Patents

Literature

39results about How to "Overcoming easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano inorganic antibacterial fiber masterbatch and preparation method thereof

ActiveCN105694438AGood dispersionFully dispersedMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentMasterbatchFiber

The invention discloses a nano inorganic antibacterial fiber masterbatch and a preparation method thereof. The nano inorganic antibacterial fiber masterbatch is composed of, by weight, 1-30 parts of fiber resin, 1-50 parts of nano inorganic antibacterial powder, 1-5 parts of silicon oil, 1-10 parts of a silane coupling agent, 1-5 parts of isocyanate and 0.1-0.5 part of an antioxidant. The preparation method includes: adding the nano inorganic antibacterial powder into a sand mill, then adding the silane coupling agent, and grinding at a high speed until a paste state is achieved; adding the isocyanate, and grinding at a high speed to obtain organic-inorganic hybrid nanopowder; jointly subjecting the nanopowder and the fiber resin to twin-screw extrusion for preparing the masterbatch. The prepared nano inorganic antibacterial fiber masterbatch is widely applicable to various fibers.

Owner:HUIZHOU HUANMEISHENG NEW MATERIAL CO LTD

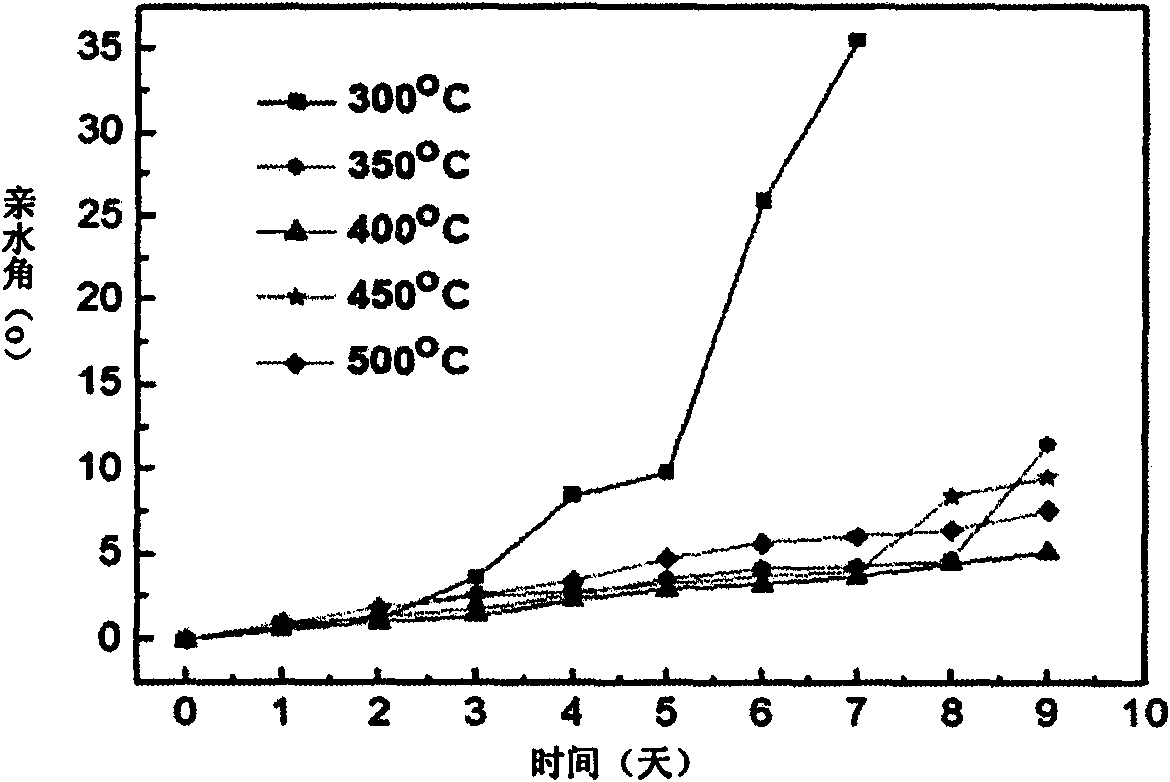

Self-cleaning super-hydrophilic thin film and preparation method thereof

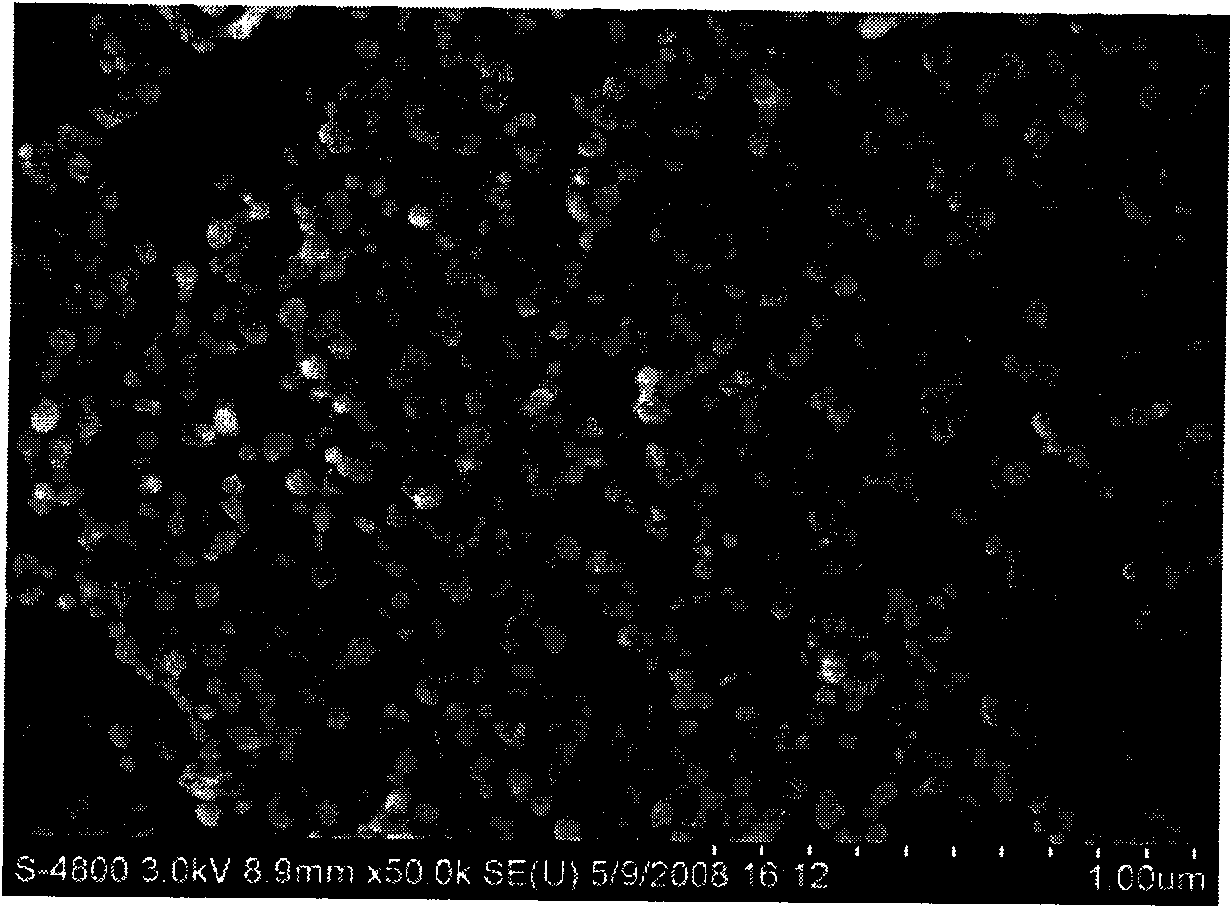

InactiveCN101602933AOvercoming easy reunionOvercoming the weakness of not being easy to recycleOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsRare earthSolvent

The invention provides a self-cleaning super-hydrophilic thin film and a preparation method thereof. The preparation method comprises the steps of using tetra-n-butyl titanate as a precursor of TiO2, using anhydrous ethyl alcohol as solvent, adding glacial acetic acid, and magnetically agitating at room temperature to obtain solution A; synchronously, taking distilled water and anhydrous ethyl alcohol, adding doping salts, and magnetically agitating the mixture to obtain solution B; slowly adding the solution B to the solution A, adding hydrochloric acid to adjust pH value to 3-5, agitating to obtain TiO2 sol, and preparing a rare-earth-doped nanometer-sized TiO2 thin film by using a film drawing machine; immersing a substrate into the sol, drawing and plating a film after glass sheet and liquid surface are stable; drying after plating a layer of film and cooling at room temperature; repeating the steps to prepare the rare earth-doped nanometer-sized TiO2 thin film with different layers; thermally treating the base plated with the TiO2 thin film, and directly using the film-plated base. The thin film of the invention overcomes the weak points that nanometer-sized powder easily aggregates and is not easily recovered, the obtained crystal form is table, and the thin film has excellent self-cleaning and hydrophilic capacities.

Owner:CENT SOUTH UNIV

Preparation method for heavy metal negative ion-removed porous nanometer composite fiber membrane

InactiveCN106955678AImprove adsorption capacityLarge capacityOther chemical processesWater contaminantsFiberIn situ polymerization

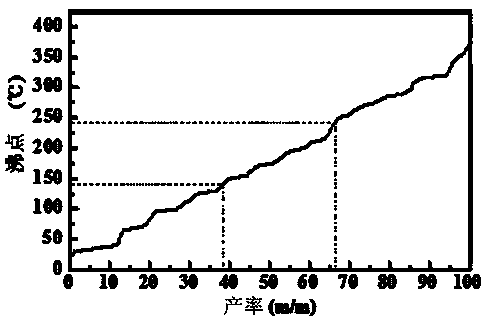

The invention discloses a preparation method for a heavy metal negative ion-removed porous nanometer composite fiber membrane. The preparation method comprises the following steps: dissolving a pore-foaming agent and a high-molecular polymer in an organic solvent; preparing a porous nanometer fiber membrane substrate through a high-pressure electrostatic spinning technology, synthesizing molybdenum disulfide nanoparticles with a hydrothermal method, uniformly mixing the molybdenum disulfide nanoparticles with a high-molecular polymer monomer, and adding a mixture into a strongly-acidic alcohol aqueous solution; under the action of an oxidizing agent, carrying out an in-situ polymerizing reaction to prepare the porous nanometer composite fiber membrane. The preparation method for the porous nanometer composite fiber membrane disclosed by the invention only needs to carry out three steps, has high yield, is easy to regulate and control, and is suitable for industrial production; heavy metal negative ions can be removed rapidly and efficiently within 30 minutes, so that the heavy metal negative ion-removed porous nanometer composite fiber membrane is 7mmol / g in maximum adsorption quantity, has high interference resistance, can be repeatedly used, and has a wide application prospect on the aspect of water environment pollution.

Owner:NANJING UNIV

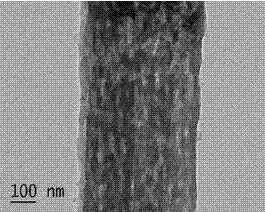

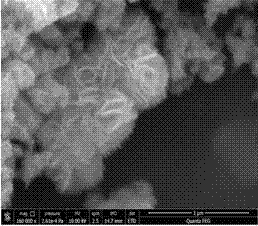

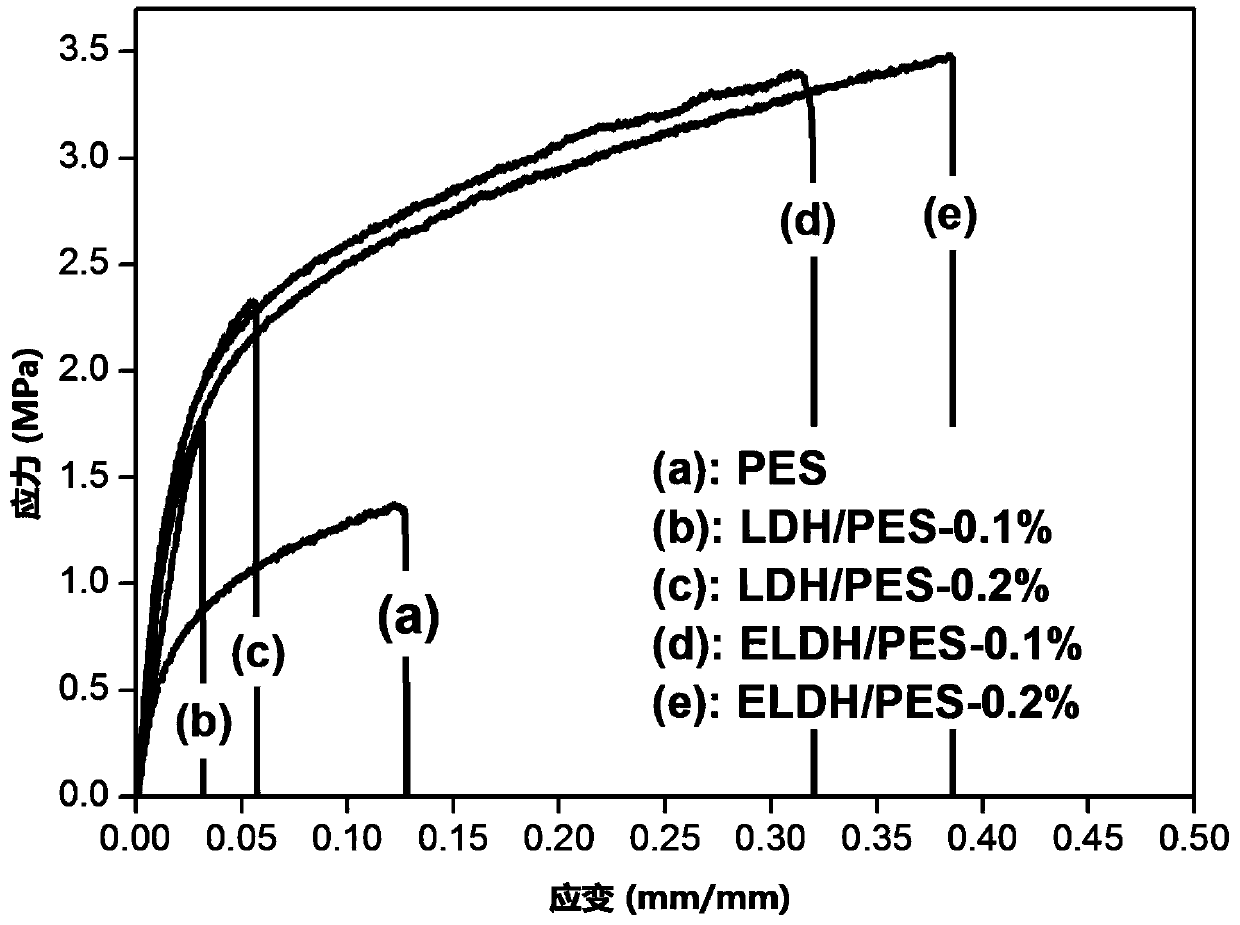

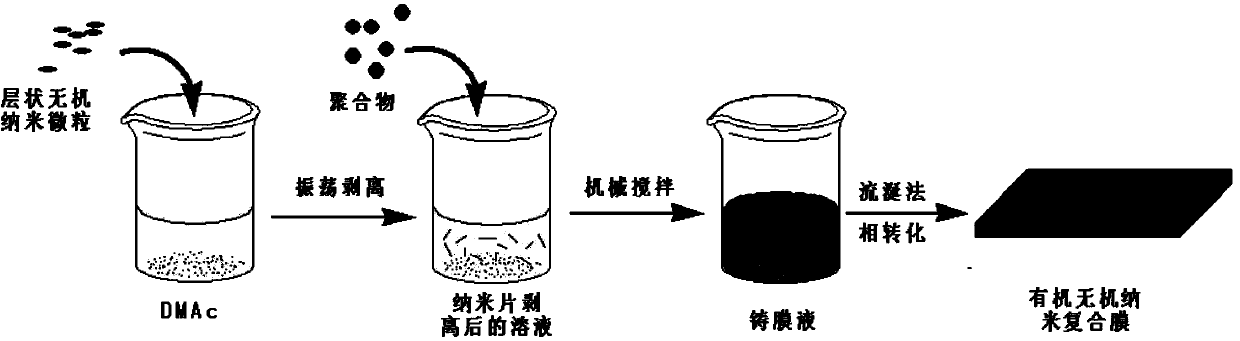

Method for preparing organic-inorganic nano-composite membranes by using layered inorganic nano particles

InactiveCN103801201AOvercoming easy reunionOvercoming dispersionSemi-permeable membranesMicroparticleNanometre

The invention belongs to the technical field of membrane preparation, and particularly relates to a method for preparing organic-inorganic nano-composite membranes by using layered inorganic nano particles, wherein the layered inorganic nano particles after being stripped by using an in-situ stripping method are used for the preparation of organic-inorganic nano-composite membranes. The method for preparing organic-inorganic nano-composite membranes by using layered inorganic nano particles disclosed by the invention is easy to operate, and simple in equipment, and can effectively overcome the disadvantages that inorganic nanomaterials are easily agglomerated, and difficult to be uniformly dispersed in the process of film forming.

