Patents

Literature

503results about How to "Reduce eccentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

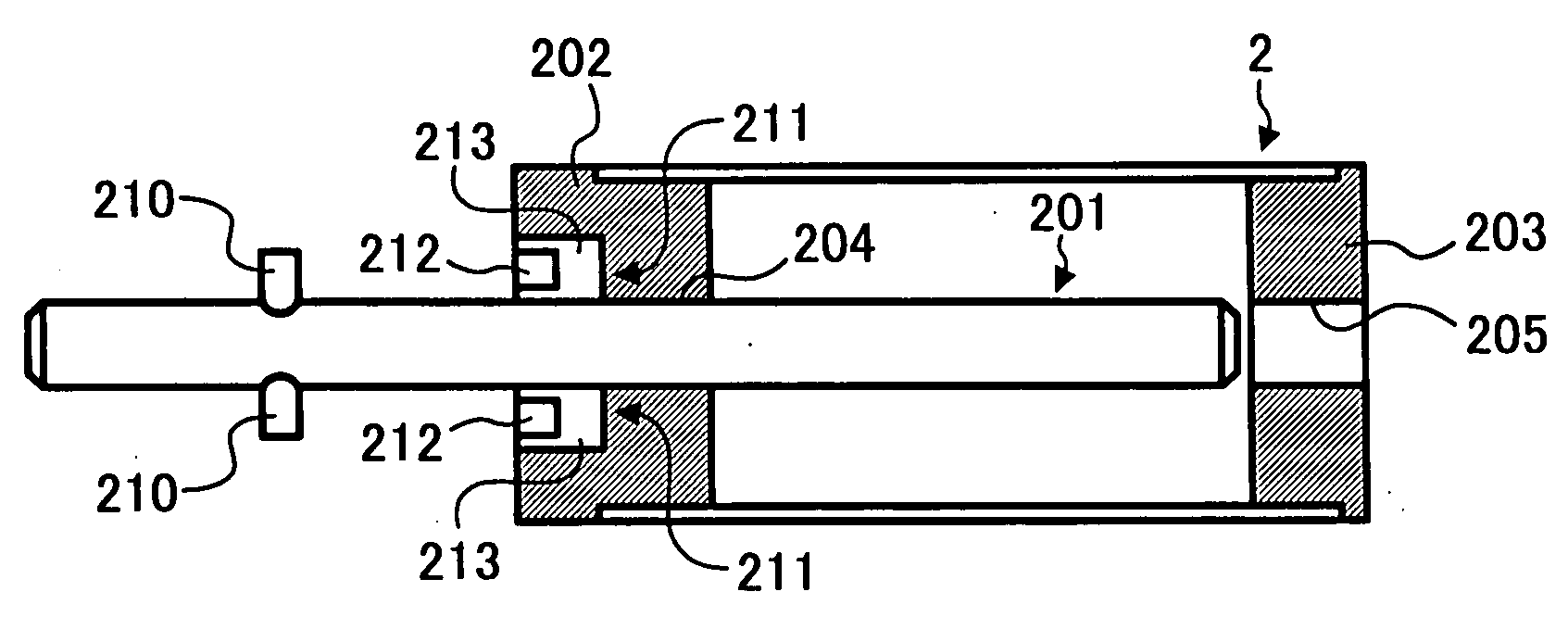

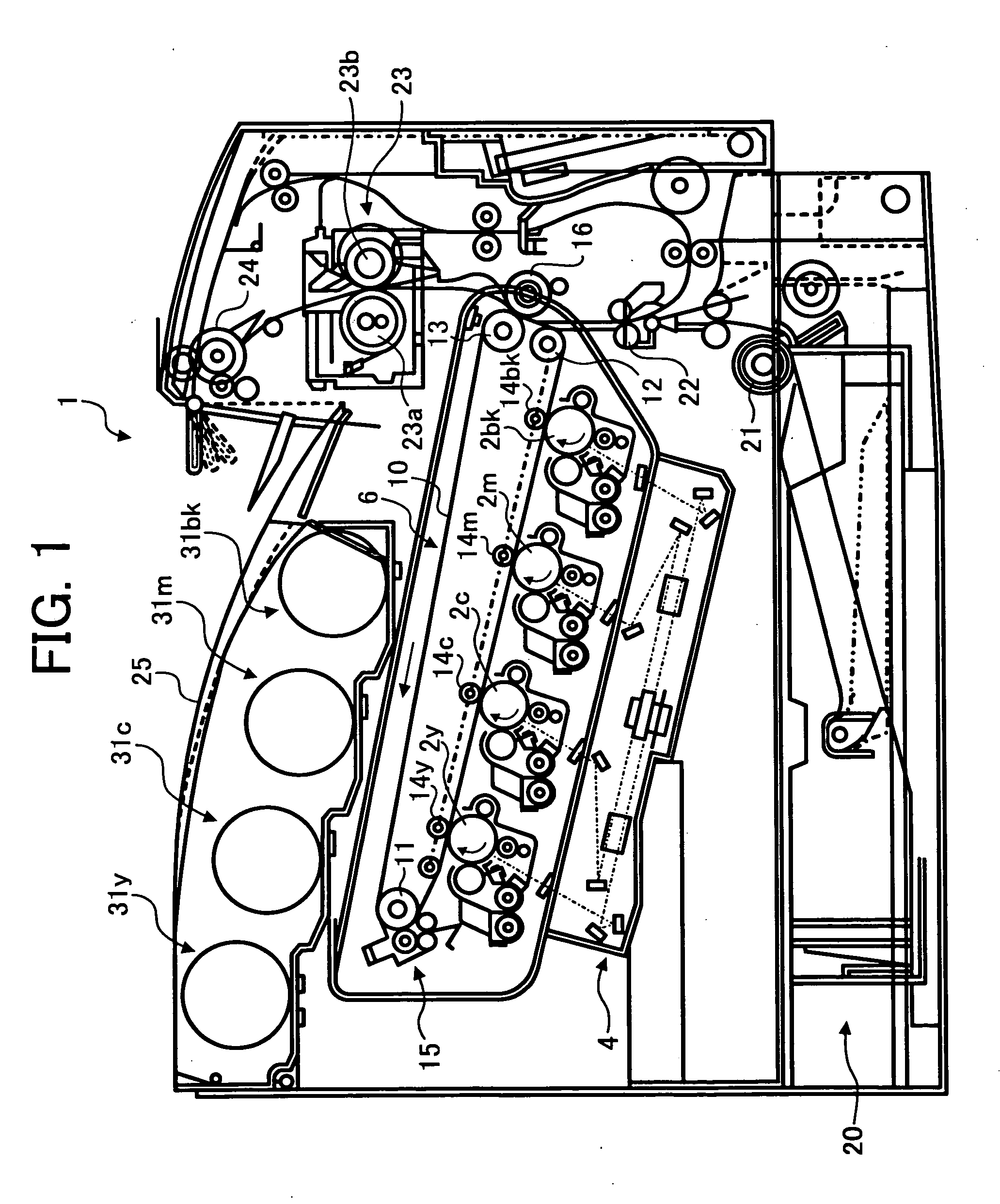

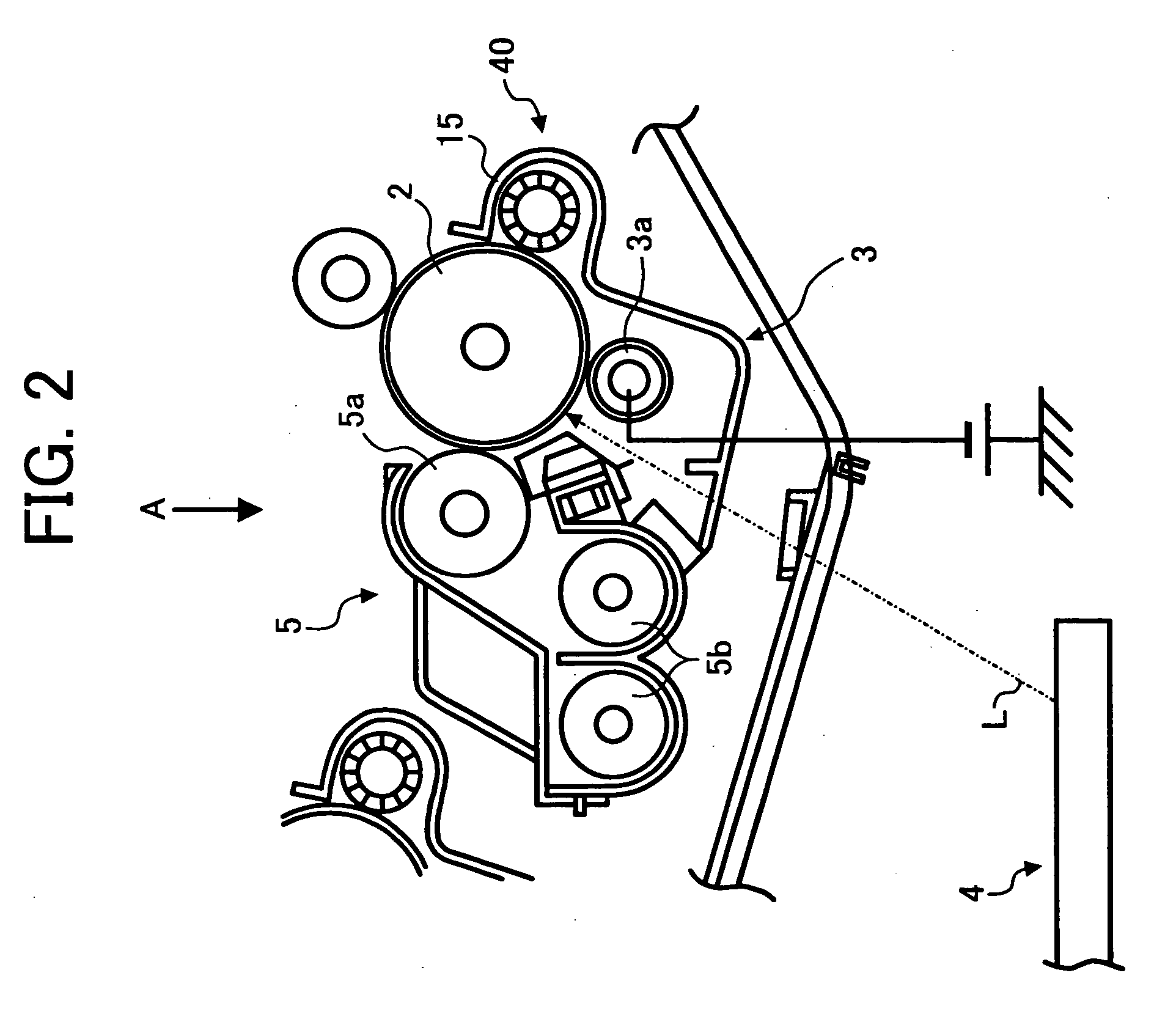

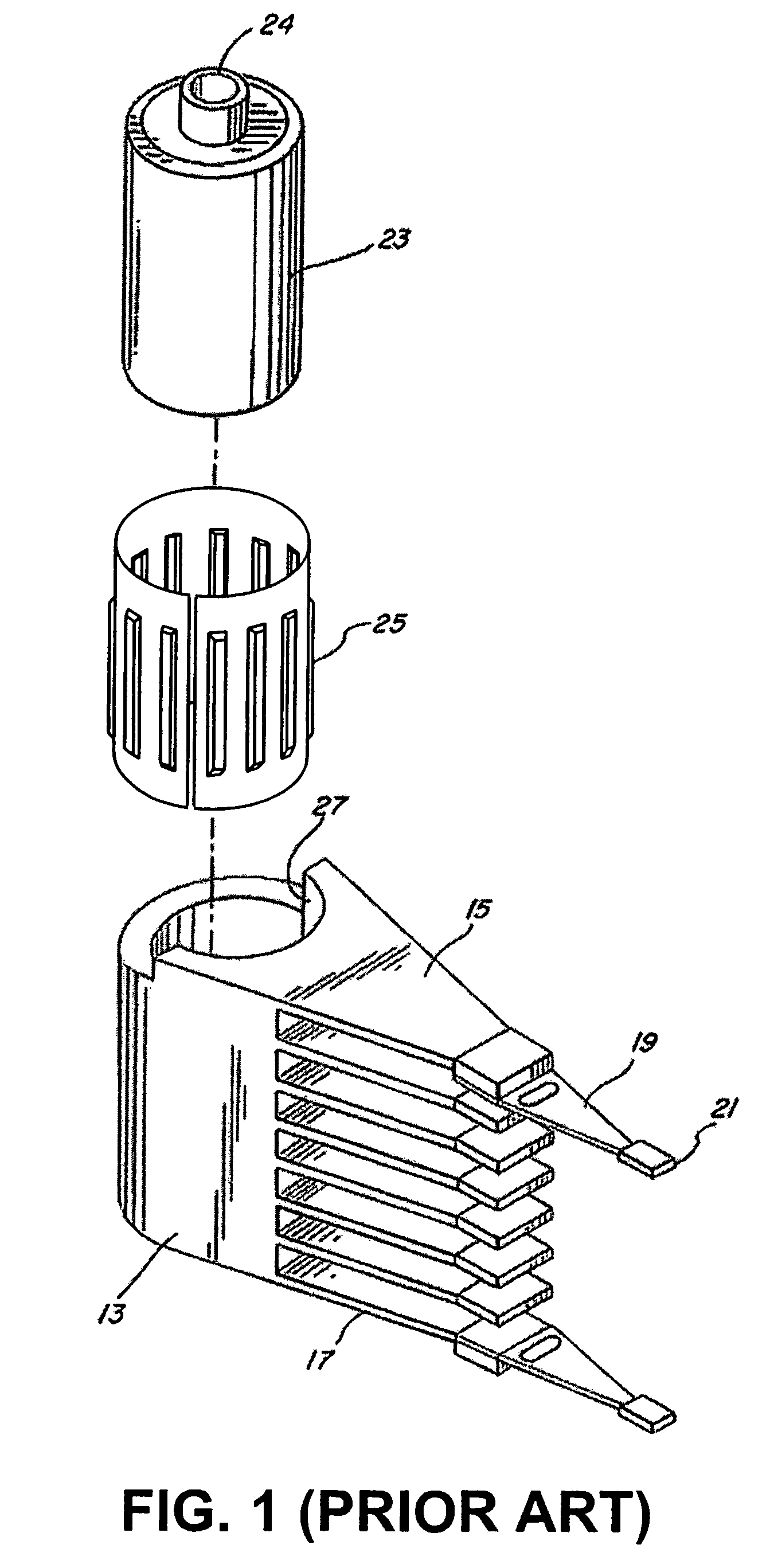

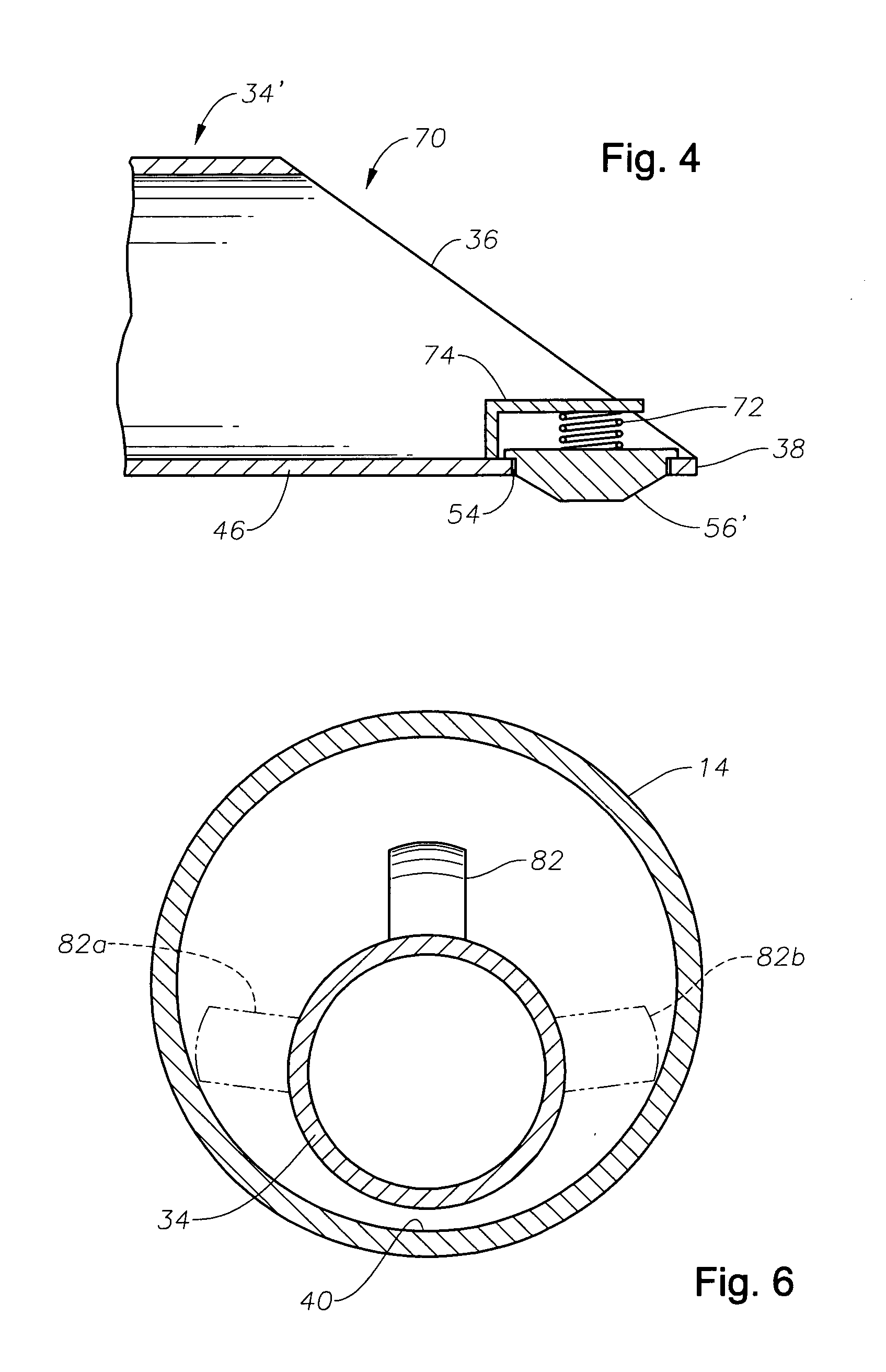

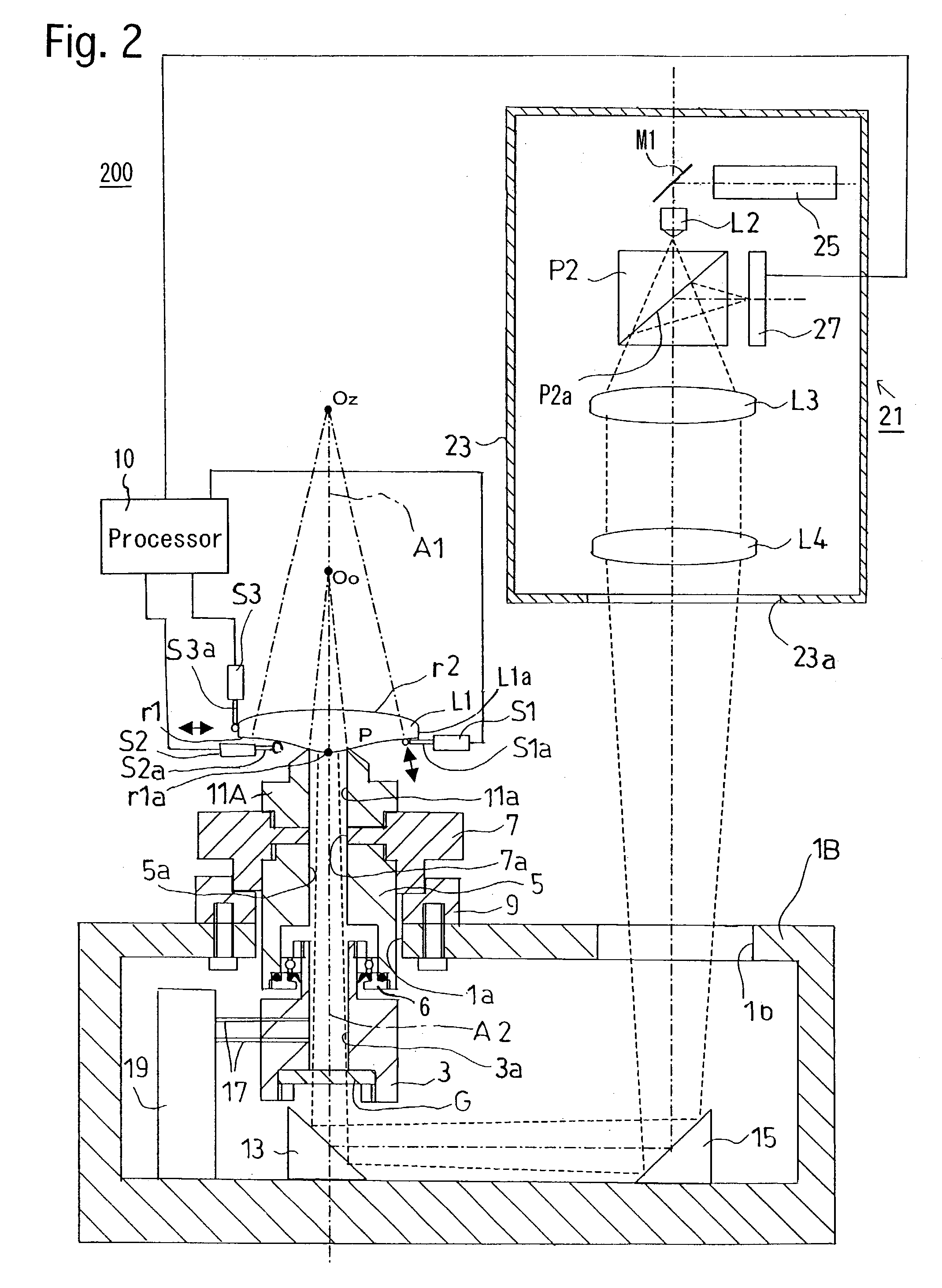

Image forming apparatus having a detachable cartridge including a photoconductive drum with axis shaft having a minimal rotational eccentricity, and a method of assembling the image forming apparatus

InactiveUS20050031374A1Reduce eccentricityAvoid turbulenceElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

Clip

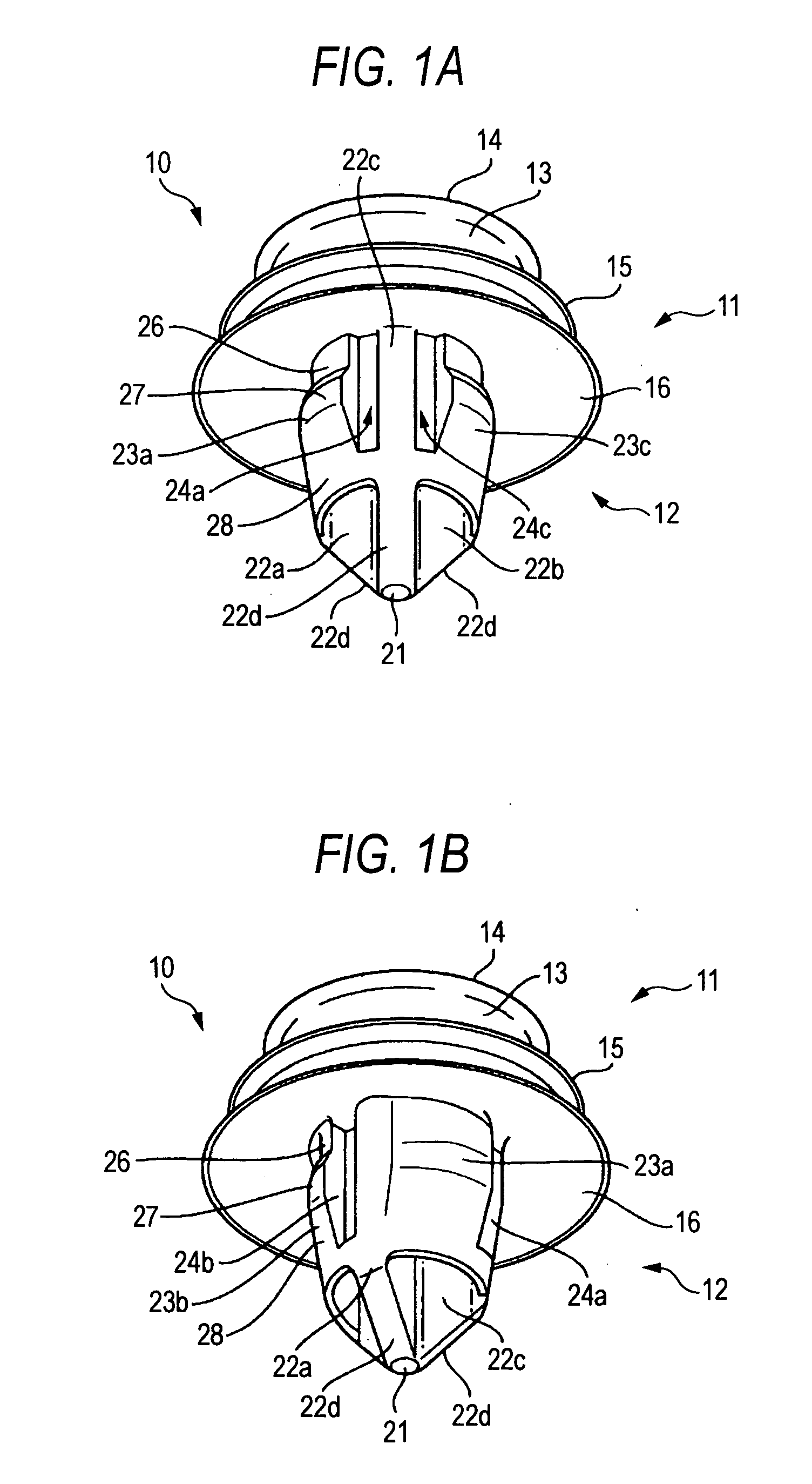

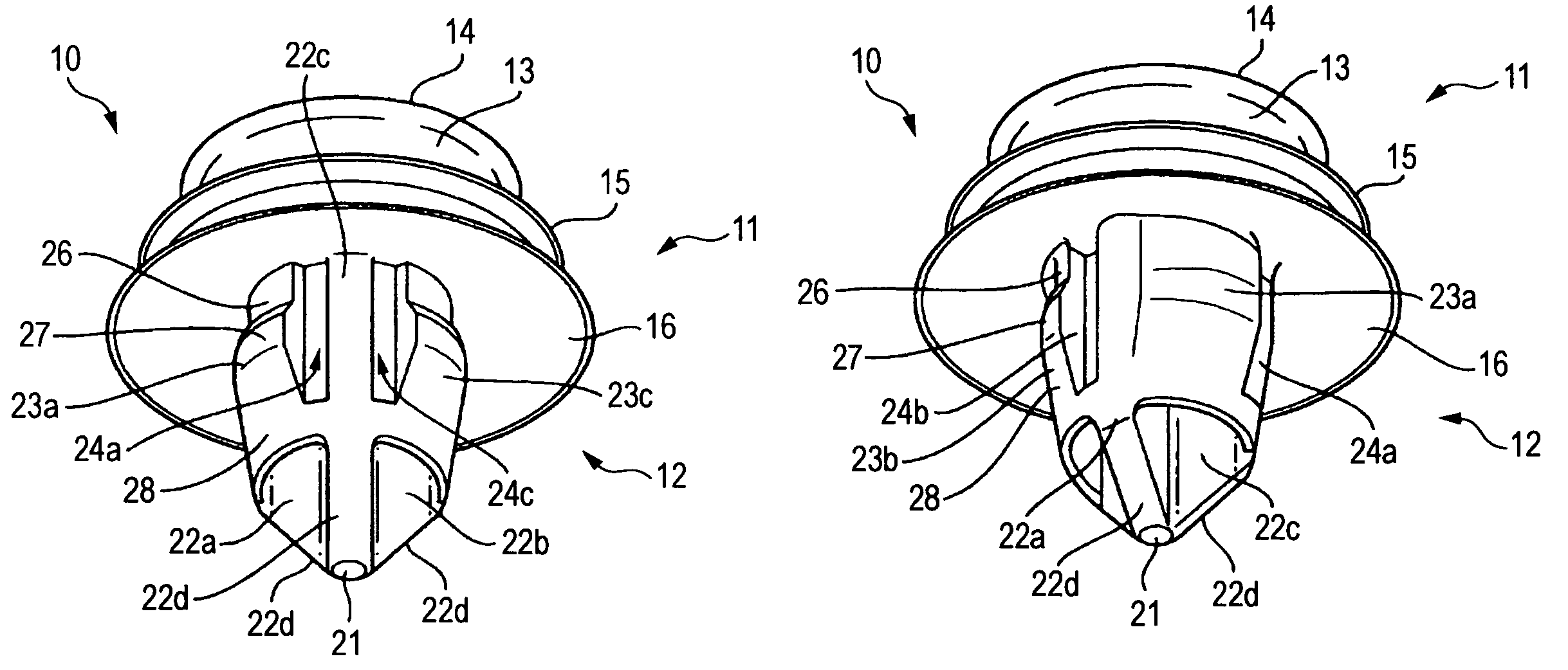

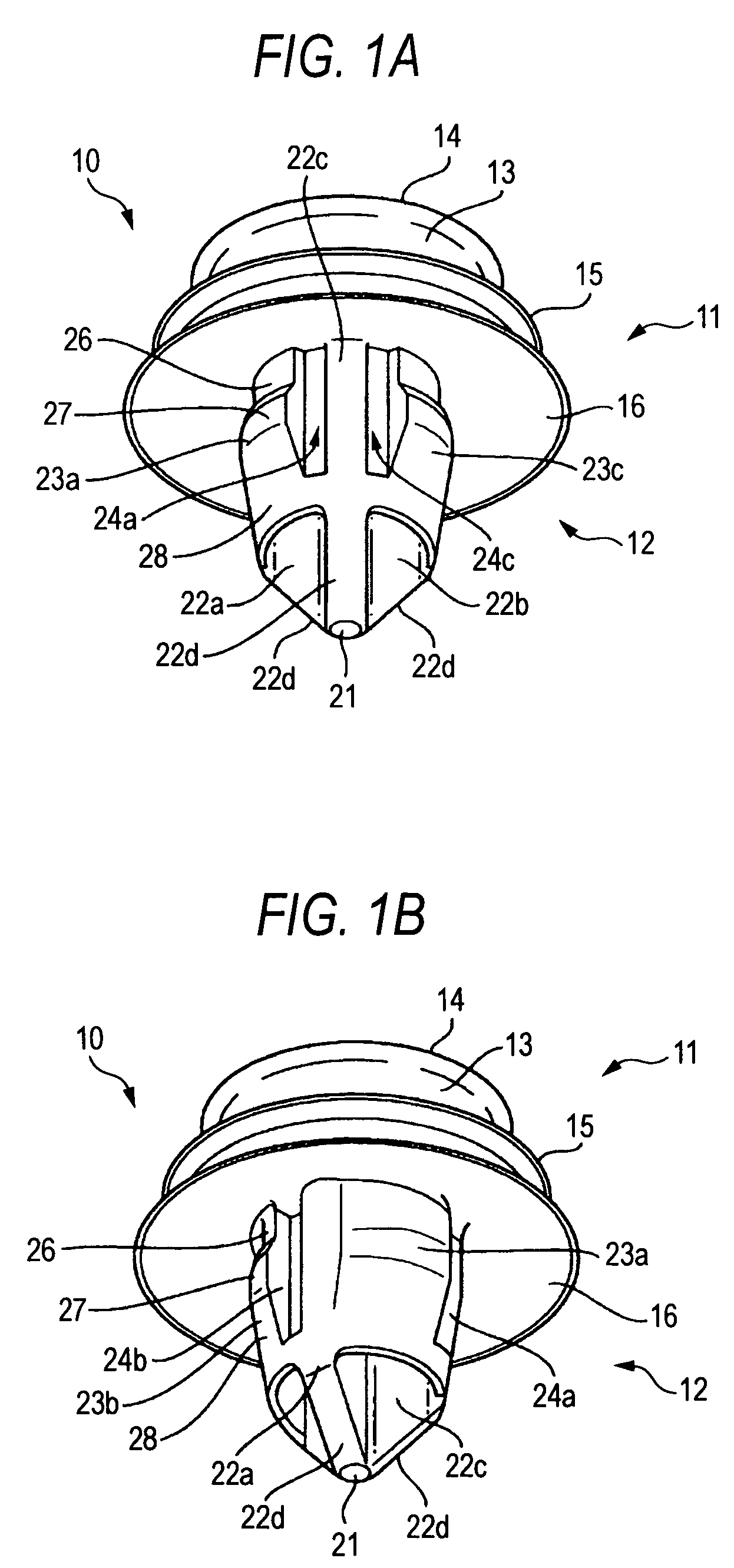

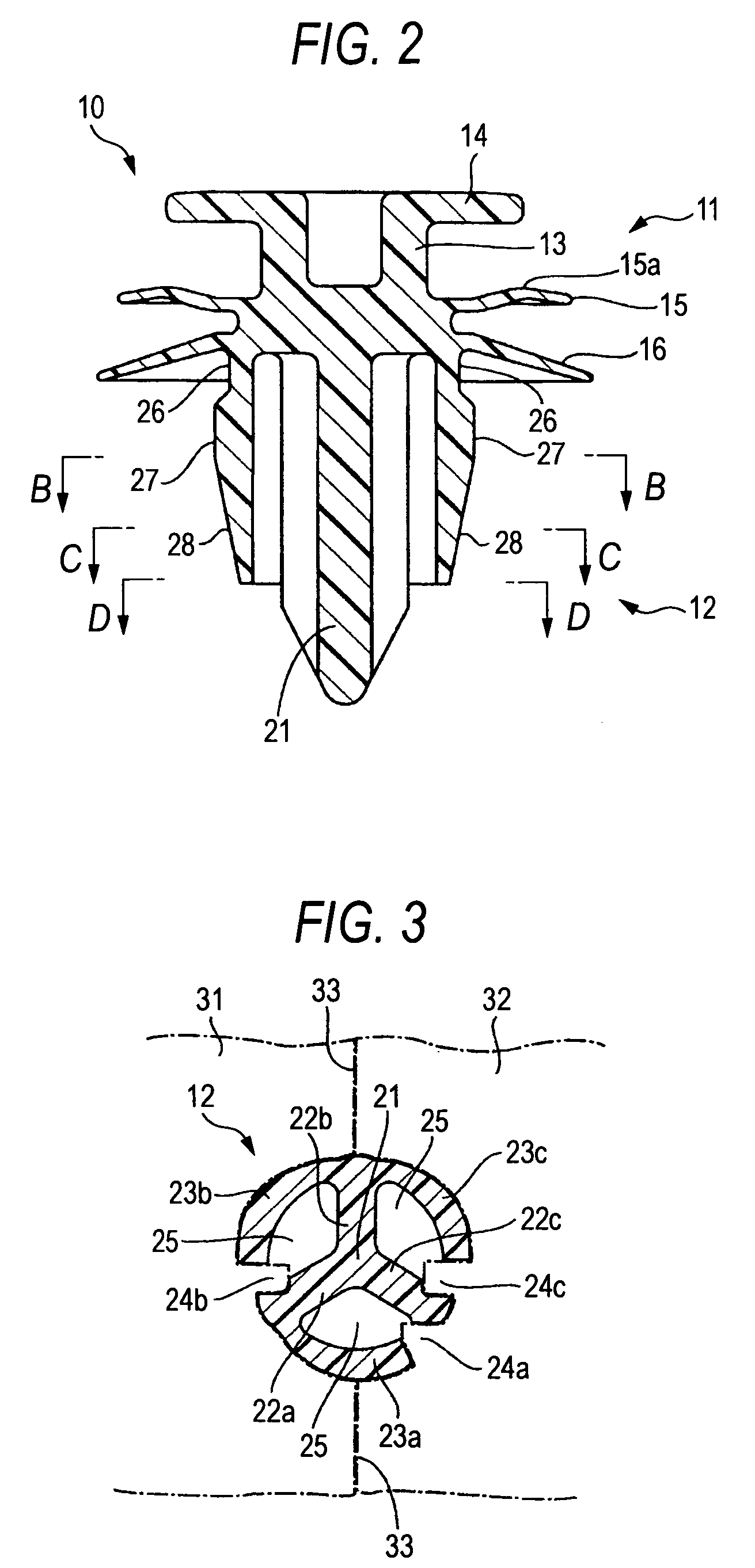

InactiveUS20050244250A1Large locking forceDisengagement of the clip can be preventedSnap fastenersFlow mixersEngineeringLower face

A clip has a head part adapted to be contacted with a peripheral edge of a fitting hole in a panel to be fitted, and a leg part adapted to be inserted into the fitting hole thereby to be engaged with the peripheral edge of the fitting hole. The leg part has a post suspended from a center of a lower face of the head part, at least three projections which are radially extended from the post in a diametrical direction and connected to the lower face of the head part at their upper ends, and engaging pieces which are extended from these projections in a circumferential direction to be respectively positioned between the projections. The engaging pieces are connected to the head part at their upper ends, and provided with slits between their circumferentially extended ends and the opposed projections.

