On-line Dressing and Shape Detection Device for Grinding Wheels Used in Ultrasonic Electrolytic Composite Grinding

A detection device and grinding wheel shaping technology, applied in the direction of abrasive surface adjustment devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of inability to obtain roughness values efficiently, easy to scratch workpieces, and easy clogging of grinding wheels and other issues to achieve the effect of avoiding excessive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

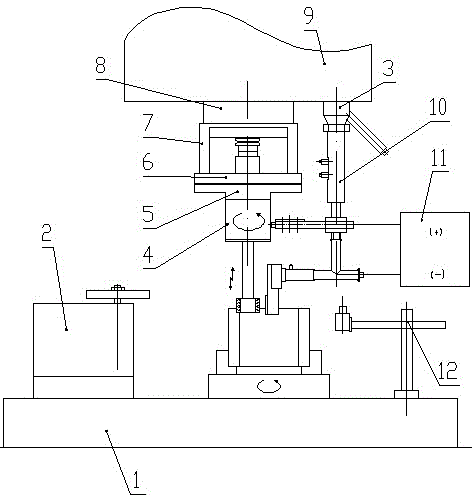

[0027] Such as Figure 1-Figure 6 As shown, the online grinding wheel dressing and shape detection device for ultrasonic electrolytic composite grinding inner circle of the present invention includes a machine tool workbench 1 and a machine tool spindle 8, and the machine tool workbench 1 is provided with a frequency-variable speed-regulating grinding wheel shaping device 2 and a movable on-line observation device 12 for observing the surface topography of the grinding wheel. The machine tool spindle 8 is provided with an ultrasonic vibrating tool system 4 . An ELID online sharpening device 10 that rotates synchronously with the machine tool spindle 8 is provided. The ultrasonic vibrating tool system 4 and the ELID online sharpening device 10 are located between the grinding wheel shaping device 2 and the grinding wheel profile online observation device 12 .

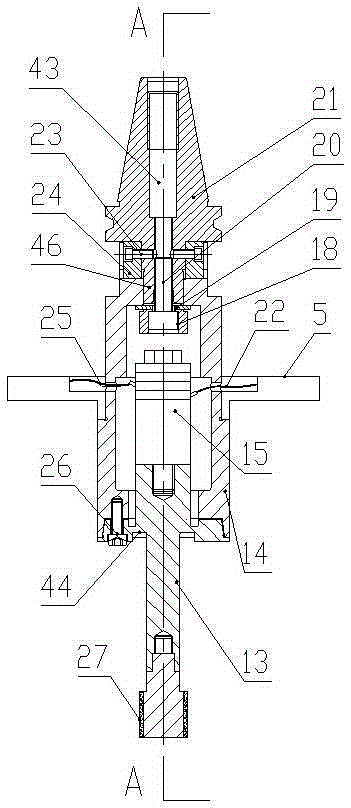

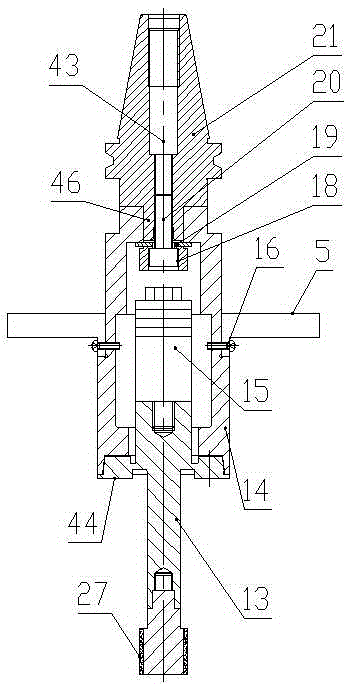

[0028] The machine tool spindle 8 is vertically arranged, and the ultrasonic vibrating tool system 4 includes a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com