Owner:ZHENGZHOU UNIV

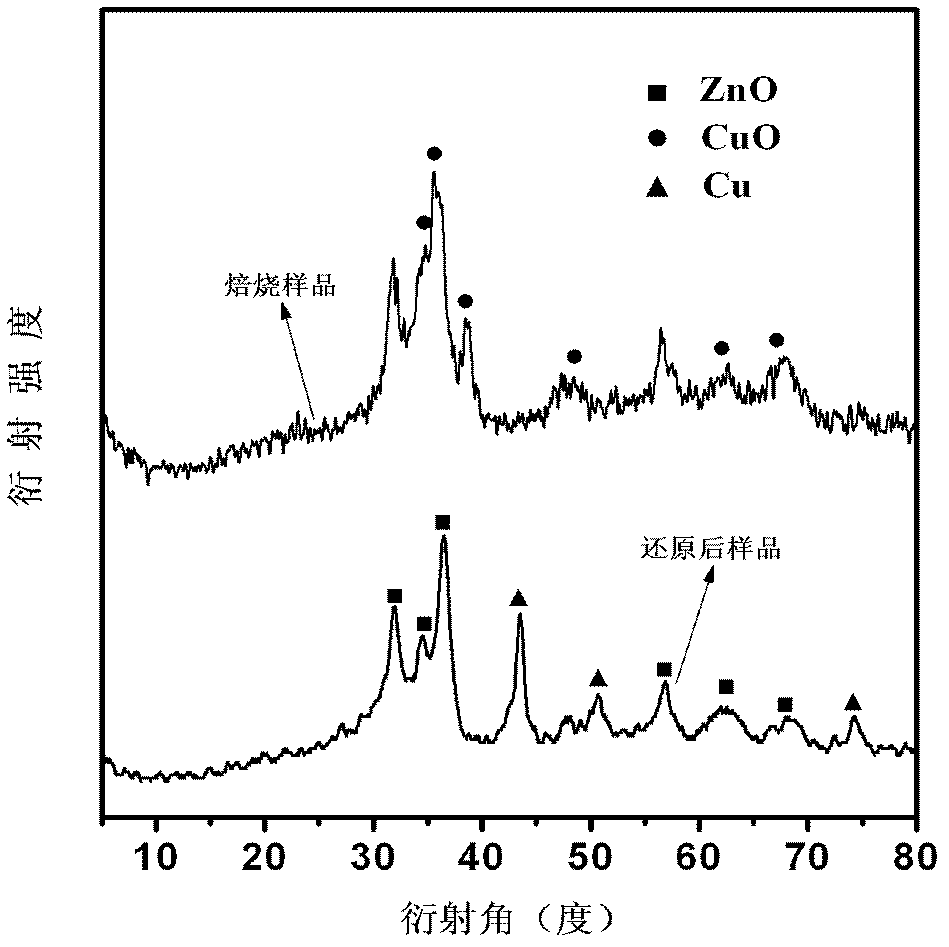

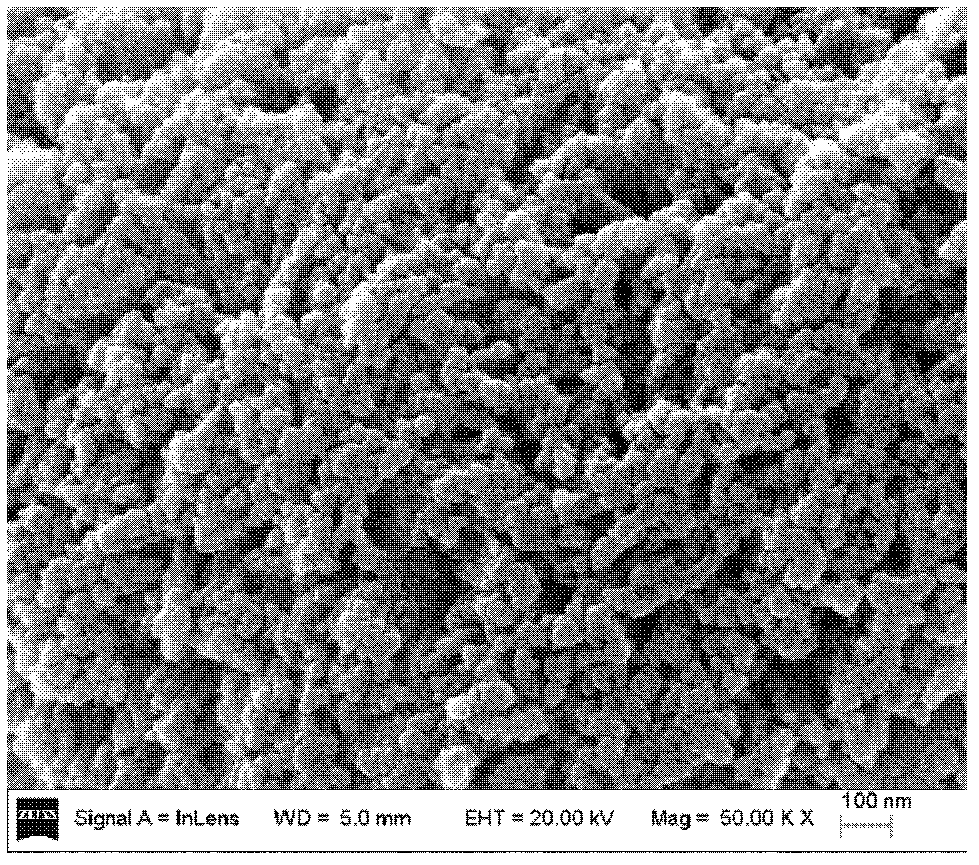

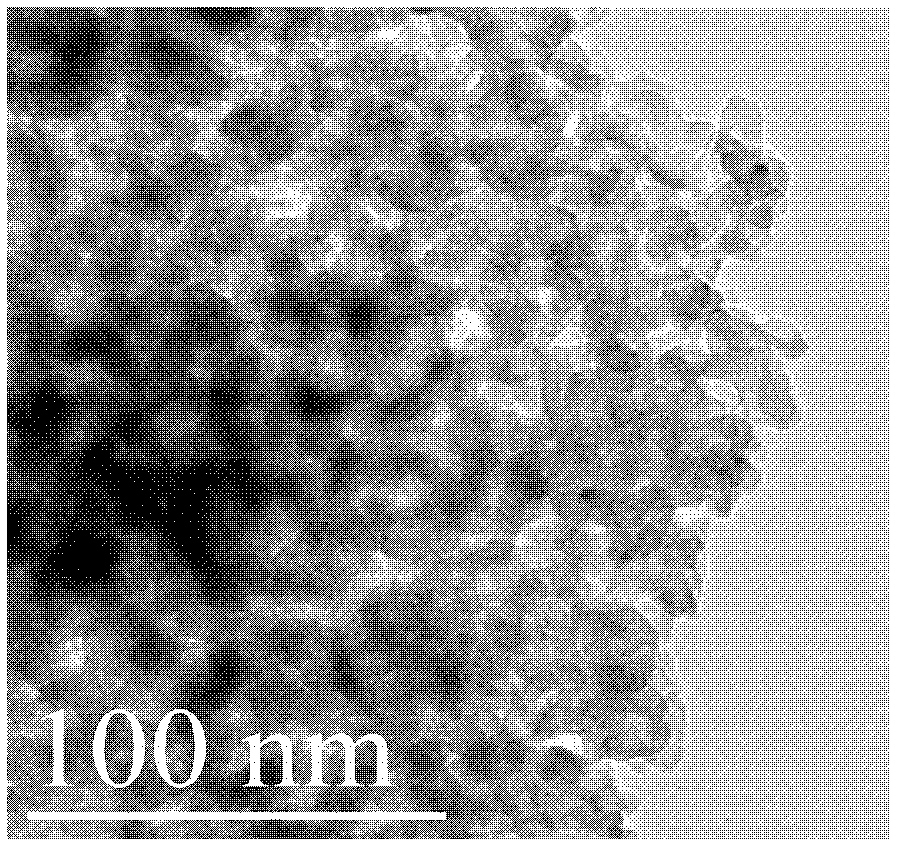

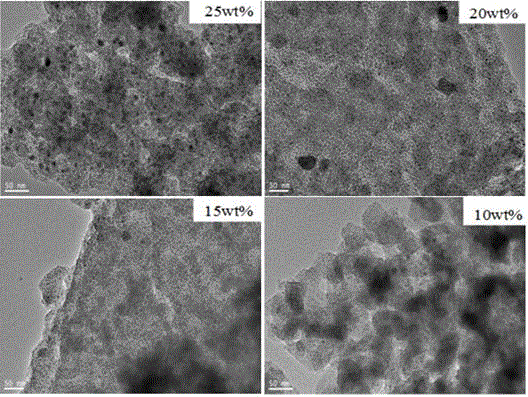

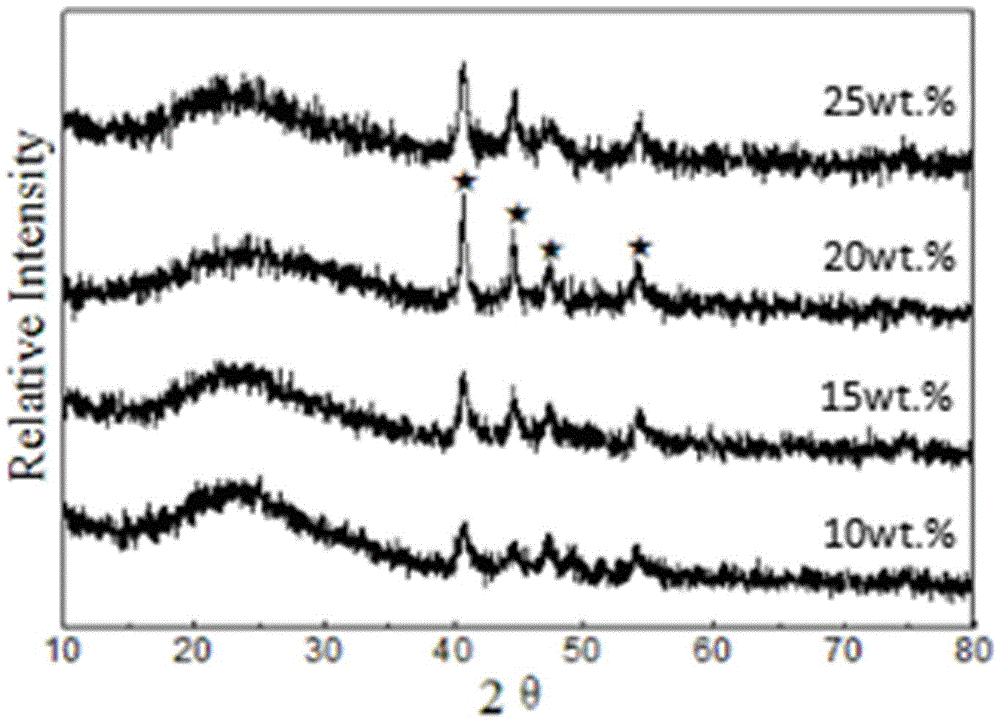

High-dispersion supported copper-based catalyst as well as preparation method and application thereof

InactiveCN103301843AImprove structural stabilityGood dispersionOrganic compound preparationHydroxy compound preparationMolecular levelCentrifugal force

The invention provides a high-dispersion supported copper-based catalyst as well as a preparation method and an application thereof. The catalyst can be represented as Cu / MO-ZrO2, wherein copper nanoparticles are uniformly dispersed on a compound metal oxide carrier, the specific surface area of the catalyst is between 60-110m<2> / g, the weight ratio of Cu is 10-40%, and the grain size of Cu is 5-20nm. Precursor nanoparticles of a compound metal hydroxide catalyst uniformly dispersed in molecular level and adjustable in constitution and structure are synthesized by the method by means of a forced micromixing effect caused by a strong shear force, a centrifugal force and a counter-acting force of an all-backmixing liquid film reactor, and a selective guide effect of a surfactant. The catalyst precursor is roasted and reduced to obtain the high-dispersion supported copper-based catalyst. The catalyst is mainly used for selective catalytic hydrogenation of dimethyl oxalate, and the conversion ratio and the selectivity respectively reach 90-100% and 85-95%. The copper-based catalyst has the characteristics of good stability and simple preparation method.

Owner:BEIJING UNIV OF CHEM TECH

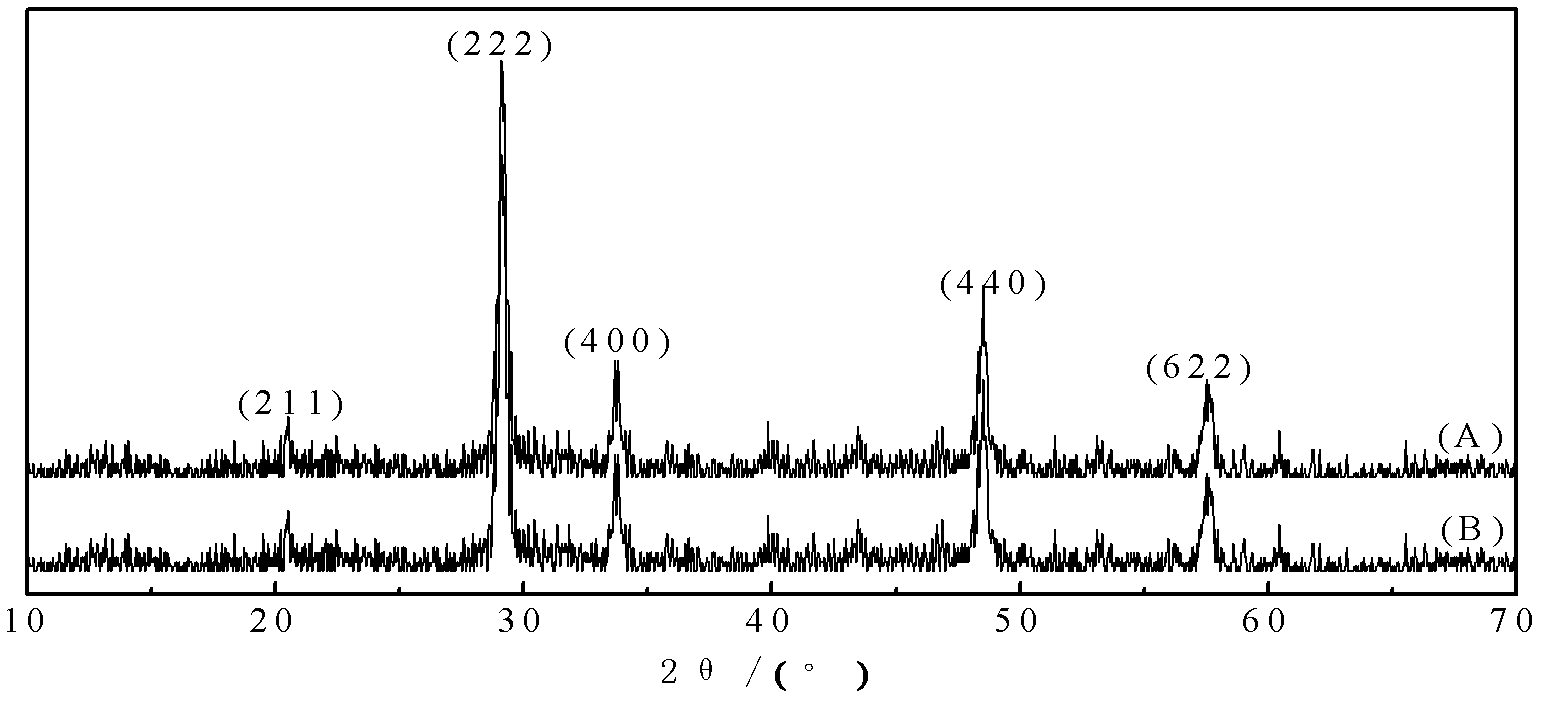

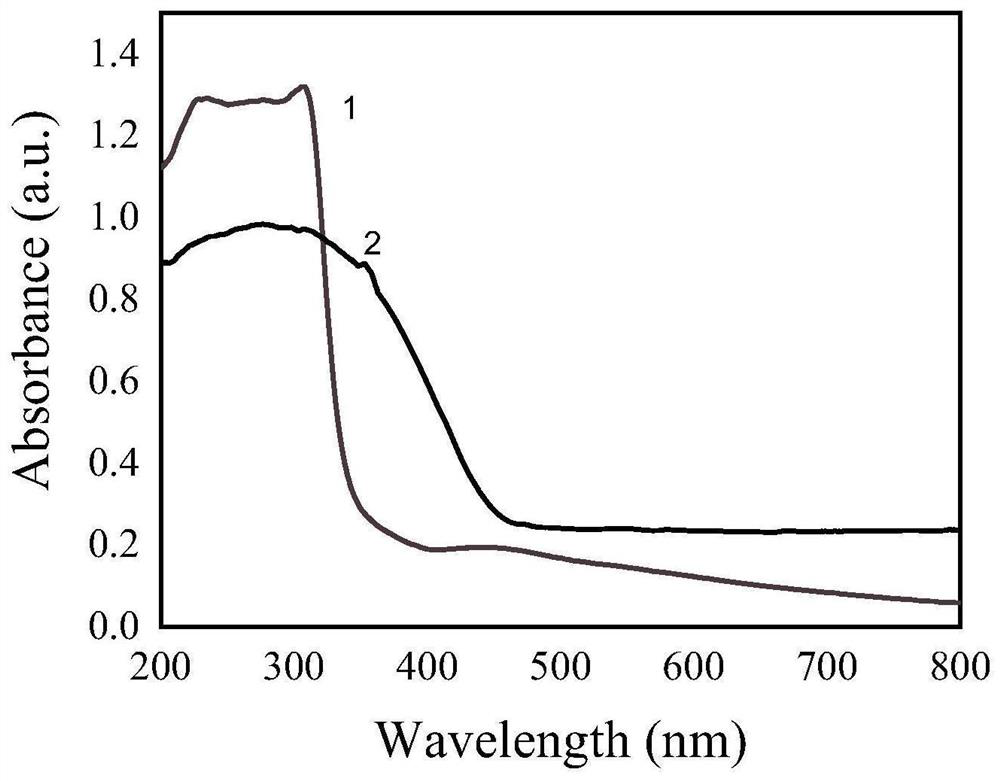

Sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate

InactiveCN102765758AHigh crystallinityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsIndiumTungstate

The invention discloses a sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate. The technical scheme point of the invention is to respectively disclose a sol-gel-hydrothermal method for preparing a bismuth tungstate catalyst and a sol-gel-hydrothermal method for preparing an indium-doped bismuth tungstate catalyst. The preparation method disclosed by the invention has the advantages of simple operation and low cost; and the prepared bismuth tungstate catalyst and the indium-doped bismuth tungstate catalyst have excellent photocatalysis performance.

Owner:HENAN NORMAL UNIV

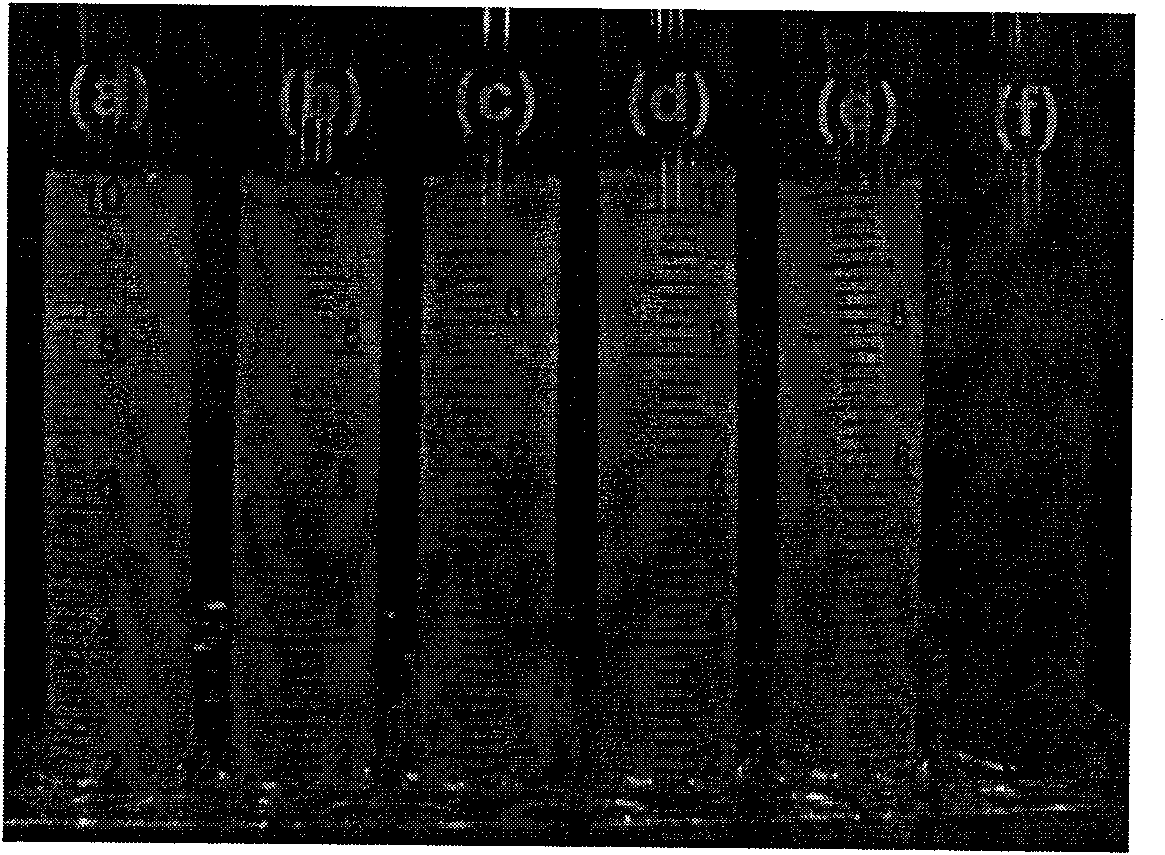

Hyaluronic acid-hydroxyapatite nano composite sphere and preparation method

InactiveCN101559241ABiologicallyWith targeted featuresGenetic material ingredientsPharmaceutical non-active ingredientsApatitePhosphate

The invention relates to a hyaluronic acid-hydroxyapatite nano composite sphere. The nano composite sphere comprises 93 to 98.7 mass percent of hydroxyapatite and 1.3 to 7.0 mass percent of hyaluronicacid, and has a spherical shape and the grain size of 20 to 200 nm. A preparation method for the hyaluronic acid-hydroxyapatite nano composite sphere comprises the following process steps: (1) preparation of a hyaluronic acid saccharoid solution; (2) reaction and synthesis: adding an aqueous solution of calcium salt and an aqueous solution of phosphate into the hyaluronic acid saccharoid solutionprepared in step (1) with agitating, then regulating the pH value of a reaction system to make the pH value stabilize from 9 to 11, and carrying out the aging for at least 48 hours at the room temperature and normal pressure; and (3) product collection and drying. The nano composite sphere has the unique targeting characteristics (CD44 receptor) in vivo, and has good application prospect in the field of medicine and gene targeting transportation.

Owner:SICHUAN UNIV

High-stability environment-friendly carbon nanotube water dispersing liquid and preparation method thereof

The invention discloses a high-stability environment-friendly carbon nanotube water dispersing liquid and a preparation method thereof. The method comprises the steps: according to the mass parts, mixing 1-5 parts of carbon nanotubes, 0.5-20 parts of lignosulfonate and 0.1-5 parts of deionized water; and carrying out grinding treatment, adding water to dilute, adjusting the pH to 6-8, adding a stabilizer, and carrying out ultrasonic dispersion to obtain the stably dispersed carbon nanotube water dispersing liquid. The stabilizer is one or more of triton X-100, sodium dodecyl sulfate, sodium dodecyl benzene sulfonate, dodecyl sulfobetain and sodium methyl palmitate sulfonate. The high-stability environment-friendly carbon nanotube water dispersing liquid has the advantages of good dispersion effect of carbon nanotubes, high stability, high concentration, short technological process and preparation period, environmental friendliness and good compatibility with water-based resin.