Owner:PIOLAX CO LTD

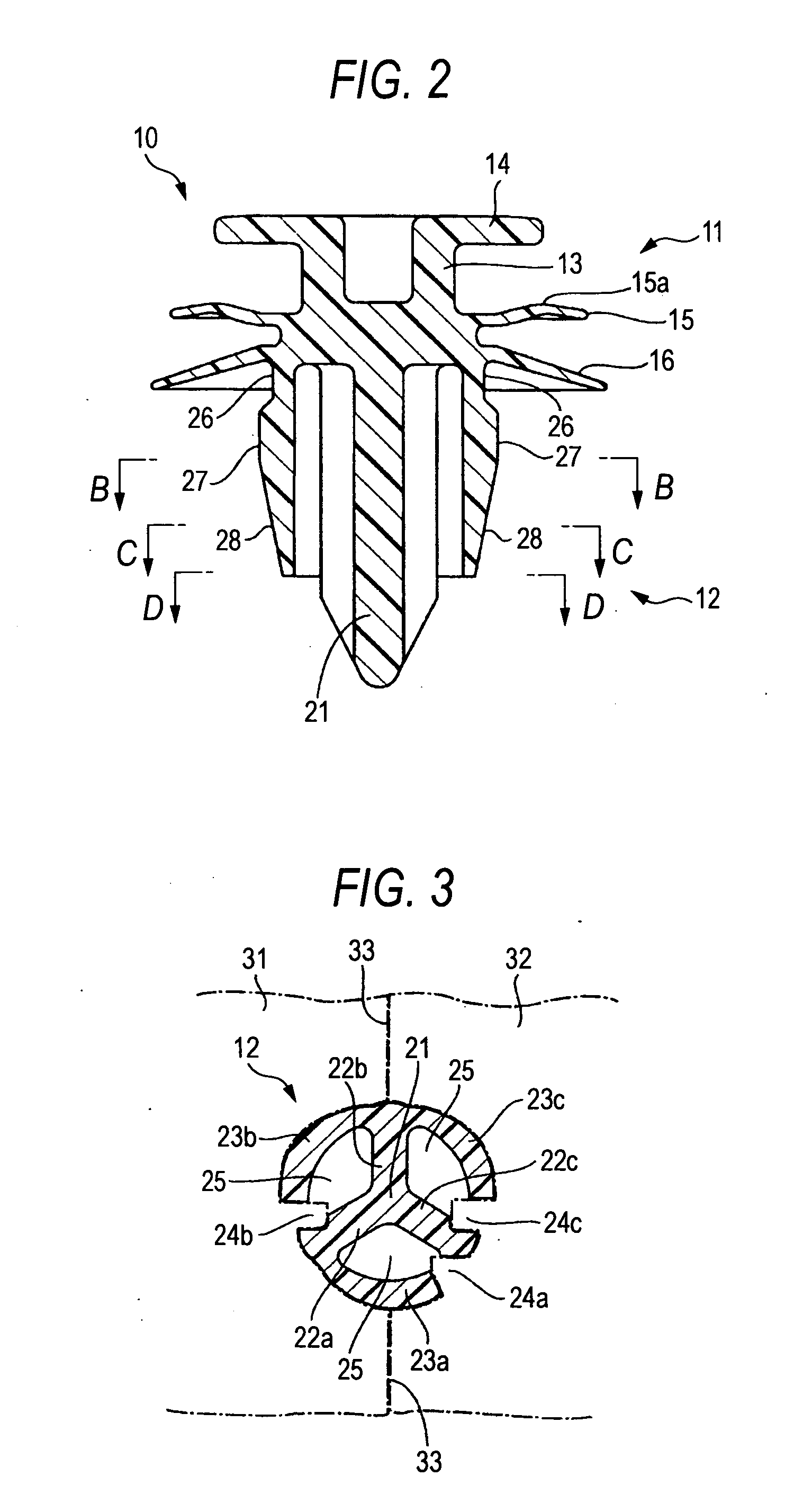

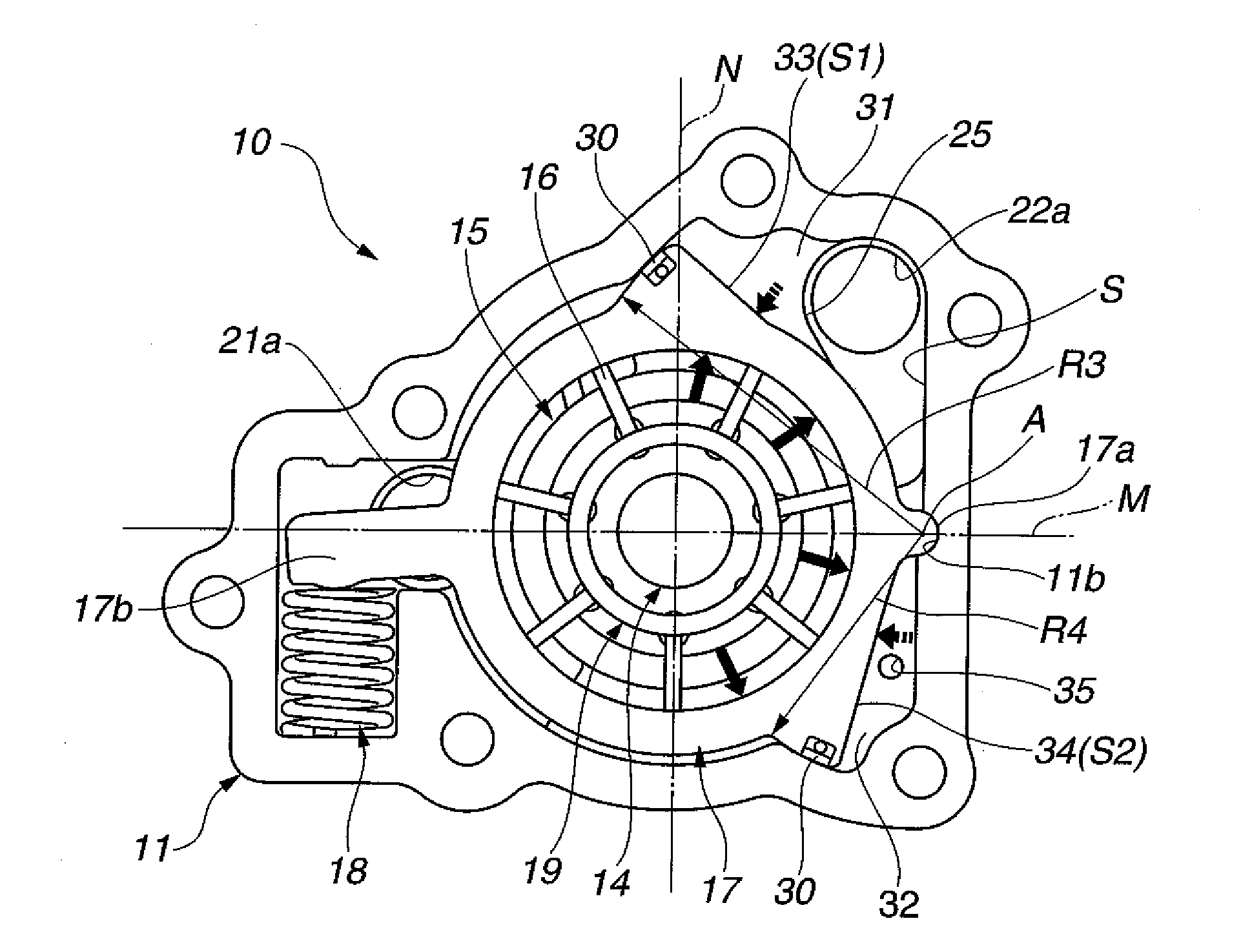

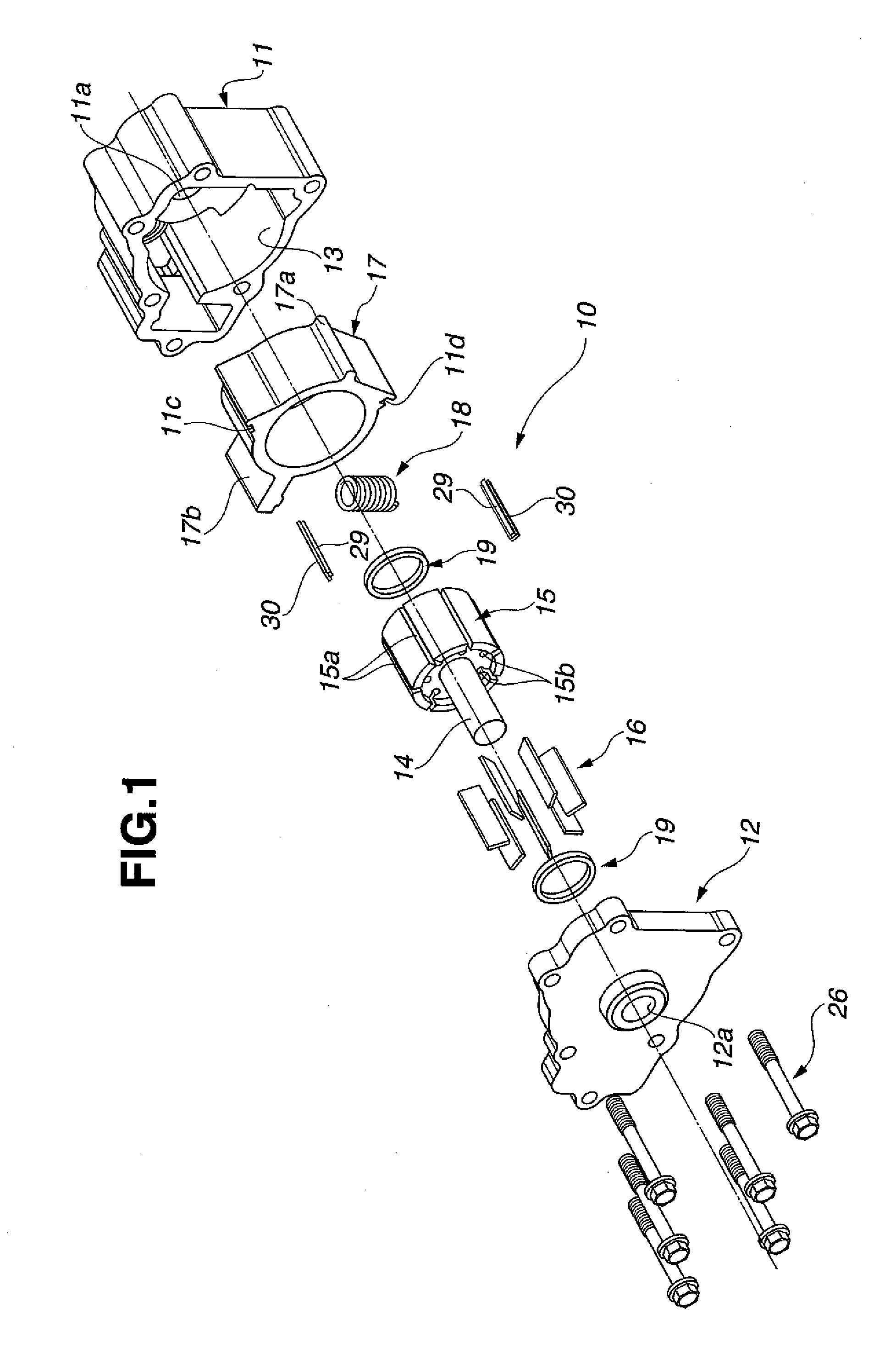

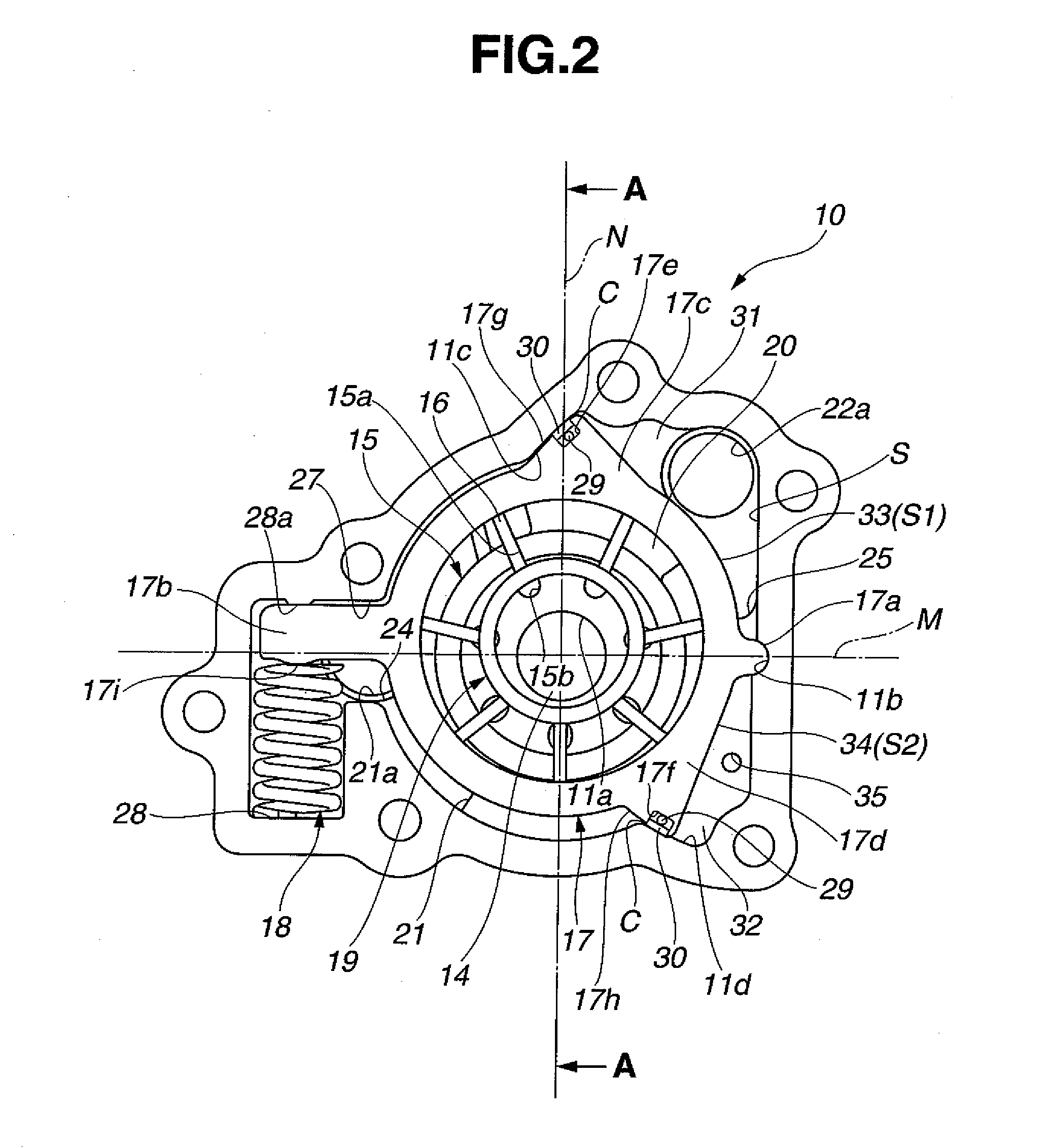

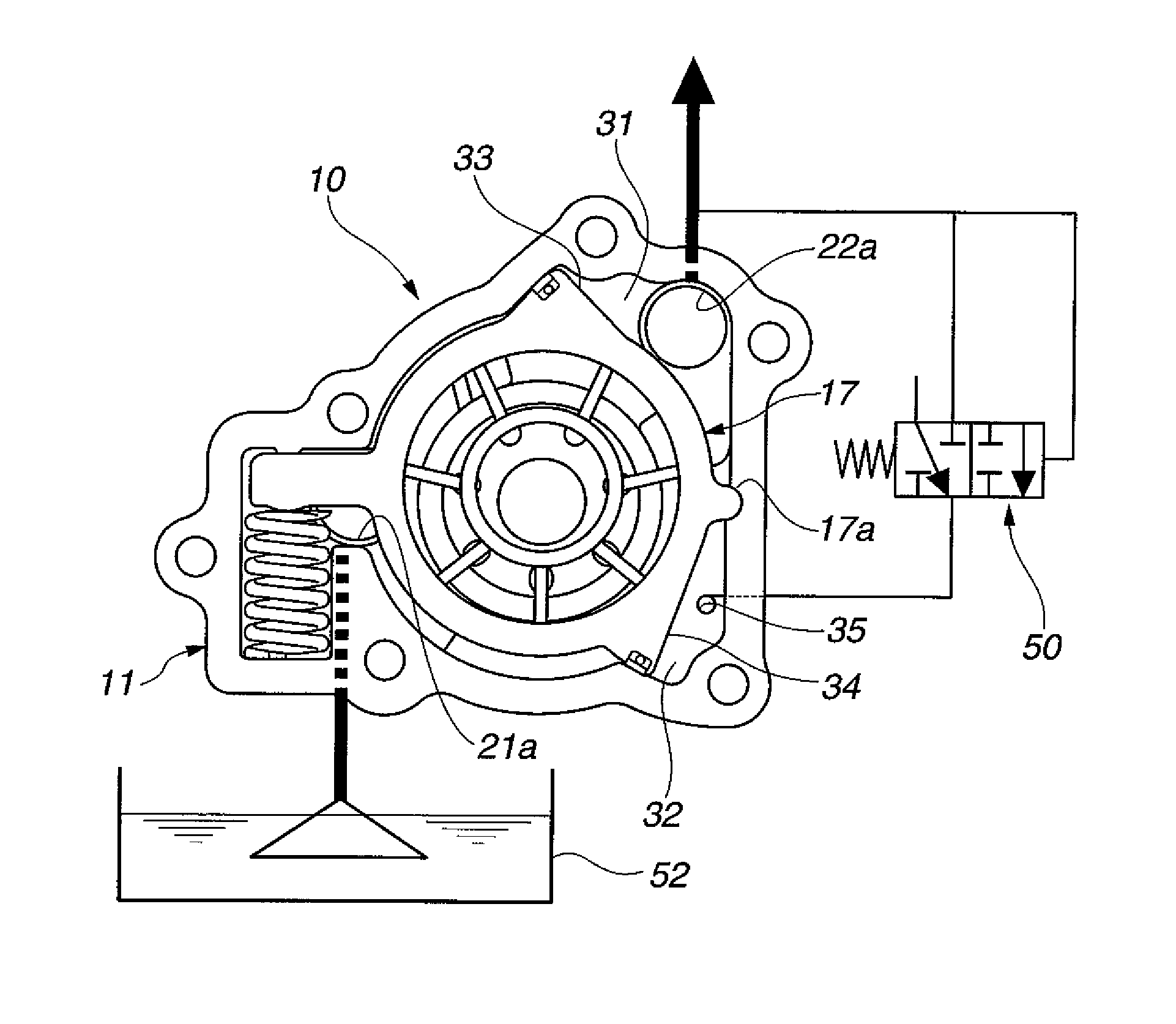

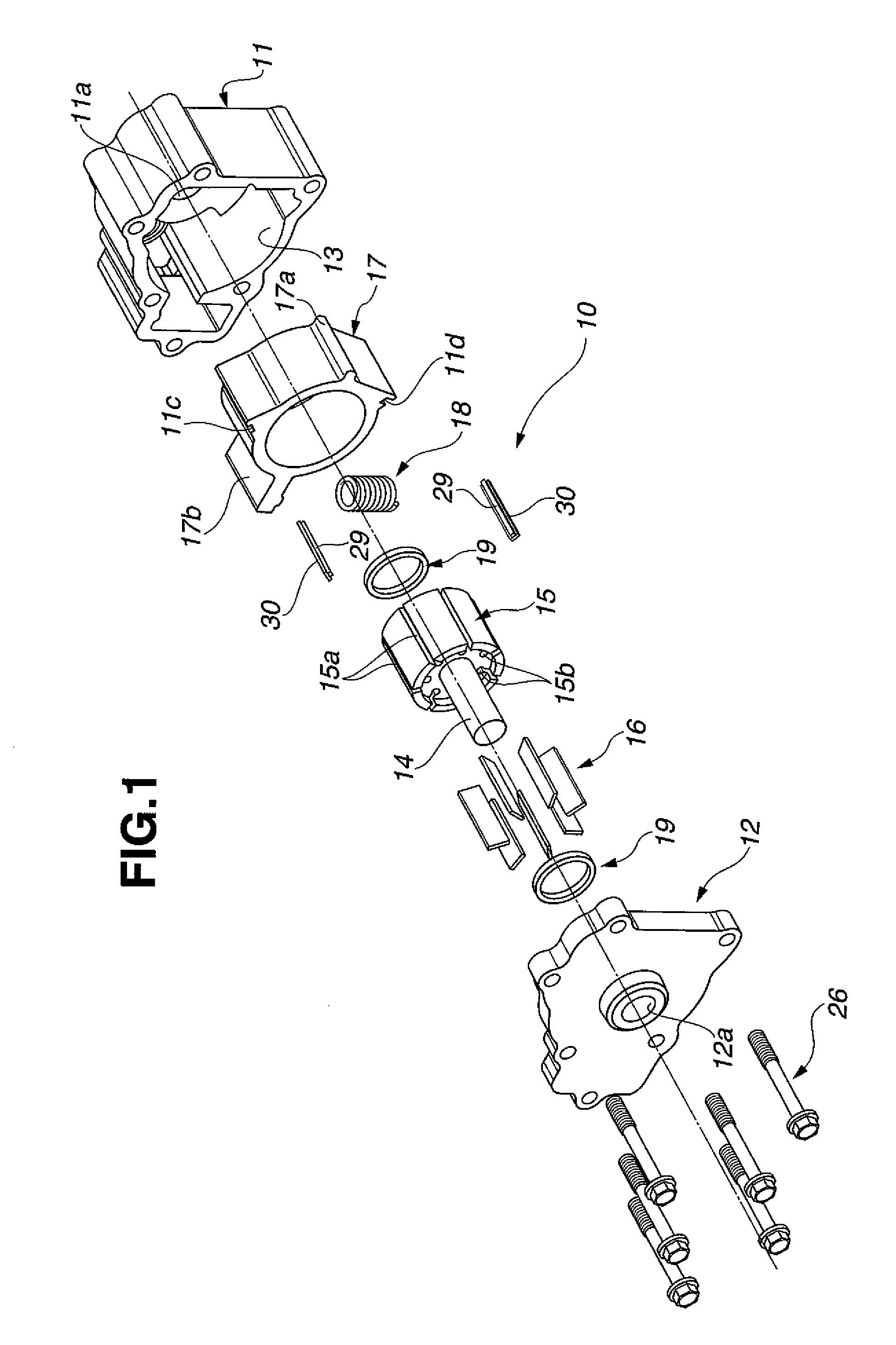

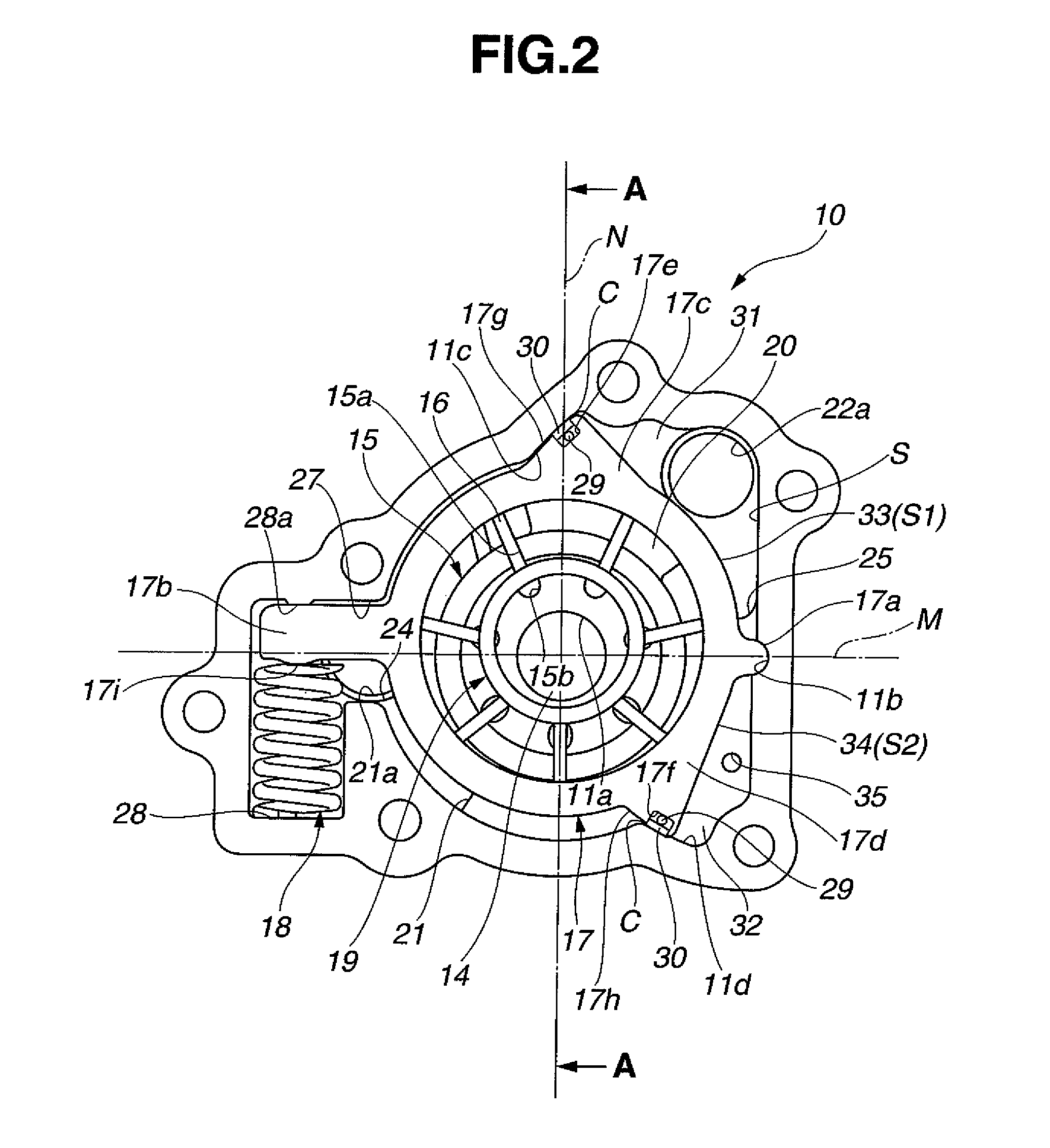

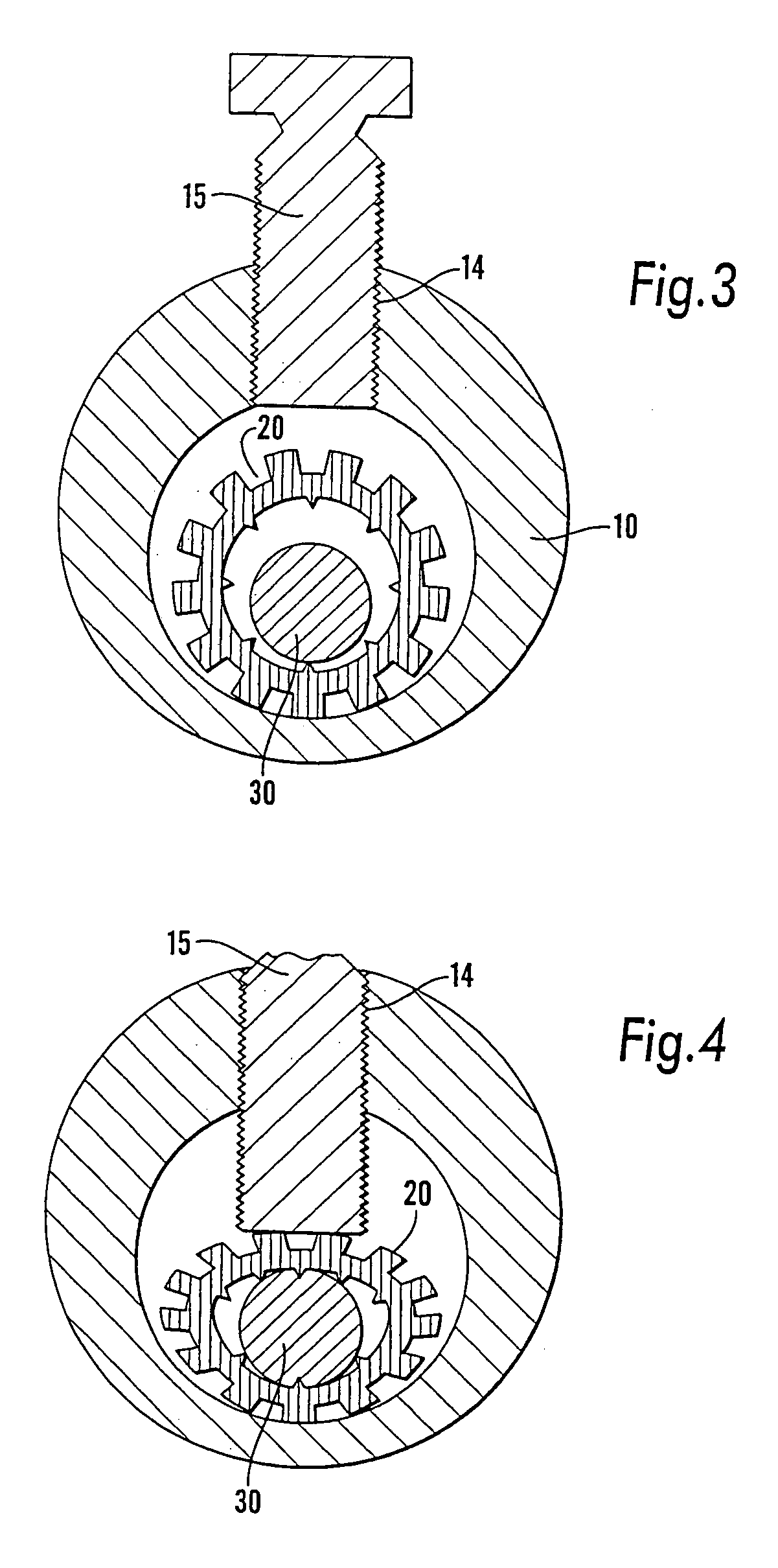

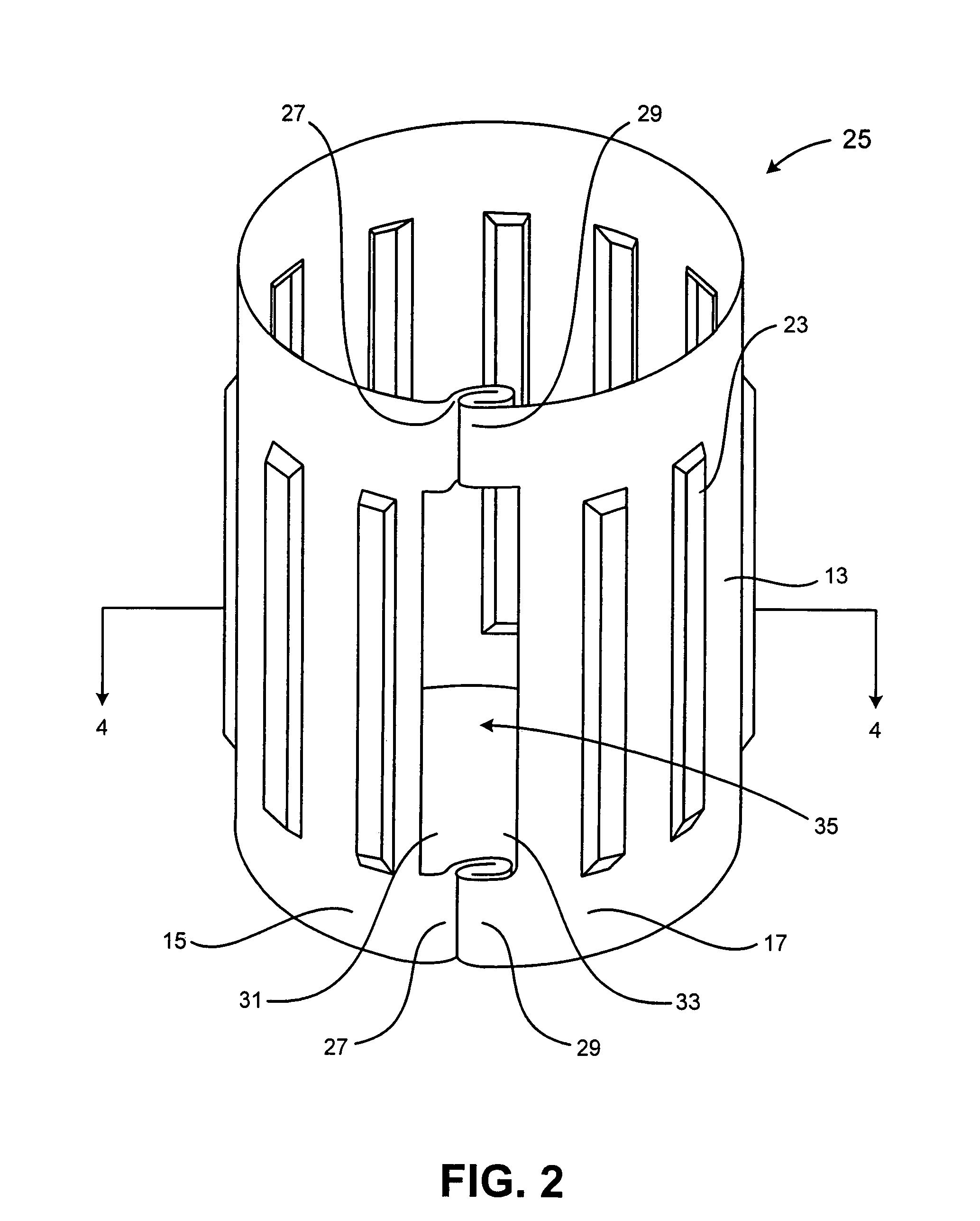

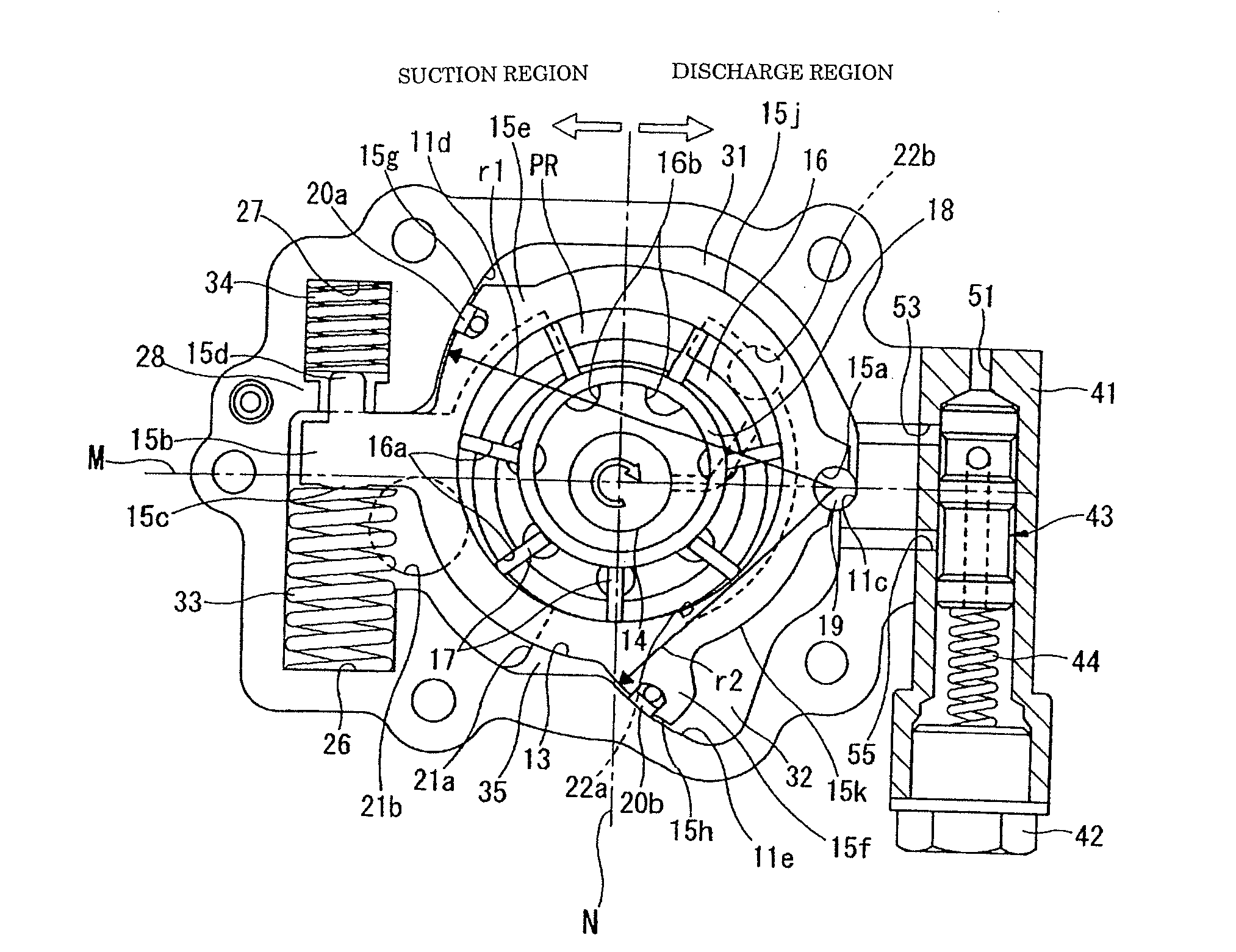

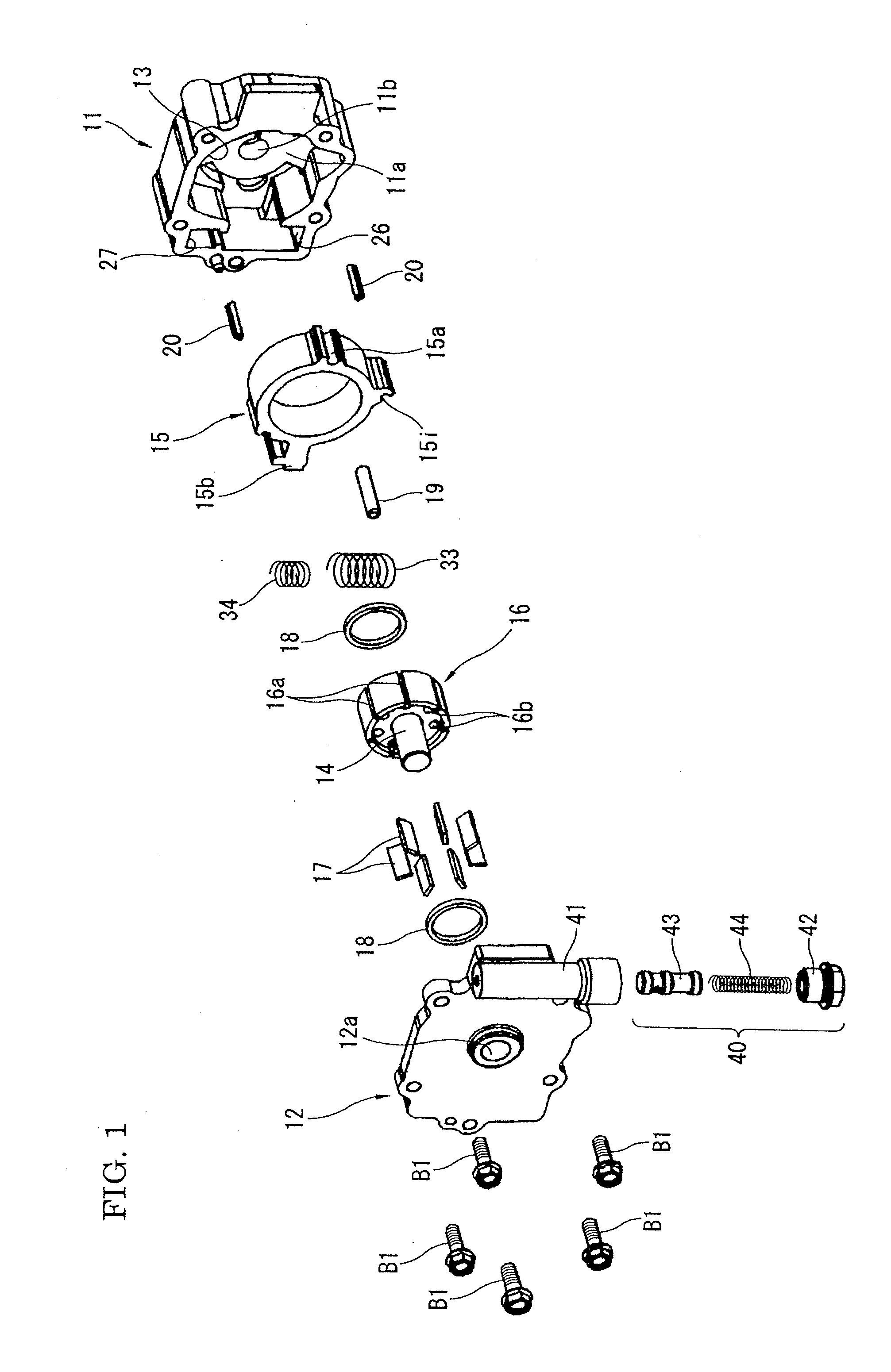

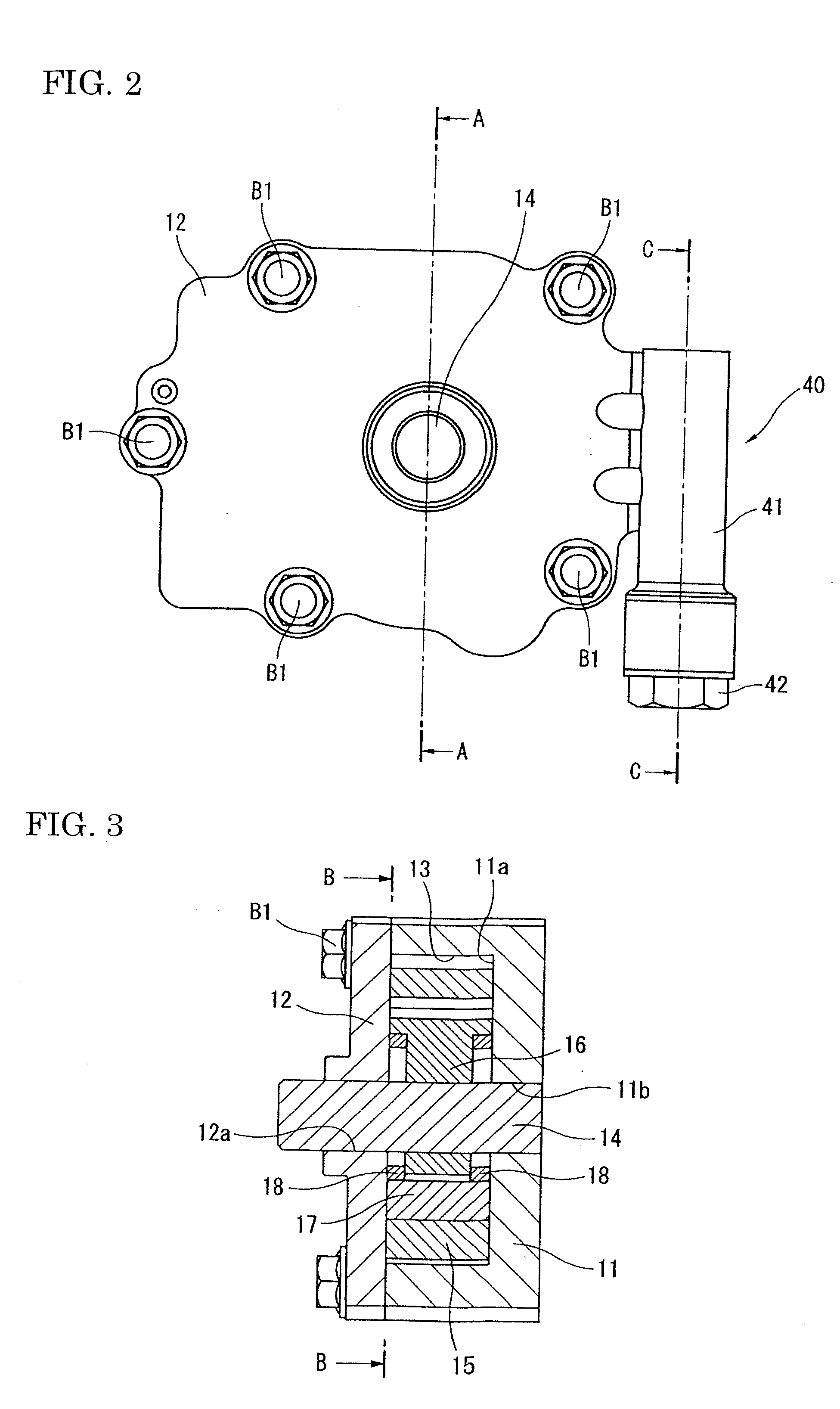

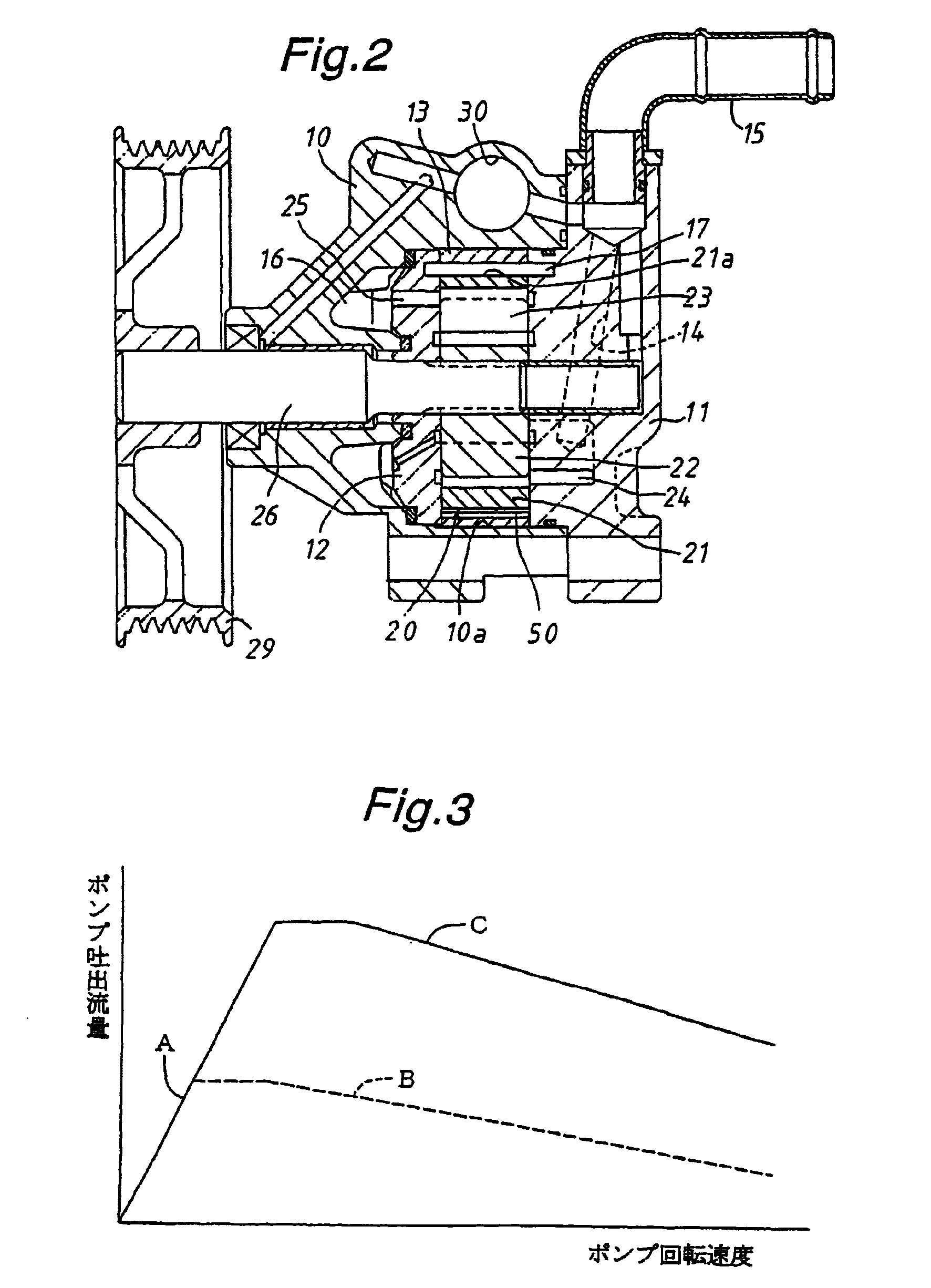

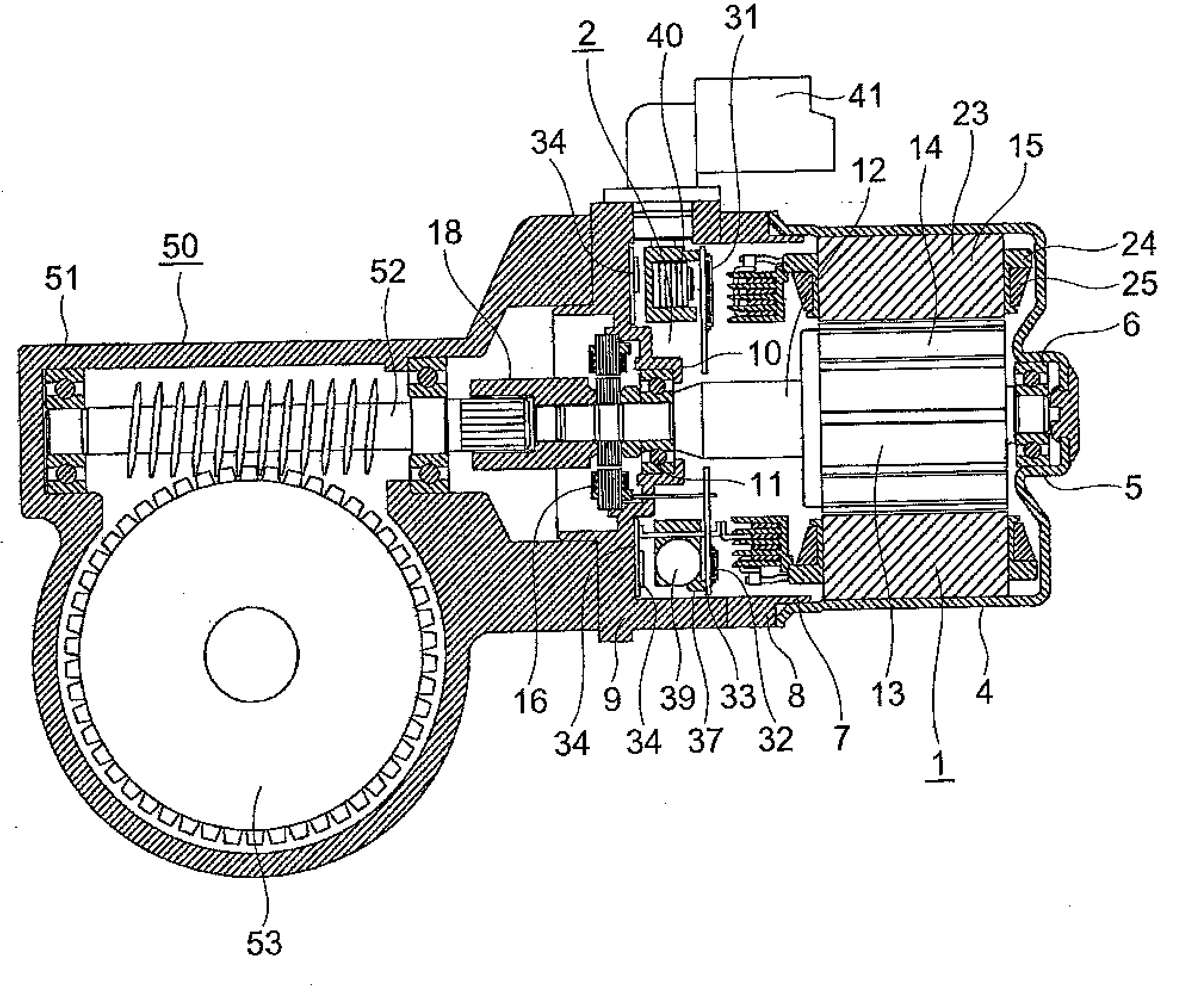

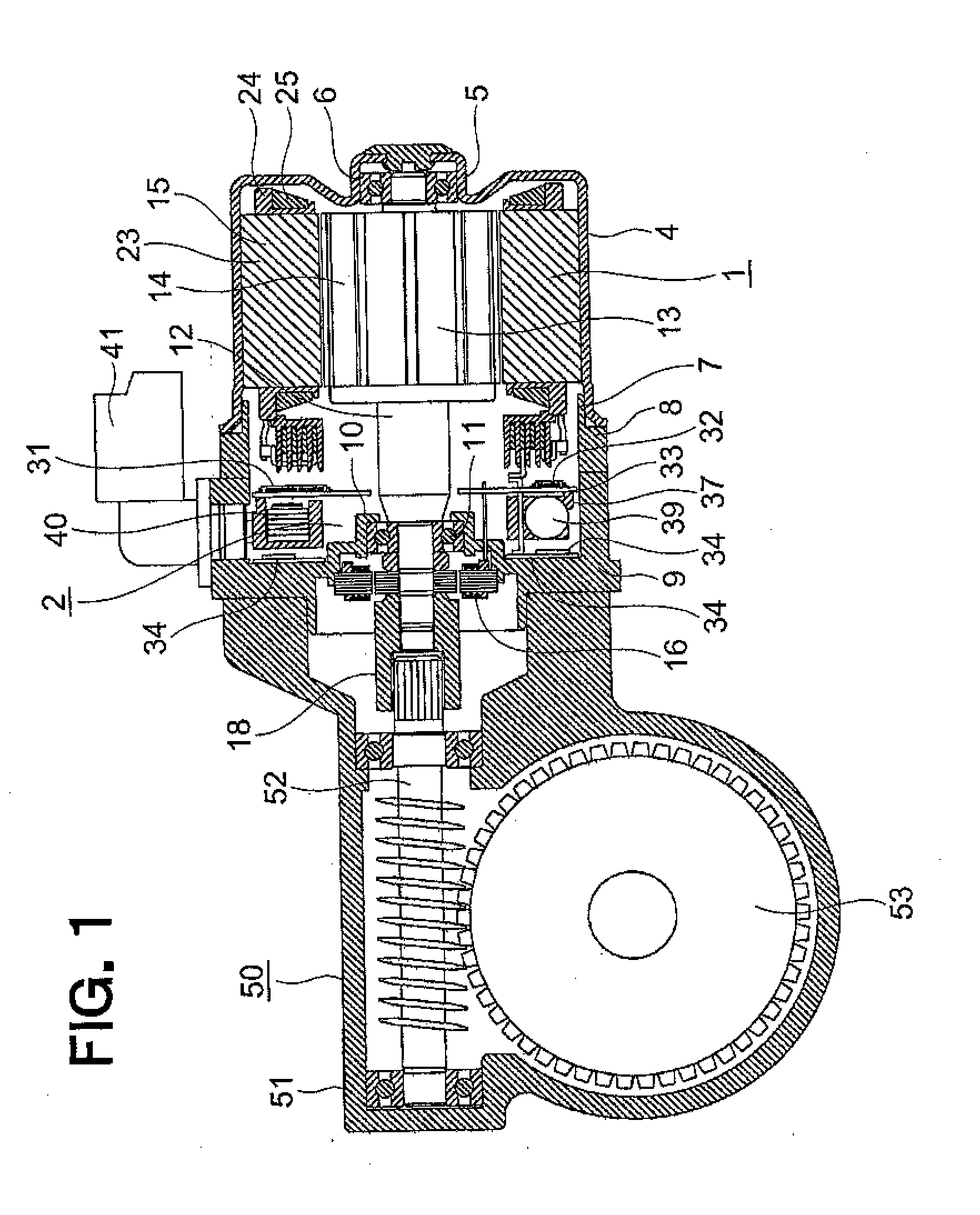

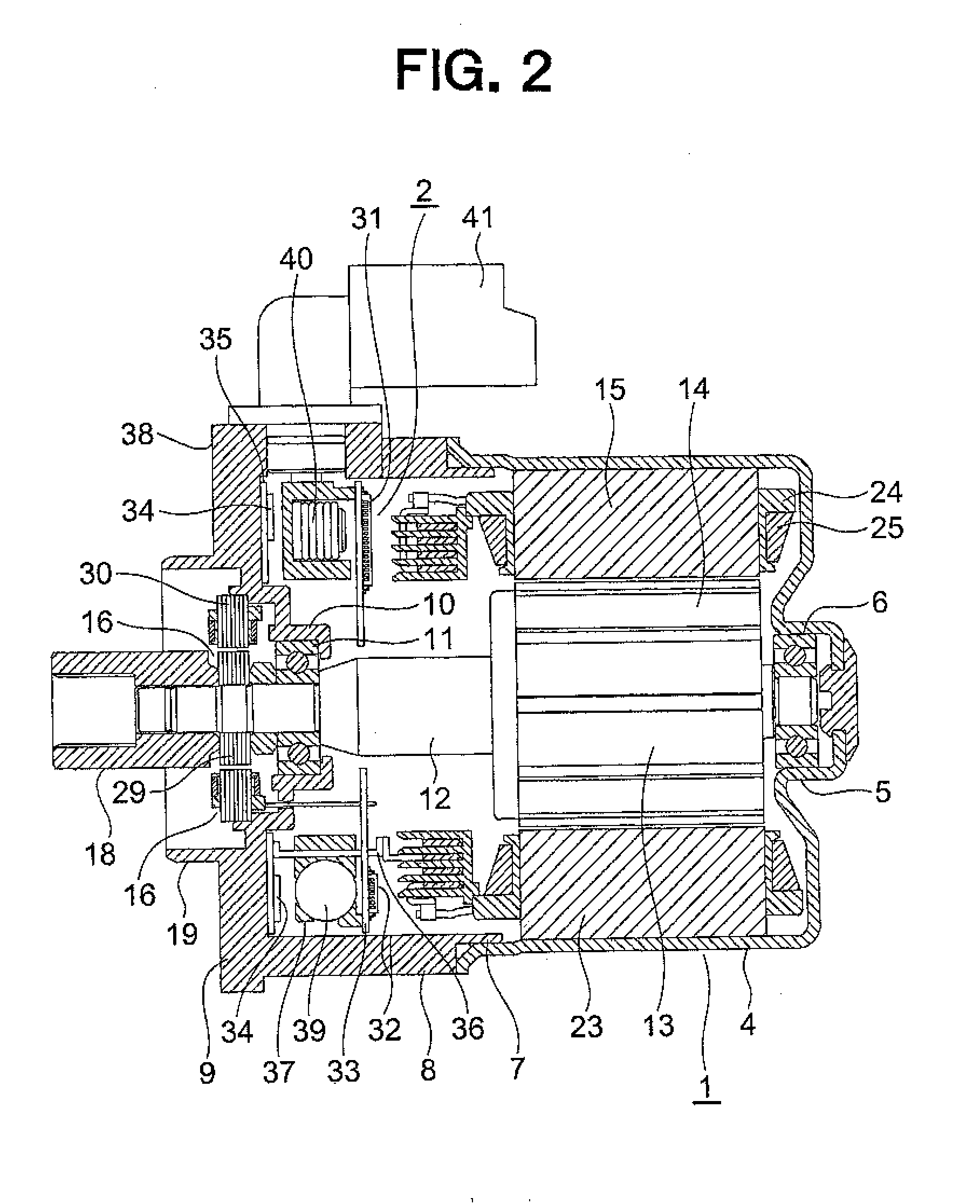

Variable displacement pump

ActiveUS20100226799A1Increase biasing forceOvercomes drawbackPump componentsOscillating piston enginesVariable displacement pumpDischarge pressure

A variable displacement oil pump for an automotive engine. The oil pump includes a cam ring accommodating thereinside a pump element having a rotor. The cam ring is swingingly movably accommodated in a housing and biased in a direction to increase an eccentricity amount of the cam ring relative to the axis of the rotor by a biasing member. First and second pressure chambers are defined inside the housing by the outer peripheral section of the cam ring. The first pressure chamber is supplied with a discharge pressure to be applied to the cam ring to oppose to a biasing force of the biasing member. The second pressure chamber is supplied with the discharge pressure to be applied to the cam ring to assist the biasing force of the biasing member. Additionally, a control device is provided for controlling supply of the discharge pressure to the second pressure chamber.

Owner:HITACHI AUTOMOTIVE SYST LTD

Miniature capacitive acoustic sensor with stress-relieved actively clamped diaphragm

InactiveUS20080247573A1Reduce eccentricityReduce impactSemiconductor electrostatic transducersElectrostatic transducer microphonesElectromagnetic interferenceEngineering

An acoustic sensor is disclosed which can be fabricated on a single chip with an electronic detection circuit by modular integration of the fabrication processes. An advantage of the disclosed acoustic sensor with on-chip signal detection circuit is smaller overall device size and lower sensitivity to electromagnetic interference and vibration. A second advantage of the disclosed acoustic sensor is the combined stress-relief and electrostatic clamping design of the diaphragm, which allows for further reduction of the diaphragm size, and hence device size, without compromising the microphone acoustic sensitivity, and at same time eliminates issues with diaphragm bow normally associated with stress-relief techniques.

