Sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate

A technology of bismuth tungstate and hydrothermal method, applied in chemical instruments and methods, tungsten compounds, catalysts for physical/chemical processes, etc., can solve the problem of grain agglomeration and uneven particle size distribution, reduce the photocatalytic performance of bismuth tungstate, It is not conducive to problems such as compound doping of multiple elements, and achieves good photocatalytic activity, complete crystal form, and good crystal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Prepare 10mL of bismuth nitrate solution with a concentration of 0.024mol / L and ammonium tungstate solution with a concentration of 0.001mol / L. Under stirring conditions, mix 3.6mL and 1.8mL of EDTA with a concentration of 0.1mol / L The solution is added to the bismuth nitrate solution and the ammonium tungstate solution respectively;

[0013] (2) Mix the above two transparent solutions evenly and keep in a water bath at 60°C for 24 hours to obtain a wet gel, and dry the wet gel at 110°C to obtain a dry gel;

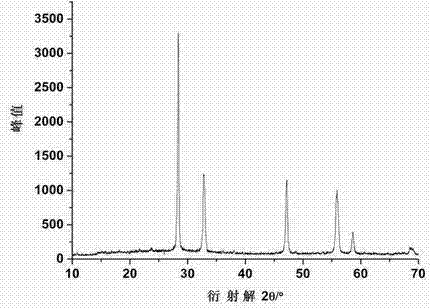

[0014] (3) Move the dry gel into a hydrothermal reaction kettle, add 50ml of deionized water and adjust the pH of the reaction solution to 2.0 with nitric acid, then keep it at 220°C for 12 hours, then cool it down to room temperature naturally. The obtained product was centrifuged, washed three times with deionized water, and dried in vacuum at 60°C to obtain a bismuth tungstate photocatalyst with high catalytic activity. It can be seen from the X-ray diffract...

Embodiment 2

[0016] (1) Prepare 10 mL of bismuth nitrate solution with a concentration of 0.24 mol / L and ammonium tungstate solution with a concentration of 0.01 mol / L, and mix 7.2 mL and 3.6 mL of 0.5 mol / L EDTA solution is added to bismuth nitrate solution and ammonium tungstate solution;

[0017] (2) Mix the above two transparent solutions evenly and keep in a water bath at 80°C for 24 hours to obtain a wet gel, and dry the wet gel at 110°C to obtain a dry gel;

[0018] (3) Move the dry gel to a hydrothermal reaction kettle, add 50ml of deionized water and adjust the pH of the reaction solution to 11.0 with ammonia water, then keep it at 240°C for 6 hours, then cool it down to room temperature naturally. The obtained product was centrifuged, washed three times with deionized water, and vacuum-dried at 60° C. to obtain a bismuth tungstate photocatalyst with high catalytic activity.

Embodiment 3

[0020] (1) Prepare 10mL of bismuth nitrate solution with a concentration of 0.12mol / L and ammonium tungstate solution with a concentration of 0.005mol / L. EDTA solution is added to bismuth nitrate solution and ammonium tungstate solution;

[0021] (2) Mix the above two transparent solutions evenly and keep in a water bath at 60°C for 12 hours to obtain a wet gel, and dry the wet gel at 110°C to obtain a dry gel;

[0022] (3) Move the dry gel into a hydrothermal reaction kettle, add 50ml of deionized water and adjust the pH of the reaction solution to 2.0 with nitric acid, then keep it at 180°C for 36 hours, then cool it down to room temperature naturally. The obtained product was centrifuged, washed three times with deionized water, and vacuum-dried at 60° C. to obtain a bismuth tungstate photocatalyst with high catalytic activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com