Washing machine

a washing machine and drum technology, applied in the field of washing machines, can solve the problems of significant noise in the drum, bothersome users, and vibration of the drum, and achieve the effects of reducing noise, rapid dehydration, and reducing eccentricity of the drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, exemplary embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

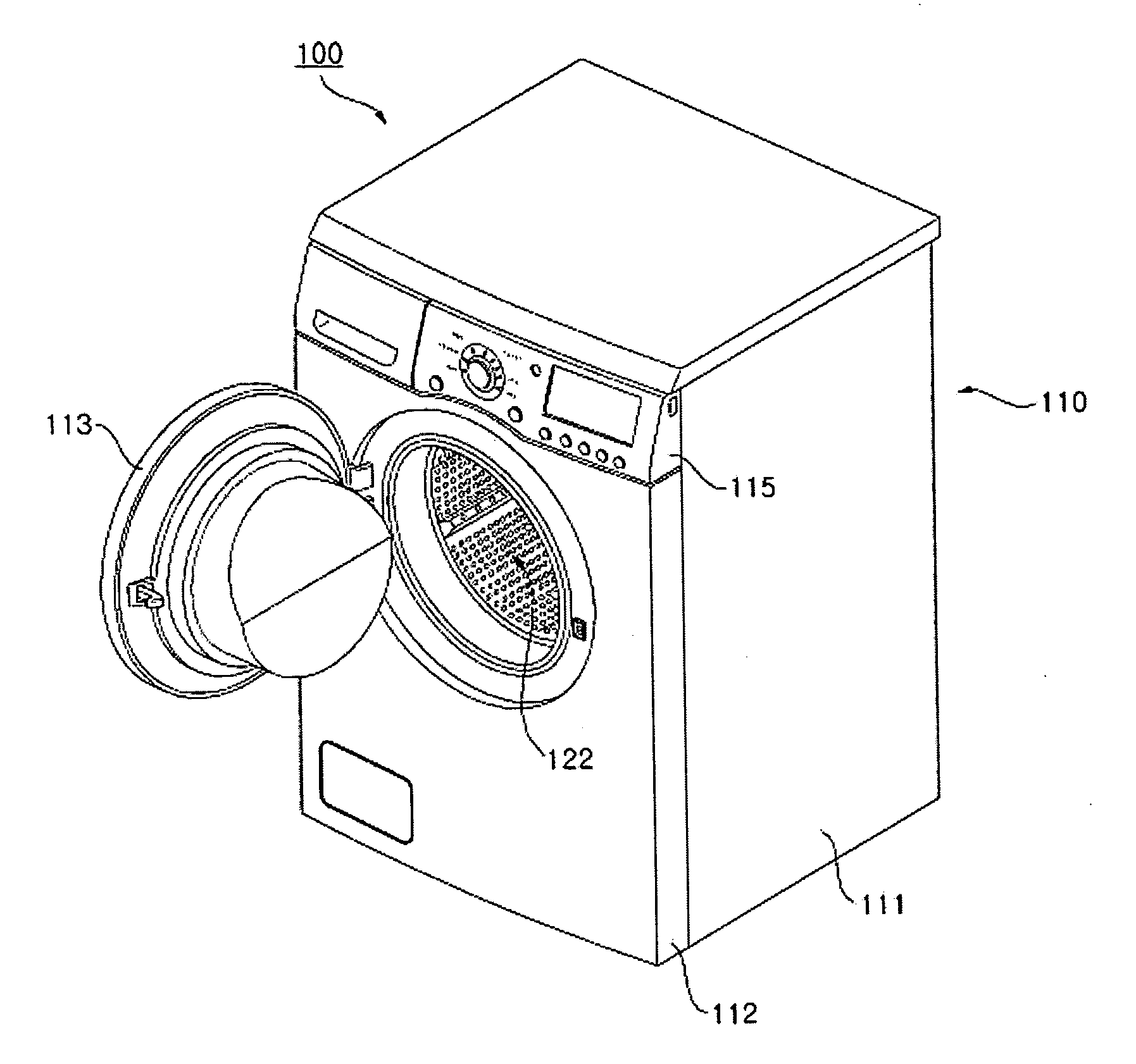

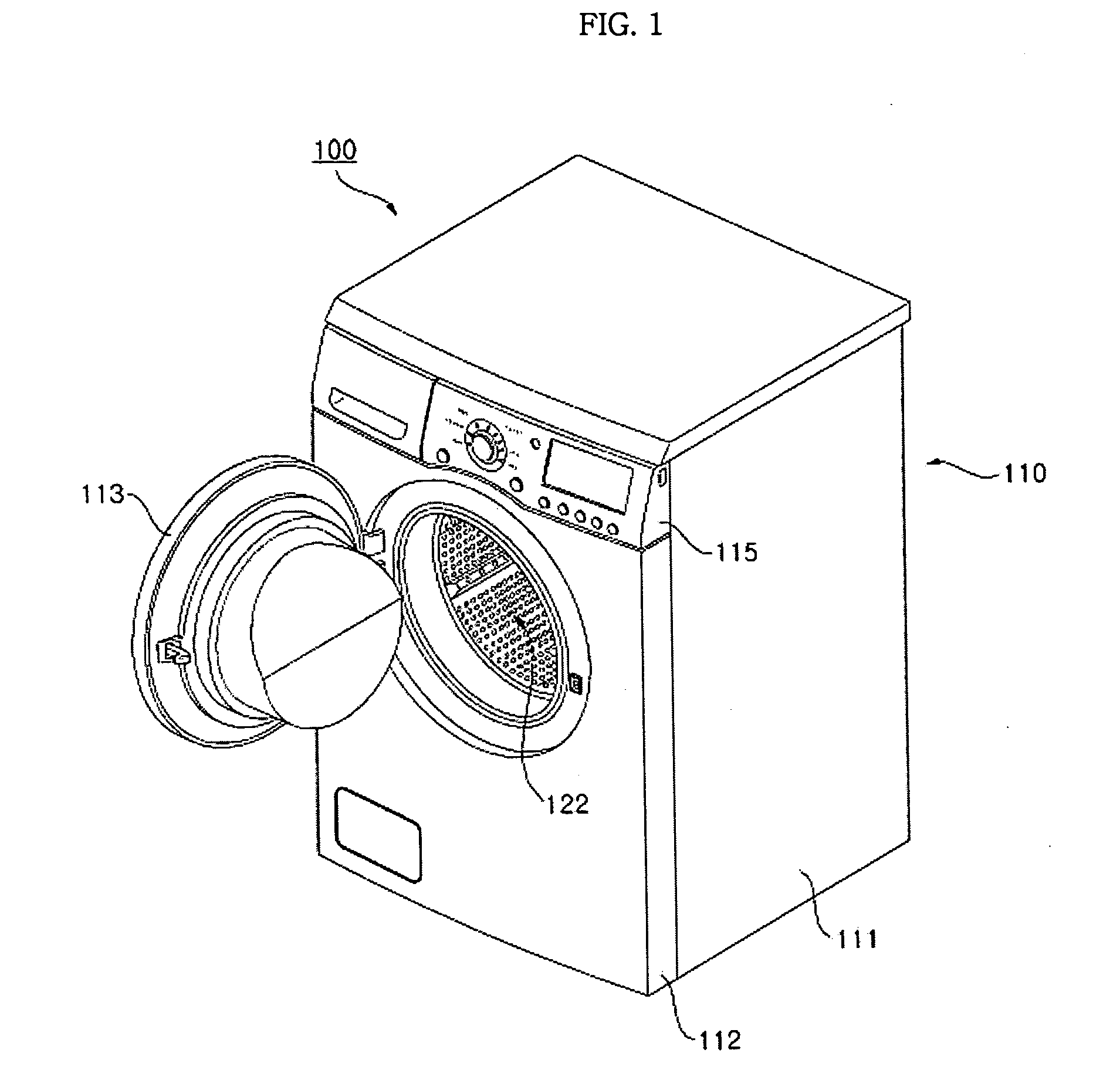

