Encapsulation structure and method of the high-speed semiconductor light emission component

A technology of light emission components and packaging structures, which is applied in the manufacture of semiconductor devices, semiconductor lasers, semiconductor/solid-state devices, etc., can solve problems such as difficult to achieve high speed, achieve the effect of reducing eccentricity, reducing load, and facilitating debugging and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

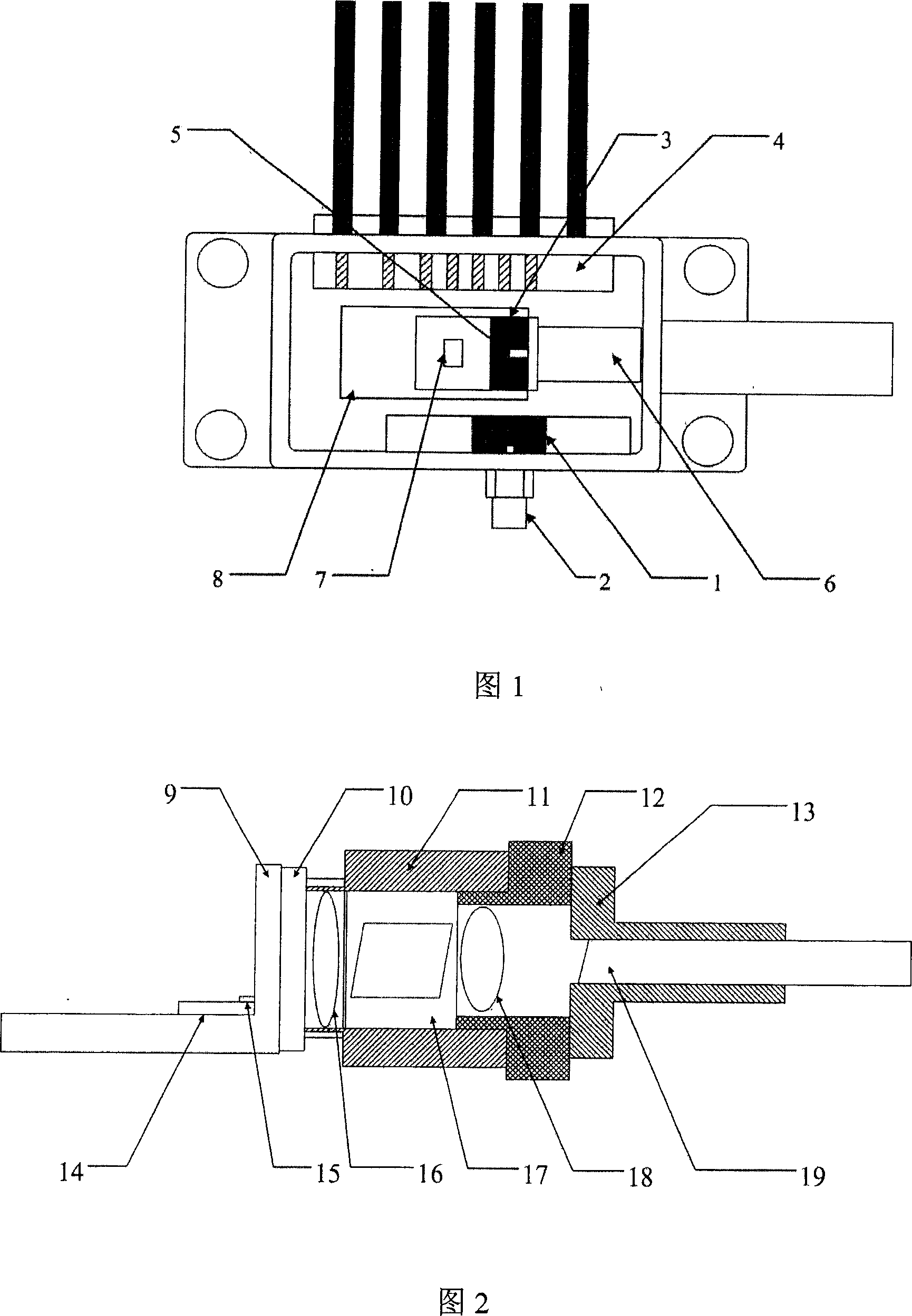

[0044] The packaging structure of the present invention in Fig. 1 uses two separate heat sinks to realize the low-loss input of radio frequency signals from the radio frequency connector to the light emitting device. The two heat sinks are operated separately and finally connected by gold wires or gold ribbons, so that The difficulty of packaging operation is reduced, and the packaging yield is improved. 1 is a dielectric substrate with a coplanar waveguide transmission line (denoted as CPWI) connected to the radio frequency connector; 3 is a coplanar waveguide transmission line (denoted as CPW2) for inputting high-frequency signals to the light emitting device, matching resistors and Dielectric heat sink substrate for DC wiring electrodes; the substrate material can be ceramic materials such as alumina, aluminum nitride, beryllium oxide, high-resistance silicon wafers, etc., but not limited to these; the back of the substrate is metallized and can have sides Metallization and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com