Owner:SOUTH CHINA UNIV OF TECH

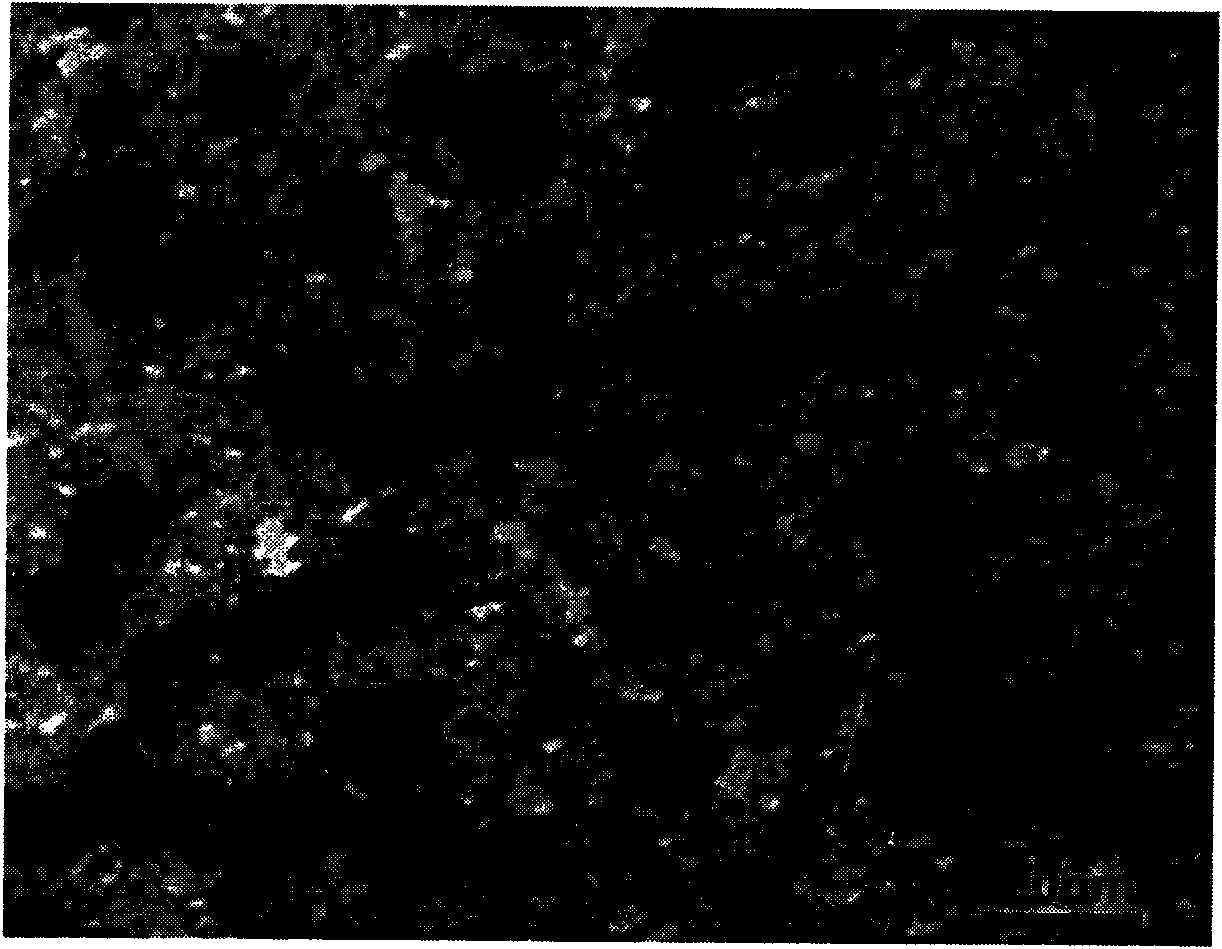

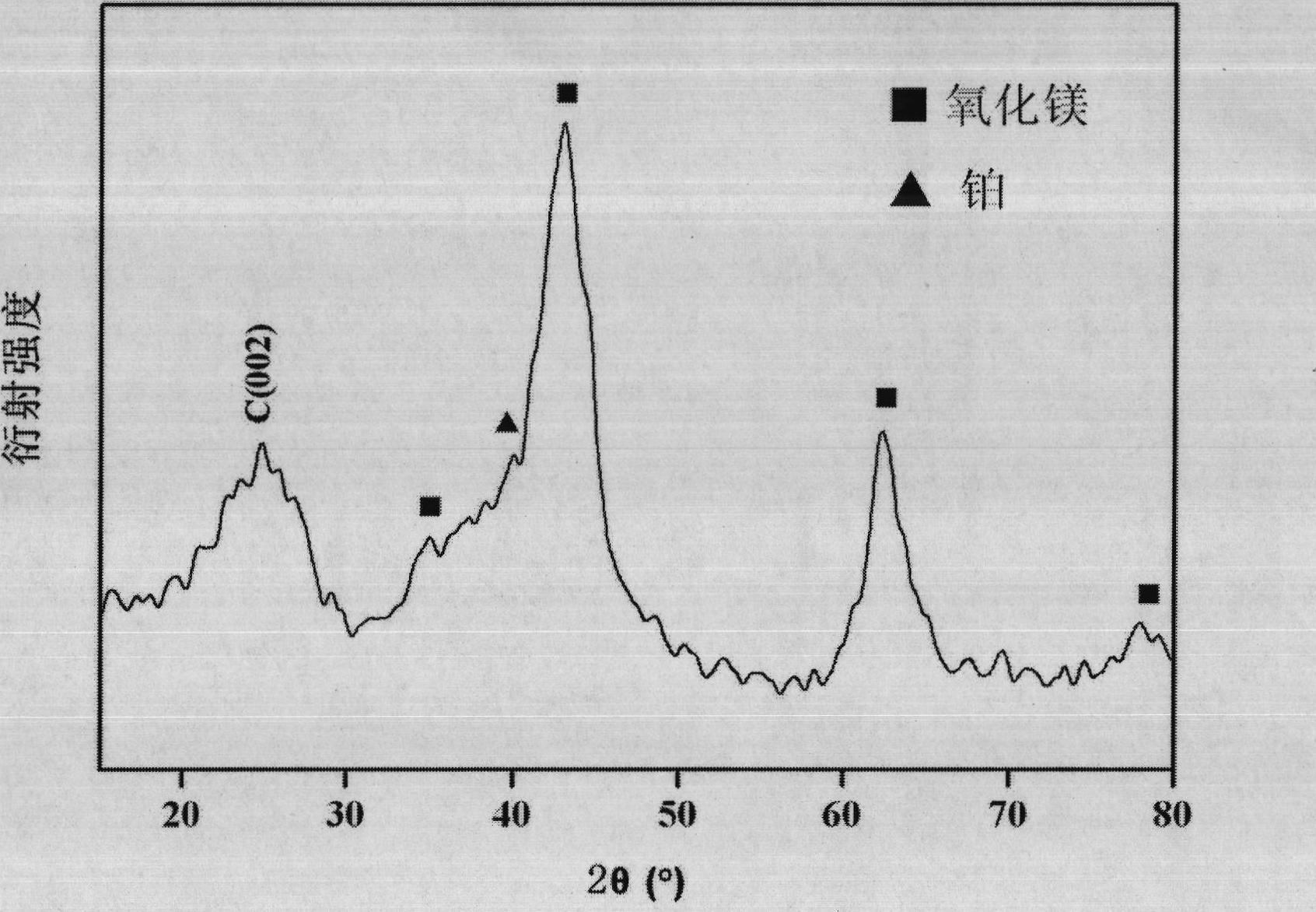

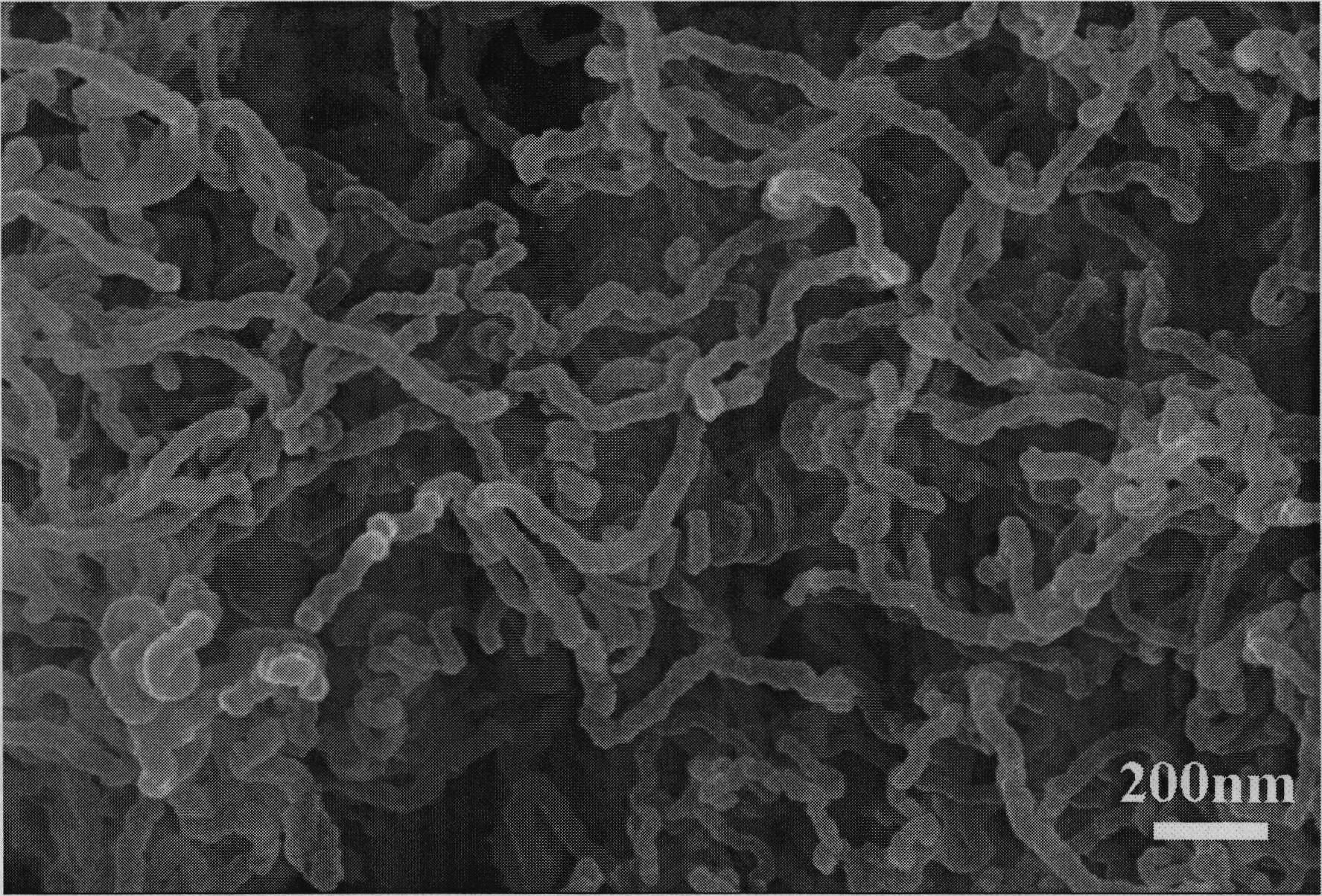

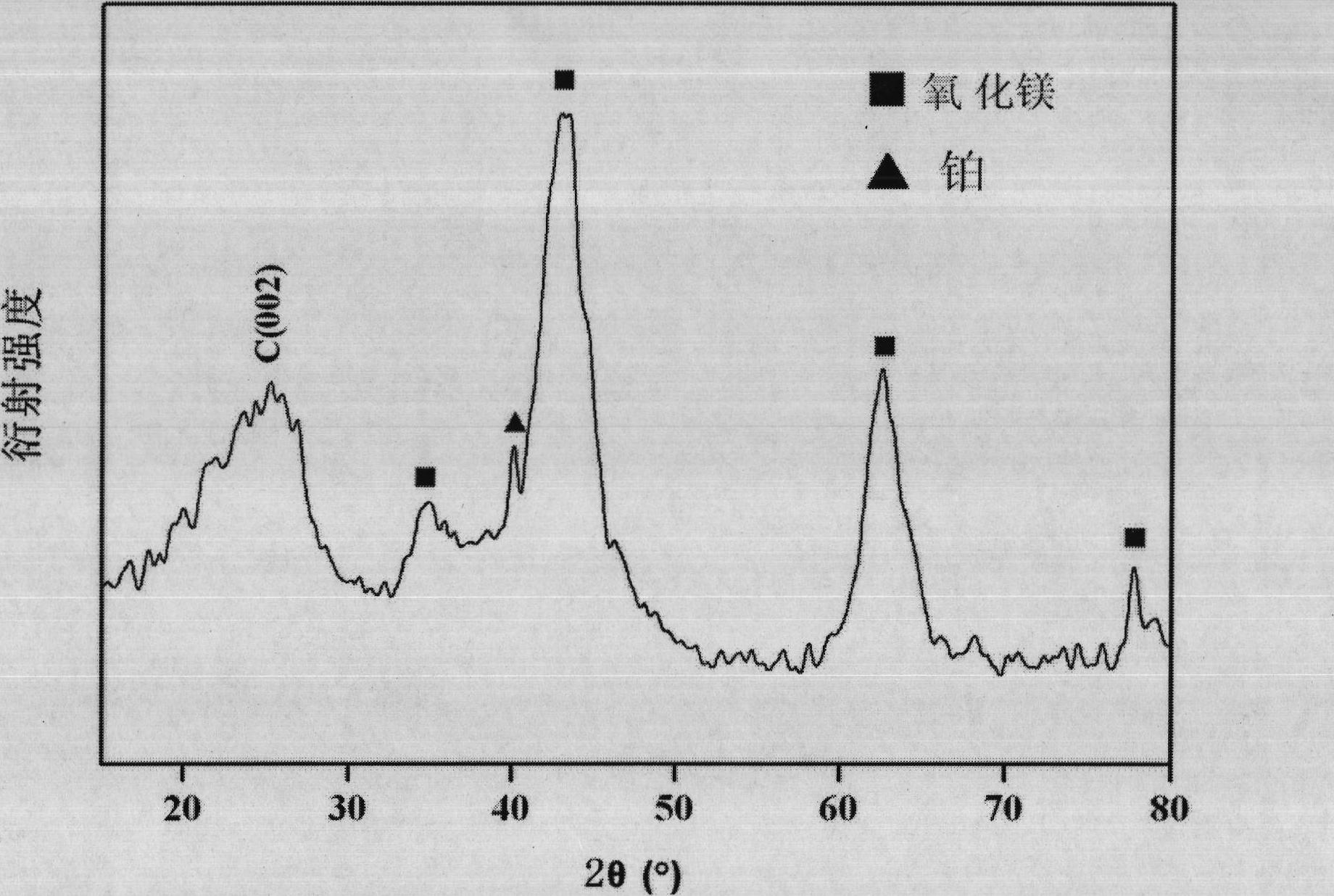

Stratiform bimetal hydroxide for growing carbon nano-fibers and preparation method thereof

InactiveCN102059113AEvenly distributedOvercoming easy reunionFibre chemical featuresMetal/metal-oxides/metal-hydroxide catalystsDecompositionCarbon source

The invention discloses a stratiform bimetal hydroxide for growing carbon nano-fibers and a preparation method of the stratiform bimetal hydroxide, which belong to the technical field of preparation of nano materials. PtCl62 is introduced into layers of the stratiform bimetal hydroxide by adopting a co-precipitation method, a composite metal oxide loaded high-dispersion Pt-based catalyst is prepared by baking, and an acetylene gas is cracked by a chemical vapor deposition method to catalyze and grow a carbon nano-fiber material. In the method, a hydrogen in situ reduction Pt species generated by acetylene decomposition is used for obtain high-dispersion Pt nano-particles with the particle size of 6 to 40 nm, and then the Pt nano-particles are used for adsorbing the carbon generated by acetylene cracking, so the carbon nano-fiber material of which the diameter is 15 to 80 nm and the length is 1.2 to 6 mum can be grown. The stratiform bimetal hydroxide and the preparation method have the advantages of overcoming the defects of the conventional metal catalyst that the preparation cost is high, agglomeration is easily generated among metal particles and the particle size is difficult to control, and greatly saving the production cost and reducing environmental pollutions by using acetylene as a reducing gas and a carbon source to grow the carbon nano-fibers.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing three-dimensional manometer load-type catalyst

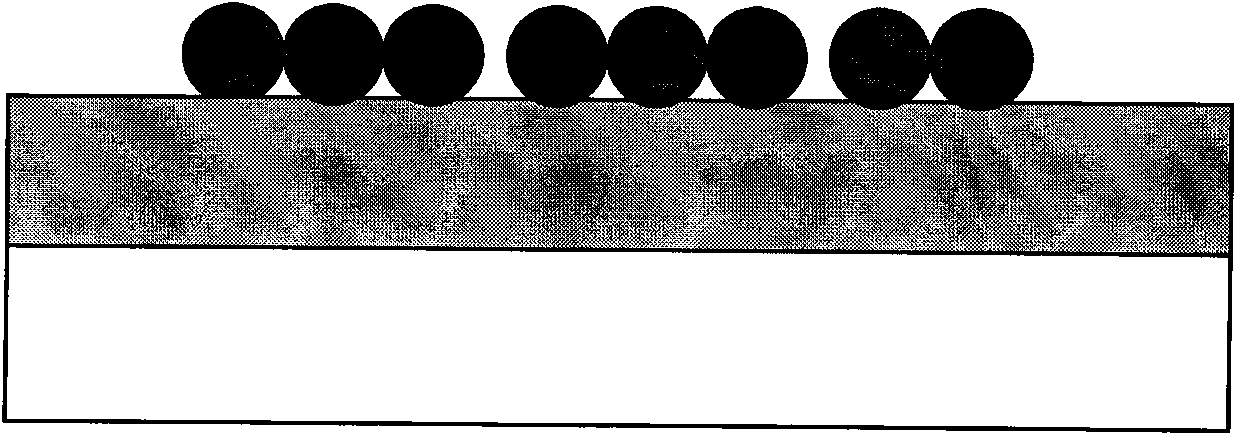

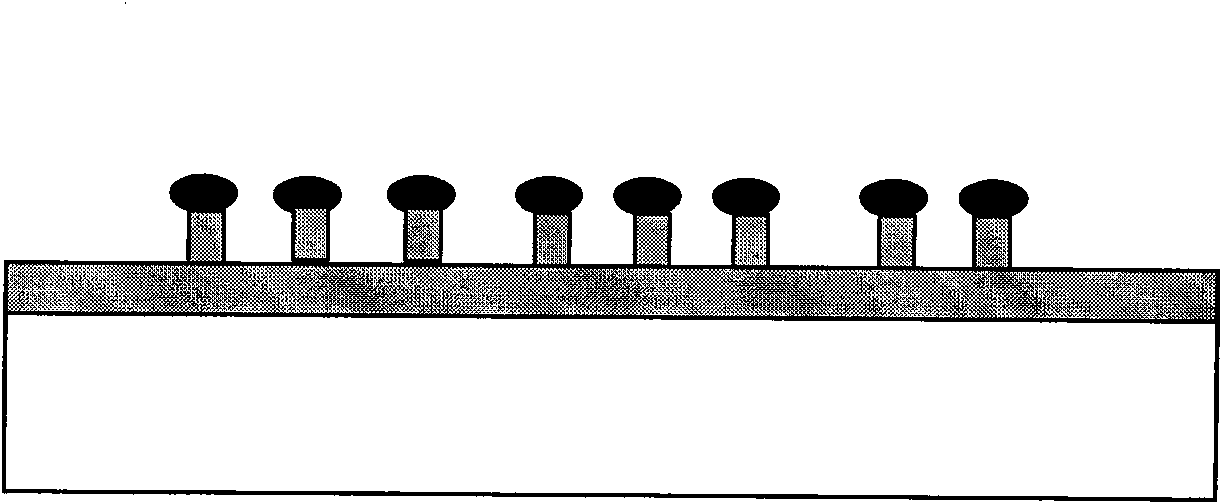

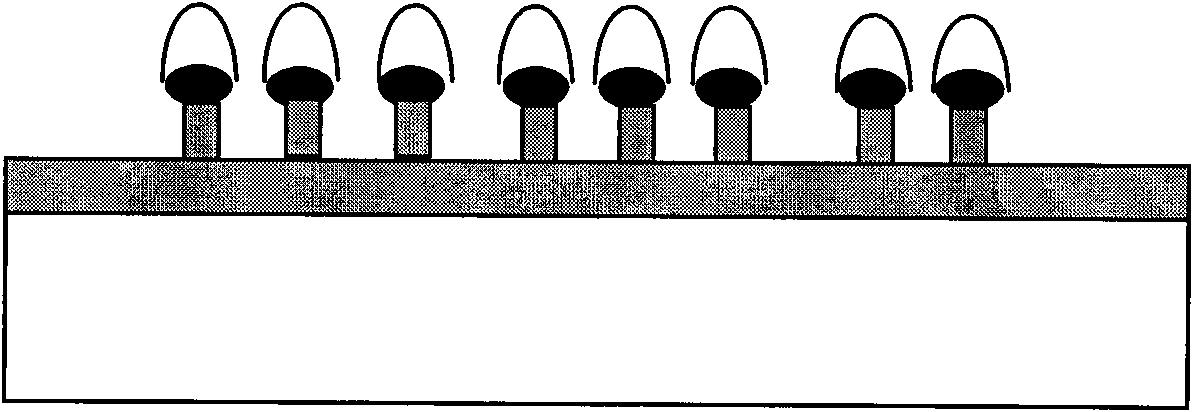

InactiveCN101574670AEasy to makeSimple preparation processWater/sewage treatment by irradiationWater contaminantsNanometreDry etching

The invention relates to a method for preparing a three-dimensional manometer load-type catalyst, comprising the following steps of: (1) covering solution with nanosphere on a substrate evenly and drying; (2) using the nanosphere as a mask plate and adopting dry etching or wet corrosion based on different etching or corroding rate with the substrate; and (3) depositing a catalyst material. The method has simple process, low cost and is easy to be promoted and used. The scale of the catalyst carrier in the three-dimensional direction is within the nanometer magnitude and the body of the carrier has larger specific surface area so that the catalyst acts on large areas, and the catalyst materials are highly dispersed, easily recycled and can be reused.

Owner:DONGHUA UNIV

Preparation method and application of coupled modified nanometer yttrium oxide

InactiveCN102504146AOvercoming easy reunionOvercome the disadvantage of non-oil solubilityAdditivesWear resistantEthylene Homopolymers

The invention discloses a preparation method and application of coupled modified nanometer yttrium oxide. The preparation method comprises the following steps that: the nanometer yttrium oxide is weighed and is added into methylbenzene, and ultrasonic dispersion is carried out; glacial acetic acid and silane coupling agents are added, the materials are stirred for taking reaction, then, centrifugal separation is carried out, homopolymers and unreacted monomers are extracted, and vacuum drying is carried out for obtaining the silane coupling agent modified yttrium oxide; then, the silane coupling agent modified yttrium oxide is taken, methylbenzene is added, and the ultrasonic dispersion is carried out; initiating agents azodiisobutyronitrile and monomer methyl acrylate are heated to 75 DEG C in nitrogen gas atmosphere, the initiating agents are slowly added to take reaction with the monomers, then, the centrifugal separation is carried out, the homopolymers and the unreacted monomers are extracted, and the coupled grafted modified nanometer yttrium oxide is obtained after the vacuum drying; the modified nanometer yttrium oxide is used as an extreme-pressure wear-resistant and abrasion-reduction additive to be ultrasonically dispersed into liquid paraffin wax base oil or finished product lubricating oil; and good extreme-pressure wear-resistant and abrasion-reduction effects are shown.