Owner:NOVUSONIC CORP

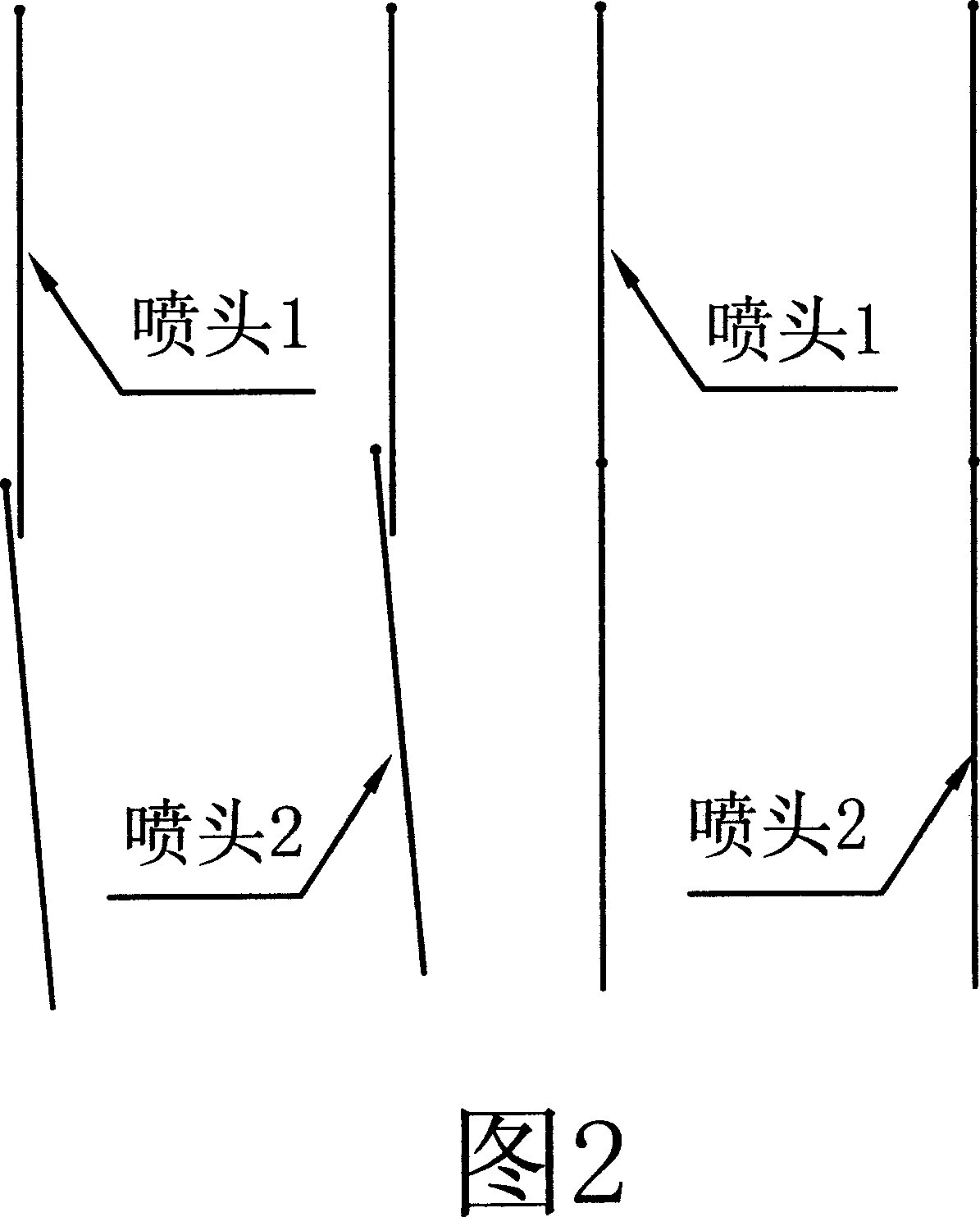

Nozzle regulating mechanism and its regulating method, and device for using the said nozzle regulating mechanism

InactiveCN101054021AWide range of adaptationGuaranteed distanceInking apparatusMechanical constructionEngineering

The invention relates to a nozzle adjustment mechanism of equipment using such nozzle and adjustment method thereof and the equipment using the nozzle adjustment mechanism. The nozzle adjustment mechanism includes nozzles, connection frame, bottom board, wherein the nozzles is fixed to the connection frame, and the turning position of the nozzle is adjusted by coordination of eccentric bolt and locating pin, and angle of pressure spring is adjusted to implement return adjustment; the connection frame equipped with the nozzles inserts into mounting hole arranged on the bottom board, and the position where the connection frame and the nozzles locate on the bottom board is adjusted by forward and backward adjusting the bolt and the pressure spring covering the bolt. The invention has advantages of easy adjustment and high adjustment precision by improving the mechanical structure.

Owner:BEIJING MEIKEYI

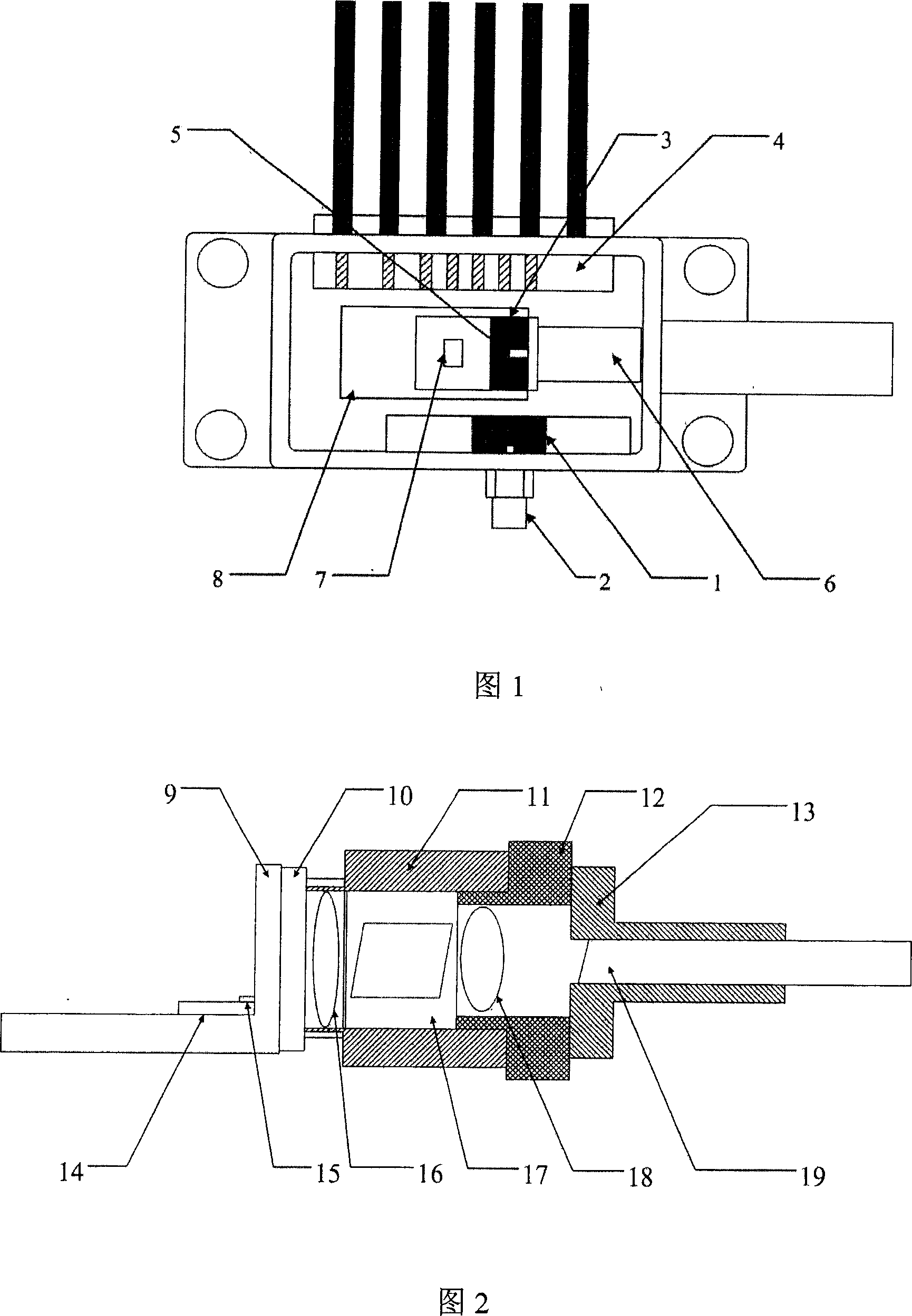

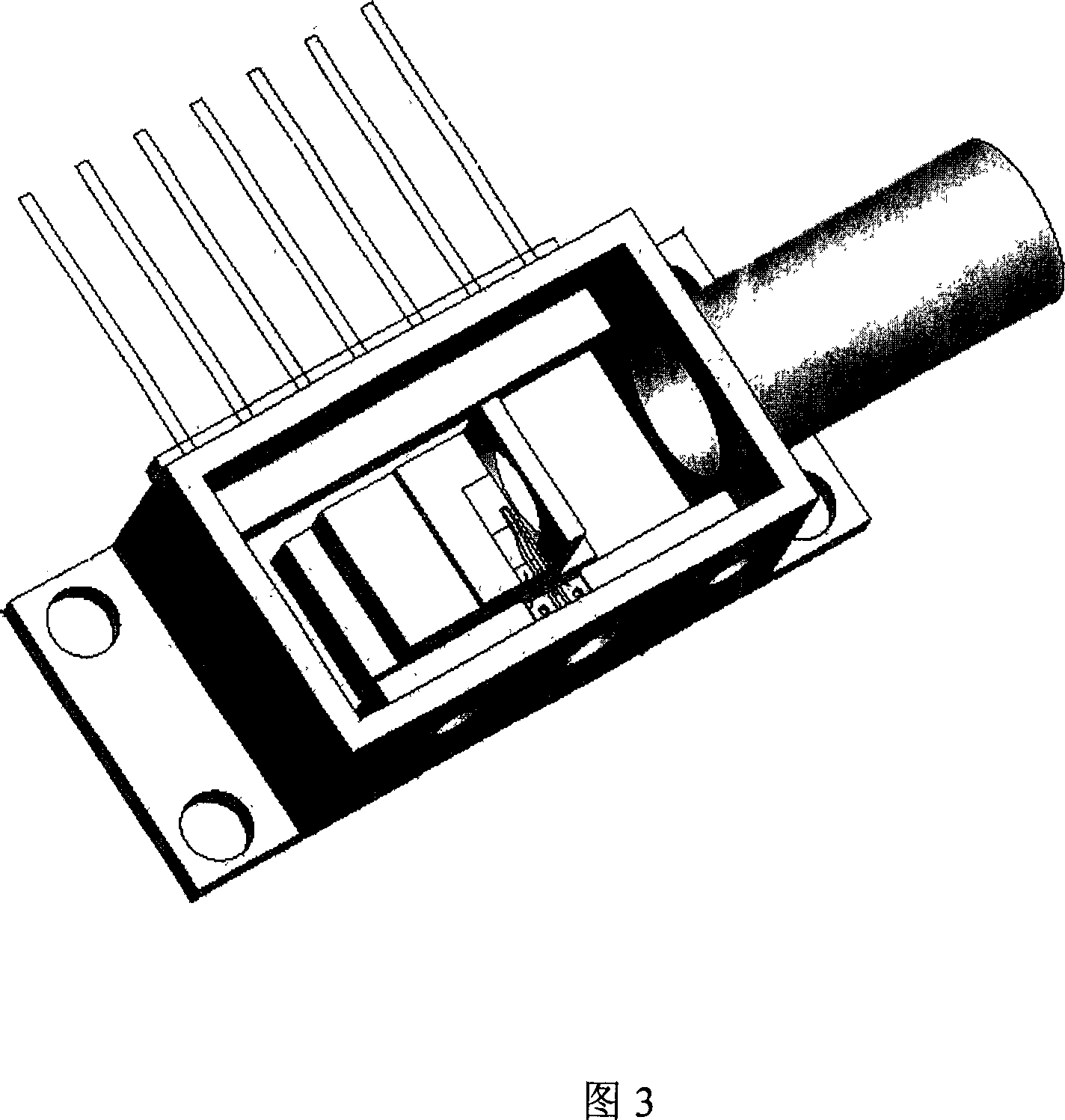

Encapsulation structure and method of the high-speed semiconductor light emission component

InactiveCN101017956AReduce loadEasy to install and debugLaser detailsSemiconductor/solid-state device detailsCoplanar waveguideWorking temperature

The package structure for a high-speed semiconductor light emission assembly comprises: a dish-type case with RF connector, a semiconductor refrigerator to control the work temperature of emission chip, a KOVAR metal heat sink, a medium heat sink substrate, a light emission device, a thermistor, a backlight detector, the metal wire to connect dc connection electrode and case pin, a coplanar waveguide transmission lie on medium substrate, and optical coupling assembly. Wherein, it uses BTF standard package form for dc terminals outside the case.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

