Preparation method of two-dimensional titanium carbide/carbon nanotube loaded platinum particle composite material

A technology of two-dimensional titanium carbide and carbon nanotubes is applied in the field of preparation of two-dimensional titanium carbide/carbon nanotube-supported platinum particle composite materials, which can solve the problems to be further studied and the like, and is beneficial to large-scale industrial production, The effect of large specific surface area and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

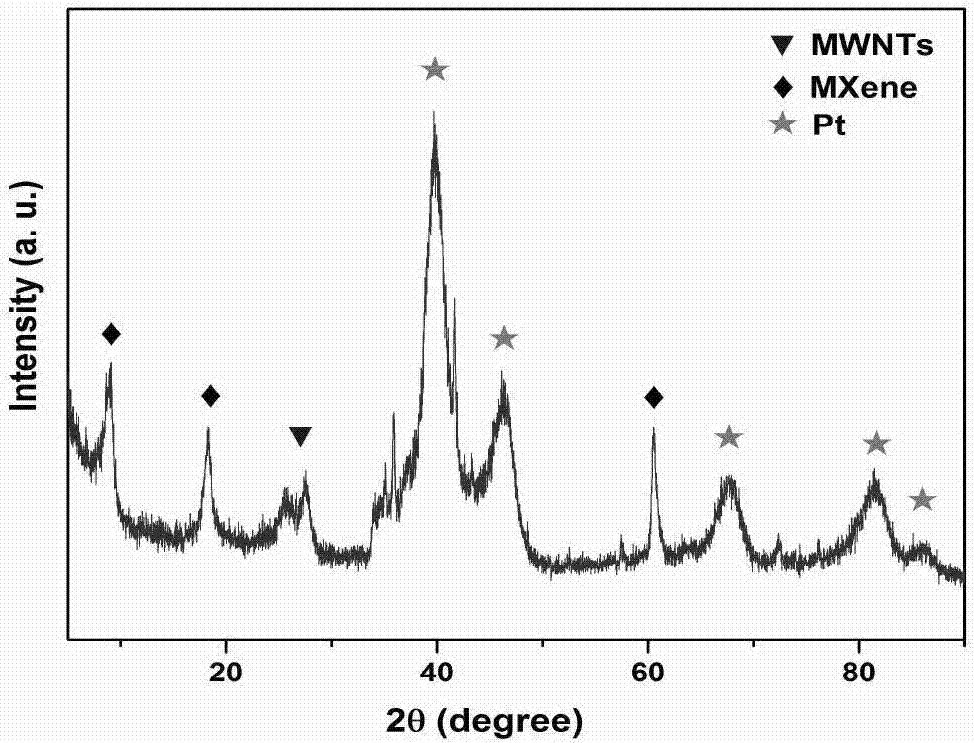

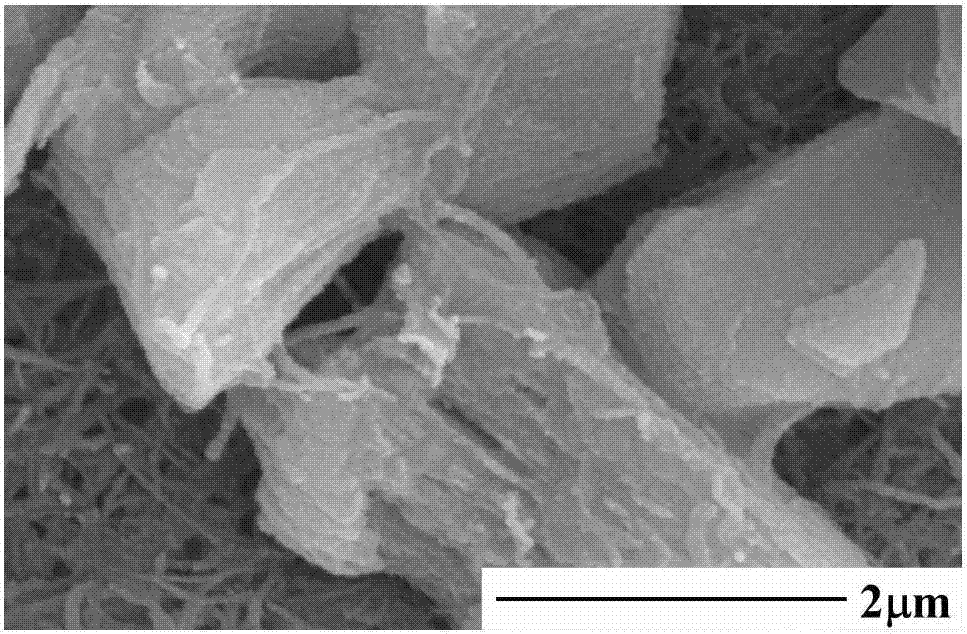

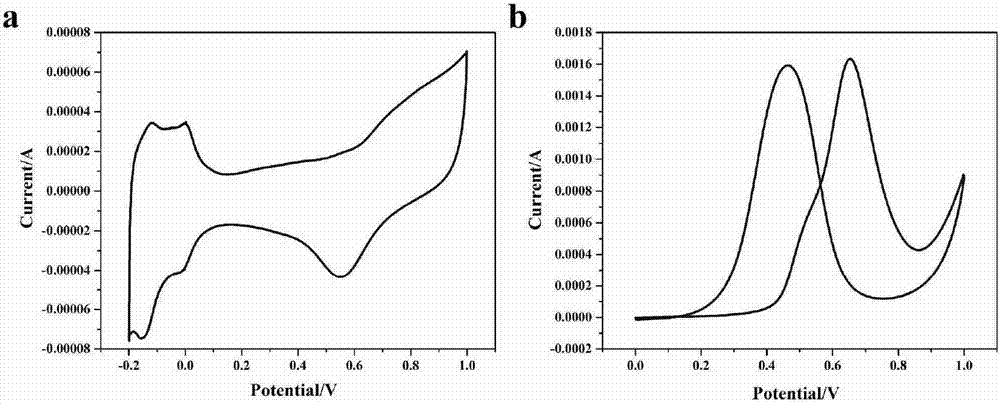

[0033] 0.3g of Ti 3 AlC 2 Powder (sifted through a 400-mesh sieve, Ti 3 AlC 2 The particle size is less than 38 μm) soaked in 20mL of 40% HF acid solution at 25°C, and reacted for 24h to obtain a suspension. The obtained suspension was centrifuged and washed several times with water at 4000 rpm for 5 min until the pH value of the supernatant obtained from the last centrifugation was close to neutral. The obtained precipitated product was placed in a vacuum drying oven and dried at 60°C to obtain the MXene phase Ti 3 C 2 powder. Take 100mg of MWNTs and place them in 100mL of a mixed solution of concentrated nitric acid and concentrated sulfuric acid, and reflux at 100°C for 3 hours, where the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1. The resulting suspension was centrifuged and washed several times with water at 8000 rpm for 10 min until the pH of the supernatant obtained from the last centrifugation was close to neutral. The obtaine...

Embodiment 2

