Waveguide core layer, mode spot converter, silicon optical device, and optical communication unit

A mode spot converter and waveguide core technology, applied in the field of optical communication, can solve the problems of high cost, large optical loss, poor channel uniformity, etc., and achieve the effects of precise docking, reducing optical loss, and improving channel uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

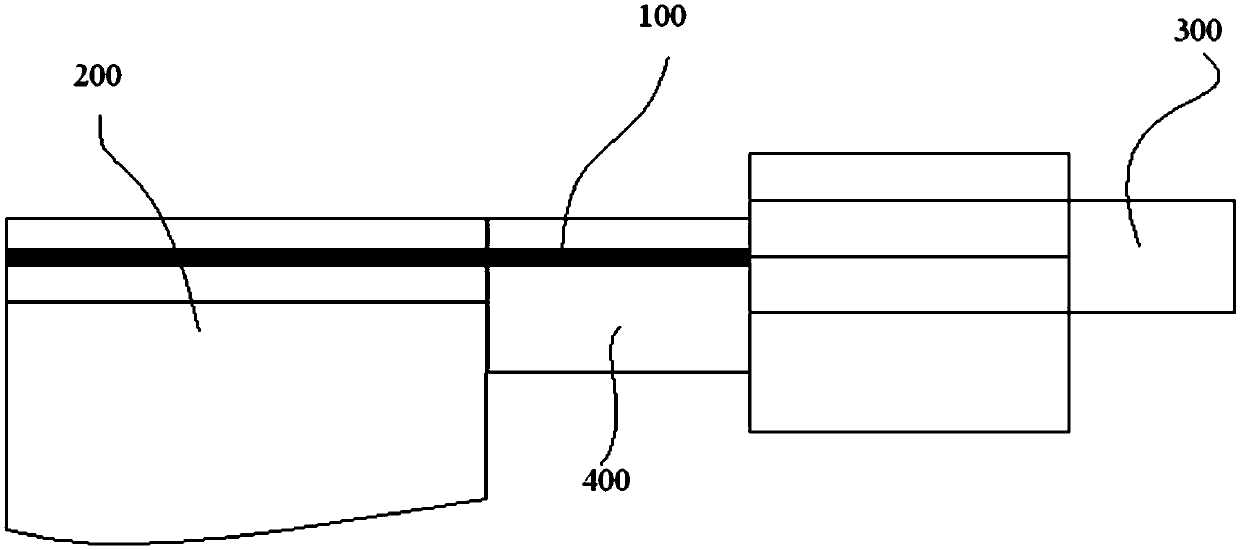

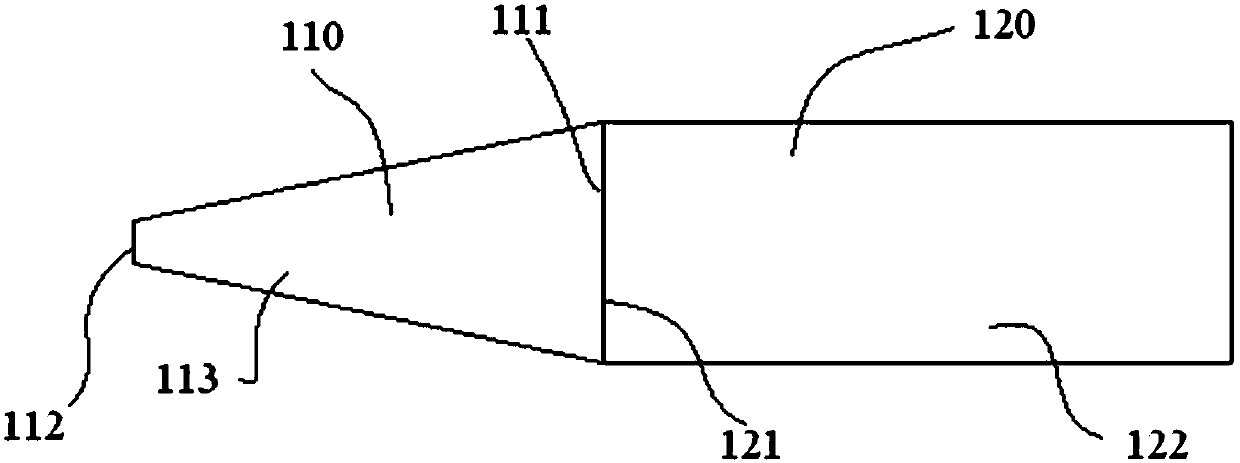

[0058] figure 1 This is a schematic connection diagram of Embodiment 1 of the waveguide core layer of this application; figure 2 for figure 1 Schematic diagram of the overall structure of the middle waveguide core. Please refer to figure 1 with figure 2 , This embodiment provides a waveguide core layer 100, including: a first waveguide region 110 and a second waveguide region 120 connected in a first direction; and the first waveguide region 110 and the second waveguide region 120 are both along the first direction Extension; the end of the first waveguide region 110 away from the second waveguide region 120 is used to connect to the silicon optical chip 200, the end of the second waveguide region 120 away from the first waveguide region 110 is used to connect to the optical fiber 300; the first waveguide region 110 is along The size in the second direction increases from the end away from the second waveguide region 120 to the end close to the second waveguide region 120; the...