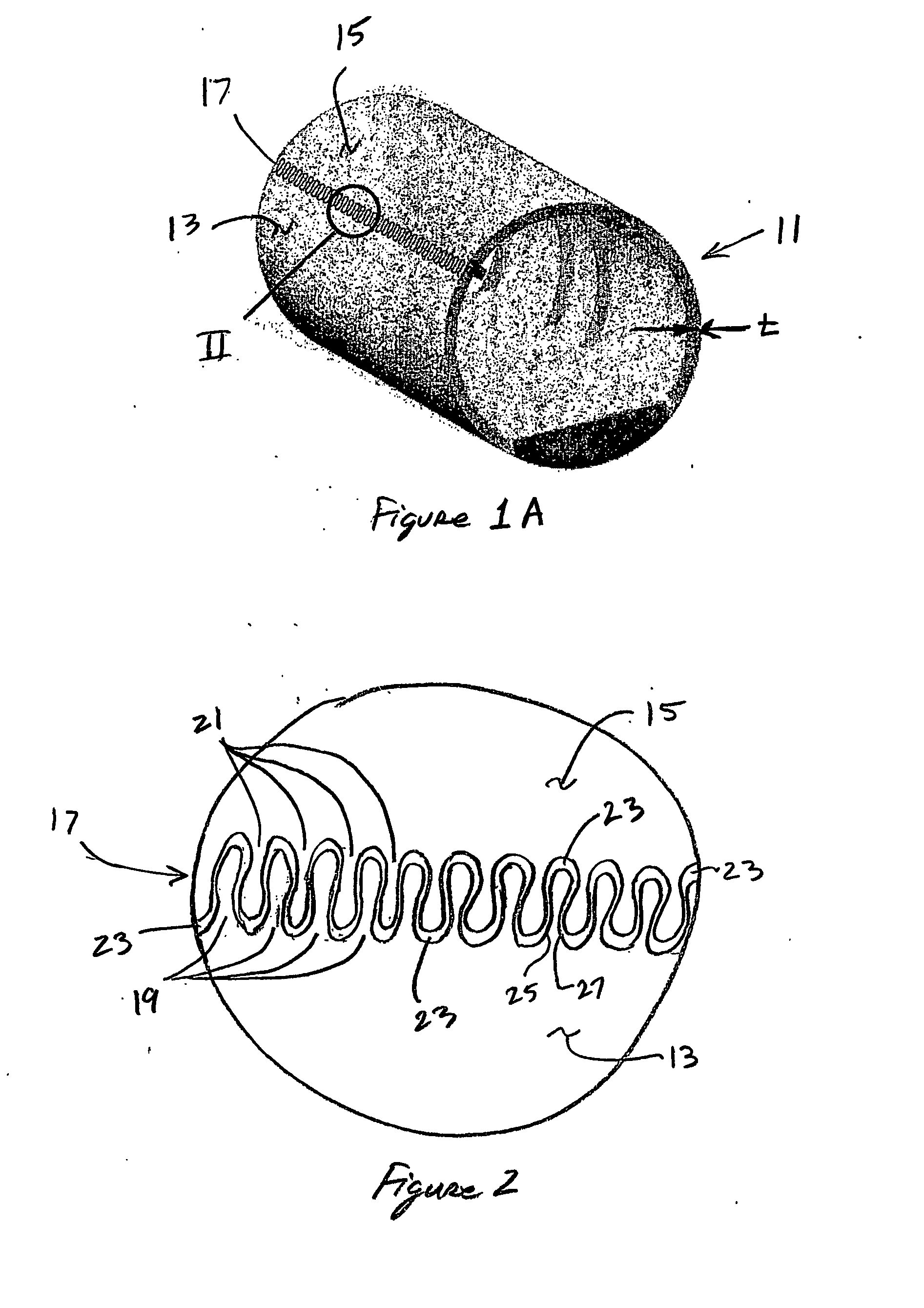

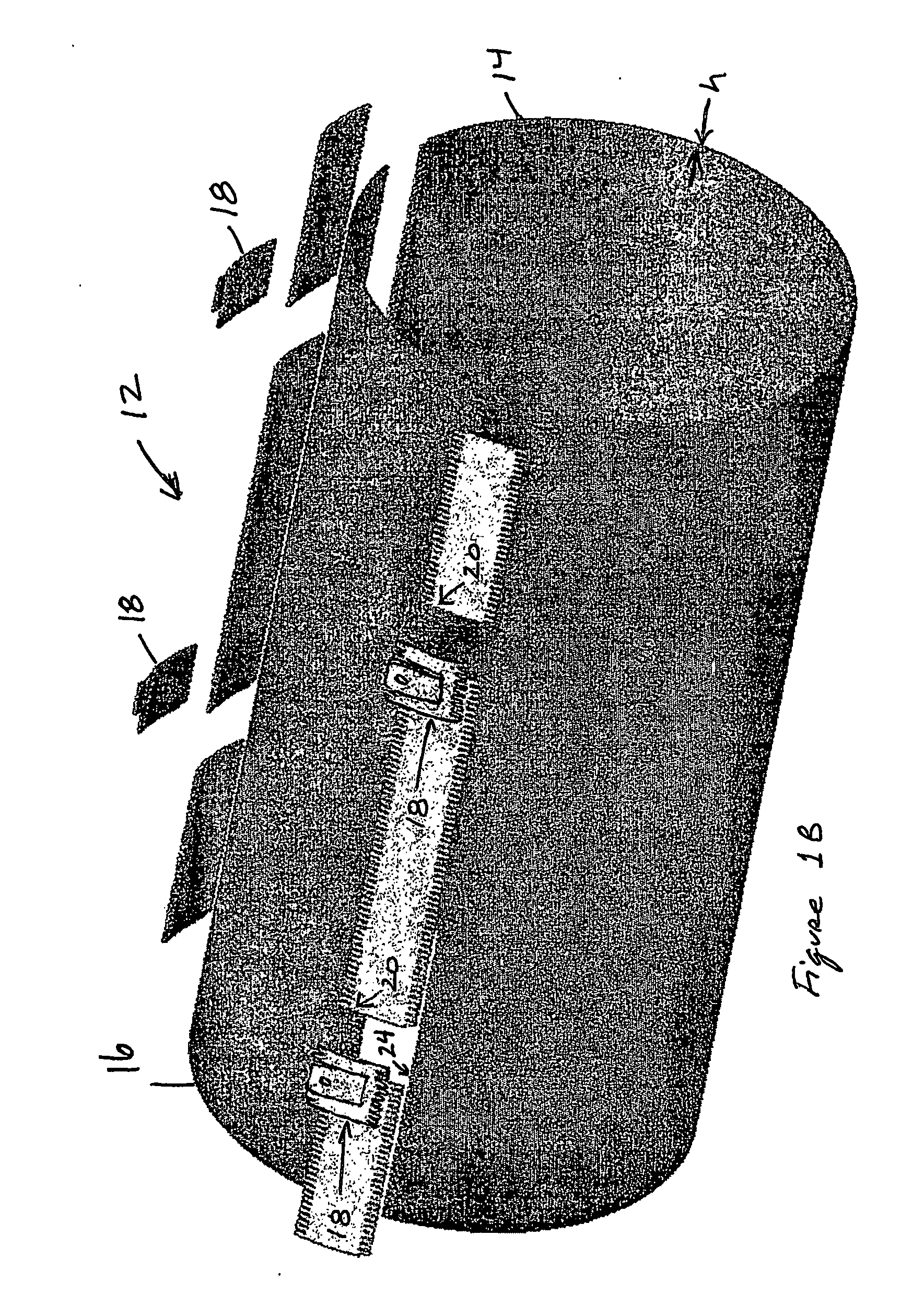

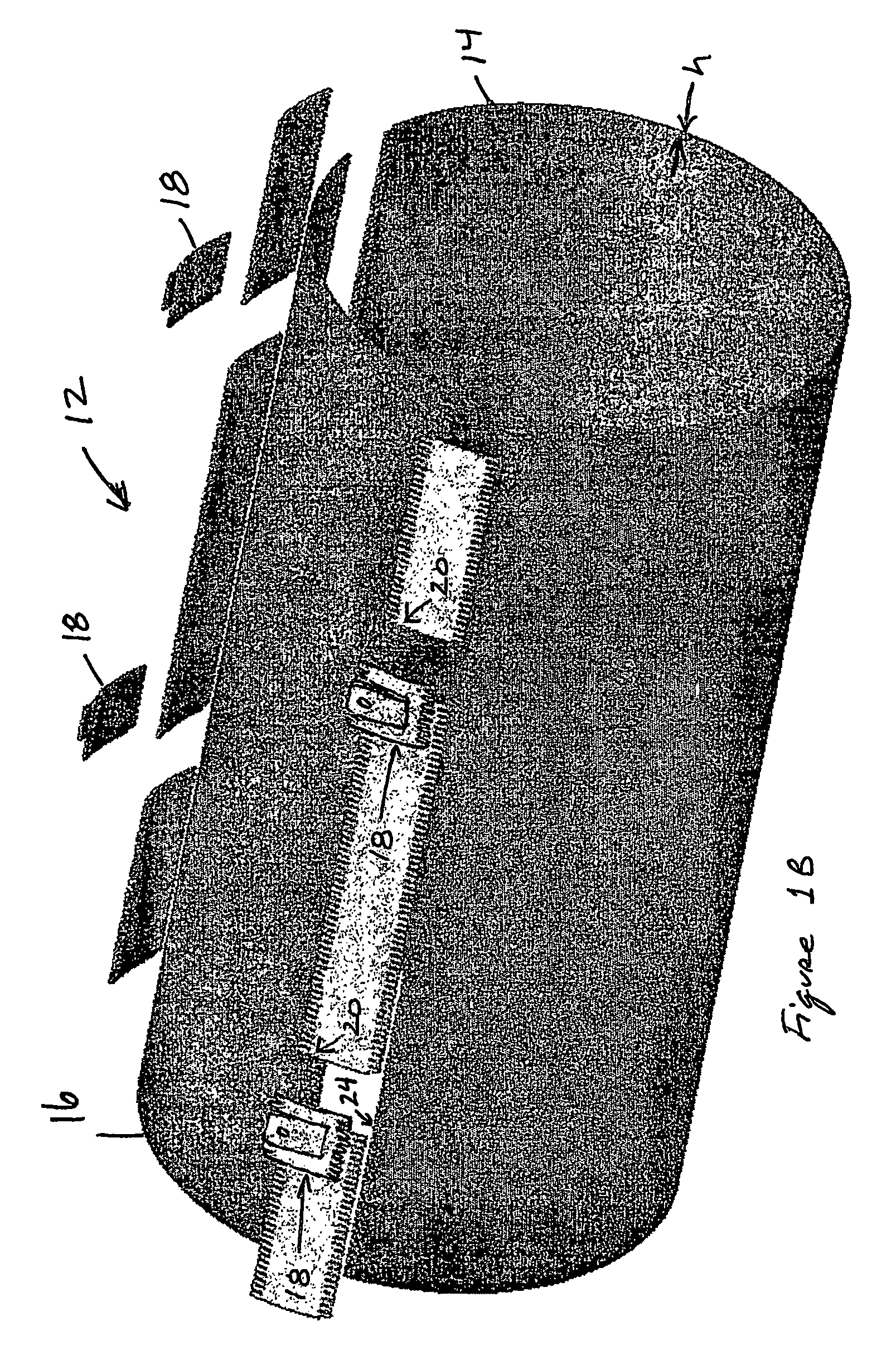

Interlocking tooth bond for assembly of fiber composite laminates

ActiveUS20060251847A1Cost efficientEffective weightAdhesive processesLamination ancillary operationsComposite laminatesImproved method

An improved method of joining fiber composite laminates is disclosed. Two fiber composite laminates may be joined together end-to-end. The bonding is done through the thickness of the fiber composite laminates. There are two ways to form the bond: (1) non-interlocking; and (2)

Owner:BELL HELICOPTER TEXTRON INC

Variable displacement pump

ActiveUS8684702B2Overcomes drawbackReduce eccentricityPump componentsOscillating piston enginesCamDischarge pressure

Owner:HITACHI AUTOMOTIVE SYST LTD

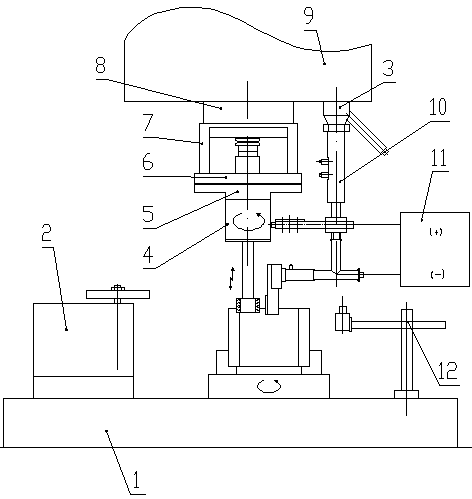

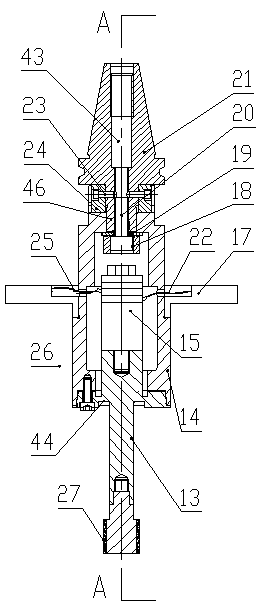

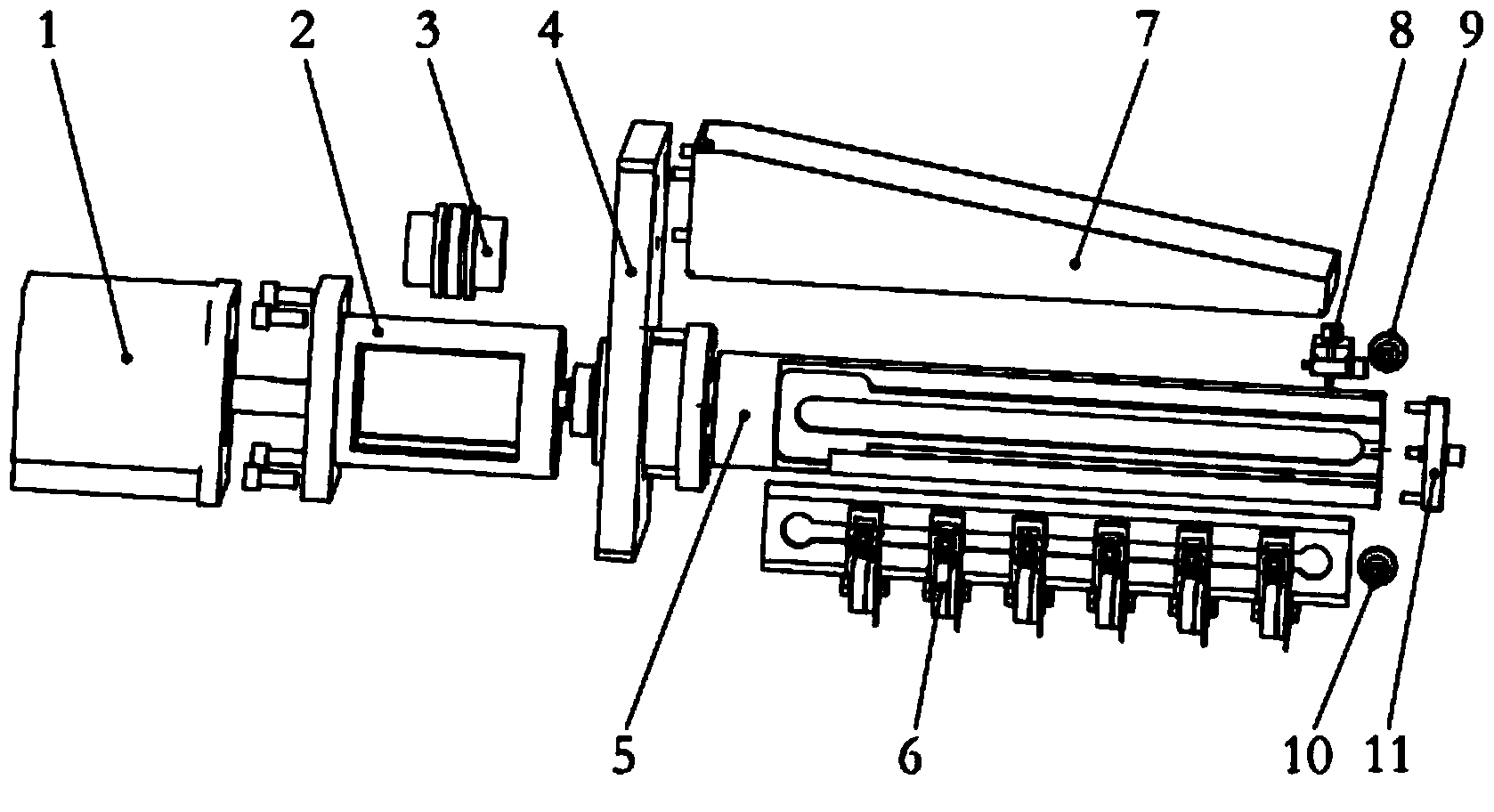

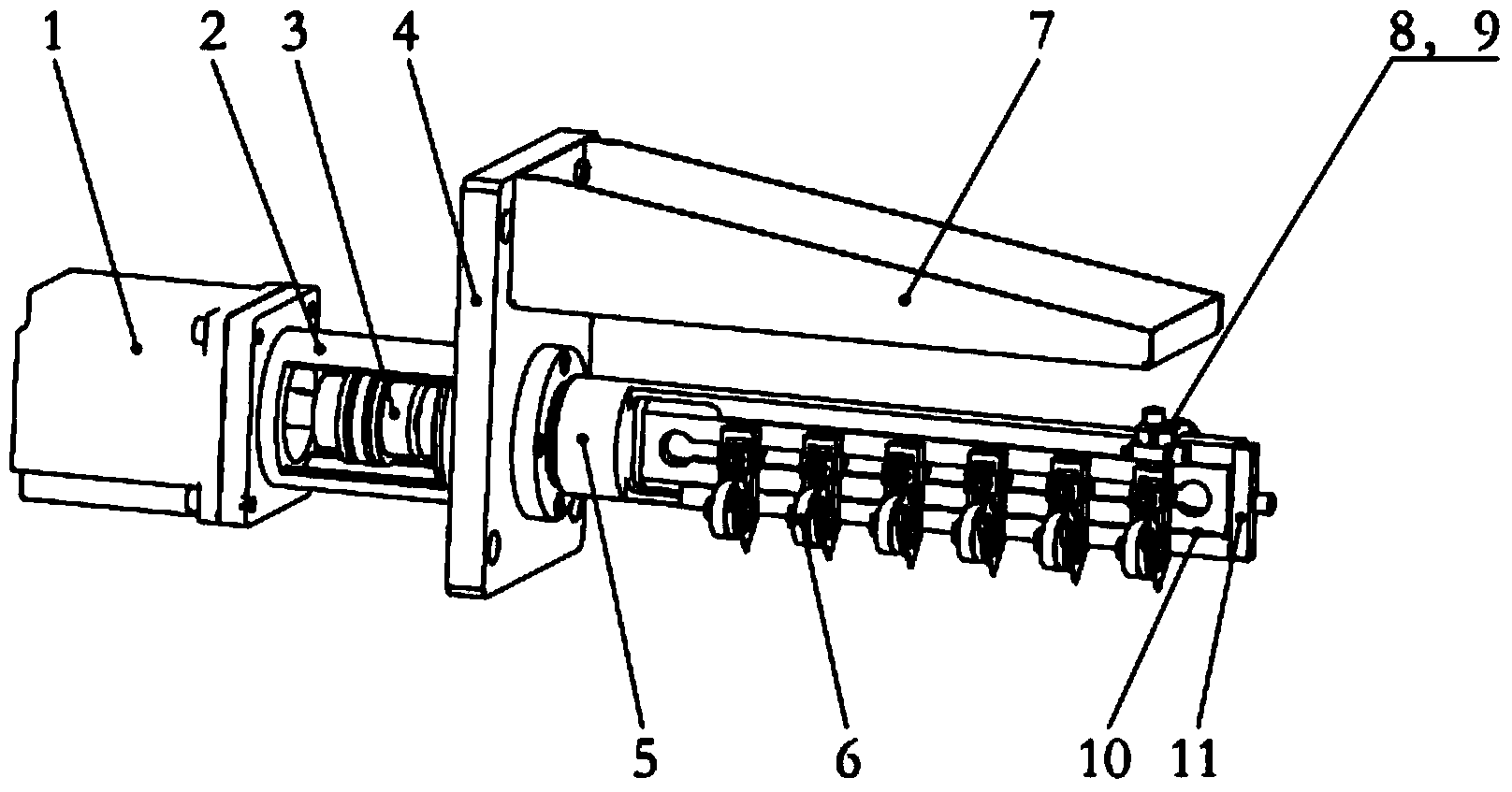

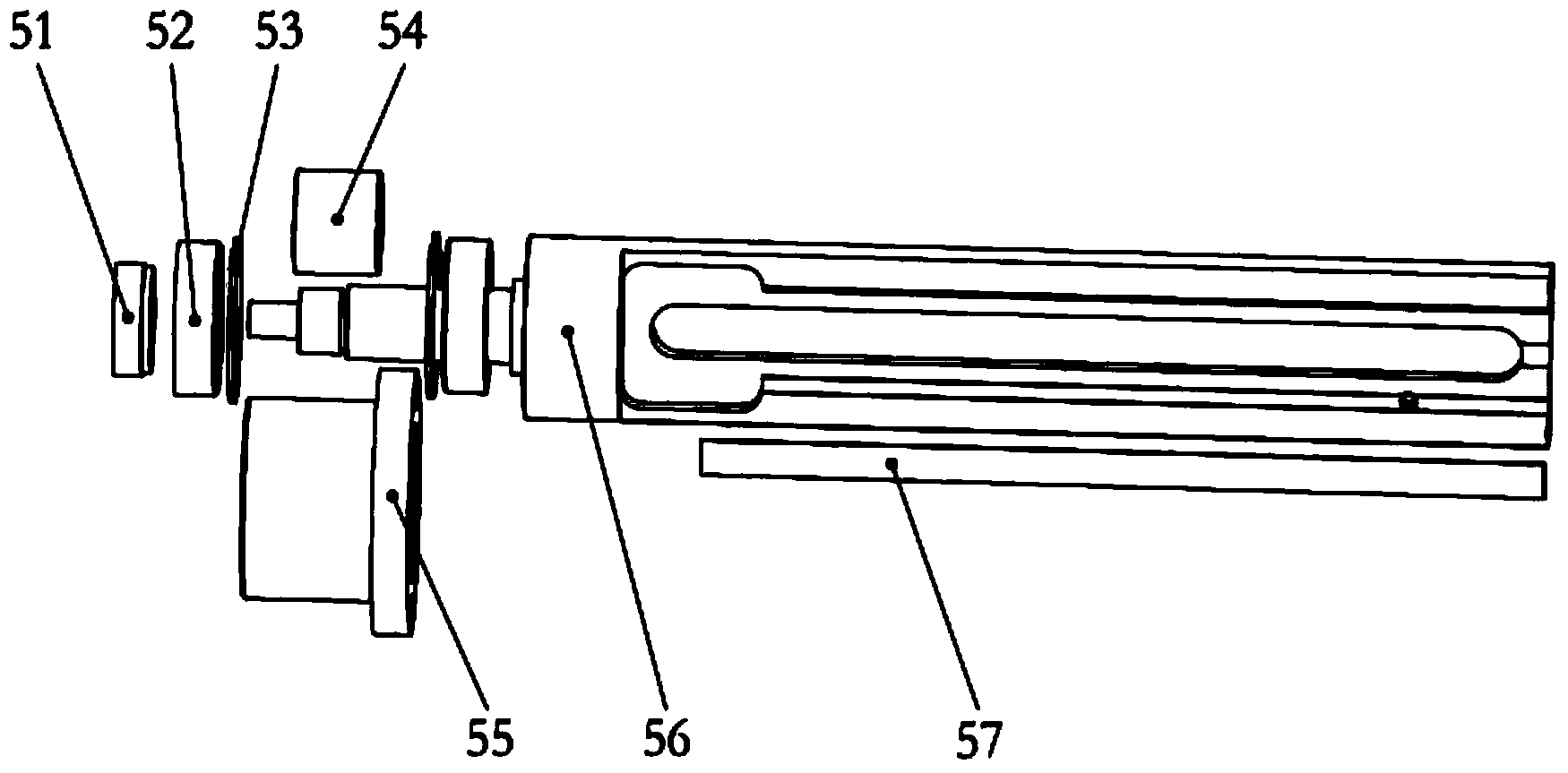

Online finishing and morphology detecting device for grinding wheel for performing ultrasonic electrolytic combined grinding on inner circles

ActiveCN103753397AAutomatically maintain grinding capacityReduce eccentricityGrinding feed controlAbrasive surface conditioning devicesEngineeringUltrasonic vibration

The invention provides an online finishing and morphology detecting device for a grinding wheel for performing ultrasonic electrolytic combined grinding on inner circles. The online finishing and morphology detecting device comprises a machine tool worktable and a machine tool spindle, wherein the machine tool worktable is provided with a grinding wheel shaping device and a grinding wheel morphology online observing device; the speed of the grinding wheel shaping device can be regulated in a frequency converting manner; the grinding wheel morphology online observing device can be used for movably observing the morphology of the surface of the grinding wheel in an online manner; the machine tool spindle is provided with an ultrasonic vibration tool system; an outer ring fixing sleeve is arranged outside the machine tool spindle; an ELID (electrolytic in-process dressing) online dressing device is arranged on the outer ring fixing sleeve; the ELID online dressing device and the machine tool spindle rotate synchronously; and the ultrasonic vibration tool system and the ELID online dressing device are positioned between the grinding wheel shaping device and the grinding wheel morphology online observing device. While ultrasonic vibration grinding is realized, ELID grinding wheel online finishing or grinding wheel online observing can be performed according to working requirements, a multi-process combined high-efficiency mirror finishing technology is formed and is a technical support for application of high-efficiency machining to ultra-smooth surfaces of crisp and hard materials in the field of advanced technologies such as national defense and aerospace, and the theoretical value and the practical value are important.

Owner:CONPROFE TECH GRP CO LTD +1

Electrical connector with deformable insert

InactiveUS6875045B1More controlled deformationSecure and efficient electrical connectionContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsElectrical conductorEngineering

Electrical connectors are provided including a connector body with a tubular socket to receive an electrical conductor. A clamping means is arranged to secure the electrical conductor within the socket. A socket insert fits within the socket so as to reduce the effective size of the socket. The socket insert is tubular and is adapted to be deformed by the clamping means into retaining engagement with the electrical conductor.

