Preparation method of nano-spinel nickel cobalt lithium manganate

A nano spinel, nickel cobalt lithium manganate technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of poor product batch repeatability, difficult to control particle morphology, and unfavorable industrial production, etc. To achieve the effect of simple and easy process, narrow particle size distribution and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of nano-spinel type nickel-cobalt lithium manganese oxide (LiNi 0.5 co 0.05 mn 1.45 o 4 ) preparation method, comprising the following steps:

[0042] The first step, preparation of nano-scale Ni 0.5 co 0.05 mn 1.45 (OH) 2 Precursors, specifically:

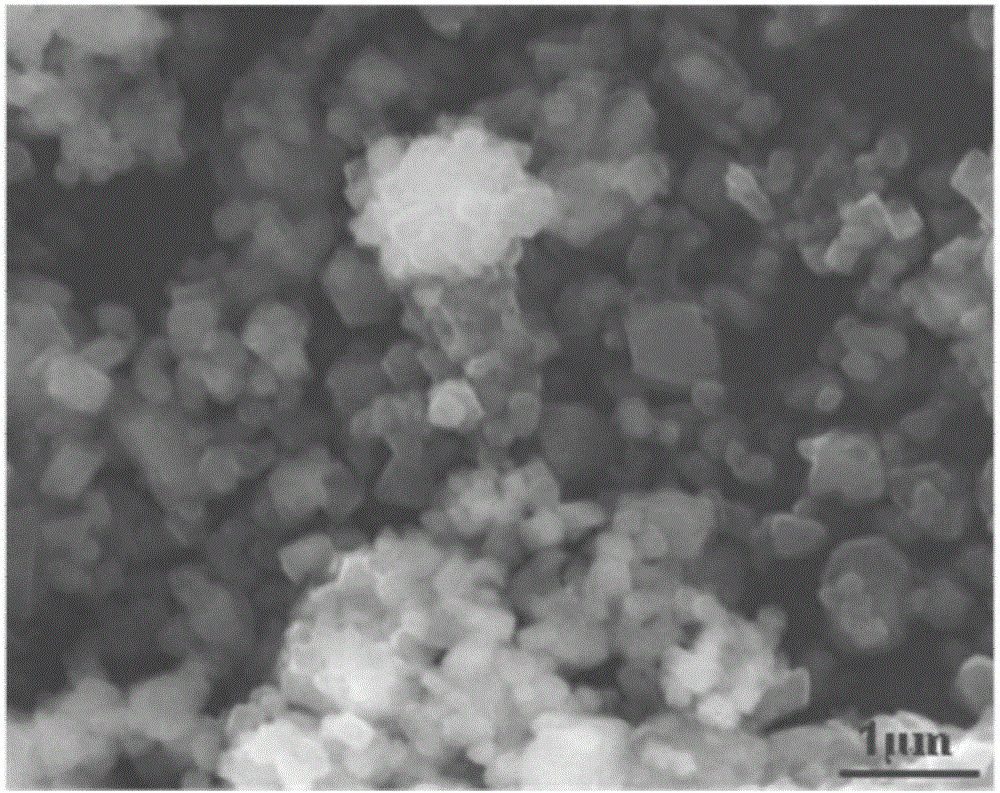

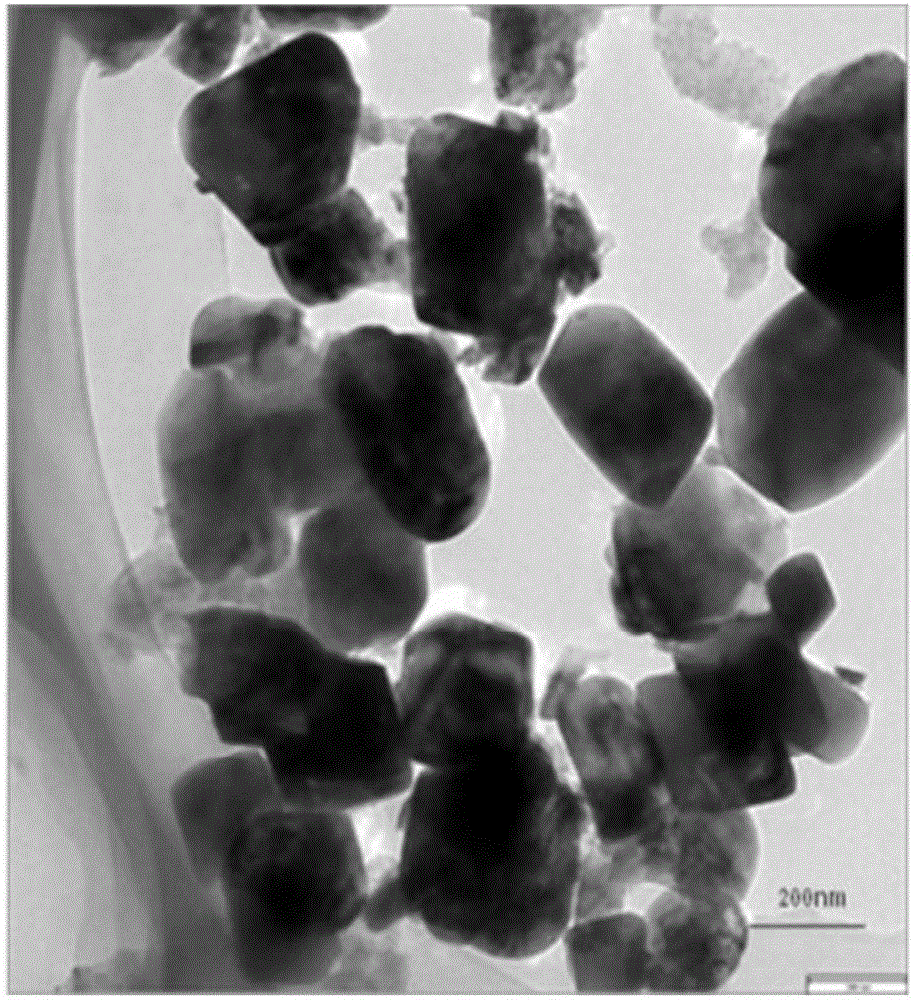

[0043] Mix nickel salt, cobalt salt, and manganese salt according to the ratio to form a mixed solution with a total cation concentration of 0.2mol / L; use a spiral channel type rotating bed high-gravity reactor to generate a high-gravity field, and control the high-gravity reactor The rotor speed is 1000rpm, the slurry mixture is placed in the supergravity field for reaction and circulation, and the mixed alkali solution composed of sodium hydroxide and ammonia water is added dropwise to the supergravity field reactor according to the proportioning ratio, and the post-reaction solution ( The pH value is 11.0); the solution after the reaction is filtered, washed with distilled water and dried to obtain nanosca...

Embodiment 2

