Washing machine with water filling port type balancing ring and control method thereof

A control method and technology of a gimbal ring, which are applied to the control device of a washing machine, other washing machines, household appliances, etc., can solve the problems of inability to adjust the load eccentricity of the washing machine, waste motor drive energy consumption, etc., and achieve shortened dehydration time, simple structure, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

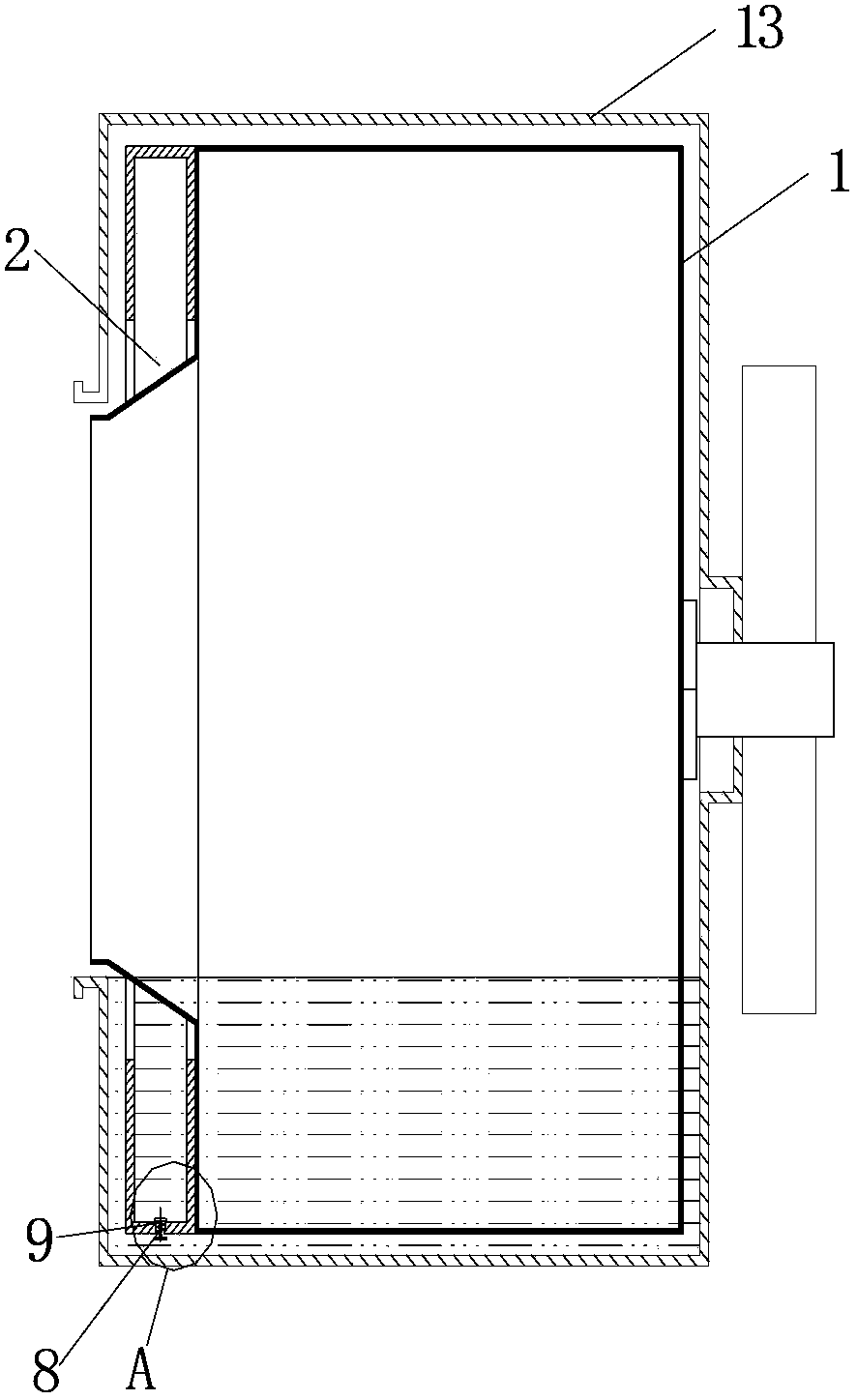

[0050] Such as figure 1 , figure 2 As shown, the washing machine with the water injection port balance ring described in this embodiment is a drum washing machine, and the water injection port balance ring is embedded in the inner cylinder 1. The diameter is greater than the diameter of the water injection port of the inner cylinder 1 to ensure that the washing water can enter the inside of the balance ring.