Owner:GUANGDONG UNIV OF TECH

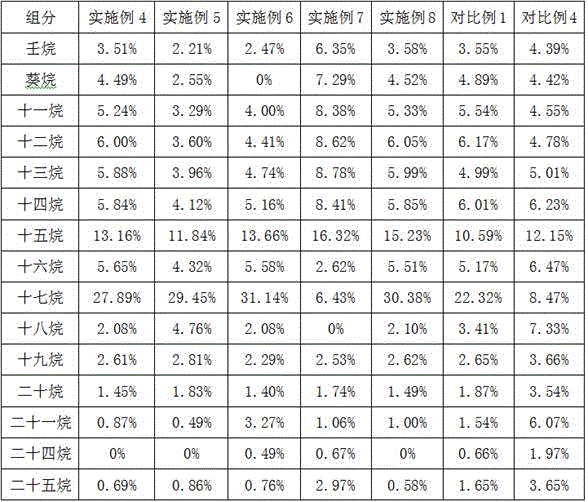

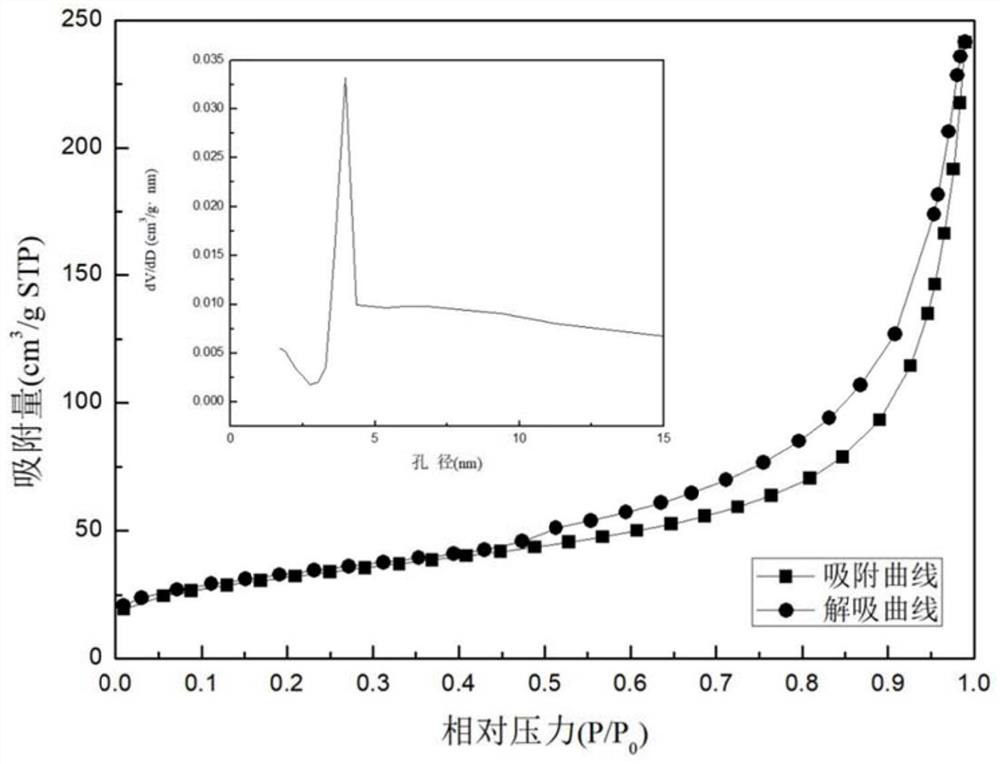

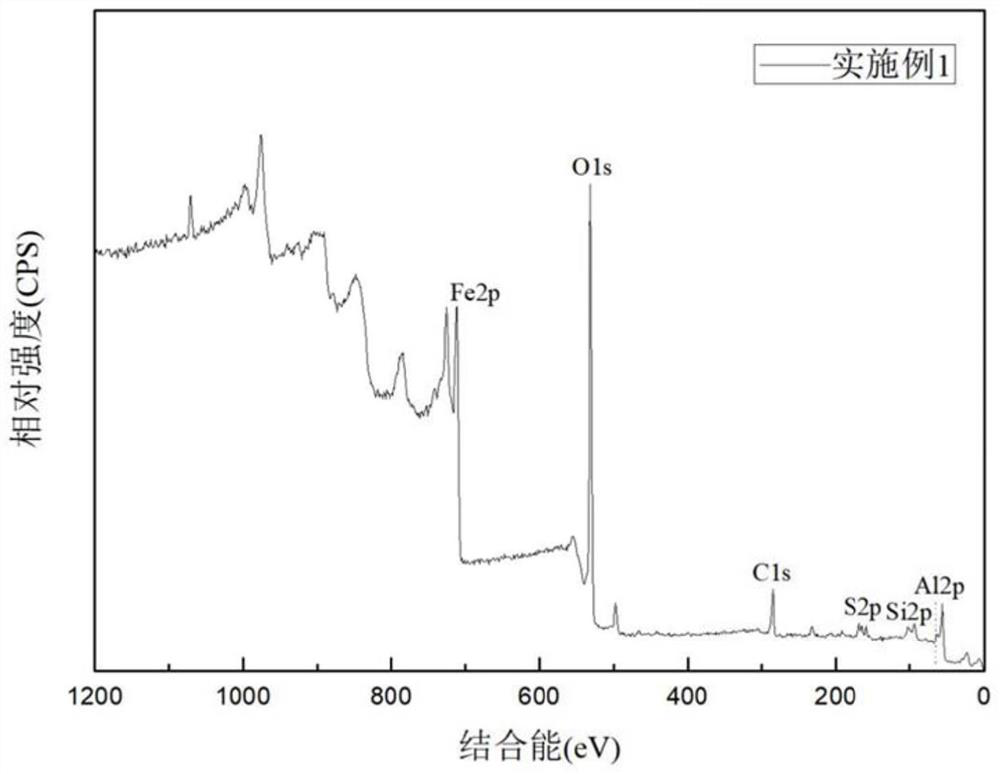

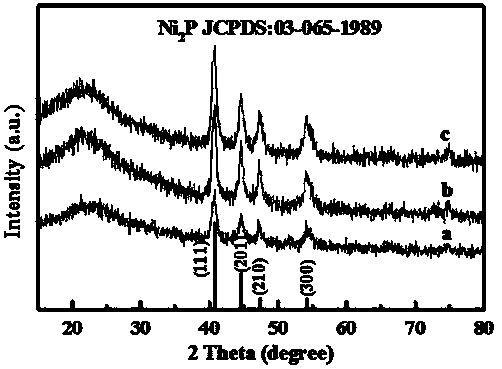

Preparing of Ni2P/Zr-MCM-41 catalyst and application for preparing biofuel by catalyzed biolipid

ActiveCN105536860ALarge specific surface areaIncrease acidityMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkanePtru catalyst

The invention provides preparing of Ni2P / Zr-MCM-41 catalyst and application for preparing biofuel by catalyzed biolipid. A preparing method comprises: preparing a Zr-MCM-41 carrier, then weighing nickel nitrate and diammonium hydrogen phosphate with a molar weight of Ni to P, preparing into a solution, then adsorbing the solution with the carrier, taking out, and roasting to obtain a precursor; rising temperature of the precursor to 250 DEG C at 10 DEG C / min in hydrogen, then rising to 350 DEG C at 5 DEG C / min, then rising to 450-650 DEG C at 1 DEG C / min, keeping for 2h, finally cooling to room temperature, and performing passivation for 2h in low O2 concentration to obtain the catalyst. The method is simple and easy to realize, the catalyst is low in price, the hydrodeoxygenation efficiency is high, hydrodeoxygenation of manioca oil can be better catalyzed, the biofuel is high in straight-chain paraffin content, main components are petroleum diesel and aviation kerosene, the calorific value is high, the stability is high and the catalyst has very high industrial application prospect.

Owner:HAINAN UNIVERSITY

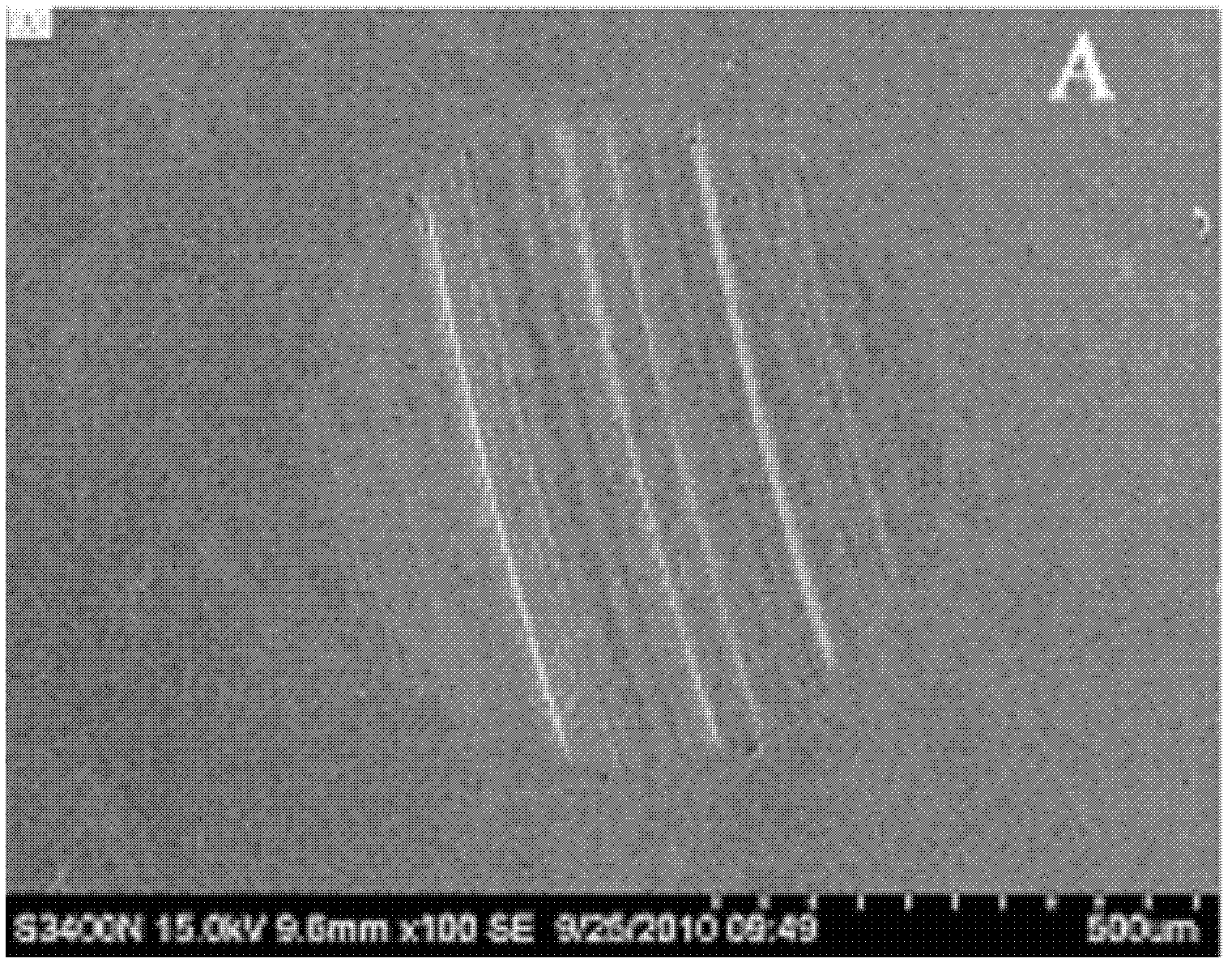

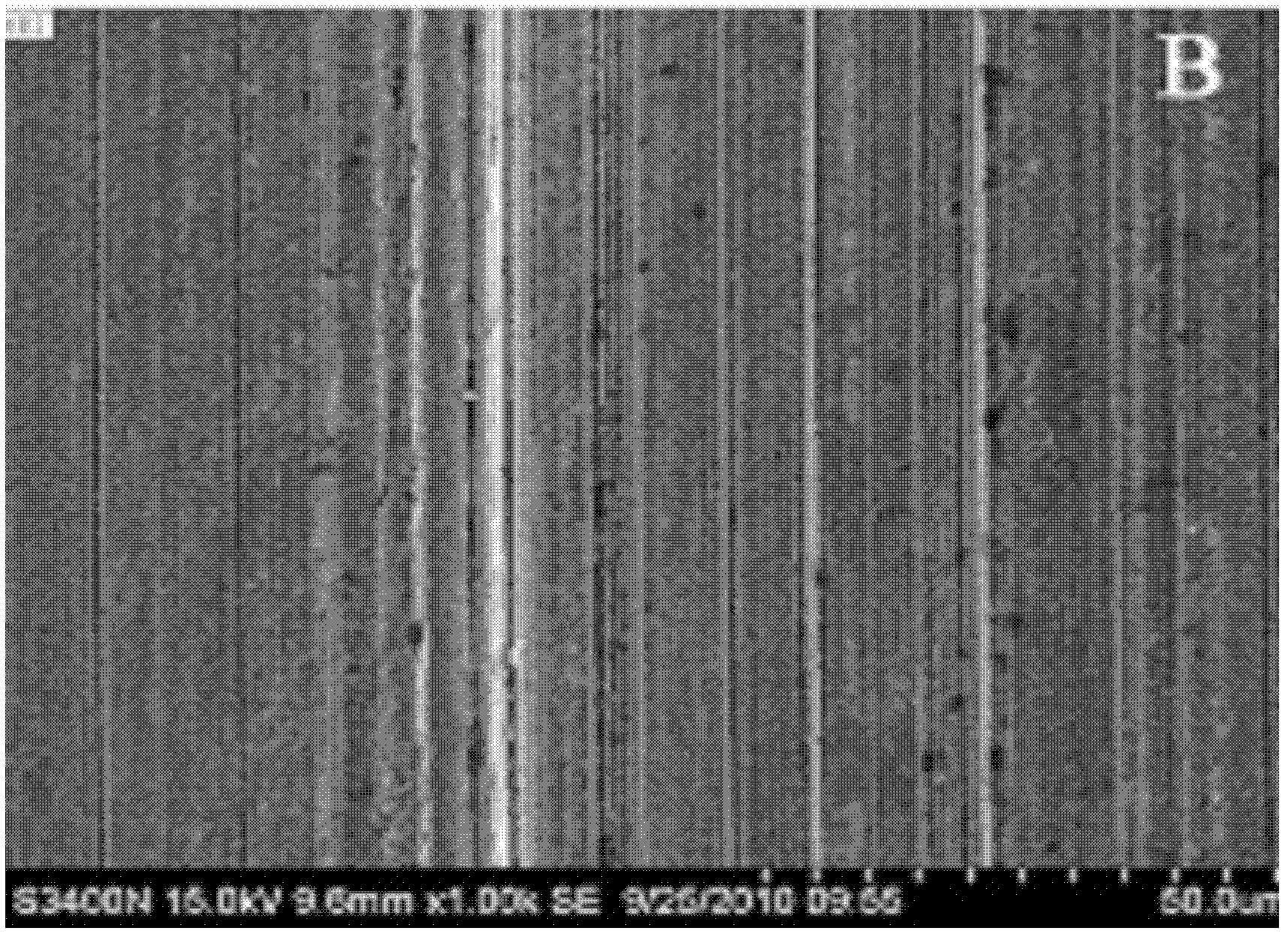

Method for gradient and length-diameter ratio CNTs reinforced copper-based composite materials of laser-induction composite melting deposition

InactiveCN103170627AOvercoming easy reunionOvercoming dispersionManufacturing cost reductionCarbon nanotube

The invention discloses a method for gradient and length-diameter ratio CNTs reinforced copper-based composite materials of laser-induction composite melting deposition. The method for the gradient and length-diameter ratio CNTs reinforced copper-based composite materials of the laser-induction composite melting deposition is characterized by comprising a first step of adopting a method of rotating electrophoresis to carry out screening on carbon nano tubes, a second step of respectively and evenly mixing the screened and obtained carbon nano tubes with copper alloy powder on a ball grinding mill according to a length-diameter ratio in a gradient-increase mode, and a third step of adopting the method of laser-induction composite melting deposition to prepare the CNTs reinforced copper matrix composite materials of the length-diameter ratio. The method for the gradient and length-diameter ratio CNTs reinforced copper-based composite materials of the laser-induction composite melting deposition has the advantages that the carbon nano tubes are screened and obtained through a method of rotating the electrophoresis, chemical nickel plating processing is carried out on copper matrix composite powder distributed of the CNTs in a disperse mode, high temperature oxygen of the copper matrix composite powder and wetting performance of the CNTs and a copper alloy are improved, gradient distribution of the CNTs which are different in length-diameter ratio in the copper matrix composite materials is achieved, valuable materials are notably saved, manufacturing cost is reduced, and a manufacturing cycle is shortened.

