Online finishing and morphology detecting device for grinding wheel for performing ultrasonic electrolytic combined grinding on inner circles

A detection device and a grinding wheel shaping technology, which are used in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc. Nano surface and other problems, to avoid the effect of excessive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

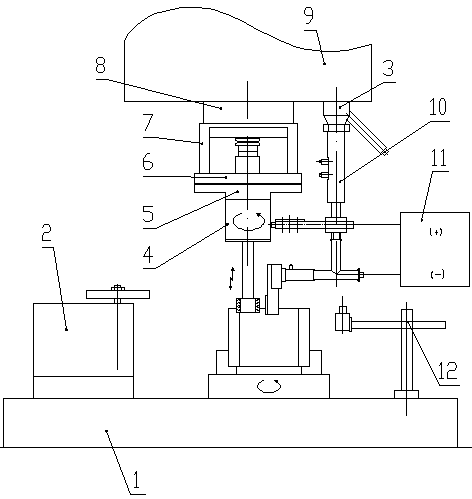

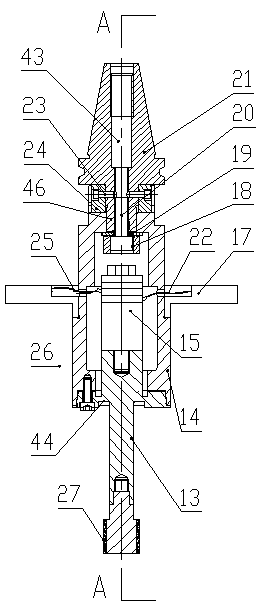

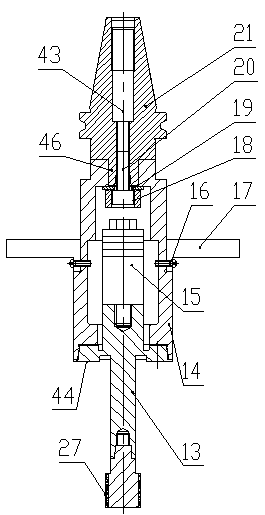

[0027] Such as Figure 1-Figure 6 As shown, the ultrasonic electrolytic composite grinding inner circle grinding wheel on-line dressing and shape detection device of the present invention includes a machine tool workbench 1 and a machine tool spindle 8, and the machine tool workbench 1 is provided with a grinding wheel shaping machine with variable frequency speed regulation. The device 2 and the movable on-line observation device 12 for observing the surface topography of the grinding wheel, the machine tool spindle 8 is provided with an ultrasonic vibrating tool system 4, the machine tool spindle 8 is provided with an outer ring fixing sleeve 9, and an outer ring fixing sleeve 9 An ELID on-line sharpening device 10 that rotates synchronously with the machine tool spindle 8 is installed on it. The ultrasonic vibrating tool system 4 and the ELID on-line sharpening device 10 are located between the grinding wheel shaping device 2 and the grinding wheel profile on-line observatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com