Washing machine with active water injection balancing ring and control method thereof

A balancing ring and washing machine technology, which is applied to the control device of washing machines, other washing machines, household appliances, etc., can solve the problems of wasteful motor drive energy consumption, inability to adjust the load eccentricity of washing machines, etc., so as to reduce the production process and cost, and shorten dehydration Time, the effect of eliminating eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

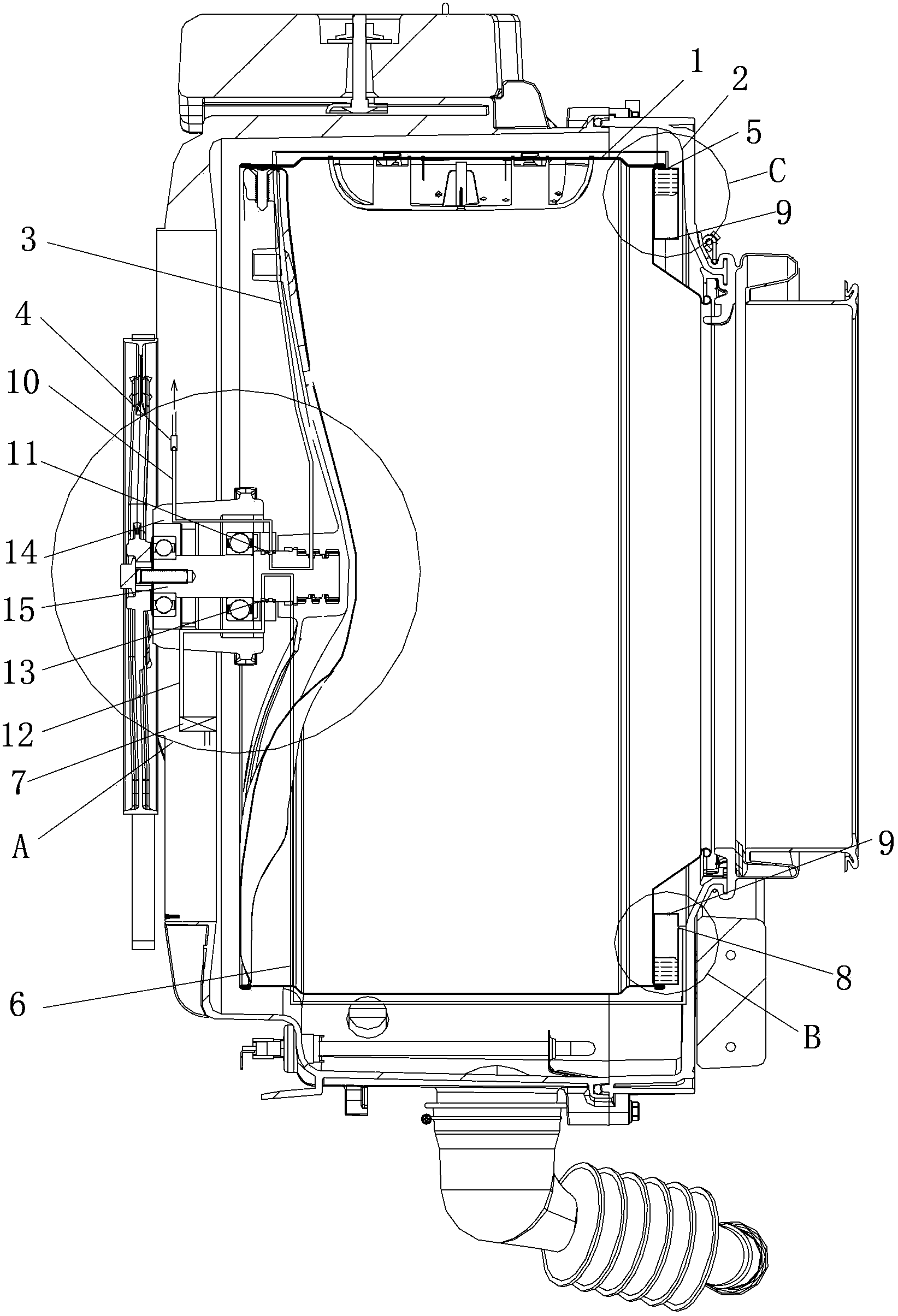

