Patents

Literature

52results about How to "No stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

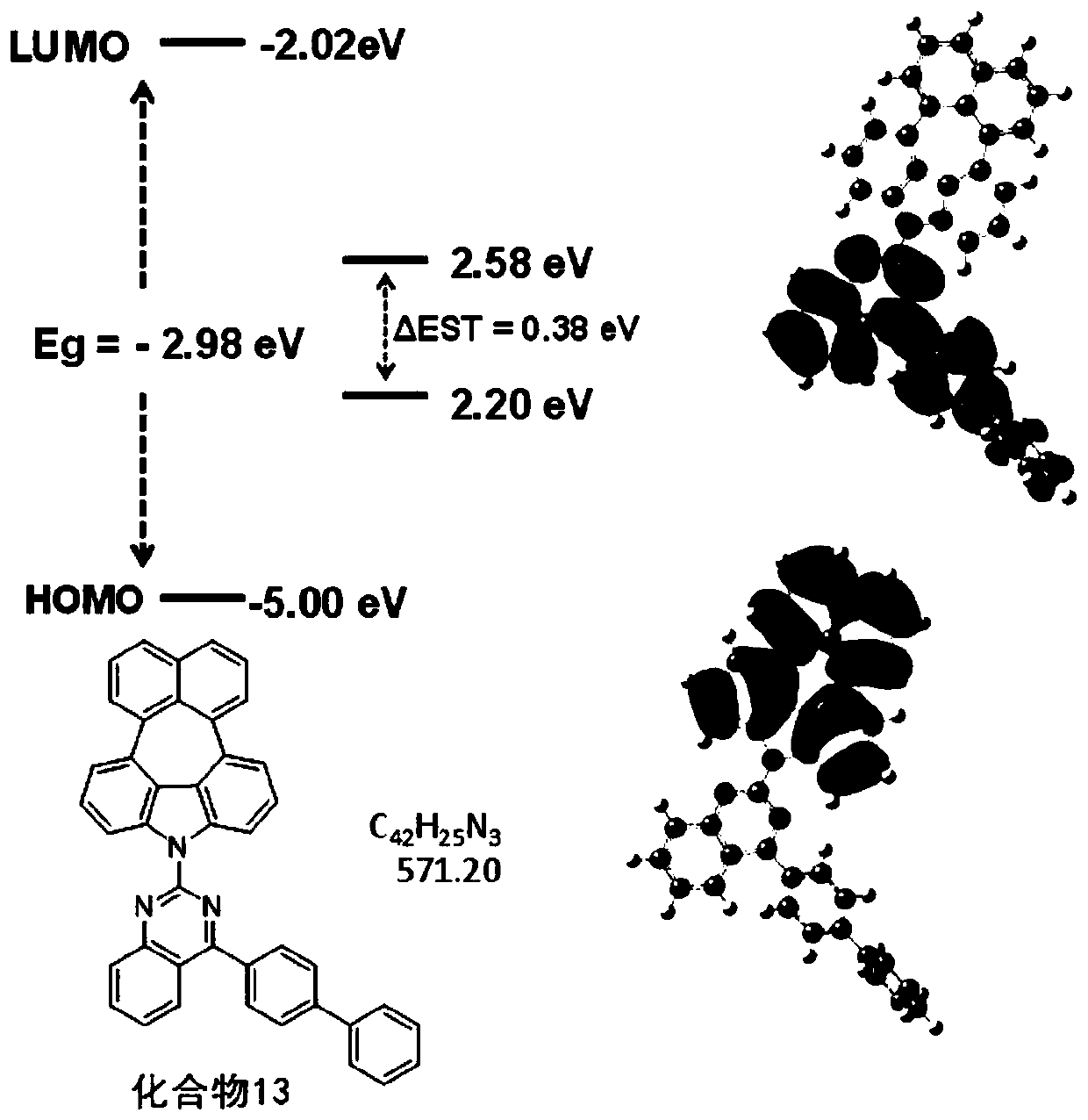

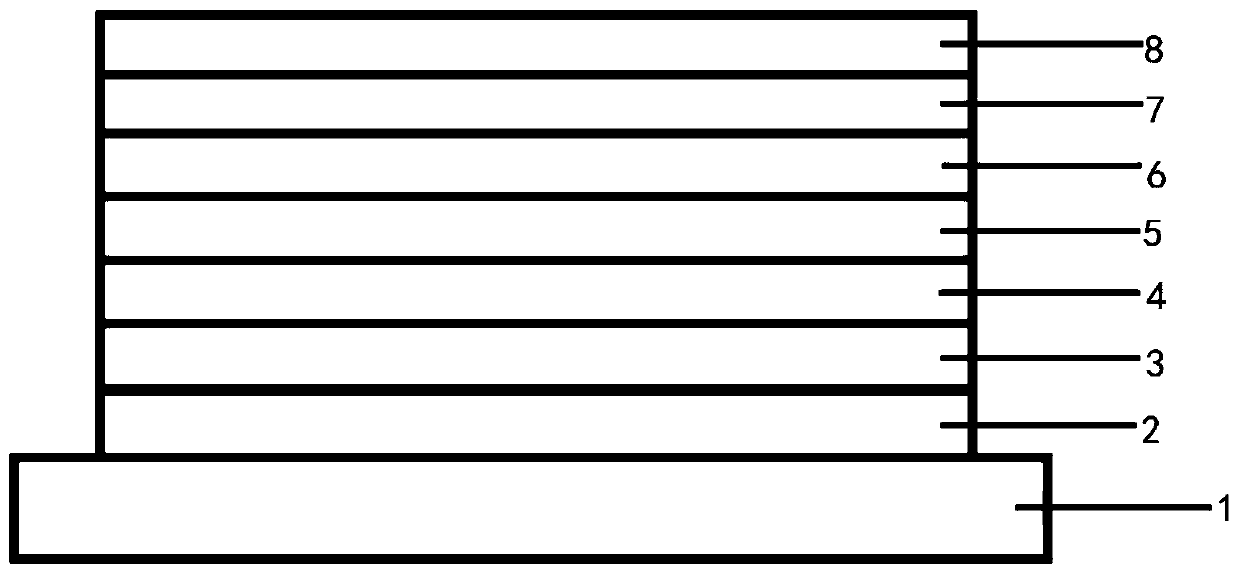

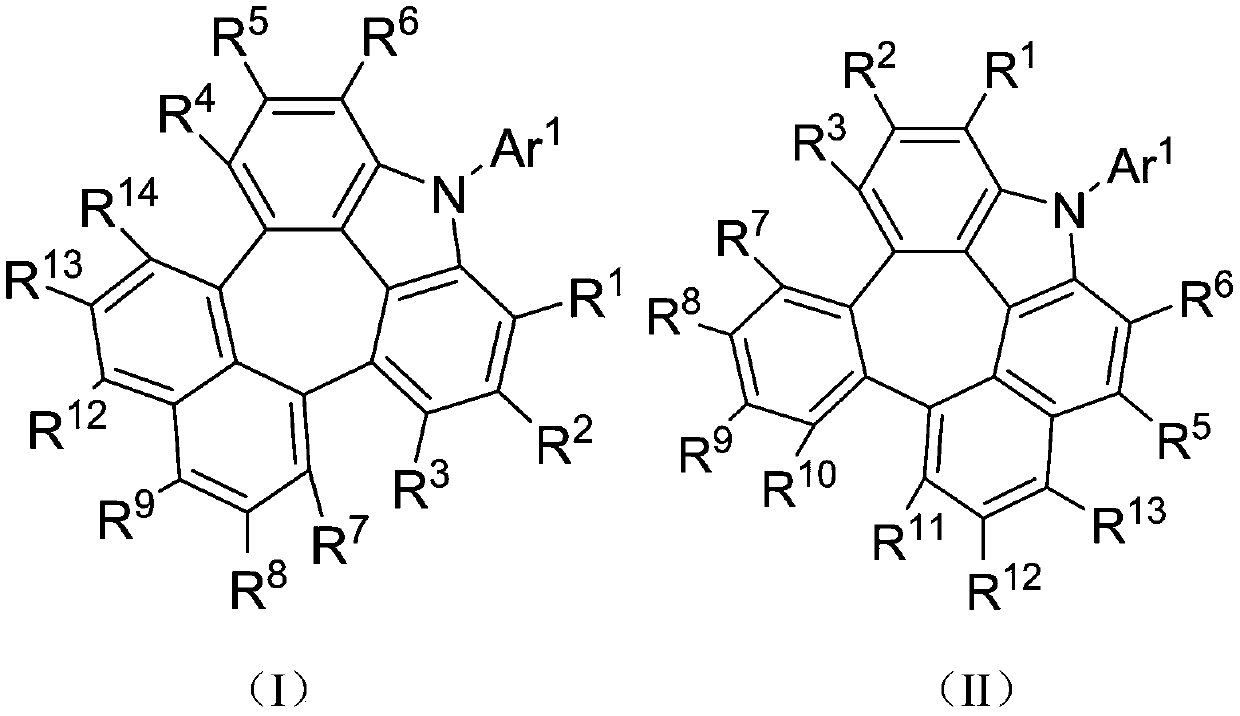

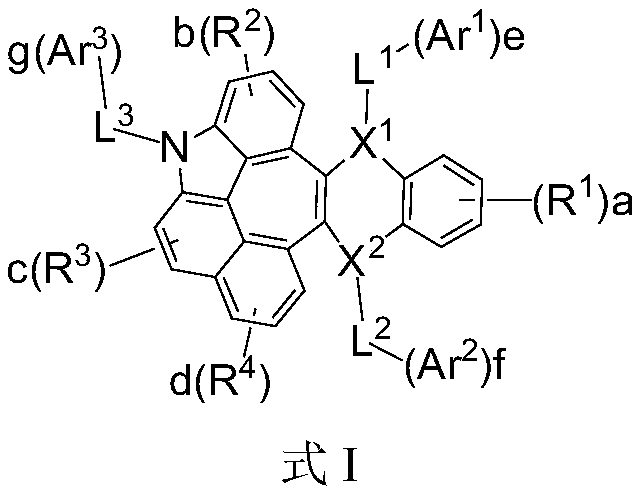

Condensed-ring compound and preparation method and application thereof

InactiveCN110698387AReduced bandgap widthPrevent backflowGroup 5/15 element organic compoundsSolid-state devicesOrganic electroluminescenceMaterials science

The invention discloses a condensed-ring compound and a preparation method and an application thereof. The condensed-ring compound has a structure represented by formula (I) or formula (II). The HOMOand LUMO energy levels of the fused-ring compound are completely separated, so that the energy gap width of the material is reduced, the three-wire energy level is improved, and the energy backflow from the object material to the main material is avoided to reduce the luminous efficiency; HOMO and LUMO energy levels are matched with adjacent materials, and the driving voltage is small. The devicehas large molecular structure size and good intramolecular conjugation, so it has good thermal stability, can avoid thermal decomposition of materials during film formation or use, avoids loss of material layer function, and improves luminous efficiency and luminous performance of the device. The invention also provides a preparation method of the fused-ring compound and its application as an organic electroluminescent material.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

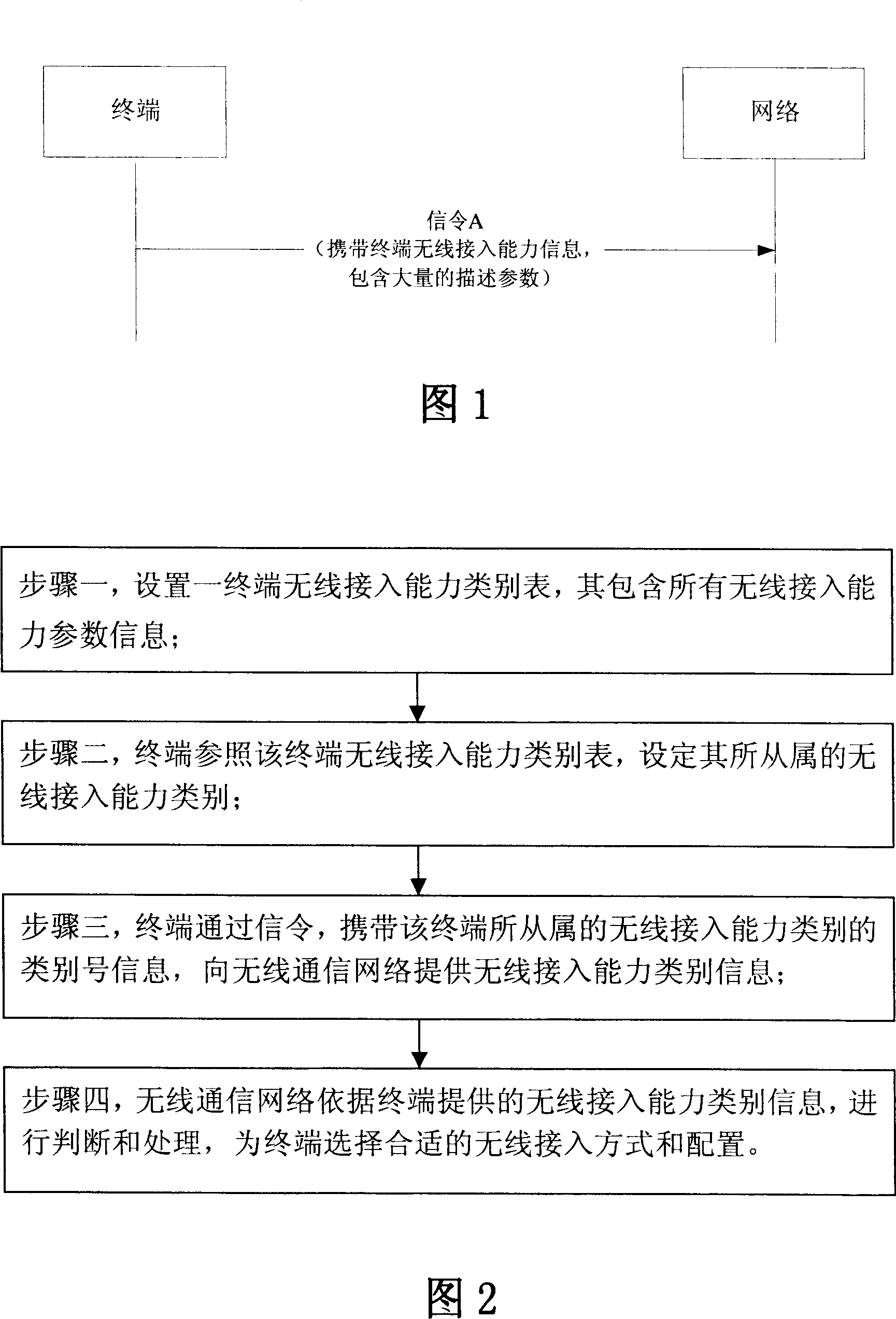

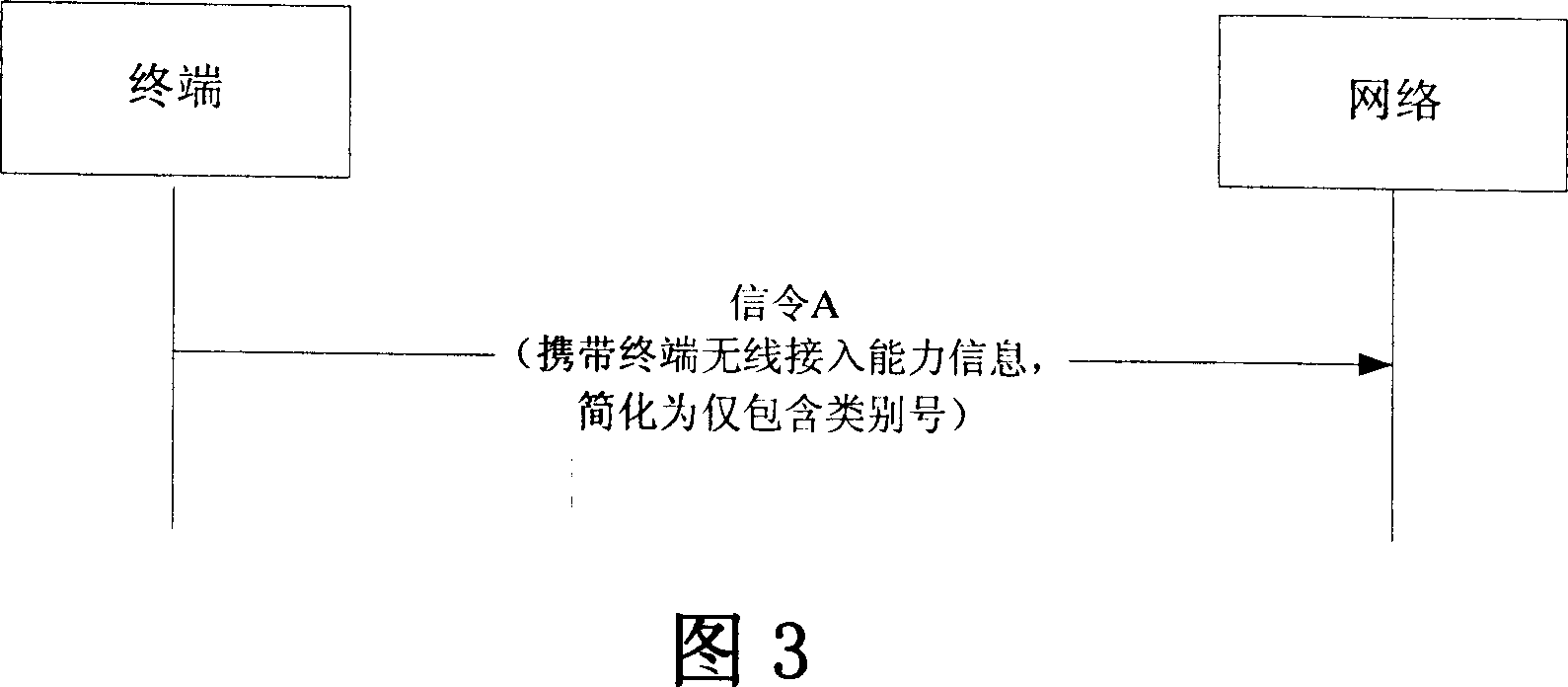

Terminal wireless access method and its system

ActiveCN1964293AReduce data volumeEfficient and reliable transmissionData switching by path configurationAccess methodCommunications system

The related terminal wireless access method comprises: 1. setting a terminal wireless access capacity table contained all access capacity parameters; 2. storing the access capacity parameters in terminal and decides the subordinate capacity type; 3. providing the access capacity information to a wireless communication network; and 4. deciding ad processing to select the proper access type and configuration. This invention is high efficient and simple.

