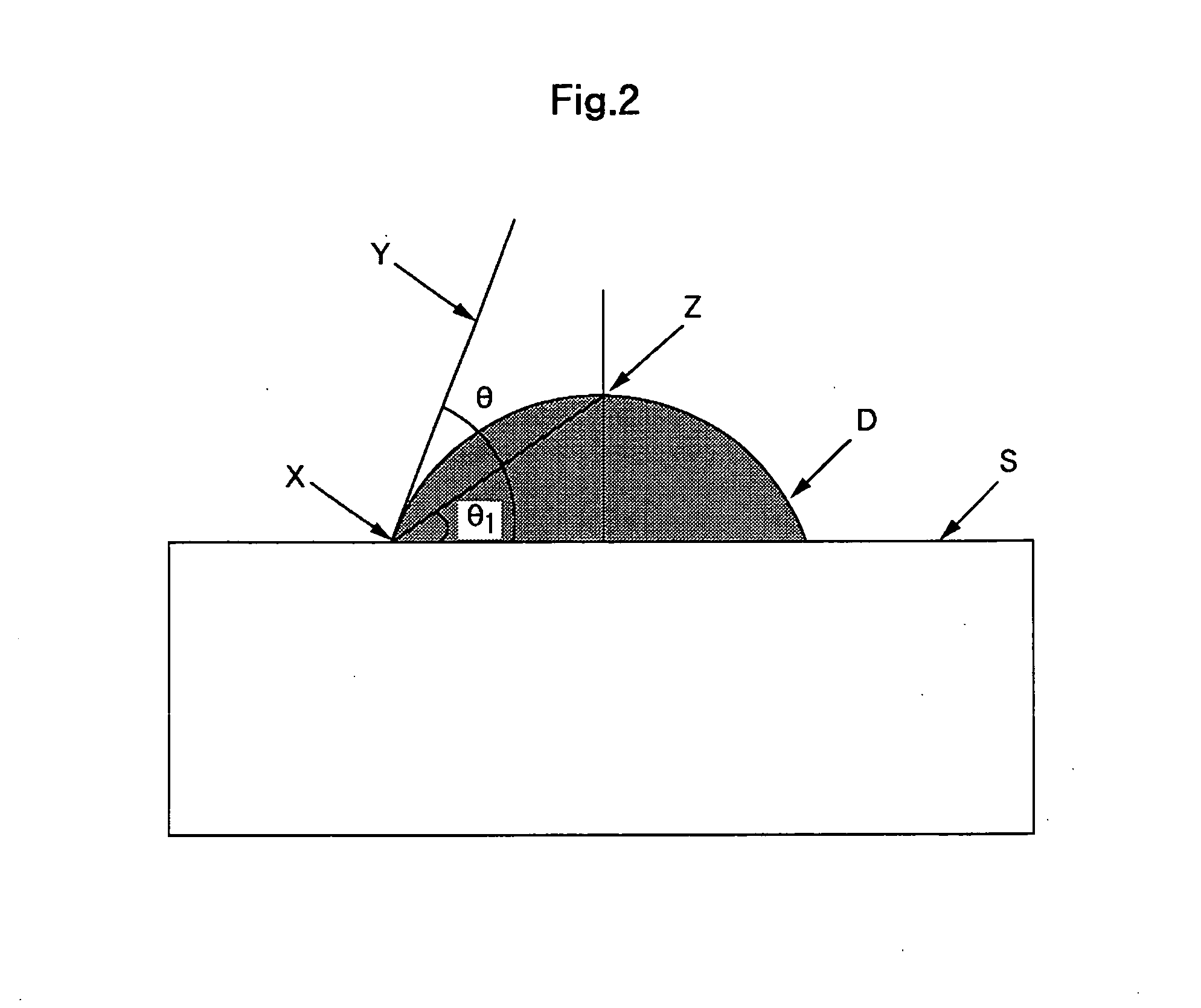

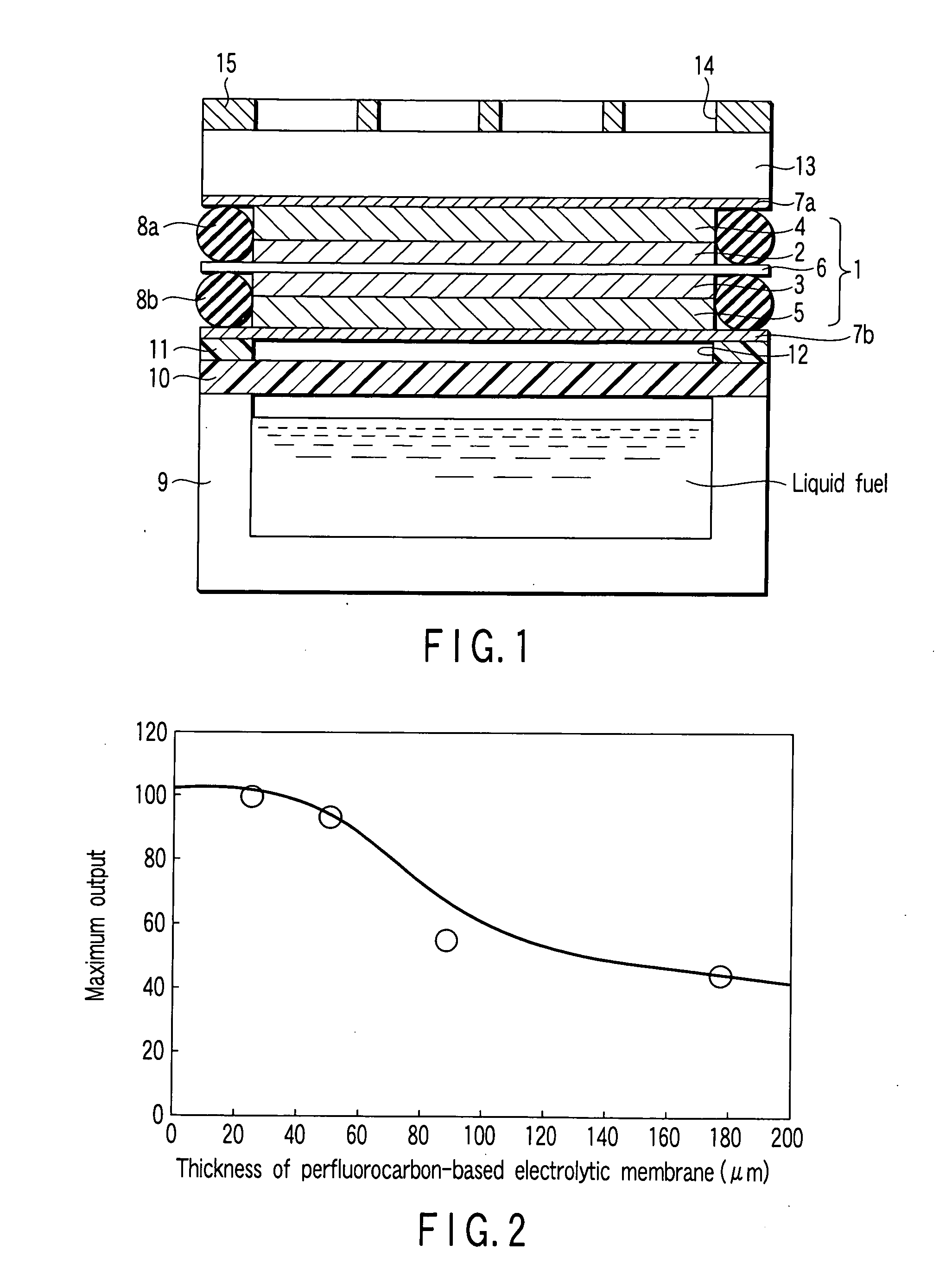

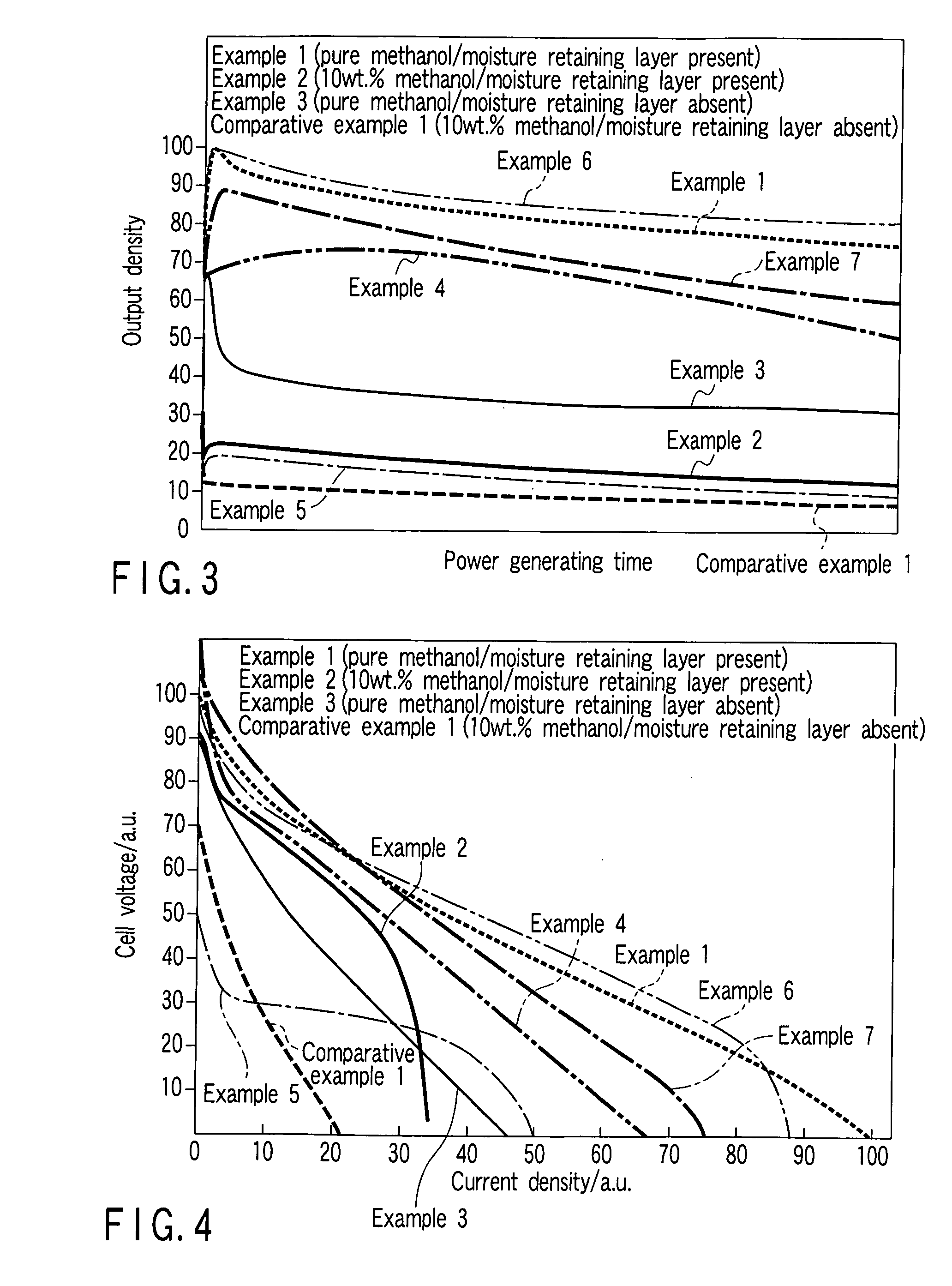

Fuel cell

InactiveUS20070059575A1Improve output performancePrevent evaporationWater management in fuel cellsCell component detailsFuel cellsProton

A fuel cell includes a cathode catalyst layer, an anode catalyst layer, a proton-conductive membrane provided between the cathode catalyst layer and the anode catalyst layer, and a fuel transmitting layer that supplies a vaporized component of a liquid fuel to the anode catalyst layer. Water generated in the cathode catalyst layer is supplied to the anode catalyst layer via the proton-conductive membrane. The liquid fuel is one of a methanol aqueous solution having a concentration of over 50% by molar and liquid methanol.

Owner:KK TOSHIBA

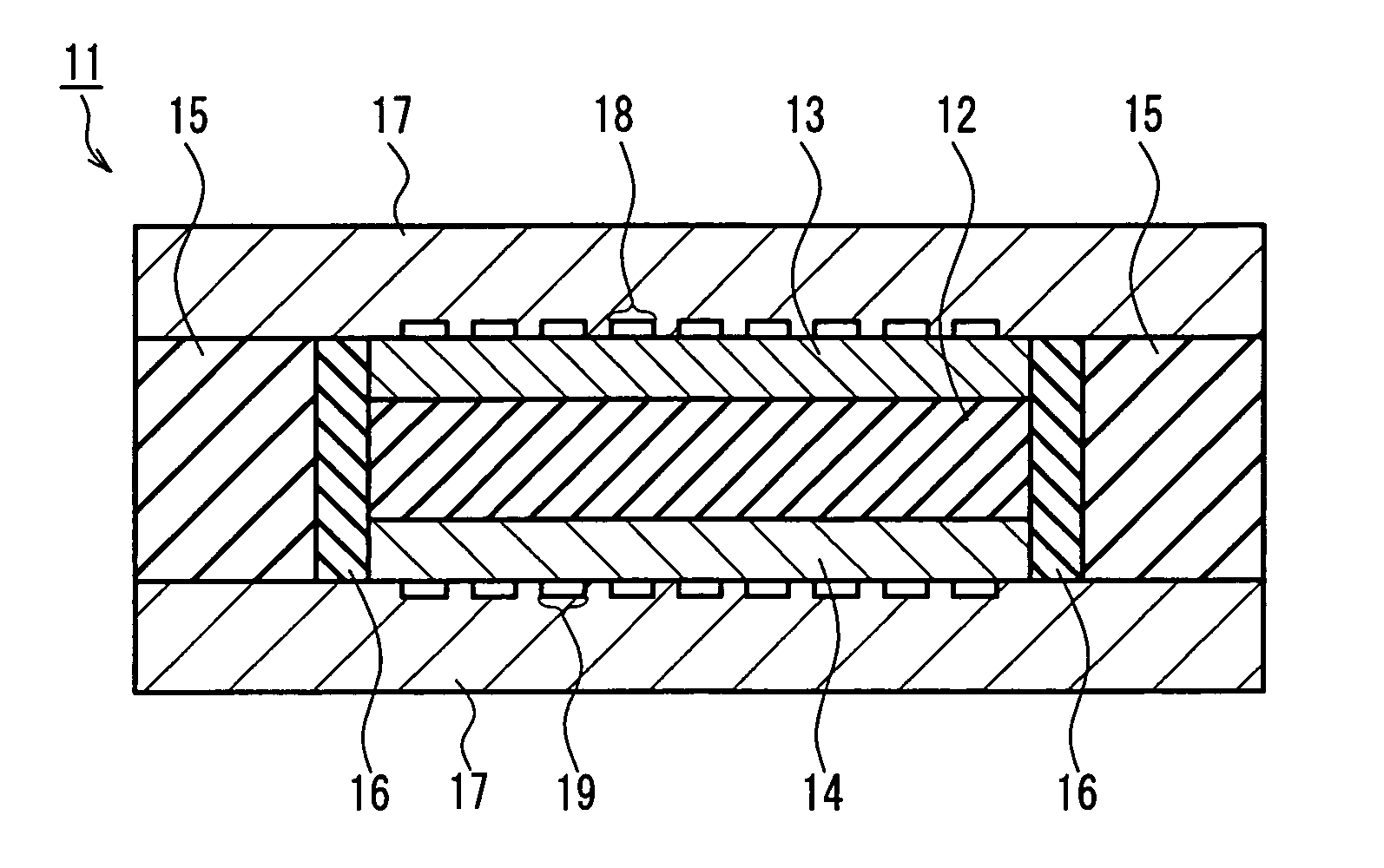

