Nano-level zero-valent iron carrier as well as preparation method and application thereof

A zero-valent iron, nano-scale technology, applied in the field of material chemistry, can solve the problems of loss of activity and the limitation of mass transfer of organic pollutants, and achieve the effect of promoting mass transfer, avoiding the formation of secondary pollutants, and overcoming easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The nano-scale zero-valent siderophores prepared by the preparation method provided by the present invention can have an iron loading of more than 20%, and the applicable range is 20%-29%, or 24%-29%, 27%-29%, and the highest can be Up to 28% ~ 29%; Fe 0 The average particle size can reach below 40nm.

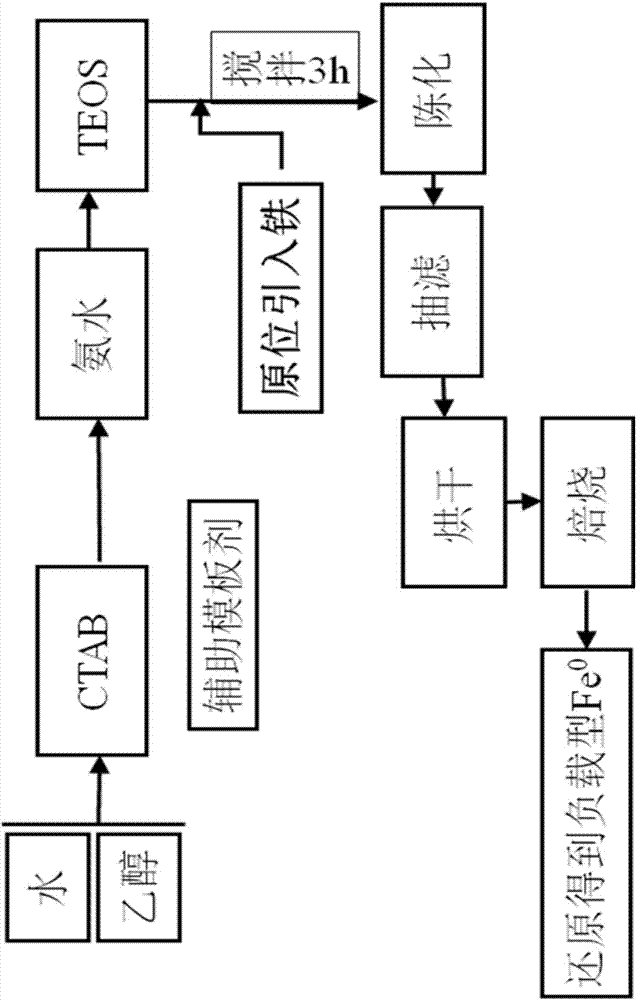

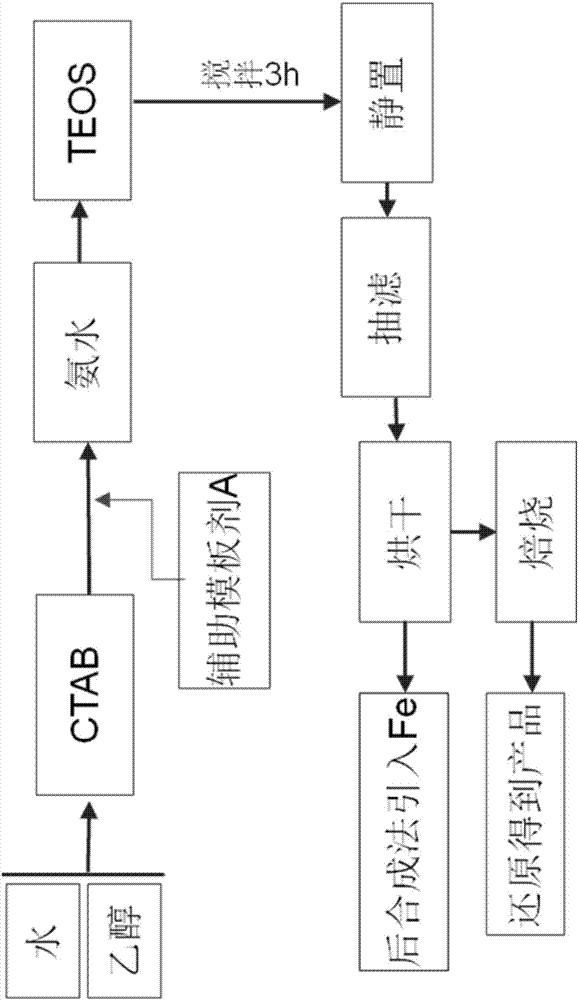

[0034] A method for preparing nano-scale zero-valent siderophores, using cationic surfactants as templates and L-ascorbic acid as auxiliary template modifiers to react with silicon sources in alkaline solution systems to prepare modified silicon-based mesoporous molecular sieves ;

