Automatic eccentric correcting method and device for machining hollow shaft

An automatic deviation correction and hollow shaft technology, applied in the field of mechanical processing, can solve problems such as low efficiency, low precision, and cumbersome methods, and achieve the effects of high efficiency, improved machining accuracy, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

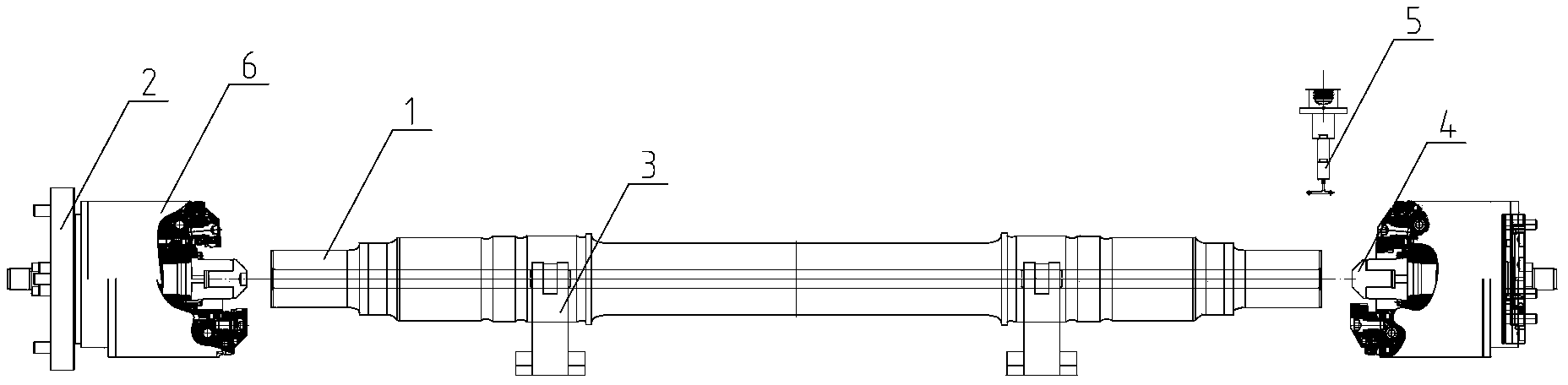

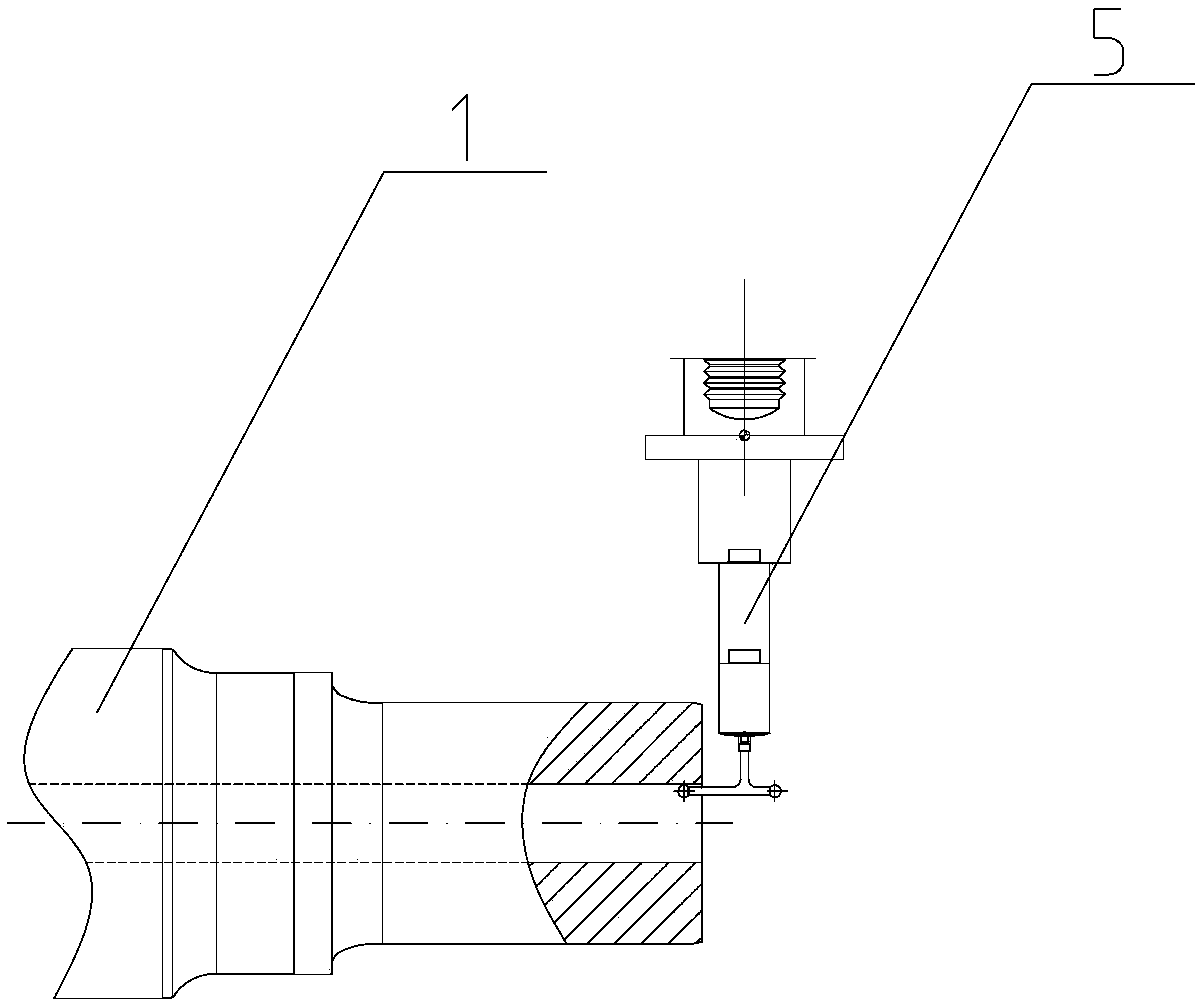

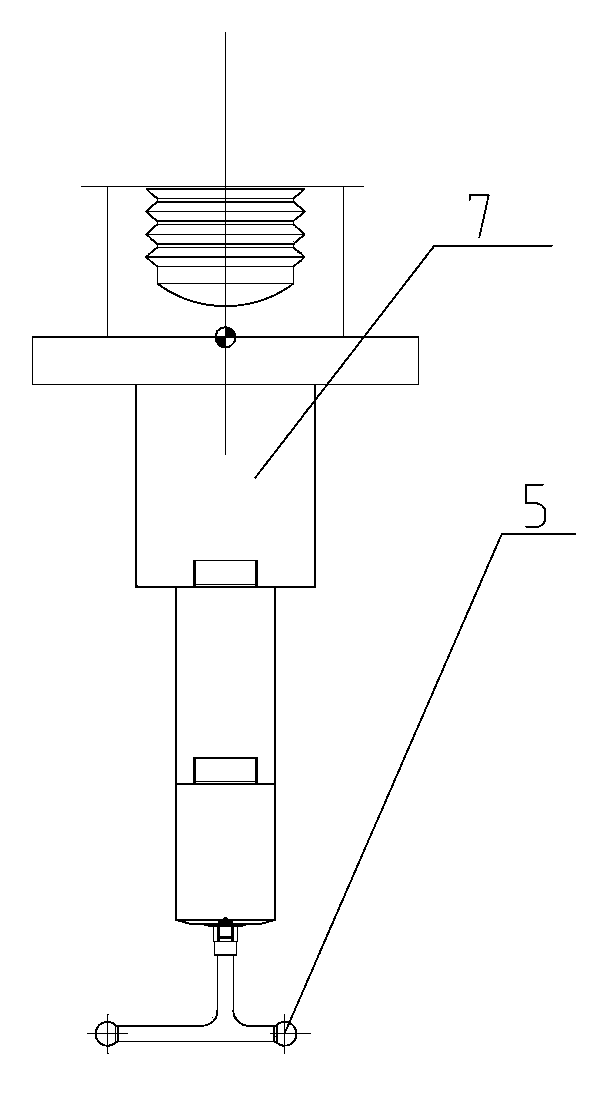

[0030] like figure 1 As shown, an automatic deviation correction device for hollow shaft processing is installed on the turning machining center 2 of the hollow shaft 1, the hollow shaft 1 refers to the hollow axle used on the rail vehicle, and the turning machining center 2 is used to realize the positioning of the hollow shaft 1, The machining of the outer circle and the inner hole of the hollow shaft 1. In this embodiment, the axis of the turning machining center 2 refers to the axis of the main shaft 6 of the turning machining center, and the central axis of the main shaft 6 is the rotation axis of the main shaft 6 . The hollow shaft 1 preliminarily processed by the turning machining center 2 generally has an eccentricity of more than 0.4mm on one side of the drilling.

[0031] like figure 1 As shown, there are two center frames 3 on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clamping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com