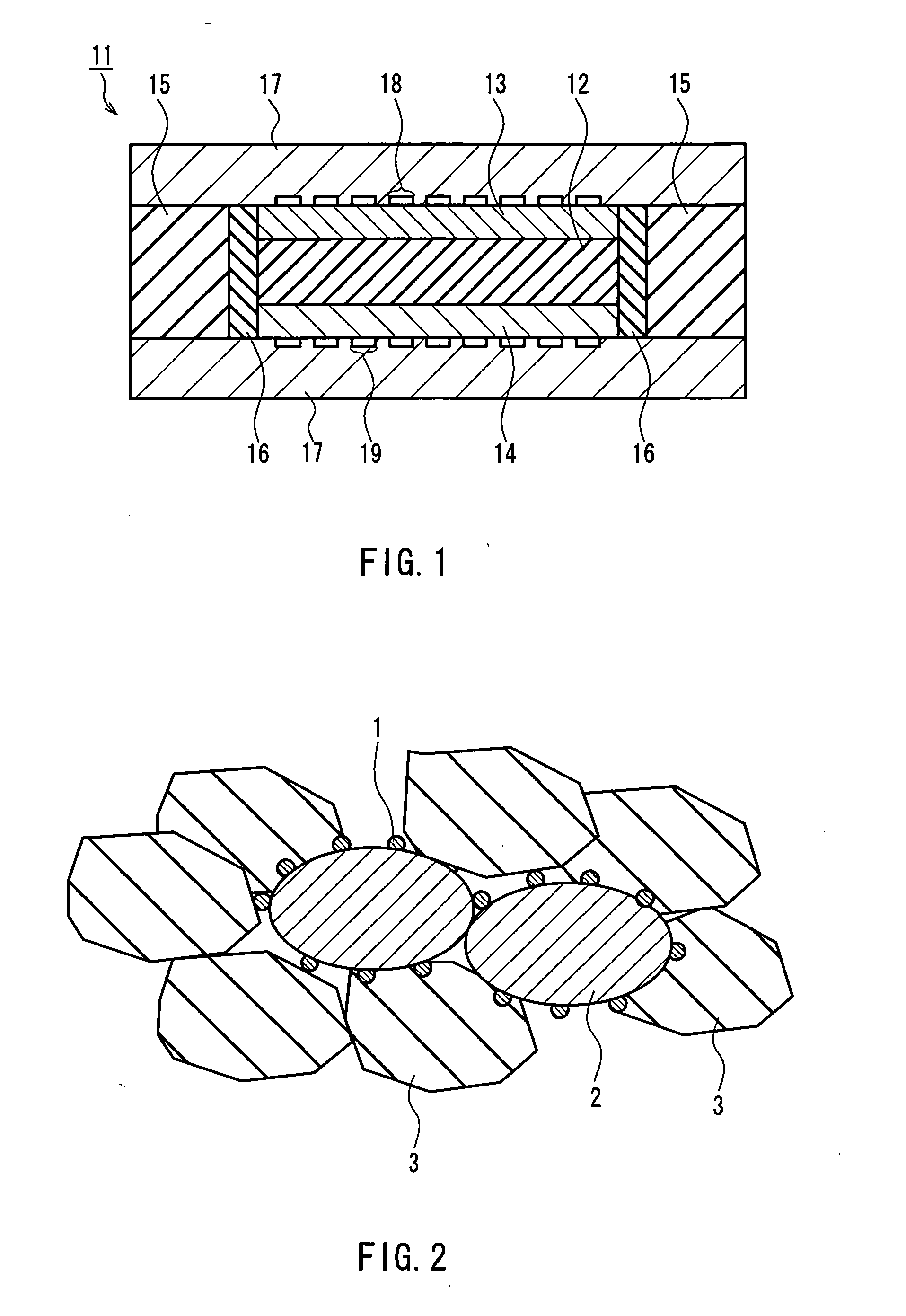

Solid oxide fuel cell and method for producing same

The present invention provides a solid oxide fuel cell with superior power generation characteristics even at lower temperatures (for example, in a range of 200° C. to 600° C. and preferably in a range of 400° C. to 600° C.) and a method for manufacturing the same. The solid oxide fuel cell is such that the solid oxide fuel cell includes an anode, a cathode, and a first solid oxide held between the anode and the cathode, the anode includes metal particles (2), an anode catalyst (1), and ion conducting bodies (3), the anode catalyst (1) is attached to the surface of the metal particles (2), and the first solid oxide and the ion conducting bodies (3) have either one of an ionic conductivity that is selected from oxide ionic conductivity and hydrogen ionic conductivity.