Owner:ZTE CORP

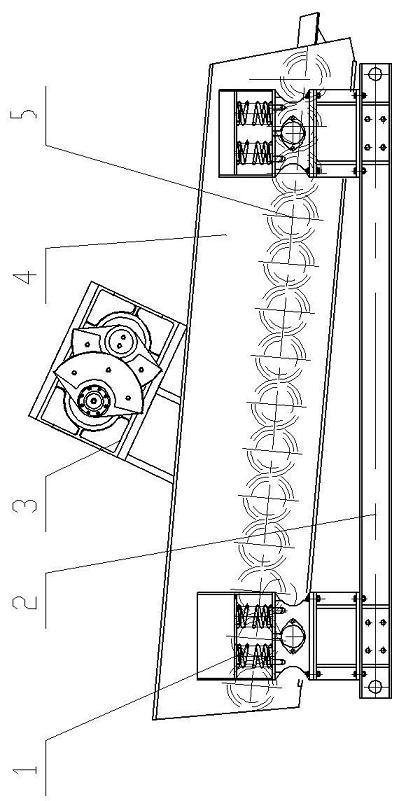

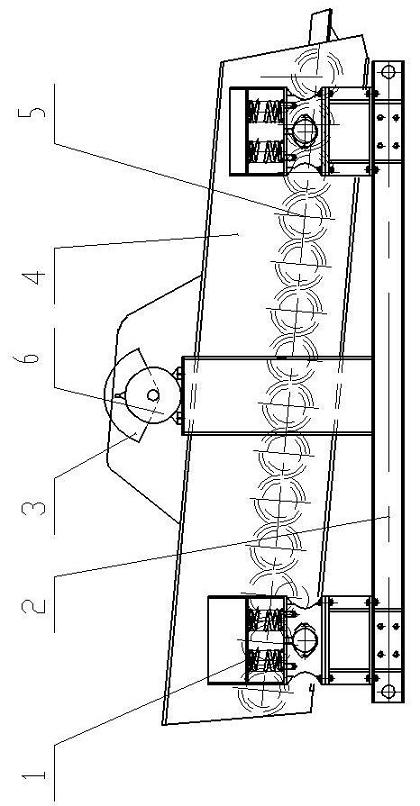

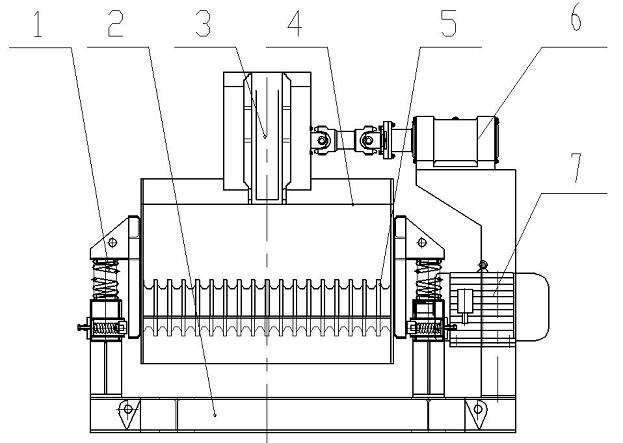

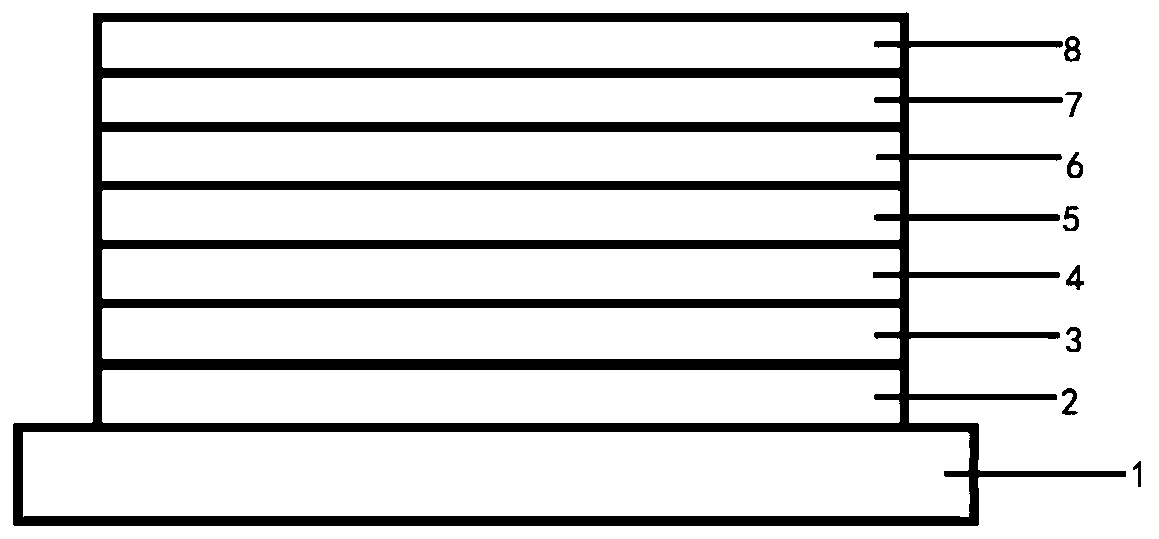

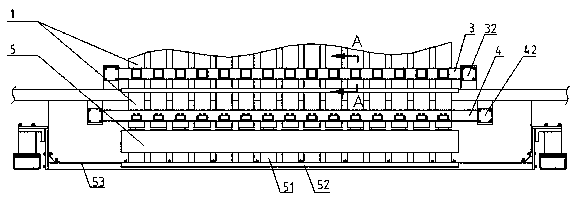

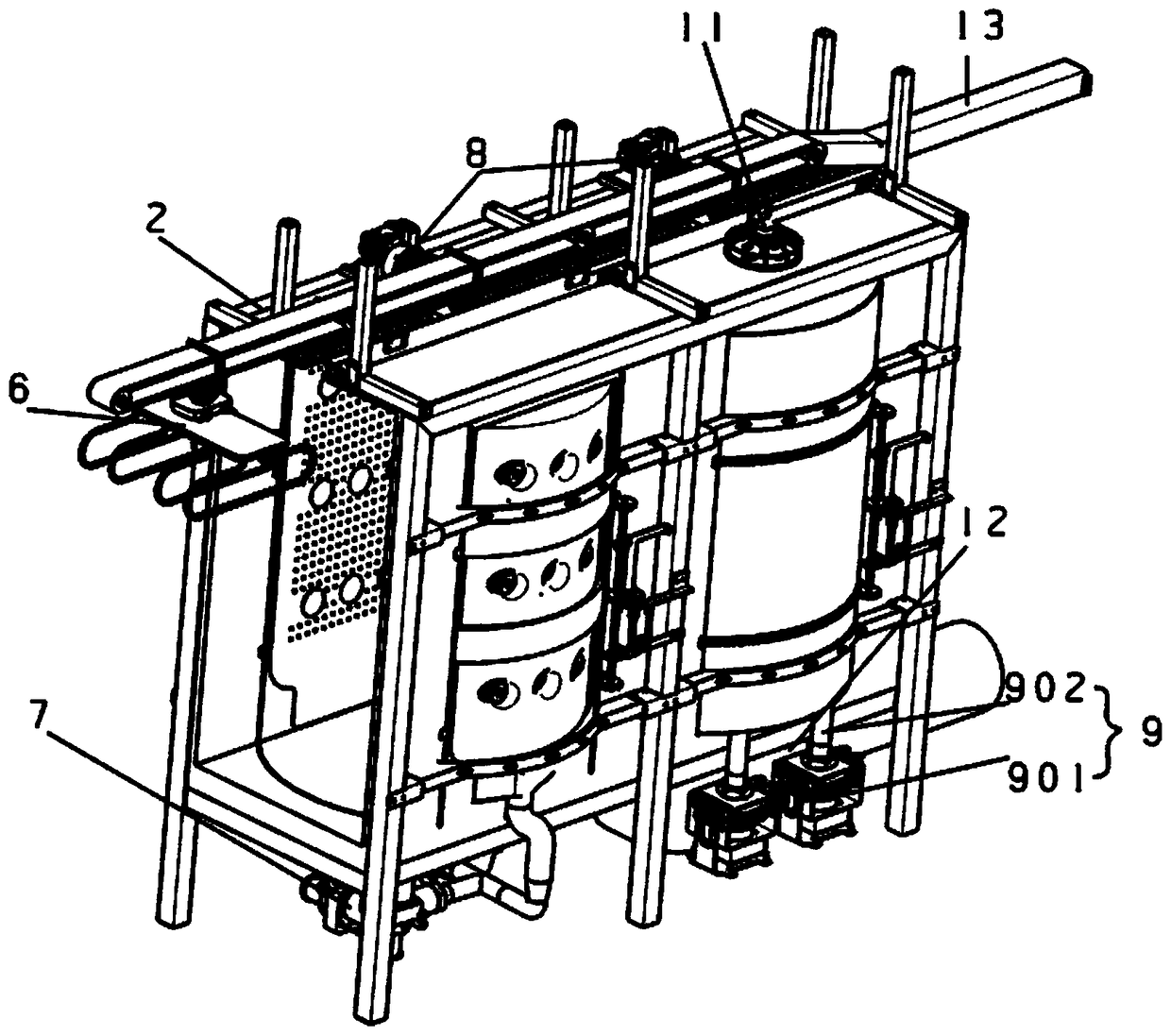

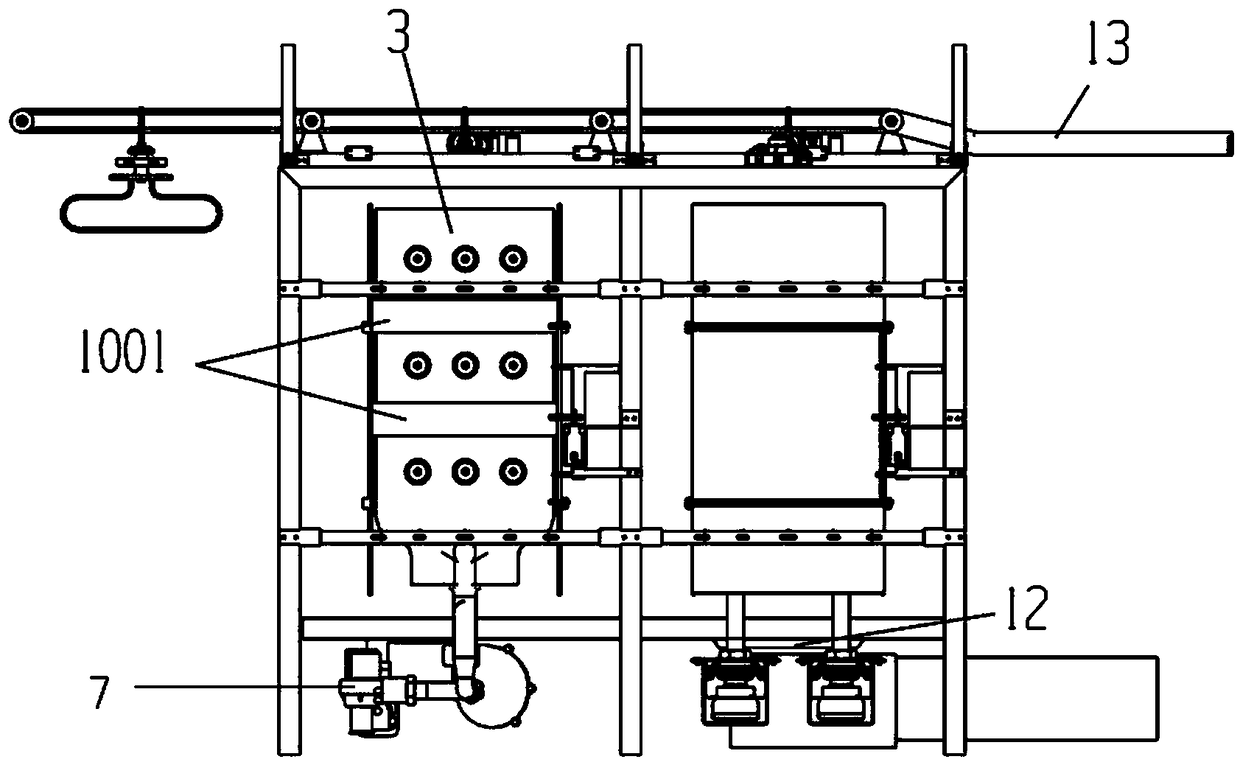

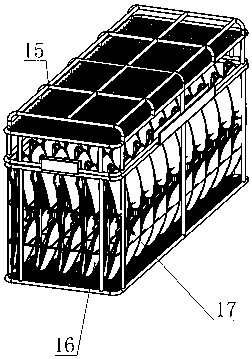

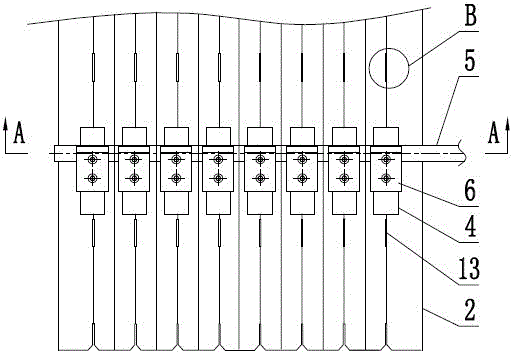

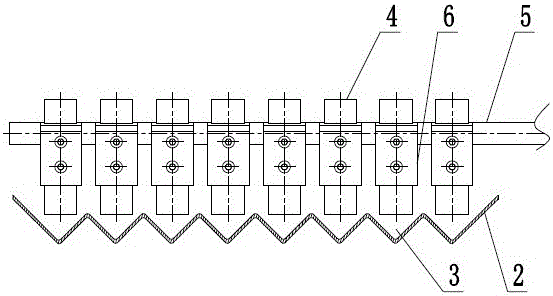

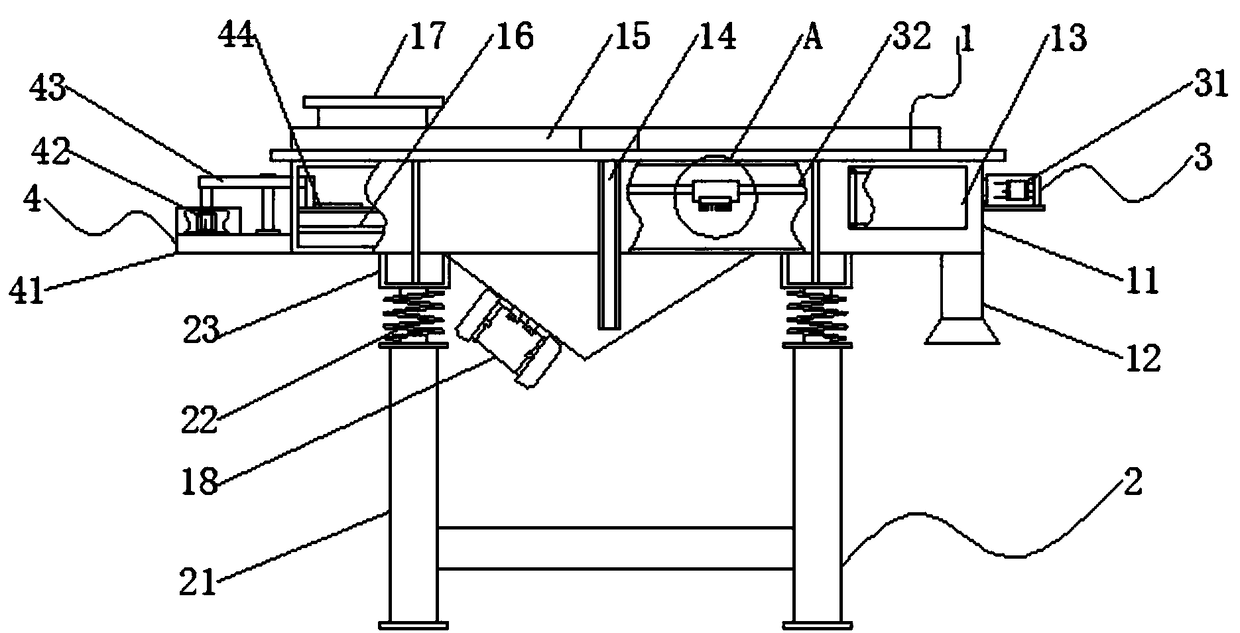

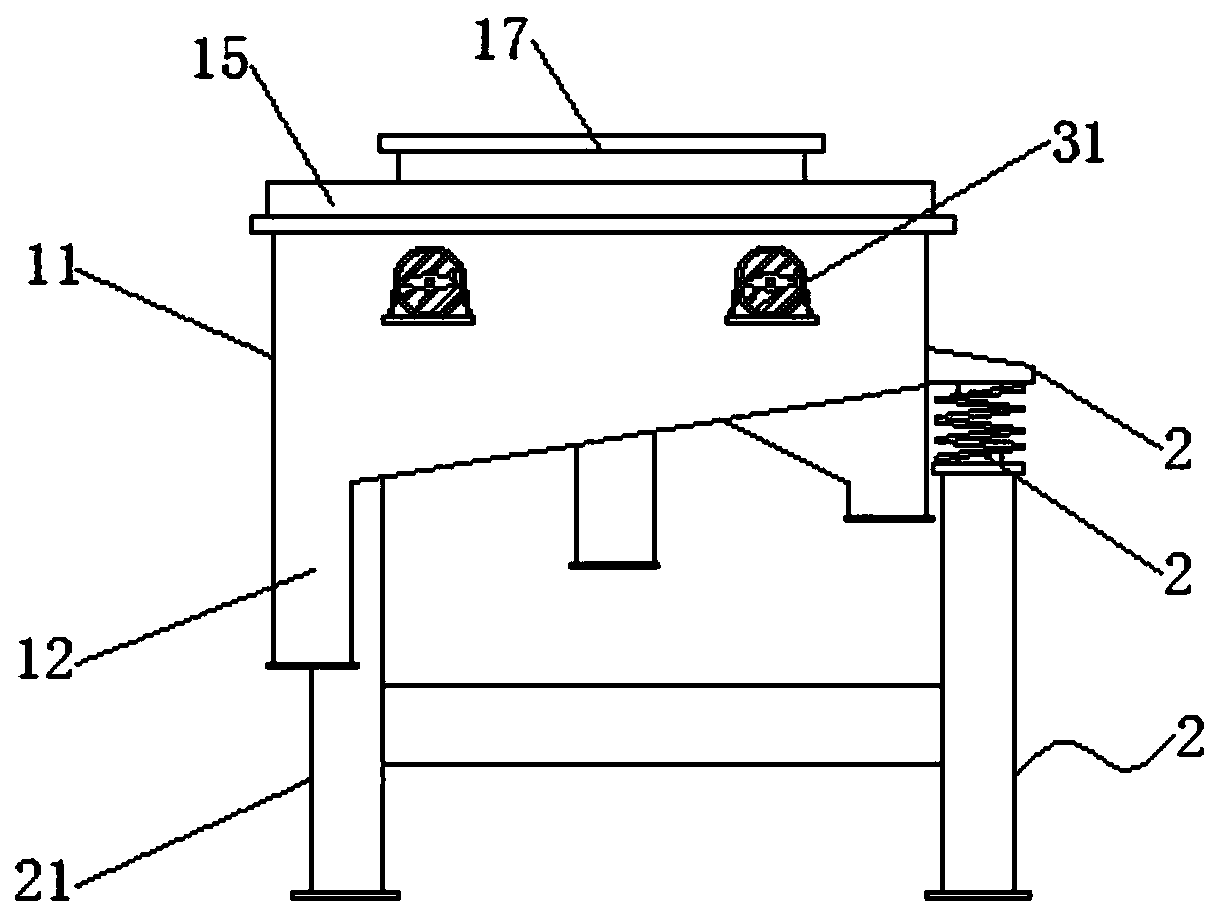

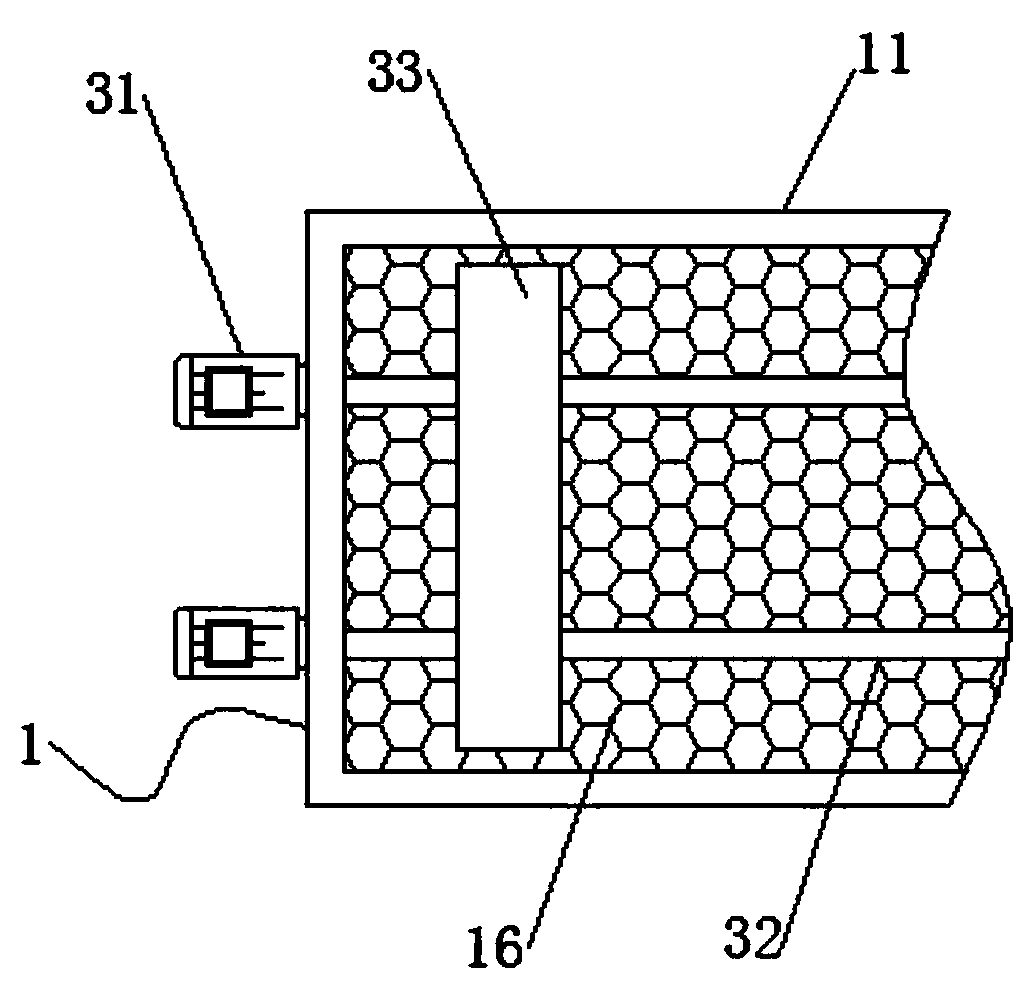

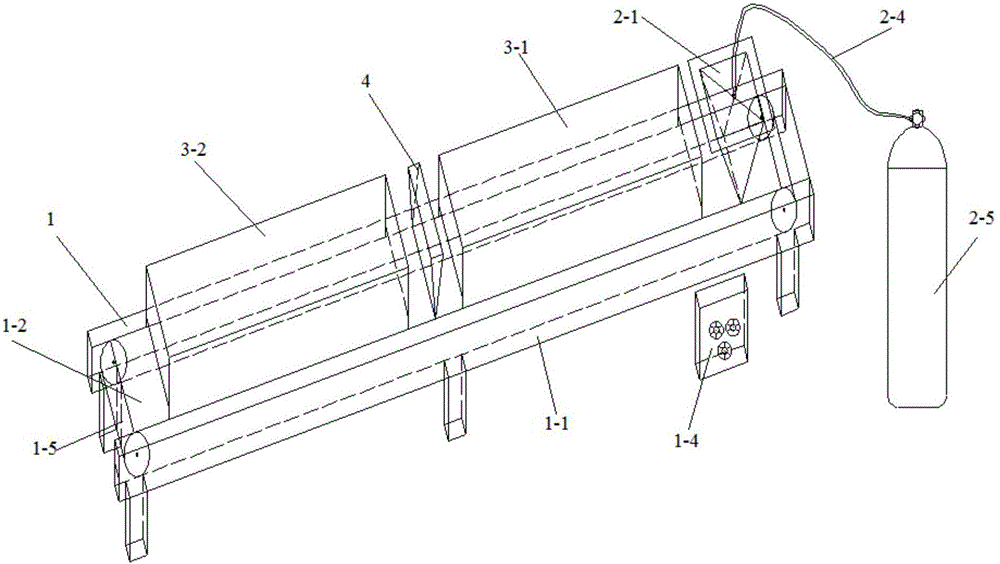

Vibrating type roller screen

InactiveCN102310041AImprove sieving abilityImprove screening efficiencySievingScreeningMotor driveDrive shaft

The invention relates to a vibrating type roller screen which belongs to the field of vibration screening machinery. The invention aims to solve the problem of screening efficiency influence by roller screen stocking or blockage. The vibrating type roller screen mainly comprises a screen box, a roller type screening surface, a vibrator, a vibration attenuating support device and a base, wherein the vibrator is arranged on the screening box or installed on a side plate of the screening box; the vibrator is a double-shaft straight vibrator or a single-shaft round vibrator; the screening box is installed on the base by the vibration attenuating support device; and a motor drive device of the roller type screening surface and a roller of the screening surface are rigidly connected for participating in vibration or connected by a universal drive shaft without participating in vibration. The screening performance of the screening surface is strengthened, and the screening efficiency and the processing capability are obviously improved. The invention has no stocking or hole blockage and is especially suitable for screening viscous and wet materials containing more water.

