Zero-valent iron composite material and preparation method and application thereof

A technology of composite materials and zero-valent iron, applied in the field of environmental chemistry, can solve the problems of particle surface active site decline, application hindrance, easy agglomeration, etc., and achieve the effects of easy popularization and application, convenient operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

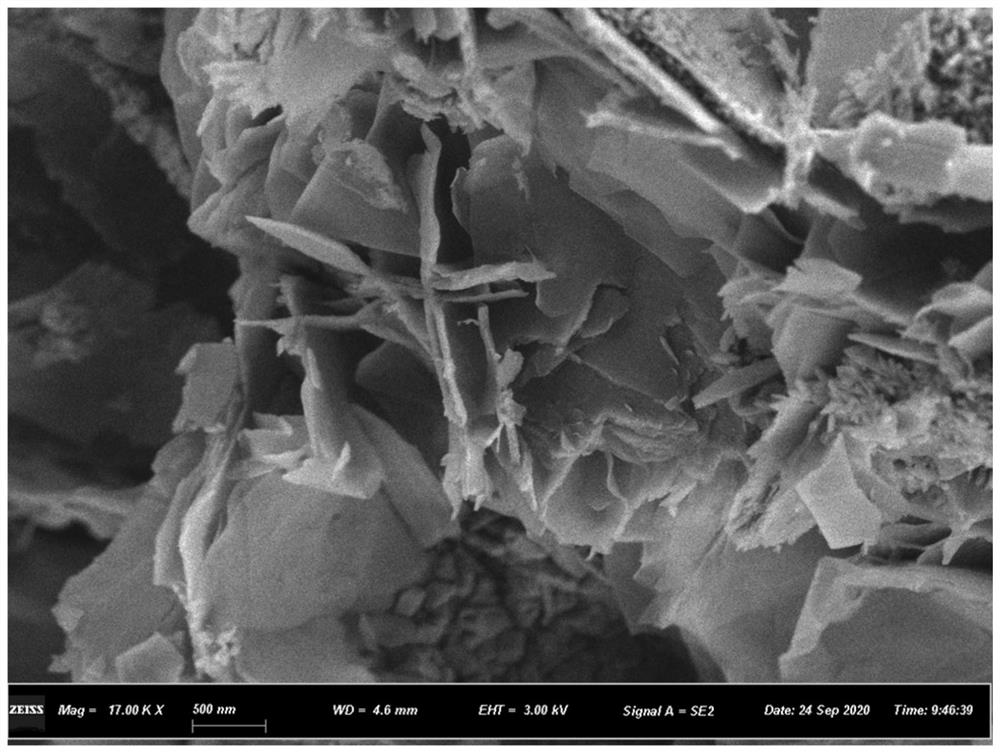

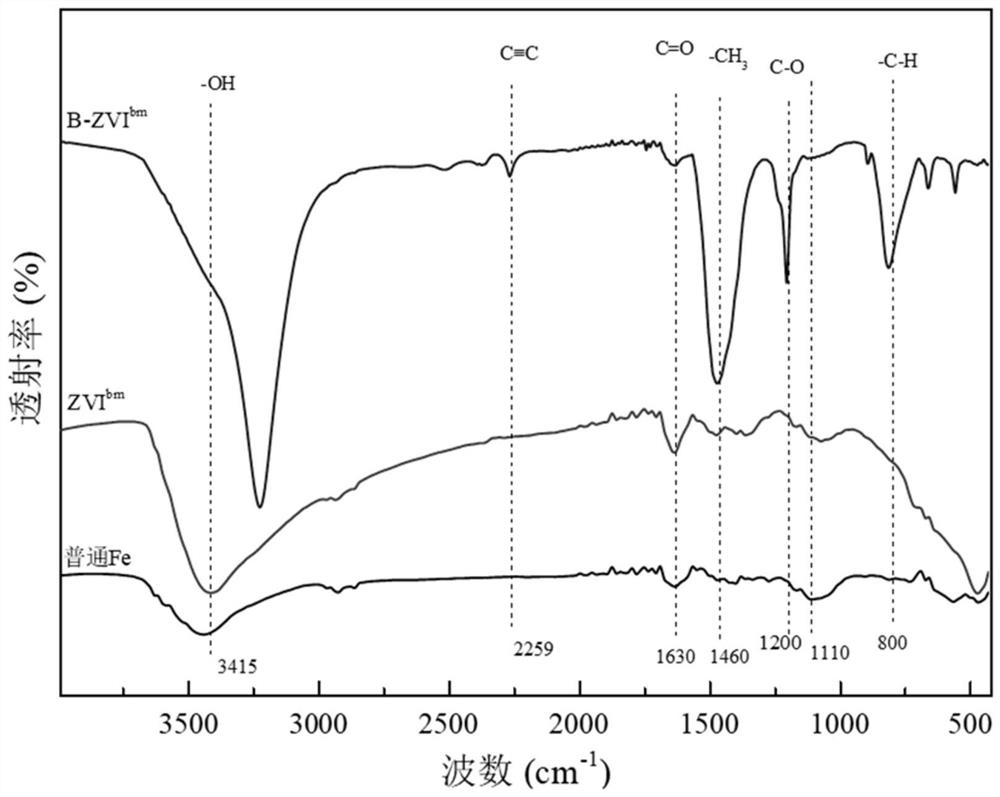

Image

Examples

Embodiment 1

[0044] In this embodiment, a zero-valent iron composite material is prepared, and the specific process is as follows:

[0045] S1: Put 56g of reduced iron powder and 6g of boric acid into a ball mill jar, the rotating speed is 300r / min, and the ball milling time is 12h to obtain boric acid ball milled zero-valent iron (B-ZVI bm );

[0046] S2: Continue to put 2g of zeolite into the ball mill, keep the rotating speed at 300r / min, and the ball milling time is 12h to obtain the zero-valent iron composite material (ZB-ZVI bm ).

Embodiment 2

[0048] In this embodiment, a zero-valent iron composite material is prepared, and the specific process is as follows:

[0049] S1: Put 56g of reduced iron powder and 4.9g of boric acid into a ball mill jar, the rotating speed is 350r / min, and the ball milling time is 10h to obtain boric acid ball milled zero-valent iron (B-ZVI bm );

[0050] S2: Continue to drop 3g of zeolite into the ball mill, keep the rotating speed at 350r / min, and the ball milling time is 12h to obtain the zero-valent iron composite material (ZB-ZVI bm ).

Embodiment 3

[0052] In this embodiment, a zero-valent iron composite material is prepared, and the specific process is as follows:

[0053] S1: Put 5.6g of reduced iron powder and 0.4946g of boric acid into a ball mill jar, the rotating speed is 400r / min, and the ball milling time is 6h to obtain boric acid ball milled zero-valent iron (B-ZVI bm );

[0054] S2: Continue to put 0.6g zeolite into the ball mill, keep the rotating speed at 400r / min, and the ball milling time is 6h, to obtain the zero-valent iron composite material (ZB-ZVI bm ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com