[0035] Introduce Fe into the precursor of the modified silicon-based mesoporous molecular sieve by in-situ synthesis before the modified silicon-based mesoporous molecular sieve is released from the mold 2+ , and use a reducing agent to reduce under the protection of an inert gas; the modified silicon-based mesoporous molecular sieve loaded with zero-valent iron obtained after demoulding is...

Embodiment

[0056] 1. Experimental part

[0057] 1.1. Reagents and instruments

[0058] The main reagents for synthesizing the mesoporous molecular sieve matrix of the present invention include ethyl orthosilicate, cetyltrimethylammonium bromide, ammonia water, and ethanol; the modifying reagents include L-ascorbic acid; the medicine of the catalytic active part includes ferrous sulfate heptahydrate ; The catalytic degradation probe has p-chlorophenol. All the above reagents were of analytical grade and used directly without any extraction.

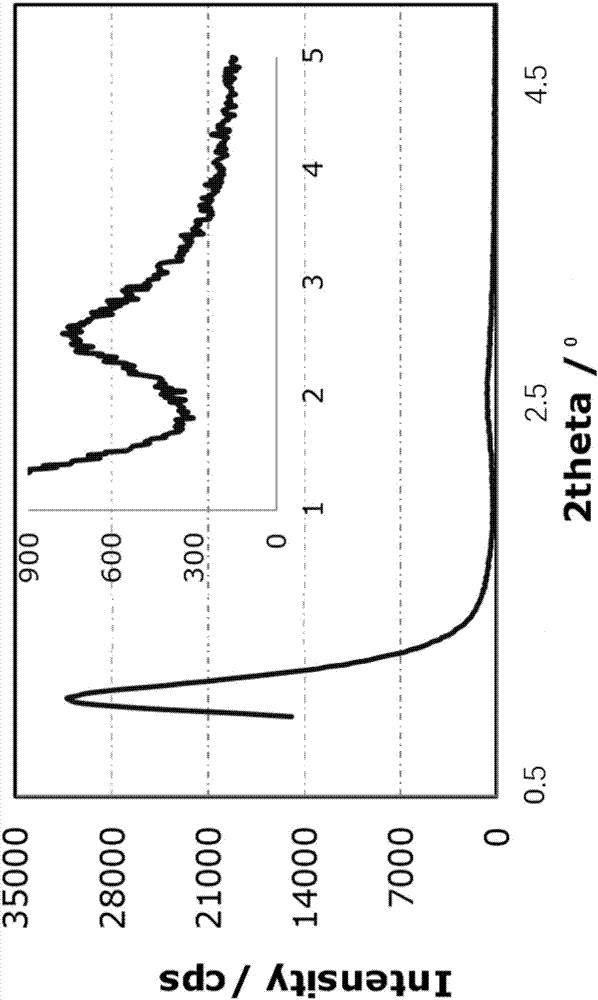

[0059] The present invention uses XRD (Expert Powder) to analyze the order degree of the carrier molecular sieve and the prepared materials, uses SEM and TEM (JEM-2100F) to characterize the topological structure of the materials; uses N2-adsorption and desorption (3H-2000A) to investigate Pore channel and specific surface area characteristics of the carrier; use ultraviolet-visible spectrophotometer (UV-1700) and atomic absorption spectrometer (T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com