Preparation method and application of high-toughness and high-transparency heat-sealable cellulose membrane

A cellulose film, high toughness technology, applied in the direction of sustainable manufacturing/processing, sustainable packaging, climate sustainability, etc., can solve the problems of cumbersome steps, not completely degradable, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

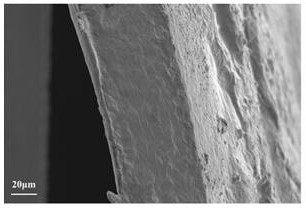

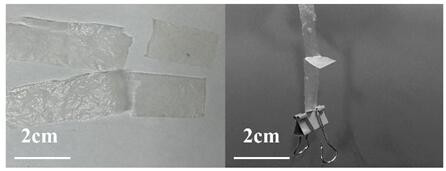

[0030] The specific steps of a method for preparing a high-toughness and high-transparency heat-sealable cellulose film are as follows:

[0031] (1) Dissolve a certain quality of plant fiber in a certain concentration of chloride salt solution, stir at a constant speed at a certain temperature to dissolve, until it is in a transparent light yellow viscous state;

[0032] (2) Prepare a certain proportion of mixed plasticizer, stir and mix at a certain temperature to a flowing state, and blend with the cellulose solution in an appropriate proportion to obtain a mixed solution;

[0033] (3) Pour the mixed solution into the film maker for film coating, select the appropriate thickness for the film maker, and scrape and coat the film on the glass plate;

[0034] (4) Immediately after scraping, it is placed in a certain volume of coagulation bath, and the organic solvent is replaced for an appropriate time;

[0035] (5) Replace the organic solvent in step (4), and continue to repla...

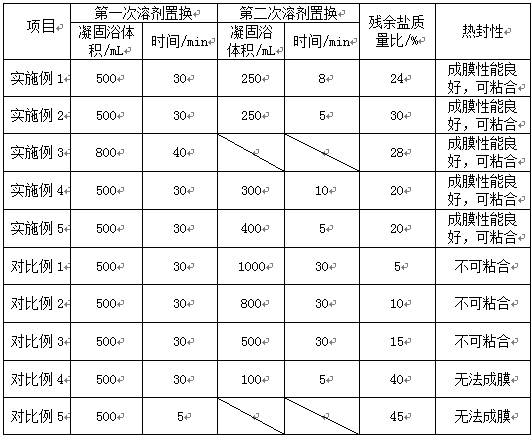

Embodiment 1

[0042] The preparation method of the high-toughness and high-transparency heat-sealable cellulose film of the present embodiment includes:

[0043] (1) Dissolve 0.8 g of cotton fiber in a 70% zinc chloride solution, and stir at a constant speed at 90 °C to dissolve until it is in a transparent light yellow viscous state;

[0044] (2) The mass ratio of glycerol and sorbitol is 2:1, the mass ratio of the total amount of glycerol and sorbitol to the cellulose film solution system is 15%, and the mixture is stirred and mixed at 90 °C until it is in a flowing state, and mixed with cellulose. The solution is blended to obtain a mixed solution;

[0045] (3) Pour the mixed solution into the film maker for film coating. The film maker is selected with a thickness of 750 µm, and the film is formed by scraping on the glass plate;

[0046] (4) Immediately after scraping, put it into 500 mL of ethanol for 30 min of organic solvent replacement;

[0047] (5) Replace the organic solvent in ...

Embodiment 2

[0050](1) Dissolve 0.8 g of flax fiber in a zinc chloride solution with a mass fraction of 70%, and stir at a constant speed at 70 °C to dissolve until it is in a transparent pale yellow viscous state;

[0051] (2) The mass ratio of glycerol and sorbitol is 2:1, and the mass ratio of the total amount of glycerol and sorbitol to the cellulose film solution system is 10%. Stir and mix at 80 °C to a flowing state, and mix with cellulose. The solution is blended to obtain a mixed solution;

[0052] (3) Pour the mixed solution into the film maker for film coating. The film maker is selected with a thickness of 250 µm, and the film is formed by scraping on the glass plate;

[0053] (4) Immediately after scraping, put it into 500 mL of organic ethanol for 30 min of organic solvent replacement;

[0054] (5) Replace the organic solvent in step (4), and continue to replace the organic solvent in 250 mL of ethanol for 5 min, so that the residual salt mass ratio of the cellulose membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com