Owner:威领新能源股份有限公司

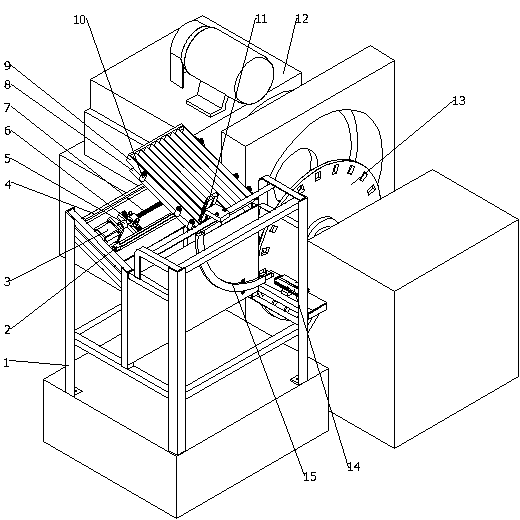

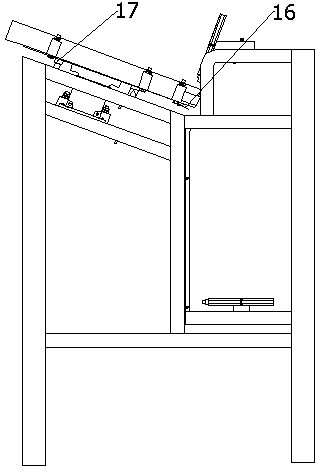

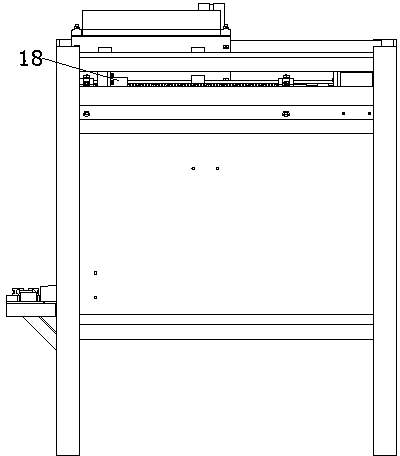

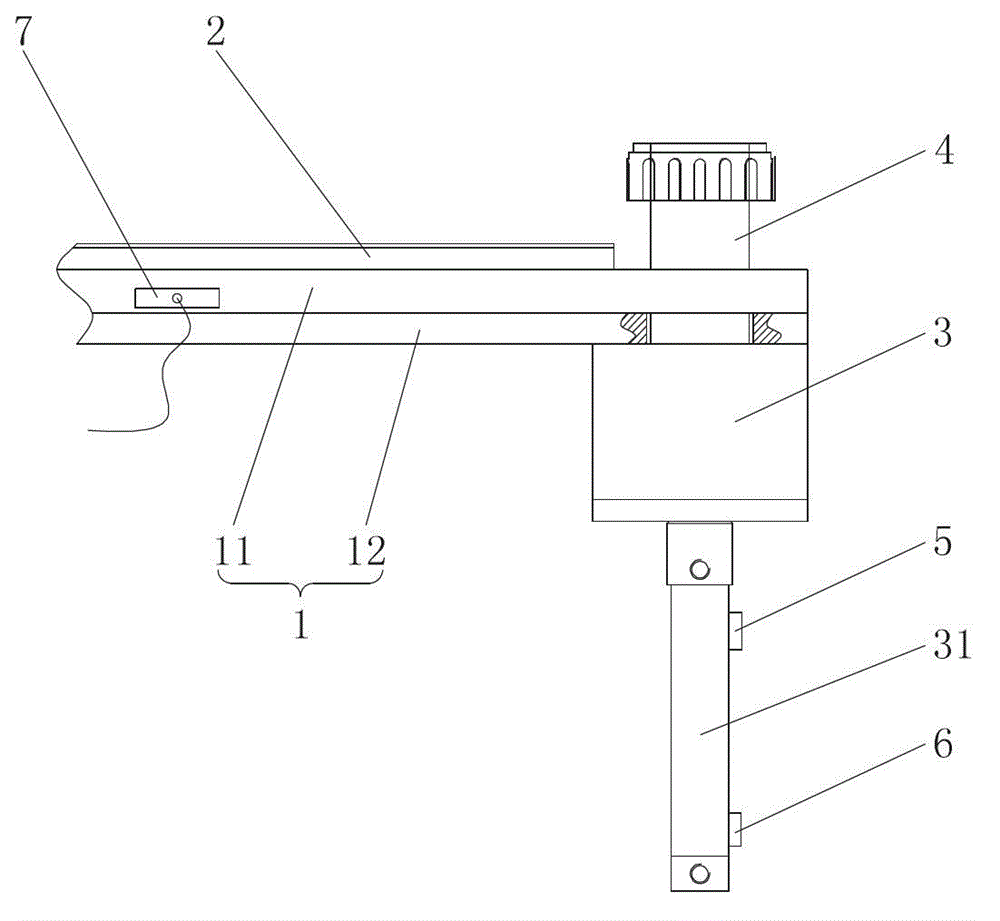

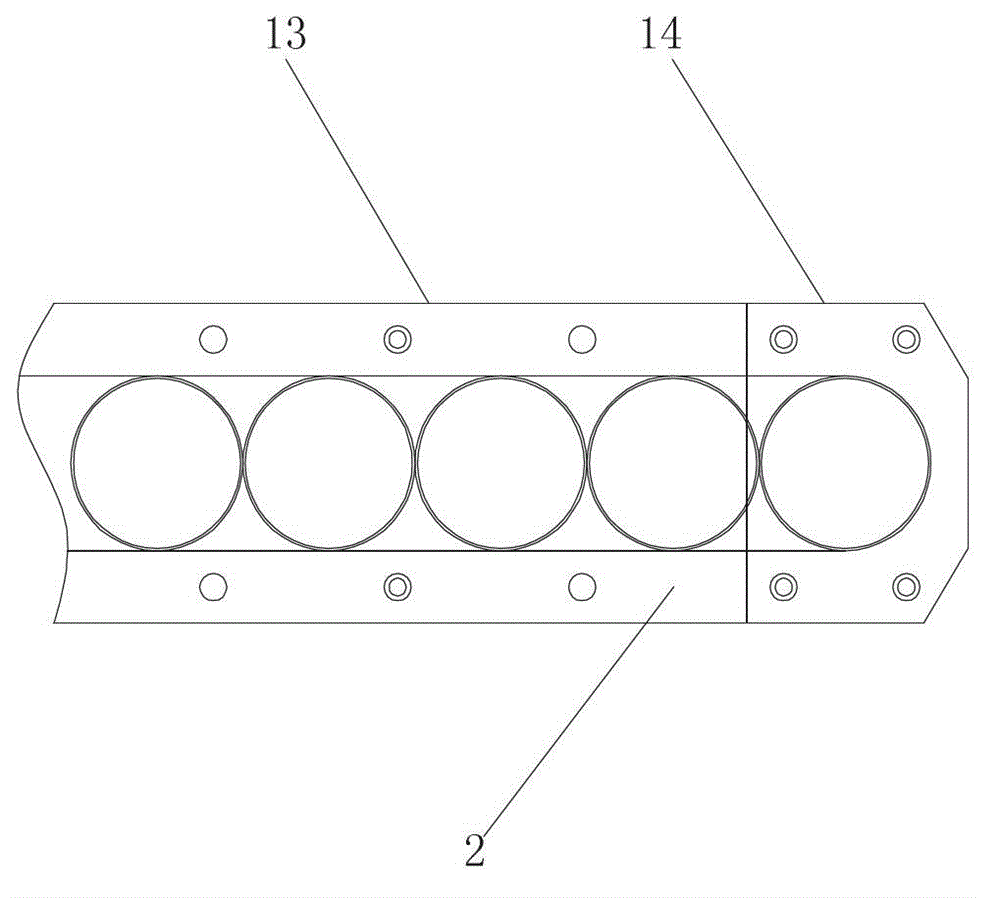

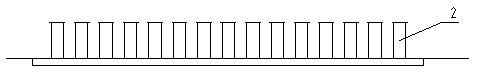

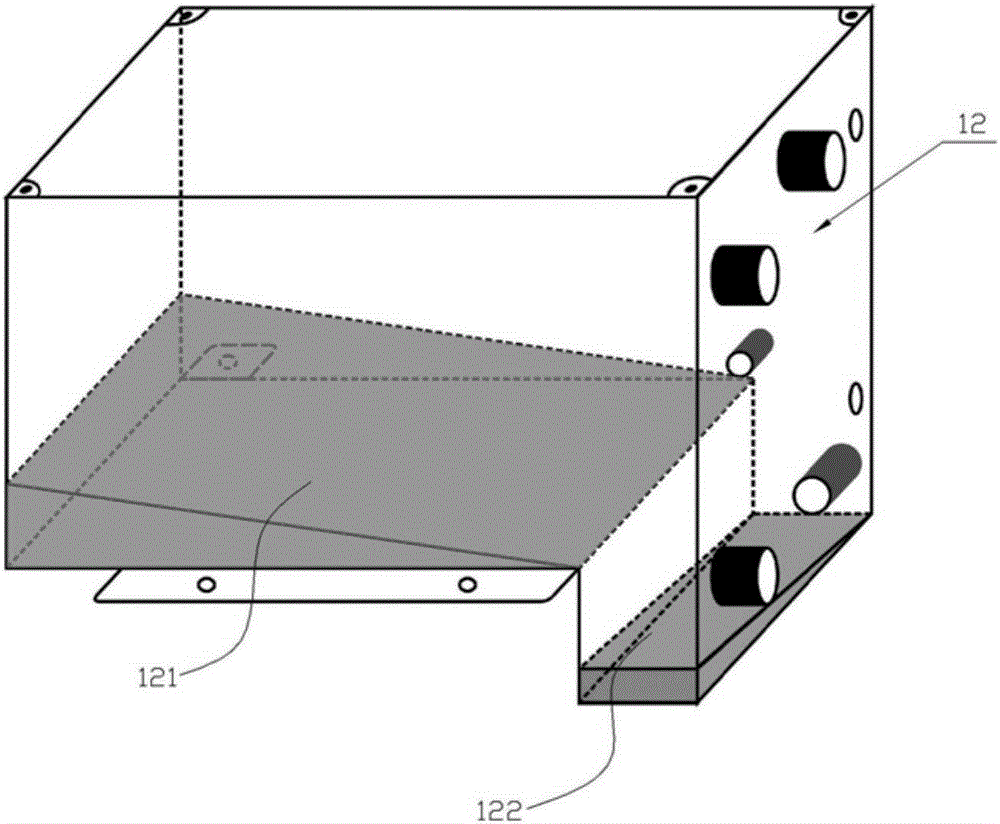

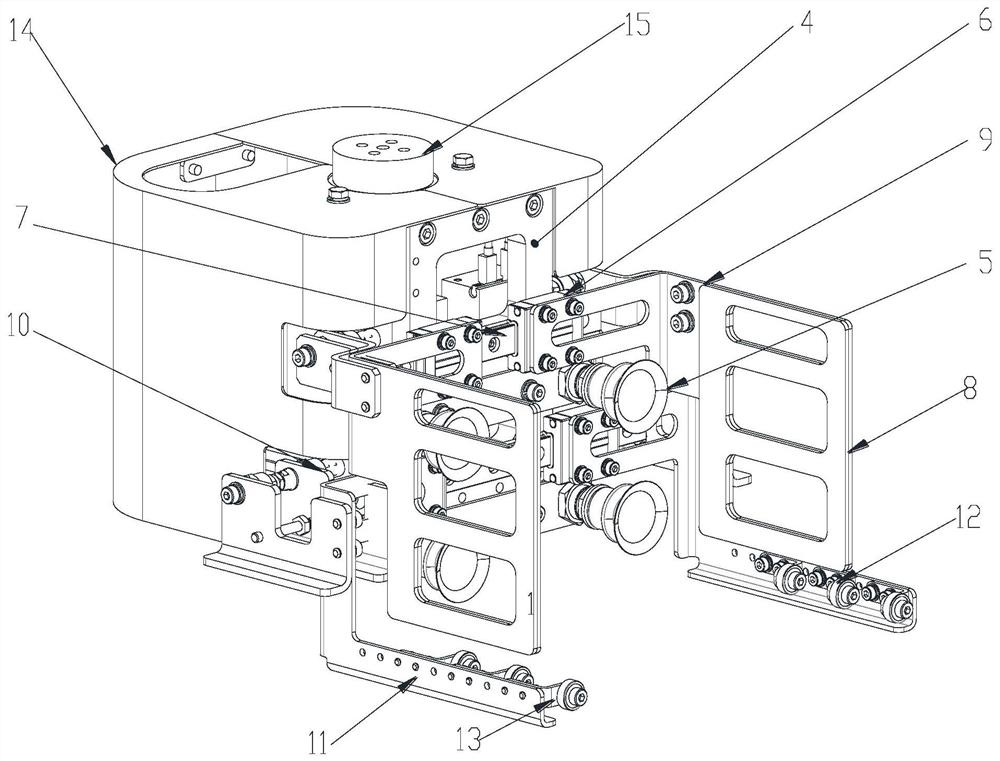

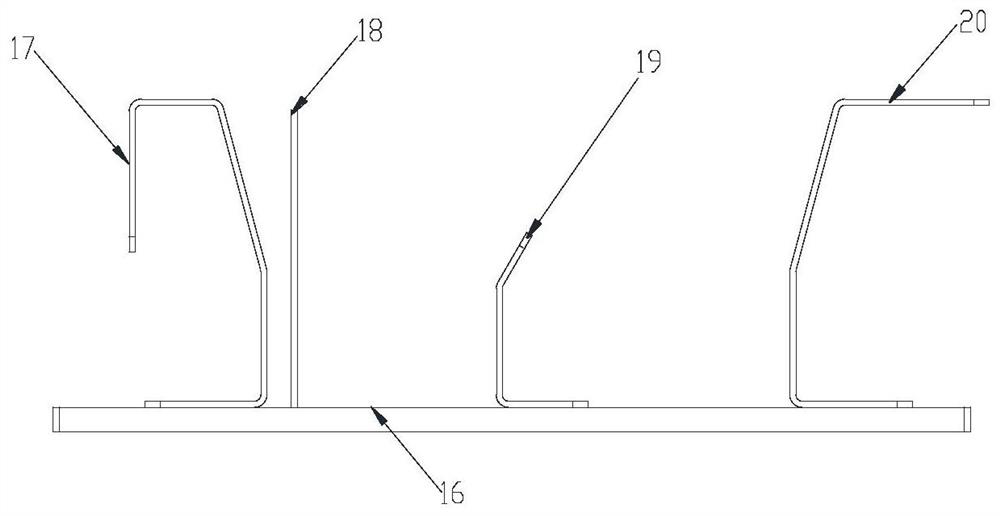

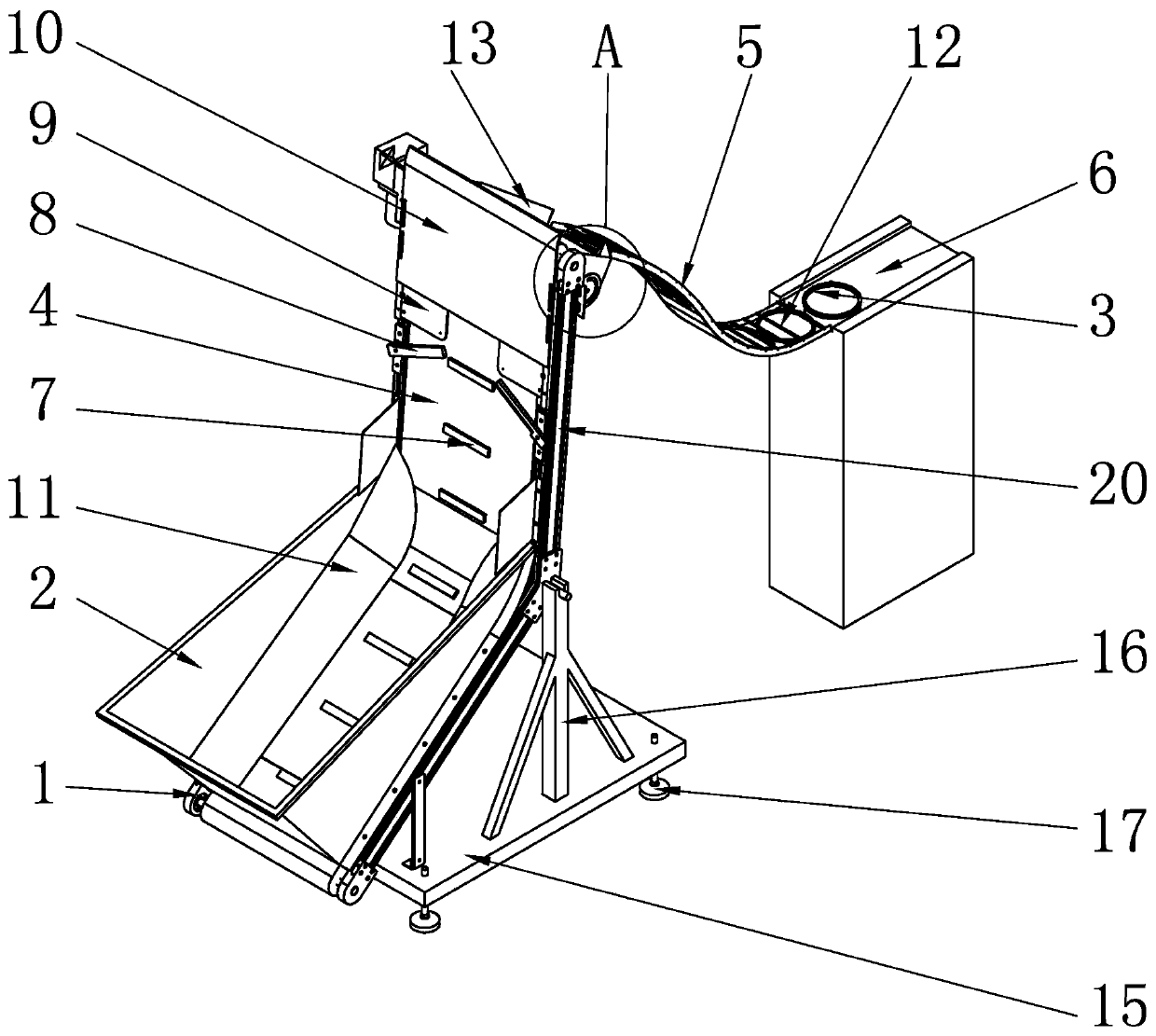

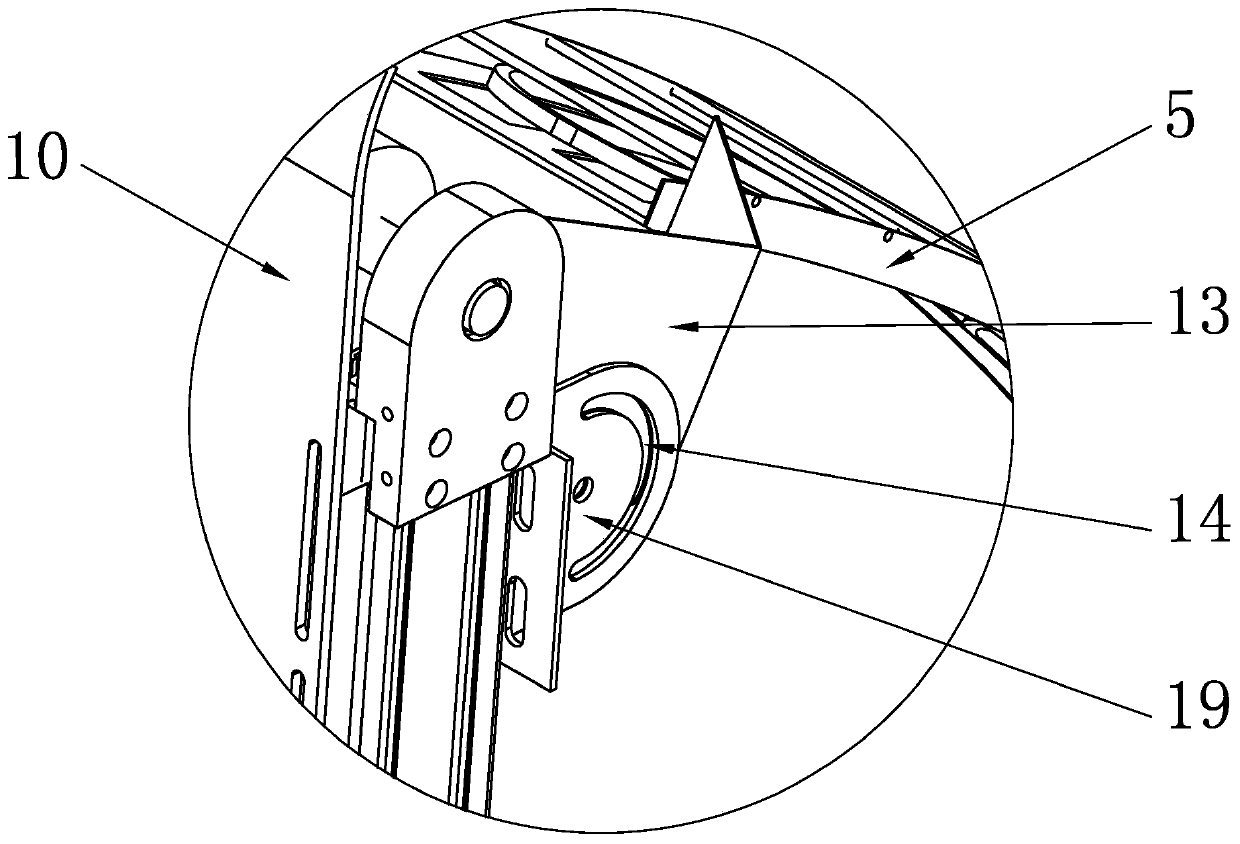

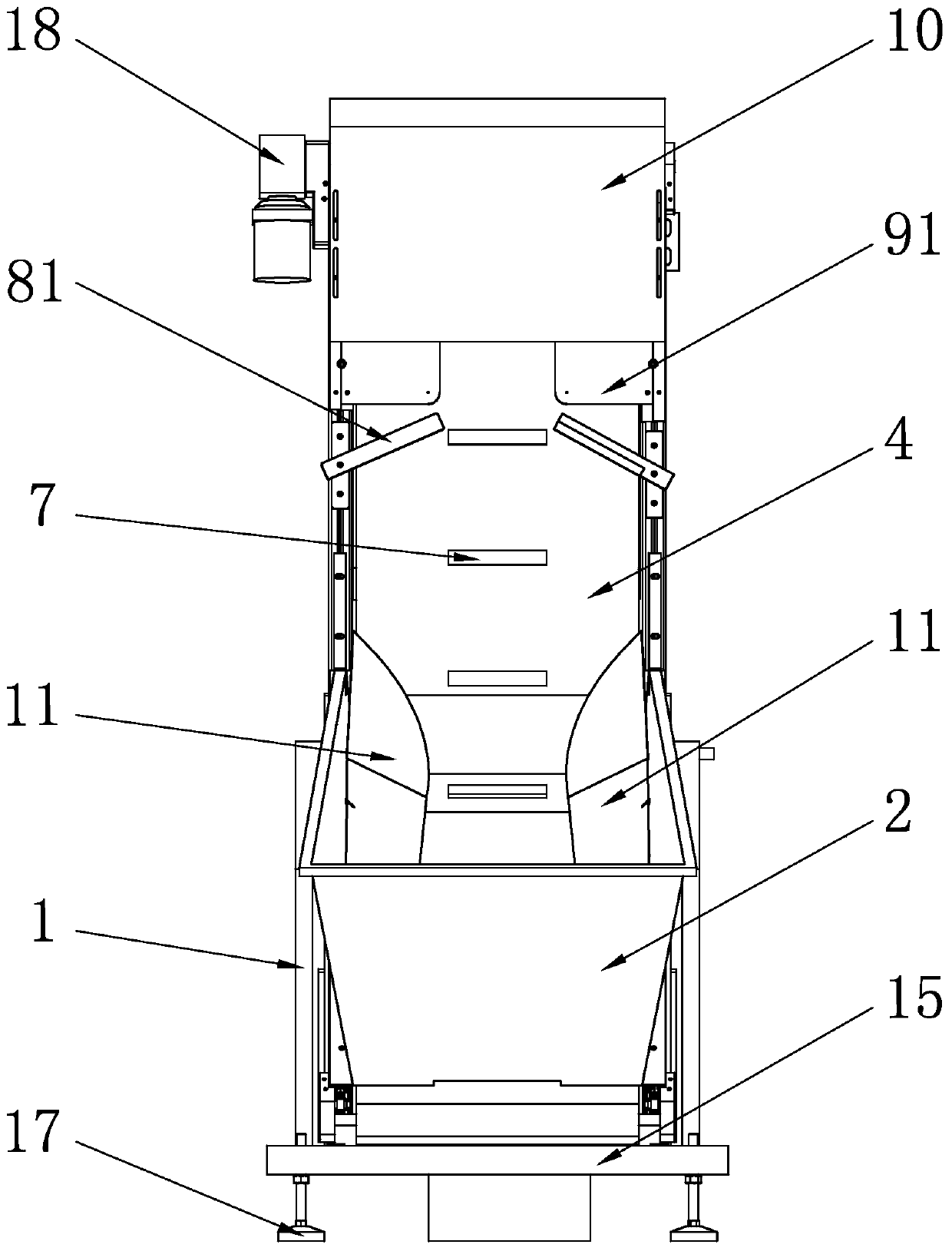

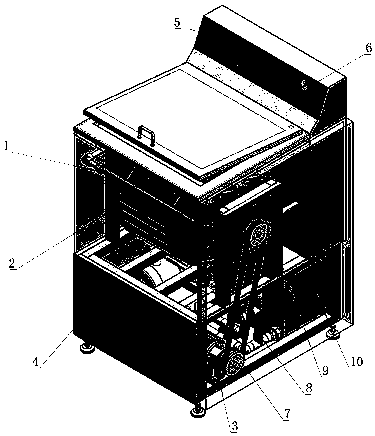

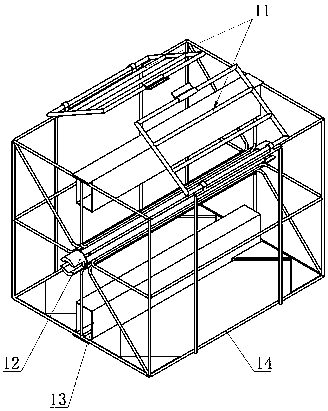

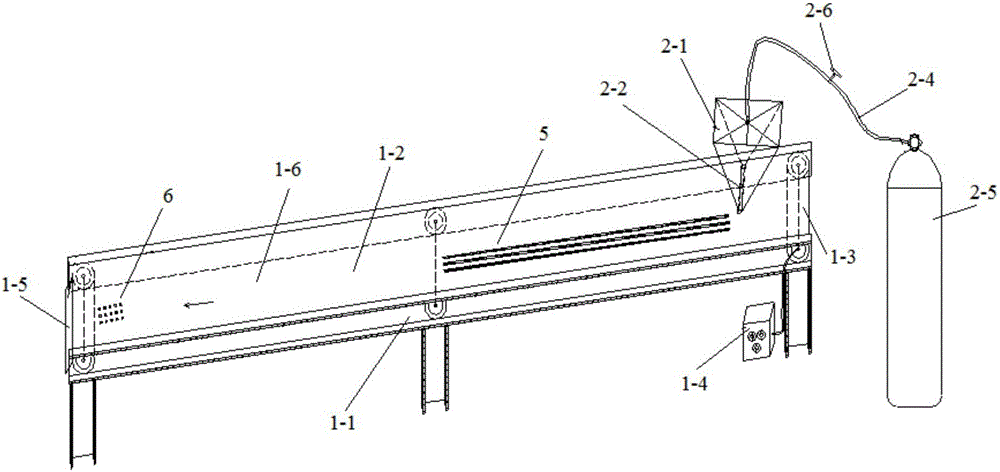

Automatic feeding device for grinding both sides of slip sheets

InactiveCN103128615ANo stackingLabor savingPlane surface grinding machinesProgrammable logic controllerControl system

The invention relates to an automatic feeding device for grinding both sides of slip sheets. The automatic feeding device comprises a main frame, a feeding box, a feeding box bracket, a feeding box stepping mechanism, a slip sheet ejecting and feeding device and a PLC (programmable logic controller) control system. The PLC control system controls all the devices to transfer the slip sheets from the feeding box to a grinding tool according to the feeding and producing time so as to realize the continuous, efficient and automatic feeding process. The traditional method of manual feeding of slip sheets is changed to automatic feeding, and thus, the processing efficiency is improved, efficient and continuous processing is guaranteed and labor is saved.

Owner:SICHUAN UNIV

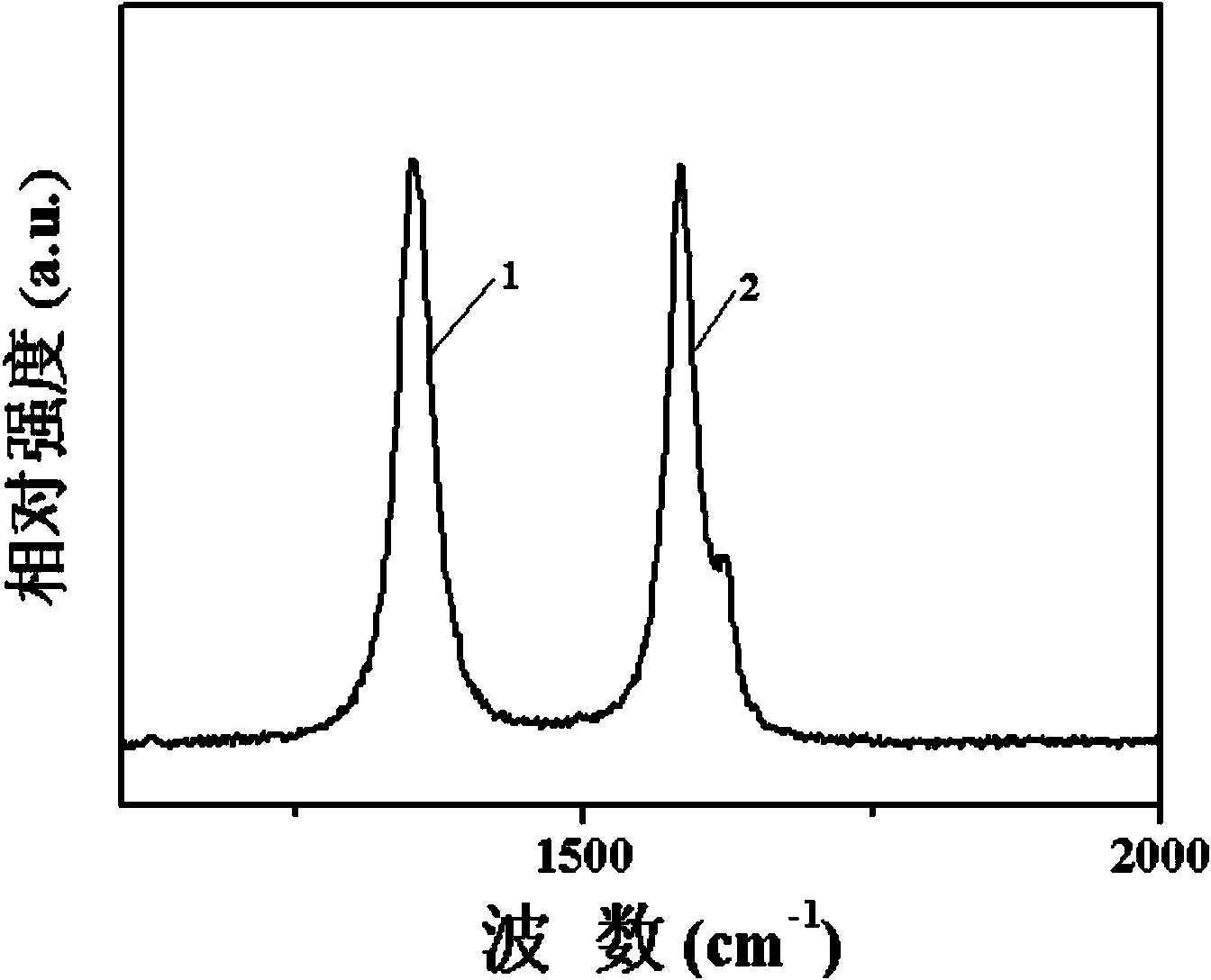

Method for preparing composite electrode material of carbon nano-tube-graphene supercapacitor

ActiveCN103824704AImprove conductivityLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureGas phaseCarbon nanotube

The invention relates to a method for preparing composite electrode materials, in particular to a method for preparing a composite electrode material of a carbon nano-tube-graphene supercapacitor. The method solves the problem that preparing temperature of graphene prepared through an existing CVD method is high, and the graphene of centimeter level cannot serve as the electrode material to be applied to the supercapacitor. The method comprises the steps of arranging a substrate material in a plasma enhanced chemical vapor deposition vacuum device, feeding argon, raising the temperature to 700 DEG