Manufacturing method of watch exterior parts

A manufacturing method and a technology of appearance parts, which are applied in the field of watch appearance parts manufacturing, can solve problems such as allergic reactions, nickel dissolution, and harm to the human body, and achieve the effects of light wearing, simplified processing technology, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

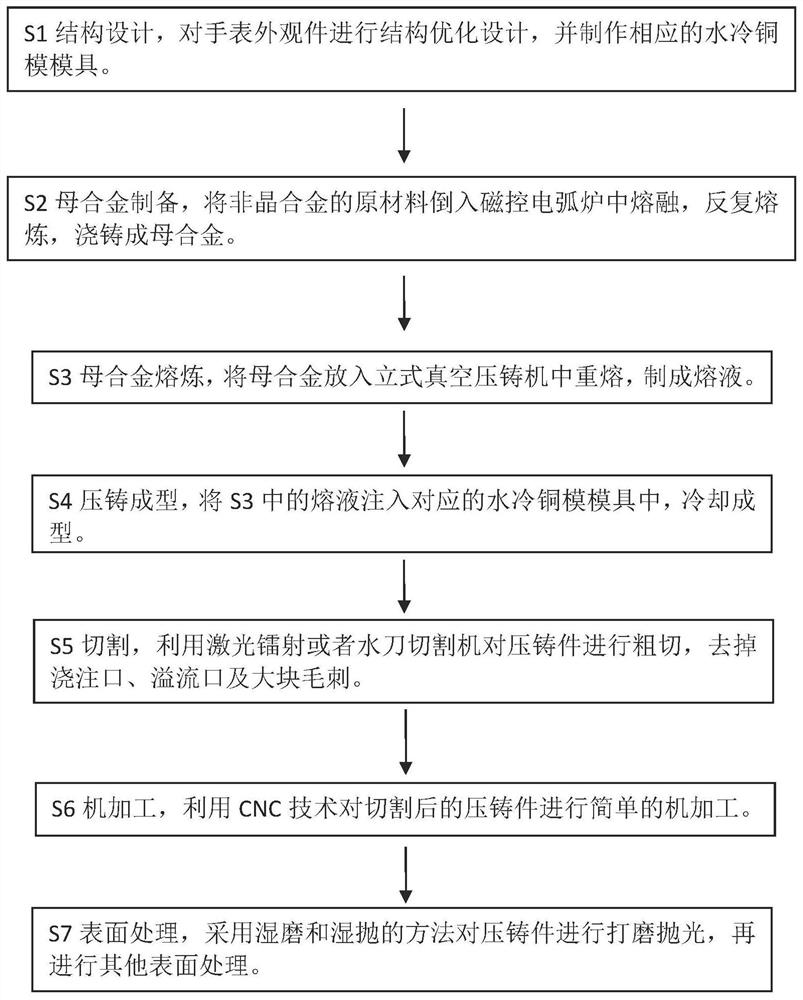

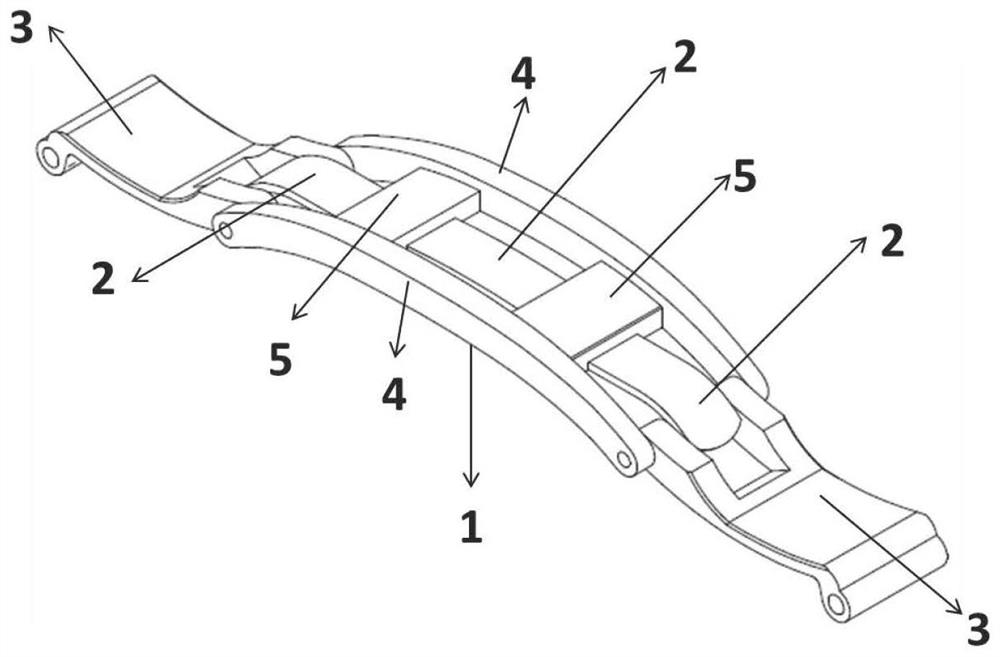

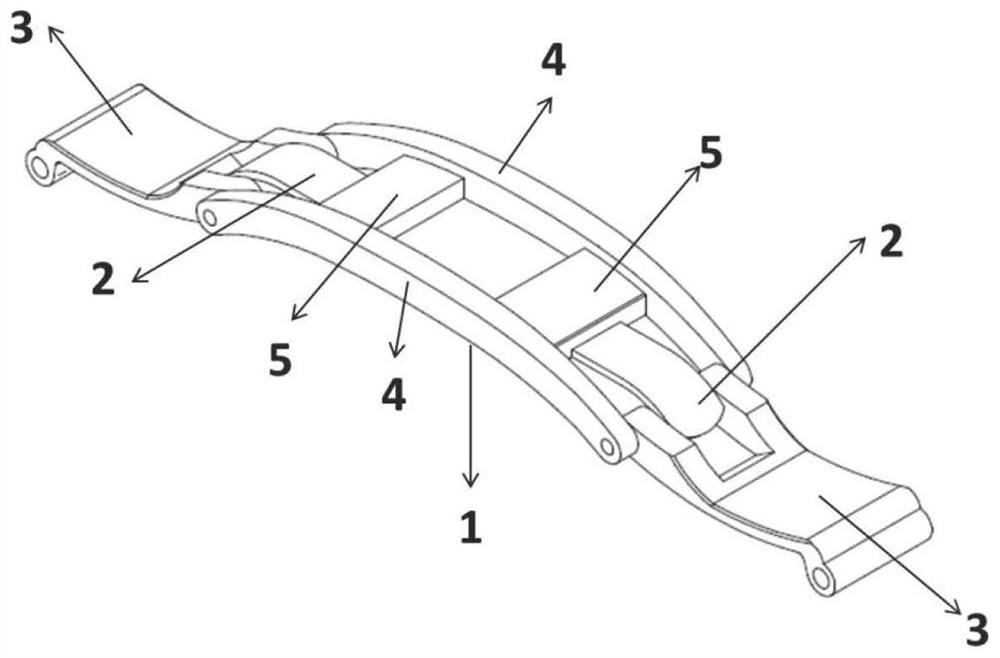

[0035] Such as image 3 As shown, the first embodiment of the present invention provides an amorphous alloy as a raw material, a light and thin structure and a watch appearance part manufacturing method that meets the functional requirements of the components to produce a watch buckle, which specifically includes the following steps:

[0036] S1 structure design, optimize the design of watch buckle structure, the thickness of the shrapnel is designed to be 0.3mm, and make corresponding water-cooled copper molds for each part of the buckle according to the designed structure.

[0037] Preparation of S2 master alloy. Mix the raw materials of zirconium-based amorphous alloy evenly and pour them into a magnetron electric arc furnace to melt them. Make a melt under the atmosphere of Ar gas. Stir them evenly by using electromagnetic force. Melt them repeatedly for 5 times and cast them into master alloys. alloy;

[0038] S3 master alloy smelting, put the master alloy into a vertica...

Embodiment 2

[0046] Such as Figure 4 As shown, the second embodiment of the present invention provides an amorphous alloy as a raw material, a light and thin structure and a watch appearance part manufacturing method that meets the functional requirements of the components to produce a watch buckle, which specifically includes the following steps:

[0047] S1 structure design, optimize the design of watch buckle structure, the thickness of the shrapnel is designed to be 0.1mm, and make corresponding water-cooled copper molds for each part of the buckle according to the designed structure.

[0048] Preparation of S2 master alloy. Mix the raw materials of iron-based amorphous alloy evenly and pour them into a magnetron electric arc furnace to melt them. Make a melt under the atmosphere of Ar gas. Stir them evenly by using electromagnetic force, repeatedly smelt them 6 times, and cast them into master alloys. alloy;

[0049] S3 master alloy smelting, put the master alloy into a vertical vac...

Embodiment 3

[0057] Such as Figure 5 As shown, the method for manufacturing a watch appearance part provided by Embodiment 3 of the present invention uses an amorphous alloy as a raw material, has a light and thin structure and meets the functional requirements of the component to produce a watch back cover, which specifically includes the following steps:

[0058] S1 structure design, optimized design of watch back cover structure, the thickness of the back cover vertical wall 6 is designed to be 0.5mm, and the corresponding water-cooled copper mold for the back cover is made according to the designed structure.

[0059] Preparation of S2 master alloy. Mix the raw materials of titanium-based amorphous alloy evenly and pour them into a magnetron electric arc furnace to melt them. Make a melt under the atmosphere of Ar gas. Stir it evenly by using electromagnetic force, repeatedly smelt it 5 times, and cast it into a master alloy. alloy;

[0060] S3 master alloy smelting, putting the mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com