Owner:BENSON & HEDGES

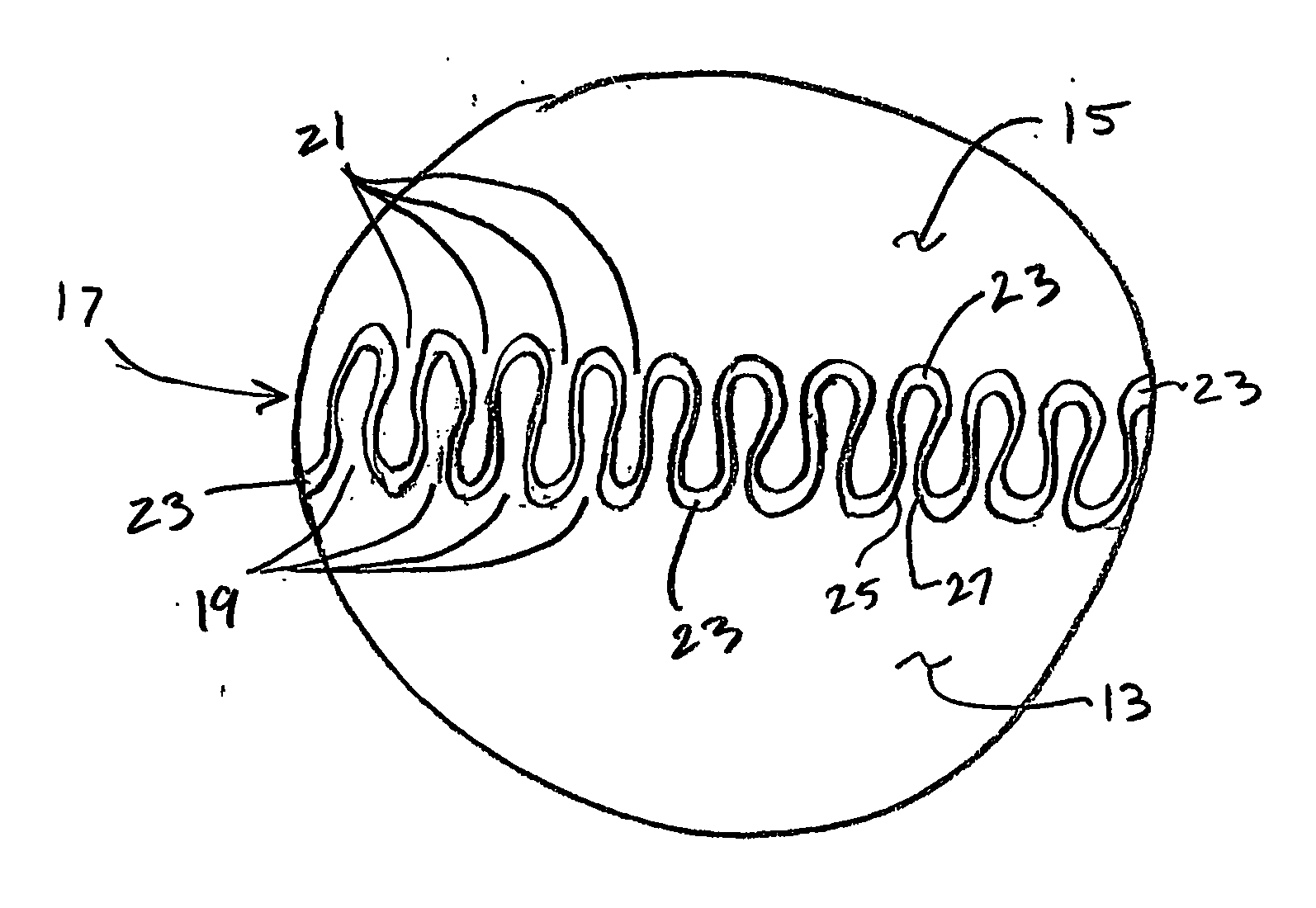

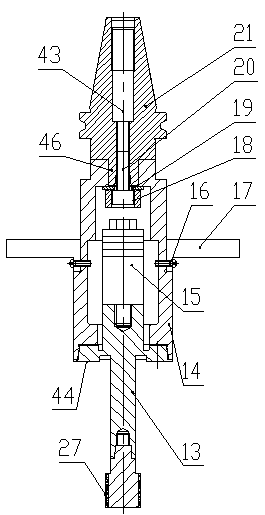

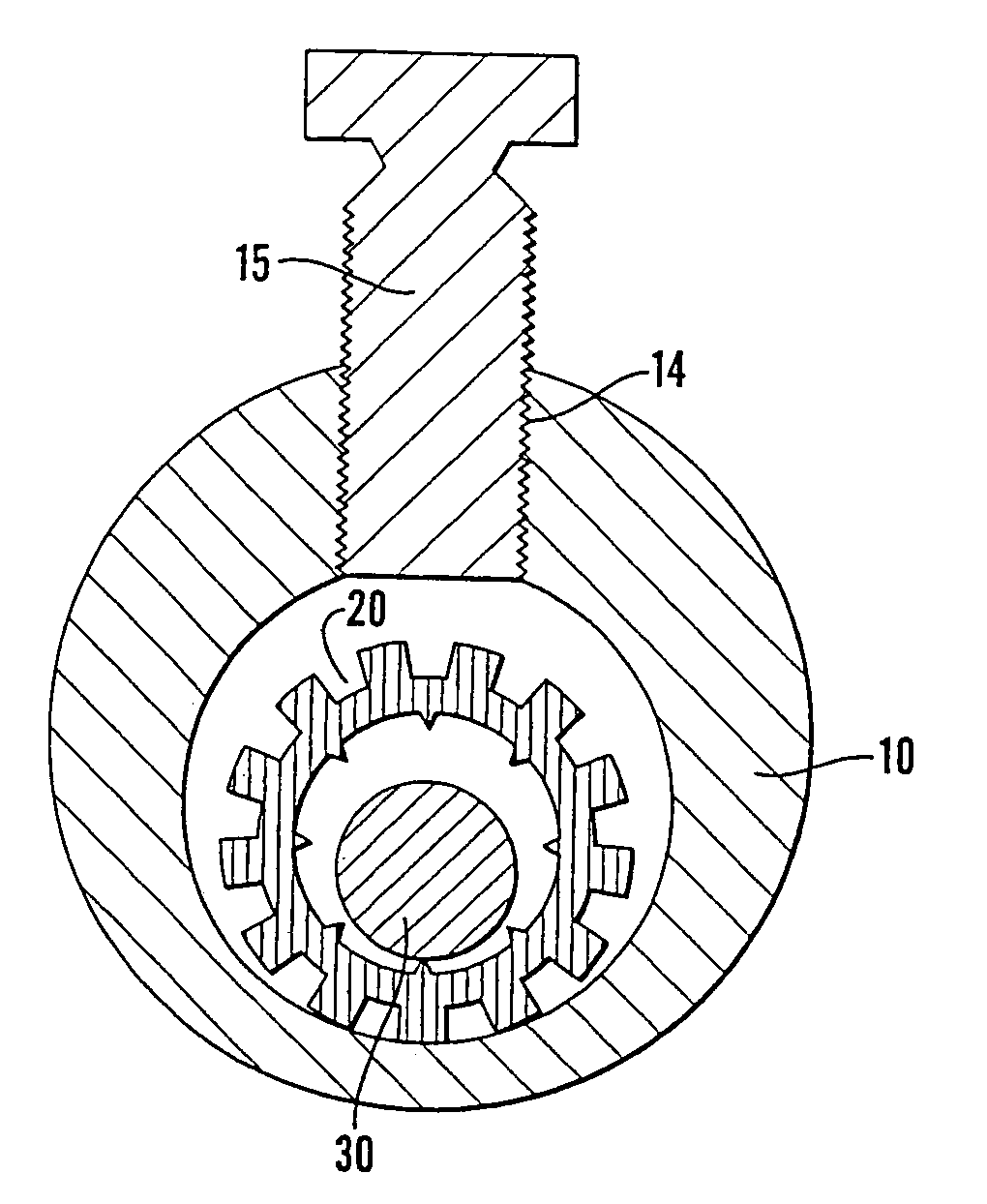

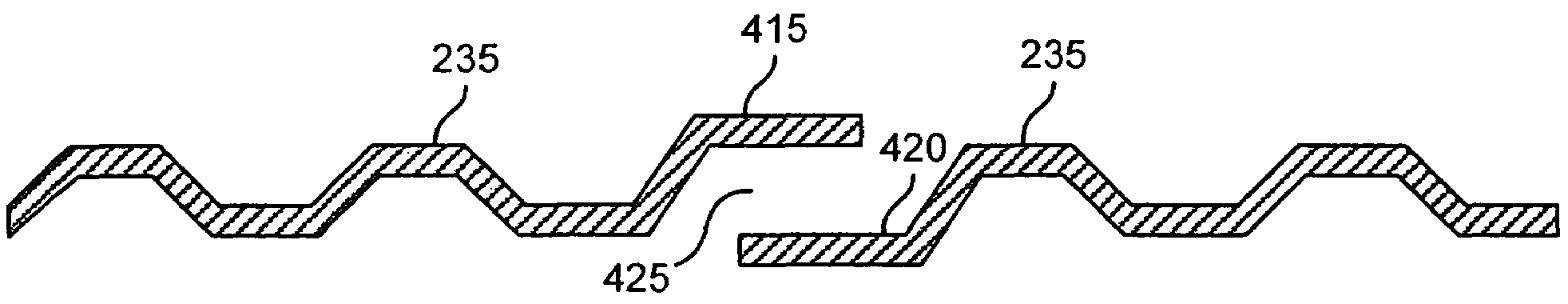

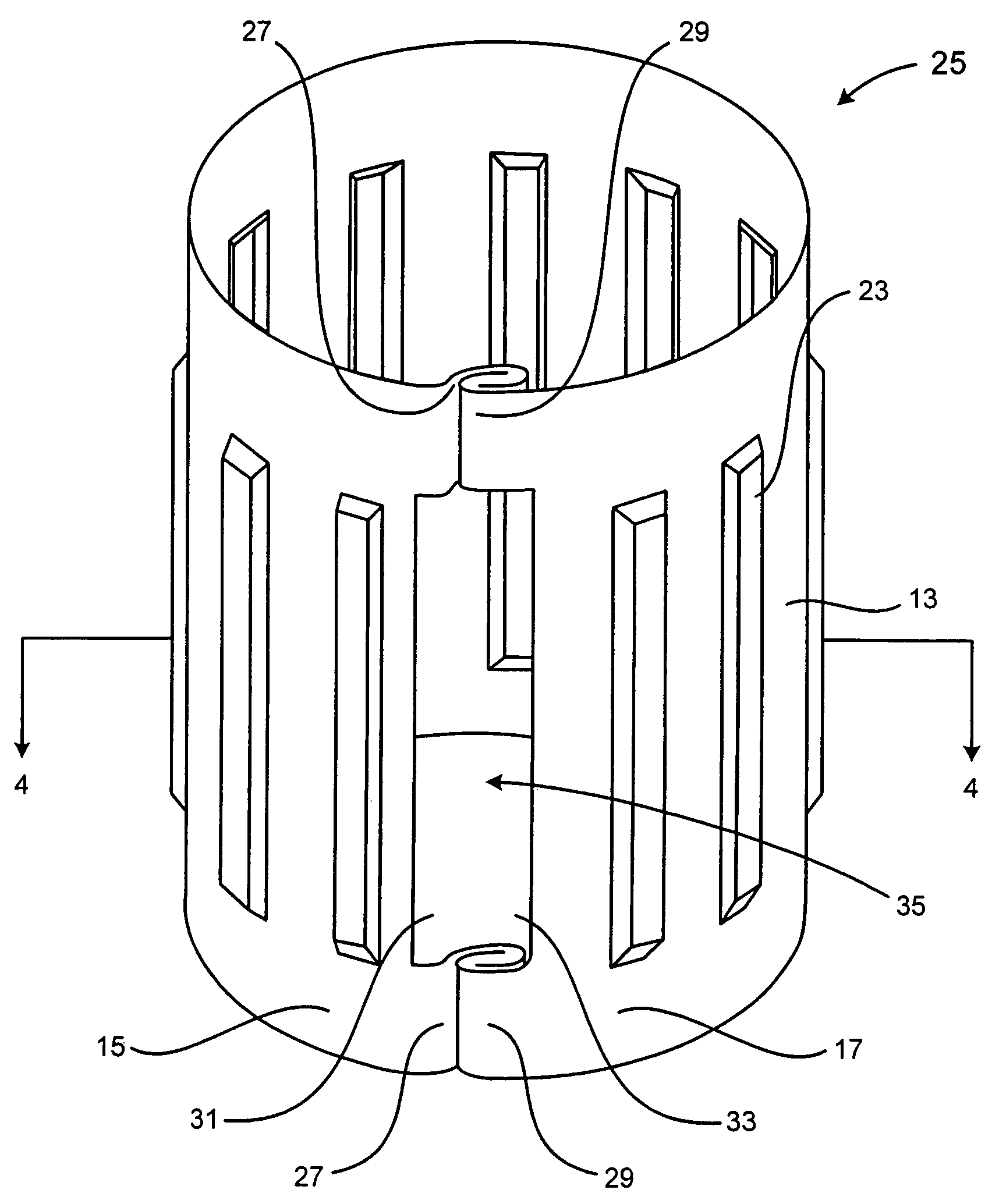

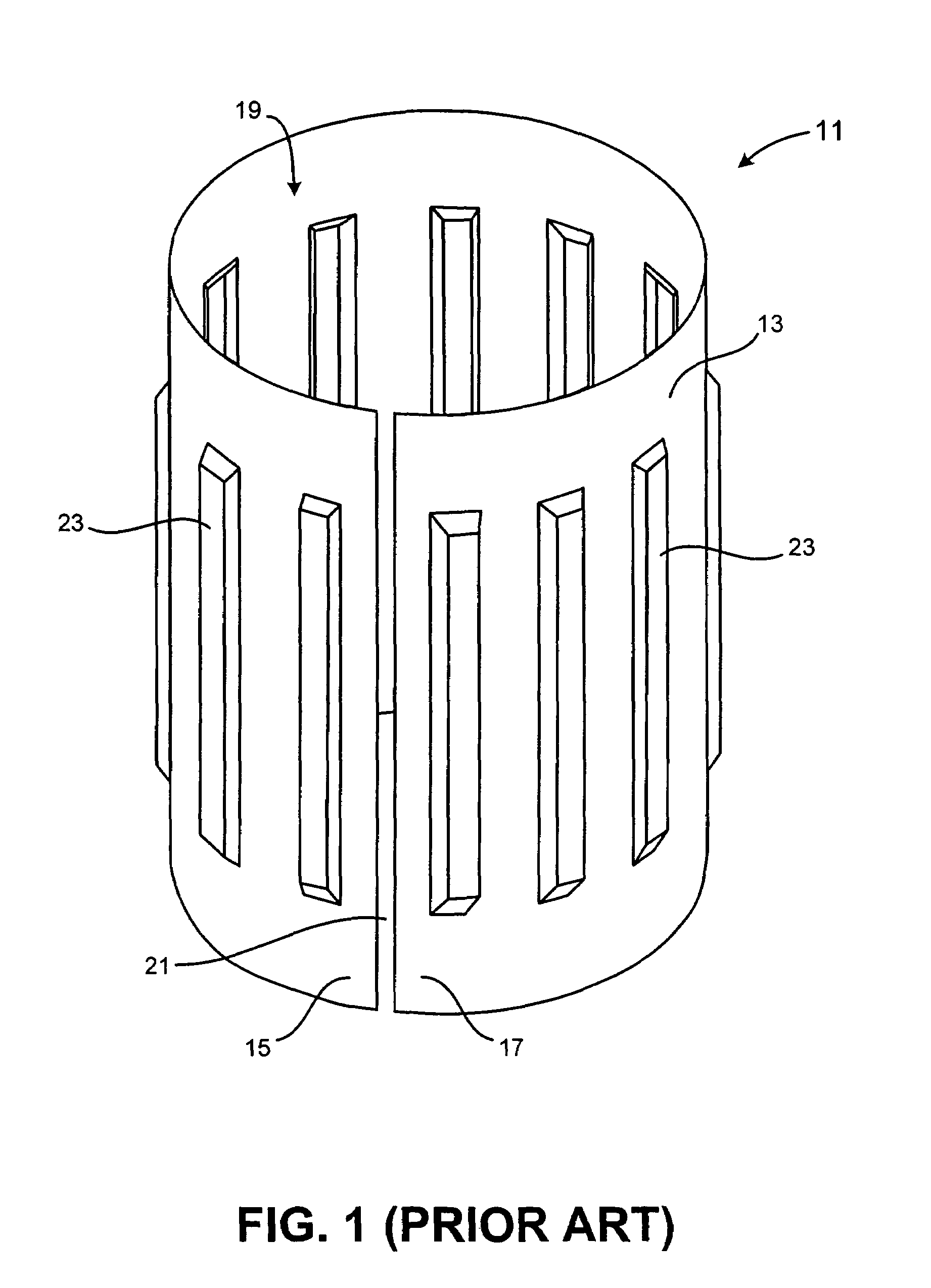

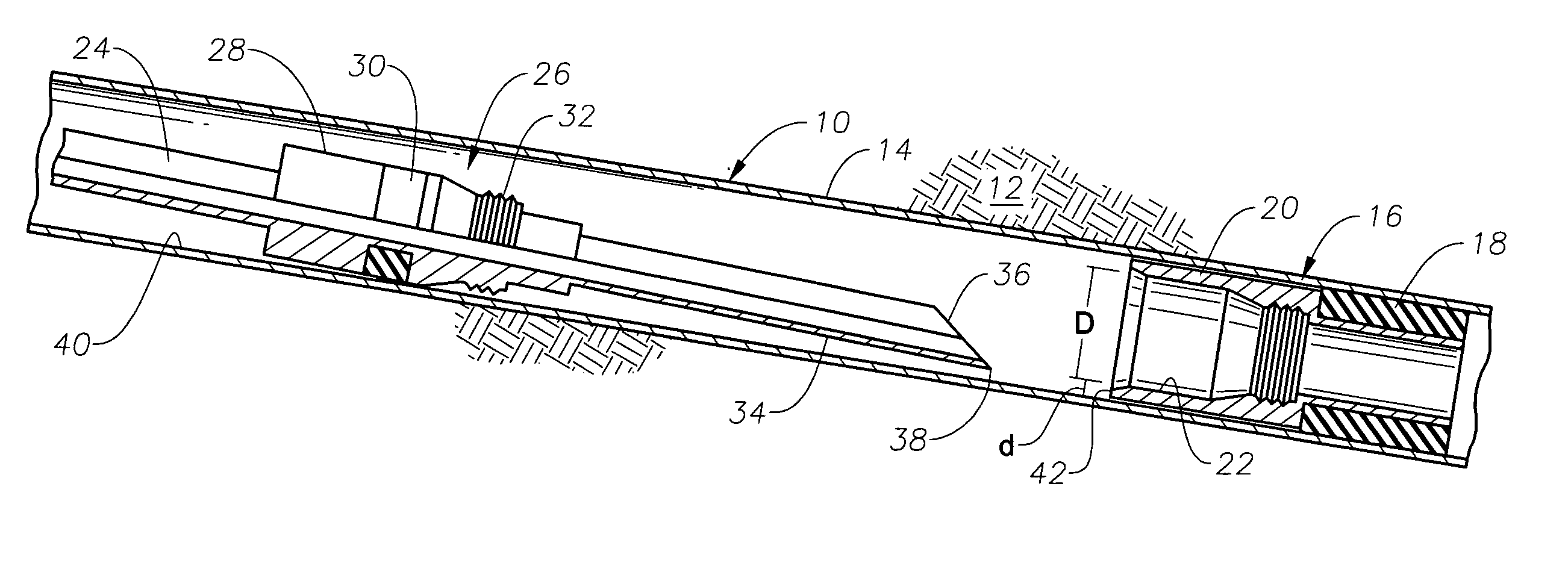

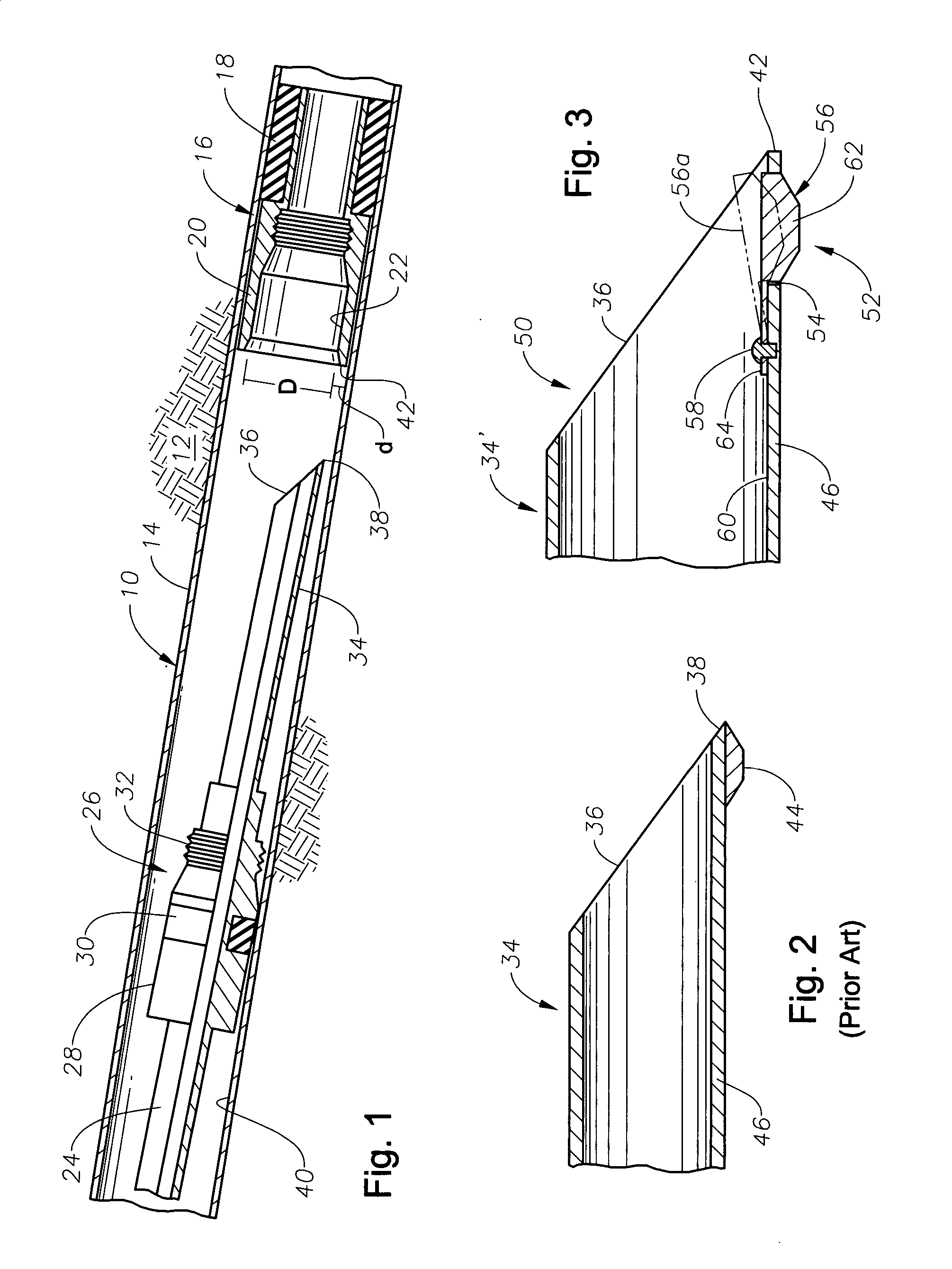

Tolerance ring for data storage with overlapping tab feature for mass control

ActiveUS7554771B2Reduce eccentricityMaintains mass eccentricityShaftsRecord information storageEngineeringActuator

Owner:INTRL PLEX TECH INC

Clip

InactiveUS7549829B2Large locking forceDisengagement of the clip can be preventedSnap fastenersFlow mixersLower faceSurface plate

A clip has a head part adapted to be contacted with a peripheral edge of a fitting hole in a panel to be fitted, and a leg part adapted to be inserted into the fitting hole thereby to be engaged with the peripheral edge of the fitting hole. The leg part has a post suspended from a center of a lower face of the head part, at least three projections which are radially extended from the post in a diametrical direction and connected to the lower face of the head part at their upper ends, and engaging pieces which are extended from these projections in a circumferential direction to be respectively positioned between the projections. The engaging pieces are connected to the head part at their upper ends, and provided with slits between their circumferentially extended ends and the opposed projections.

Owner:PIOLAX CO LTD

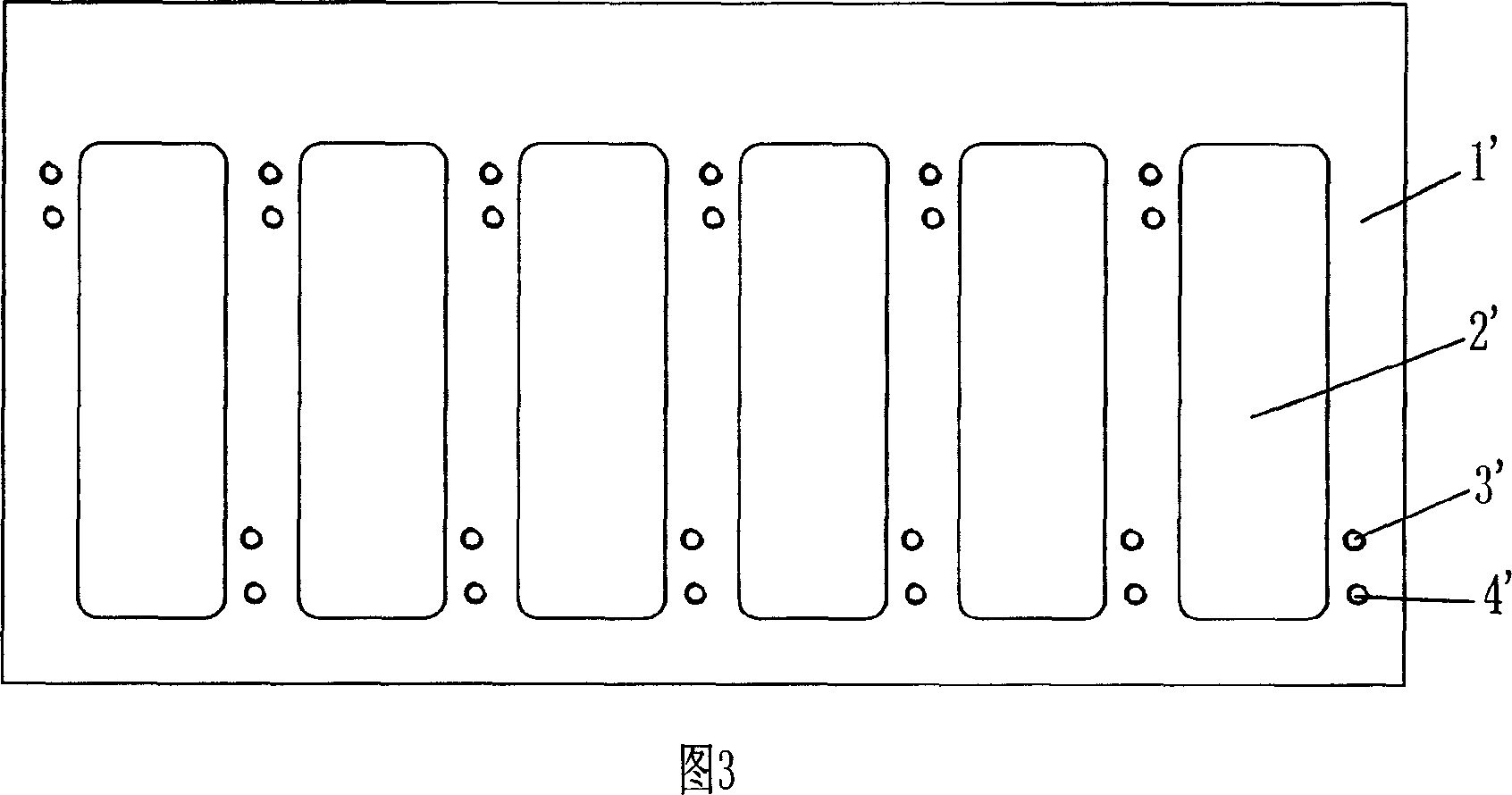

On-line slitting device suitable for RFID (Radio Frequency Identification) tag production

ActiveCN103817721AExtended service lifeConsistent axial spacingMetal working apparatusCouplingEngineering

The invention provides an on-line slitting device suitable for RFID (Radio Frequency Identification) tag production, and belongs to the field of RFID encapsulation. The on-line slitting device comprises a supporting pillar component, a blade moving plate, slitting blade components, a blade distance adjusting component, a blade moving plate adjusting component, a coupler and a motor, wherein the supporting pillar component comprises a supporting pillar, and the surface of the supporting pillar is provided with a sliding groove; the blade moving plate is arranged in the sliding groove; the slitting blade components are arranged on the blade moving plate; the blade distance adjusting component is detachably arranged on the supporting pillar and is used for adjusting the axial distance of the slitting blade components adjacent to the blade distance adjusting component; the blade moving plate adjusting component is used for driving the blade moving plate to slide axially in the sliding groove of the supporting pillar, and thus the axial positions of multiple slitting blade components can be integrally adjusted; one end of the coupler is connected to the other end of the supporting pillar; an output shaft of the motor is connected with the other end of the coupler, the supporting pillar and the multiple slitting blade components which are located on the supporting pillar can be driven to rotate together through the rotation of the motor, and thus the angles of the multiple slitting blades can be integrally adjusted. According to the on-line slitting device suitable for the RFID tag production, provided by the invention, the positions and the angles of the slitting blades can be conveniently adjusted, the slitting efficiency can be increased, and the service life of the slitting blades can be prolonged.

Owner:HUBEI HUAWEIKE INTELLIGENT TECH

Tolerance ring for data storage with cut-out feature for mass control

ActiveUS7583476B2Improve eccentricityMaximum flexibilityShaftsRecord information storageActuatorControl theory

A tolerance ring configured to improve mass eccentricity of an actuator arm assembly. The tolerance ring has a cylinder with a predetermined length between two ends, with a gap along the predetermined length of the cylinder, the gap having a first and a second edge, the cylinder having an aperture in the surface of the cylinder at the second edge.

Owner:INTRL PLEX TECH INC

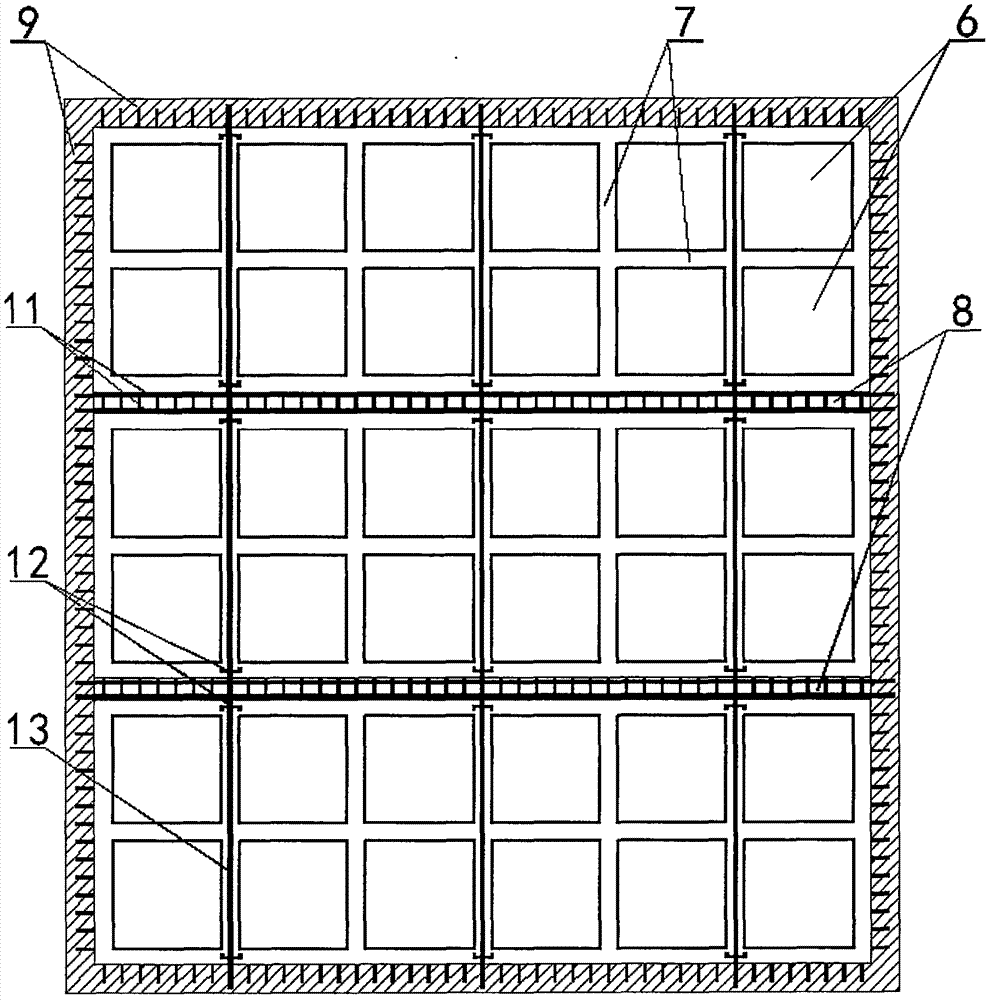

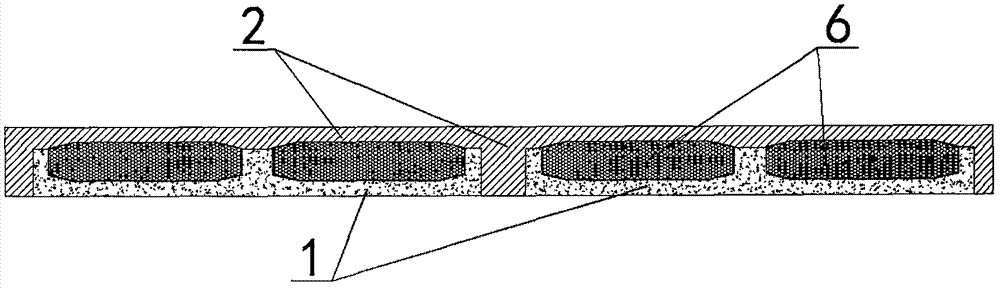

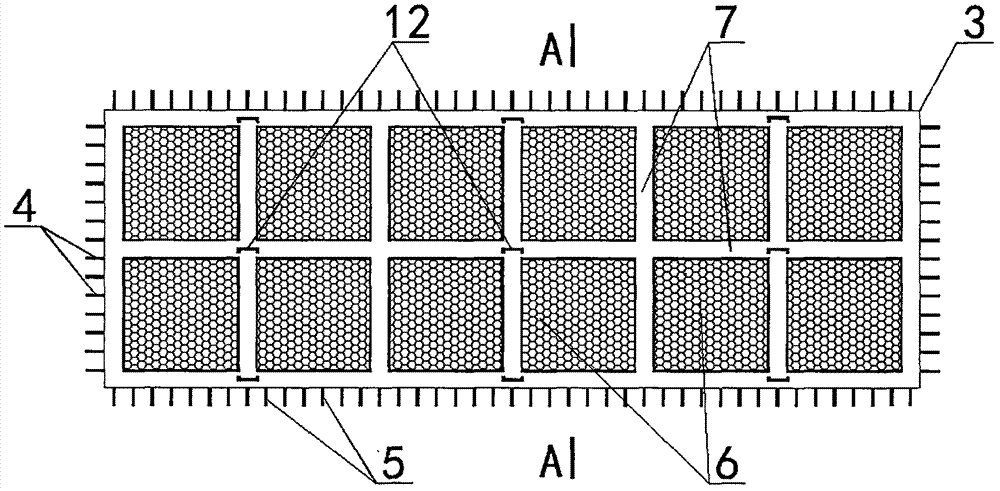

Prestressed hollow composite slab

ActiveCN107313539ALight weightApplicable span is largeFloorsBuilding reinforcementsPre stressComposite slab

The invention relates to a prestressed hollow composite slab and a manufacturing method thereof, and belongs to the field of normal building construction. The composite slab comprises prefabricated pieces (1) and composite layers (2). Thickness of a bottom plate (3) of each prefabricated piece (1) is greater than or equal to 35 mm and less than or equal to 60 mm, prestressed steel wires (4) in the bottom plate are located at the upper parts of transversal steel bars (5), and the length of each prestressed steel wire (4) and each transversal steel bar (5) extending out of the corresponding bottom plate (3) is greater than or equal to 50 mm; the width of each prefabricated piece is greater than or equal to 1500 mm, light-weight material filling pieces (6) are arranged at the upper part of each prefabricated piece (1); the heights of concrete solid ribs (7) between adjacent filling pieces are greater than or equal to 50 mm; the transversal steel bars (5) between adjacent prefabricated pieces (1) are overlaid in a joint area (8), upper part steel bars (10) of the composite slab are bound, composite layer concrete is poured, and the composite slab is formed. According to the prestressed hollow composite slab and the manufacturing method thereof, the self-weight of the composite slab is light, the stiffness in the longitudinal direction and the transversal direction is high, the application range is large, and transportation and installation are convenient. The prestressed hollow composite slab and the manufacturing method thereof have good economic efficiency and applicability, and play a role on promoting the development of building technology.

Owner:徐焱

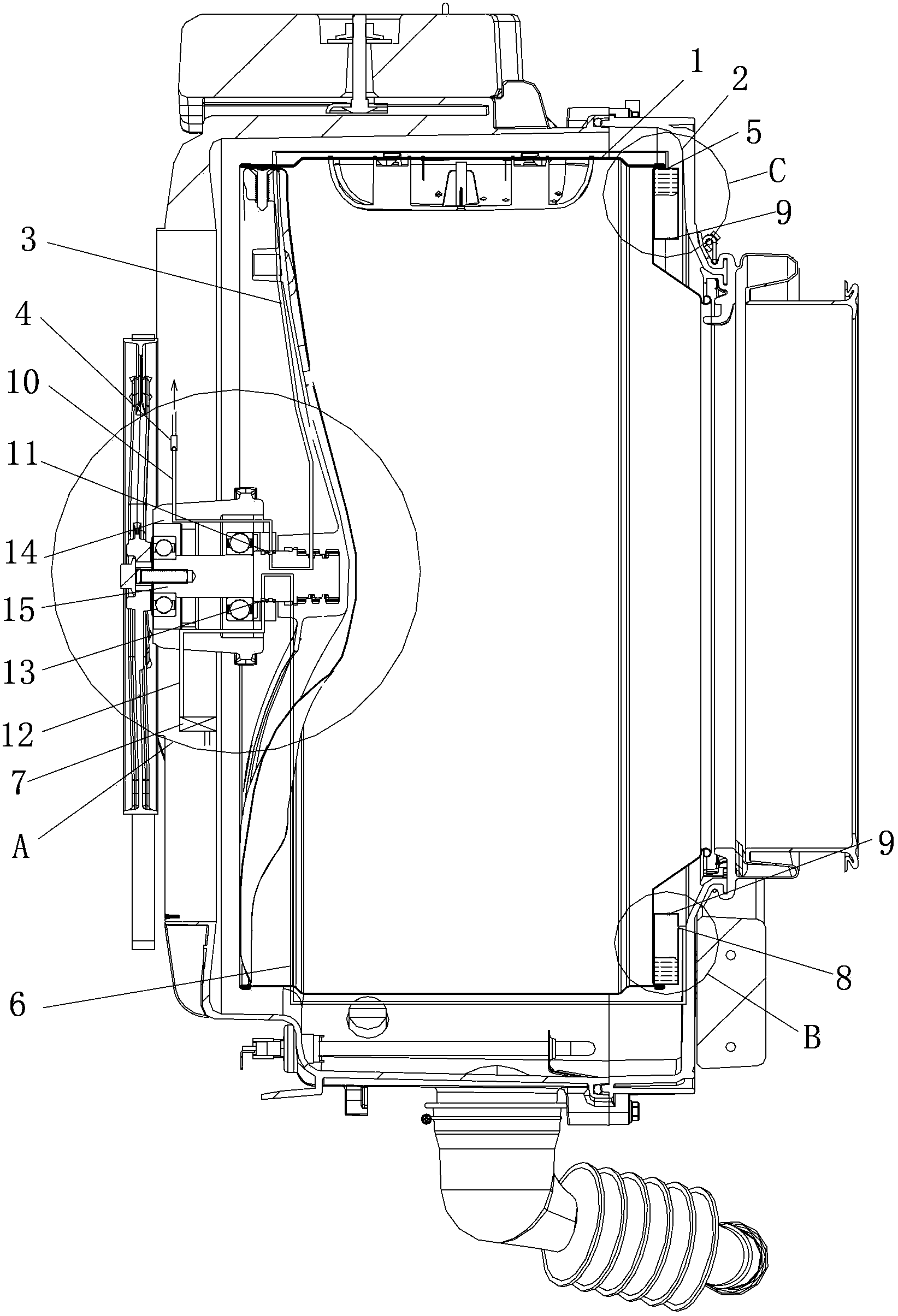

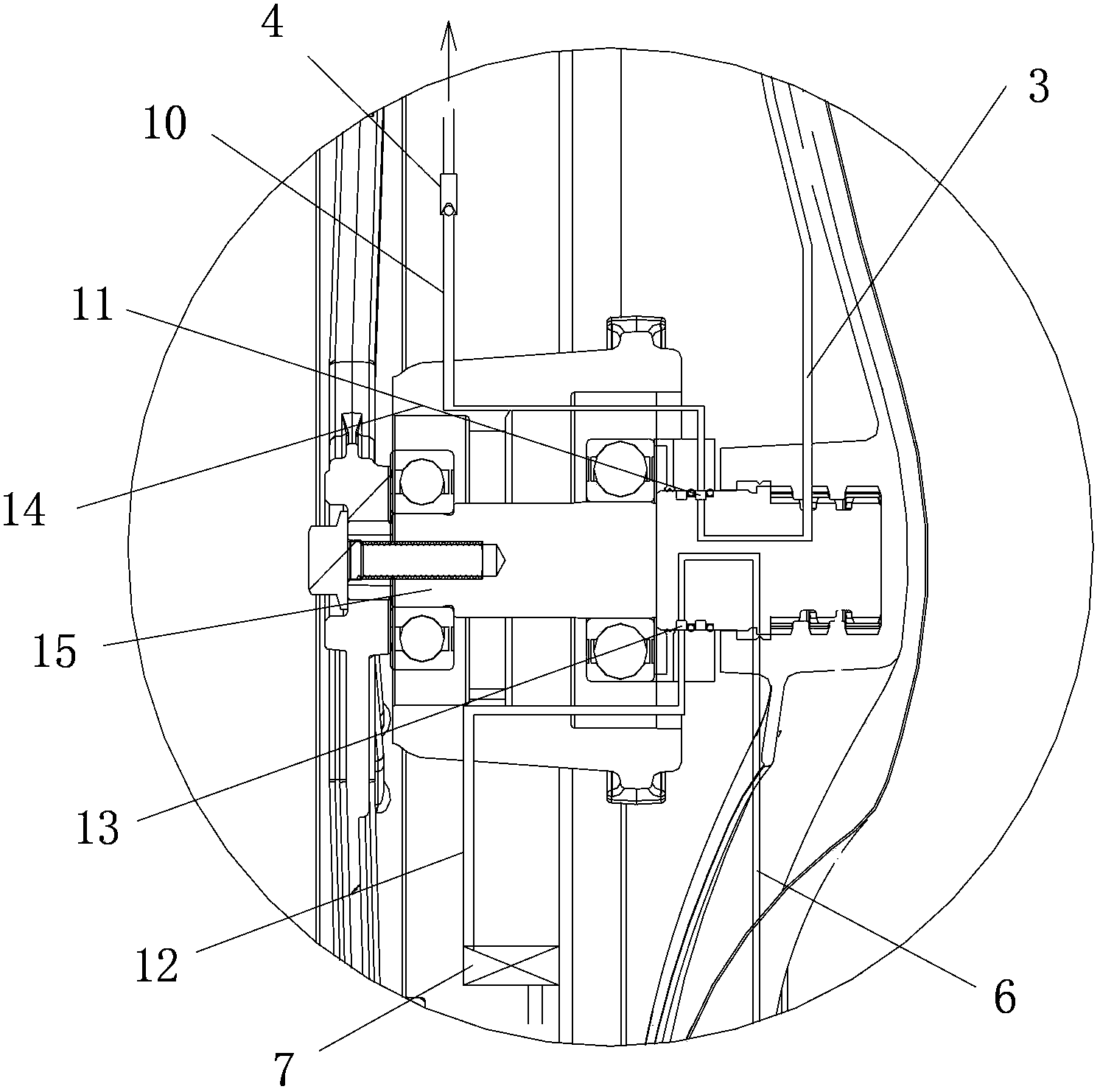

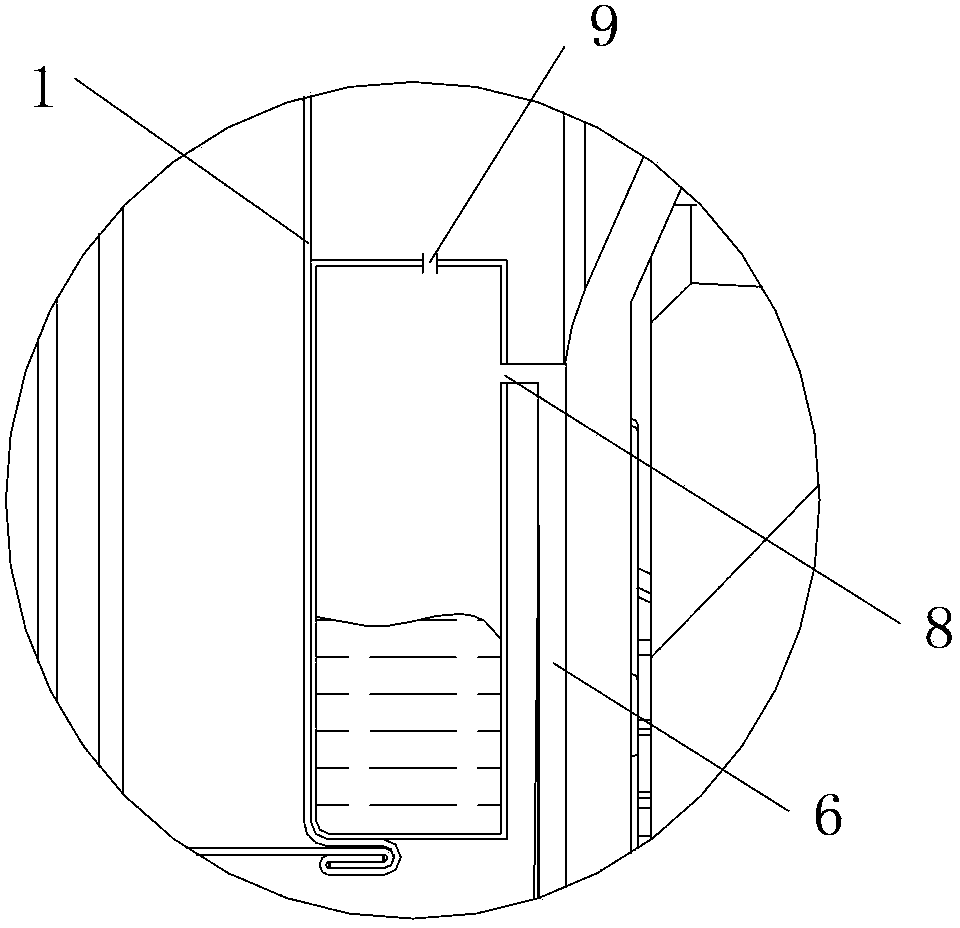

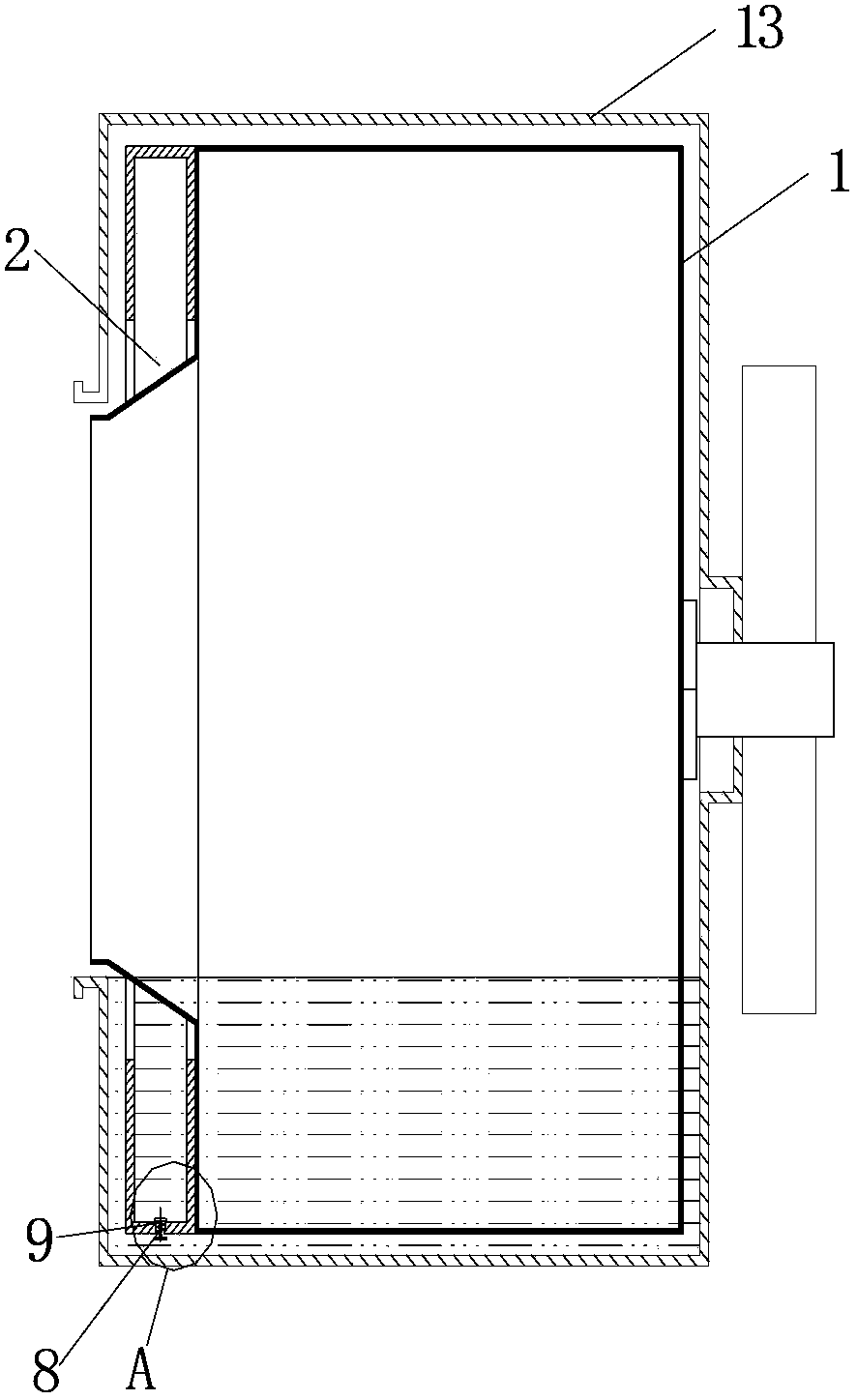

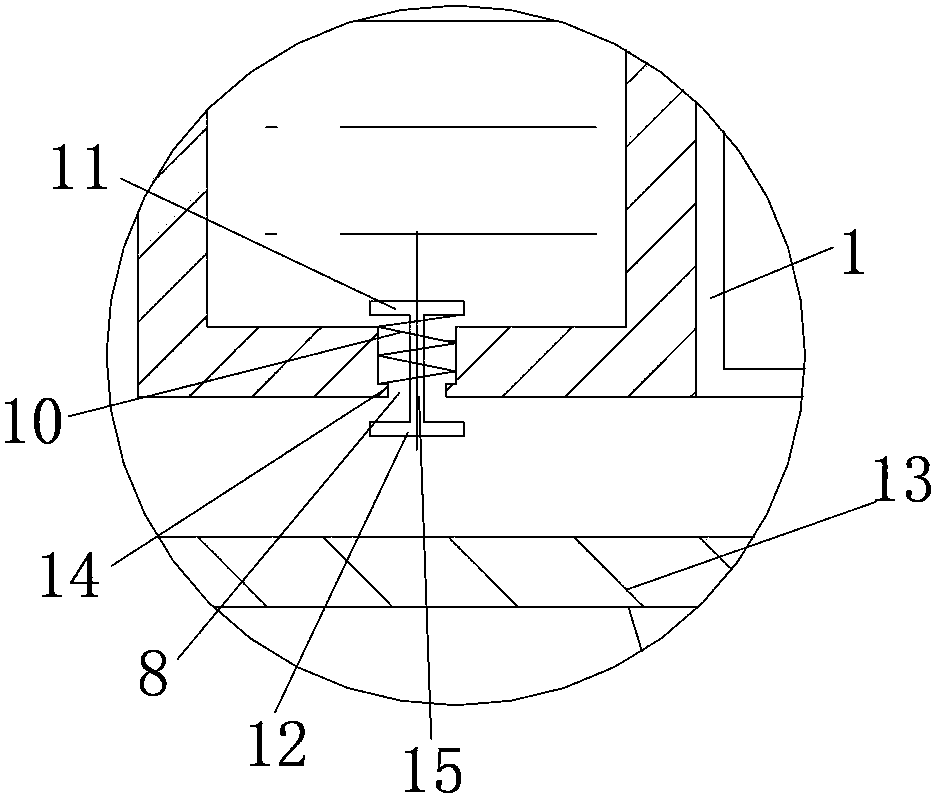

Washing machine with active water injection balancing ring and control method thereof