C-900 DEG C, then feeding carbon source gas to adjust pressure intensity for deposition, after deposition is finished, stopping feeding the carbon source gas, the substrate material is cooled to below 100 DEG C, and the composite electrode material of the carbon nano-tube-graphene supercapacitor is obtained. The method is used for preparing the composite electrode material of the carbon nano-tube-graphene supercapacitor.

Owner:HARBIN INST OF TECH

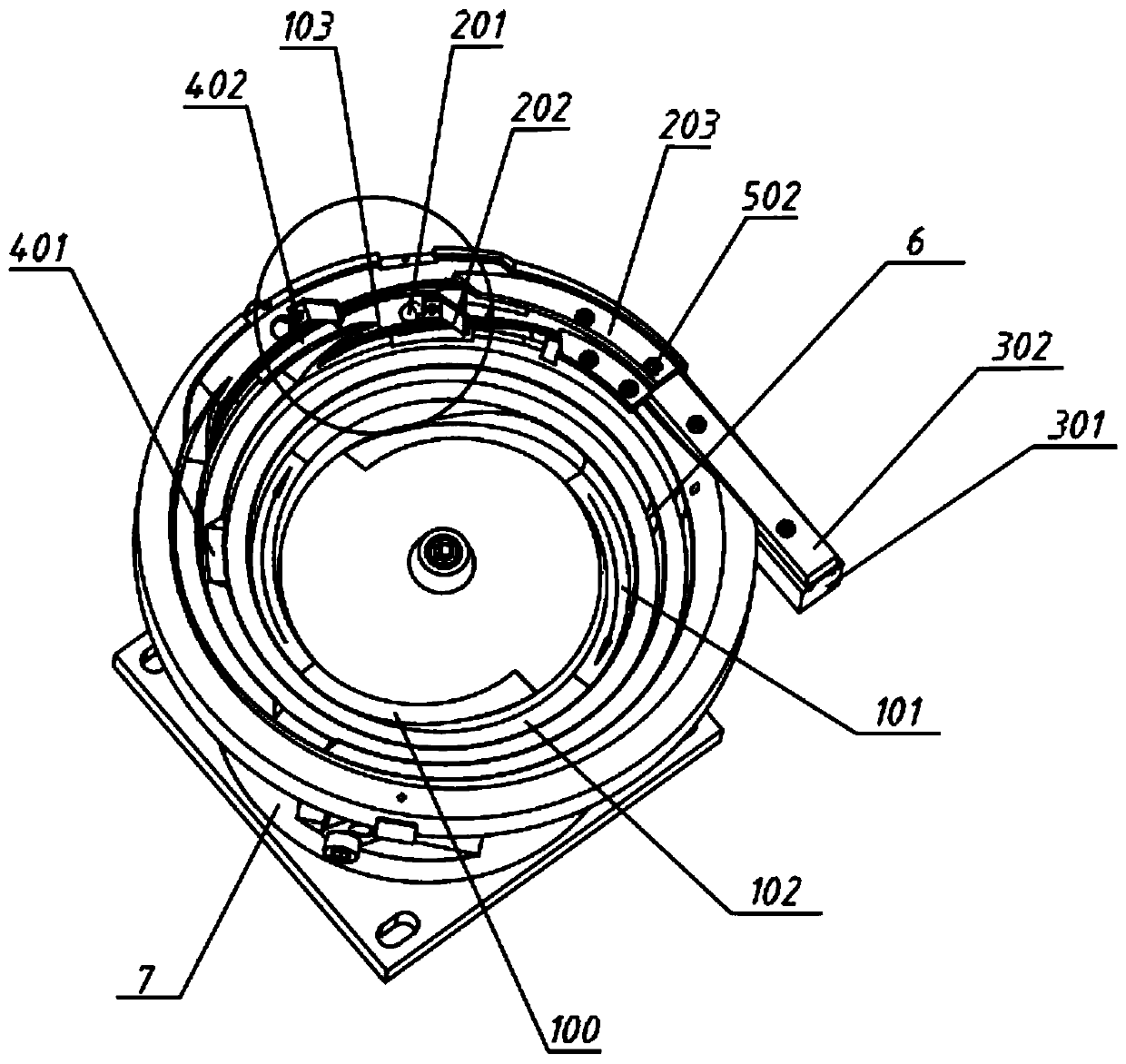

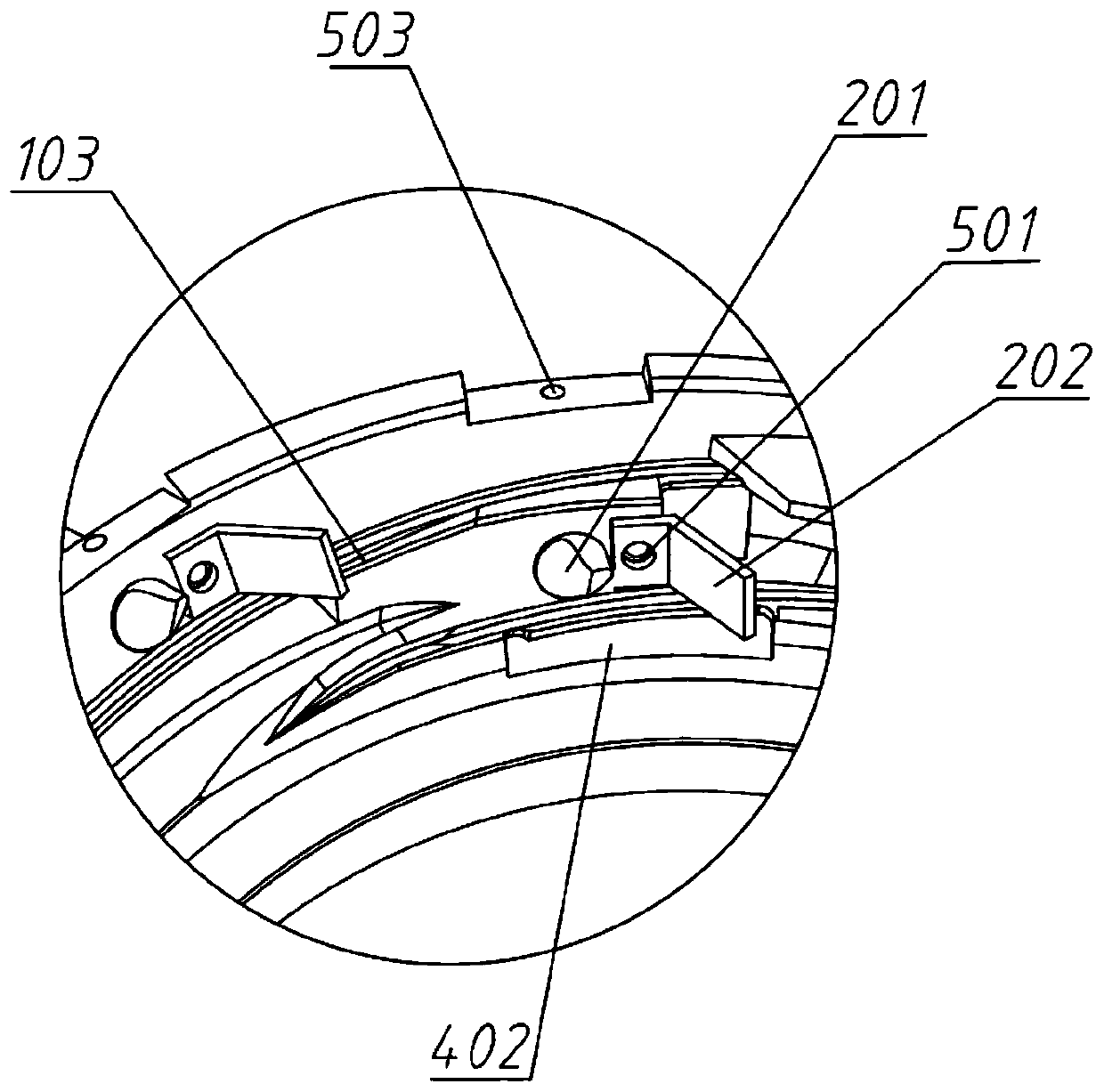

Silver contact automatic feeding vibrating disk

ActiveCN110127338ASmooth dischargeEfficient supplyJigging conveyorsConveyor partsEngineeringFriction force

The invention discloses a silver contact automatic feeding vibrating disk. The silver contact automatic feeding vibrating disk comprises a vibrating disk body, a plurality of turnover rails fixed on the vibrating disk body, and a plurality of material screening mechanisms which are in one-to-one correspondence with the turnover rails; a circular hopper is arranged on the vibrating disk body, the turnover rails are arranged in an interactive spiral upward mode and along the inner side wall of the hopper, and a guide groove is formed by the turnover rails and the inner side wall of the hopper; the guide groove comprises a feeding groove section, a conveying groove section, and a material screening groove section, wherein the feeding groove section, the conveying groove section and the material screening groove section are integrally connected from bottom to top in sequence, and the tail end of the feeding groove section is flush and connected with the bottom surface of the hopper; and each material screening mechanism is fixed on the side wall of the material screening groove section, wherein each material screening mechanism comprises a turnover column, a height limiting sheet and amaterial overlapping-preventing pressing plate. According to the silver contact automatic feeding vibrating disk, materials are enabled to face the same direction through the gravity and friction force of the rails, the materials are adjusted to a correct feeding angle by the turnover columns, unqualified materials are screened out by the height limiting sheet, discharging of the materials is more smooth due to the material overlapping-preventing pressing plate, so that the efficiency of material screening and feeding and the material feeding fault-tolerant rate are improved.