Embodiment 2

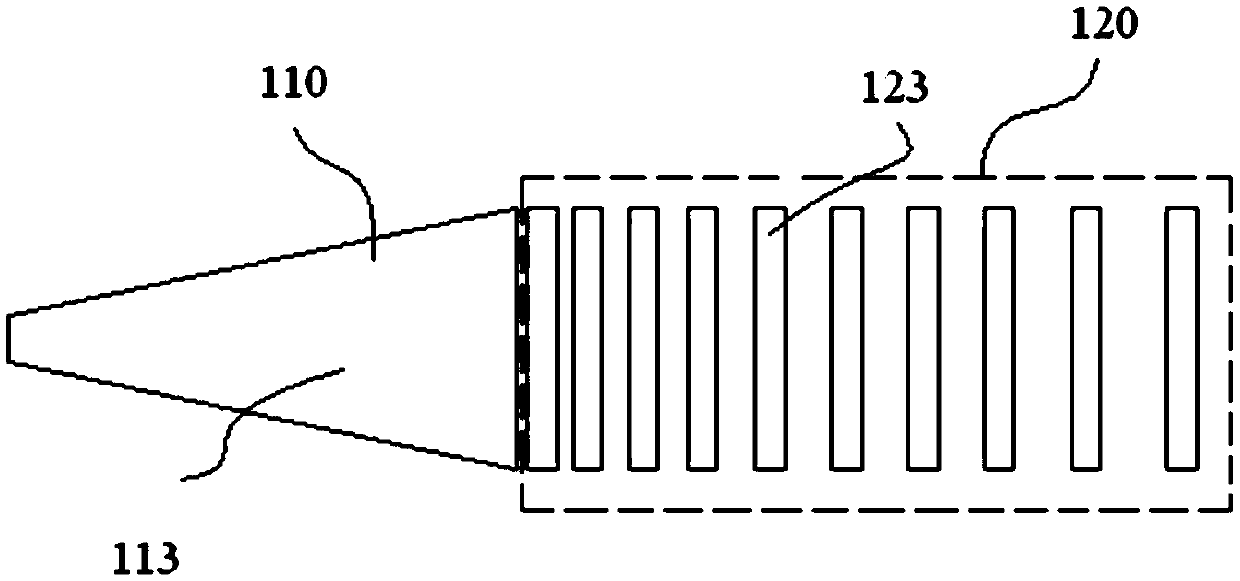

[0073] In this embodiment, the method of changing the refractive index of the second waveguide region 120 is improved on the basis of the first embodiment. For other structures, reference may also be made to the first embodiment, which will not be repeated here. image 3 This is a schematic diagram of the overall structure of Embodiment 2 of the waveguide core layer of this application. image 3 Here, the first direction may be the left-right direction in the figure, the second direction may be the up-down direction in the figure, and the third direction may be a direction perpendicular to the paper surface. Please refer to image 3 , The second waveguide region 120 includes a plurality of second solid waveguide portions 123 arranged at intervals along the first direction, and one of the plurality of second solid waveguide portions 123 close to the first waveguide region 110 has a second cross section 121, and the second cross section 121 is located at an end of the second solid ...

Embodiment 3

[0080] This embodiment is an improvement on the structure of the first waveguide region 110 on the basis of the first or second embodiment. For the structure of the second waveguide region 120, please refer to the first or second embodiment, which will not be repeated here. . Figure 4 This is a schematic diagram of the overall structure of Embodiment 3 of the waveguide core layer of this application. Figure 4 Here, the first direction may be the left-right direction in the figure, the second direction may be the up-down direction in the figure, and the third direction may be a direction perpendicular to the paper surface. Please refer to Figure 4 , The first waveguide region 110 includes: a first sub-waveguide region 114 and a second sub-waveguide region 116 arranged in sequence along the first direction; an end of the second sub-waveguide region 116 away from the first sub-waveguide region 114 and the second waveguide region 120 Connection; the first sub-waveguide region 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com