[0051] In this embodiment, there is no water injection part 5 and drain pump 4, the balance ring partly enters the washing water, and part of the washing water is inside the balance ring, and part of the washing water is taken away when the balance ring rotates, and is taken away when the balance ring rotates at a high speed The washing water inside the balance ring will cling to the outer circumference and rotate together with the balance ring to balance the load eccentricity (see Figure 5 ).

[0052] The washing water in the washing machine described in this embod...

Embodiment 2

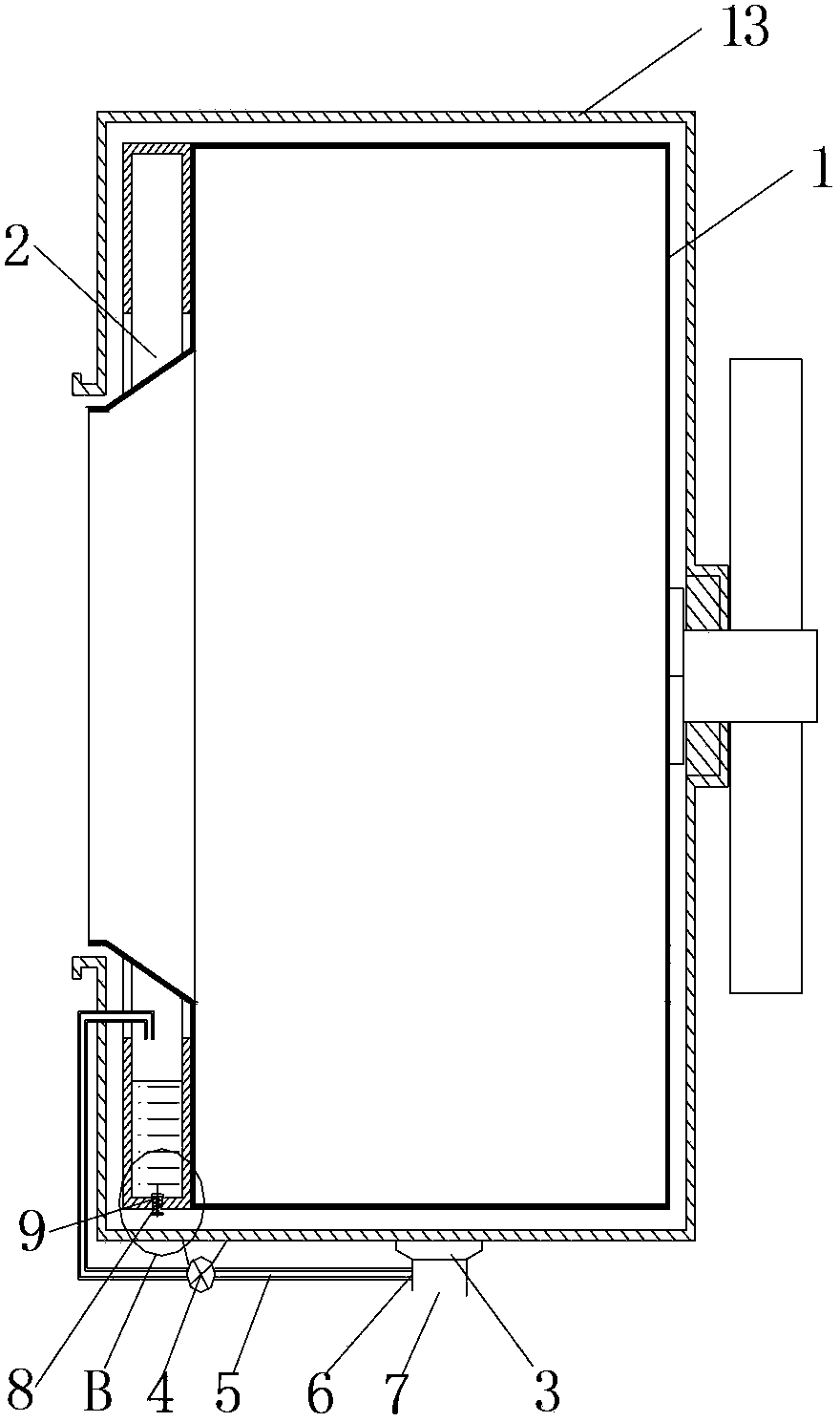

[0054] Such as image 3 , Figure 4 As shown, the washing machine with the water injection port balance ring described in this embodiment is a drum washing machine, and the balance ring is arranged at the clothes insertion port of the inner cylinder 1 of the washing machine. The balance ring is a circular structure, and the inside of the balance ring is along A water injection port 2 is provided around the inner circle for washing water to enter the balance ring to balance the eccentricity of the inner cylinder 1 load. The water injection port is a ring of water injection ports distributed on the inner circumference of the annular balance ring. The water injection part 5 is fixed and can be arranged at the bottom of the