[0050] Embodiment 2-Example 3 differs from Example 1 in that: the temperature and time of roasting in a microwave muffle furnace have: in Example 2, the roasting temperature is 780 ° C, and the roasting time is 10h; in Example 3 The calcination temperature is 950°C, and the calcination time is 14h.

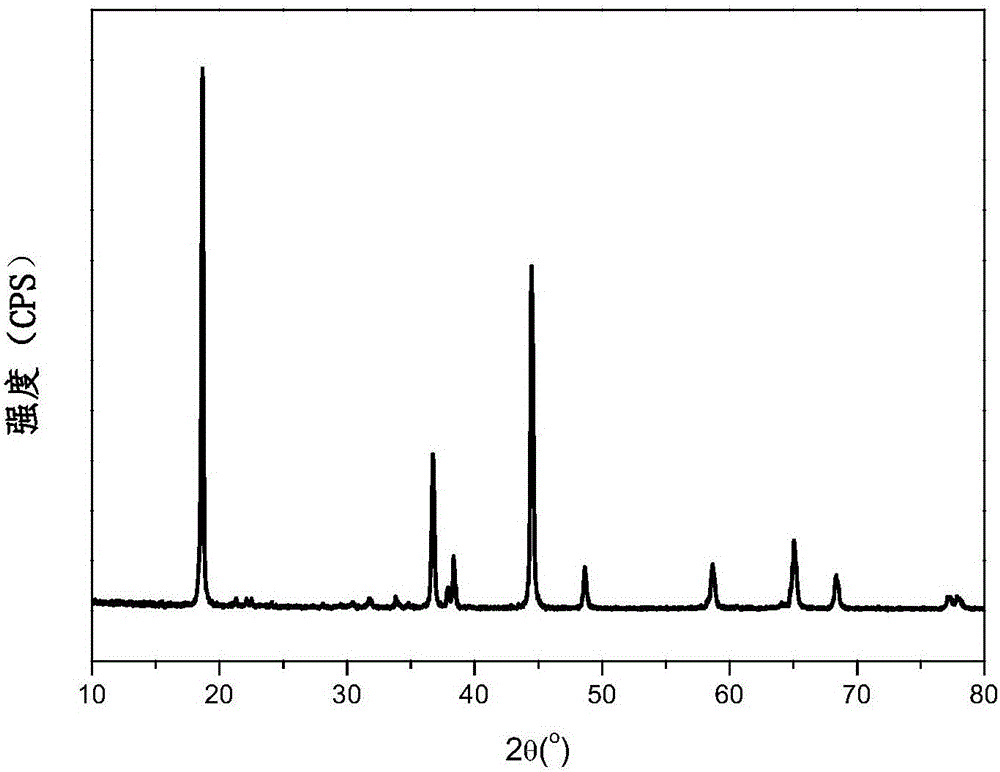

[0051] Embodiment 2 and embodiment 3 gained nano spinel type LiNi 0.5 co 0.05 mn 1.45 o 4 The XRD test results are detailed in Figure 4 , in combination with Examples 1-3, from Figure 4 It can be seen that under the microwave calcination conditions of 750°C and 950°C, other impurity phases will be produced, and the diffraction peaks of impurities are more obvious. However, under the calcination condition of 880°C, the crystal form is good, and there is no impurity peak. It can be seen that the calcination temperature has a great influence on the crystal form, and it is better to control the calcination temperature at about 880°C in order to obtain nano-nickel cobalt lithiu...

Embodiment 4

[0053] Embodiment 4-Example 5 differs from Example 1 only in the concentration of total cations, specifically: the concentration of total cations in Example 4 is 0.1mol / L, and the concentration of total cations in Example 5 is 0.25mol / L L.

[0054] Embodiment 4-embodiment 5 gained nano spinel type LiNi 0.5 co 0.05 mn 1.45 o 4 The XRD test results are detailed in Figure 5 . In conjunction with embodiment 1, embodiment 4 and embodiment 5 (see Figure 5 ) shows that: when the concentration of total cations is about 0.20mol / L, the crystallinity of the prepared sample is high, and no impurities are produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com