ActiveCN104120584AReduce weightReduce manufacturing process and costOther washing machinesControl devices for washing apparatusEnergy consumptionMechanical engineering

The invention relates to a washing machine with an active water injection balancing ring and a control method of the washing machine. The washing machine comprises an outer barrel and an inner barrel. The balancing ring is arranged at an opening of the inner barrel. The balancing ring is of a circular ring structure. A hollow cavity is formed in the balancing ring. The washing machine is further provided with a water inlet structure and a water drainage structure, wherein the water inlet structure is used for injecting water into the hollow cavity to balance the load eccentric quantity, and the water drainage structure is used for discharging water in the water inlet structure. According to the washing machine, the quantity of filler in the balancing ring can be changed, the unbalance effect caused by too little filler and excessive balance caused by too much filler are avoided, and the problem that the quantity of the filler in the balancing ring of a common washing machine can not be changed is solved. The balancing ring is hollow inside, and no filler with a fixed quantity is arranged in the balancing ring, so the weight of the balancing ring is reduced, the manufacturing processes of the balancing ring is simplified, the manufacturing cost is lowered, and the production efficiency is improved; moreover, energy consumption is lowered, accurate control over balance is achieved, the dehydrating vibration and noise are lowered, the distribution frequency is reduced, and the dehydrating time is greatly shortened.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

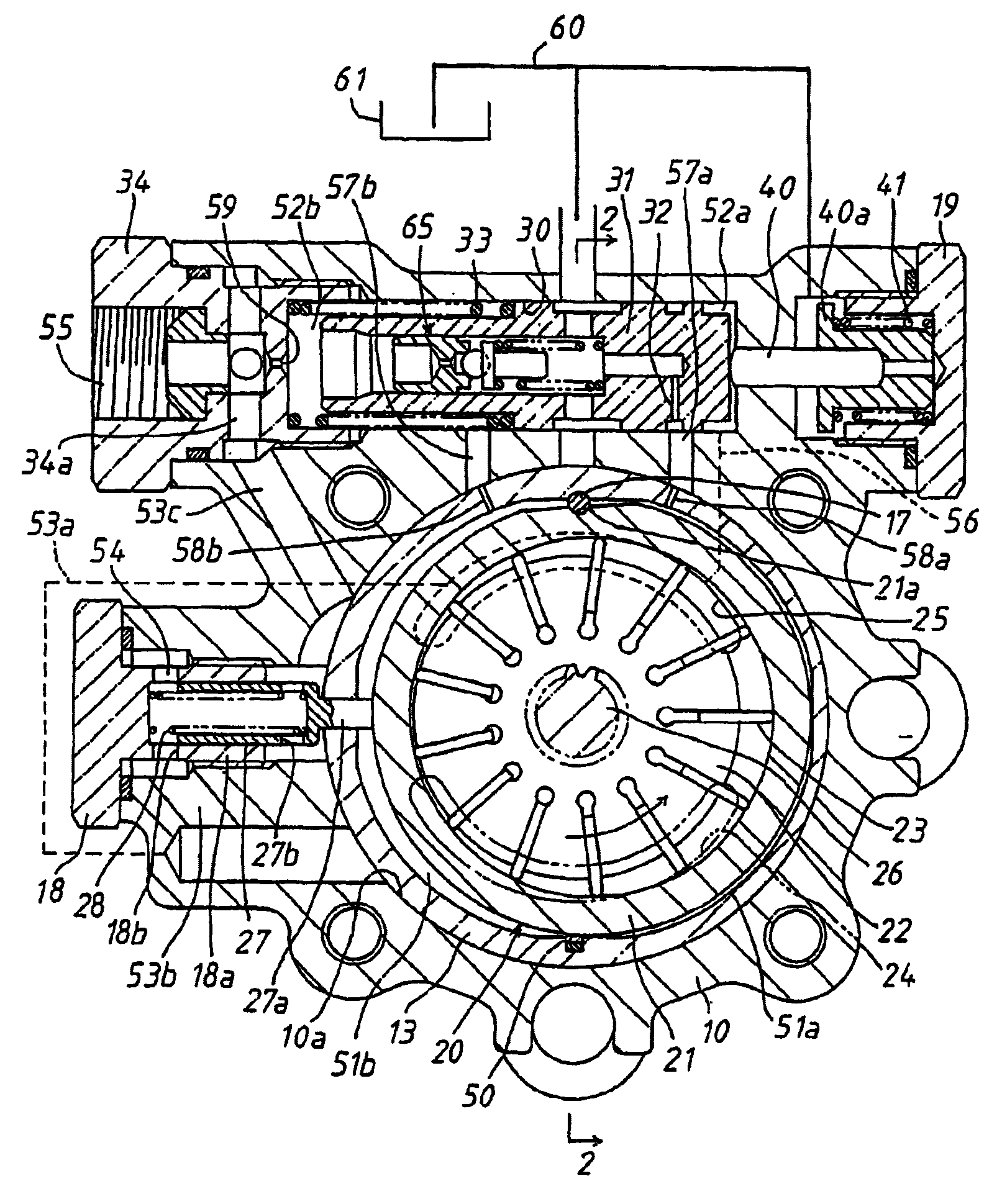

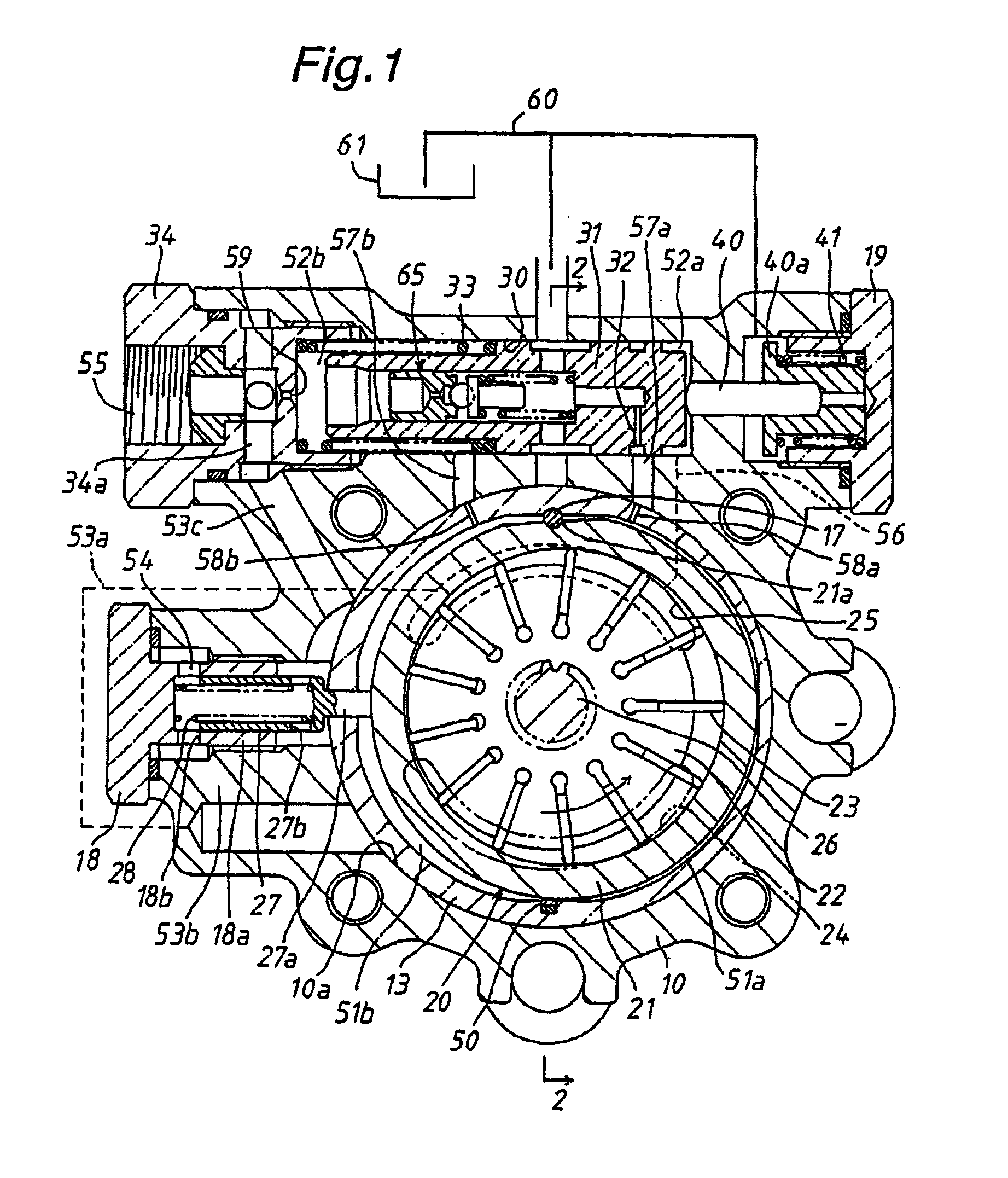

Variable Displacement Oil Pump

InactiveUS20130164162A1Reduce eccentricityEnlarge eccentricityOscillating piston enginesRotary piston pumpsDischarge pressurePressure level

An oil pump includes first and second control chambers, a biasing mechanism, and a changeover mechanism. The changeover mechanism connects the first control chamber with a drain portion when a valving element is in a first position, introduces a discharge pressure into the first and second control chambers when the valving element reaches a second position, and drains oil of the second control chamber to the drain portion and introduces the discharge pressure into the first control chamber when the valving element reaches a third position. The changeover mechanism changes from the first position to the second position, when the discharge pressure becomes higher than a pressure level at which the cam ring can move against a set load of the biasing mechanism, and is lower than a pressure level at which a biasing force of the biasing mechanism is increased in a stepwise manner.

Owner:HITACHI AUTOMOTIVE SYST LTD

Variable displacement pump

InactiveUS7128542B2Increase thrustEccentricOscillating piston enginesRotary piston pumpsInternal pressureDifferential pressure

In a hydraulic pump, a cam ring is provided in a cylindrical adaptor for movement in a radial direction, and a differential pressure control valve is provided to control internal pressure and load pressure at the front and back sides of a variable orifice to be introduced into action chambers and formed at the opposite sides of the cam ring for controlling a discharge amount of the pump in accordance with the rotation speed of the pump. The differential pressure control valve is operated under the internal pressure and load pressure respectively introduced into action chambers and the load of a thrust spring biasing the differential pressure control valve toward the internal pressure chamber. The load of the thrust spring is increased or decreased in accordance with an increase or a decrease of the load pressure. The increase or decrease of the load pressure is effected by a load pressure responsive piston loaded by a thrust spring and engaged with the differential pressure control valve at one end thereof in the internal pressure chamber.

Owner:TOYODA MASCH WORKS LTD

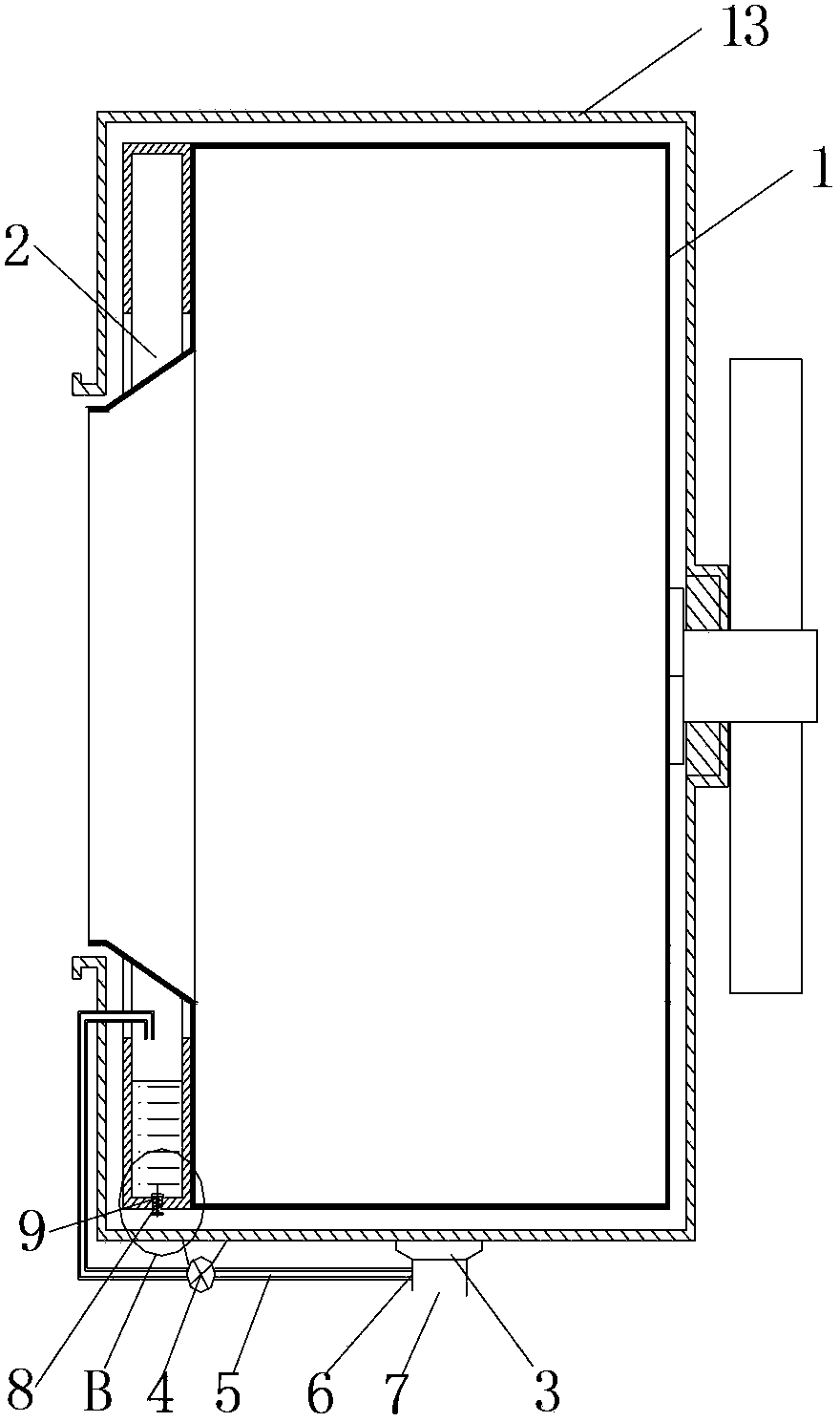

Washing machine with water filling port type balancing ring and control method thereof

ActiveCN104120583AReduce weightThe production process is simpleOther washing machinesControl devices for washing apparatusPort typeEnergy consumption

The invention relates to a washing machine with a water filling port type balancing ring and a control method of the washing machine. The washing machine comprises an outer barrel and an inner barrel. The balancing ring is arranged at a clothes charging port of the inner barrel. The balancing ring is of a circular ring structure. The inner circumference of the balancing ring is provided with water filling ports, and the water filling ports are used for supplying water into the balancing ring as balancing liquid to balance the load eccentric quantity. The outer circumference of the balancing ring is provided with at least one water drainage port which can be opened or closed. According to the washing machine, the balancing ring is hollow inside, and no filler with a fixed quantity is arranged in the balancing ring, so the weight of the balancing ring is reduced greatly, sealing does not need to be considered, the manufacturing processes of the balancing ring are simplified, the manufacturing cost is reduced, and the production efficiency is improved; the washing machine with the water filling port type balancing ring does not need to drive the filler in the balancing ring to rotate together, so energy consumption is lowered, an appropriate amount of water can be injected according to the measured load eccentric quantity, the unbalance effect caused by too little filler and excessive balance caused by too much filler are avoided, and the problem that the quantity of the filler in the balancing ring of a common washing machine can not be changed is solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Interlocking tooth bond for assembly of fiber composite laminates

ActiveUS7731817B2Cost efficientEffective weightAdhesive processesLamination ancillary operationsComposite laminatesImproved method

An improved method of joining fiber composite laminates is disclosed. Two fiber composite laminates may be joined together end-to-end. The bonding is done through the thickness of the fiber composite laminates. There are two ways to form the bond: (1) non-interlocking; and (2) interlocking.

