Single metal/multi-wall carbon nano tube type composite material, preparation method and application thereof

A multi-walled carbon nanotube, metal element technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. Unable to achieve uniform distribution and controllable particle size, etc., to achieve the effect of overcoming uneven dispersion and improving anti-poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

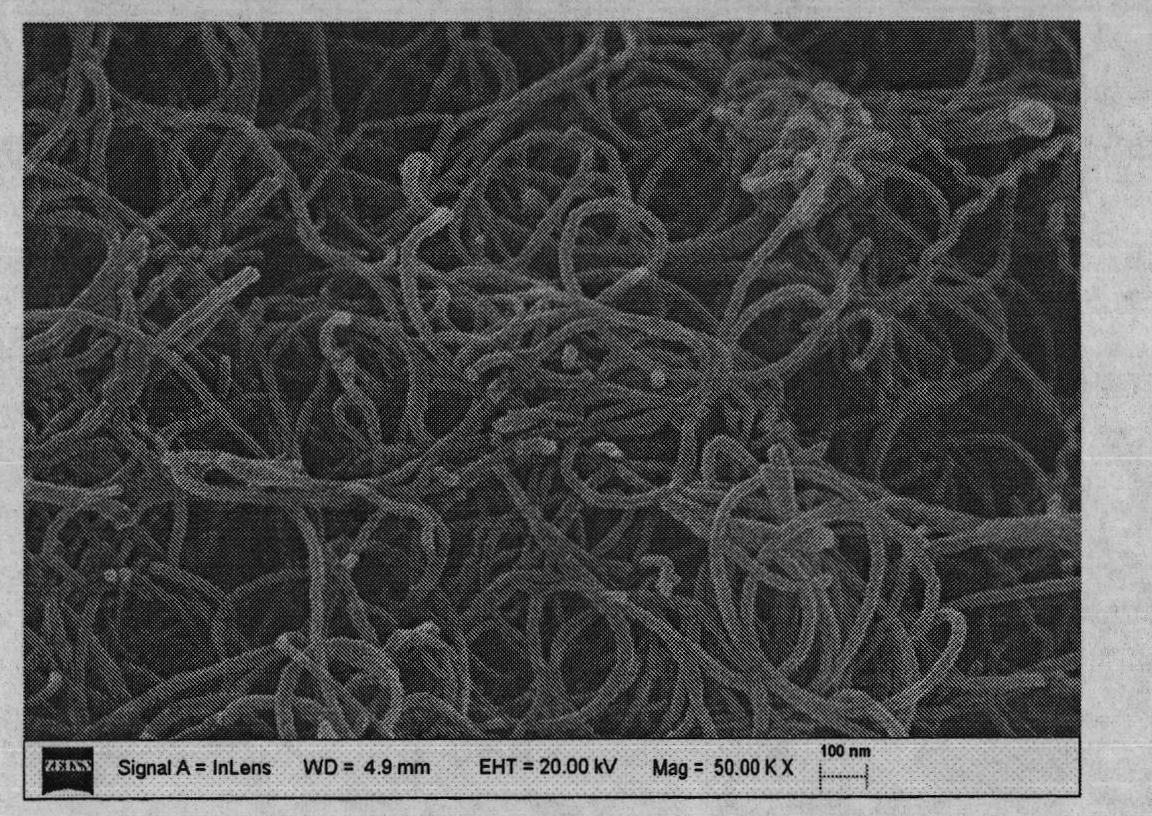

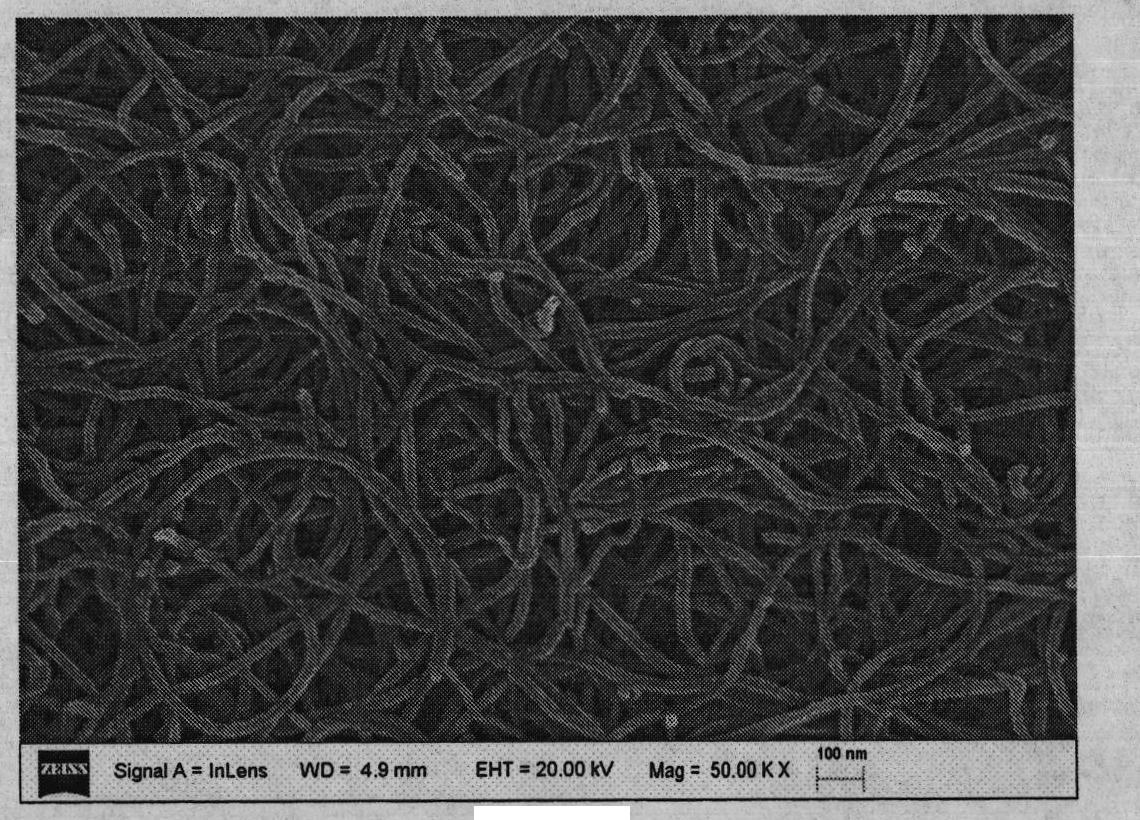

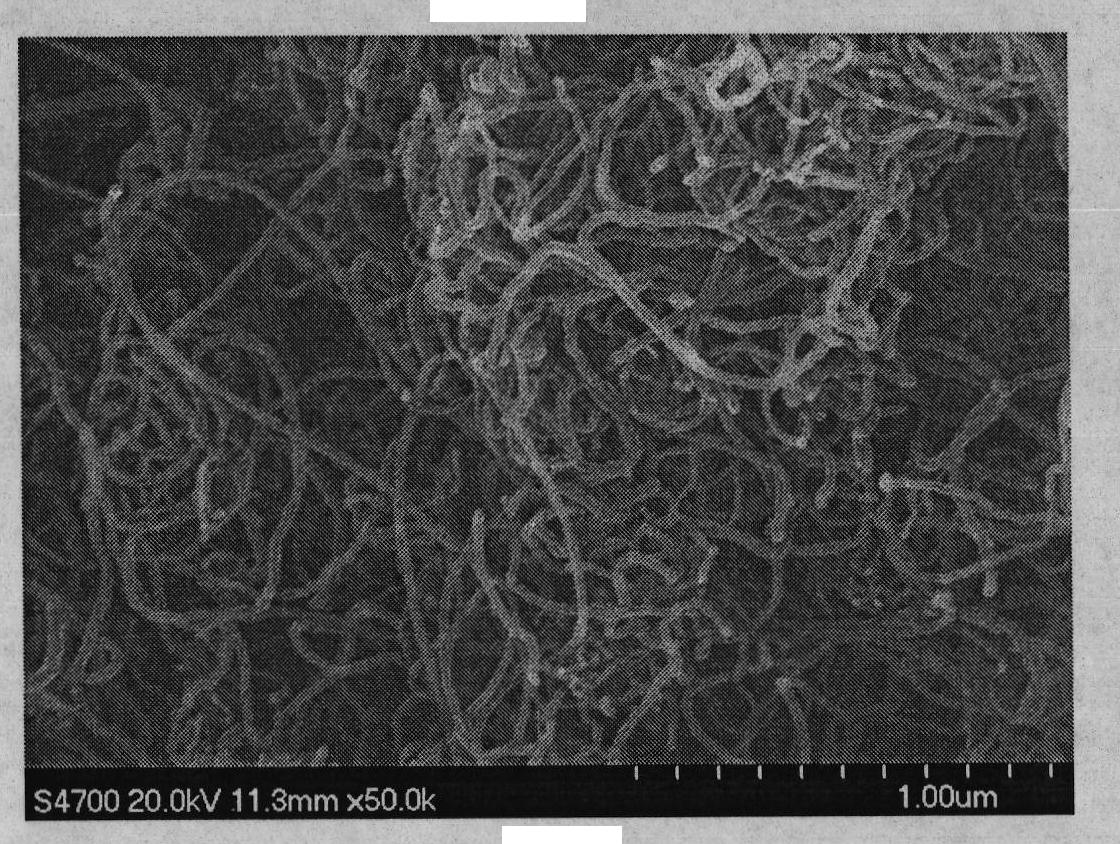

Image

Examples

Embodiment 1

[0030] 1.8626gCo(NO 3 ) 2 ·6H 2 O and 1.2004gAl(NO 3 ) 3 9H 2 O was prepared into 80mL salt solution, and then 2.3063g urea was added to make a mixed solution.

[0031] Put the above solution into a 100ml polytetrafluoroethylene resin liner, put it into a miniature autoclave to seal it, put the kettle into an oven for crystallization at 150°C for 24 hours, take out the liner after cooling, and take out the reactant , filtered with suction, washed twice with deionized water, and dried at 70°C for 15 hours.