Owner:NANCHANG HANGKONG UNIVERSITY

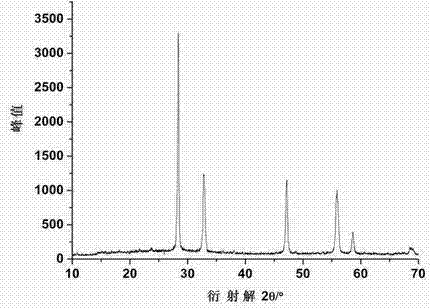

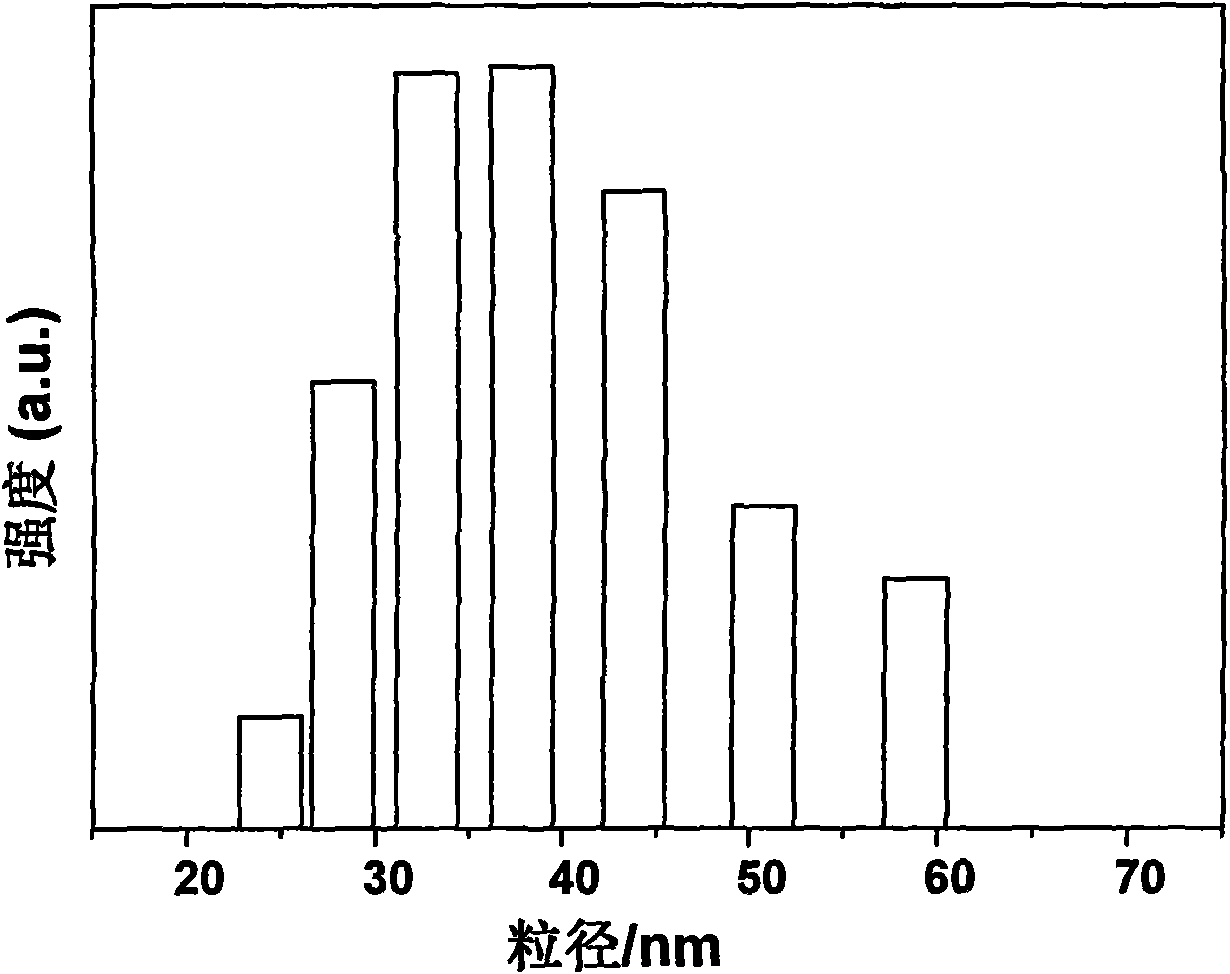

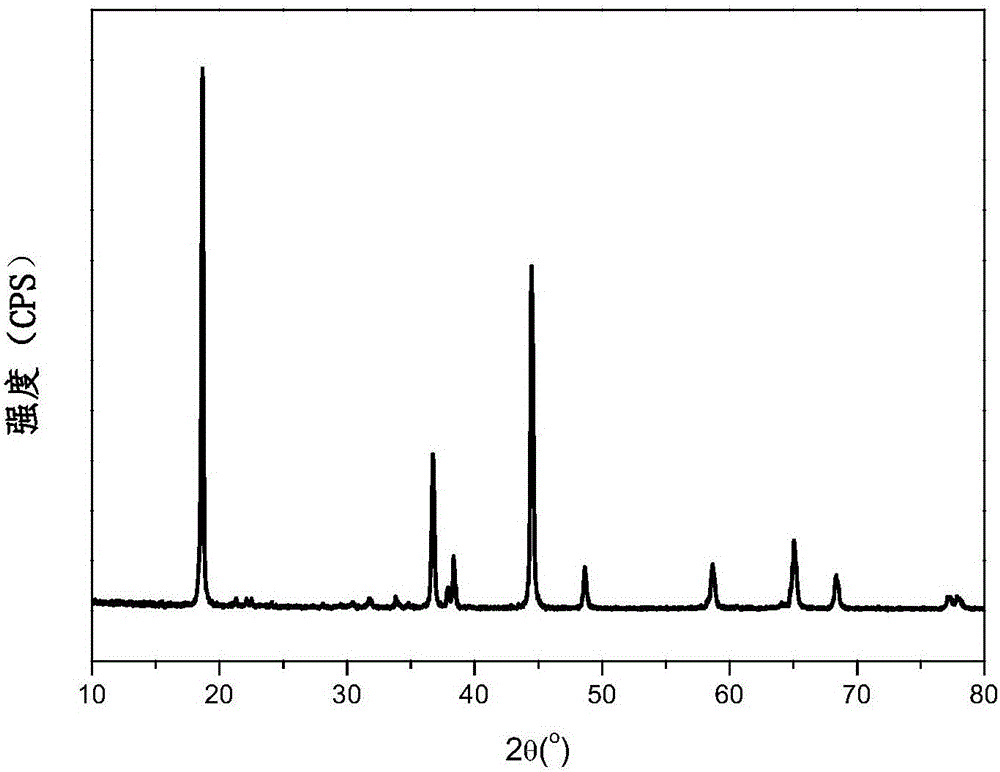

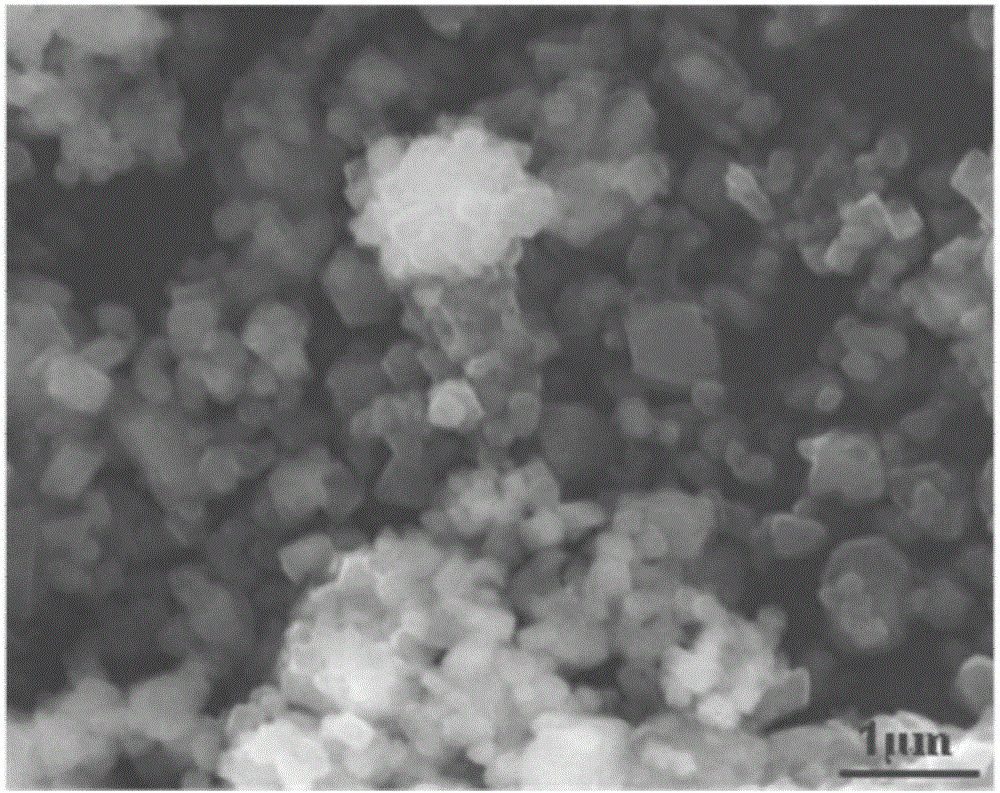

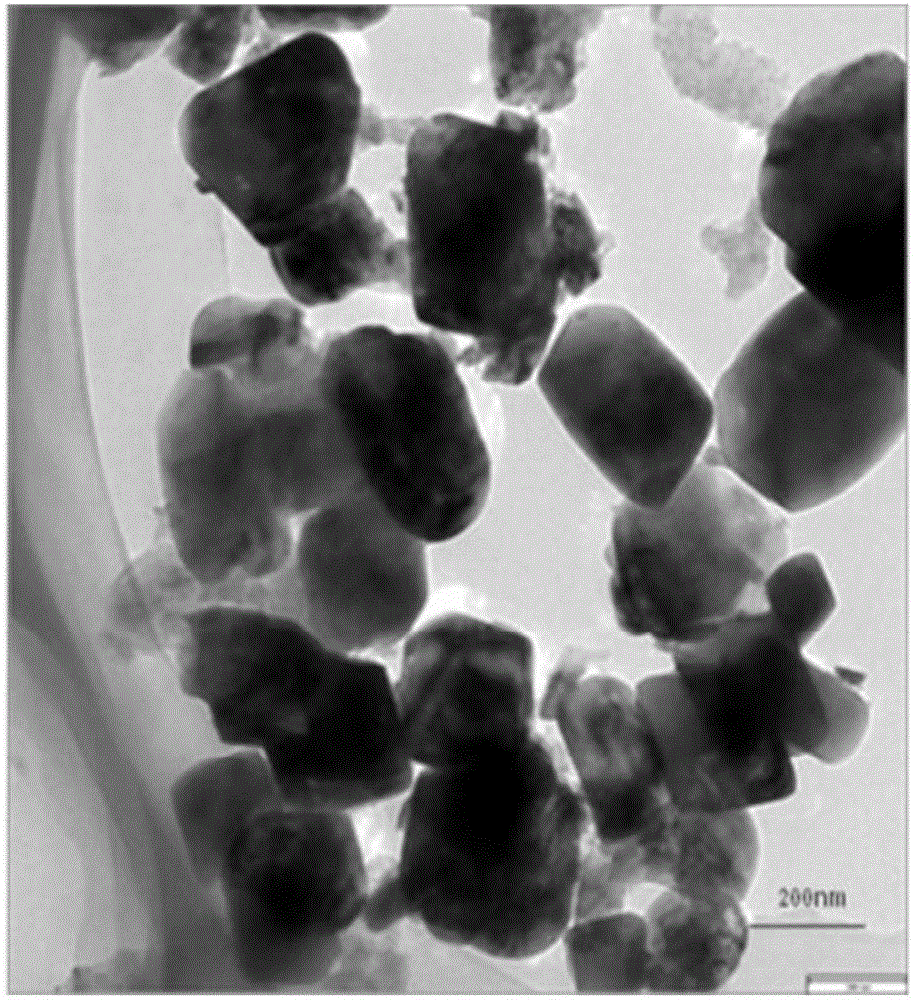

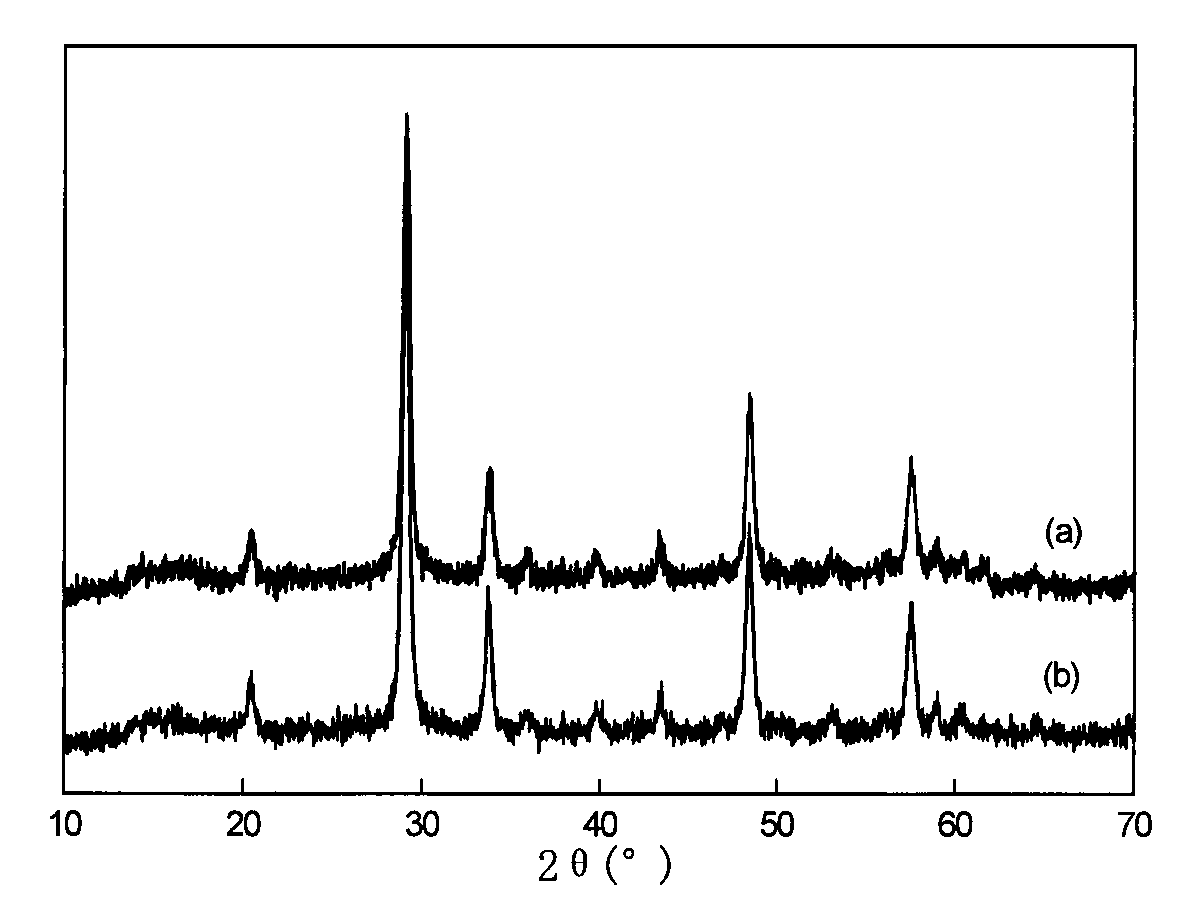

Preparation method of nano-spinel nickel cobalt lithium manganate

ActiveCN106241894AOvercoming uneven particle size distributionOvercoming easy reunionNickel compoundsFiltrationManganate

The invention provides a preparation method of nano-spinel nickel cobalt lithium manganate. The method comprises the following steps: 1. preparation of nano nickel cobalt lithium manganate precursor: uniformly mixing a nickel salt, a cobalt salt and a manganese salt to obtain a mixed solution, adding into a hypergravity field reactor, reacting, and sequentially carrying out filtration, washing and filtration on the reaction solution to obtain the nano precursor; and 2. uniformly mixing the nano precursor obtained in the step 1 with a lithium salt, and sequentially carrying out presintering, roasting and annealing to obtain the nano-spinel nickel cobalt lithium manganate. The method has the advantages of simple technique and low cost, is easy to operate, and can implement quick mass production. The prepared nickel cobalt lithium manganate has the advantages of controllable particle size (the average particle size is 200nm or so), narrow particle size distribution, no aggregation, high crystallinity and complete crystal form.

Owner:XIANGTAN UNIV

Nano-silver/graphene/cellulose fiber composite material with polyethyleneimine as binder and preparation method of nano-silver/graphene/cellulosic fiber composite material

InactiveCN109440475AEasy to reuniteWith washing resistanceBiochemical fibre treatmentVegetal fibresCellulose fiberSilver particles

The invention discloses a nano-silver / graphene / cellulosic fiber composite material with polyethyleneimine as a binder and a preparation method of the nano-silver / graphene / cellulosic fiber composite material. Polyethyleneimine modified nano-silver particles, modified polyethyleneimine modified AgNPs and polyethyleneimine-modified graphene are deposited layer by layer on surfaces of cellulose fibers. According to the invention, polyethyleneimine and modified polyethyleneimine are adopted as a reducing agent and a stabilizer of AgNPs, polyethyleneimine is adopted as a reducing agent and a modifier of graphene oxide, and the preparation method has the advantages of simple process, mild reaction, green and environmental protection, and the like. Polyethyleneimine plays an effective role in bonding among cellulose fibers, nano-silver and graphene. When the prepared AgNPs and graphene are used for finishing cellulose fibers, the defects of easy agglomeration, poor washing resistance and poorlong-term durability of nano materials existing in the conventional nano material finishing method are overcome, and the prepared nano-silver / graphene / cellulosic fiber composite material has excellent antibacterial, anti-UV, antistatic, far infrared and washable properties and other properties.

Owner:苏州吉晟信纺织有限公司

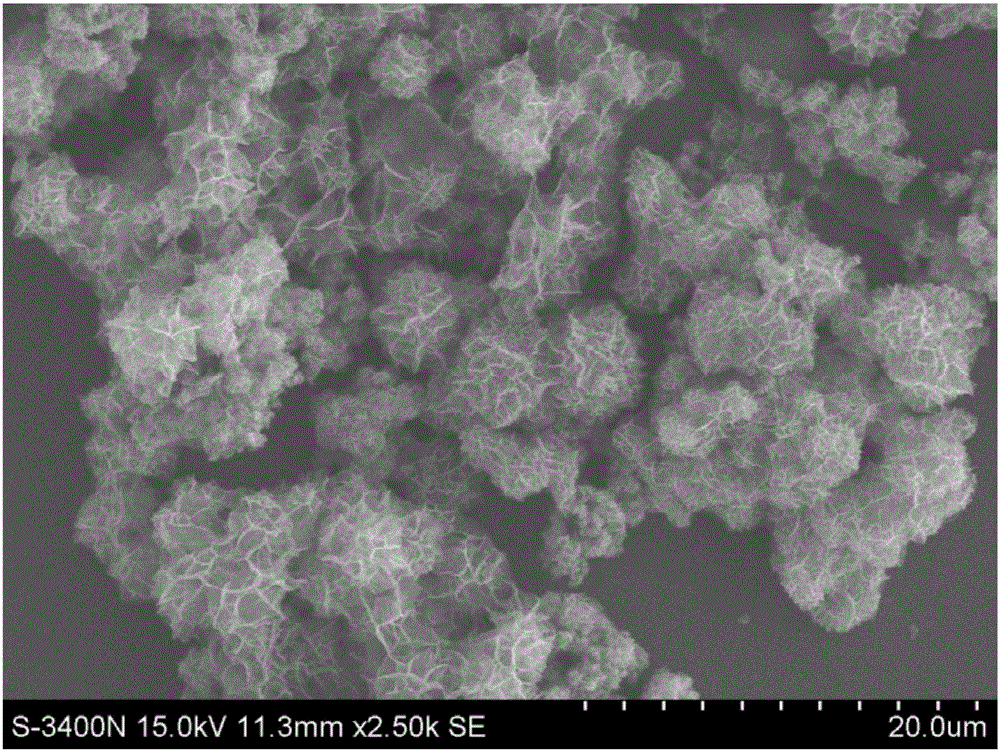

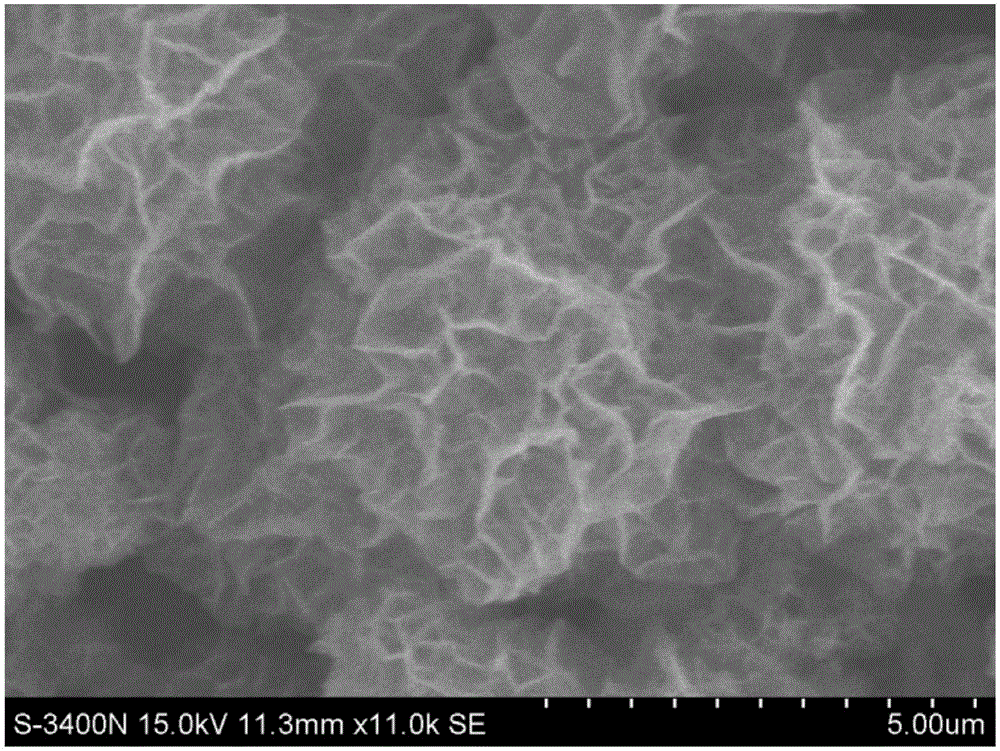

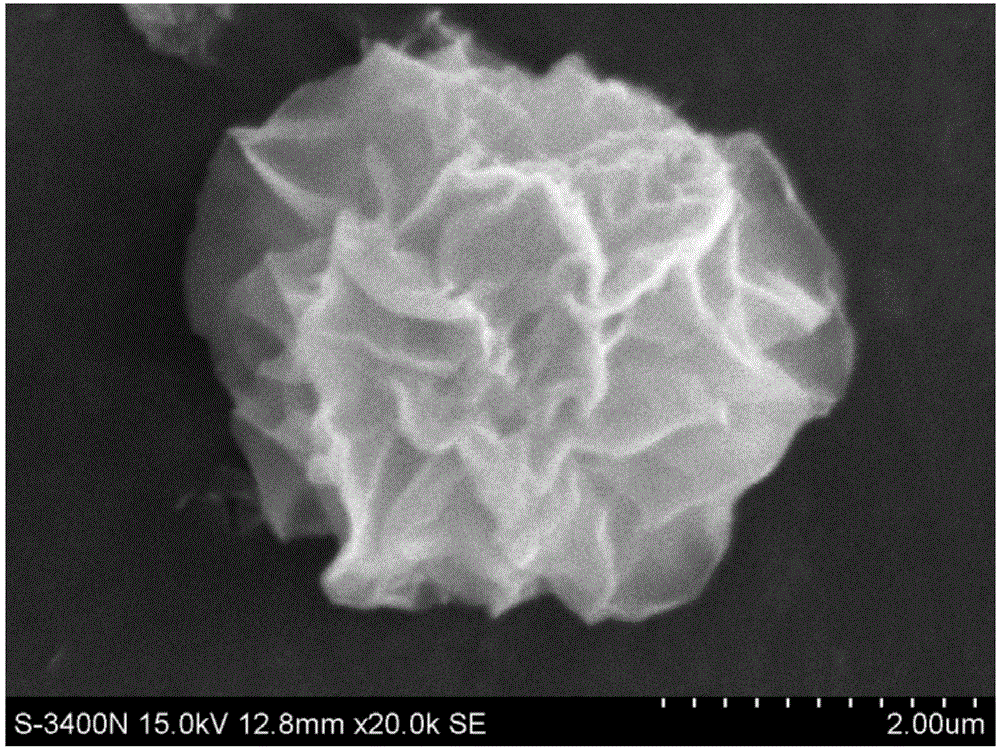

Graphene coupling flower-ball Ni-Mn bimetal oxide three-dimensional class structure electrode material and preparation method thereof

ActiveCN106229163AOvercoming easy reunionOvercoming poor cycle performanceHybrid capacitor electrodesCell electrodesCvd grapheneOxide

The invention discloses a graphene coupling flower-ball Ni-Mn bimetal oxide three-dimensional class structure electrode material and a preparation method thereof. The method disclosed by the invention comprises the steps of firstly obtaining graphene sponge (GOS) through freeze drying; carrying out hydrothermal composition on a nickel source, a manganese source and the graphene sponge (GOS); and finally carrying out high-temperature calcination to obtain a graphene coupling flower-ball Ni-Mn bimetal oxide (LGS). The graphene coupling flower-ball Ni-Mn bimetal oxide three-dimensional composite material obtained by a hydrothermal method, a freeze drying method and a high-temperature calcination method is good in thermal stability, high in crystallinity and high in shape and form controllability, and is an ideal energy material.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Method for preparing surface-modified nanometer yttrium oxide by emulsion polymerization and application thereof

InactiveCN101638524AOvercoming easy reunionOvercome the disadvantage of non-oil solubilityAdditivesPigment treatment with macromolecular organic compoundsFriction effectWear resistant

The invention discloses a method for preparing surface-modified nanometer yttrium oxide by emulsion polymerization and an application thereof. The preparation method has the following steps of: first,preparing nanometer yttrium oxide suspension, adding emulsifier dodecyl trimethyl ammonium chloride, ultrasonically processing, stirring and diffusing for 3h; then, heating to 60 DEG C in nitrogen atmosphere, adding monomer styrene and butyl acrylate with a fixed quality ratio, and finally adding initiator ammonium persulphate to initiate polymerization reaction at 75 DEG C; drying the compound particles obtained after the finishing of the polymerization reaction to obtain the surface-modified nanometer yttrium oxide; and directly ultrasonically diffusing the modified nanometer yttrium oxidein liquid paraffin base oil or finished lubricant as an extreme-pressure, wear-resistant and anti-friction additive. The surface-modified nanometer yttrium oxide has excellent extreme-pressure, wear-resistant and anti-friction effects.