Owner:PANASONIC CORP

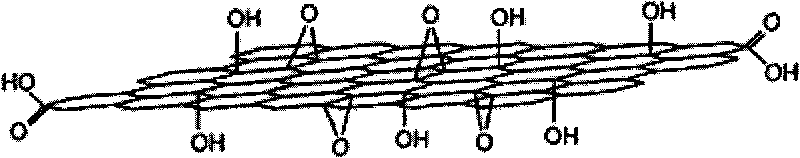

PtRu/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740786AReductiveGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetrizoateSodium acetate

The invention discloses a preparation method of PtRu / graphene nano electro-catalyst, comprising the following steps of: ultrasonically dispersing oxidized nano graphite sheets into liquid polylol; then adding a chloroplatinic acid solution and a sodium acetate solution, sufficiently mixing, wherein the content of the oxidized nano graphite sheets contained in a mixture is 0.3-1.1 g / L, the concentration of chloroplatinic acid is 0.0004-0.002 mol / L, the concentration of ruthenium chloride is 0.0004-0.0013 mol / L, and the concentration of sodium acetate is 0.005-0.027 mol / L; transferring the mixture to a microwave hydro-thermal reaction kettle for microwave hydro-thermal reaction for 5-10 minutes; and filtering, washing and drying to obtain the PtRu / graphene nano electro-catalyst, wherein the mass fraction of a PtRu alloy contained in the PtRu / graphene nano electro-catalyst is 20-40 percent, the mass fraction of graphene is 80-60 percent, the atomic ratio of the PtRu alloy is Pt:Ru=1:2-1.5:1, and the liquid polylol is propanetriol or glycol. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared PtRu / graphene nano electro-catalyst has good electrocatalysis property for the oxidation of methanol and ethanol and is widely used as anode catalysts of direct methanol fuel cells.

Owner:ZHEJIANG UNIV

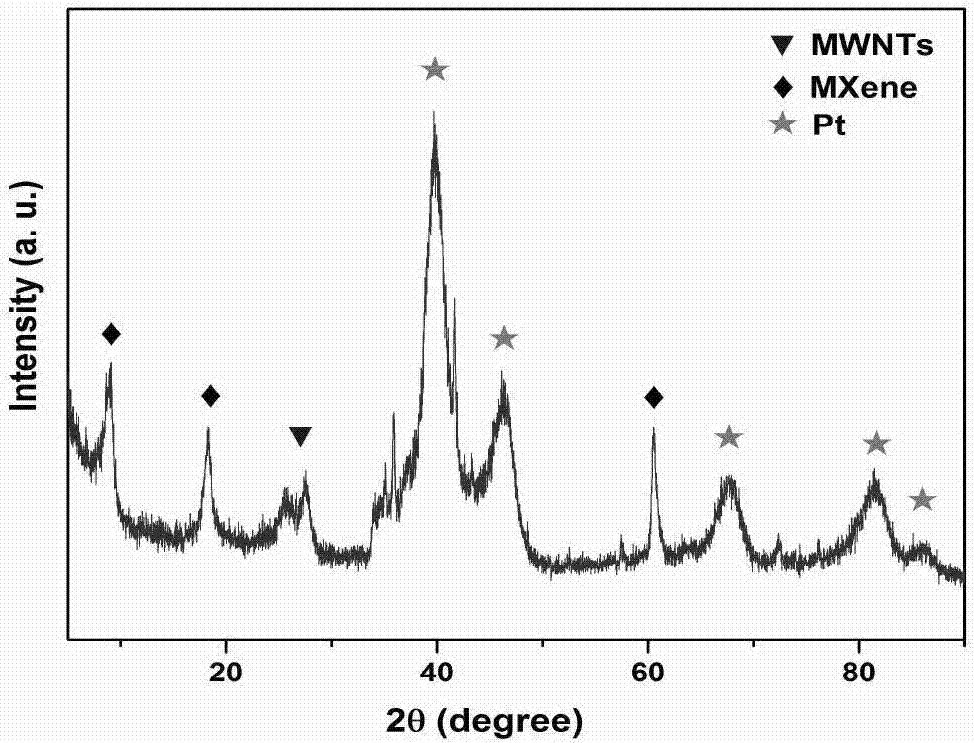

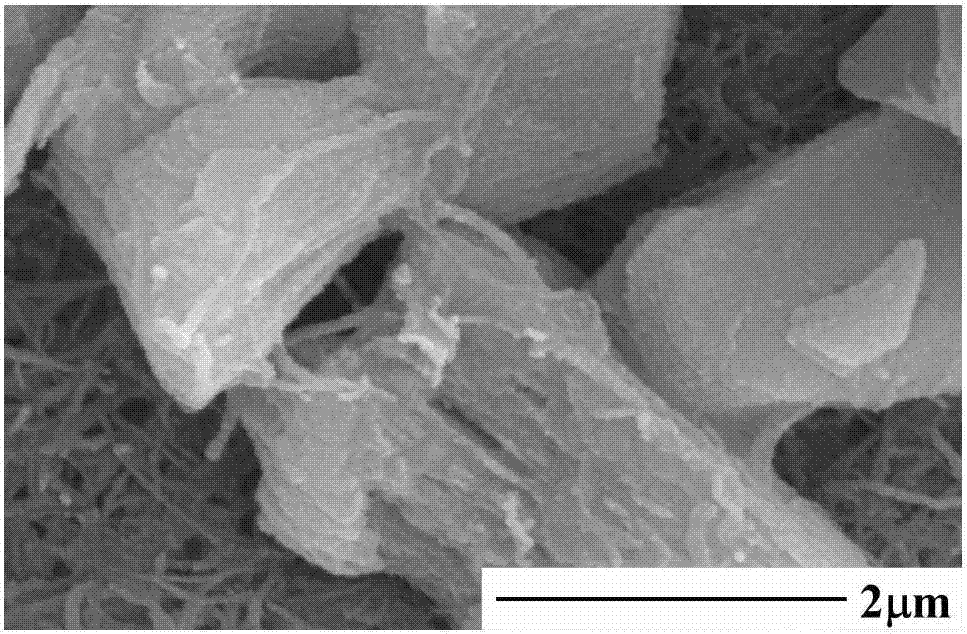

Preparation method of two-dimensional titanium carbide/carbon nanotube loaded platinum particle composite material

ActiveCN106981667ALarge specific surface areaImprove conductivityCell electrodesFinal product manufacturePlatinumFuel cells

The invention discloses a preparation method of a two-dimensional titanium carbide / carbon nanotube loaded platinum particle composite material. The preparation method comprises the following steps: preparing two-dimensional titanium carbide by chemically peeling off an aluminum atomic layer in Ti3AlC2 by means of HF; and combining the two-dimensional titanium carbide with MWNTs by means of a solvothermal method, and meanwhile, loading the platinum nanoparticles to obtain the Ti3C2 / MWNTs-Pt nano composite material. The preparation method provided by the invention is simple, controllable in process, good in repeatability and low in cost, and industrial production on a large scale is facilitated. The prepared Ti3C2 / MWNTs-Pt nano composite material is large in specific surface area and good in electric conductivity, can be used as an anode catalyst of a direct methanol fuel cell, and shows excellent catalytic activity on methanol oxidation.