[0032] Put the LDH precursor prepared above into a muffle furnace, raise the temperature to 700°C at a heating rate of 5°C / min, and keep it at 700°C for 120 minutes to obtain the corresponding roasted products, wherein the roasted products are cobalt oxide and cobalt aluminum spinel.

[0033] Spread 43 mg of the roasted product prepared above in a porcelain boat, put the porcelain boat into a horizontal quartz tube located in a tubular heating furnace, feed in nitrog...

Embodiment 2

[0037] 0.9313gCo(NO 3 ) 2 ·6H 2 O, 0.8205gMg(NO 3 ) 2 ·6H 2 O and 1.2004gAl(NO 3 ) 3 9H 2 O was prepared into 80mL salt solution, and then 2.3063g urea was added to make a mixed solution.

[0038] Put the above mixed solution into a 100ml polytetrafluoroethylene resin liner, put it into a miniature autoclave to seal, put the still in an oven for crystallization at 100°C for 15 hours, take out the liner after cooling, and take out The reactant was suction filtered, washed twice with deionized water, and dried at 70°C for 15 hours.

[0039] Put the LDH precursor prepared above into a muffle furnace, raise the temperature to 700°C at a heating rate of 5°C / min, and keep it at 700°C for 120 minutes to obtain the corresponding roasted products, wherein the roasted products are cobalt oxide, oxide Magnesium and cobalt aluminum spinel.

[0040] Spread 48 mg of the roasted product prepared above in a porcelain boat, put the porcelain boat into a horizontal quartz tube located...

Embodiment 3

[0044] Weigh 3.7252g Co(NO 3 ) 2 ·6H 2 O and 2.4008gAl(NO 3 ) 3 9H 2 O was dissolved in 160ml deionized water to make a mixed salt solution, and then weighed 1.5361gNaOH and 1.6962gNaOH 2 CO 3 Make a mixed alkali solution, put the mixed salt solution in a 500mL three-necked flask, add the mixed alkali solution to the salt solution drop by drop under constant stirring until pH = 10, and age the mixture in a water bath at 60°C for 6 hours , after the reaction was completed, suction filtered, washed with deionized water until neutral, and dried at 70°C for 20 hours.

[0045] Put the LDH precursor prepared above into a muffle furnace, raise the temperature to 700°C at a heating rate of 5°C / min, and keep it at 700°C for 120 minutes to obtain the corresponding calcined products, wherein the calcined products are cobalt oxide and sharp spar.

[0046] Spread 75 mg of the roasted product prepared above in a porcelain boat, put the porcelain boat into a horizontal quartz tube lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com