Owner:厦门兴泰克机电有限公司

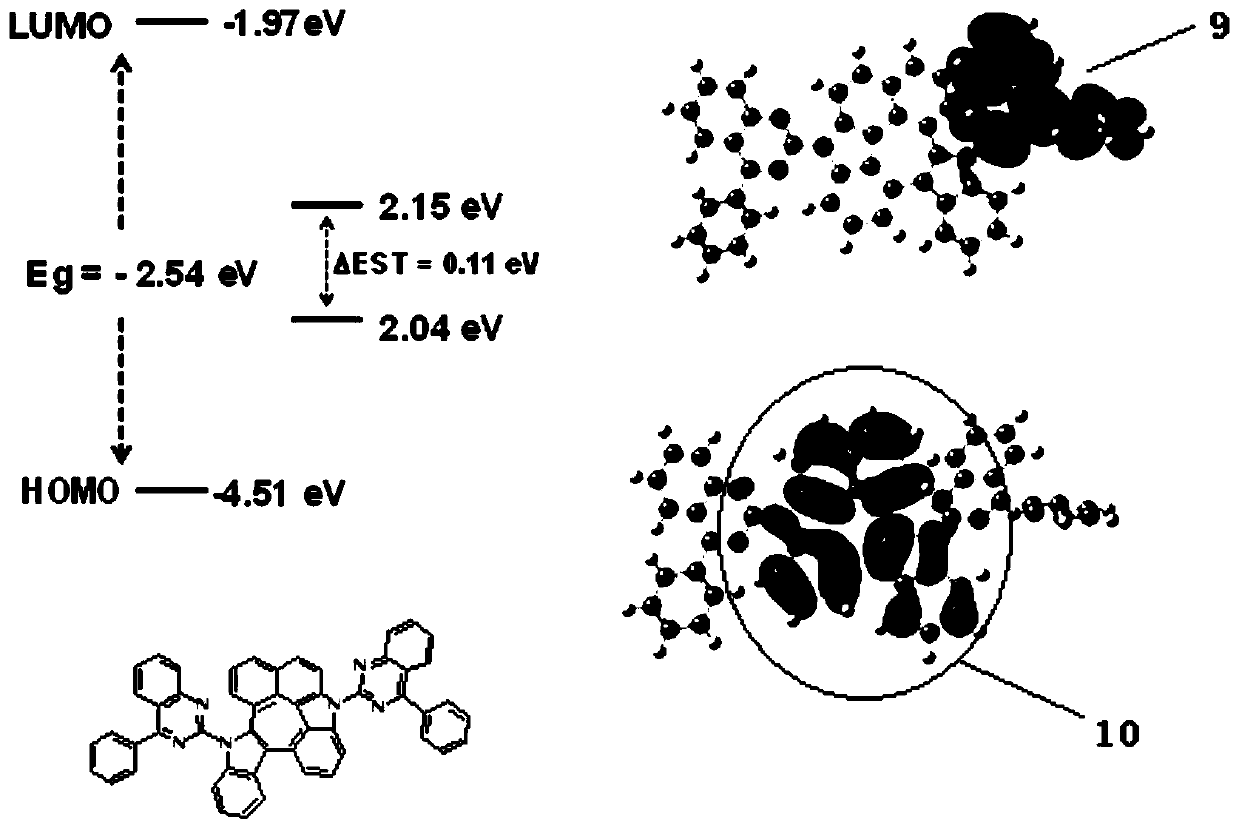

Organic compound and preparation method and application thereof

ActiveCN111072674AEasy injectionEasy transferOrganic chemistrySolid-state devicesHigh energyHeat stability

The invention provides an organic compound as well as a preparation method and application thereof. The organic compound has a structure as shown in a formula I, the organic compound has a relativelyhigh thermal decomposition temperature; the triplet state energy level is high; the energy level difference between HOMO and LUMO is relatively small; HOMO and LUMO energy levels of the compound withthe specific structure are matched with a hole transport layer and an electron transport layer; meanwhile, due to the specific three-dimensional configuration, material molecules cannot be stacked; annihilation caused by existence of high-energy excitons is reduced, the energy transfer efficiency is improved, the luminous efficiency is improved, the driving voltage is reduced, the light-emitting stability is relatively high, the color cast is effectively reduced, the thermal decomposition temperature is high, the thermal stability is relatively high, and the luminous efficiency and the luminous performance of the device are improved.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

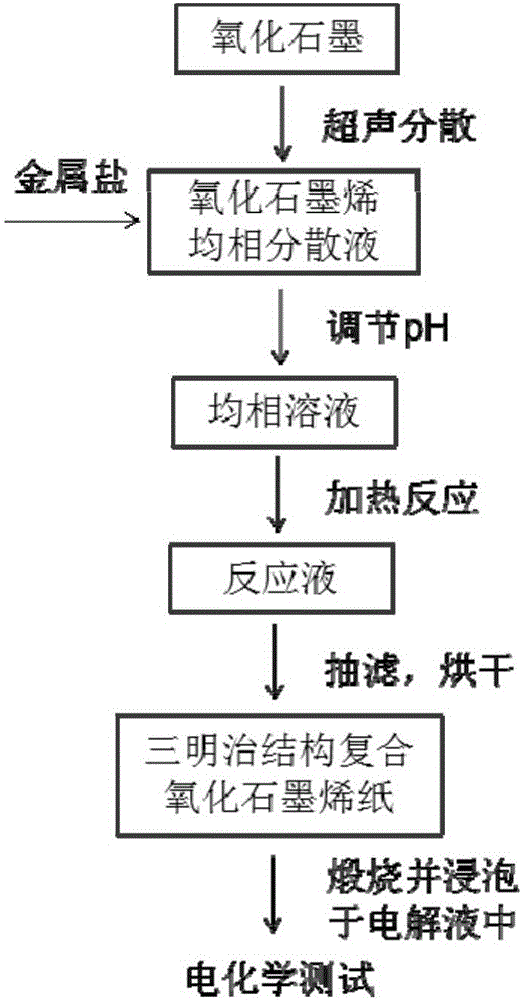

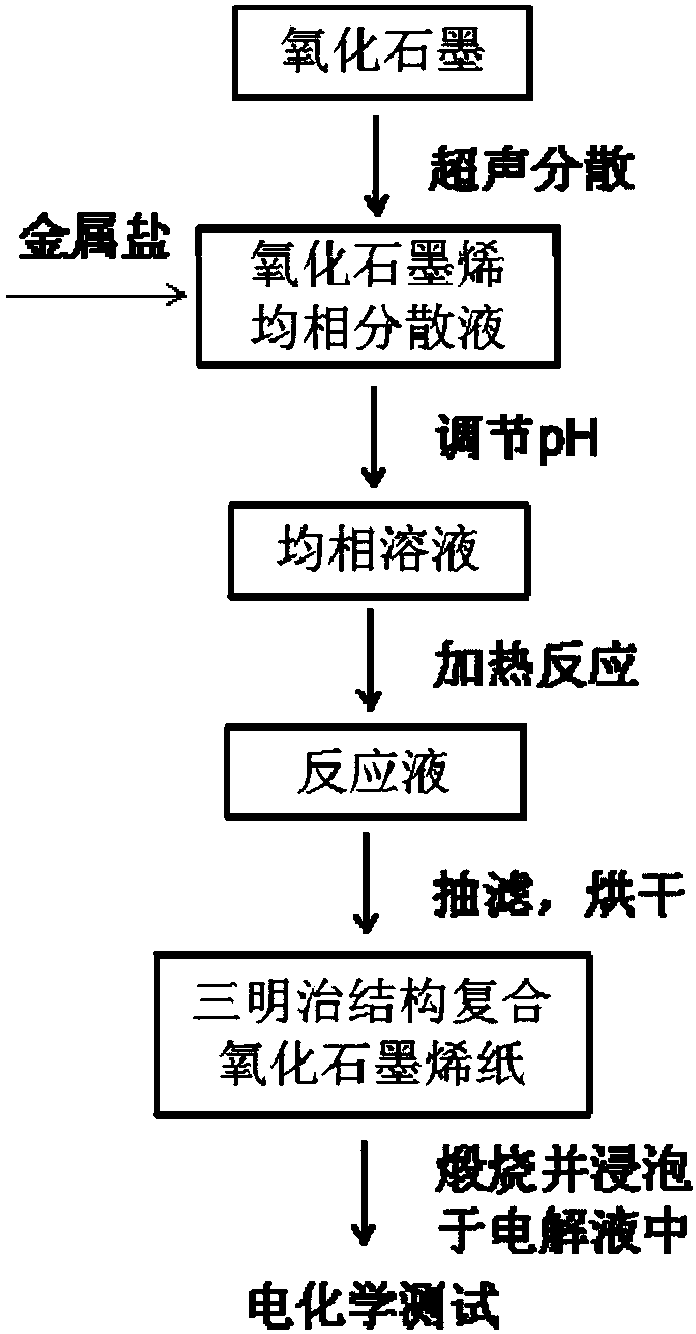

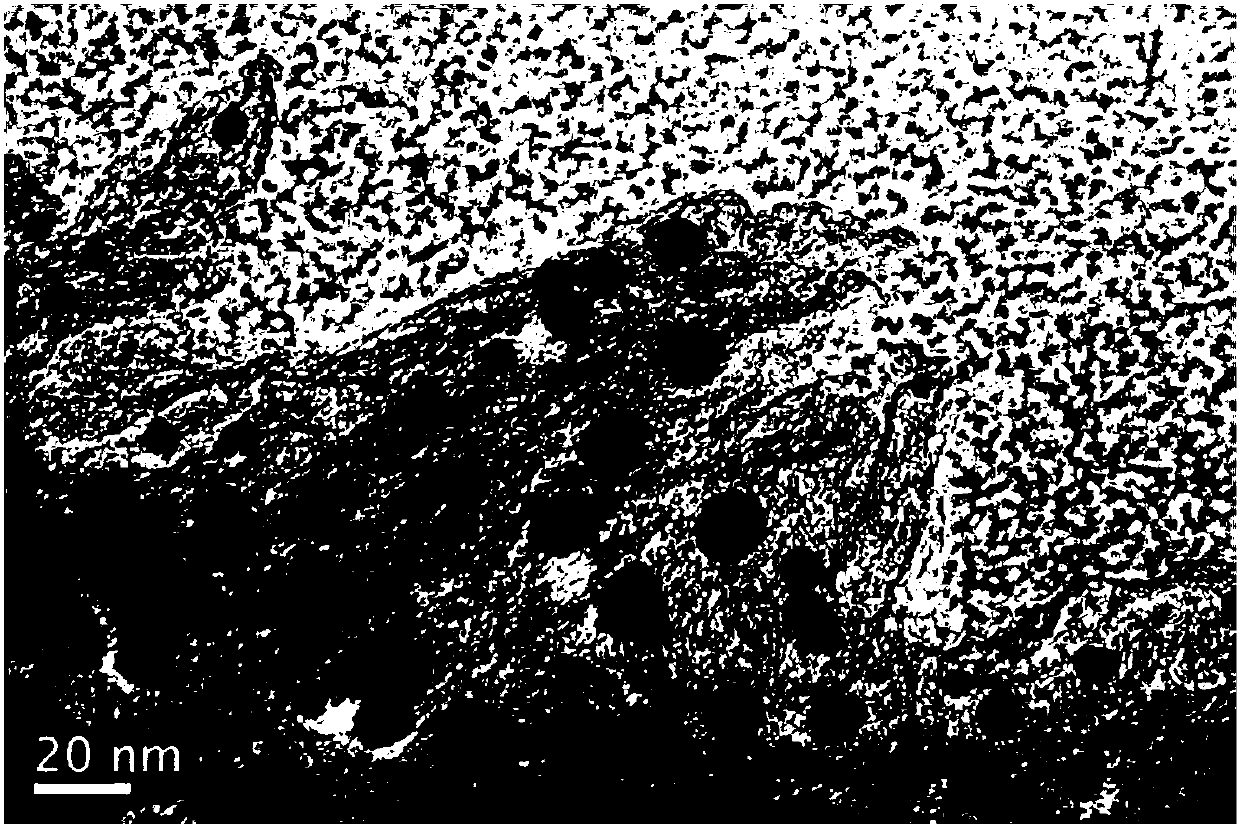

Method for preparing electrode material of sandwich structured composite graphene oxide paper

ActiveCN105845456AFacilitate electron transferGood supportHybrid capacitor electrodesHybrid/EDL manufactureSolventGraphene oxide paper

The invention belongs to the field of preparation of composite electrode materials, and in particular relates to preparation of an electrode material of a piece of sandwich structured composite graphene oxide paper. The electrode material of the sandwich structured composite graphene oxide paper is prepared through a one-step method. The method specifically comprises the following steps of ultrasonically dispersing graphite oxide in a solvent, adding transition metal salt to discontinuously stir, such that the system is uniformly mixed, reacting at 80-150 DEG C for 8-12 h after adjusting pH to alkalinity, and performing suction filtration, washing and drying at low temperature so as to obtain the electrode material of the sandwich structured composite graphene oxide paper. To improve the electrochemical property of the electrode material, the electrode material is roasted and immersed in electrolyte after being roasted. The preparation material is cheap and available in raw material, simple and convenient in process operation and low in production cost, and is suitable for industrial production; and furthermore, the prepared electrode material has excellent electrochemical property.

Owner:CHANGZHOU UNIV +1

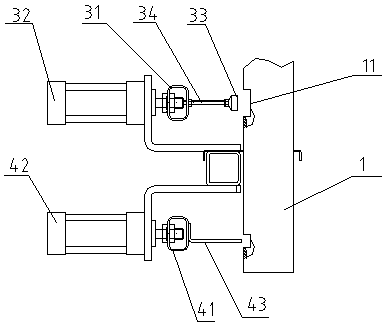

Cap delivery device of cap screwing machine

InactiveCN102976084AConveying orderlyNo stackingCapsClosure using capsLower limitBiomedical engineering

The invention relates to a cap delivery device of a cap screwing machine. The cap delivery device comprises a cap guide groove, wherein the cap guide groove consists of two side plates and a bottom plate; the cap guide groove comprises a delivery part and a cap delivery part; a cap pressing plate covers the delivery part; a hole is formed in the bottom plate of the cap delivery part, a cap delivery cylinder is arranged below the bottom plate of the cap delivery part, and a push shaft of the cap delivery cylinder is coaxially and fixedly connected with a cap delivery rod; the cap delivery rod is coaxial with the hole, and the size of the cap delivery rod is matched with that of the hole; an upper limit sensor and a lower limit sensor are arranged on the cap delivery cylinder; and a cap deficiency sensor is arranged on the cap guide groove. The cap delivery device has the advantages of simple structure, excellent cap delivery effect and capability of automatically judging cap deficiency and stopping.

Owner:JIANGSU TOM PACKAGING MACHINERY

Discharging device and discharging method

PendingCN109677903ANo stackingEasy to operateConveyor partsSmall footprintElectrical and Electronics engineering