[0035] 0.3g of Ti 3 AlC 2 Powder (sifted through a 400-mesh sieve, Ti 3 AlC 2 Particle size less than 38 μm) was soaked in 20 mL of 40% HF acid solution at 25°C, and reacted for 48 hours to obtain a suspension. The obtained suspension was centrifuged and washed several times with water at 5000 rpm for 5 min until the pH value of the supernatant obtained by the last centrifugation was close to neutral. The obtained precipitated product was placed in a vacuum oven and dried at 80°C to obtain the MXene phase Ti 3 C 2 powder. Take 80 mg of MWNTs and place them in 100 mL of a mixed solution of concentrated nitric acid and concentrated sulfuric acid, and reflux at 100 °C for 4 h, where the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1. The resulting suspension was centrifuged and washed several times with water at 8000 rpm for 10 min until the pH of the supernatant obtained from the last centrifugation was close to neutral. The obtained precip...

Embodiment 3

[0037] 0.3g of Ti 3 AlC 2 Powder (sifted through a 400-mesh sieve, Ti 3 AlC 2 Particle size less than 38 μm) was immersed in 15 mL of 40% HF acid solution at 40°C, and reacted for 24 hours to obtain a suspension. The obtained suspension was centrifuged and washed several times with water at 4000 rpm for 5 min until the pH value of the supernatant obtained from the last centrifugation was close to neutral. The obtained precipitated product was placed in a vacuum oven and dried at 80°C to obtain the MXene phase Ti 3 C 2 powder. Take 50 mg of MWNTs and place them in 80 mL of a mixed solution of concentrated nitric acid and concentrated sulfuric acid, and reflux at 110 °C for 2.5 h, where the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1. The resulting suspension was centrifuged and washed several times with water at 8000 rpm for 10 min until the pH of the supernatant obtained from the last centrifugation was close to neutral. The obtained p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com