Owner:GUANGDONG UNIV OF TECH

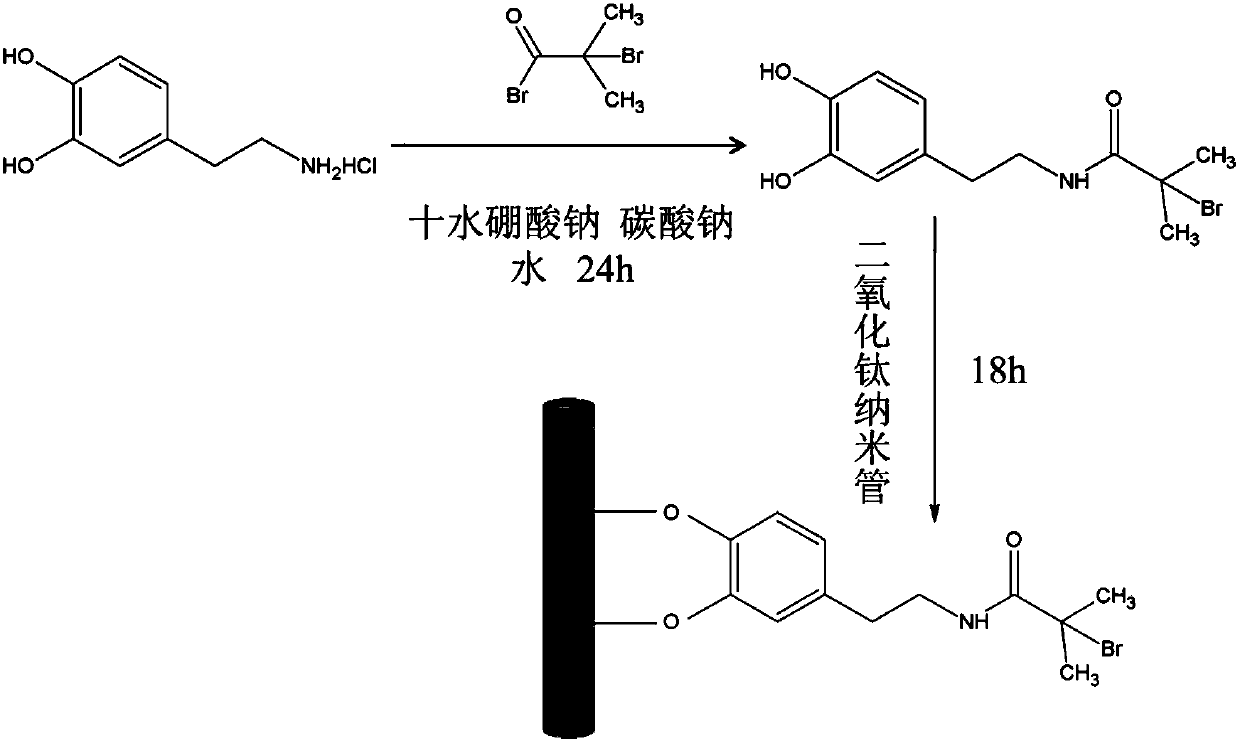

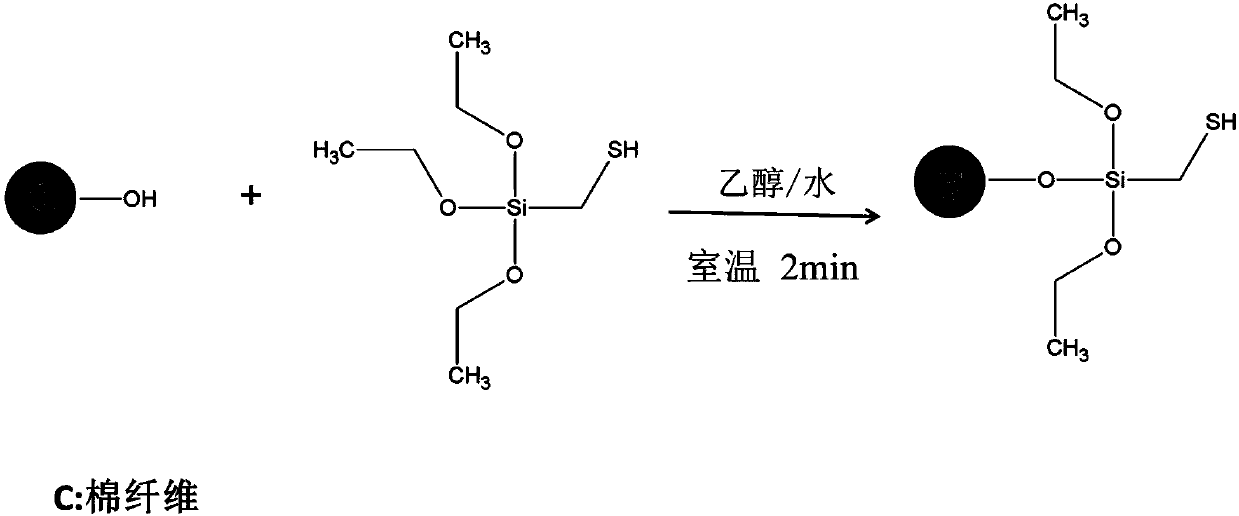

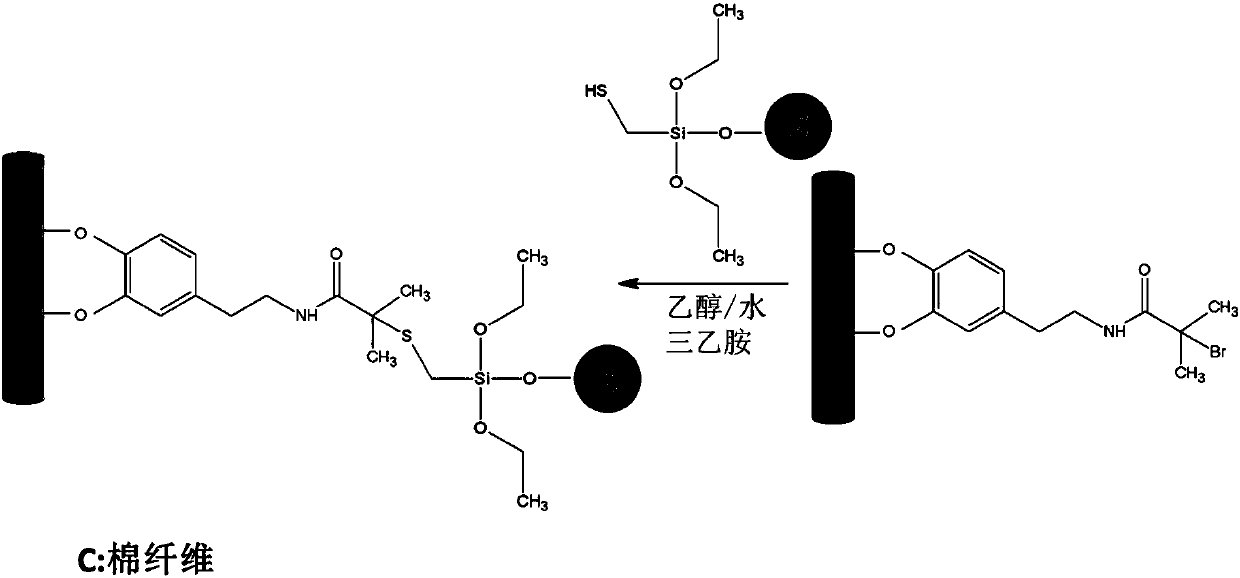

Method for preparing titanium dioxide nanotube/cotton fabric photocatalytic material based on click chemistry

ActiveCN107675483AHigh yieldSimple methodWater/sewage treatment by irradiationWater contaminantsClick chemistryDyeing wastewater

The invention relates to a method for preparing a titanium dioxide nanotube / cotton fabric photocatalytic material based on click chemistry. The method includes the synthesis of pretreated cotton fabrics, the synthesis of reduced cotton fabrics, the synthesis of bromo-dopamine hydrochloride, the synthesis of bromo-titanium dioxide nanotubes and the synthesis of the titanium dioxide nanotube / cottonfabric photocatalytic material based on click chemistry. The method is simple, low in cost, middle in conditions, high in product yield, less in side reaction and environmentally friendly. The prepared titanium dioxide nanotube / cotton fabric photocatalytic material based on click chemistry is high in adsorption efficiency and good in stability, has good photocatalytic effect and excellent environmental friendliness, and can be used to treat dyes in printing and dyeing wastewater and expand the application of the cotton fabrics in the photocatalytic adsorption of dye wastewater.

Owner:DONGHUA UNIV

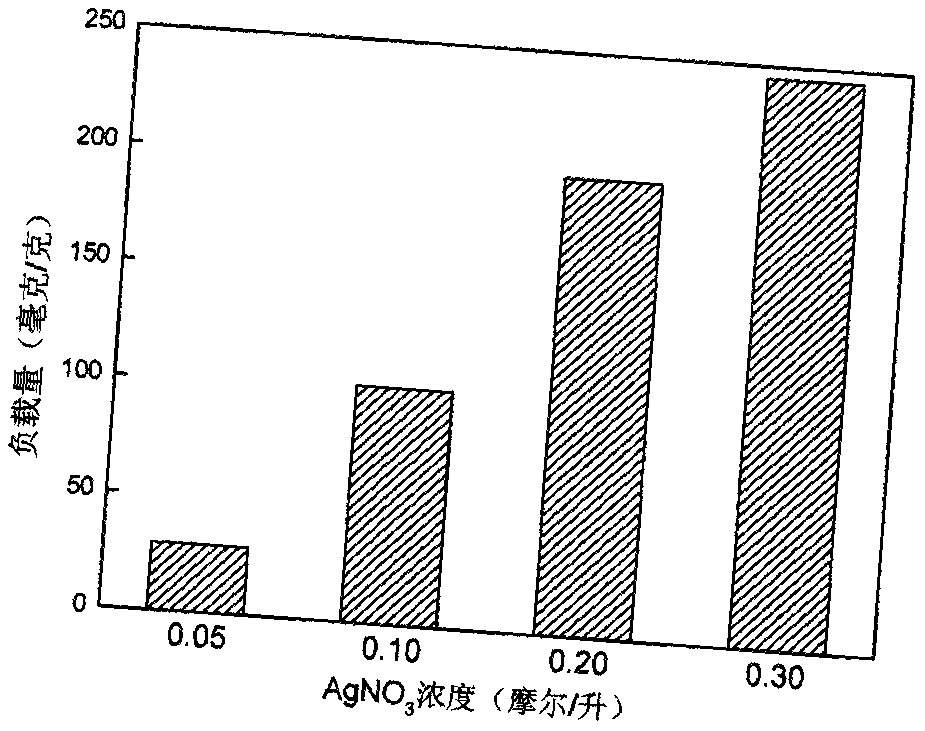

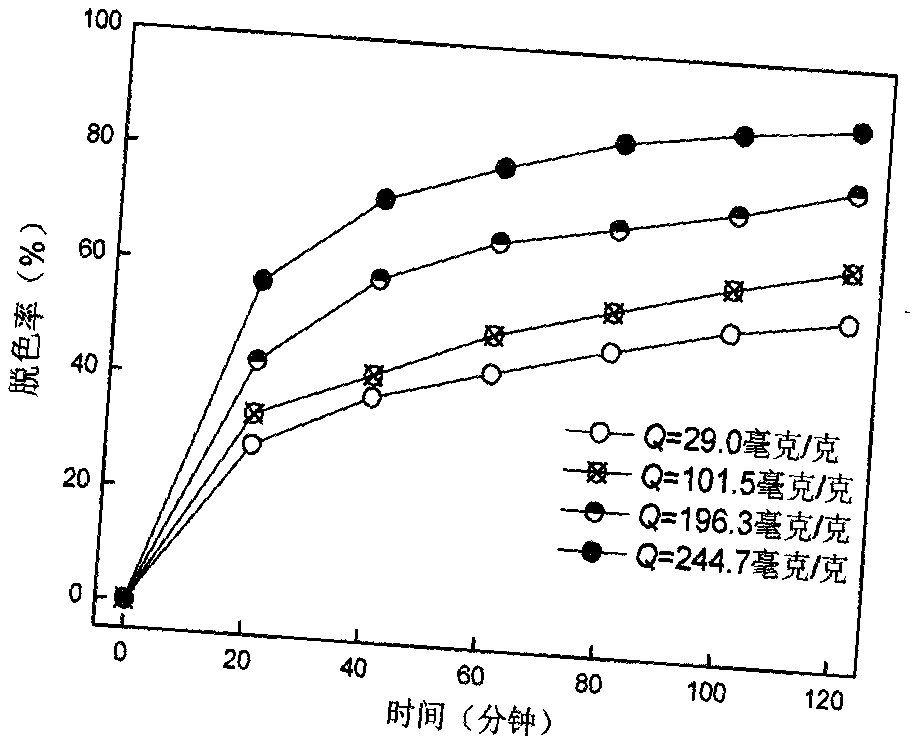

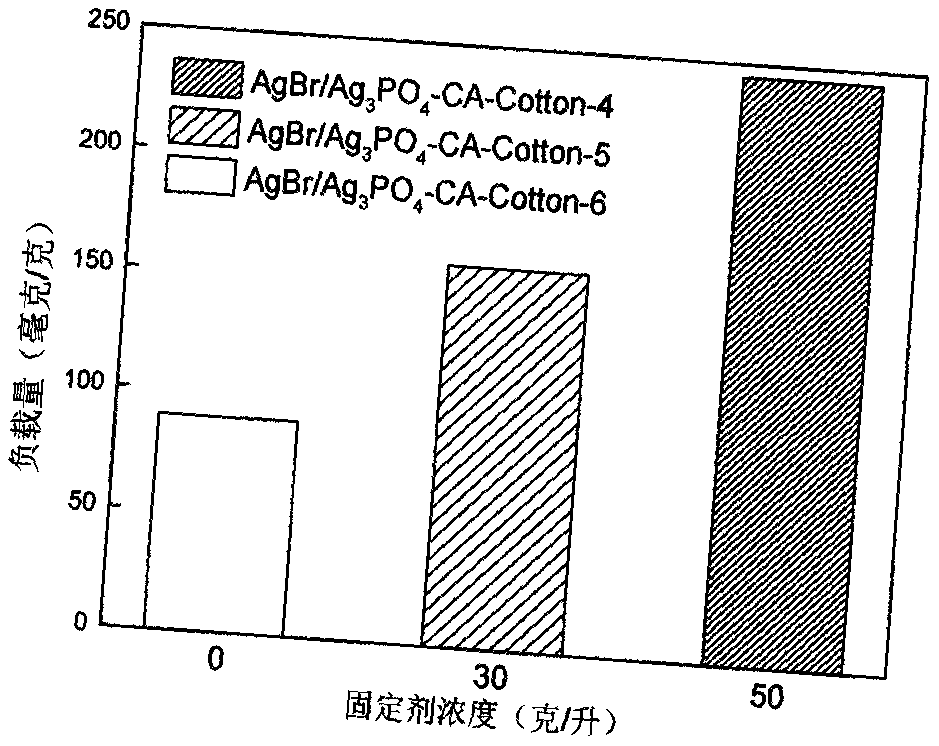

Novel method for loading silver phosphate photocatalyst on surface of cotton fabric

ActiveCN112742484AIncrease load strengthImprove light corrosion resistanceWater/sewage treatment by irradiationWater treatment compoundsFiberSilver bromide

The invention designs a novel method for loading a silver phosphate photocatalyst on the surface of a cotton fabric. The method is characterized in that silver phosphate is firmly loaded on the surface of the modified cotton fabric through three steps, firstly, the silver phosphate is loaded, and in the process, synthesis of the silver phosphate and loading of the modified cotton fabric are synchronously carried out, so that the silver phosphate is firmly combined with fibers; secondly, the surface modification of the silver bromide not only effectively inhibits the photocorrosion phenomenon of the silver phosphate, but also enhances the load of the silver bromide on the fiber surface; and thirdly, after-treatment of the fixing agent is carried out, the binding strength of the silver phosphate and the fibers is further enhanced. When the prepared silver phosphate loaded modified cotton fabric is applied to dye wastewater purification treatment, the silver phosphate loaded modified cotton fabric has excellent photocatalytic oxidation activity and reusability under visible light. In addition, the method not only utilizes the characteristics that the cotton fabric is easy to modify and the like, but also overcomes the defects that the silver phosphate powder is easy to agglomerate and the like in the application process, so that the industrial application of the silver phosphate photocatalyst is promoted.

Owner:TIANJIN POLYTECHNIC UNIV

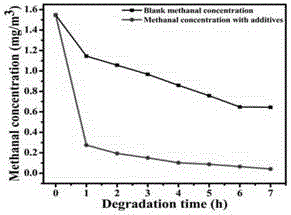

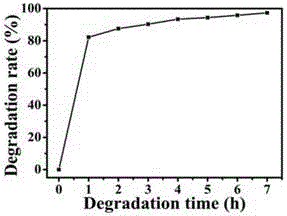

Preparation method of bentonite inorganic gel with photocatalysis activity

ActiveCN104448952AOvercoming easy reunionOvercome the disadvantages of difficult recyclingPhysical/chemical process catalystsPigment physical treatmentEnvironmental resistanceSodium Bentonite

The invention belongs to the technical field of chemical processes, and particularly relates to a preparation method of a bentonite inorganic gel with photocatalysis activity. The preparation method comprises the following steps: (1) preparing modified bentonite slurry; (2) preparing a diphase precursor; and (3) mixing and uniformly stirring the modified bentonite slurry prepared in the step (1) and the diphase precursor prepared in the step (2) till a mixed solution forms a transparent sol, drying, and then calcining through an air or argon atmosphere to obtain the bentonite inorganic gel. The preparation method disclosed by the invention can be used for modifying the hydrophilic bentonite into a hydrophobic material with the photocatalysis activity by utilizing a surface active agent and a modifying agent and applying the hydrophobic material to a green environment-friendly coating, can not only be used for overcoming the defects of easiness for agglomeration, low possibility in recycling and the like of a raw material, but also be used for thoroughly decomposing the toxic and harmful substances, namely formaldehyde and the like which are generated by environment-friendly decoration, thus enhancing the practicability.

Owner:HAMI SHENTU NEW MATERIALS TECH CO LTD

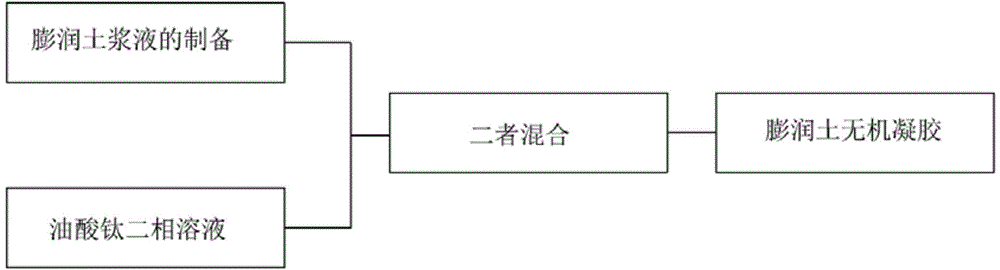

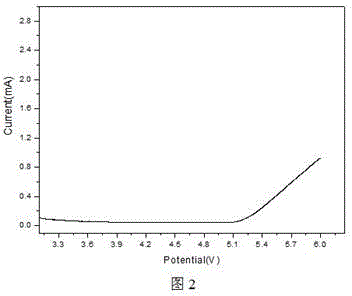

Auto-doped gel polymer electrolyte and preparation method thereof

InactiveCN104485480AOvercoming easy reunionOvercoming dispersionSecondary cellsPolymer electrolytesPolymer science

The invention relates to an auto-doped gel polymer electrolyte and a preparation method thereof. The auto-doped gel polymer electrolyte is characterized by comprising the following steps: firstly, preparing an auto-doped polymer, specifically adding monomers while controlling the molar ratio of the added monomers to carbon-carbon double bonds in siloxane to be (5:1) to (1:5), reacting at 70-80 DEG C for 7-12 hours by taking 2wt.% azodiisobutyronitrile as a catalyst and methylbenzene as a solvent, acidifying with 1.5-2.0vl.% of hydrochloric acid solution for 3-5 hours, finally introducing nitrogen at 120 DEG C and processing for 24-30 hours; and secondly, preparing the auto-doped gel polymer electrolyte from the prepared polymer as a base body, wherein the adding amounts of the polymer, the organic solvent and the liquid electrolyte are respectively 3-7g, 50ml and 7-3g. The auto-doped gel polymer electrolyte has the beneficial effects that the inorganic packing is introduced to the polymer in a chemical bond connection manner, so that the problems that additionally added packing is easy to agglomerate and difficult to disperse are thoroughly overcome; novel base bodies of gel polymer electrolyte are developed; the film-forming property and the dimensional space stability of the gel polymer electrolyte are improved; and a certain foundation is laid for application of the gel polymer electrolyte in practical production.