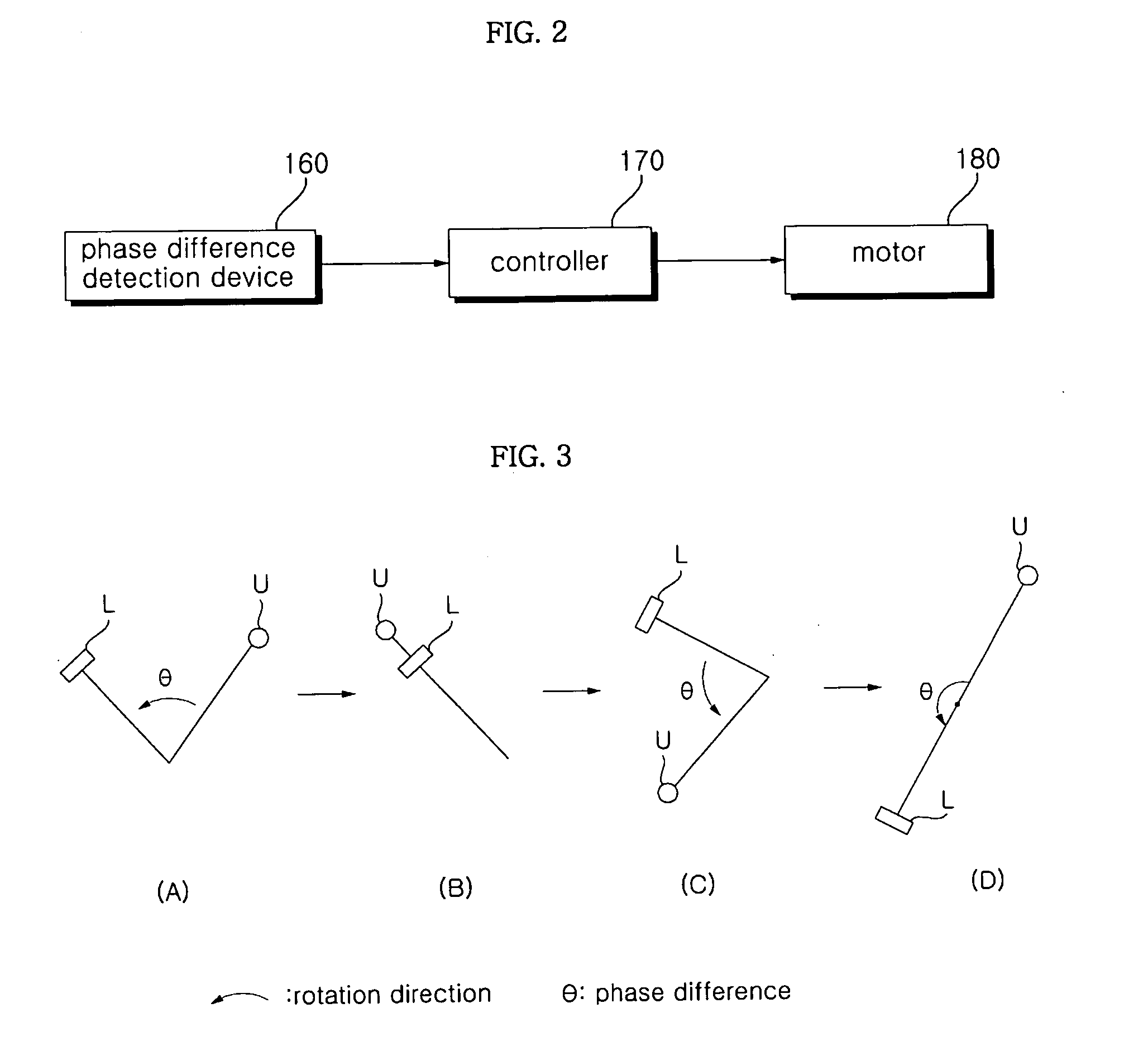

[0023]FIG. 1 is a perspective view illustrating a washing machine 100 according to an exemplary embodiment of the present invention. FIG. 2 is a block diagram illustrating an example of control flow of the washing machine 100 of FIG. 1.

[0024]Referring to FIG. 1, the washing machine 100 includes a cabinet 110, having a drum 122 disposed within the cabinet 110 for washing laundry therein, a washing water supply device (not shown) for injecting washing water to the drum, and a drainage device (not shown) for discharging the washing water to the outside after a washing cycle is terminated in the drum 122. A tub (not shown) may be disposed within the cabinet 110, which surrounds the drum 122.

[0025]A driving device (not shown) may also be included for delivering the rotary power to the drum 122 wash, rinse and dehydrate the laundry. The drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com