Owner:远大可建科技有限公司

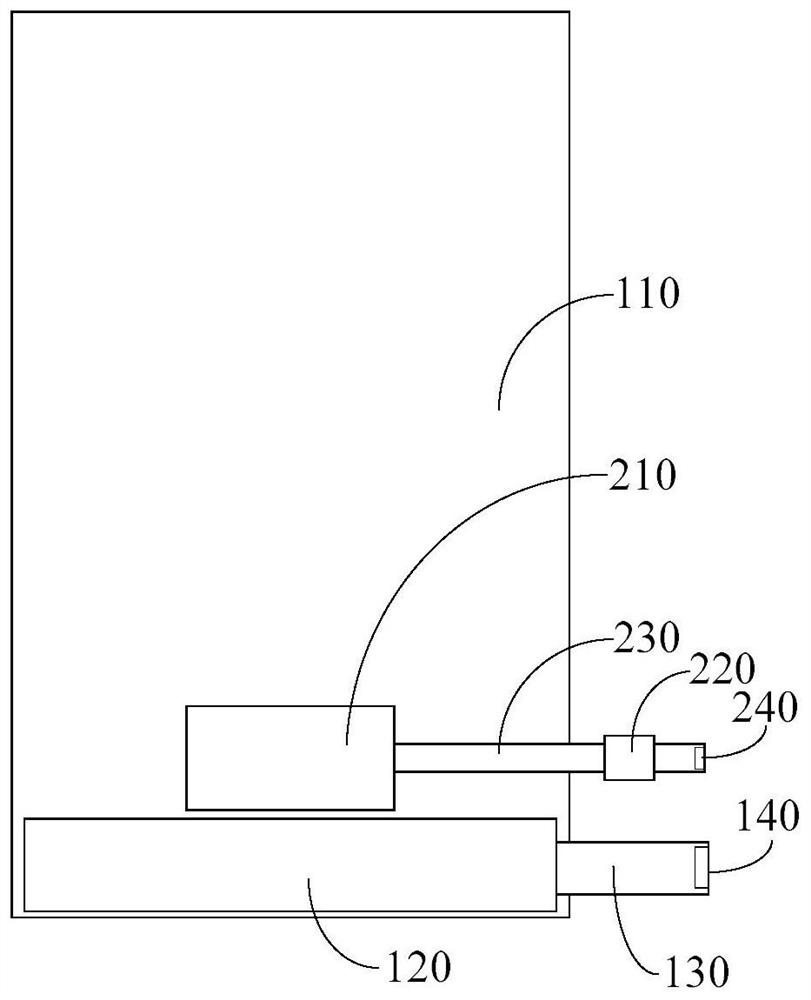

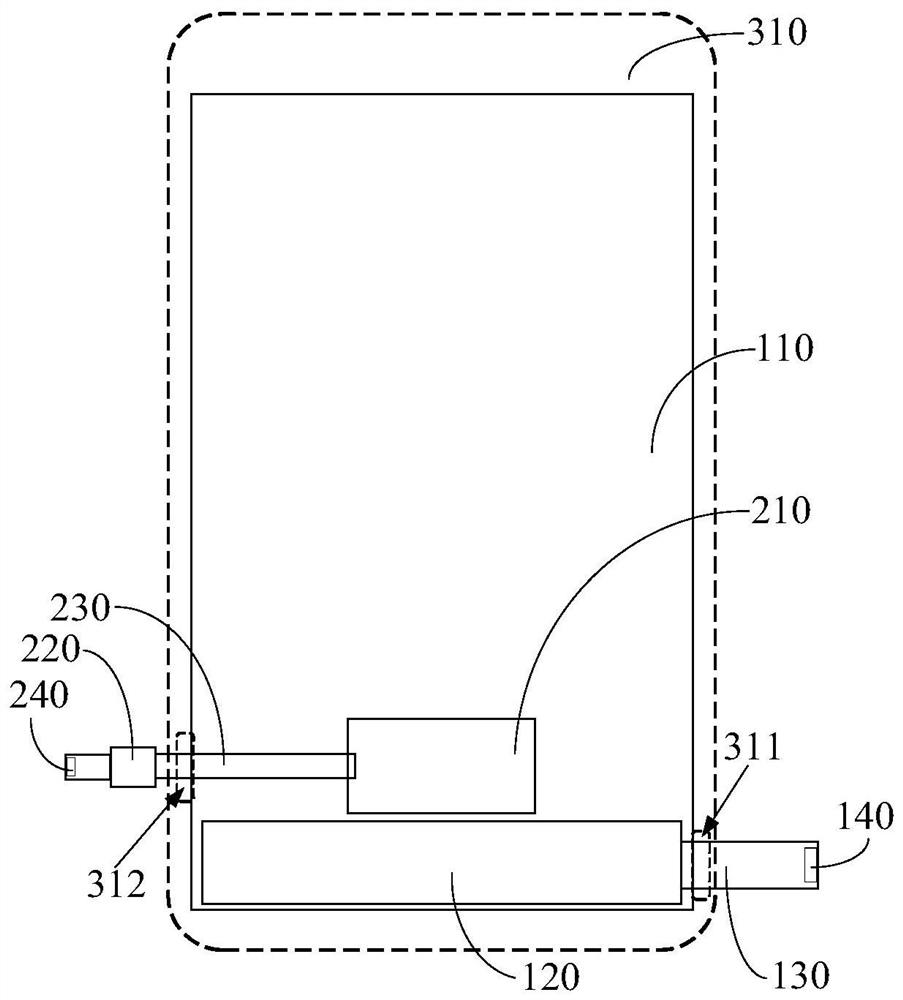

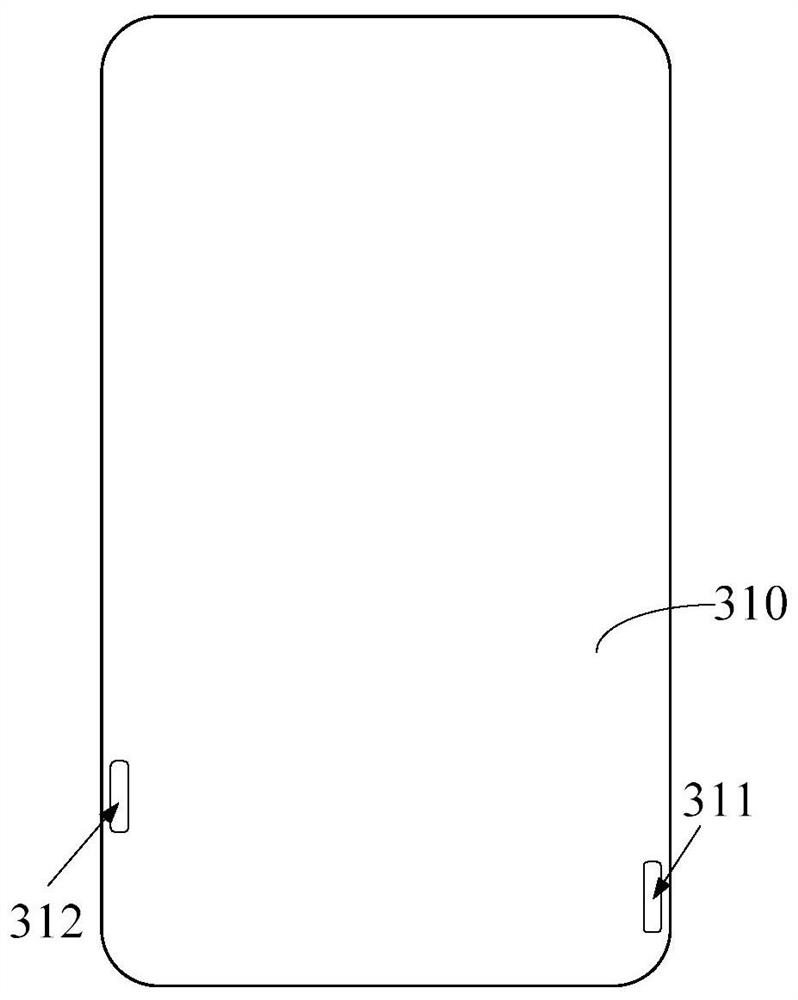

Electronic equipment

PendingCN112163464AWith under-screen fingerprint recognition functionFacilitate the development of light and thinDigital data processing detailsPrinted circuit aspectsComputer hardwareEmbedded system

The invention discloses electronic equipment, and belongs to the field of communication equipment. The electronic equipment comprises a display module, a fingerprint identification module and a firstcircuit board, wherein the display module comprises a display screen, a second circuit board and a first connecting part, the display screen is electrically connected with the second circuit board, and the second circuit board is electrically connected with the first circuit board through the first connecting part; and the fingerprint recognition module comprises a fingerprint sensor, a fingerprint driving unit and a second connecting part, the fingerprint sensor is arranged on the side, deviating from the display surface, of the display screen, the fingerprint sensor and the fingerprint driving unit are distributed at intervals, and the fingerprint sensor and the fingerprint driving unit are electrically connected with the first circuit board through the second connecting part. The electronic equipment disclosed by the technical scheme can solve the problems that in existing electronic equipment, a fingerprint driving unit occupies a large area on a circuit board of a display screen,and due to the fact that a fingerprint signal and a display signal are transmitted out together, the number of design constraint conditions of a first circuit board is large and the design difficultyis large.

Owner:VIVO MOBILE COMM CO LTD

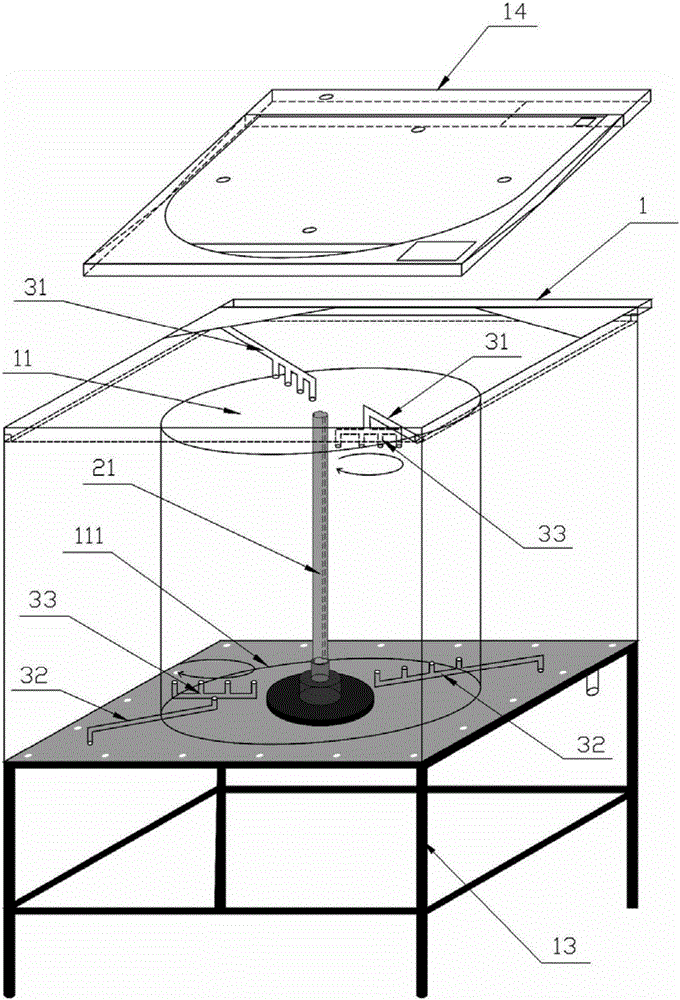

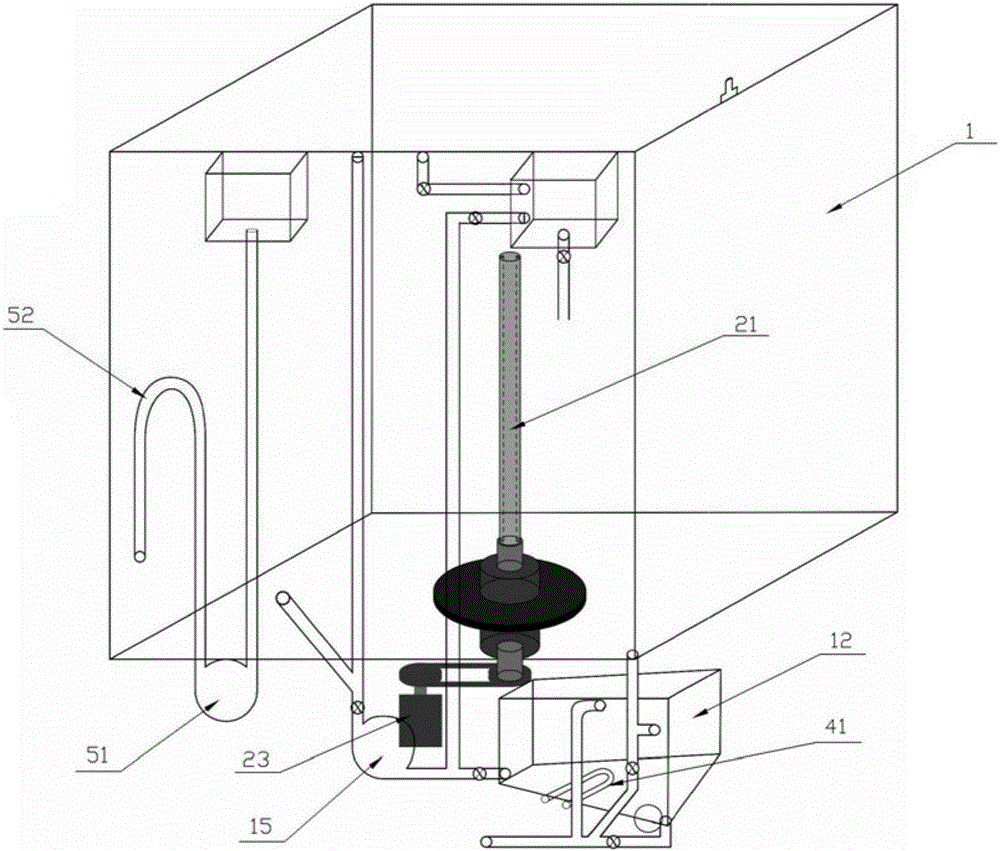

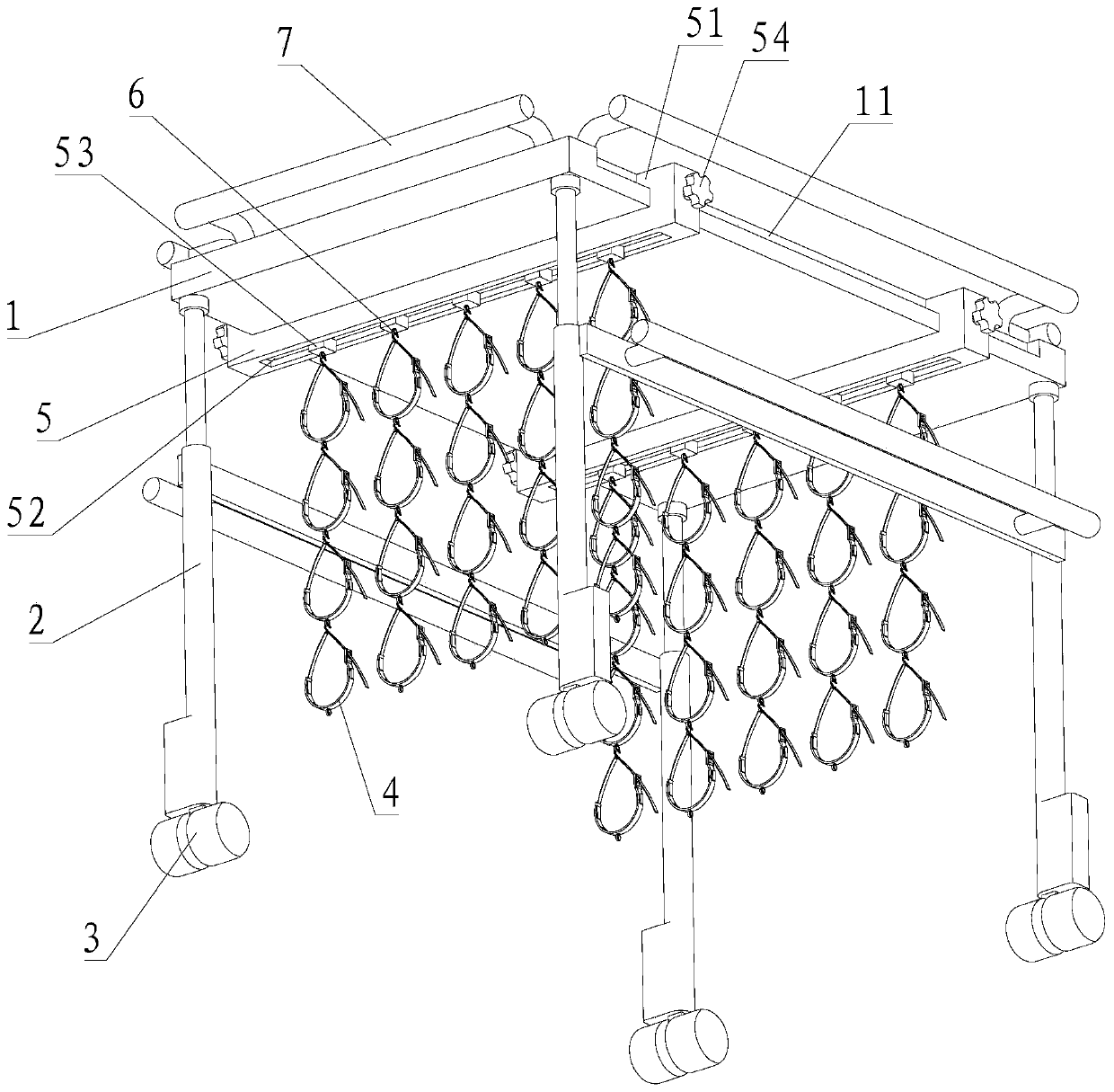

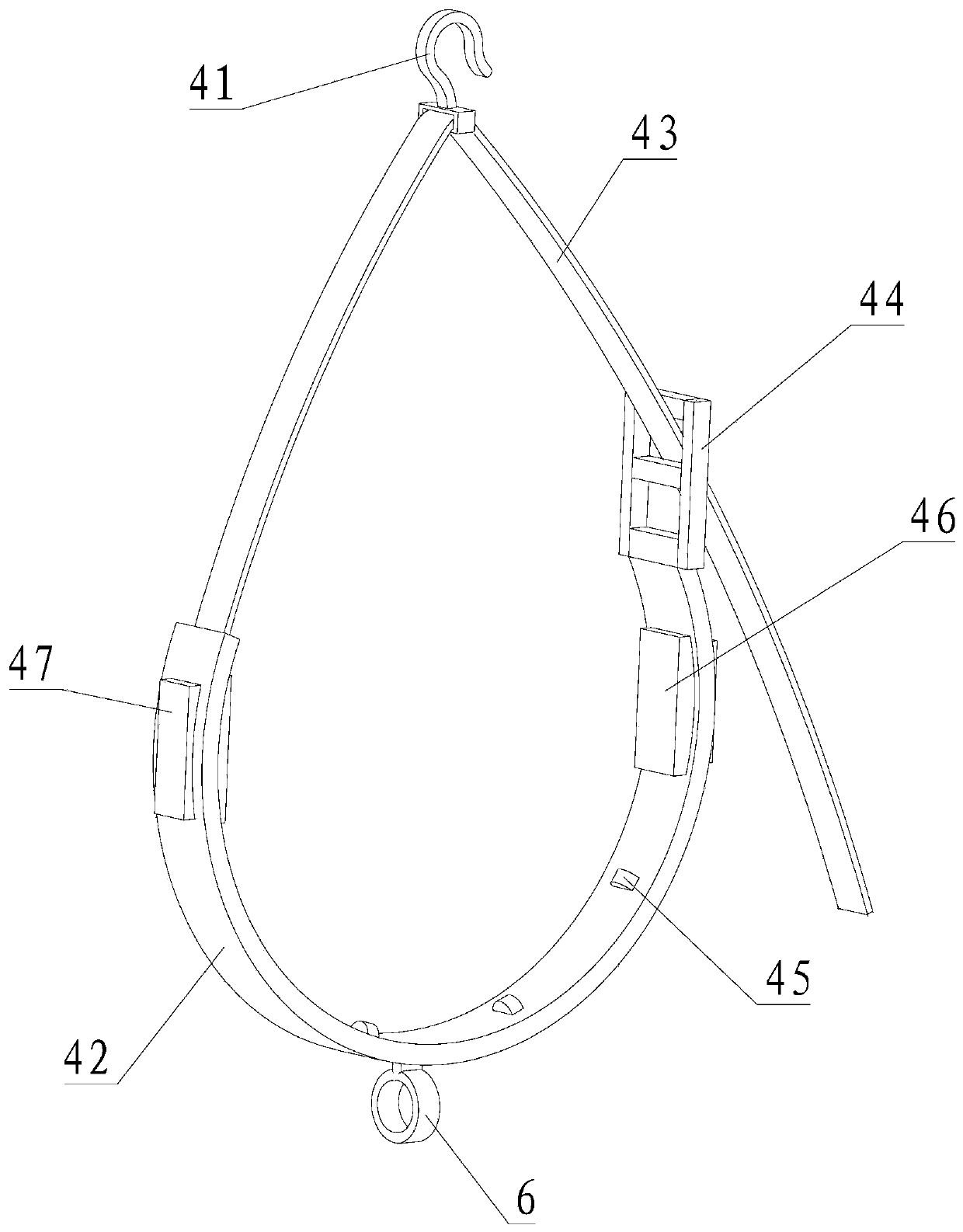

A kind of rotating glasses cleaning equipment and its cleaning basket

ActiveCN103913855BImprove cleaning efficiencyBest tangential flushing forceSpectales/gogglesCleaning using liquidsEngineeringMechanical engineering

Owner:GUANGZHOU CAIBIAO 3D GLASSES

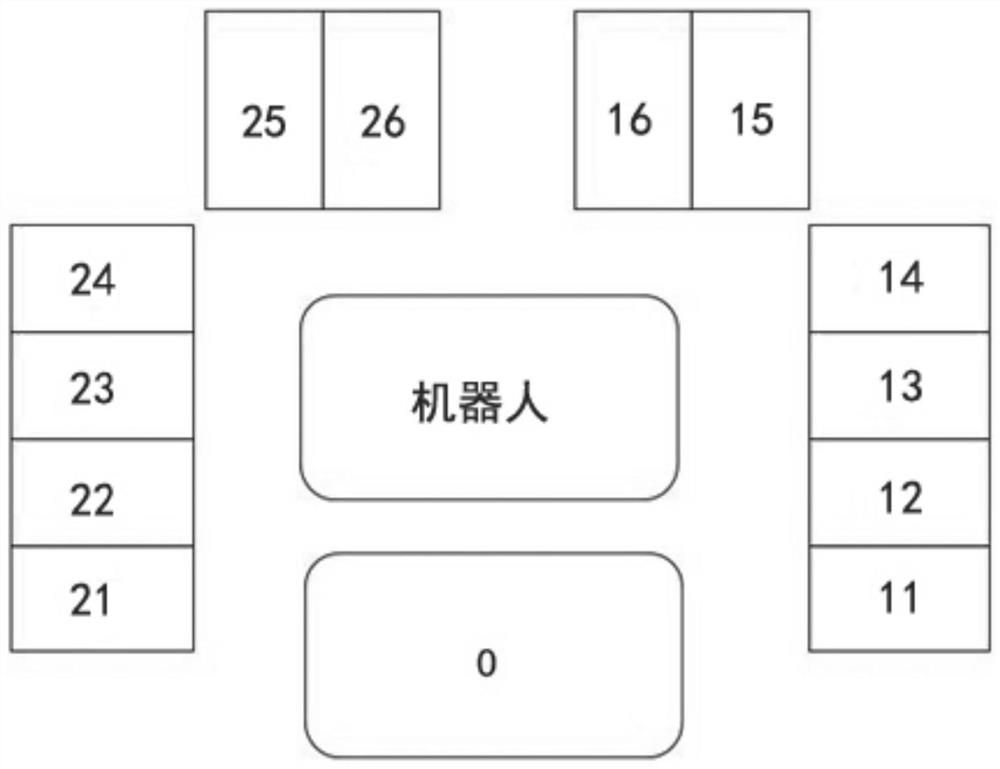

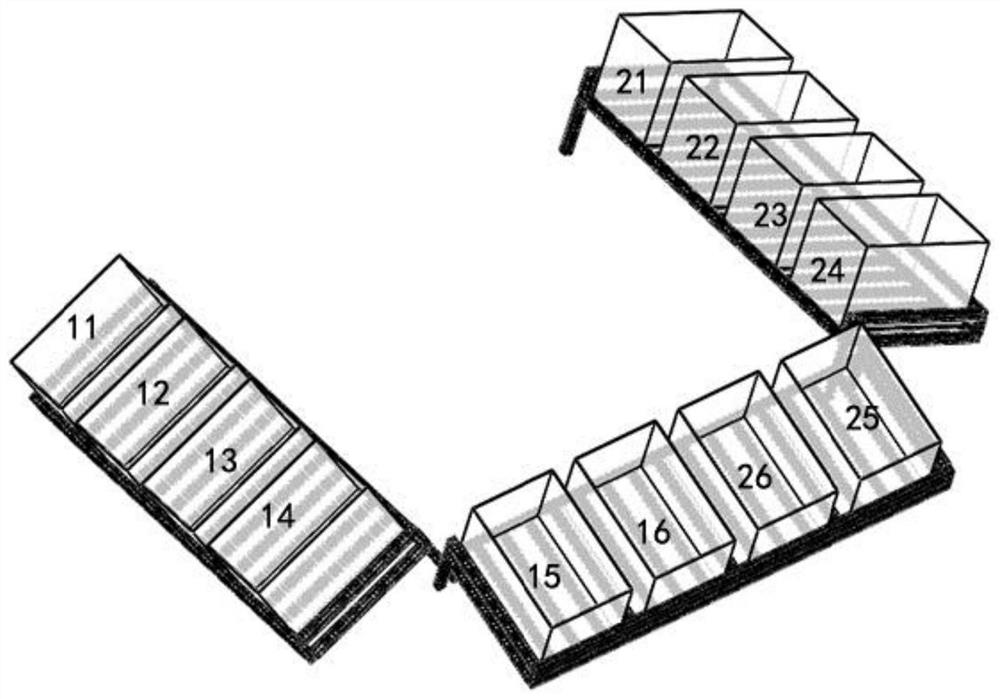

Efficient sorting method of robot

ActiveCN112372644ASimplify motion calculationsPrevent mutual collisionProgramme-controlled manipulatorEngineeringReal-time computing