Owner:BELL HELICOPTER TEXTRON INC

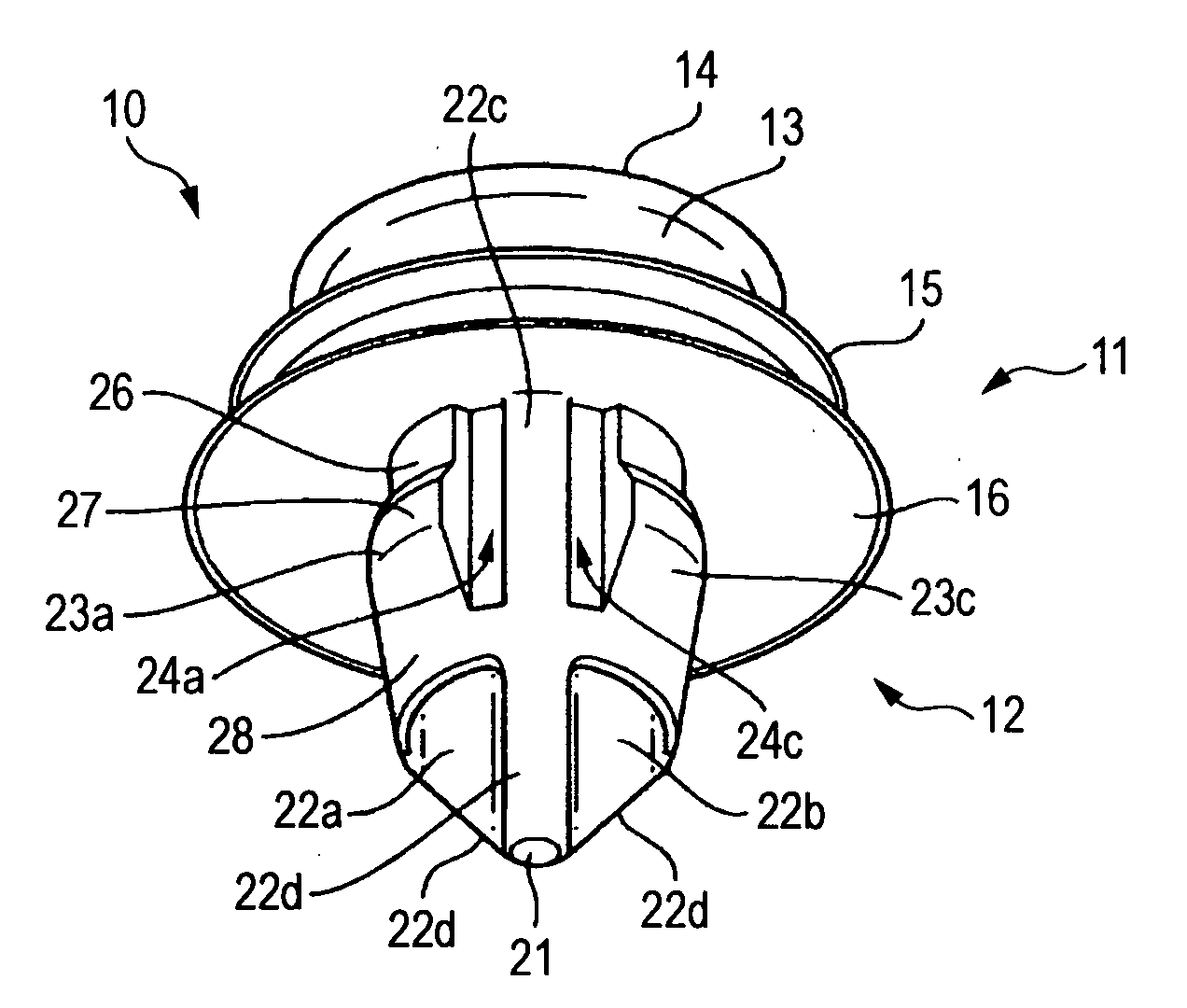

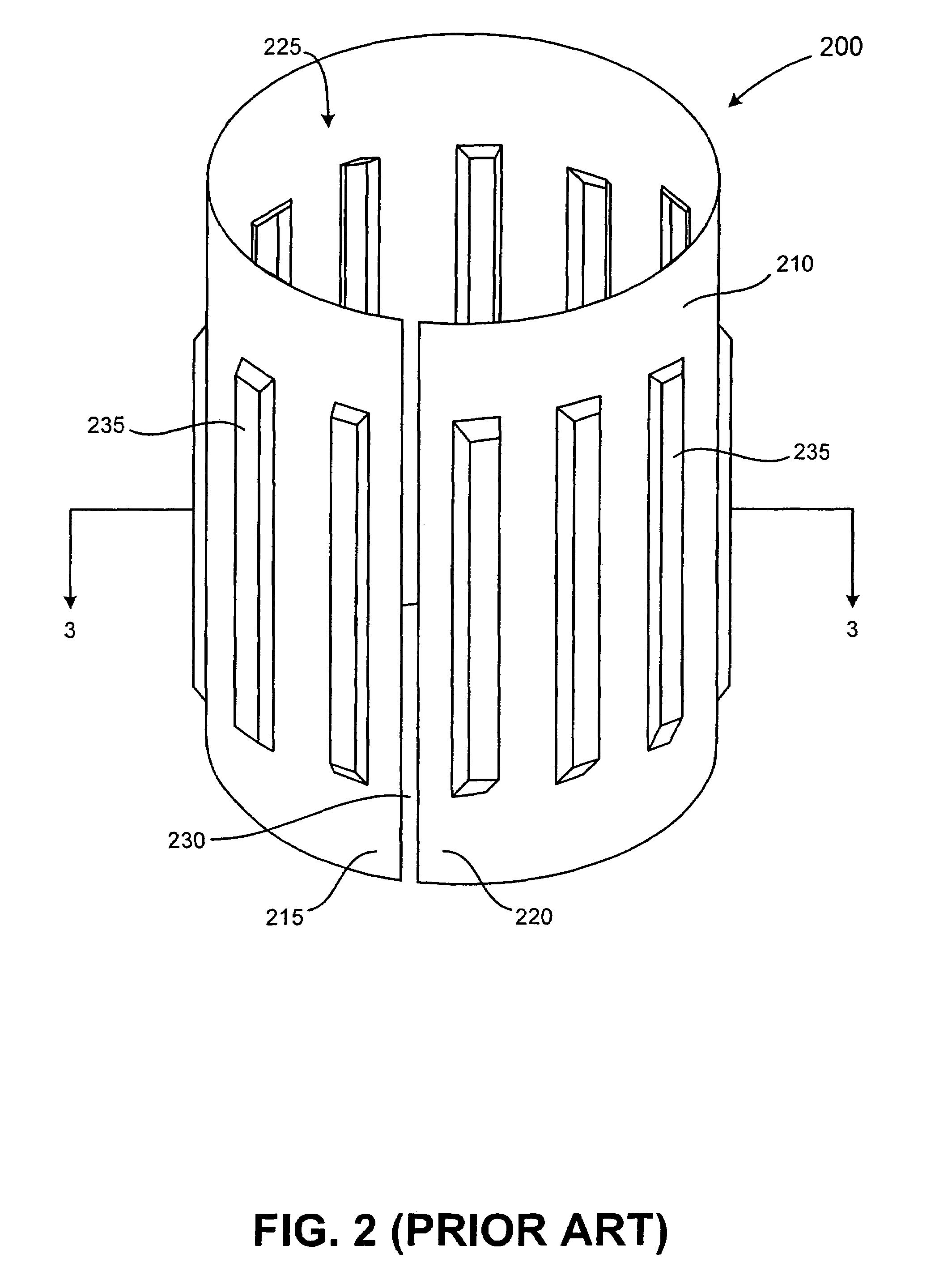

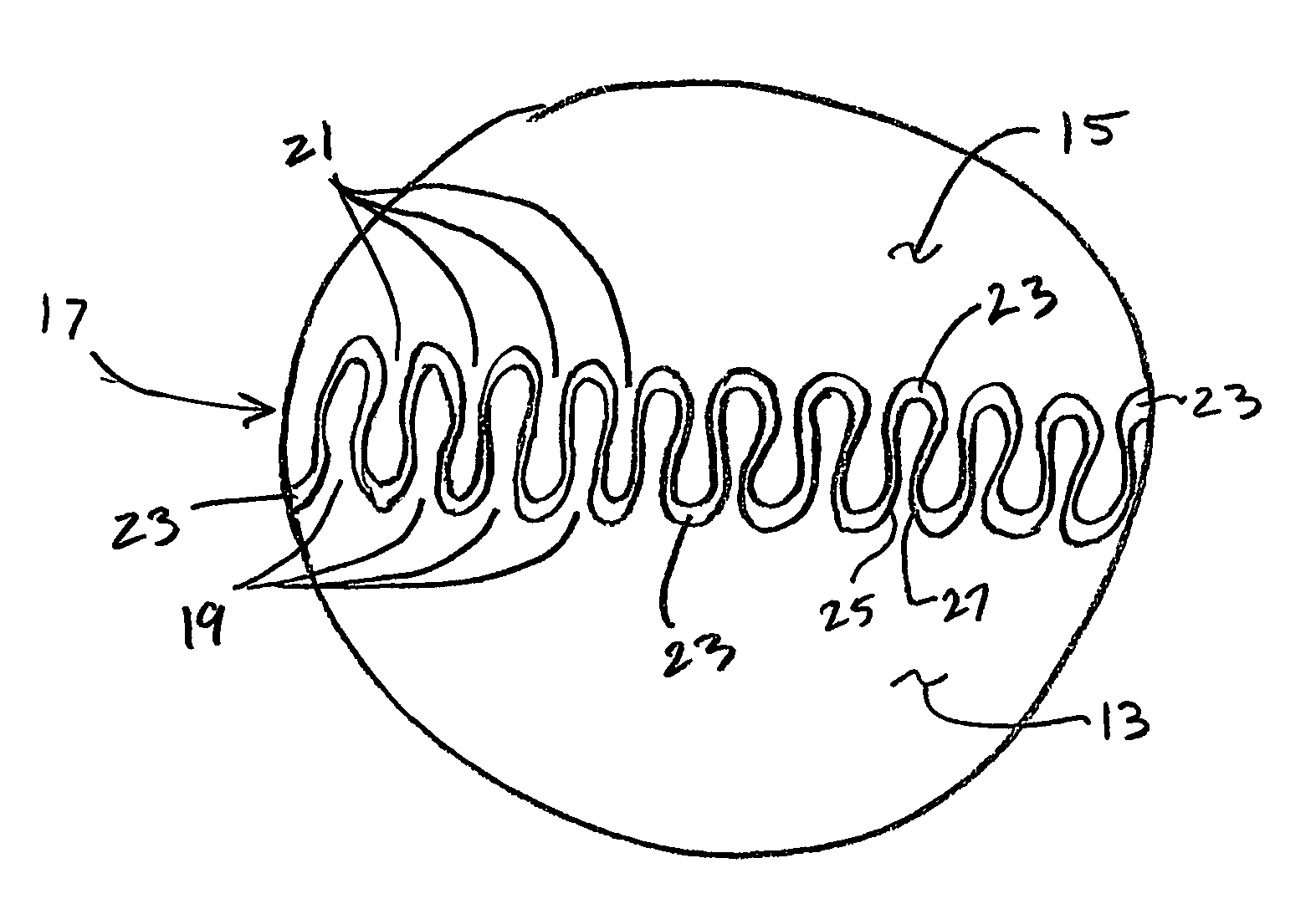

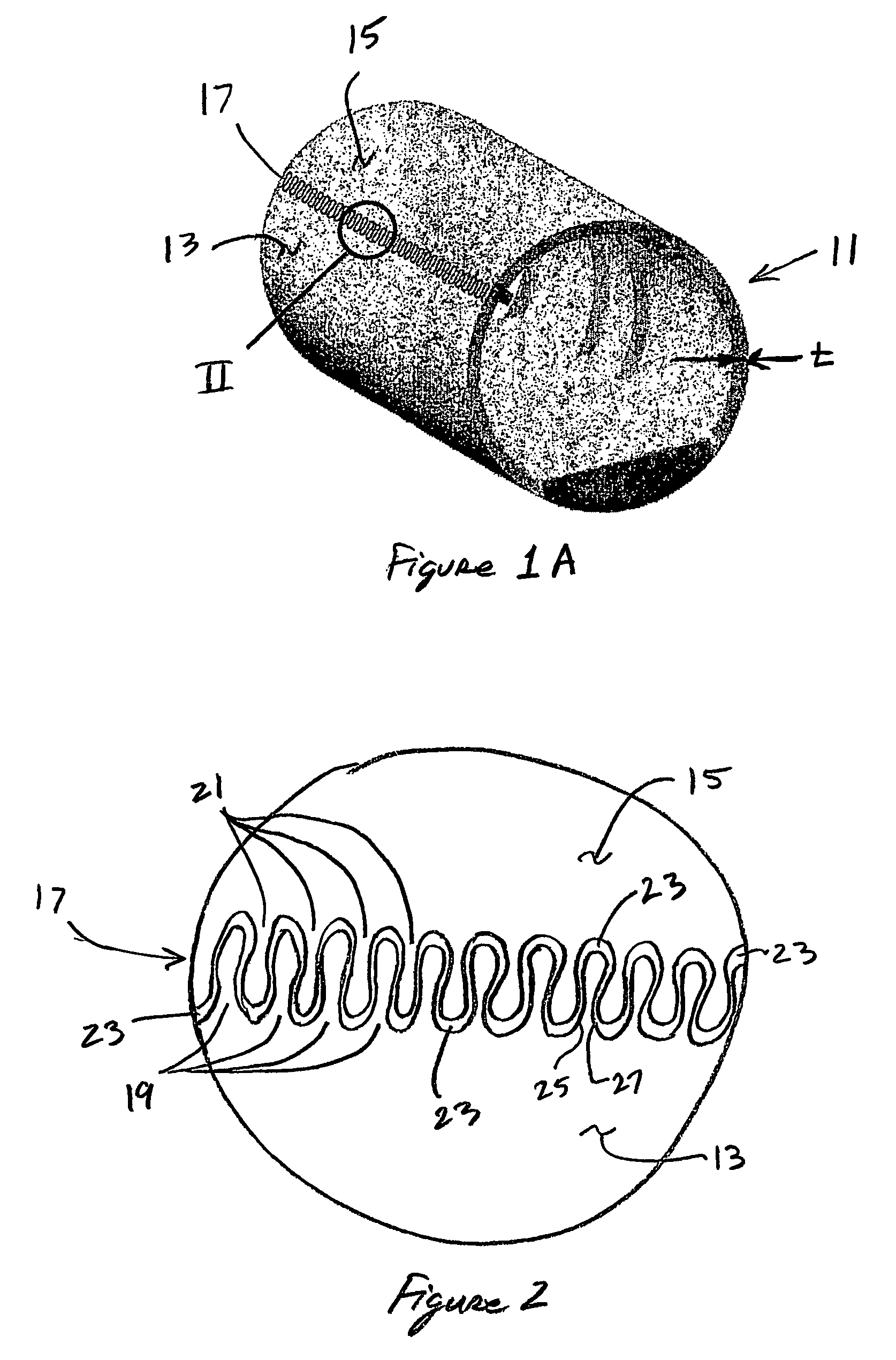

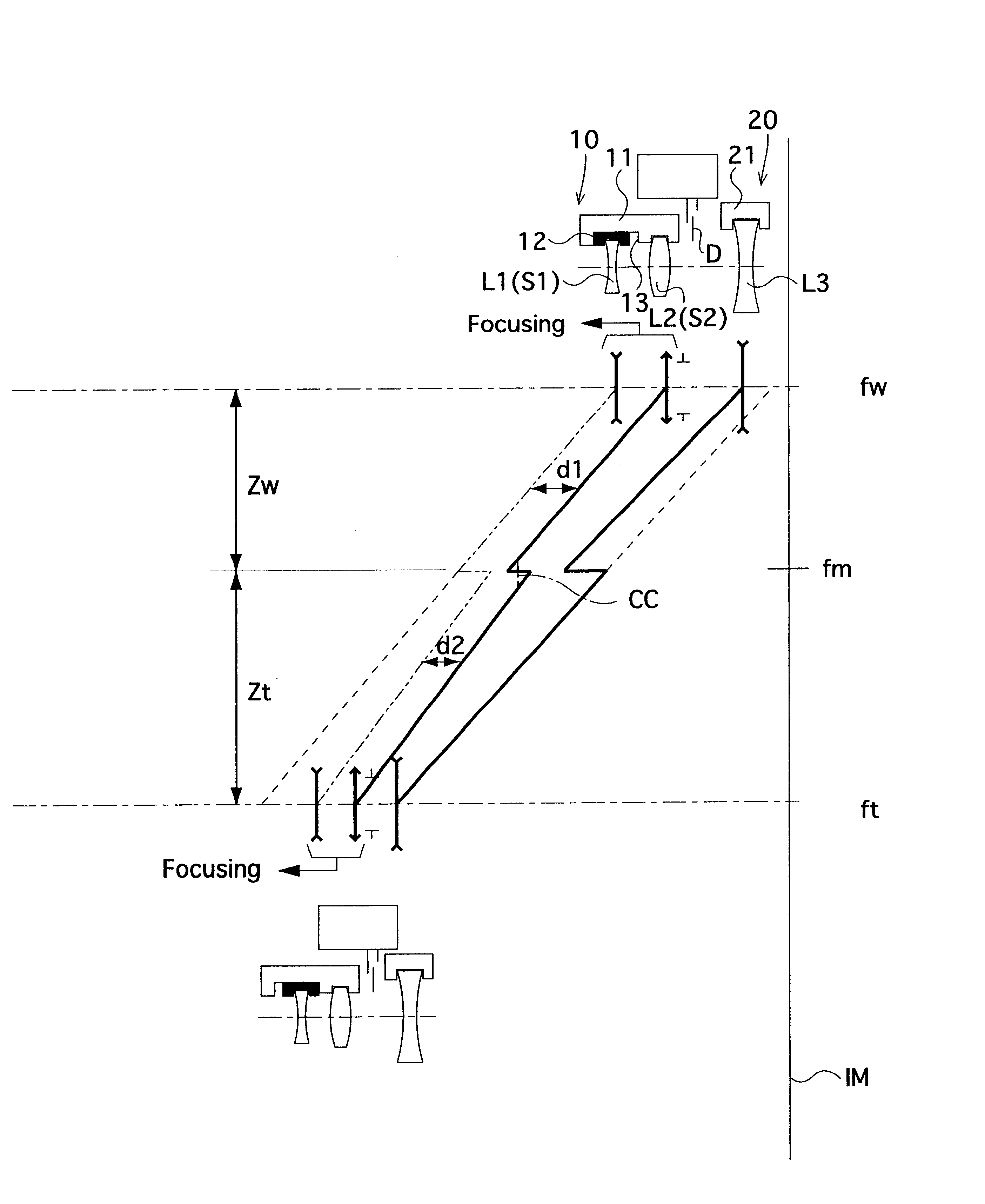

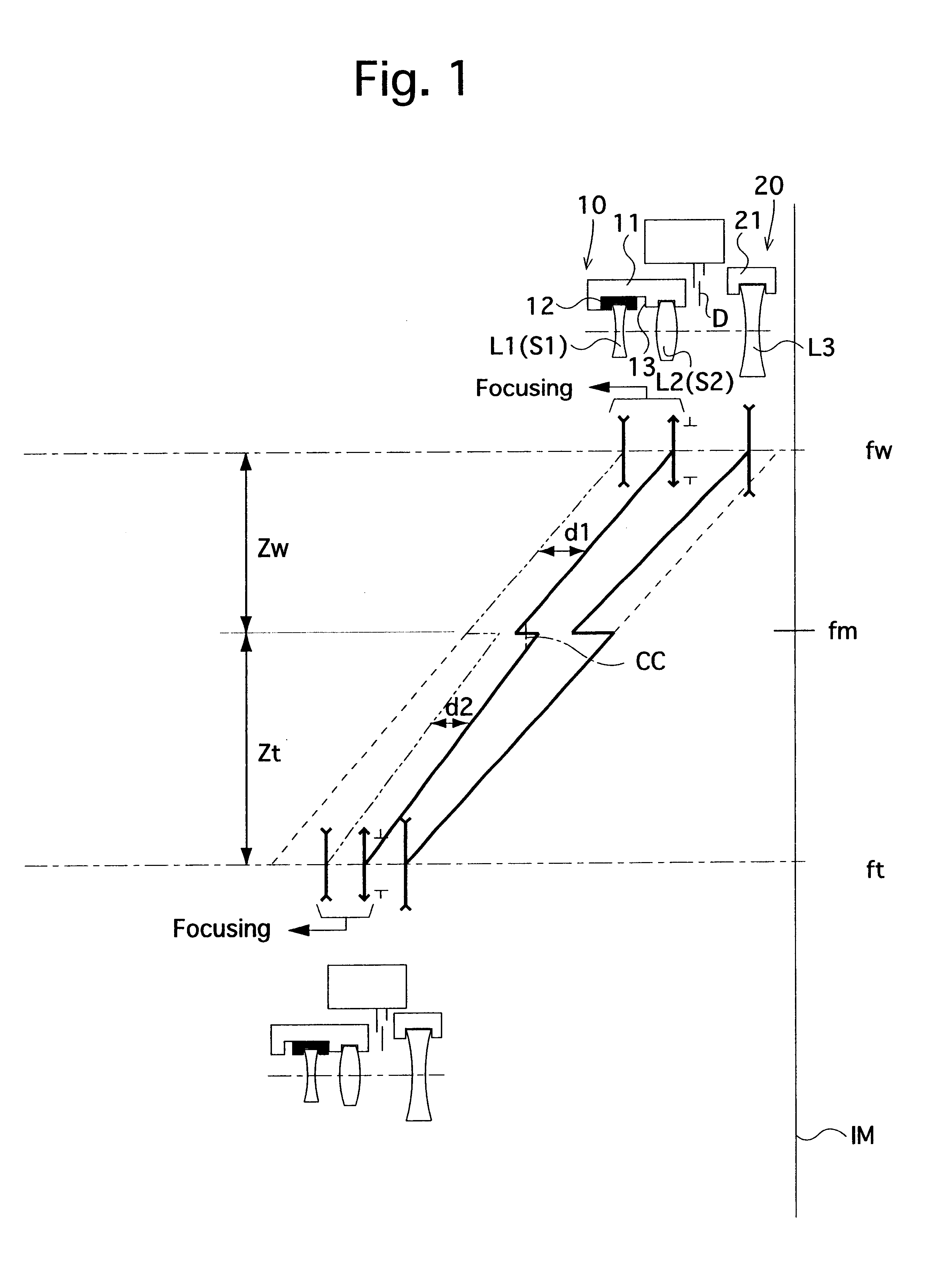

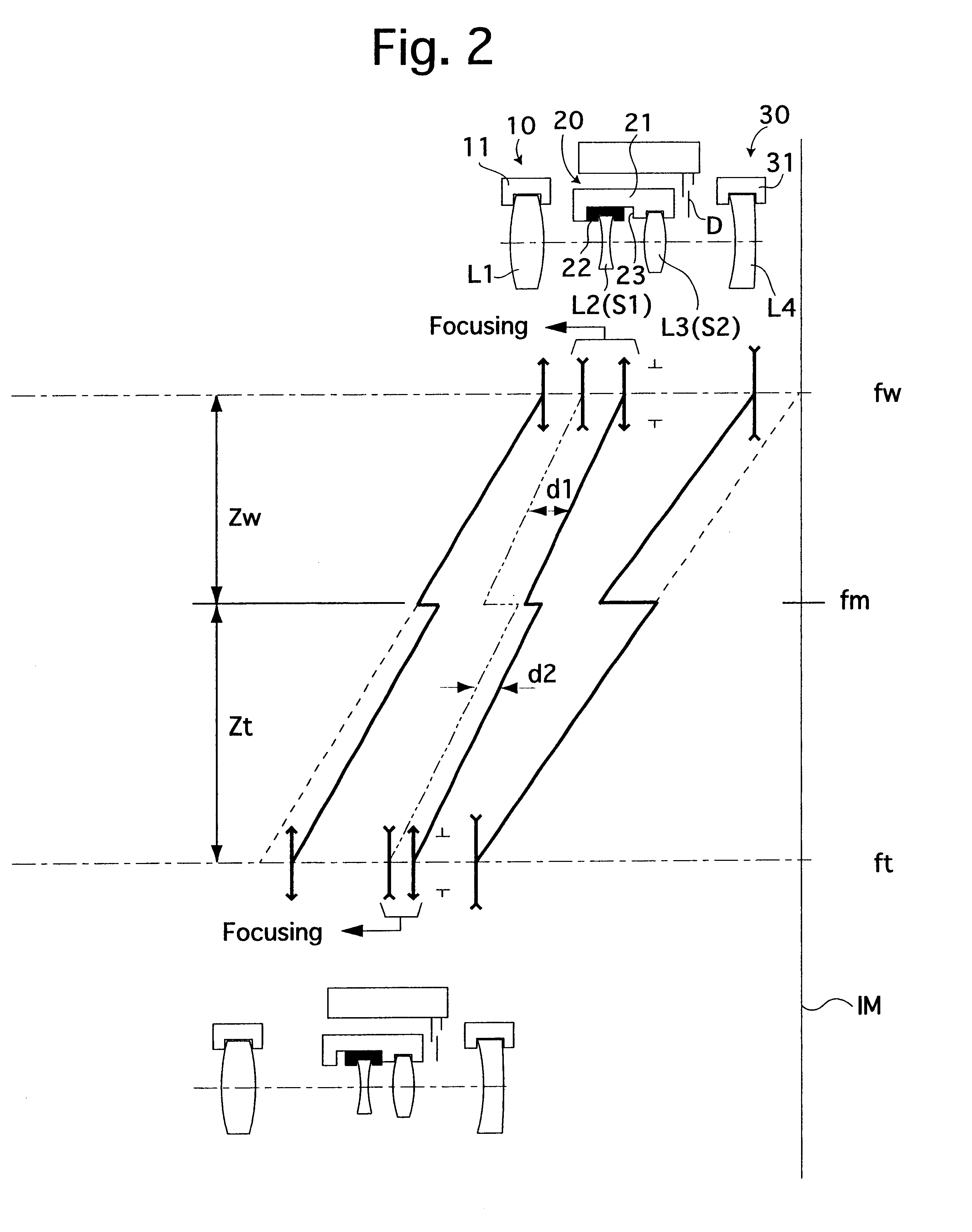

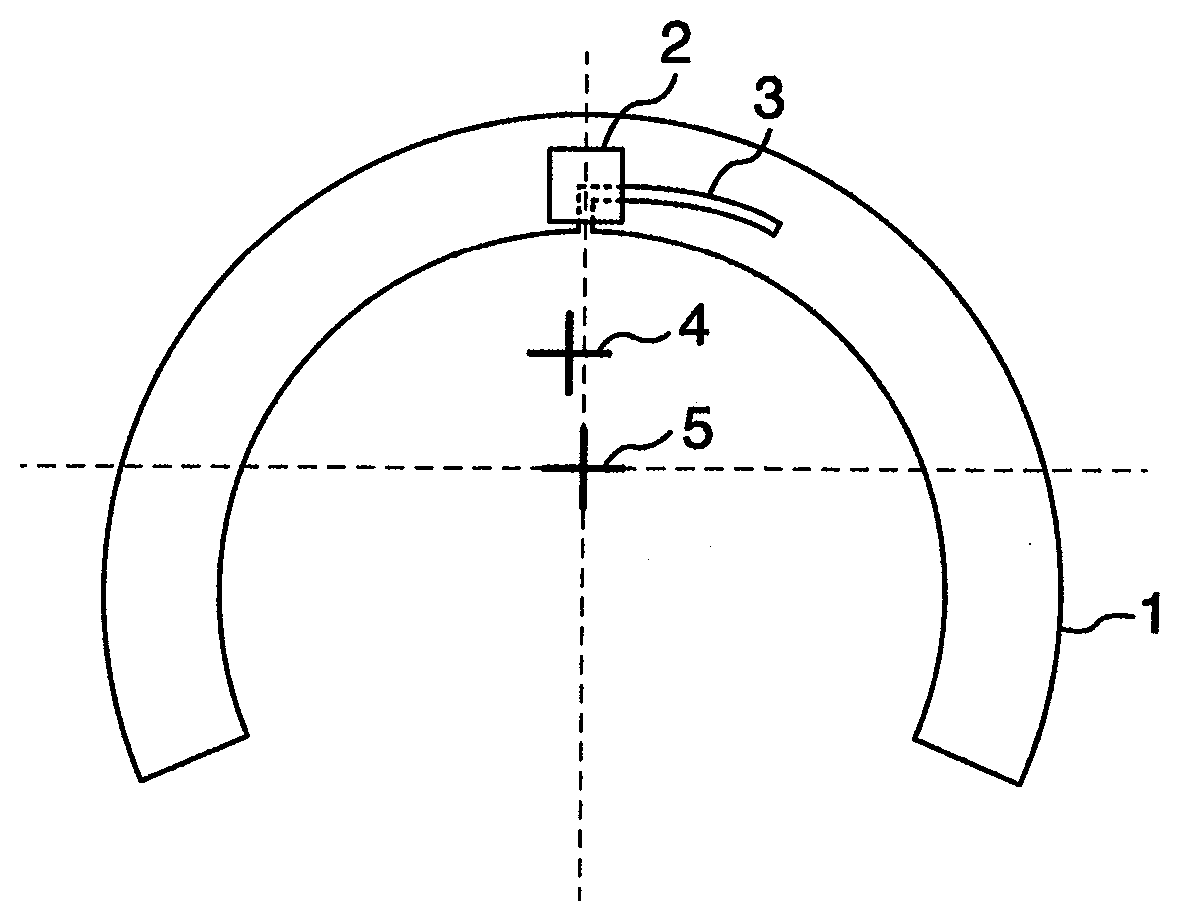

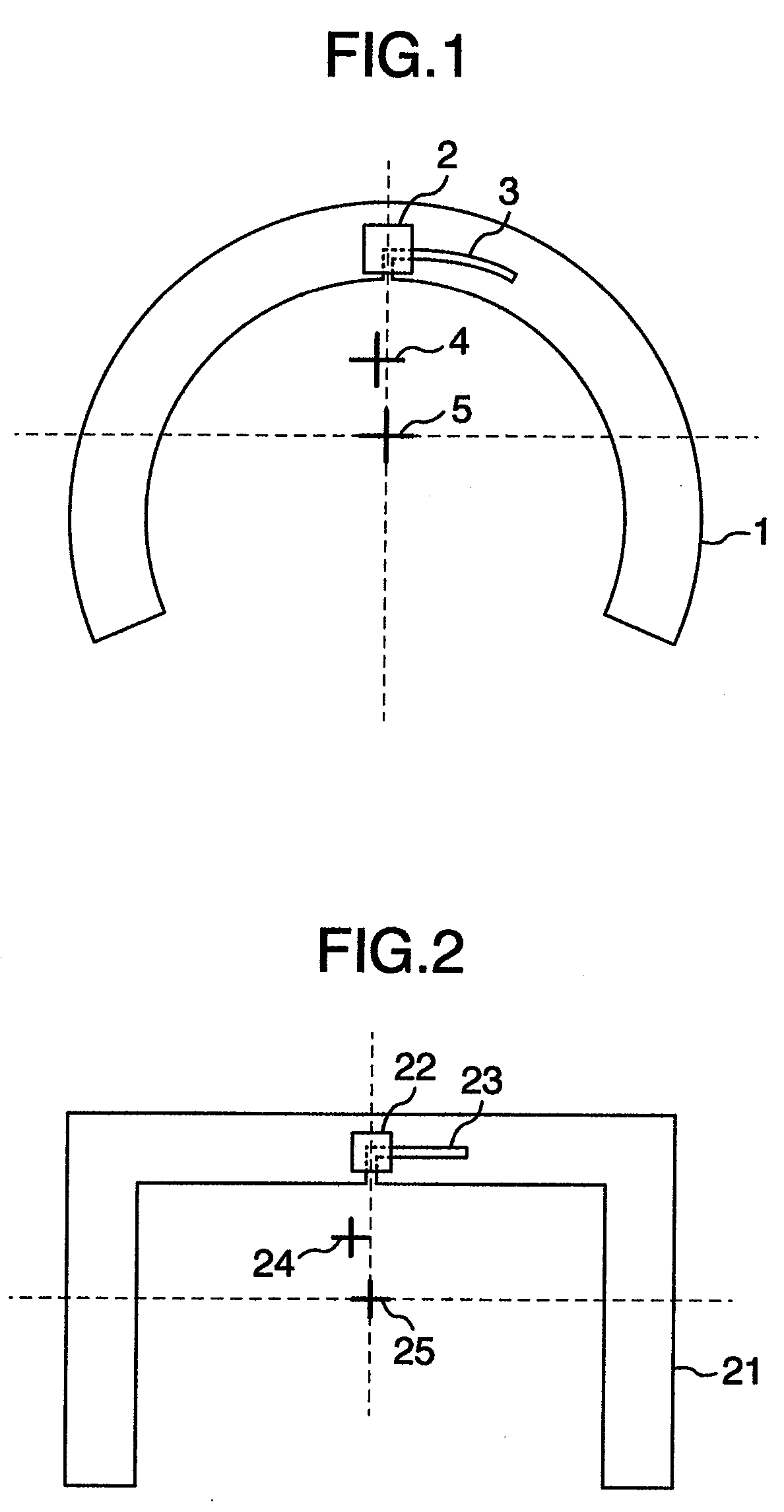

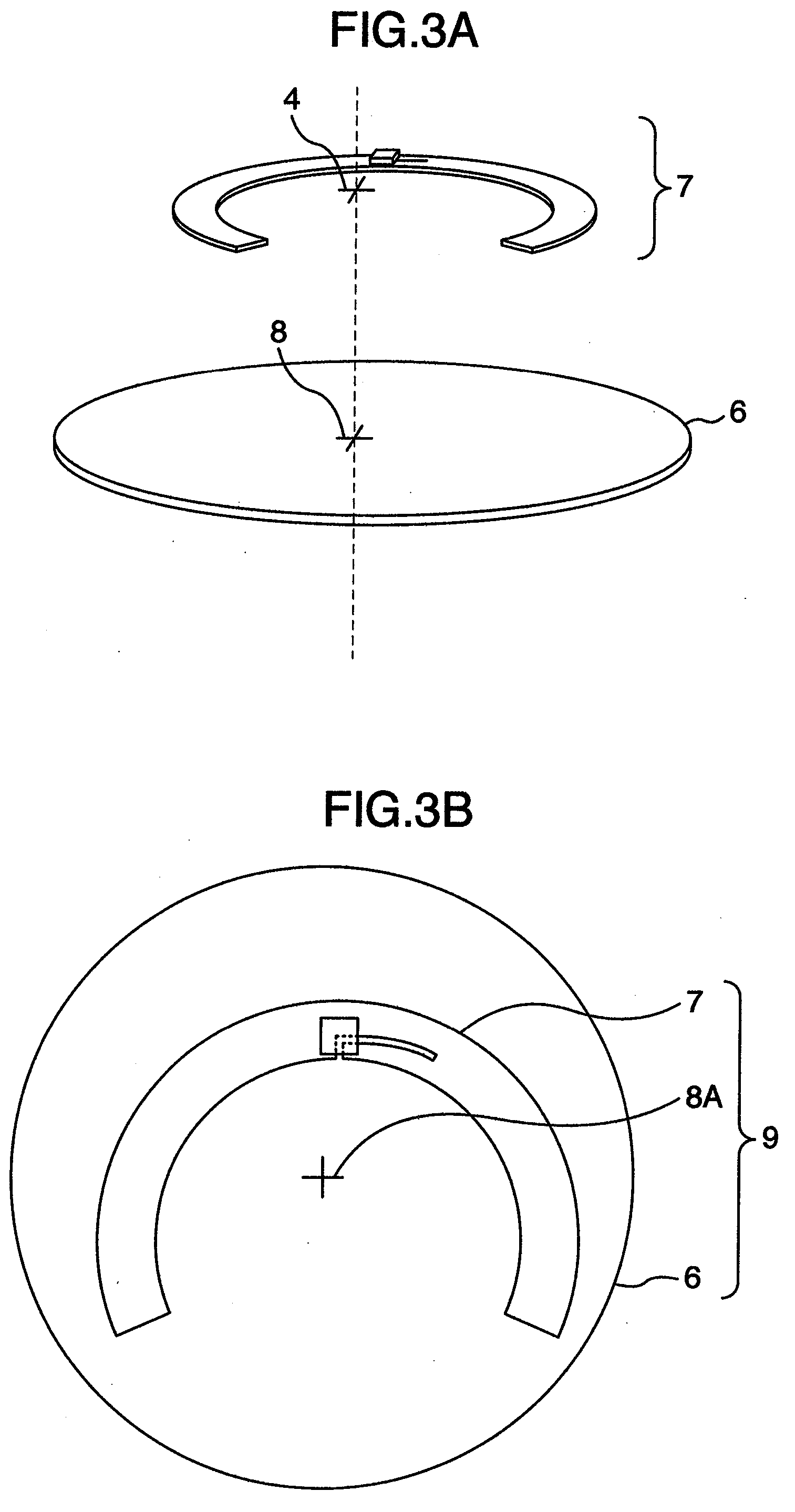

Eccentricity-prevention mechanism for a pair of lens-supporting rings

An eccentricity-prevention mechanism includes a pair of lens-supporting rings for supporting a pair of lens groups, respectively; and a pair of positioning recesses and a follower projection formed on one and the other of opposed surfaces of the pair of lens-supporting rings, such that the follower projection engages with one of the pair of positioning recess to define a relative position of the pair of lens-supporting rings with respect to the optical axis, at a mutually close position and at a mutually distant position. At least three pairs of the positioning recesses and at least three follower projections are provided at different positions in a circumferential direction, so that eccentricity between the pair of lens-supporting rings is eliminated when all of the follower projections are concurrently brought into engagement with corresponding positioning recesses.

Owner:ASAHI KOGAKU KOGYO KK

Washing machine

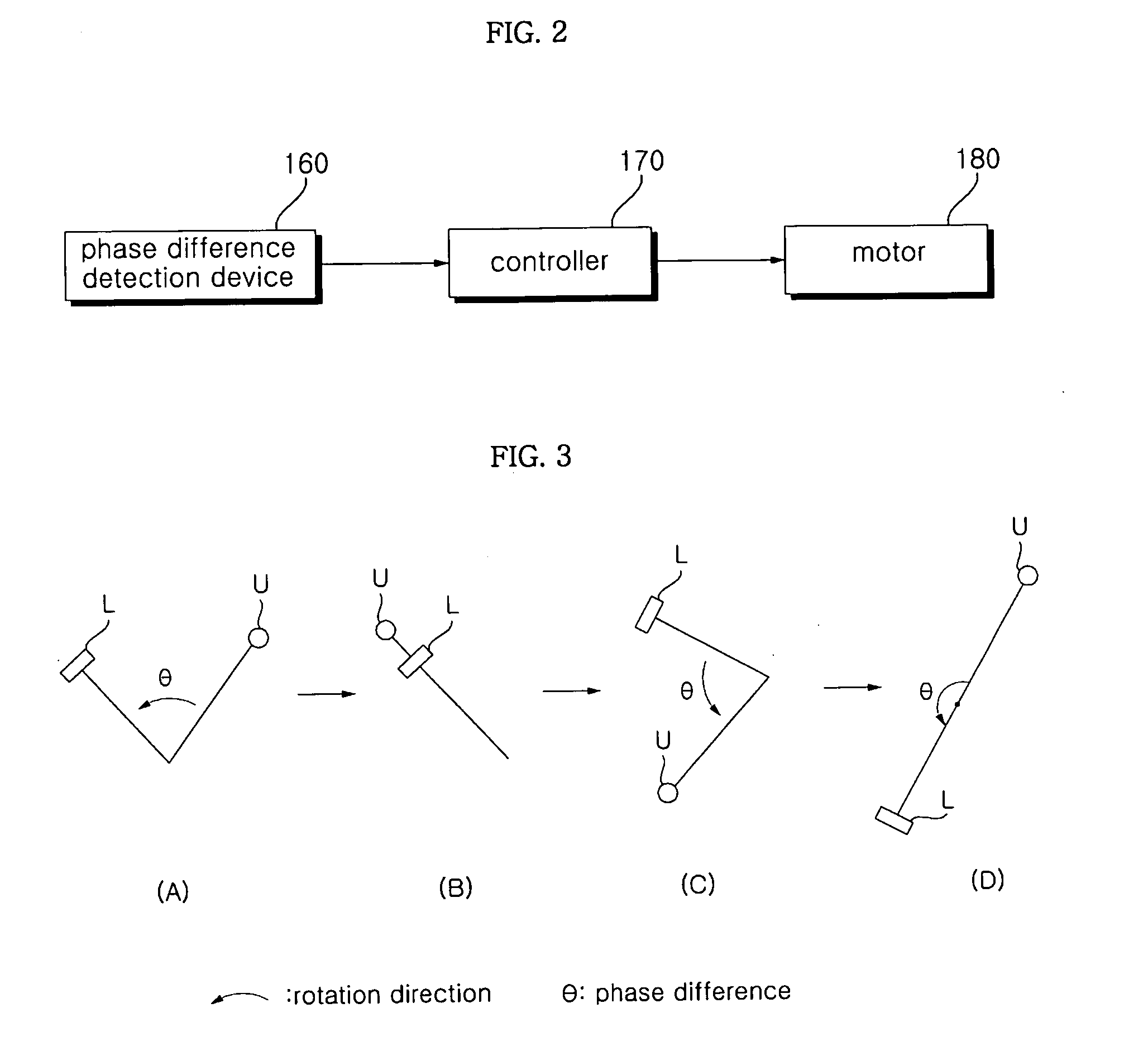

InactiveUS20090308110A1Dehydration fastReduce noiseOther washing machinesControl devices for washing apparatusMachine controlPhase difference

A washing machine is provided. The washing machine controls a dehydration rotation speed by detecting a phase difference between a ball balancer and the laundry. Further, the washing machine controls a dehydration rotation speed at a dehydration segment based on a dehydration rotation speed of a driving device. Thereby, the washing machine minimizes energy using in a dehydration process by accelerating the dehydration rotation speed at a point at which a phase difference between the ball balancer and the laundry is a maximum. Further, by accelerating the dehydration rotation speed at a point at which the phase difference is a maximum, a vibration of the washing machine is remarkably reduced.

Owner:LG ELECTRONICS INC

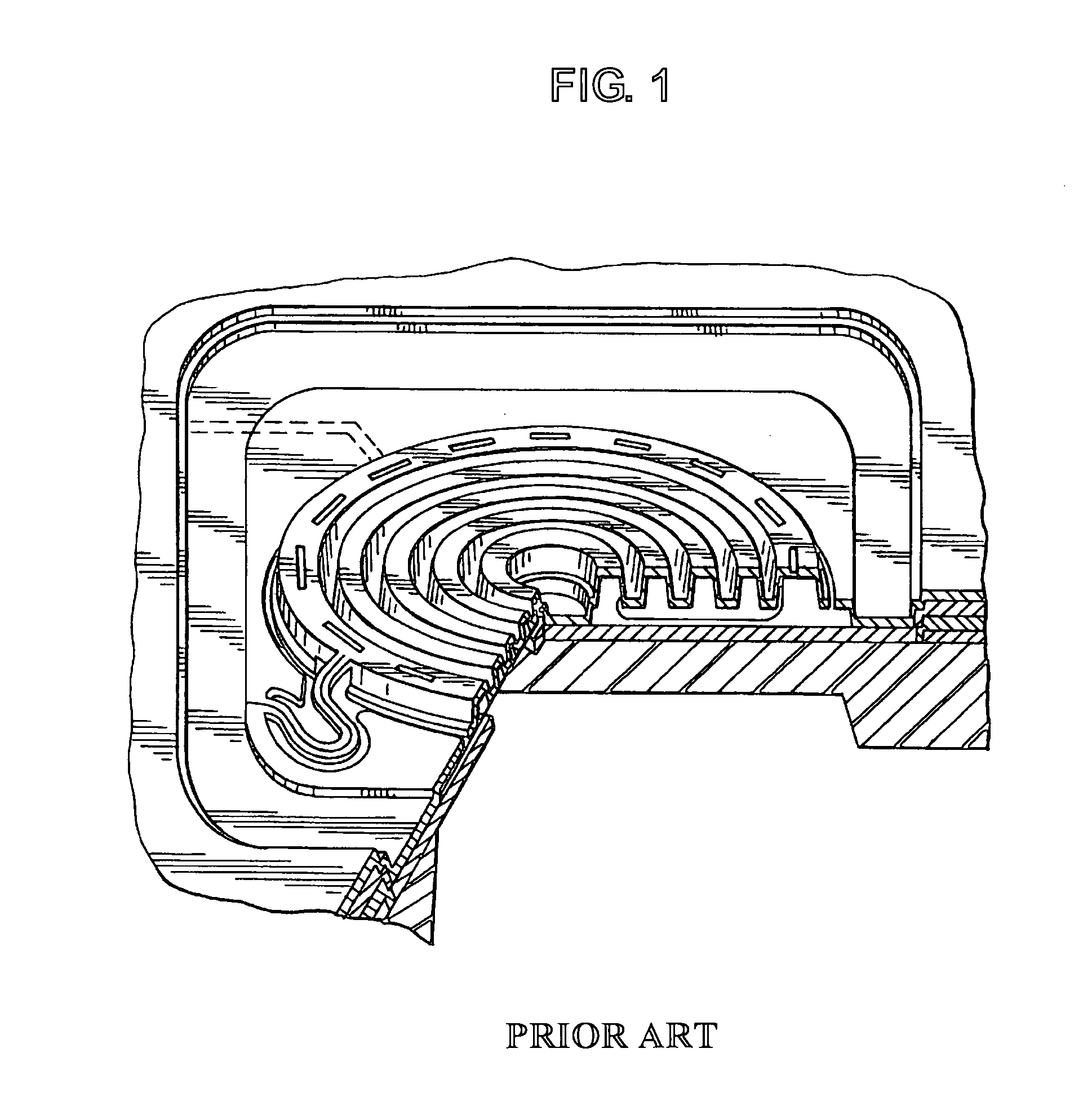

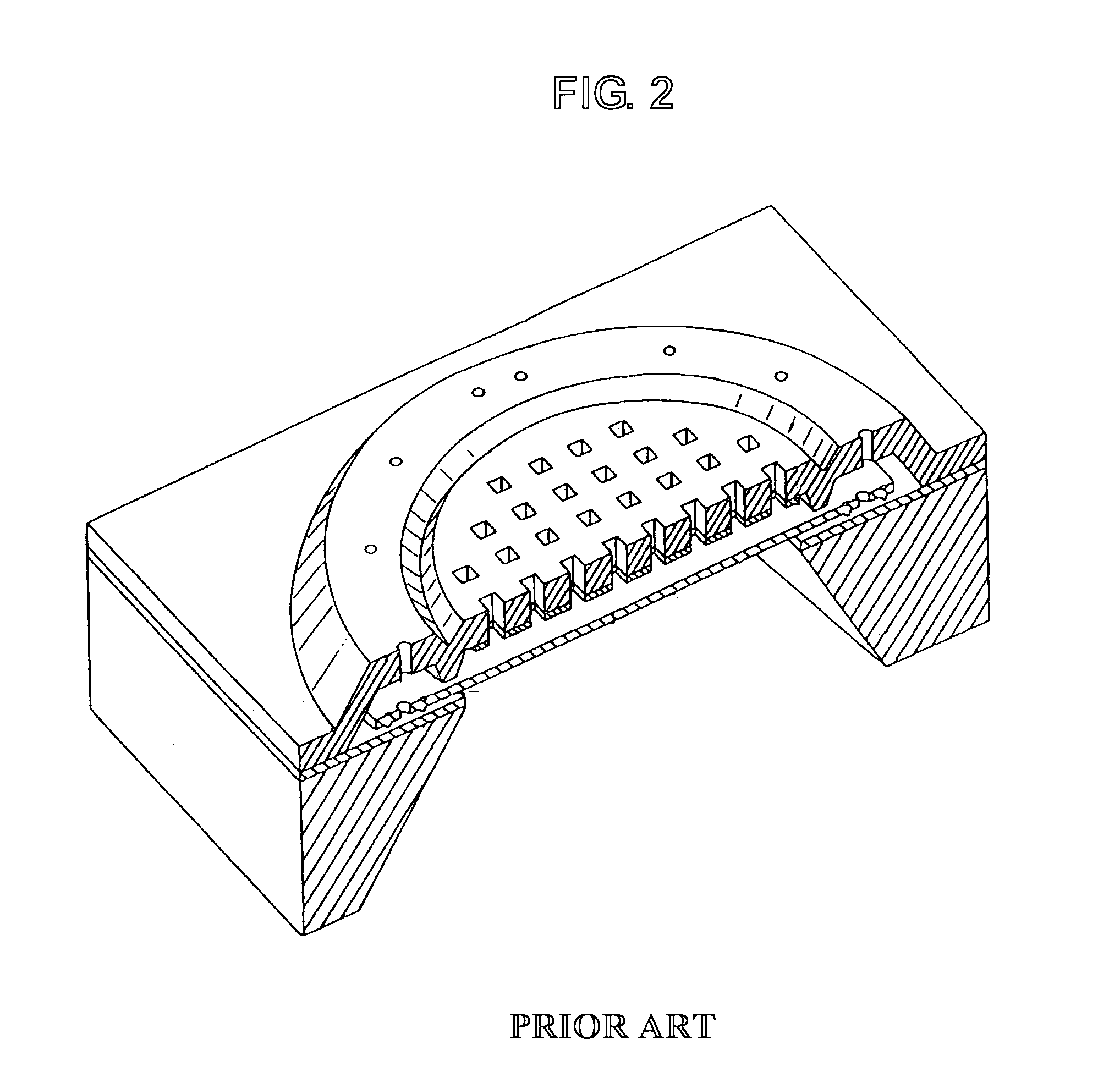

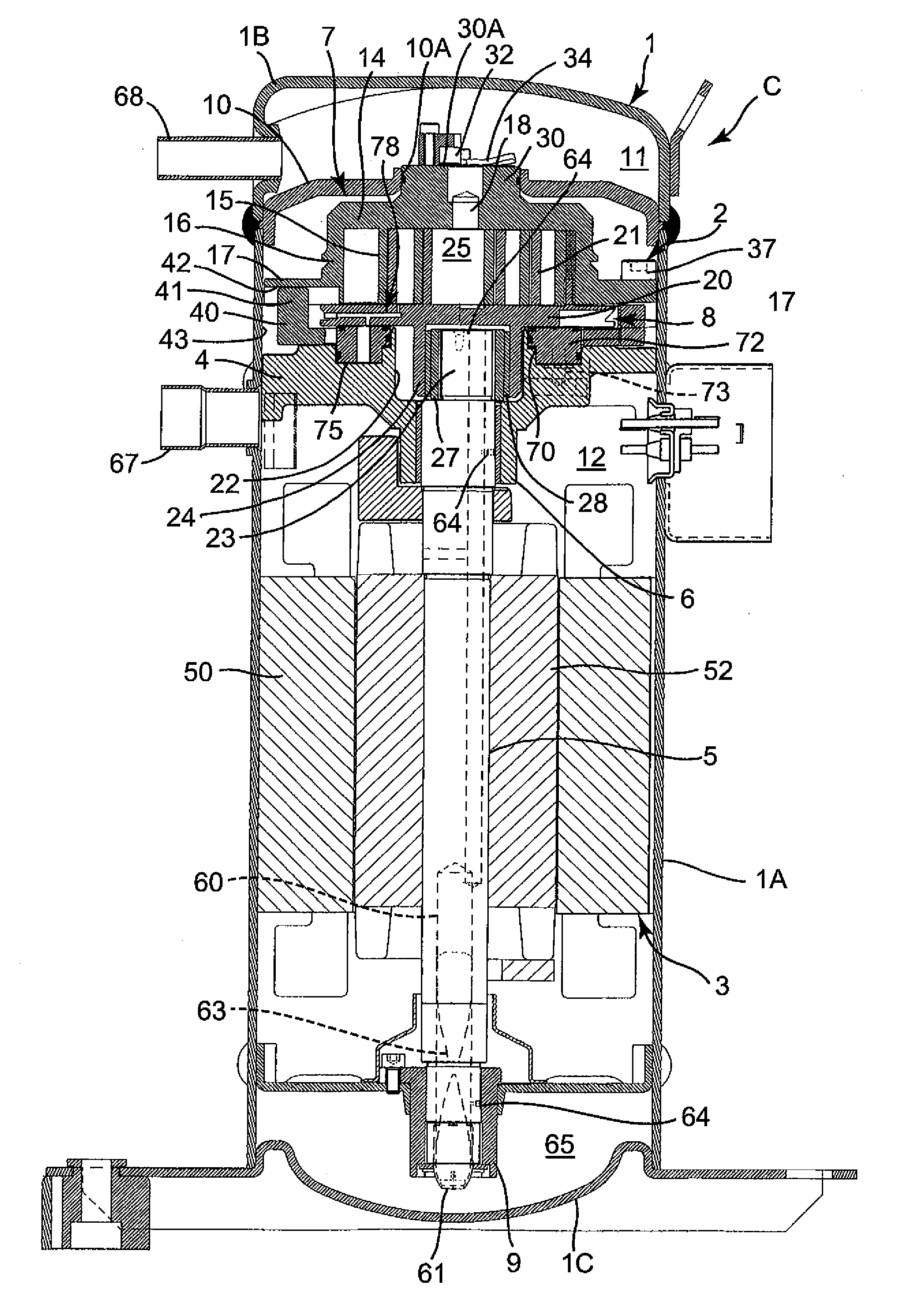

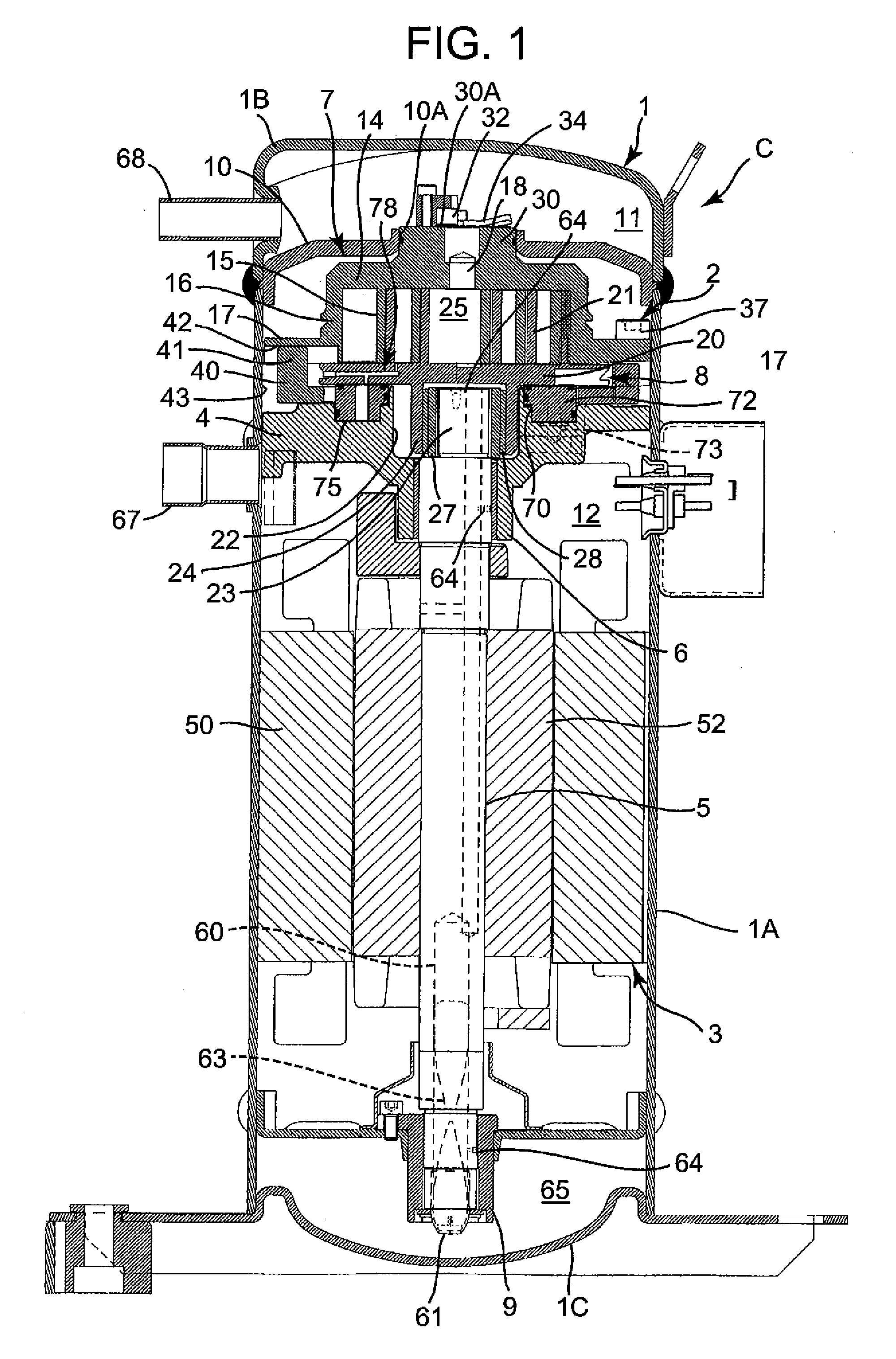

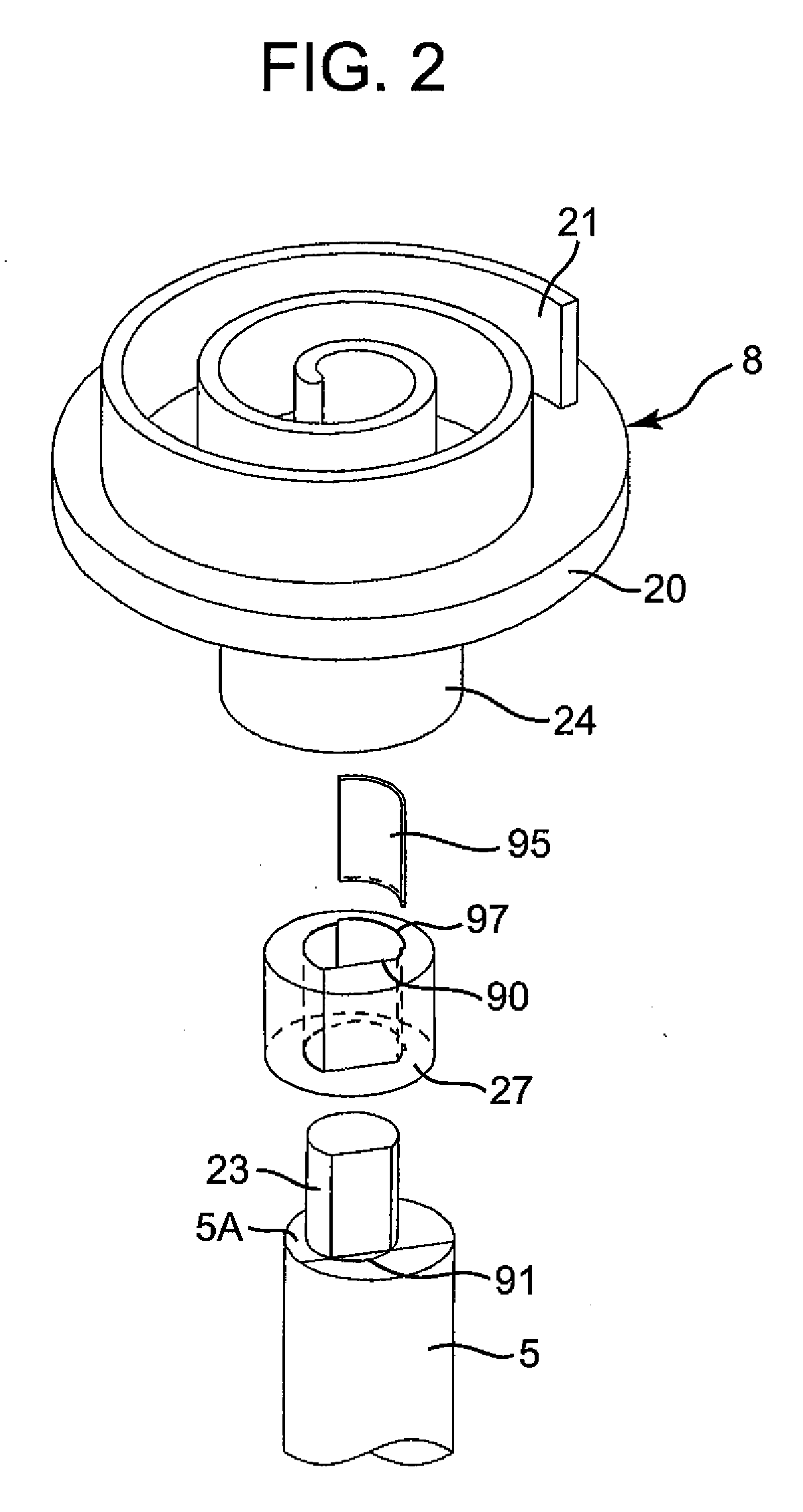

Scroll compressor

InactiveUS20090246057A1Eliminate disadvantagesSuppressing start loadEngine of arcuate-engagement typeOscillating piston enginesEngineeringOrbit

There is disclosed a scroll compressor having an object of stabilizing the moving of an orbit scroll while suppressing the start load of the scroll compressor. In the scroll compressor, a slide bush having a slide face forming a predetermined angle with respect to the direction of gas load of a gas in a compression chamber is interposed on an eccentric shaft of a shaft for driving the orbit scroll, so that when the load of the gas in the compression chamber is applied, the eccentric amount of the eccentric shaft increases. The scroll compressor includes a spring member interposed between the slide bush and the eccentric shaft and configured to constantly urge the eccentric shaft to decrease the eccentric amount of the eccentric shaft, and this spring member urges the eccentric shaft to press the eccentric shaft onto the slide face of the slide bush.