Owner:HOHAI UNIV

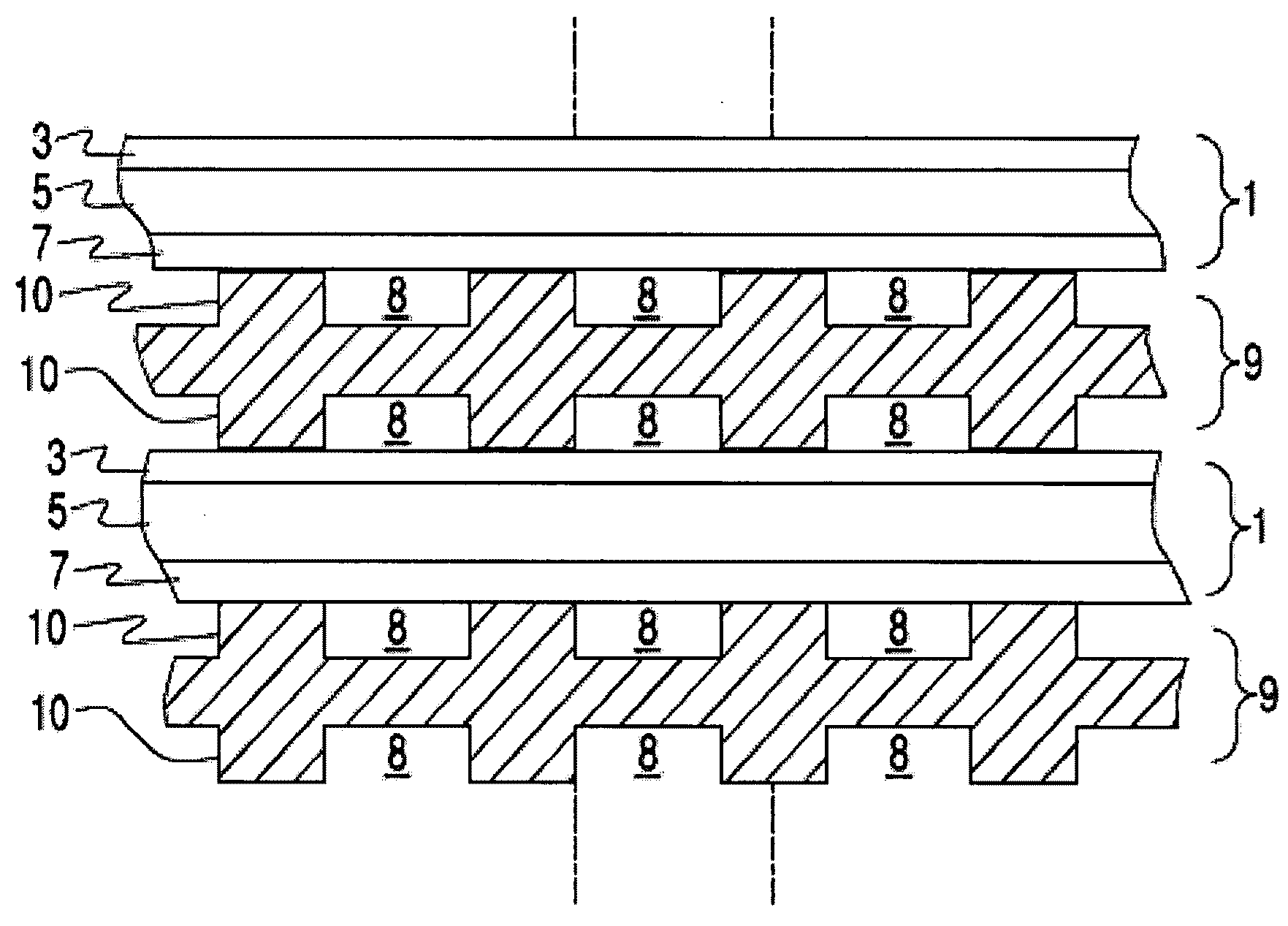

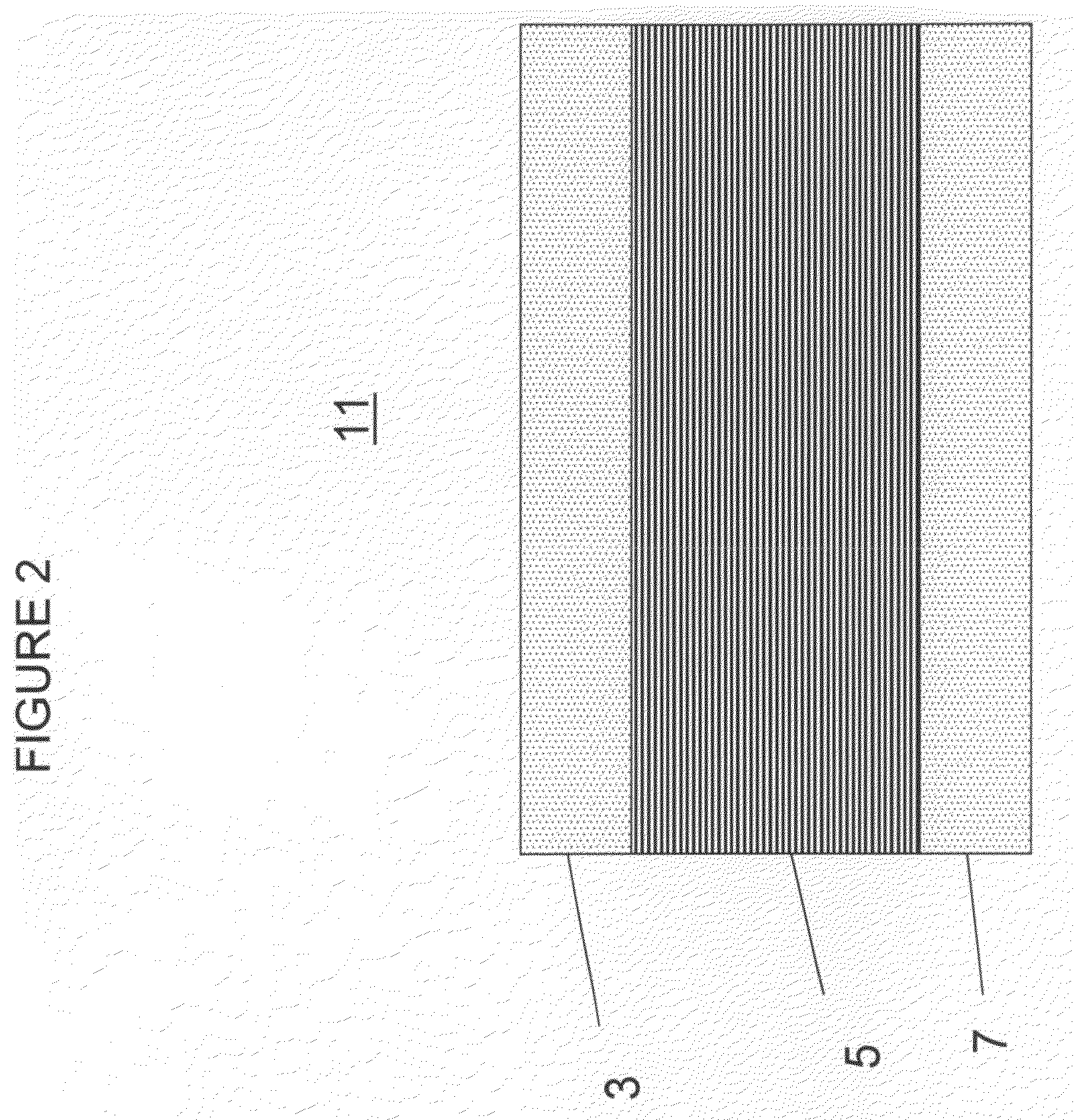

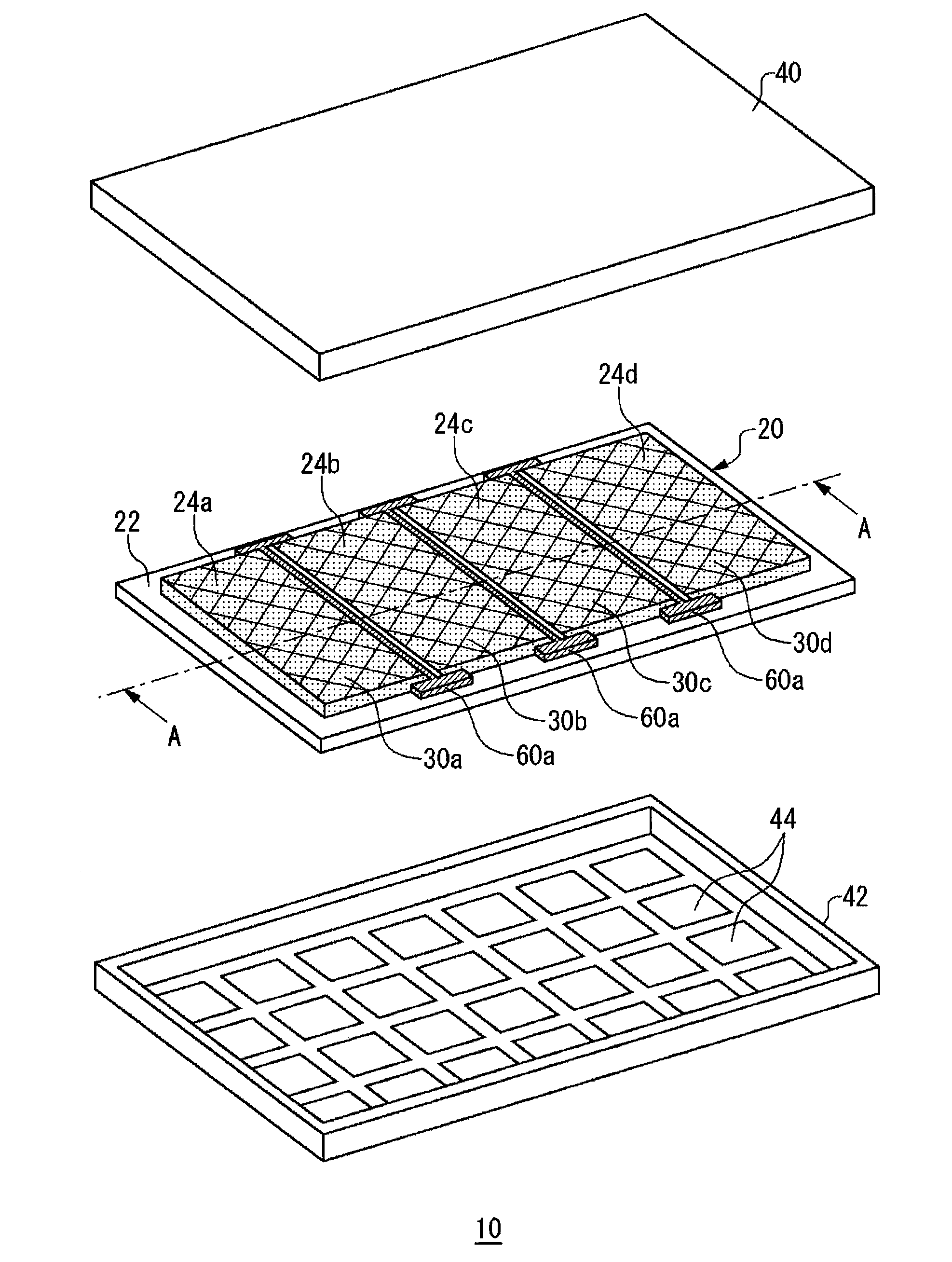

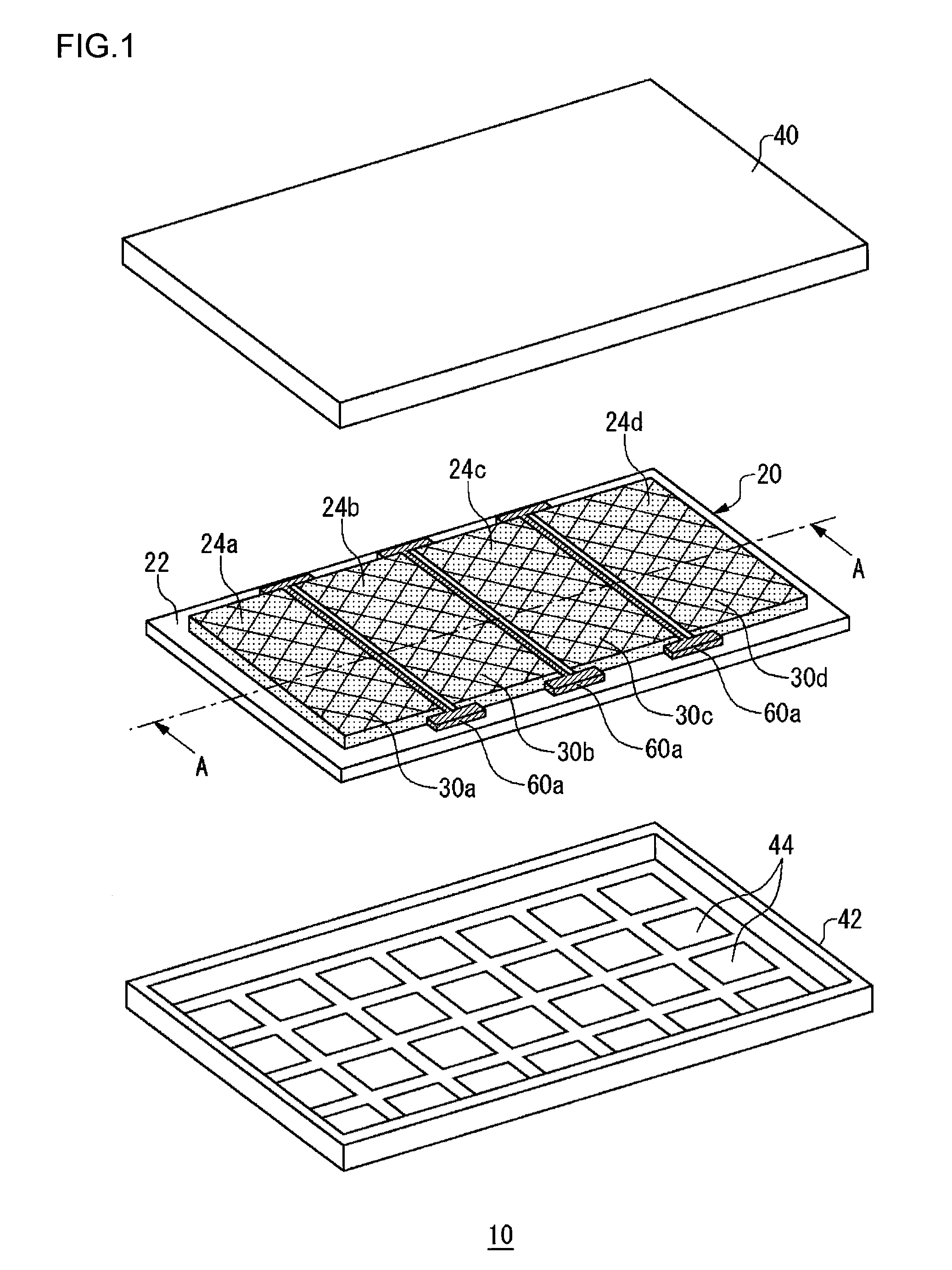

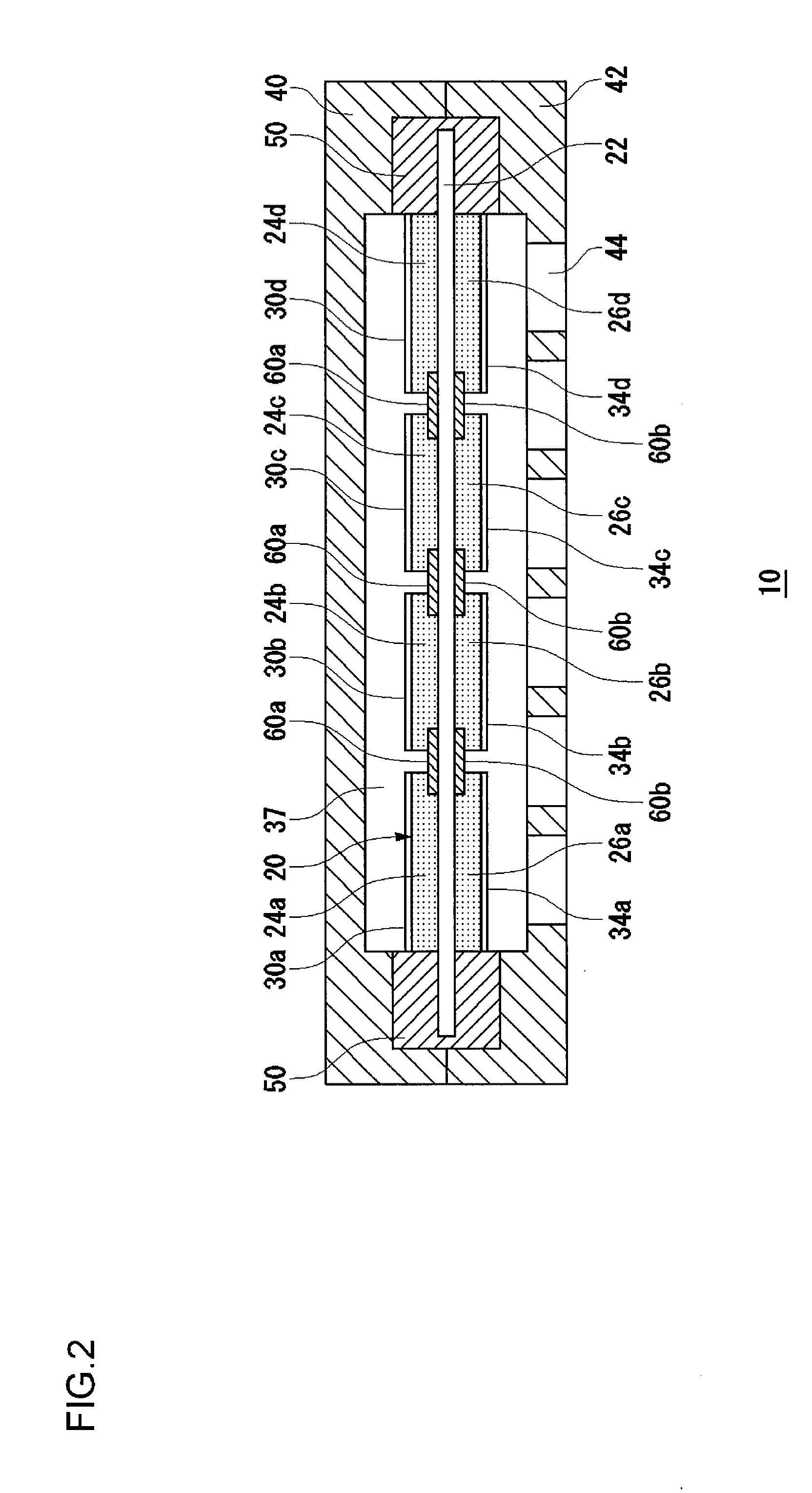

Membrane electrode assembly and fuel cell

InactiveUS20090246593A1Reduce intervalAvoid damageFuel cells groupingActive material electrodesFuel cellsOrganic chemistry

A membrane electrode assembly includes an electrolyte membrane, anode catalyst layers, and cathode catalyst layers provided counter to the anode catalyst layers, respectively. An insulating layer is provided on the electrolyte membrane between adjacent anode catalyst layers. An insulating layer is provided on the electrolyte membrane between adjacent cathode catalyst layers. The resistivity of the insulating layer is preferably identical to or higher than that of the electrolyte membrane.

