Stratiform bimetal hydroxide for growing carbon nano-fibers and preparation method thereof

A layered bimetallic and carbon nanofiber technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, fiber chemical characteristics, chemical instruments and methods, etc., can solve the difficult-to-control and easy-to-aggregate particle size of metal particles , high preparation cost and other issues, to achieve the effect of simple operation, uniform distribution of active components and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

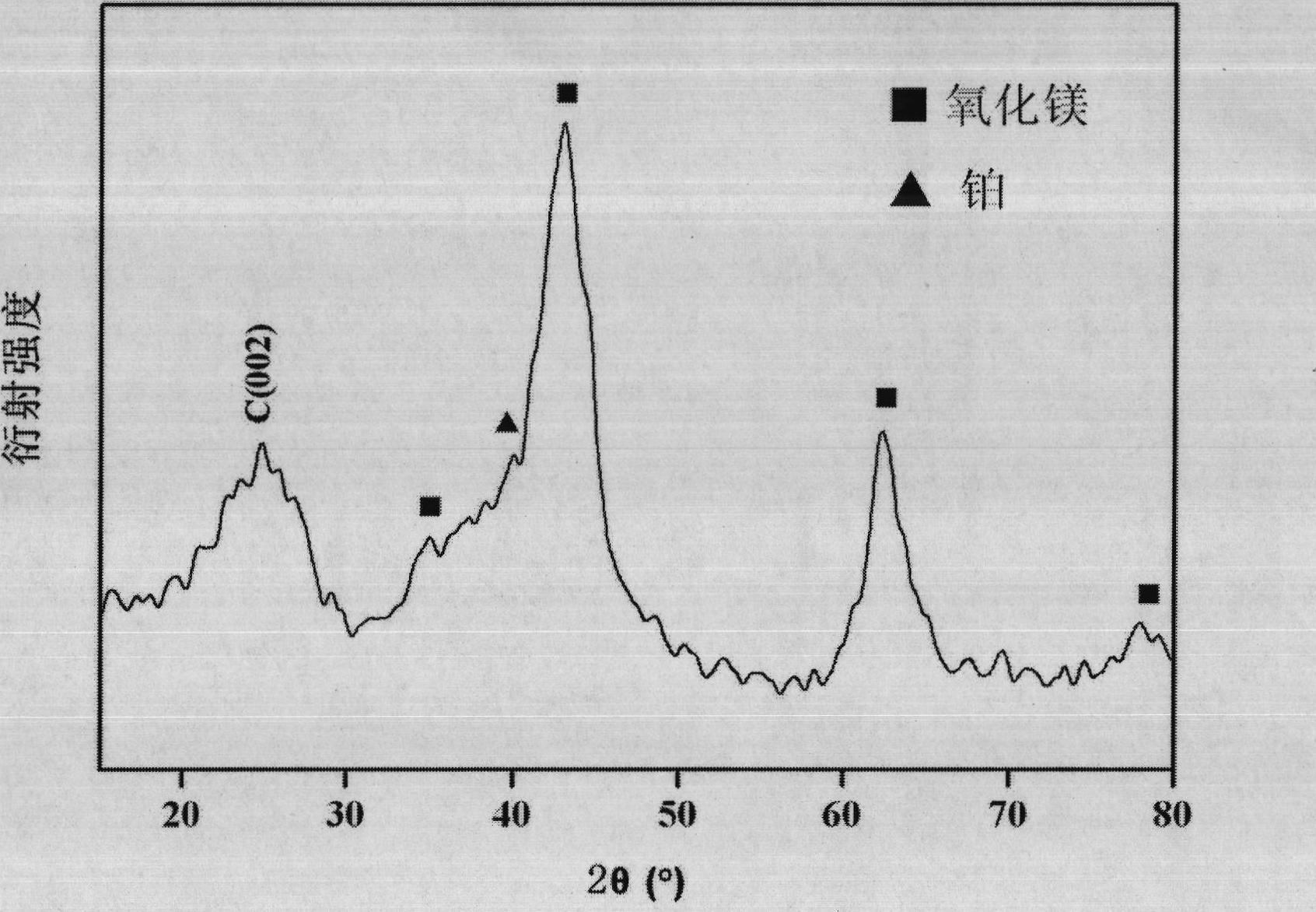

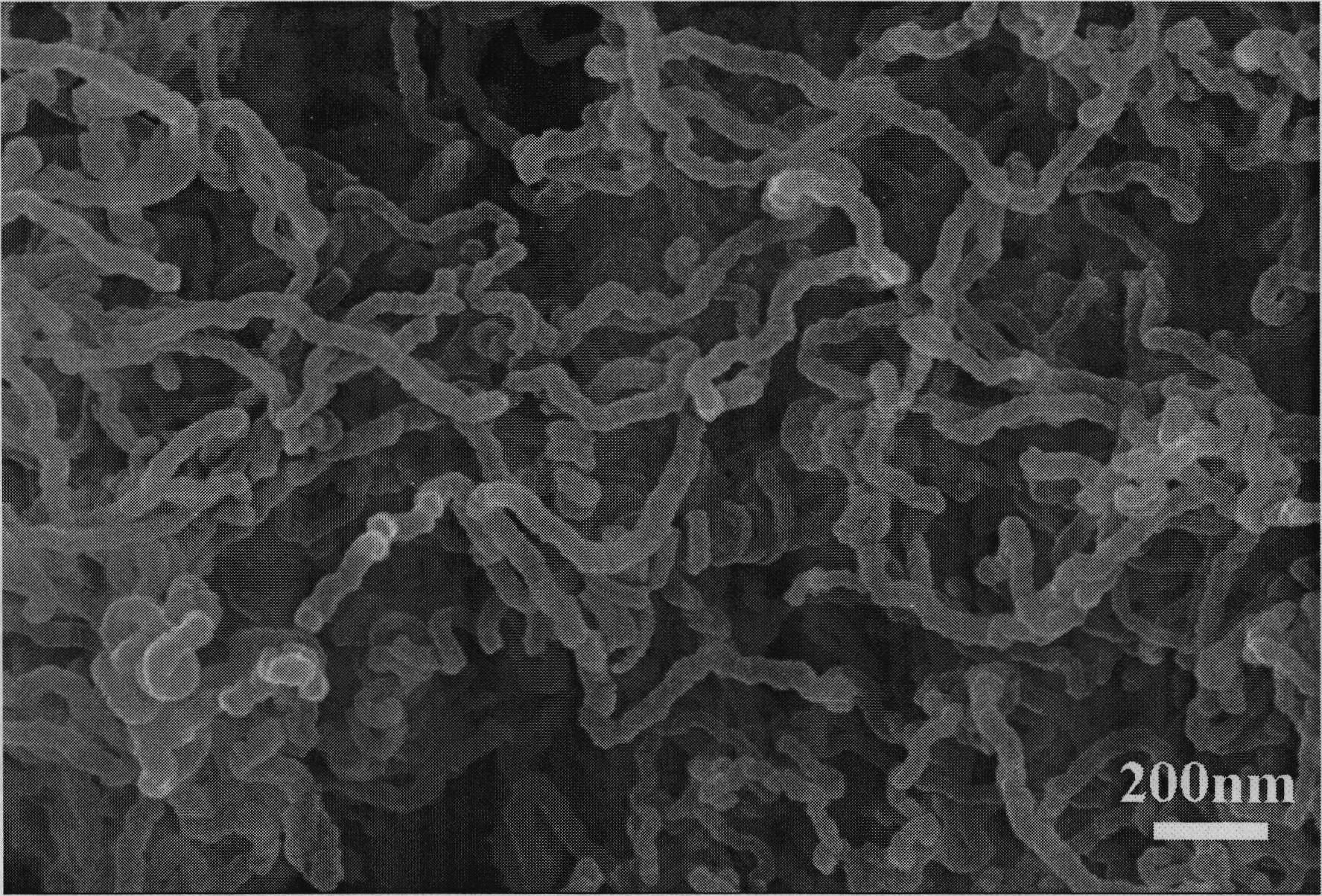

Embodiment 1

[0024] Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and H 2 PtCl 6 ·6H 2 O was dissolved in 100ml deionized water to prepare a salt solution and put it into a three-necked flask, Mg 2+ The molar concentration of Al is 0.75mol / L, Al 3+ The molar concentration is 0.25mol / L, PtCl 6 2- 0.03mol / L; then configure a certain proportion of NaOH and Na 2 CO 3 Dissolve in 100ml deionized water to prepare mixed alkali solution, wherein the molar concentration of NaOH is 1.6mol / L, NaOH 2 CO 3 The molar concentration is 0.5mol / L. Under the condition of constant stirring at room temperature, the above alkaline solution was slowly added dropwise to the mixed salt solution until the final pH of the solution was 9, and then transferred to a 60° C. water bath for 12 hours of crystallization reaction. After the reaction, the product was cooled to room temperature, centrifuged and washed with deionized water until the filtrate was neutral, and finally dried in an oven at 60°C for 24 hour...