washing machine. When the inner cylinder 1 rotates, the water injection part 5 and the balance ring Relative rotation takes place, but the water injection part 5 can stretch into the balance ring inside all the time. During the washing and rinsing process of ...

Embodiment 3

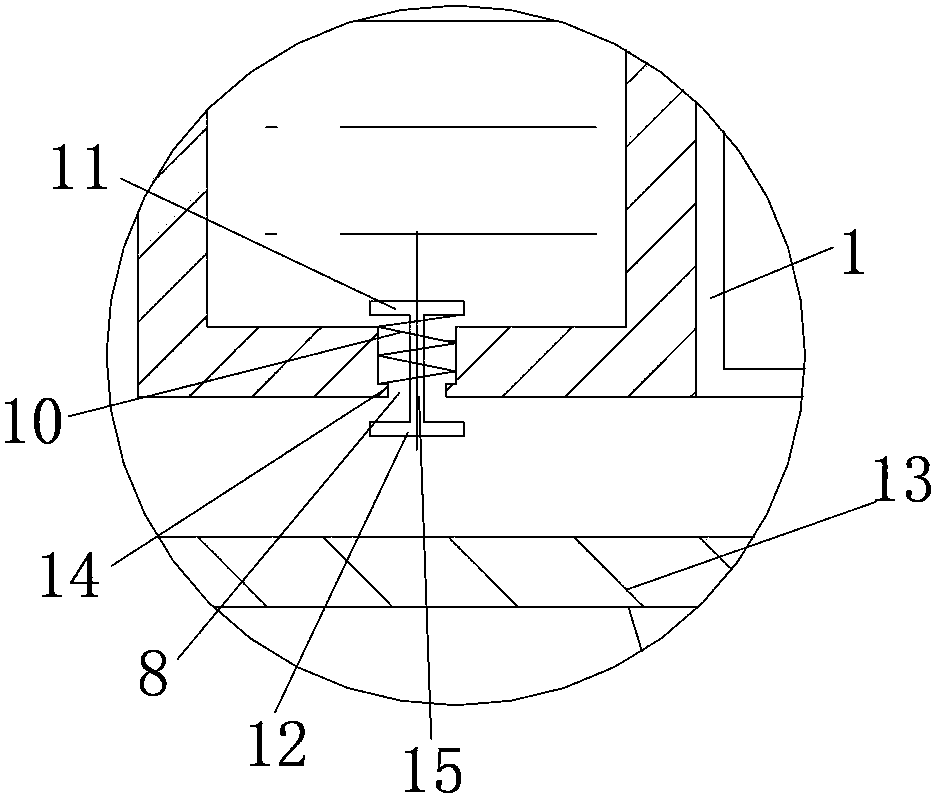

[0060] Such as figure 2 As shown, the drain valve in this embodiment includes a spring 10, a blocking piece 11 and a second blocking piece 12 located at both ends of the spring, a connecting piece 15 is arranged between the blocking piece 11 and the second blocking piece 12, and the spring 10 is sleeved on the On the connector 15, the spring 10 and the connector 15 are located in the drain port 8, one end of the spring 10 is connected to the outer end of the drain port 8, and the other end is connected to the baffle 11, the baffle 11 is located inside the balance ring, and the second gear Sheet 15 is positioned at balance ring outside, and there is certain distance between catch piece 11 and balance ring inner wall, and the outside of the outlet 8 of balance ring is provided with positioning, the clamping projection 14 of fixed spring 10, and spring 10 is connected with clamping projection 14.

[0061] The shape of the baffle 11 matches the shape of the water outlet 8, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com