Owner:SANYO ELECTRIC CO LTD

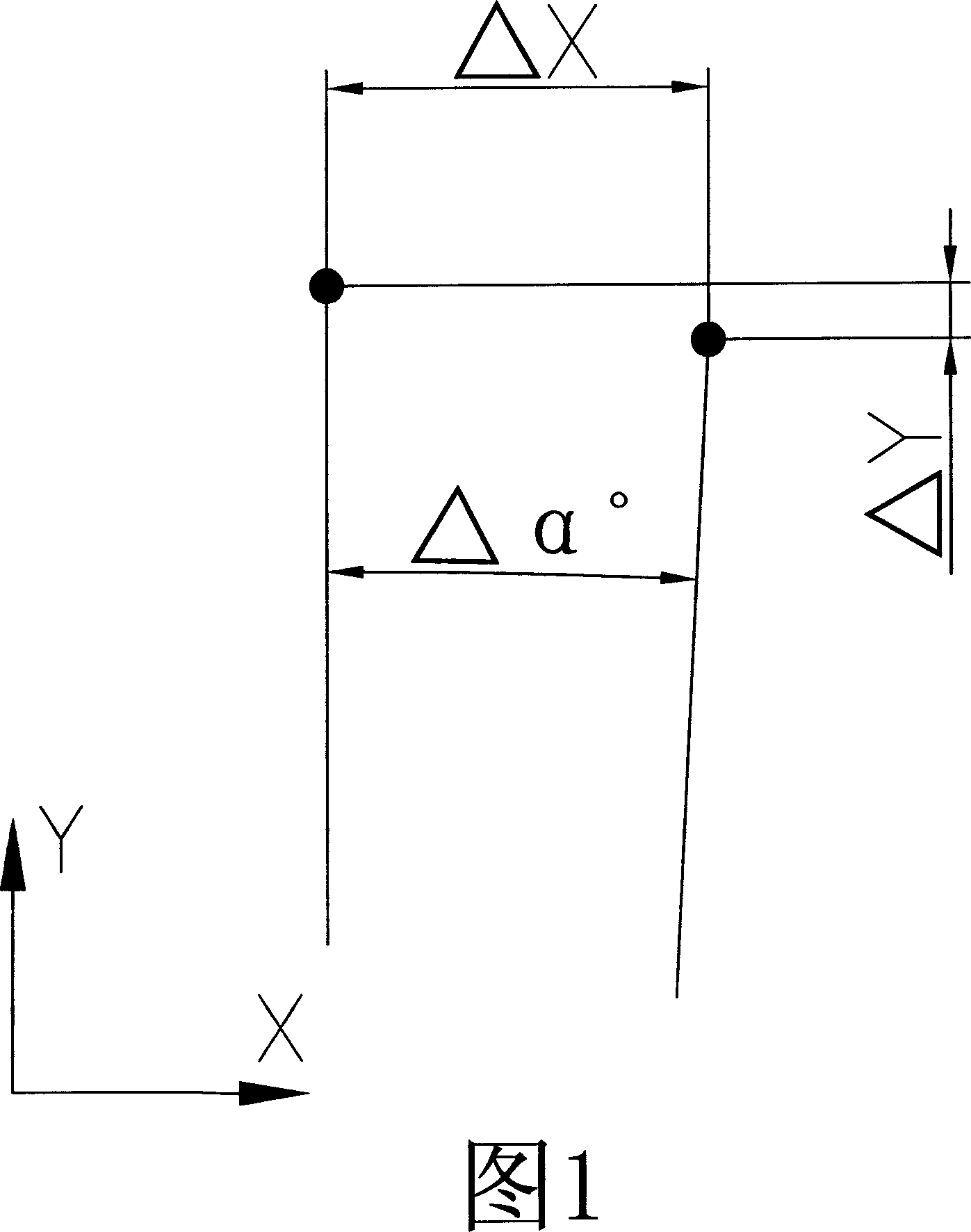

Automatic eccentric correcting method and device for machining hollow shaft

ActiveCN103624271ASimplify the operation processImprove efficiencyAuxillary equipmentTurning machinesEngineeringMechanical engineering

The invention relates to an automatic eccentric correcting method and device for machining a hollow shaft. The automatic eccentric correcting method comprises the following steps that the hollow shaft is fixed to a turning center; the X coordinate value and the Y coordinate value of the axial center of an eccentric inner hole of the hollow shaft are measured, and the eccentric amount of the eccentric inner hole is calculated; an inner hole chamfer is machined with the axial center of the eccentric inner hole as the benchmark; the hollow shaft is automatically pre-tightened to enable the axial center of the eccentric inner hole to coincide with the axial center of the turning center, and automatic eccentric correction is achieved; the outer circle of the hollow shaft is turned roughly; the inner hole of the hollow shaft is turned in a fine mode, and then eccentric correction is finished. The automatic eccentric correcting method and device for machining the hollow shaft can achieve automatic eccentric correction of the eccentric hollow shaft on the turning center, is simple in operation process and is high in efficiency, and the production efficiency is improved by 5-8 times compared with a manual method. The eccentric amount of the outer circle and the inner hole of the hollow shaft can be lowered to below 0.3mm, and the machining accuracy of the hollow shaft is largely improved.

Owner:CRRC QINGDAO SIFANG CO LTD

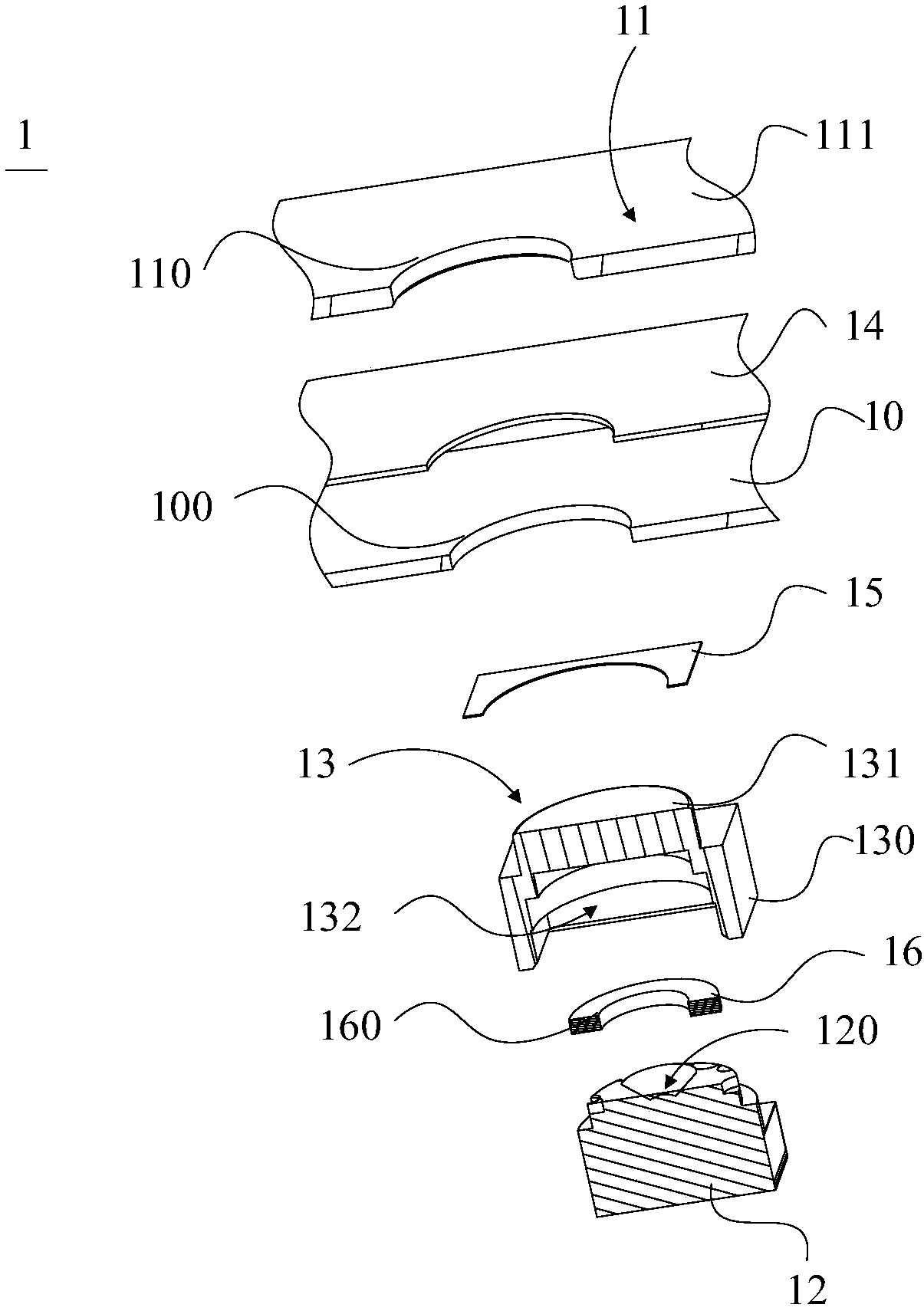

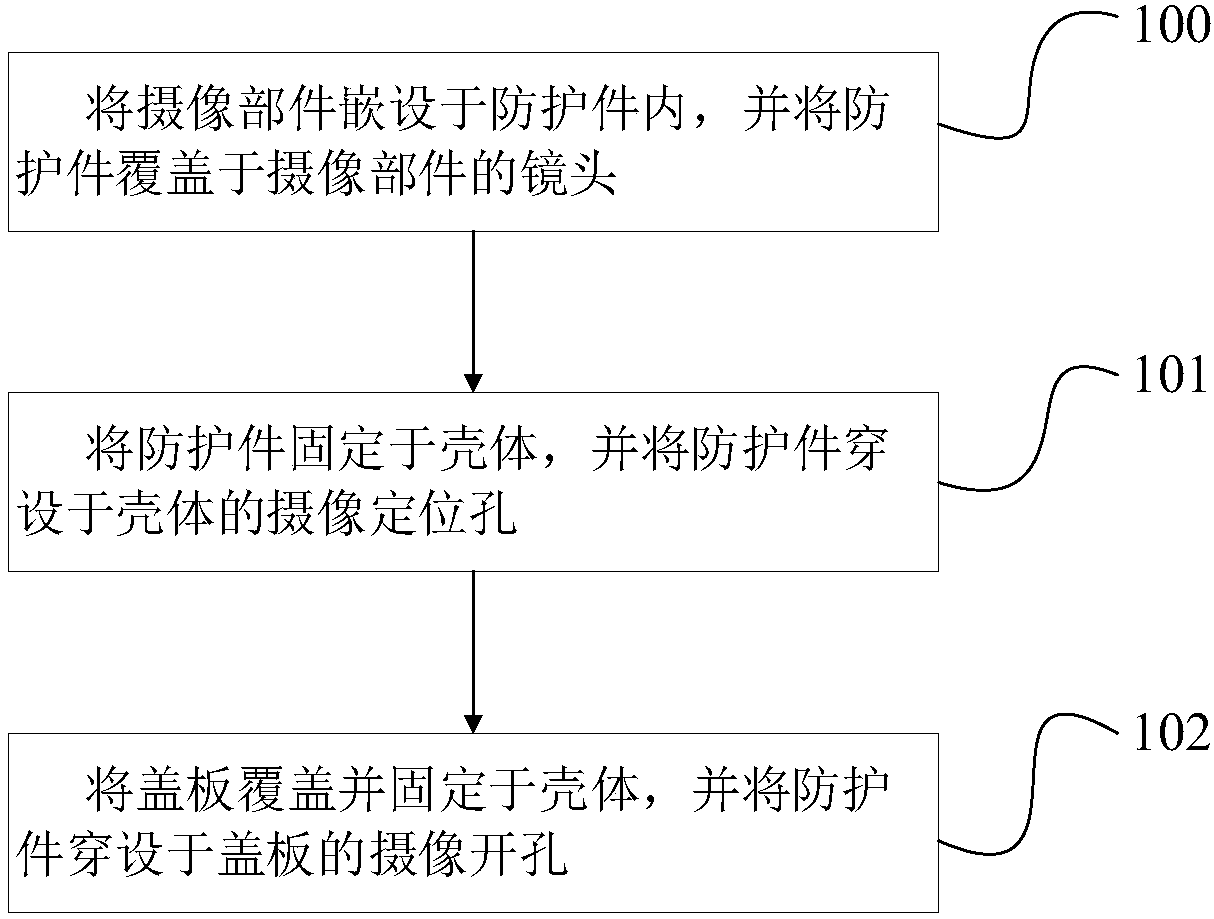

Camera module, mobile terminal, and method for assembling camera module

InactiveCN107707805AImprove assembly accuracyGood lookingTelevision system detailsColor television detailsCamera moduleEngineering

The invention discloses a camera module, a mobile terminal, and a method for assembling a camera module. The camera module includes a casing provided with a photographing positioning hole, a cover plate provided with a photographing hole, a photographing part, and a protective part. The photographing part is embedded into the protective part. The protective part is used for light to pass through,is fixed to the casing, and sequentially passes through the photographing positioning hole and the photographing hole. The assembling method includes the following steps: embedding the photographing part into the protective part; fixing the protective part equipped with the photographing part to the casing, and making the protective part pass through the photographing positioning hole of the casing; and covering the casing with the cover plate, fixing the cover plate to the casing equipped with the protective part, and making the protective part pass through the photographing hole of the coverplate. Through the setting of the protective part, the deviation of the photographing part from the photographing hole of the cover plate is reduced, the concentricity between the photographing partand photographing hole is ensured, and the assembly precision of the camera module and the mobile terminal is improved.

Owner:SHANGHAI MORUAN COMM TECH

Auto entry guide

Systems and methods for guiding a seal assembly associated with a string of production tubing, or a tubular member generally, into a receptacle within a wellbore. The muleshoe of a seal assembly is provided with an auto entry guide device in the form of a guide member or kickover lug that is radially moveable with respect to the muleshoe. The kickover lug is collapsible radially inwardly and biased radially outwardly. The auto entry guide device may also include a centralizer bowspring that is mounted upon the muleshoe. Additionally, the muleshoe is mounted for rotational movement with respect to the seal assembly.

Owner:BAKER HUGHES INC

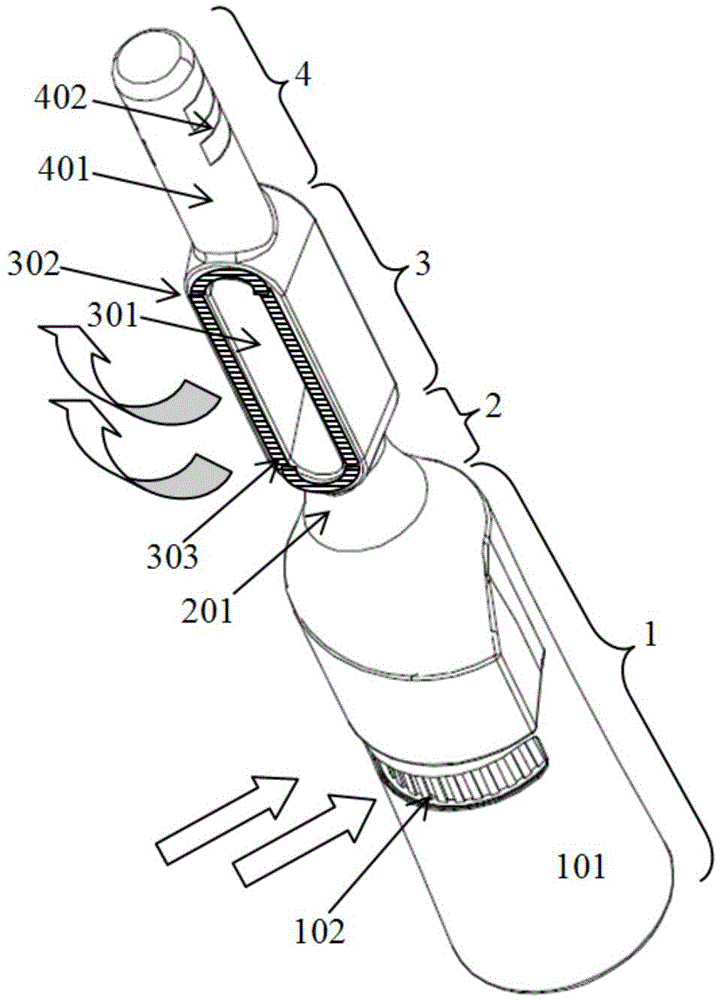

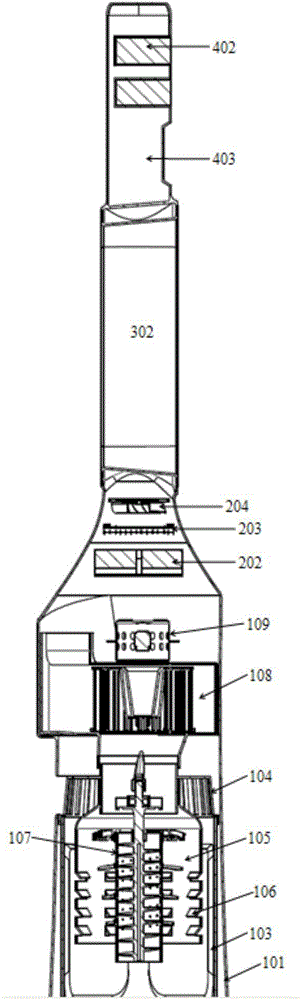

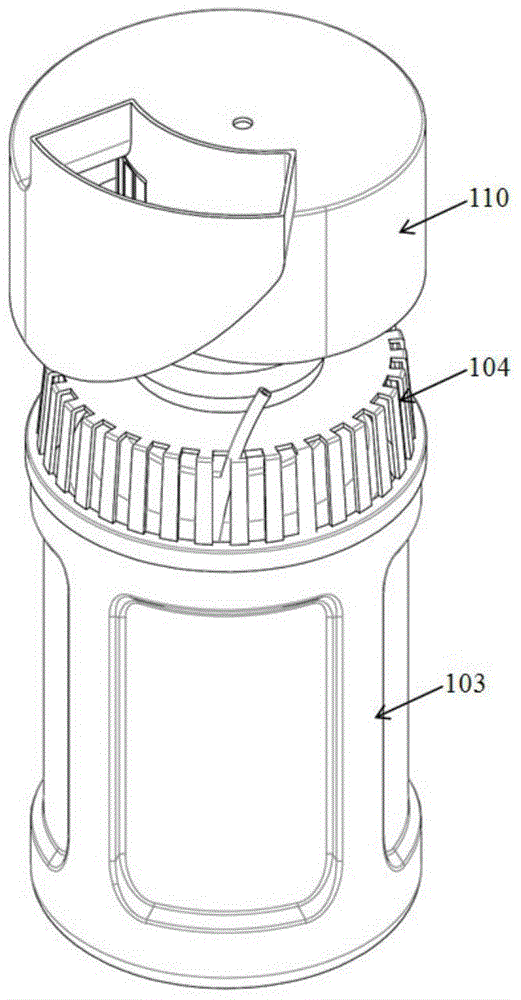

Air purifying device

ActiveCN104566648AImprove solubilityAchieve multiple touchMechanical apparatusLighting and heating apparatusHigh concentrationAir volume

The invention provides an air purifying device. The air purifying device comprises a dissolving-purifying unit, a boosting-sterilizing unit, a purifying-ventilating unit and an illuminating-displaying unit, wherein the dissolving-purifying unit is connected to the boosting-sterilizing unit; the boosting-sterilizing unit is connected to the purifying-ventilating unit; the illuminating-displaying unit is arranged on the purifying-ventilating unit. According to the air purifying device, a spraying atomizer capable of spraying purified water into high-concentration water mist is arranged in the dissolving-purifying unit for the first time, so that the dissolving degree of contaminated air in water mist is increased greatly, and the purifying effect is ensured; meanwhile, a turbine boosting structure and a ventilation unit are designed innovatively, so that the purification ventilation strength is enhanced, and sufficient air volume and air pressure are ensured; moreover, the functions of water mist purification, filtering-dust removing, ultraviolet sterilization, ozone disinfection, illumination and the like are integrated innovatively, so that the overall performance of the air purifying device is enhanced greatly, and the air purifying device has greater market competitiveness.

Owner:开平精锐电子有限公司

Motor for an electric power steering apparatus

ActiveUS20110278995A1Reduce the amount requiredNoise be amplifiedSynchronous generatorsAssociation with control/drive circuitsElectric power steeringThree-phase

Provided is a motor for an electric power steering apparatus, in which vibrations and noises are suppressed. The motor for an electric power steering apparatus includes: a motor section (1) for outputting an assist torque to a handle of a vehicle; and a controller (2) for controlling driving of the motor section (1). The motor section (1) includes: a rotor (14, 14A) having P poles; and a stator (15, 15A) provided so as to surround the rotor (14, 14A), the stator including: a stator core (23) provided with n slots formed thereon and housed in a frame (4); and three-phase stator windings (25) wound around the slots (22). The controller (2) is provided between a boss (18) and the motor section (1) so as to surround the output shaft (12).

Owner:MITSUBISHI ELECTRIC CORP

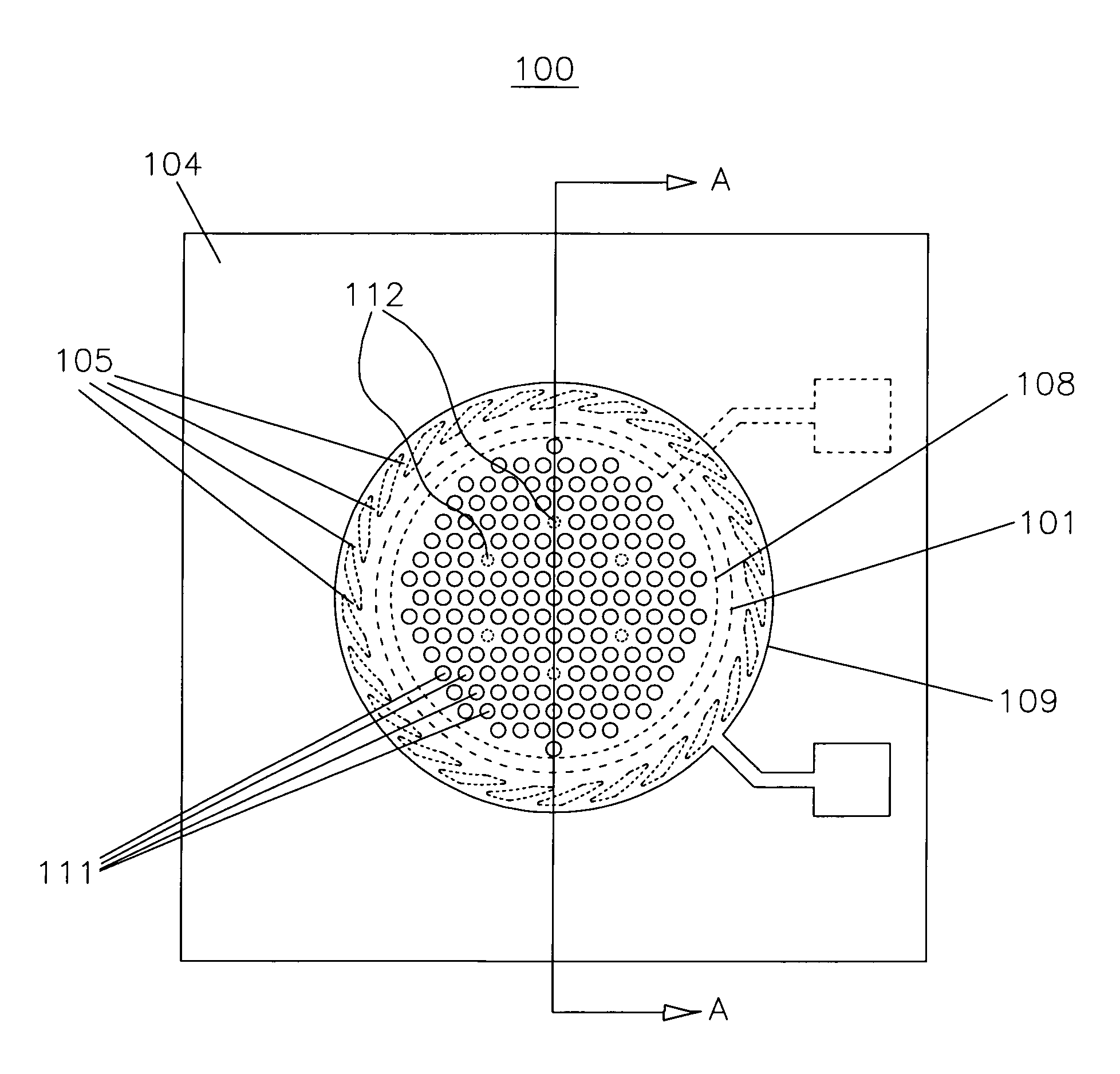

Radio frequency identification tag

InactiveUS20090085751A1Stable communication characteristicReduce the amount requiredAccessories for auxillary signalsRecord information storageEngineeringRadio frequency

An RFID tag having mounted thereon an IC chip capable of receiving and delivering information from and to an external source without contact. In the RFID tag, a central axis of its own antenna having mounted thereon the IC chip coincides with a center of the RFID tag, and an antenna width is controlled. That is, a position of the central axis of the antenna is controlled to correct the mass eccentricity of the RFID tag. Further, the RFID tag is an RFID tag having mounted thereon the IC chip capable of receiving and delivering information from and to an external source without contact, and an RFID tag having attached thereon the IC chip at a position in which a first and a second antenna lengths are different from each other.

Owner:HITACHI LTD

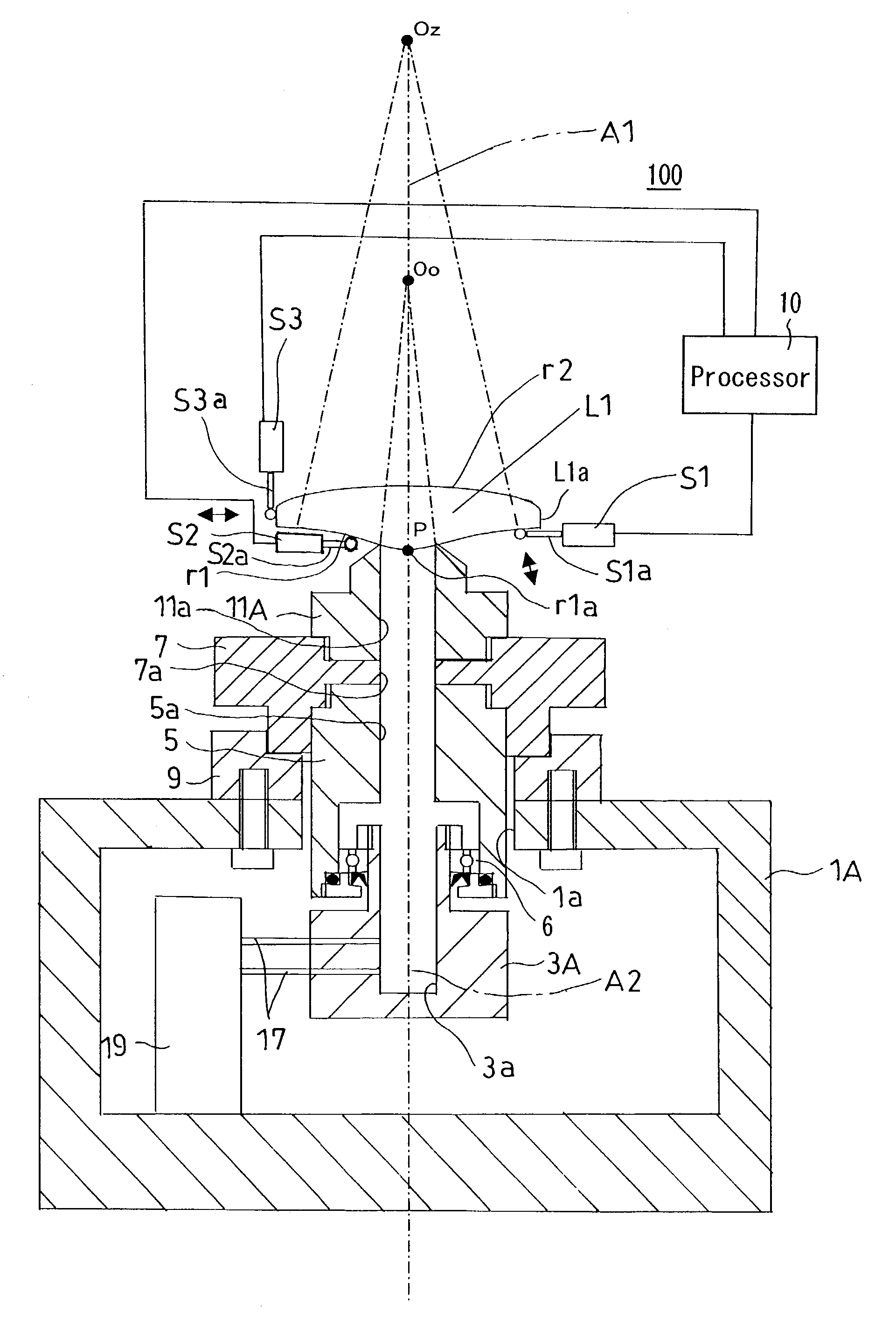

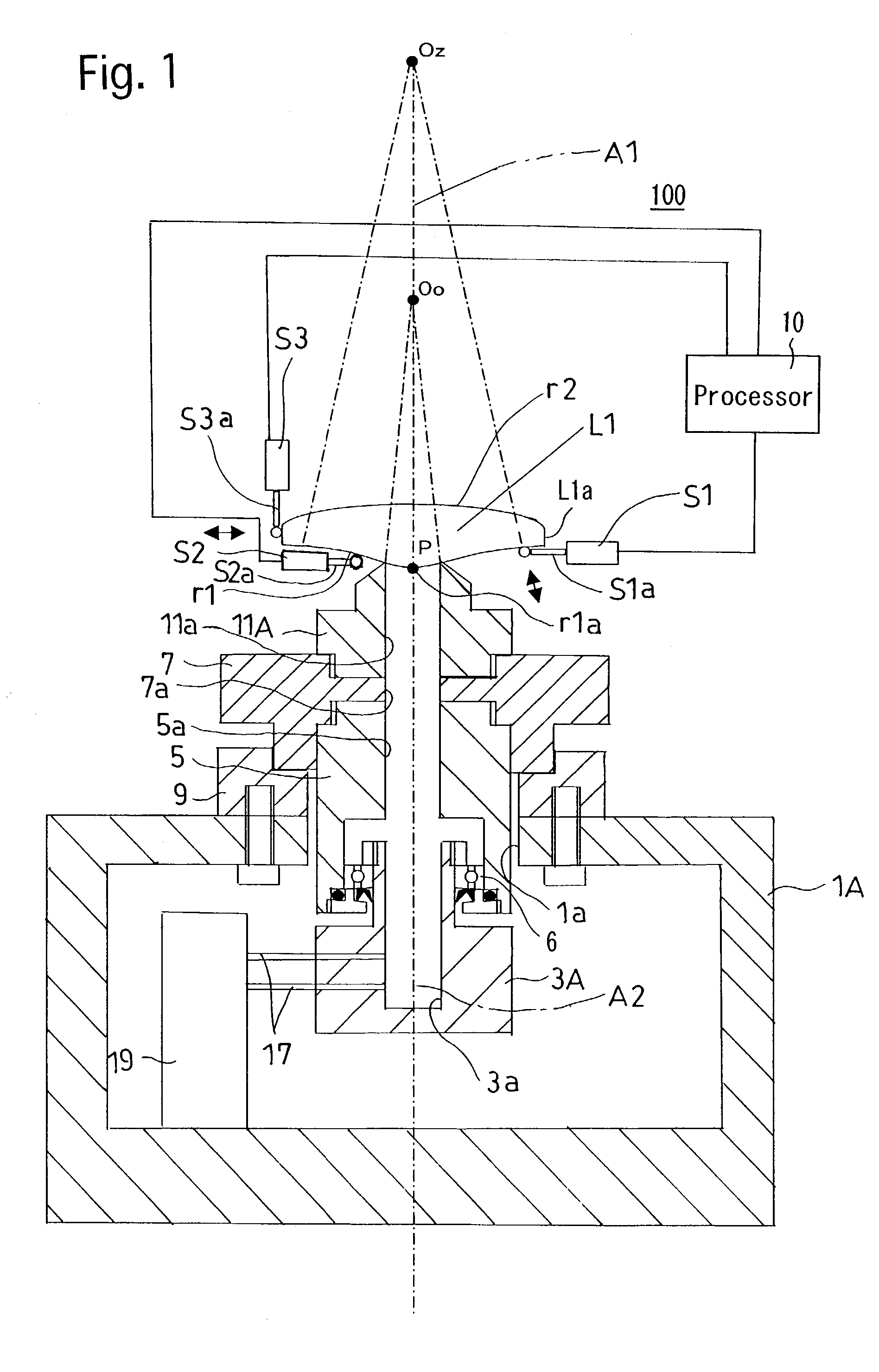

Method and apparatus for measuring eccentricity of optical lens, and method and apparatus for centering and edging optical lens

InactiveUS7046351B2High precisionReduce eccentricityOptical articlesUsing optical meansRotational axisOptics

An apparatus for measuring eccentricity of an optical lens includes a rotary lens holder which supports a first lens surface of an optical lens by vacuum aspiration; a first determining device for determining whether a curvature center of a central portion of the first lens surface is positioned on the rotational axis; a second determining device for determining whether a curvature center of a peripheral portion of the first lens surface is positioned on the rotational axis; and an eccentricity detection device which detects an eccentricity of the optical lens with respect to the rotational axis to calculate an eccentricity of a vertex of the first lens surface with respect to the radial center of the optical lens, including a detector contacts a rim of the optical lens to detect the eccentricity of the optical lens with respect to the rotational axis.

Owner:ASAHI KOGAKU KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com