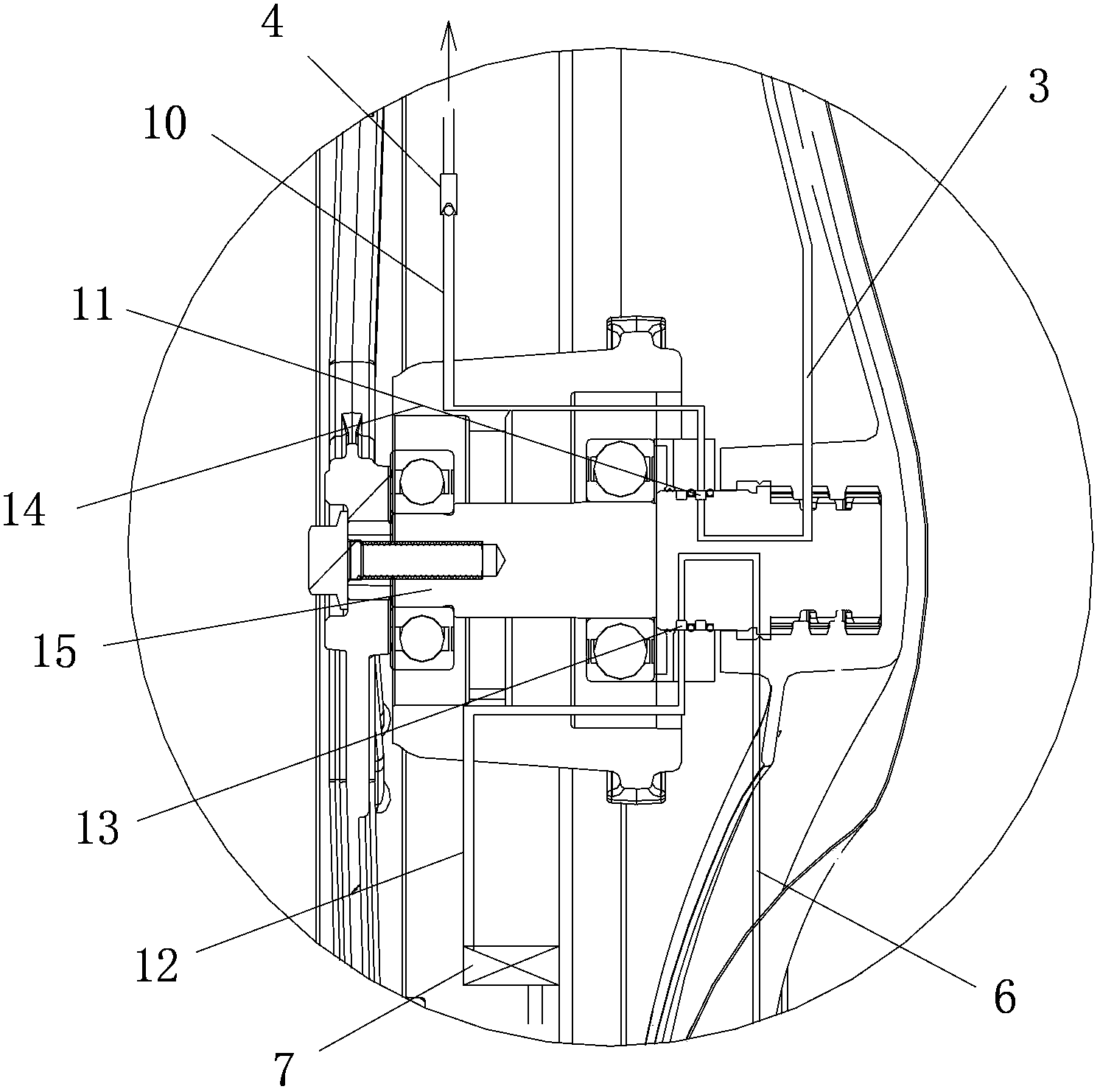

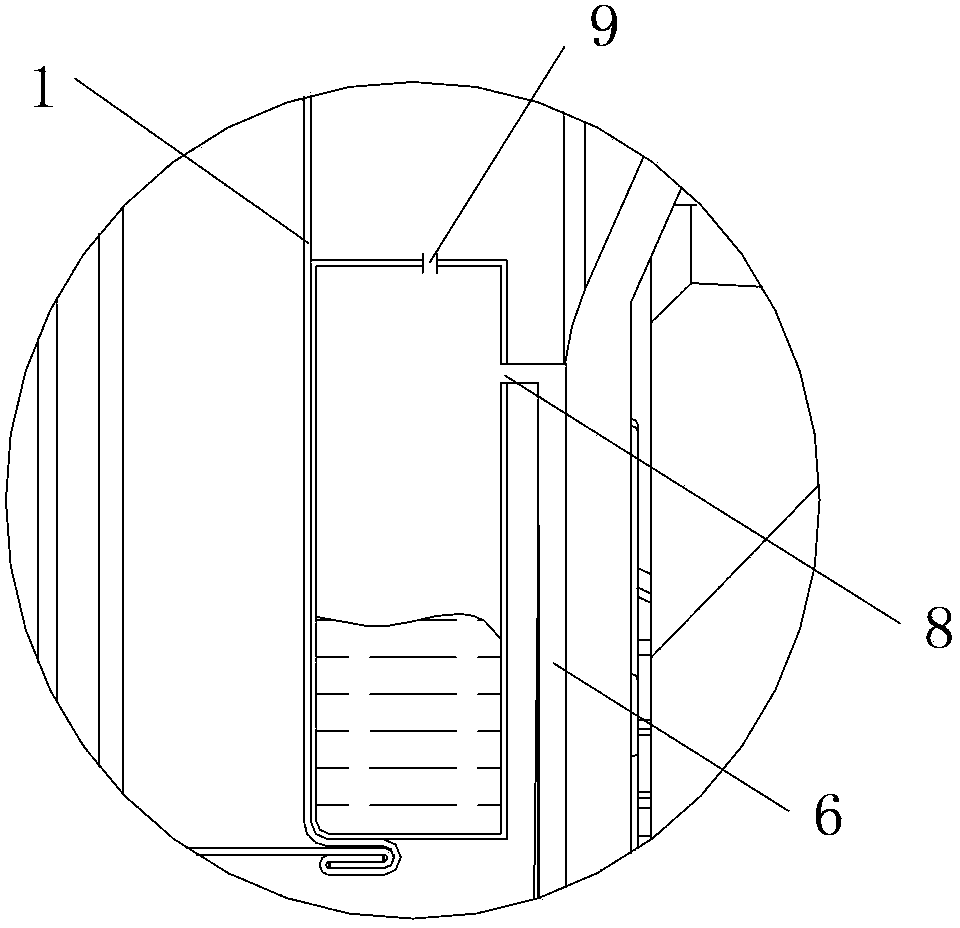

[0033] Such as figure 1 As shown, a washing machine with an active water injection balance ring according to the present invention, the washing machine includes an outer cylinder 2, an inner cylinder 1, and a balance ring is provided at the opening of the inner cylinder 1, and the balance ring is a circular structure, and the balance ring is balanced. The inside of the ring is a hollow chamber, and the washing machine is also equipped with a water inlet structure for filling the hollow chamber to balance the load eccentricity and a drainage structure for discharging the water in the balance ring. The size injects water into the balance ring through the above water inlet structure to balance the load eccentricity (see Figure 5 ), after the dehydration is completed, the water in the balance ring is discharged through the above-mentioned drainage structure. When washing and rinsing, the washing machine does not need to drive the filling in the balance ring to rotate, reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com