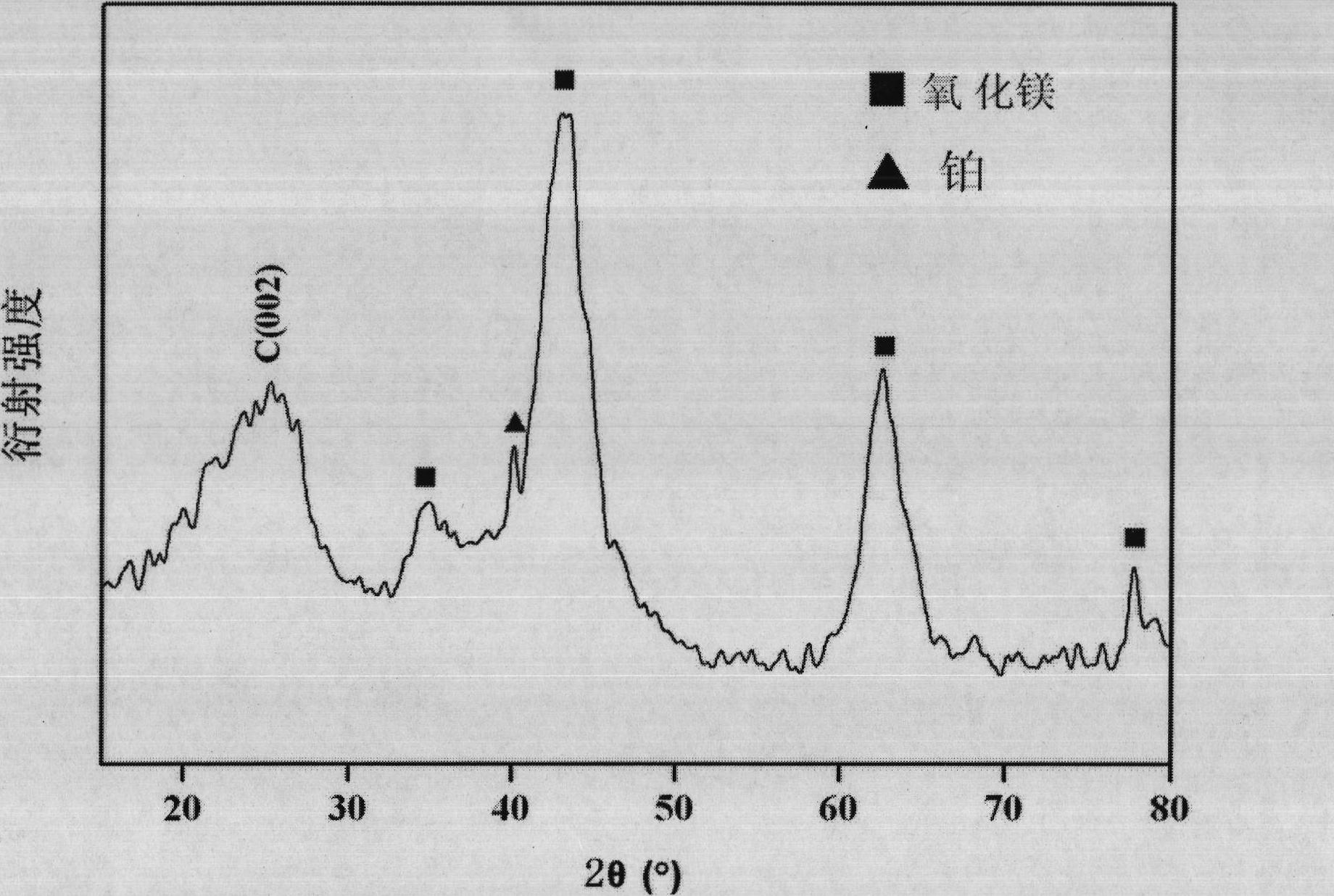

Embodiment 2

[0027] Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and H 2 PtCl 6 ·6H 2 O was dissolved in 100ml deionized water to prepare a salt solution and put it into a three-necked flask, Mg 2+ The molar concentration is 0.5mol / L, Al 3+ The molar concentration is 0.25mol / L, PtCl 6 2- 0.1mol / L; reconfigure a certain proportion of NaOH and Na 2 CO 3 Dissolve in 100ml deionized water to prepare mixed alkaline solution, wherein the molar concentration of NaOH is 1.2mol / L, NaOH 2 CO 3 The molar concentration is 0.5mol / L. Under the condition of constant stirring at room temperature, the above alkaline solution was slowly added dropwise to the mixed salt solution until the final pH of the solution was 9, and then transferred to a water bath at 60° C. for crystallization reaction for 24 hours. After the reaction, the product was cooled to room temperature, centrifuged and washed with deionized water until the filtrate was neutral, and finally dried in an oven at 60°C for 24 hours to ...

Embodiment 3

[0030] MgCl 2 ·6H 2 O, AlCl 3 ·6H 2 O and K 2 PtCl 6 Dissolved in 100ml deionized water to prepare a salt solution and put it into a three-necked flask, Mg 2+ The molar concentration of Al is 0.75mol / L, Al 3+ The molar concentration is 0.25mol / L, PtCl 6 2- 0.075mol / L, and then prepare 100ml of NaOH solution with a molar concentration of 1.6mol / L. Constant stirring at room temperature and N 2 Under protected conditions, the above alkaline solution was slowly added dropwise to the mixed salt solution until the final pH of the solution was 10, and then transferred to a water bath at 80° C. for 12 hours of crystallization reaction. After the reaction, the product was cooled to room temperature, centrifuged and washed with deionized water until the filtrate was neutral, and finally dried in an oven at 70°C for 24 hours to obtain the corresponding catalyst precursor. The above precursor samples were placed in a muffle furnace at a rate of 5 °C / min to 700 °C for 1 h to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com