Preparation method of multifunctional regenerated cellulose composite fiber

A technology for regenerated cellulose and composite fibers, which is applied to artificial filaments made of cellulose derivatives, fiber chemical characteristics, wet spinning, etc. Poor performance and other problems, to achieve the effect of overcoming easy agglomeration and stacking, excellent antistatic performance, and realizing multi-function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 100g of NaOH, 150g of urea, and 100g of cellulose carbamate into 1000g of water in turn, stir vigorously in an ice-salt bath at 0°C until completely dispersed, and set aside.

[0018] (2) Weigh 2.5g of spherical graphene oxide powder (ZL201610056421.5) into the dispersion prepared in step (1), stir in an ice-salt bath at 0°C, and stir at an initial rate of 100rpm for 4h until spherical graphite oxide Graphene is completely dispersed in the mixed solution; the stirring rate is adjusted to 400rpm, and stirred for 30min to obtain a composite spinning solution of flaky graphene oxide.

[0019] (3) The spinning solution is pre-treated by filtration, defoaming, aging, etc., and is sprayed out from the porous spinning into the NaAc coagulation bath through the injector, and then subjected to multi-stage water bath stretching and high-temperature steam stretching, wherein the first The temperature of the primary water bath is 50°C and the draw ratio is 2.1; the temper...

Embodiment 2

[0030] (1) Weigh 10g of NaOH, 100g of urea, and 75g of cellulose carbamate into 1000g of water in turn, stir vigorously in an ice-salt bath at -15°C until completely dispersed, and set aside.