The invention relates to the technical field of robots, in particular to an efficient sorting method of a robot. The efficient sorting method comprises the following steps: S1, setting the positions of a plurality of mechanical arms of the robot, and ensuring that the tail end action point of each mechanical arm can reach a plurality of working stations of the mechanical arm, and the working stations comprise an object taking point o and a plurality of placing points of the mechanical arm; S2, determining a sorting track of each mechanical arm in a dispatching system, wherein the sorting trackcomprises initial points and movement routes of all the mechanical arms; S3, obtaining the position of the mechanical arm when the mechanical arm stops working last time through a mechanical arm sensor, and initializing an initial point of the mechanical arm according to a dispatching system; and S4, enabling the robot to obtain an image of a to-be-grabbed target through a camera, converting theimage into recognizable information, and determining a corresponding placement point according to the recognizable information and the dispatching system. According to the efficient sorting method, the completion of the sorting task can be greatly improved by reasonably planning the movement and the movement track of each mechanical arm, and mechanical arm track movement calculation and error compensation in the sorting process are simplified.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

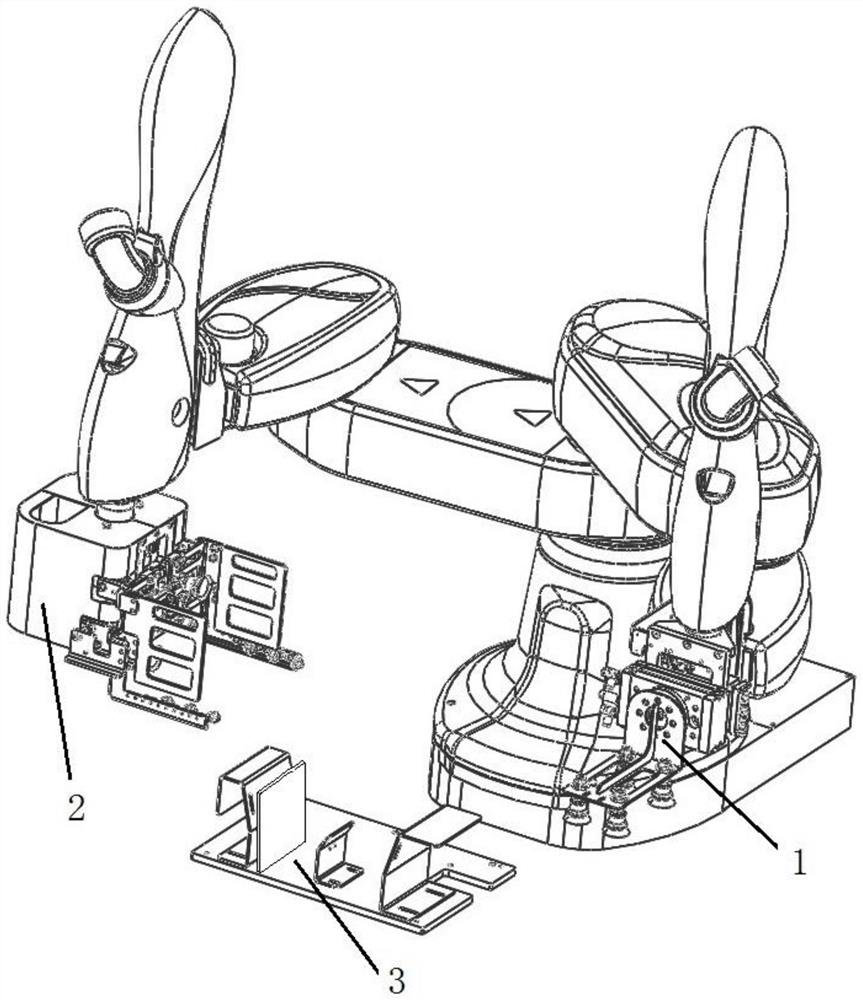

Carton folding robot and folding method thereof

PendingCN111823645AQuick lockQuick closePaper-makingBox making operationsRobot handControl engineering

The invention discloses a carton folding robot. The carton folding robot comprises a double-arm robot, a driven first mechanical hand, a second mechanical hand and an auxiliary bottom sealing tool, wherein the auxiliary bottom sealing tool is positioned under the position between the first mechanical hand and the second mechanical hand; the second mechanical hand comprises a driving arm connectedwith a robot body, a second mounting base plate connected with the driving arm, a sucking disc component arranged on the second mounting base plate, an auxiliary positioning mechanism and a closing mechanism; the auxiliary bottom sealing tool comprises a supporting base plate, an upper closing plate, a lower closing plate, an auxiliary plate and a locking plate; and the first mechanical hand and the second mechanical hand are clamped and matched on the supporting base plate to move back and forth, so that the bottom surface of a carton is closed and locked. The first mechanical hand grabs andopens the folded carton, and then the second mechanical hand clamps and positions the carton, so that a left bottom board and a right bottom board of the bottom surface of the carton are folded and closed, a front side board and a rear side board of the bottom surface of the carton are folded by the auxiliary bottom sealing tool, and thus the bottom surface of the carton is quickly closed and locked.

Owner:KAWASAKI ROBOTICS TIANJIN CO LTD

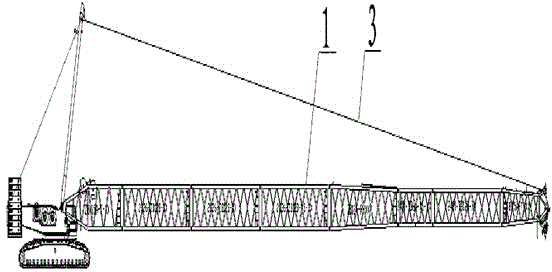

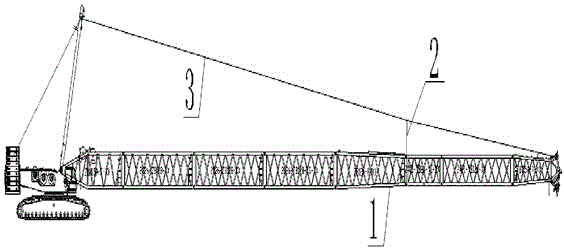

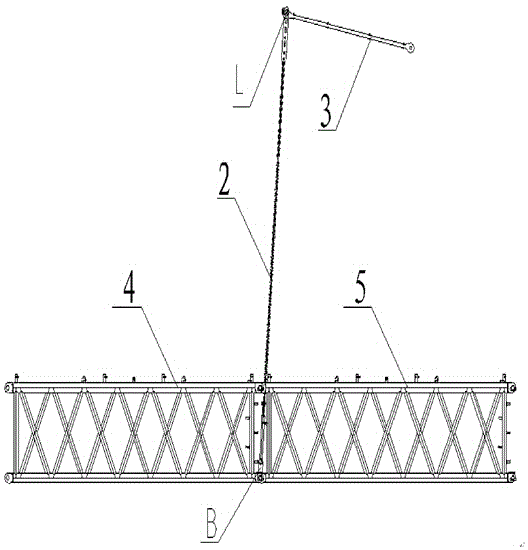

Waist rope structure

The invention discloses a waist rope structure. The waist rope structure is characterized by comprising a waist rope and a connection device, wherein one end of the waist rope is connected with the end part of the connection device; the other end of the waist rope is connected with a pull plate; the connection device is arranged in an arm frame; and the connection device is connected with a web member at the top of the arm frame by a flexible connector. According to the waist rope structure, the stability of the waist rope is improved so that the whole body of the waist rope is not in contact with the arm frame, and the service life of the arm frame and the waist rope is prolonged.

Owner:XCMG CONSTR MACHINERY

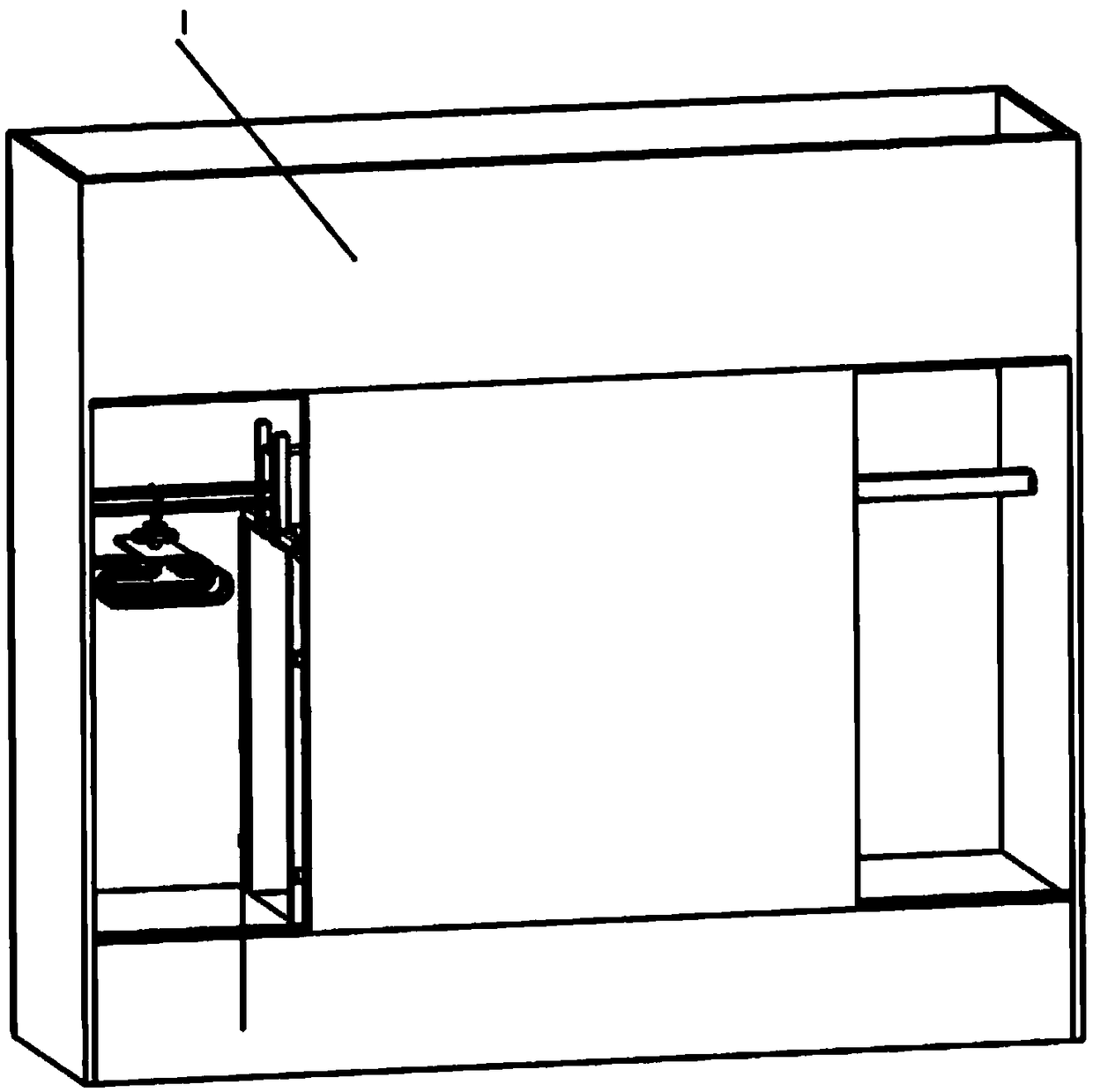

Automatic drying and washing integrated wardrobe

ActiveCN108866910AImprove cavitation effectEnhanced Airburst PowerWardrobesWashing machine with receptaclesMicrowaveProcess engineering

The invention discloses an automatic drying and washing integrated wardrobe. The automatic drying and washing integrated wardrobe comprises a wardrobe box, a washing and drying body box, an ultrasonictransmitting device, a running water washing device, a conveying guide rail device, a rotary clothes hanger, a pushing and rotating device, a drainage device, a microwave transmitting device, a sealing door device, an exhaust device, a hot air device and a clothes storage rod. The clothes washing mode of ultrasound and high-speed circulating running water washing is adopted, the cavitation effectof ultrasound is enhanced through high-speed running water, the air blasting force of cavitation bubbles generated by the ultrasound is enhanced, the clothes effect is more sufficient, and a high friction washing effect is also achieved for clothes through the high-speed running water. A stereoscopic clothes washing mode is adopted, the clothes are not piled when washed, the clothes are completely washed, a washing agent is not needed, and environmental protection and sanitation are achieved. A stereoscopic clothes drying mode in which microwaves and hot air are combined is adopted, the clothes are not piled when dried, the drying efficiency is high, and energy is saved.

Owner:QIQIHAR UNIVERSITY

Rubber ring lifter

The invention discloses a rubber ring lifter. The rubber ring lifter comprises a rack and further comprises a vertical plate and a hopper which are arranged on the rack; a plurality of rubber rings can be placed in the hopper; the bottom of the hopper and the vertical plate are provided with a conveyor belt, and the output end of the conveyor belt is connected with a receiving table through a sliding way and arranged on the vertical plate, and is higher than the hopper; the conveyor belt is provided with a plurality of lifting plates, and the space between every two adjacent lifting plates islarger than the width of one rubber ring and smaller than the width of the two corresponding rubber rings; a height limiting piece and a width limiting piece are arranged on the vertical plate and both arranged above the conveyor belt; and the height limiting piece and the width limiting piece limit passing of the rubber rings in the direction perpendicular to the output end of the conveyor belt and the width direction of the conveyor belt correspondingly, thus the rubber rings are conveyed to the sliding way through the conveyor belt one by one, and also slide down to the receiving table fromthe sliding way one by one, the rubber ring stacking phenomenon is avoided, subsequent assembling is convenient, the conveying efficiency is high, noise is small, and the cost is low.

Owner:珠海市明明机器人科技有限公司

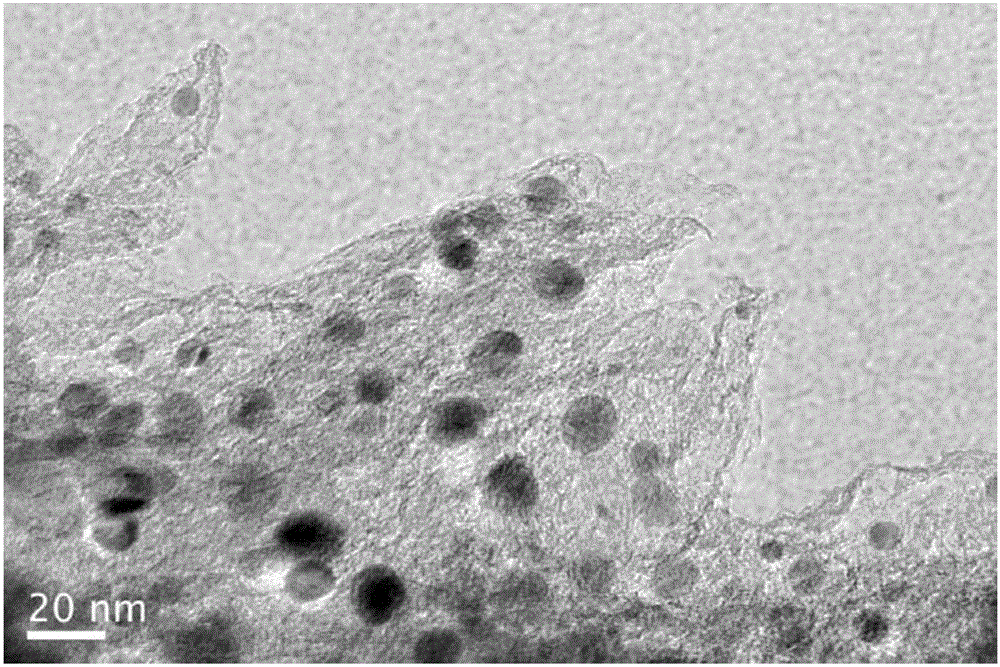

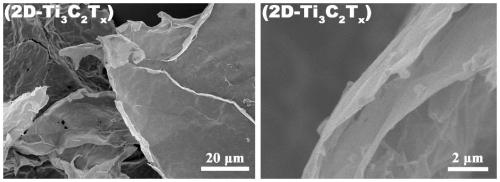

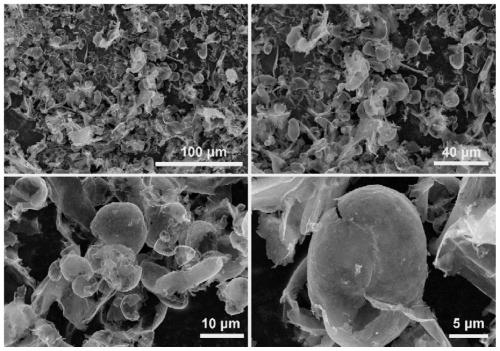

Three-dimensional cross-linked structure MXene material and preparation method thereof

PendingCN110342516ADifferent orientationsStable structureMaterial nanotechnologyCarbon compoundsFreeze dryHigh pressure

The invention provides a three-dimensional cross-linked structure MXene material and a preparation method thereof. The spray-freeze drying method adopted by the invention includes: preparing 2D-MXenenanosheets into a 0.5-5mg / mL dispersion liquid of 1-20 layers in an ultrasonic way; spraying the solution obtained in step 1 into liquid-boiling liquid nitrogen by a high pressure gun in the form of liquid droplets with a diameter of 100microm-5000microm; and volatilizing and drying of the liquid nitrogen in step 2, subjecting the obtained product to freeze drying treatment, thus obtaining non-heap structure 3D-MXene. The 3D-MXene prepared by the method provided by the invention presents the spherical, tubular and other shapes of a cross-linked structure, and can successfully solve the stacking problem of 2D-MXene nanosheets and retain a large specific surface area and the number of exposed active sites. The 3D-MXene prepared by the method provided by the invention is independent of each other and has different orientations, and is beneficial for long-term preservation and reuse.

Owner:HARBIN ENG UNIV

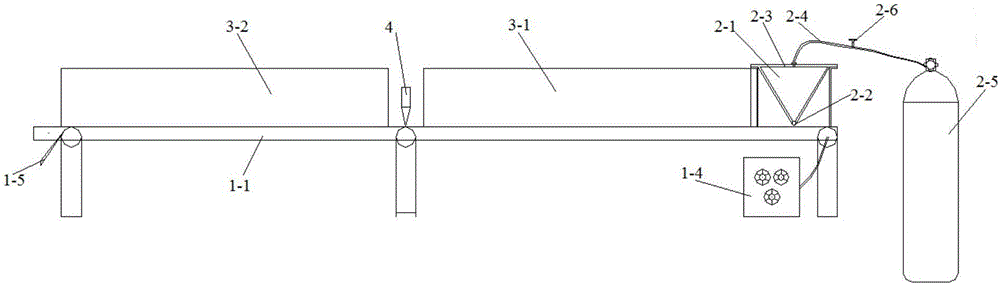

Novel horizontal glasses cleaning and drying system

InactiveCN108693643AEasy to cleanWash thoroughlySpectales/gogglesDrying gas arrangementsControl systemMetal

The invention discloses a novel horizontal glasses cleaning and drying system. The system is formed by a mechanical system and a control system. The mechanical system comprises a glasses placement framework, a transmission system, a cleaning system, a spray system (1) and a sheet metal structure (21). The glasses placement framework and the transmission system are horizontally placed in the sheetmetal structure (21). Through adopting the above scheme, by using the glasses placement framework and the transmission system which are horizontally placed in the sheet metal structure (21) and the control system of autonomous research and development, a plurality of glasses can be cleaned at one time and a batch cleaning demand is satisfied. After the glasses in a previous cleaning basket are cleaned, the cleaning basket where the glasses to be cleaned are placed is replaced so that a time interval between machine pauses is reduced and glasses cleaning efficiency is increased. The size of a whole machine is reduced and an occupied space is small.