Owner:SOUTHWEST PETROLEUM UNIV

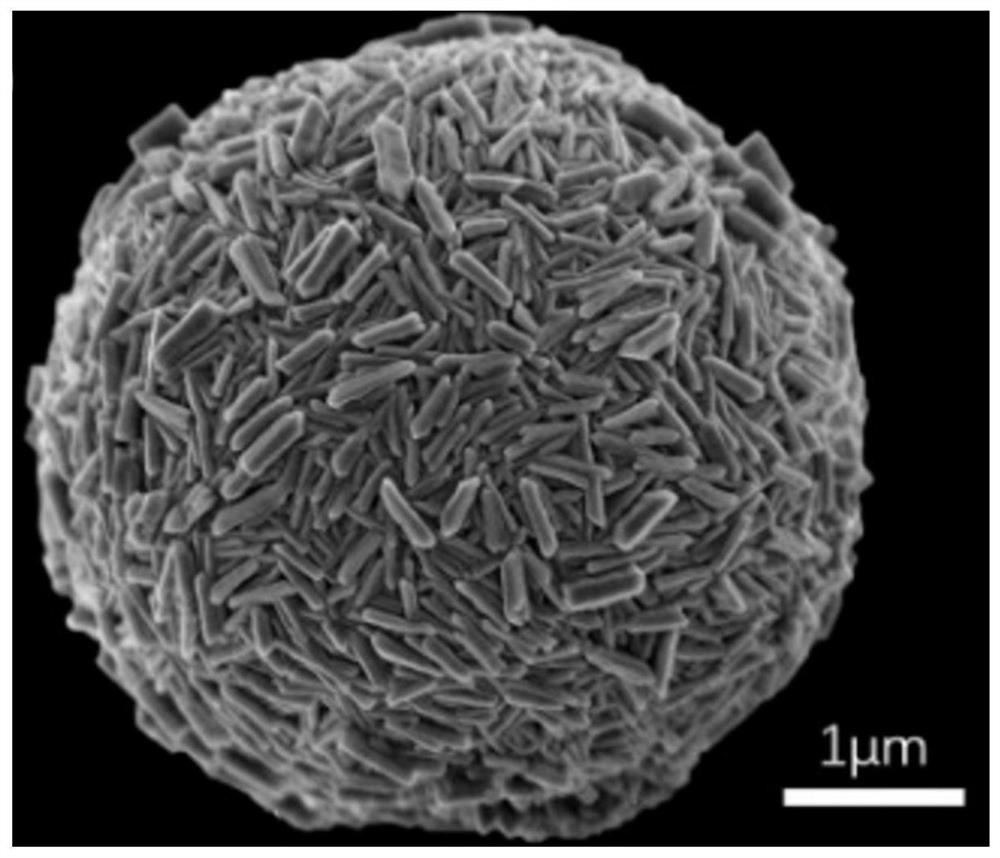

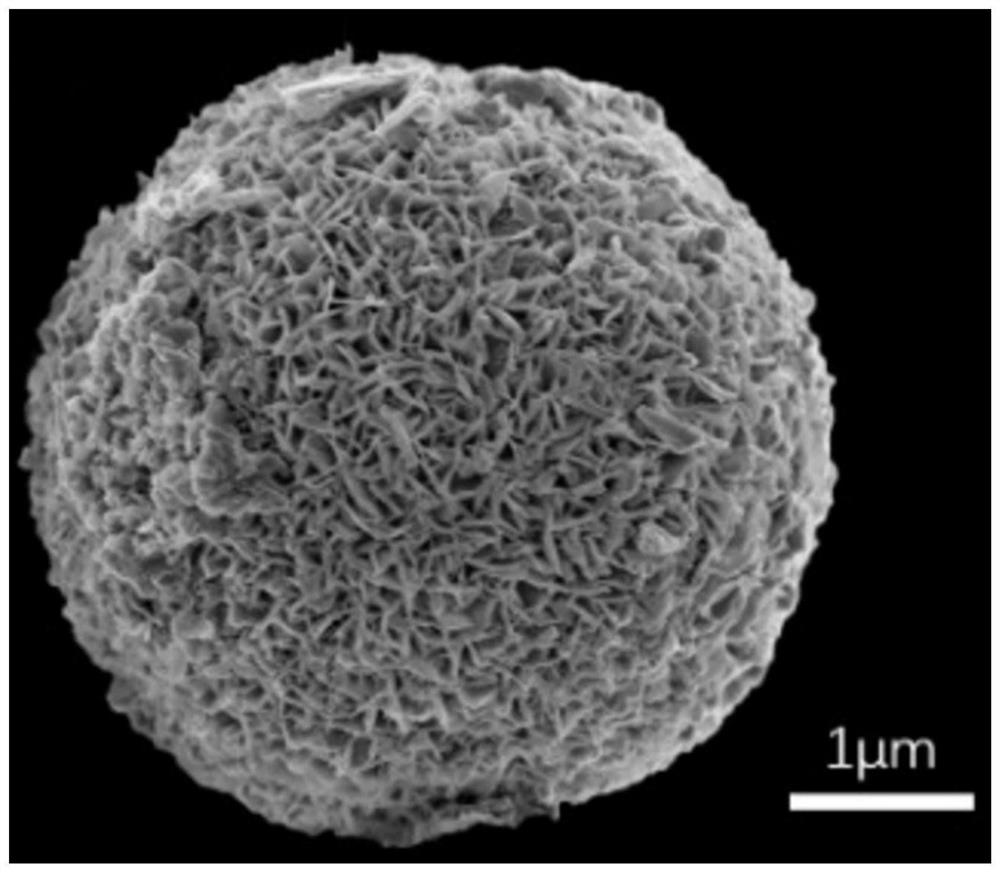

Bi-MOF-M/Bi2MoO6 visible-light-driven photocatalyst capable of efficiently degrading organic wastewater and preparation method of Bi-MOF-M/Bi2MoO6 visible-light-driven photocatalyst

ActiveCN113546688AHigh activity advantageOvercoming easy reunionWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSelf-assemblyEnvironmental chemistry

The invention discloses a Bi-MOF-M / Bi2MoO6 visible-light-driven photocatalyst capable of efficiently degrading organic wastewater and a preparation method of the Bi-MOF-M / Bi2MoO6 visible-light-driven photocatalyst, and belongs to the technical field of environment and energy. According to the preparation method, Bi-MOF-M microspheres are prepared through self-assembly, a layer of petal-shaped Bi2MoO6 is grown on the surface layers of the Bi-MOF-M microspheres through interface in-situ growth, chemical bonding type heterojunctions are formed, and the micro-nano graded flower-ball-shaped Bi-MOF-M / Bi2MoO6 visible-light-driven photocatalyst is prepared. The obtained composite visible-light-driven photocatalyst is easy and convenient to prepare, environmentally friendly, high in stability, free of residues in waste water, high in visible-light catalytic activity, capable of efficiently degrading various organic dye waste water and high-concentration antibiotic waste water under irradiation of visible light, simple in waste water treatment process, capable of being recycled and reused, capable of greatly reducing cost and suitable for industrial production, and has good industrial application prospects.

Owner:JIANGNAN UNIV

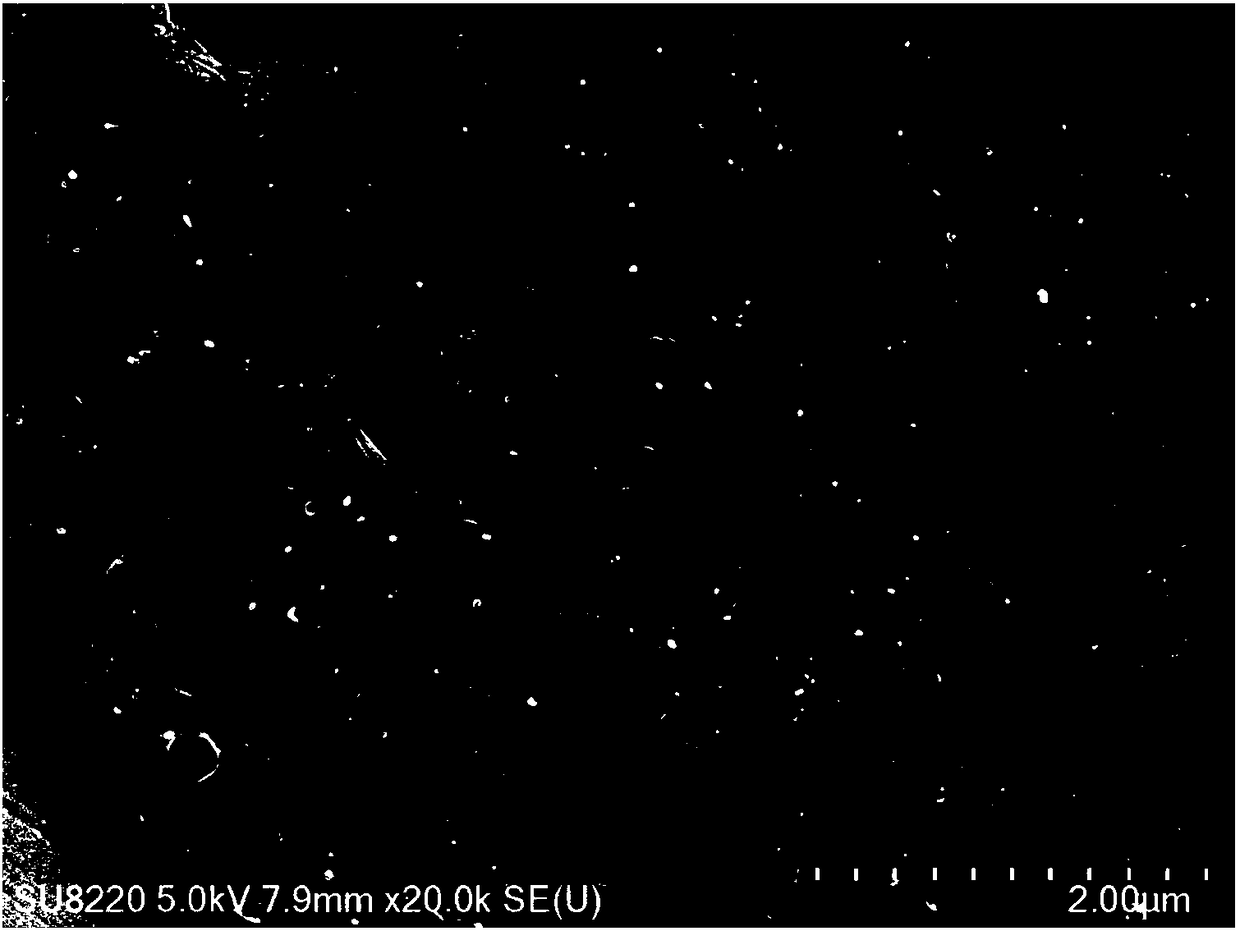

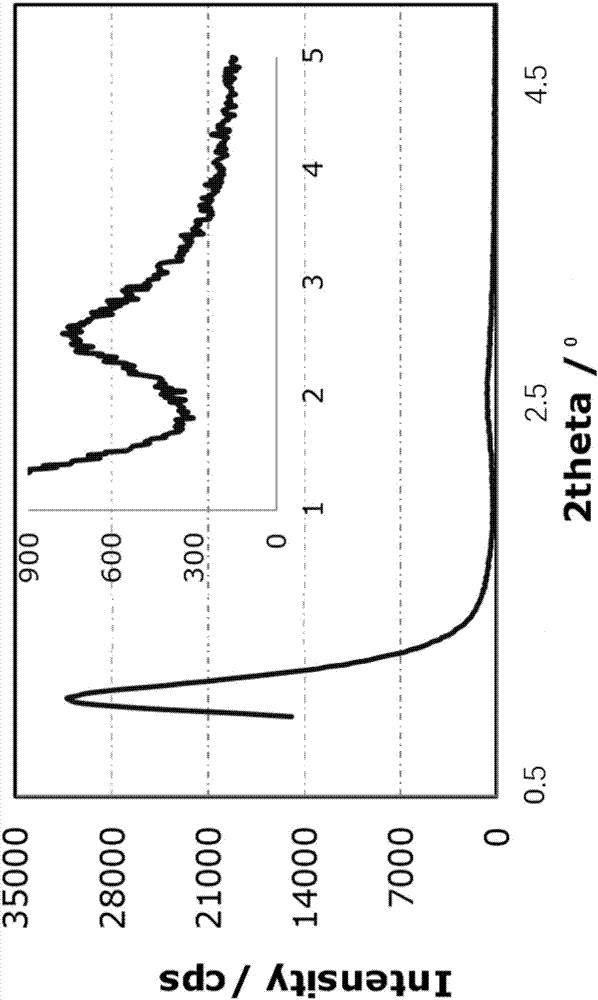

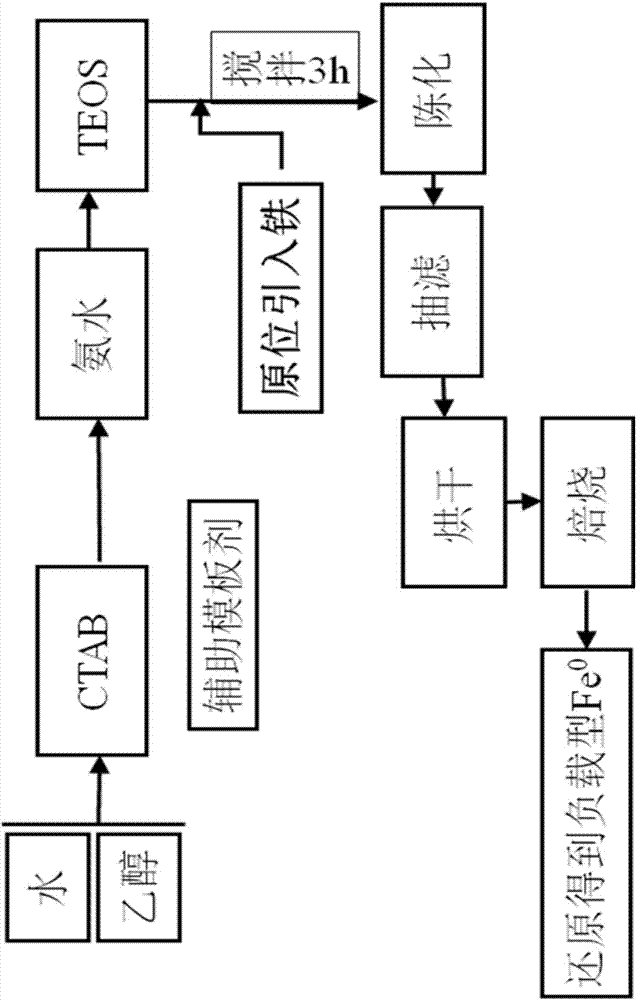

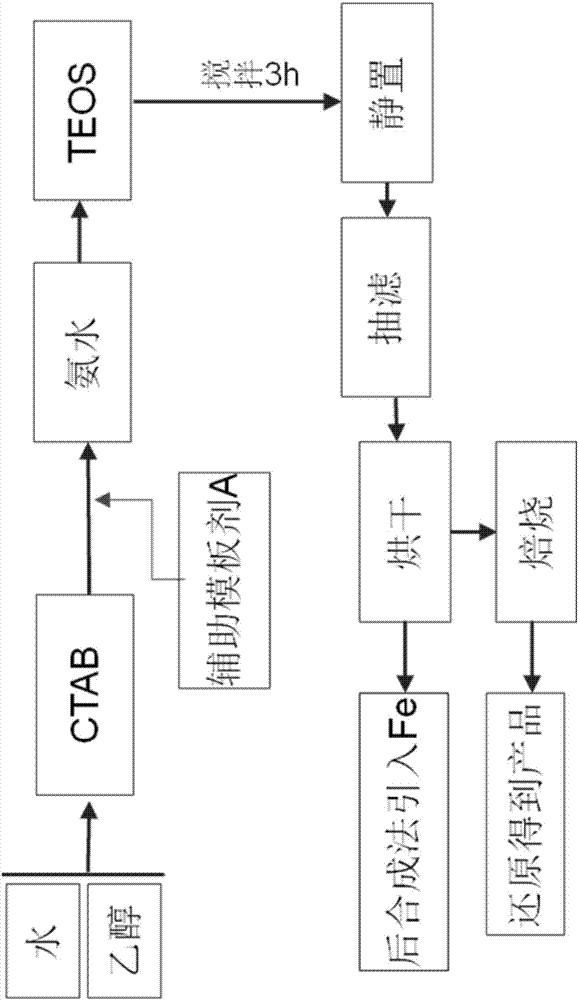

Nano-level zero-valent iron carrier as well as preparation method and application thereof

ActiveCN107243358ABio-friendlyExcellent physical and chemical characteristicsMolecular sieve catalystsWater contaminantsMolecular sieveUltrasonic assisted

The invention relates to the technical field of material chemistry, in particular to a nano-level zero-valent iron carrier as well as a preparation method and application thereof. The nano-level zero-valent iron carrier is obtained by loading zero-valent iron through a modified silicon-based mesoporous molecular sieve; the iron loading amount is less than or equal to 29 percent; the average particle of Fe0 is 40 nm or below, and the mesoporous structure of the material can be retained; HPLC (High Performance Liquid Chromatography)-based analysis of products, which are obtained by degrading parachlorophenol through the material, in water shows that the degradation rate of the parachlorophenol subjected to ultrasonic treatment for 4 hours can be up to 92 percent. Innovative use of L-ascorbic acid serving as a bifunctional agent improves the physical and chemical properties of the material, provides a new idea for synthesis of the material and provides a reference for degradation of chlorine-containing organic matters in the environment.

Owner:BEIJING UNIV OF AGRI

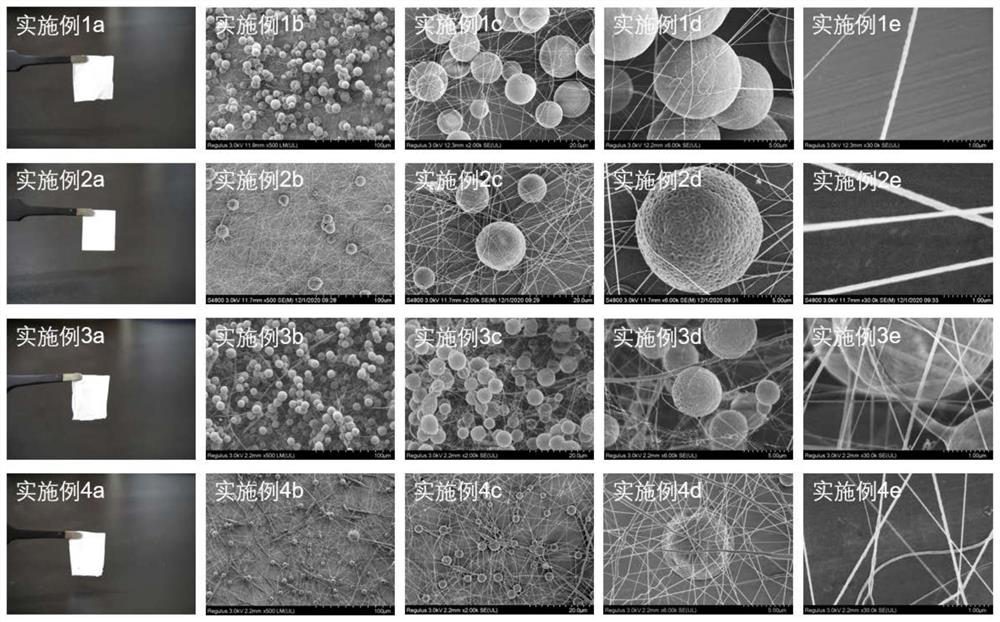

Nanofiber-based microsphere composite membrane and preparation method thereof

InactiveCN112981720ASolve the speed problemSolve the problem of low drug loadingNon-woven fabricsPolymer scienceTissue repair

The invention discloses a preparation method of a nanofiber-based microsphere composite membrane. The preparation method comprises the following steps: preparing an electrostatic spinning solution, obtaining the nanofiber-based microsphere composite membrane by adopting an electrostatic spinning technology, soaking the nanofiber-based microsphere composite membrane in absolute ethyl alcohol, taking out the nanofiber-based microsphere composite membrane, naturally drying the nanofiber-based microsphere composite membrane, removing the redundant solvent, and then drying the nanofiber-based microsphere composite membrane in a vacuum drying oven to obtain the nanofiber-based microsphere composite membrane. According to the membrane, the problems that microspheres are prone to agglomeration and poor in mechanical property can be solved through the formation of the nanofibers, and the problems that the nanofibers are high in degradation speed, low in drug loading capacity and high in drug slow release speed can be solved through the formation of the microspheres. Besides, the nanofiber-based microsphere composite membrane can simulate an extracellular matrix with a nanoscale filamentous interlaced structure, tissue repair and regeneration are facilitated, and the structure can endow the composite membrane with good mechanical properties.