Owner:SANYO ELECTRIC CO LTD

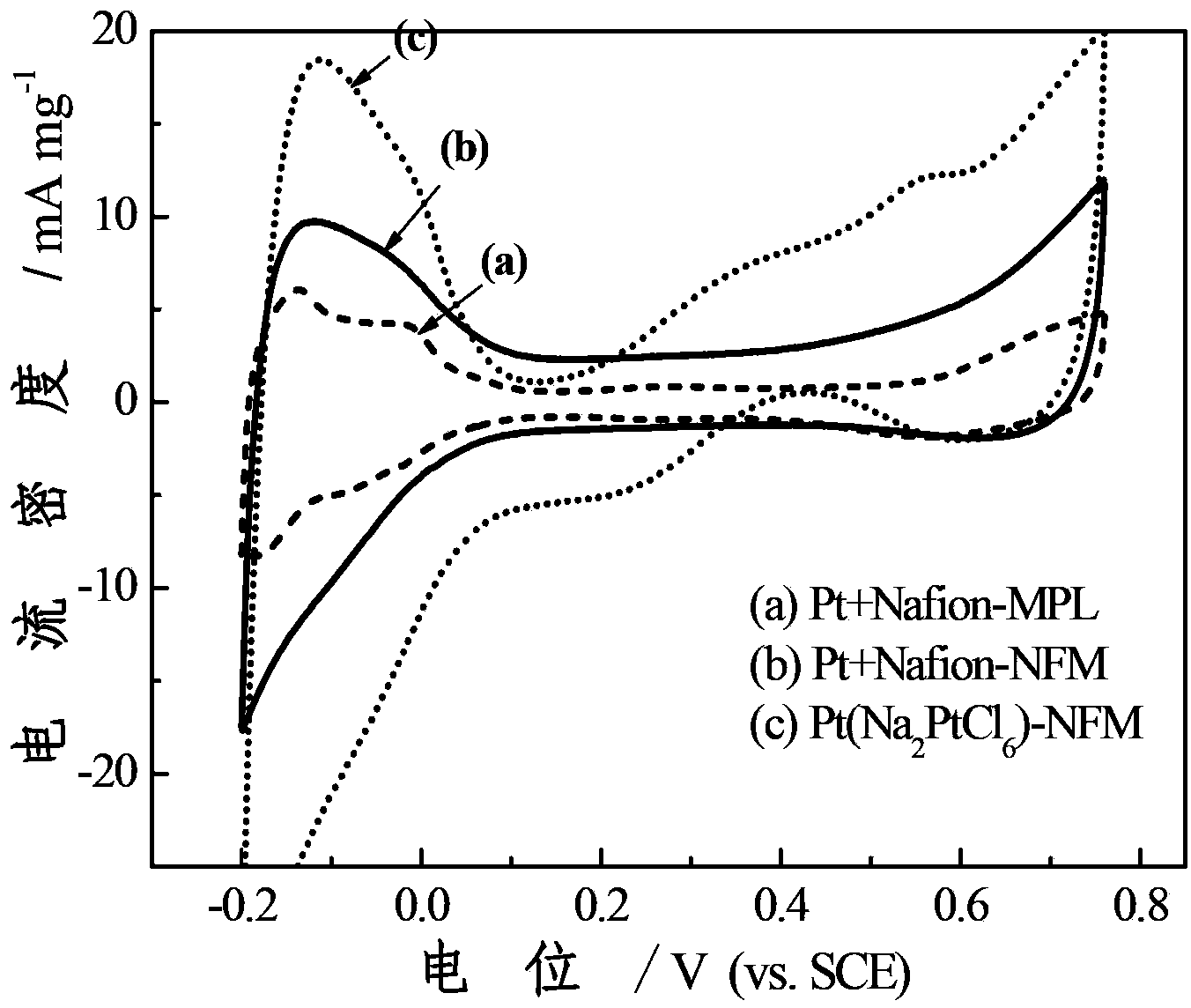

Self-humidification membrane electrode for proton exchange membrane fuel cell and preparation method thereof

InactiveCN103078122AImprove hydrophilicityGood moisturizing effectCell electrodesPtru catalystOrganic polymer

The invention discloses a self-humidification membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof. The preparation method comprises the following steps of 1, pre-treating a proton exchange membrane, 2, mixing a carbon-supported platinum or platinum-ruthenium catalyst, a perfluorinated sulfonic acid resin, a hydrophilic organic polymer and an inorganic oxide and in water or a low-boiling point solvent, carrying out ultrasonic treatment to obtain catalyst slurry, and carrying out spray-coating of the catalyst slurry on one side of the proton exchange membrane by an illumination direct-coating technology to obtain an anode catalyst layer, 3, carrying out spray-coating of slurry without the hydrophilic organic polymer and the inorganic oxide on the other side of the proton exchange membrane to obtain a cathode catalyst layer, and 4, carrying out lamination of a gas diffusion layer and the proton exchange membrane of which the two sides are coated with the catalyst layers to obtain the self-humidification membrane electrode. The anode catalyst layer contains the hydrophilic organic polymer and the inorganic oxide so that the self-humidification membrane electrode has excellent self-humidification performances at a high cell temperature and low humidity.

Owner:SOUTH CHINA UNIV OF TECH

Fuel cell and production method thereof

InactiveUS20050142433A1High densityFinal product manufactureActive material electrodesPlatinumPolymer electrolytes

In order to prevent the crossover of an organic fuel such as methanol in a fuel cell and to exhibit excellent electricity generation characteristics without impairing the utilization efficiency of the fuel, at least either of (1) a discontinuous catalyst layer being formed on a surface of an anode catalyst layer and having a higher density (existence probability) of platinum type catalyst than the anode catalyst layer and (2) an electrolyte polymer layer is formed at the interface between the anode catalyst layer and a polymer electrolyte membrane.

Owner:PANASONIC CORP

Catalyst coated membrane, membrane electrode assembly containing the same, method of producing the same, and fuel cell including the membrane electrode assembly

InactiveUS20070269699A1Improve unit performanceMaximum catalyst activityActive material electrodesNon-aqueous electrolyte accumulator electrodesCoated membraneFuel cells

A catalyst coated membrane (CCM) comprising an anode catalyst layer having a first catalyst layer composed of a non-supported catalyst and a second catalyst layer composed of a supported catalyst, a cathode catalyst layer composed of a supported catalyst, and an electrolyte membrane interposed between the anode catalyst layer and a cathode catalyst layer, the first catalyst layer of the anode catalyst layer being disposed adjacent to the electrolyte membrane; a membrane electrode assembly (MEA) comprising the catalyst coated membrane; a method of preparing the membrane electrode assembly; and a fuel cell comprising the membrane electrode assembly, are provided. The CCM, which comprises a bilayered anode catalyst layer including the first catalyst layer composed of a non-supported catalyst and the second catalyst layer composed of a supported catalyst, exhibits reduced electrical resistance and interfacial resistance, and has increased catalyst availability. The use of the CCM and an MEA having the same results in a decrease in the interfacial resistance between the electrodes and the electrolyte membrane, a decrease in the amount of the catalyst used in the electrode catalyst layer, and a decrease in the thickness deviation in the electrode layers. The fuel cell employing the MEA exhibits maximal activity of the supported catalyst, and has improved cell characteristics such as output voltage, output density, efficiency, and the like.

Owner:SAMSUNG SDI CO LTD

Fuel cell anode structure for voltage reversal tolerance

ActiveUS20090186248A1Reduce concentrationCell electrodesSolid electrolyte fuel cellsGas diffusion electrodeNoble metal

An anode catalyst layer for a fuel cell is presented having first and second catalyst compositions and a hydrophobic binder. The first catalyst composition includes a noble metal, other than Ru, on a corrosion-resistant support material; the second catalyst composition contains a single-phase solid solution of a metal oxide containing Ru. The through-plane concentration of ionomer in the catalyst layer decreases as a function of distance from the membrane interface. Gas diffusion electrodes, catalyst-coated membranes, MEAs and fuel cells having the foregoing anode catalyst layer are also described.

Owner:BDF IP HLDG

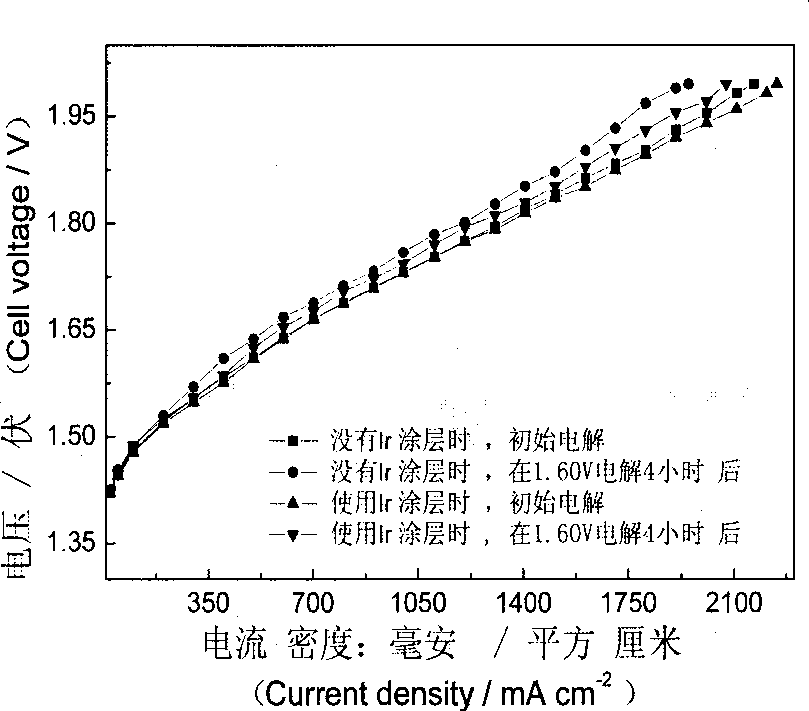

Precious metal oxide catalyst for water electrolysis

InactiveUS20140322631A1High densityLow precious metal loadingCellsActive material electrodesHigh current densityElectrolysis

Owner:UMICORE AG & CO KG

Modified aluminium-magnesium alloy fuel cell

InactiveCN101026255AAvoid defectsImprove performanceFuel and primary cellsCell electrodesFuel cellsEmulsion

This invention relates to a modified Al, Mg alloy fuel cell, the metal anode of the fuel cell is a modified AlMg alloy anode, the cathode is an air electrode composed of an anode catalyst electrode, a water-proof permeability film and conduction Cu silk screen plated with Ag, the anode catalyst electrode is a film made of a mixture of active carbon, MnO2, graphite and SiO, the water-proof permeability film is one made of the mixture of Teflon, emulsion agent, a changed material of ethane black and carbon, and the anode catalyst electrode, the water-proof permeability film and the Cu silk screen are suppressed and sintered to form the air electrodes, the electrolyte is a neutral one containing salt, said metal anode is set at the center of a sealed shell, the two air electrodes are set at both sides of the metal anode and the shell is charged with electrolyte.