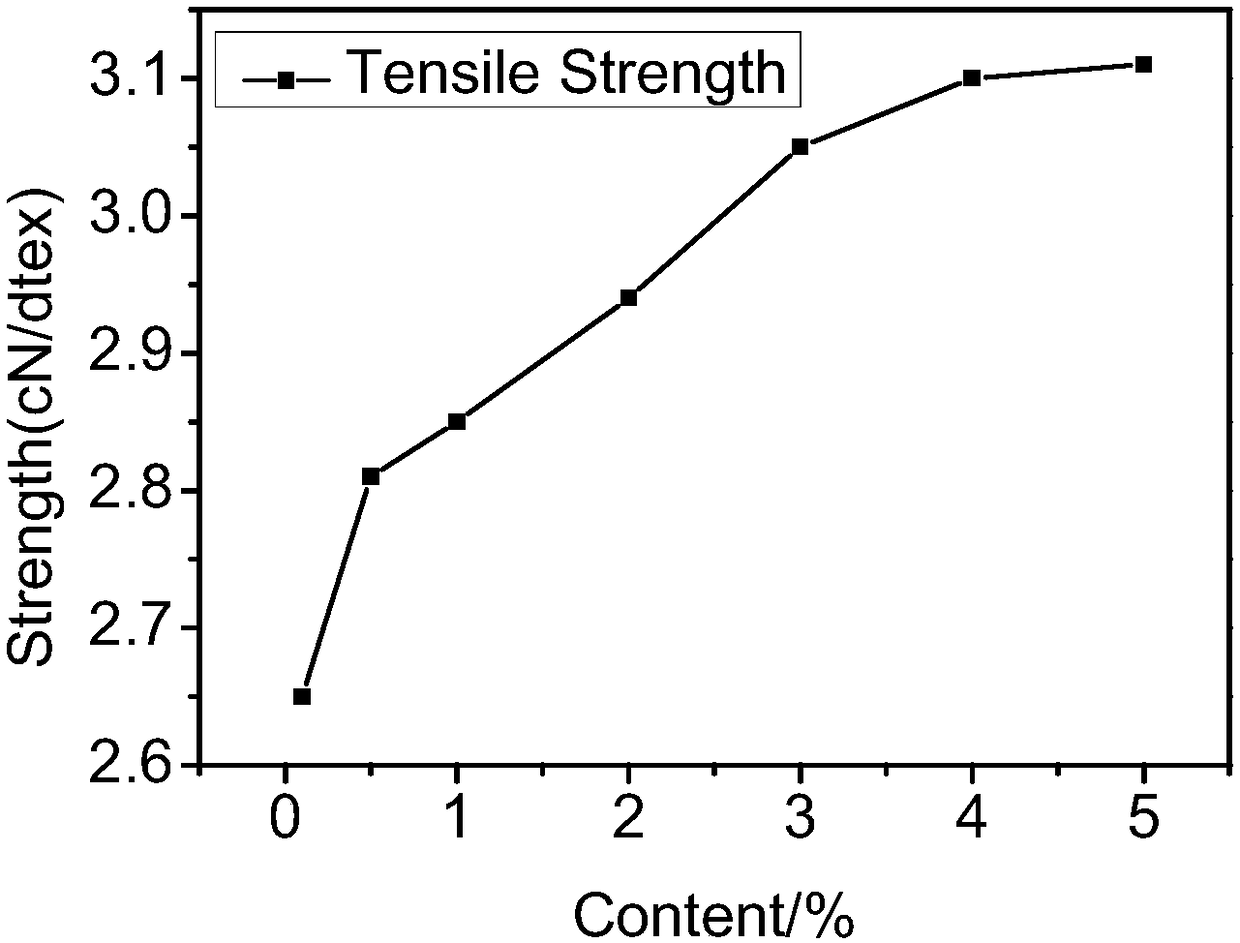

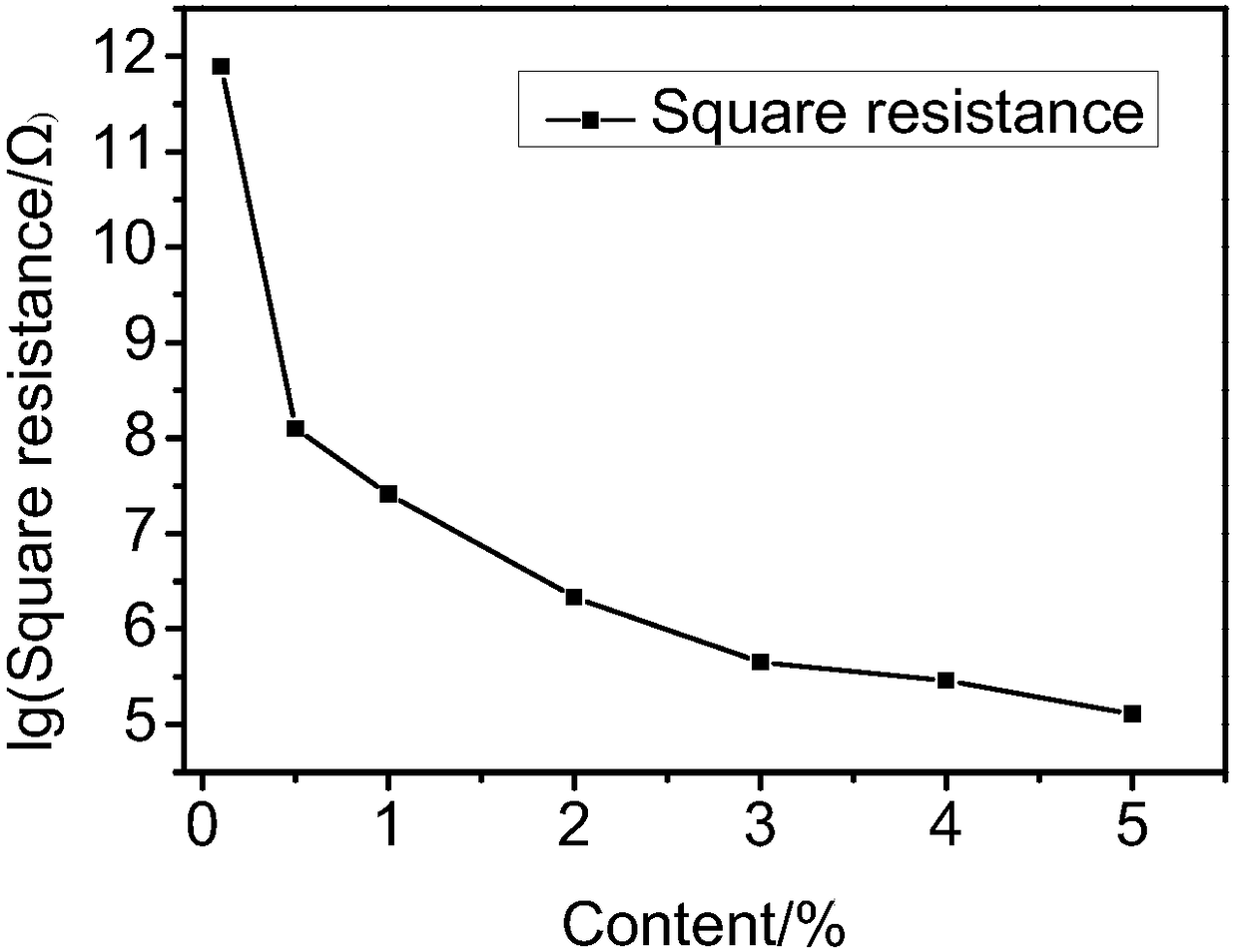

[0031] (2) Weigh 0.075g, 0.375g, 0.75g, 1.5g, 2.25g, 3g, 3.75g of spherical graphene oxide powder and add it to the dispersion prepared in step (1), and put it in the ice-salt bath at -15°C Stir at an initial rate of 50 rpm for 4 hours until the spherical graphene oxide is completely dispersed in the mixture; adjust the stirring rate to 3000 rpm and stir for 30 min to obtain a composite spinning solution of flaky graphene oxide.

[0032] (3) The spinning solution is pre-treated by filtration, defoaming, aging, etc., and is ejected from the porous spinning through the injector into the Al 2 (S0 4 ) 3Coagulation bath, after multi-stage water bath stretching and high temperature steam stretching, the first stage water bath temperature is 50°C, the draw ratio is 2.1; the second stage wate...

Embodiment 3

[0035] (1) Weigh 45g of NaOH, 120g of urea, and 90g of cellulose carbamate into 1000g of water in turn, stir vigorously in an ice-salt bath at -10°C until completely dispersed, and set aside.

[0036] (2) Weigh 1.8g of spherical graphene oxide powder and add it to the dispersion prepared in step (1), stir in an ice-salt bath at -10°C, and stir at an initial rate of 80rpm for 4h until the spherical graphene oxide is completely dispersed in the In the mixed liquor; adjust the stirring speed to 350rpm, stir for 30min, and obtain the composite spinning solution of flaky graphene oxide.

[0037] (3) The spinning solution is pre-treated by filtration, degassing and aging, and then injected into the Al through the injector from the porous spinning. 2 (S0 4 ) 3 Coagulation bath, after multi-stage water bath stretching and high temperature steam stretching, the first stage water bath temperature is 50°C, the draw ratio is 2.1; the second stage water bath temperature is 90°C, the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com