Owner:SUZHOU UNIV

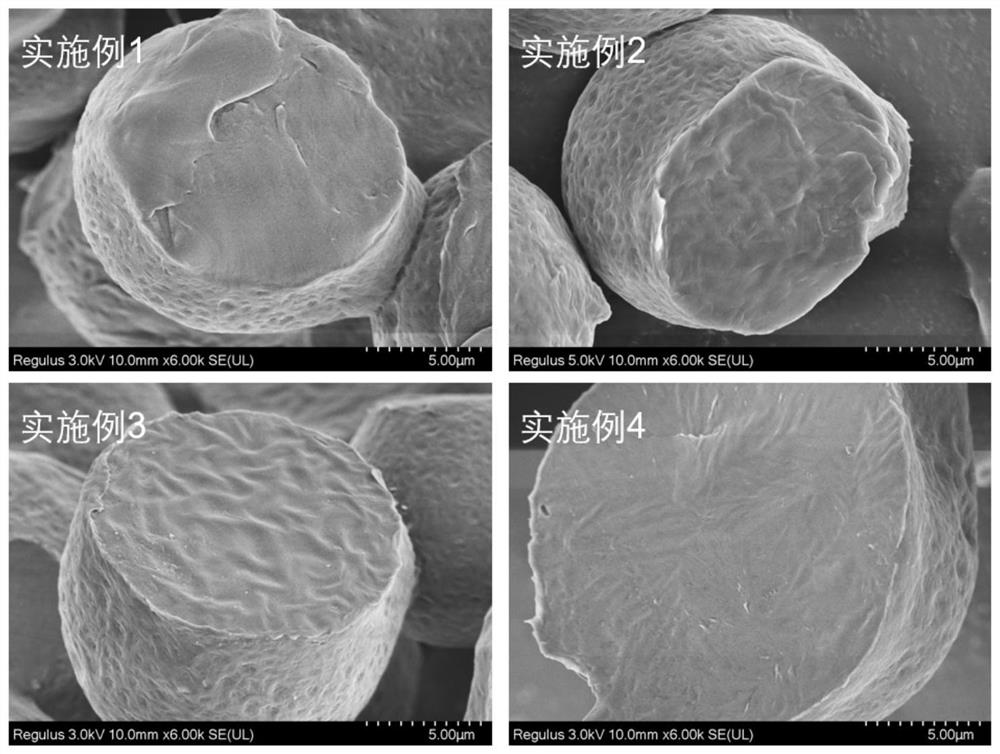

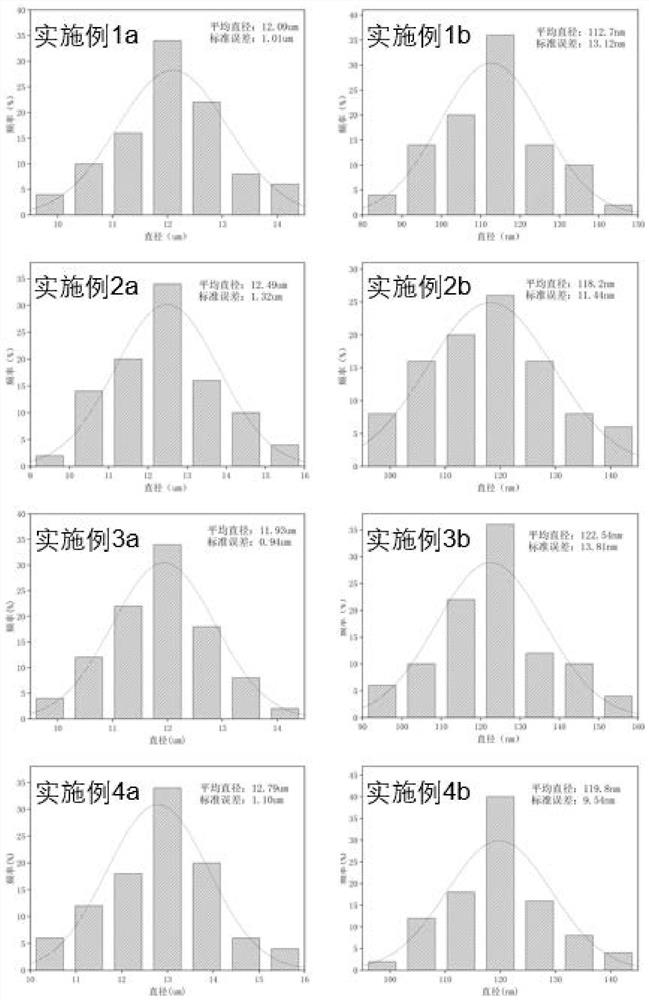

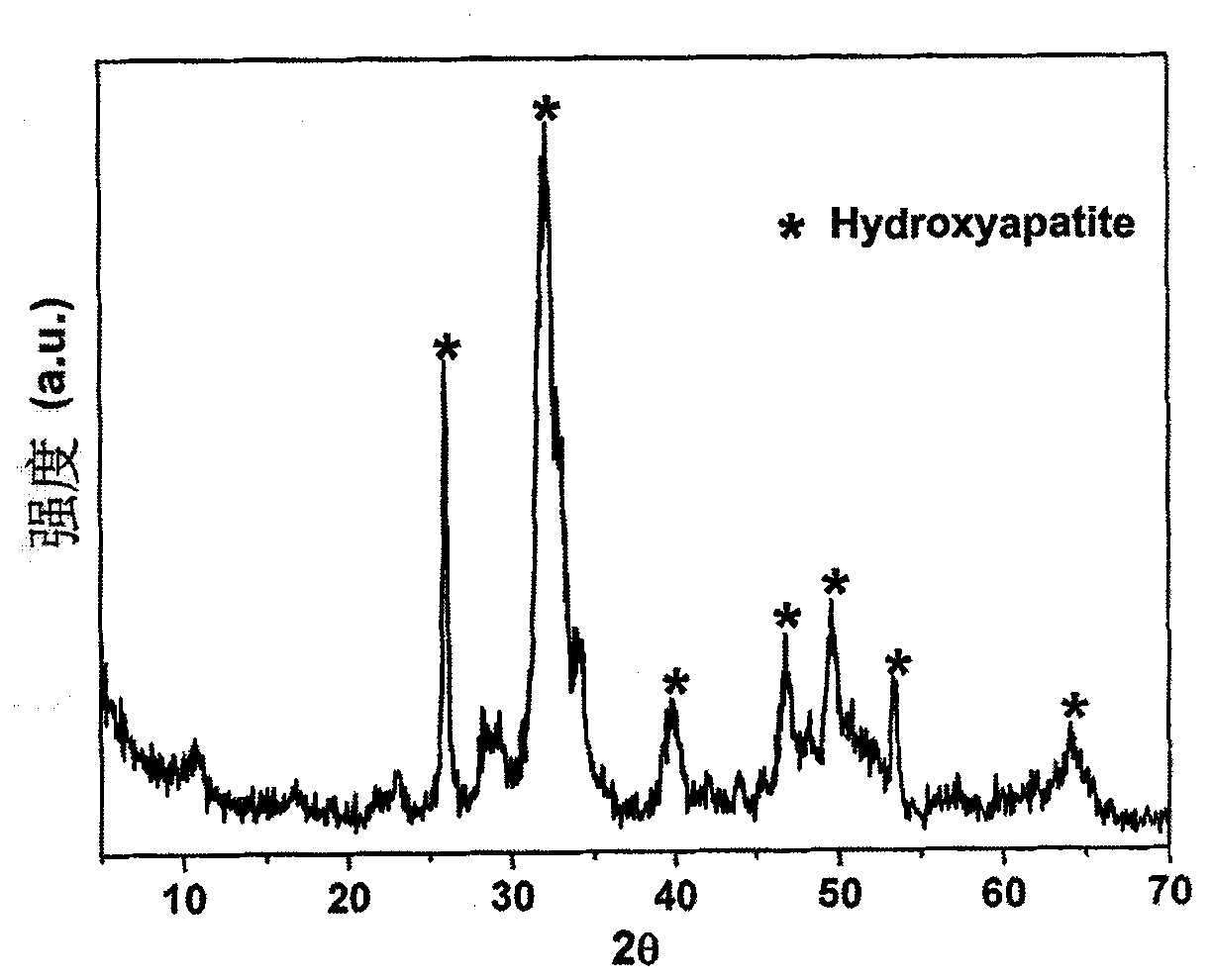

Hydroxyapatite hybridized nanometer crystal assembly, preparation method and application thereof

InactiveCN101905860AUniform size distributionOvercome uniformity issuesOther chemical processesIndividual molecule manipulationSorbentSpherical shaped

A hydroxyapatite hybridized nanometer crystal assembly is formed by assembling the nanometer crystals which contain hyaluronic acid and hydroxyapatite. The assembly is of a globular shape, with a grain size from 100 nanometers to 10 microns. The nanometer crystal has a shape of needle, silk or sheet, with a length of from 20nm to 800nm. A method for preparing the hydroxyapatite hybridized nanometer crystal assembly comprises the following steps of: (1) preparing a hyaluronic acid polysaccharide solution, (2) slowly scattering ions, and (3) collecting products and drying. The hydroxyapatite hybridized nanometer crystal assembly can be used as medical carrier, absorbent, filler, and the like.

Owner:SICHUAN UNIV

Zero-valent iron composite material and preparation method and application thereof

ActiveCN113522952AOvercoming easy reunionOvercome stabilityContaminated soil reclamationSoil remediationBrominated Diphenyl Ethers

The invention provides a zero-valent iron composite material and a preparation method and application thereof. According to the zero-valent iron composite material, the technical defects that traditional zero-valent iron is prone to agglomeration and unstable can be overcome, surface active sites are increased, meanwhile, a porous material is further adopted for coating, and therefore the activity of boric acid zero-valent iron is kept. The zero-valent iron composite material can be prepared by adopting a ball milling method, the reaction condition is simple, operation is easy, and industrialization is convenient. The zero-valent iron composite material is applied to soil remediation, soil with pollutants being polybrominated diphenyl ethers and / or heavy metal and different pollution degrees can be treated and remedied, and the zero-valent iron composite material has good development prospects.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Efficient hexavalent chromium removal agent and preparation method thereof

InactiveCN108298609AOvercoming easy reunionOvercoming activityWater contaminantsWater/sewage treatmentEcological safetyWastewater

The invention relates to the field of water treatment, in particular to an efficient hexavalent chromium removal agent. The efficient hexavalent chromium removal agent is prepared from the following raw material composition ingredients in proportion by weight: 20 parts of sponge iron with the particle diameter being 1 to 3mm, 3 to 12 parts of copper sulfate with the particle diameter being 0.1 to0.5mm and 1 to 4 parts of oxalic acid with the particle diameter being 0.3 to 0.8mm. In addition, the invention also provides a preparation method of the efficient hexavalent chromium removal agent. The removal agent has the advantages that the price is low; the acquisition is easy; the preparation method is simple; the ecological safety is high; the service life is long, and the like. An important effect can be achieved in the restoration process of hexavalent chromium polluted factory waste water, river, lake and underground water.

Owner:JILIN UNIV +1

Nano zero-valent iron modified composite mesoporous material and preparation method and application thereof

ActiveCN111633021AReduce manufacturing costEasy to manufactureContaminated soil reclamationFerrous saltsSODIUM SULFIDE NONAHYDRATE

The invention discloses a nano zero-valent iron modified composite mesoporous material and a preparation method and application thereof. The material is prepared by the following steps: (1) combininga ZSM-5 molecular sieve treated by diluted hydrochloric acid with a graphene oxide solution by a solution blending method, evaporating to dryness, carrying out centrifugal washing for multiple times,and grinding the dried product into powder for later use; and (2) dispersing ferrite and the powdery product obtained in the step (1) in a solvent, adding a mixed solution of a reducing agent and sodium sulfide nonahydrate, and reacting to obtain the nano zero-valent iron modified composite mesoporous material. The preparation process is simple, the preparation cost is low, and the preparation rawmaterials are environment-friendly; the prepared nano zero-valent iron modified composite mesoporous material has good dispersity in an aqueous solution, a large number of oxygen-containing functional groups are reserved in the material, the limitation that nano zero-valent iron is prone to agglomeration and passivation is overcome, and the composite mesoporous material can effectively remove organic pollutants and has wide application prospects in the aspect of water resource treatment.

Owner:SHANGHAI UNIV

Double-activity Ni2P/Zr-SBA-15 catalyst and preparation method and application thereof

ActiveCN109046438AHas isomerization activityWith hydrodeoxygenation (HDO) performanceMolecular sieve catalystsLiquid hydrocarbon mixture productionIsomerizationCombustion

The invention discloses a double-activity Ni2P / Zr-SBA-15 catalyst and a preparation method and application thereof. The active component of the catalyst is Ni2P, and a carrier is Zr-SBA-15. The double-activity Ni2P / Zr-SBA-15 catalyst has the advantages that the preparation is simple, and the price is low; the activities of hydrodeoxygenation and isomerization are high, the anti-carbon accumulationability is strong, the oxygen removal rate reaches 98% or above, and the curcas oil with low price can be converted into biofuel with high content of straight-chain paraffin, high calorific heat andhigh price; after reaction is finished, the coking rate of the catalyst is lower than 1.66%; the main components of the biofuel are petroleum diesel and aviation kerosene, the combustion property is good, the stability is high, the petroleum diesel and aviation kerosene can be replaced, and the good industrial application prospect is realized.

Owner:HAINAN UNIVERSITY

Preparation method of multifunctional regenerated cellulose composite fiber

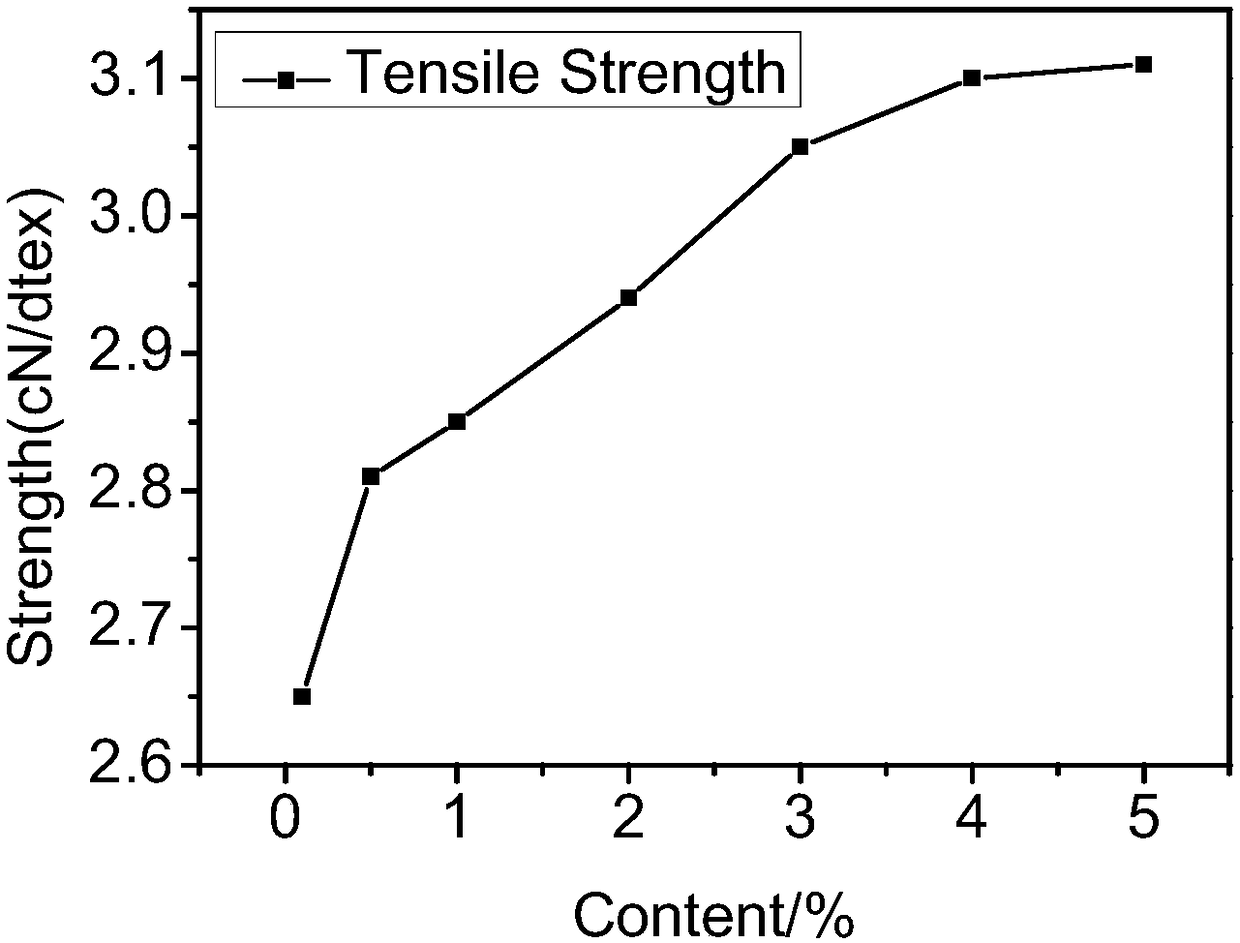

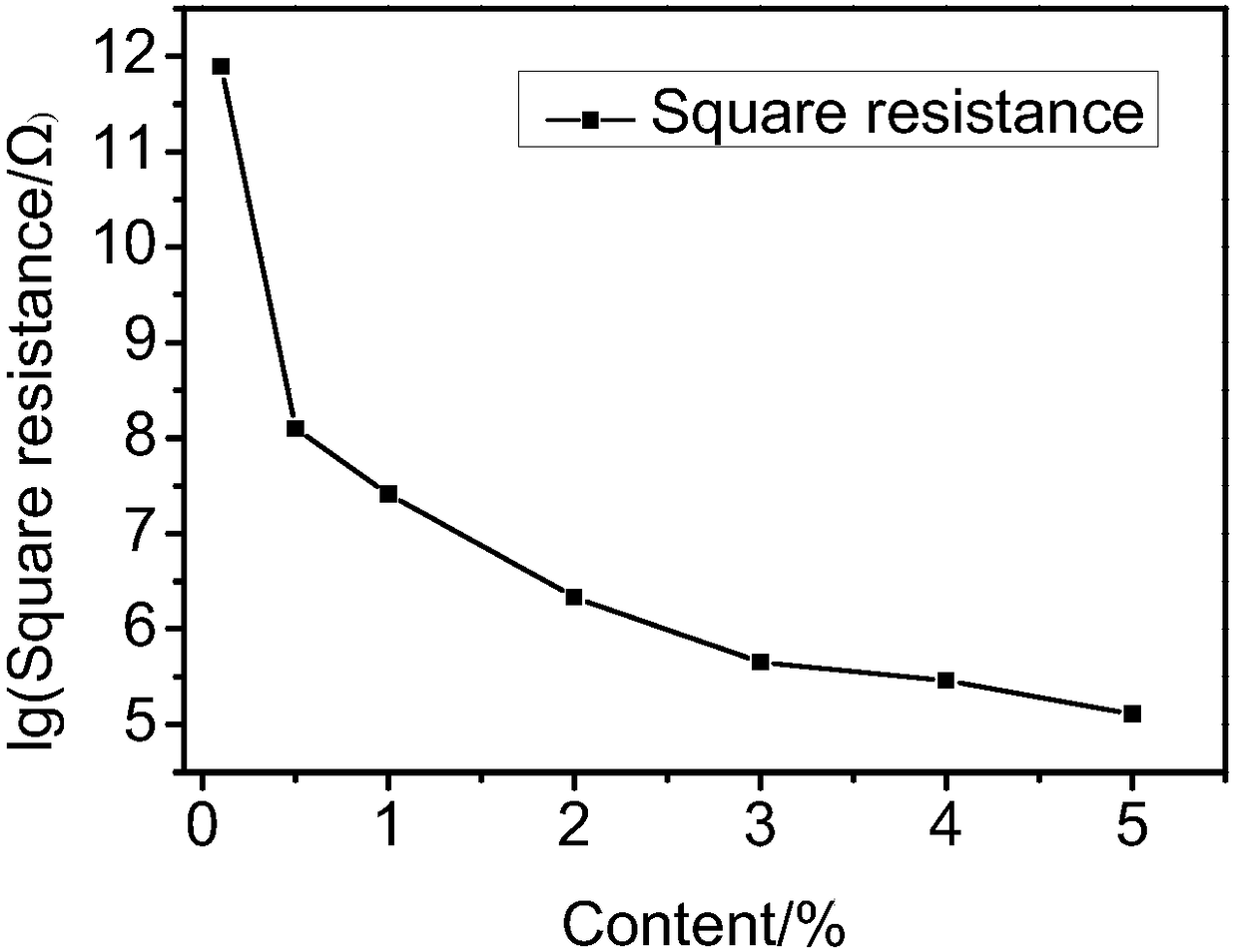

ActiveCN108277545AHigh strengthImprove antistatic performanceArtificial filaments from cellulose derivativesWet spinning methodsPolymer scienceFar infrared

The invention relates to a preparation method of multifunctional regenerated cellulose composite fiber. The preparation method comprises the following steps: mixing regenerated cellulose with oxidizedgraphene to prepare a spinning solution, spinning in a mixed coagulating bath, and then preparing the regenerated cellulose / oxidized graphene composite fiber through multi-stage washing and high-temperature steam stretching. The method is simple and extremely easy to industrialize; cellulose raw materials are wide in source and low in cost. The anti-static property of the prepared regenerated cellulose / oxidized graphene composite fiber is obviously improved; the anti-static property has designability; the multifunctional regenerated cellulose composite fiber is excellent in mechanical property, sterilization performance and anti-ultraviolet far infrared performance; meanwhile, the multifunctional regenerated cellulose composite fiber has the advantages of softness, breathability, high hygroscopicity, easiness in dyeing and the like of cellulose, and can be widely applied to the textile industry.

Owner:HANGZHOU GAOXI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com