Owner:马润芝 +3

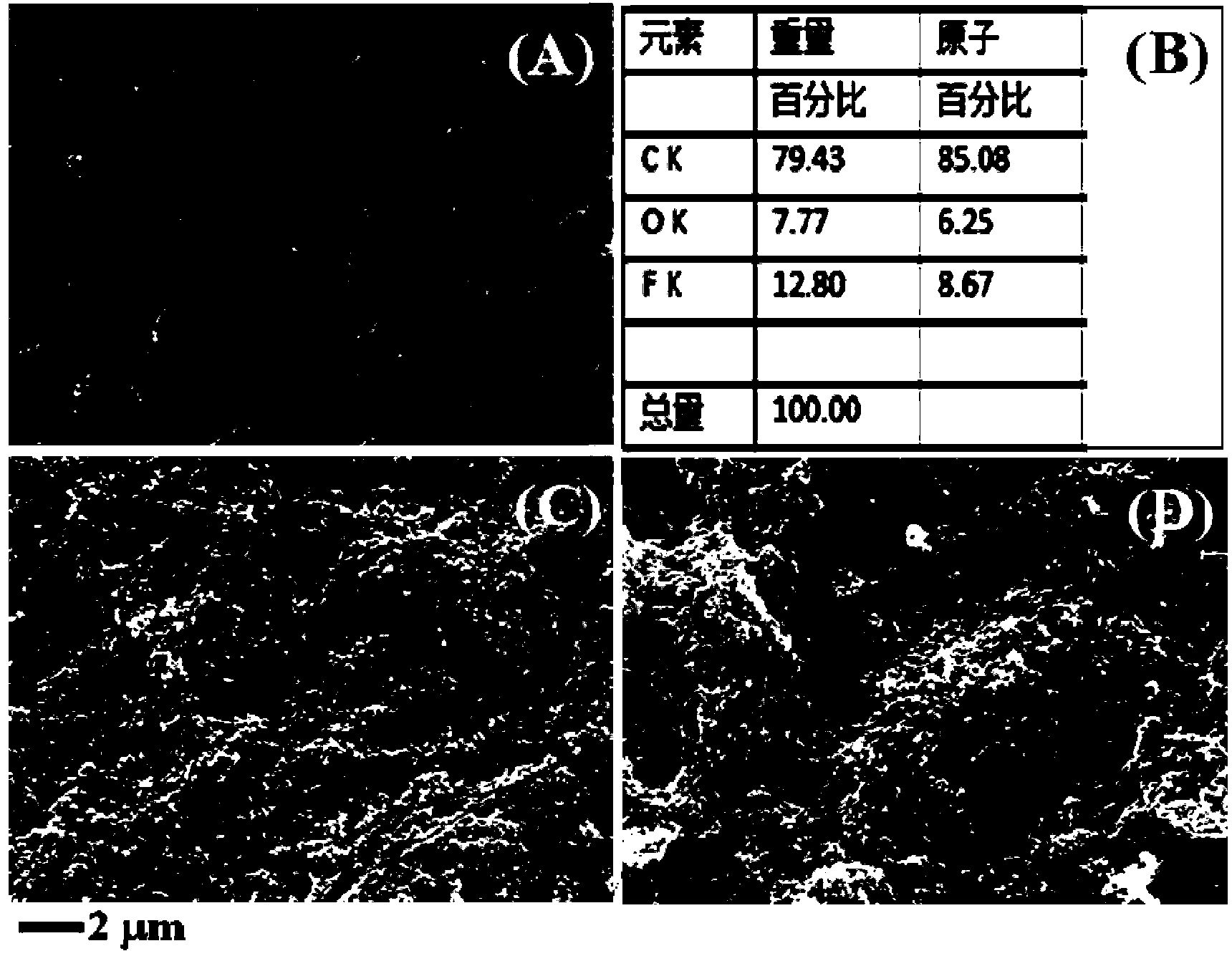

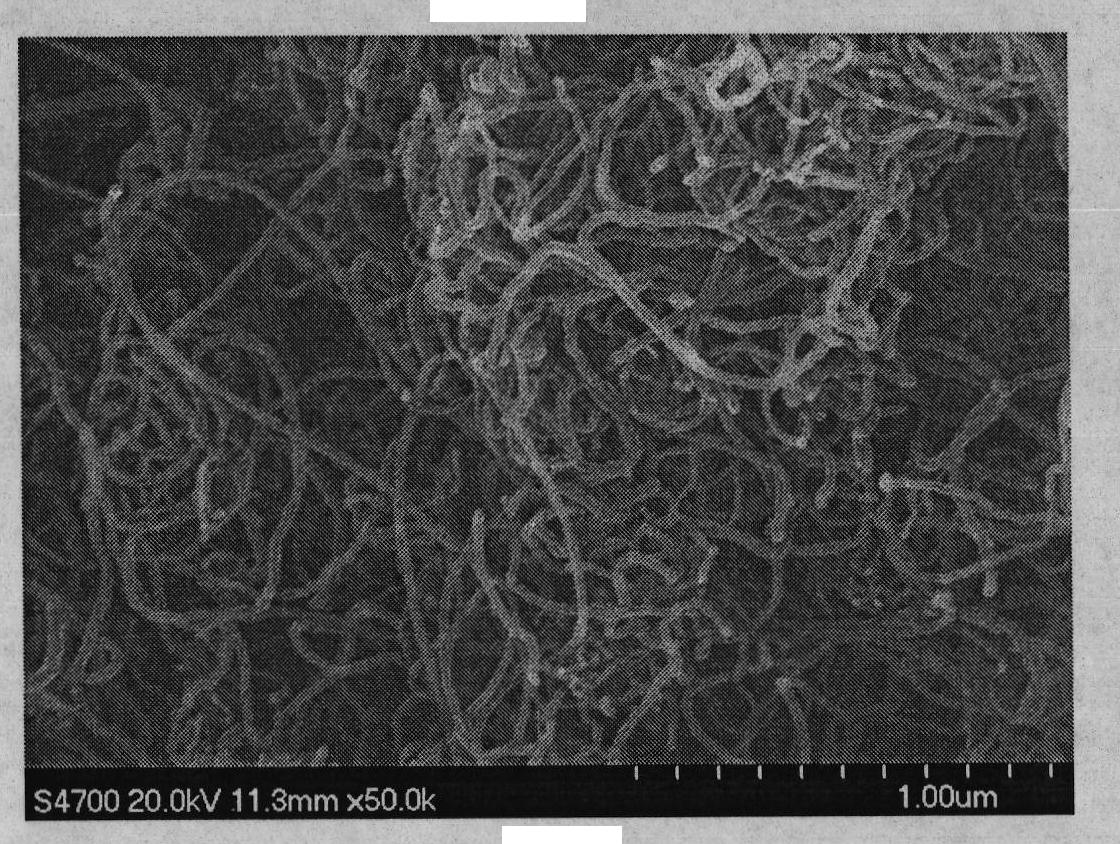

Preparation method of membrane electrode of direct methanol fuel cell

The invention relates to a preparation method of the membrane electrode of a direct methanol fuel cell. The method comprises the following steps: an electrostatic spinning technology is adopted to construct a nano-fiber network structure thin membrane mixed by active carbon powder and Nafion resin; a precious metal nano-catalyst is deposited on the surface of the manufactured nano-fiber network structure thin membrane, so that a cathode catalyst layer thin membrane and an anode catalyst layer thin membrane are manufactured respectively; or the mixture of the precious metal nano-catalyst and the Nafion resin is taken as raw materials to directly construct the cathode catalyst layer thin membrane and the anode catalyst layer thin membrane through the electrostatic spinning technology; a cathode gas diffusion layer, the anode catalyst layer thin membrane, a Nafion membrane, the cathode catalyst layer thin membrane and a cathode gas diffusion layer are hot-pressed finally, so that the aggregation of the membrane electrode of the direct methanol fuel cell is manufactured; the membrane electrode with a nano-fiber three-dimensional network structure is constructed through the electrostatic spinning technology, so that the maximization of the three-phase reaction interface of the membrane electrode is achieved, and the improvement of electrocatalytic activity, mass-transfer efficiency and utilization efficiency of the catalyst is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Single metal/multi-wall carbon nano tube type composite material, preparation method and application thereof

InactiveCN101820066AProportional controlOvercome uniformity issuesCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesCatalytic oxidation

Owner:BEIJING UNIV OF CHEM TECH

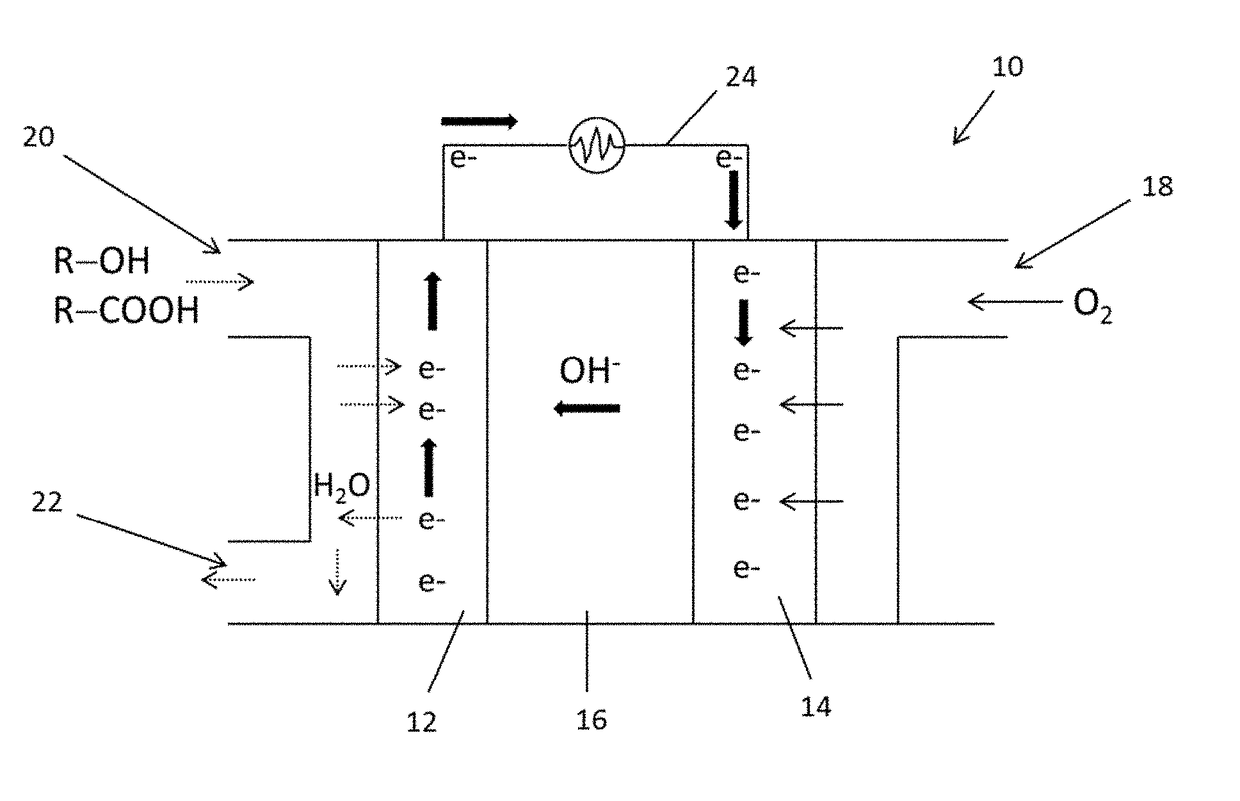

Fuel-cell system and method of generating energy from crude fuel

ActiveUS20170263945A1Improve performanceImprove adsorption capacityCell electrodesFuel cellsFuel cellsIon-exchange membranes

The present invention relates to a fuel-cell system. This system includes an anode electrode; a cathode electrode; a separator positioned between the anode electrode and the cathode electrode, wherein the separator is not an ion exchange membrane; an anode catalyst; and a cathode catalyst, wherein the cathode catalyst is a non-precious metal catalyst or metal-free catalyst. The present invention also relates to a method of generating energy from crude fuel. This method involves providing a fuel-cell system and contacting the fuel-cell system with a crude fuel under conditions effective to generate energy from the crude fuel.

Owner:IOWA STATE UNIV RES FOUND

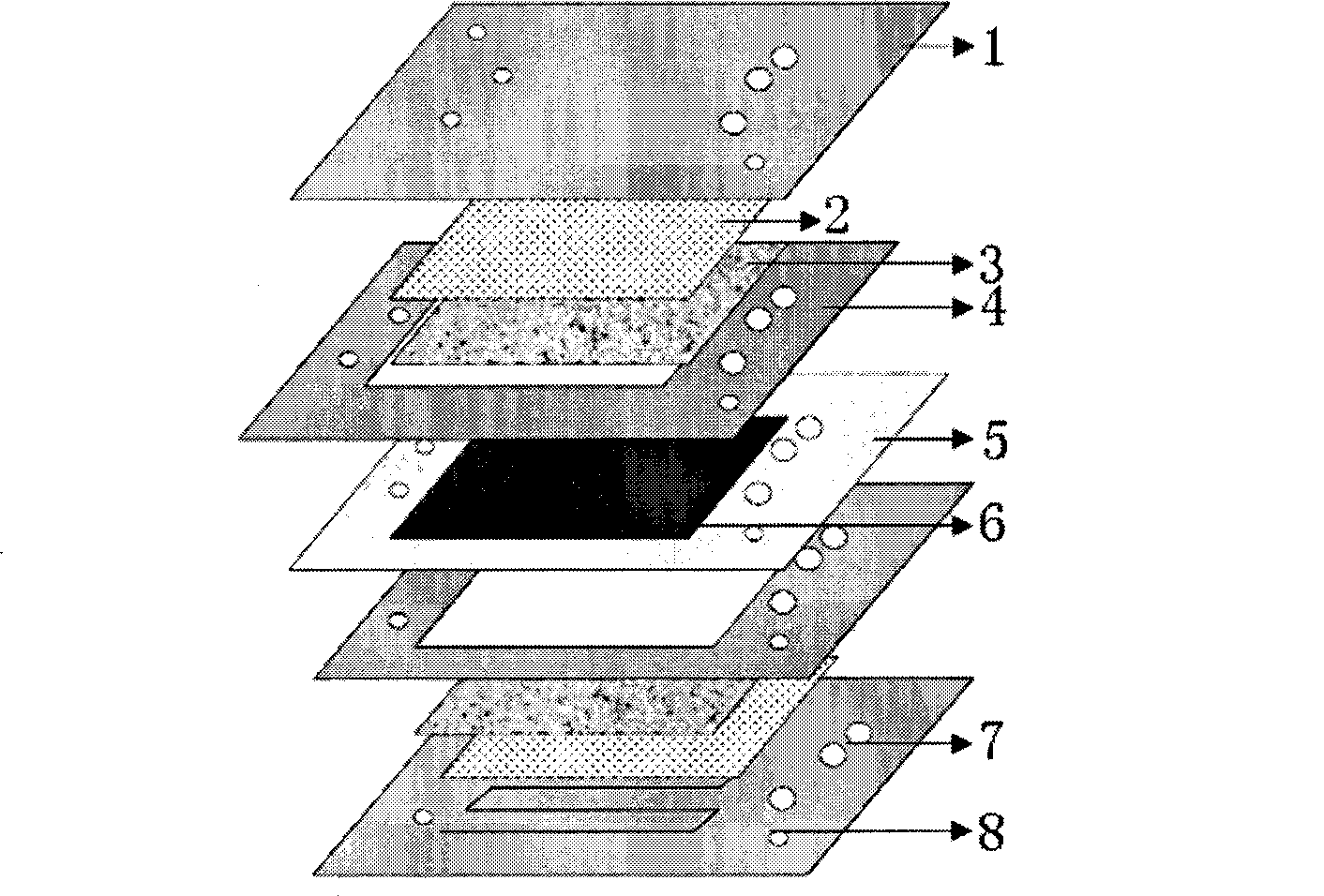

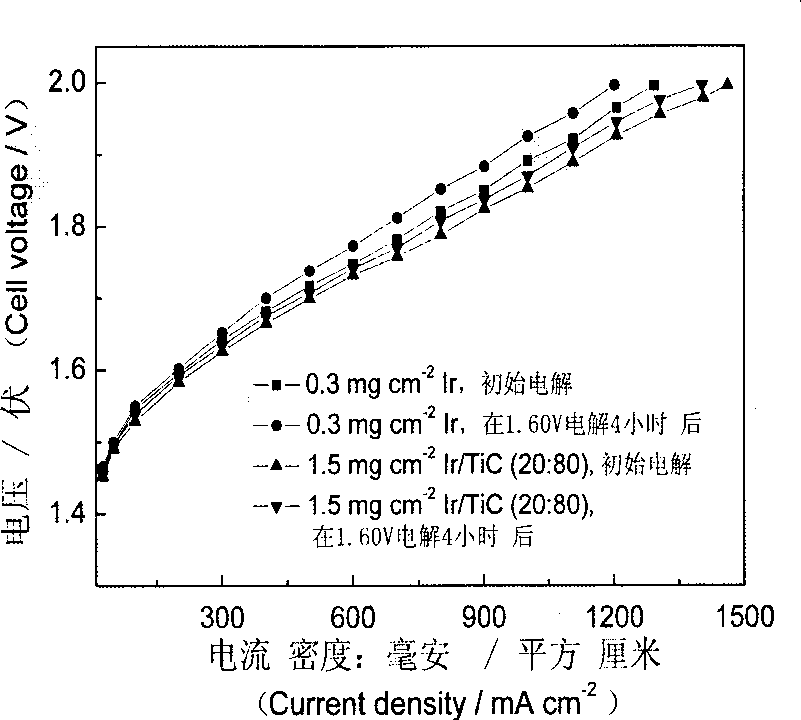

Precious Metal Oxide Catalyst for Water Electrolysis

ActiveUS20070292744A1Low oxygen overvoltageReduce energy consumptionMachining electrodesCellsOvervoltageSolubility

The invention is directed to iridium oxide based catalysts for use as anode catalysts in PEM water electrolysis. The claimed composite catalyst materials comprise iridium oxide (IrO2) and optionally ruthenium oxide (RuO2) in combination with a high surface area inorganic oxide (for example TiO2, Al2O3, ZrO2 and mixtures thereof). The inorganic oxide has a BET surface area in the range of 50 to 400 m2 / g, a water solubility of lower than 0.15 g / l and is present in a quantity of less than 20 wt. % based on the total weight of the catalyst. The claimed catalyst materials are characterised by a low oxygen overvoltage and long lifetime in water electrolysis. The catalysts are used in electrodes, catalyst-coated membranes and membrane-electrode-assemblies for PEM electrolyzers as well as in regenerative fuel cells (RFC), sensors, and other electrochemical devices.

Owner:UMICORE AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com