Owner:深圳市恒创宝莱科技有限公司

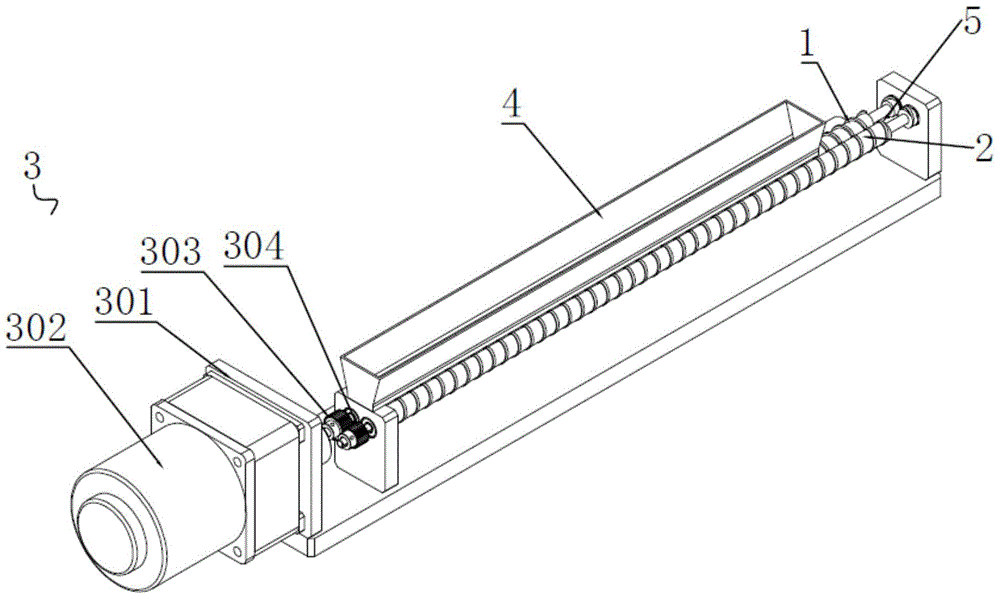

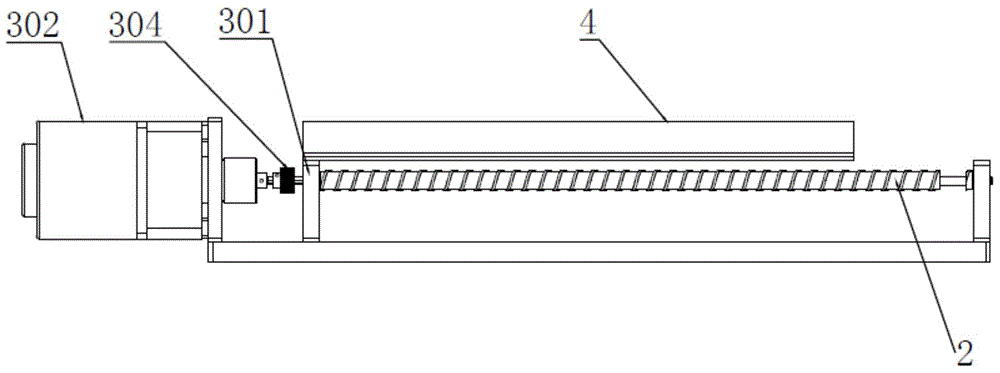

Automatic sorting sequencing device

The invention discloses an automatic sorting sequencing device which comprises a first screw rod and a second screw rod in parallel arrangement, wherein the first screw rod and the second screw rod are in the same screw pitch; the first screw rod and the second screw rod are connected with a driving mechanism which is used for driving the first screw rod and the second screw rod to synchronously and reversely rotate; a feeding device is arranged above a gap of the first screw rod and the second screw rod in parallel; a discharging port is arranged at the tail end of a spiral tooth rotating advancing direction of the first screw rod and the second screw rod. The automatic sorting sequencing device provided by the invention can be used for automatically sequencing products under the conveying of the screw rods through the reverse rotation of the two screw rods, the products are prevented from being stacked, and the other products inconsistent to the advancing directions of the screw rods fall off under the driving of the centrifugal force, so that the automatic sorting and sequencing of the products are finished, the products in consistent direction are collected at the discharging port, and the working efficiency is greatly higher than the efficiency of manual production. The automatic sorting sequencing device has the advantages of compact whole structure, small occupied space, uniform outputted products and quality guarantee.

Owner:SANKYO PRECISION HUIZHOU

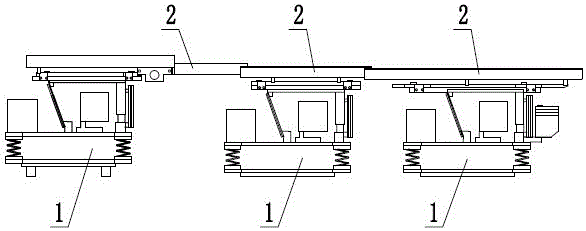

Tablet transportation device of electronic tablet counting machine

ActiveCN106218966AGood stabilityPrevent splashPackaging automatic controlMultiple stagesMechanical engineering

The invention discloses a tablet transportation device of an electronic tablet counting machine. The tablet transportation device is used for improving the counting precision of the electronic tablet counting machine, and is characterized by comprising at least two stages of vibrating transportation devices, wherein the vibrating transportation devices comprise vibration block components and feeding plates; all the feeding plates form a conveyer belt; a feeding funnel is arranged at the starting end of the conveyer belt; the stopping end of the conveyer belt leads to counting channels of an electronic counting head; and the vibration frequency of all the vibration block components is sequentially increased in the tablet transportation direction. According to the tablet transportation device, the multiple stages of vibrating transportation devices of which the frequency is sequentially increased are adopted, the tablets are spaced and are transported to the counting channels of the electronic counting head, the tablets cannot be stacked, and counting of the electronic counting head is guaranteed to be accurate; and compared with a single-stage high-frequency vibrating transportation device, the multiple stages of vibrating transportation devices of which the frequency is gradually increased have better stability and can prevent the tablets from splashing.

Owner:ZHOUSHAN SHARK PHARMA MACHINERY

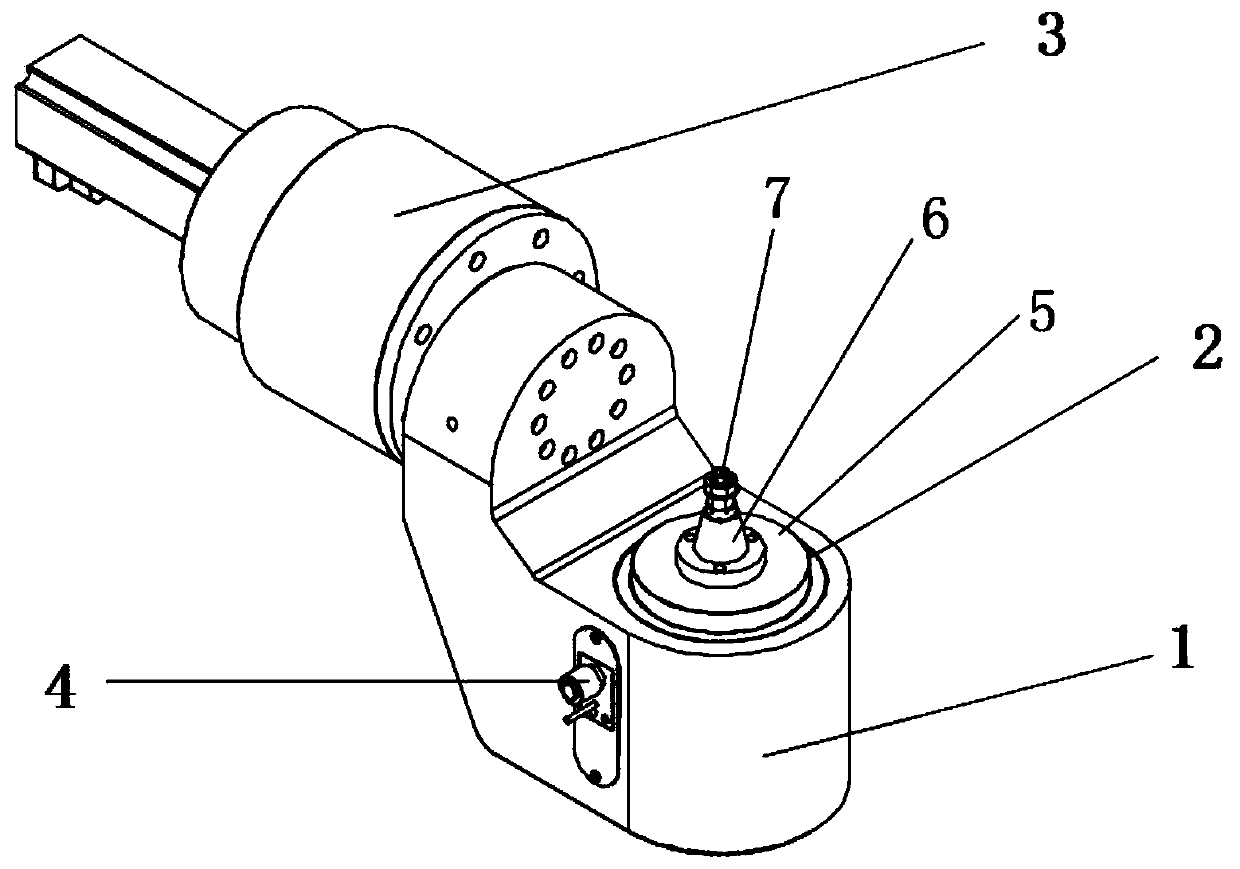

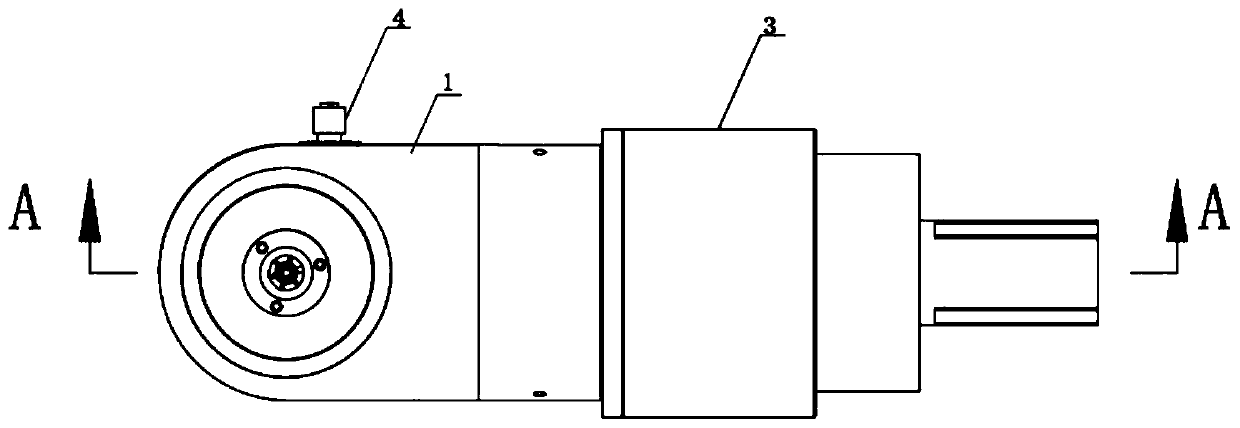

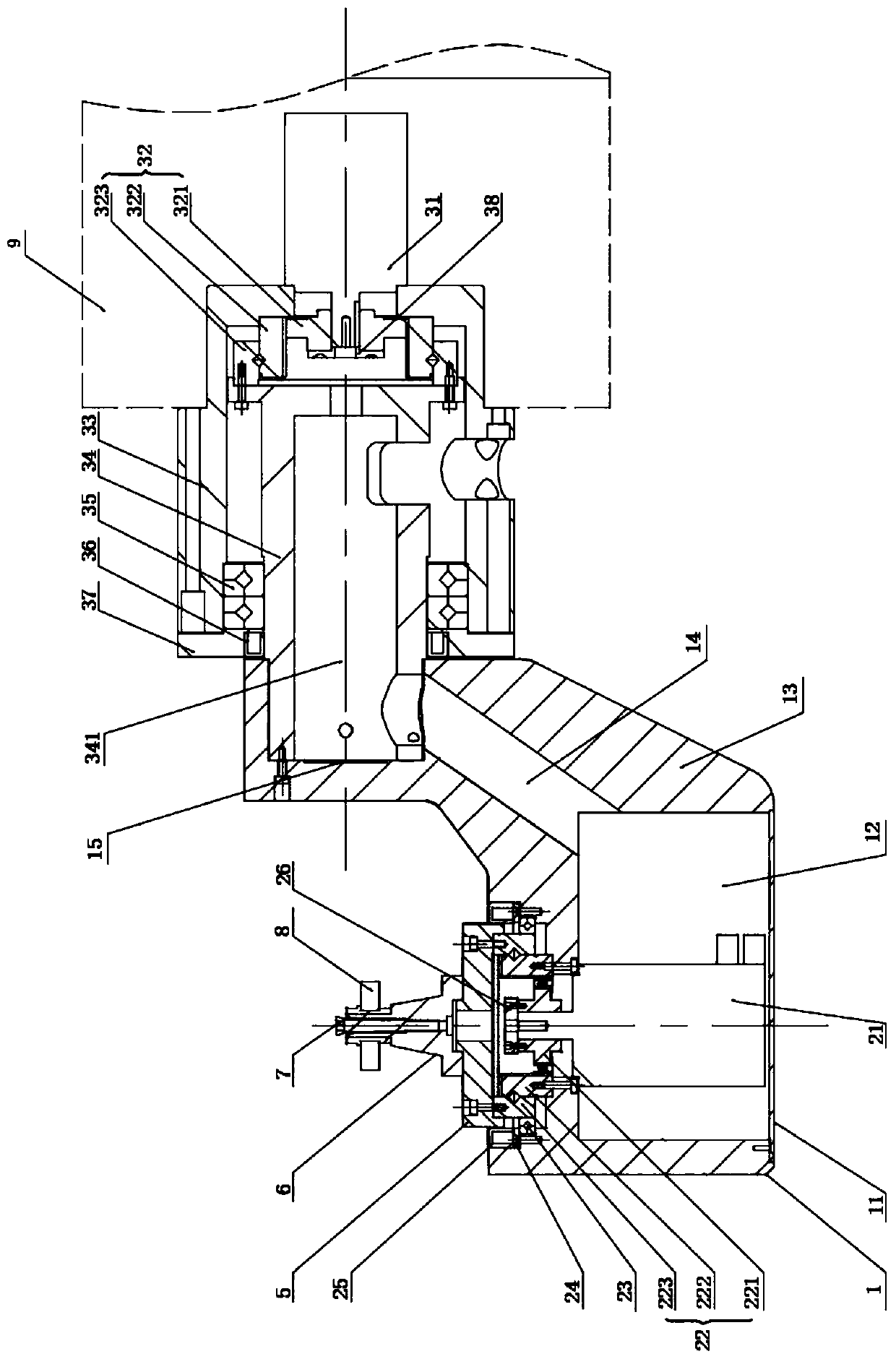

Cantilever-type five-shaft rocker arm rotating device with harmonic speed reducer

ActiveCN110814802AReduce sizeLow priceDriving apparatusPositioning apparatusRotational axisReduction drive

The invention relates to a cantilever-type five-shaft rocker arm rotating device with a harmonic speed reducer. The cantilever-type five-shaft rocker arm rotating device comprises a horizontal mounting seat, a rotating shaft assembly, a swing arm shaft assembly, a working chuck, a product clamp assembly and clamp pressing screws, wherein the horizontal mounting seat comprises a first cavity, a second cavity and a connecting part; a wiring hole is formed in the connecting part; the rotating shaft assembly is arranged in the first cavity; the swing arm shaft assembly is connected with the secondcavity; the axis of the rotating shaft assembly is perpendicular to the axis of the swing arm shaft assembly; the working chuck is in transmission connection with an output end of the rotating shaftassembly; the product clamp assembly for carrying products is mounted on the working chuck; the clamp pressing screws are arranged on the product clamp assembly; and a tool setting instrument is arranged on the side wall of the horizontal mounting seat. The cantilever-type five-shaft rocker arm rotating device has the advantages that stable operation can be kept while a tail seat supporting structure is removed, and the limitation of installation space is eliminated while large torque is provided at low rotating speed, therefore, the difficulty of tool setting is reduced, and the working efficiency is improved.

Owner:PUTIAN HENGDA MACHINERY & ELECTRICITY IND

Automatic potato screening grading device

InactiveCN109013285AIncrease the effective screening areaImprove screening efficiencySievingScreeningEngineeringReciprocating motion

The invention relates to the technical field of potato screening grading devices, and discloses an automatic potato screening grading device. The automatic potato screening grading device comprises ascreen assembly, a supporting assembly, a cleaning assembly and a uniformly-stirring assembly. The screen assembly comprises a screen box, a discharging hopper, an auxiliary overturning cover, a fixedrail, a dustproof box cover, a screen, a feeding hopper and a vibrating motor. An accommodating cavity is formed in the screen box, and the discharging hopper is positioned at the bottom end of the right side of the screen box and is fixedly connected with the screen box. The effective screening area of the screen is increased so that potatoes cannot be stacked, and the screening efficiency of the potatoes is improved. A screw rod is arranged in a machine body, a fixed seat and a cleaning brush are arranged on the screw rod, and the screw rod is used for driving the cleaning brush to performlinear reciprocating motion on the screen to clean the screen, so that impurities attached to the screen in a clamped mode are removed; and meanwhile, a cleaning overturning cover is arranged on the screen box, so that the cleaning brush is more convenient to replace, the service efficiency of the screen is improved, and the service life of the screen is prolonged.

Owner:胡在庆

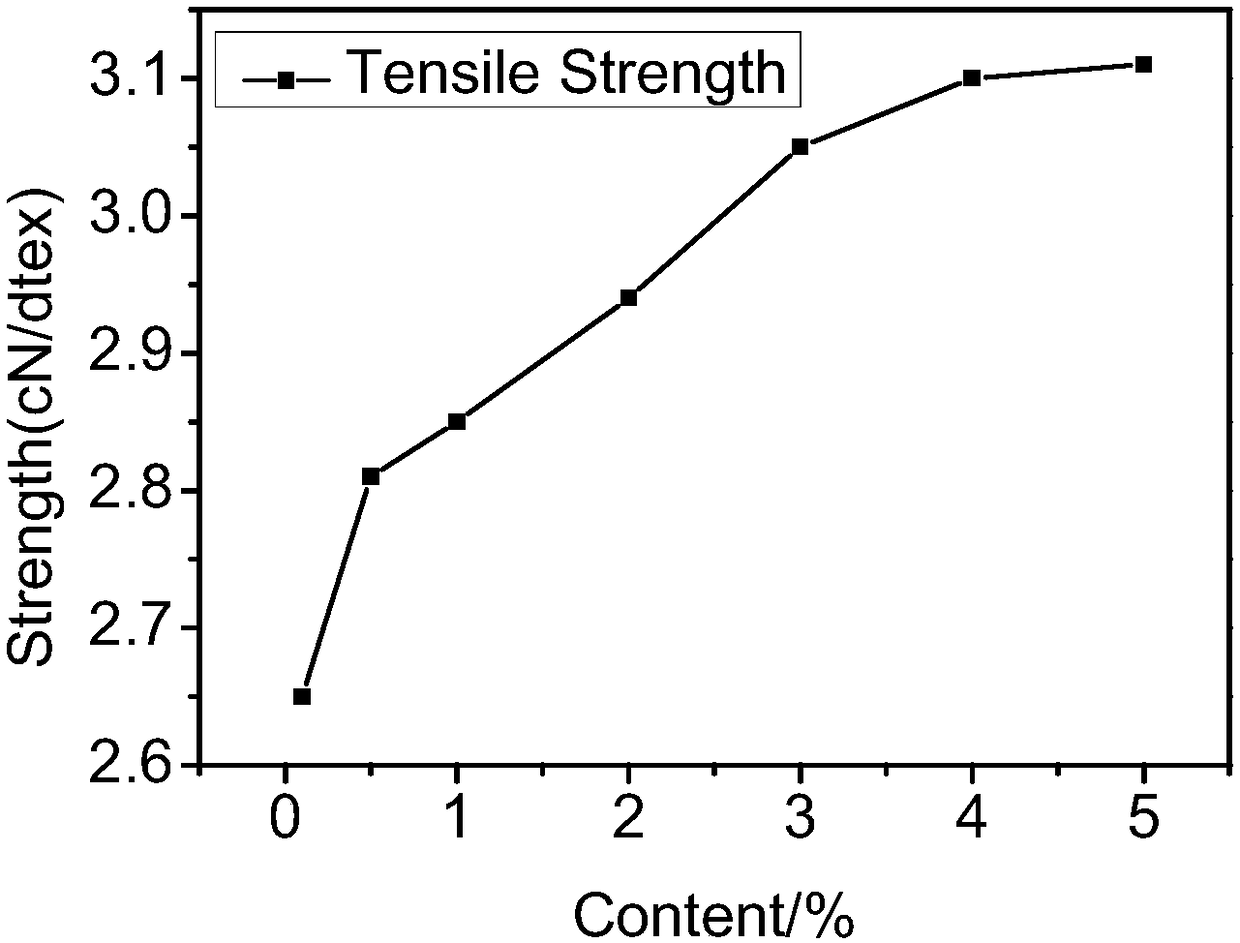

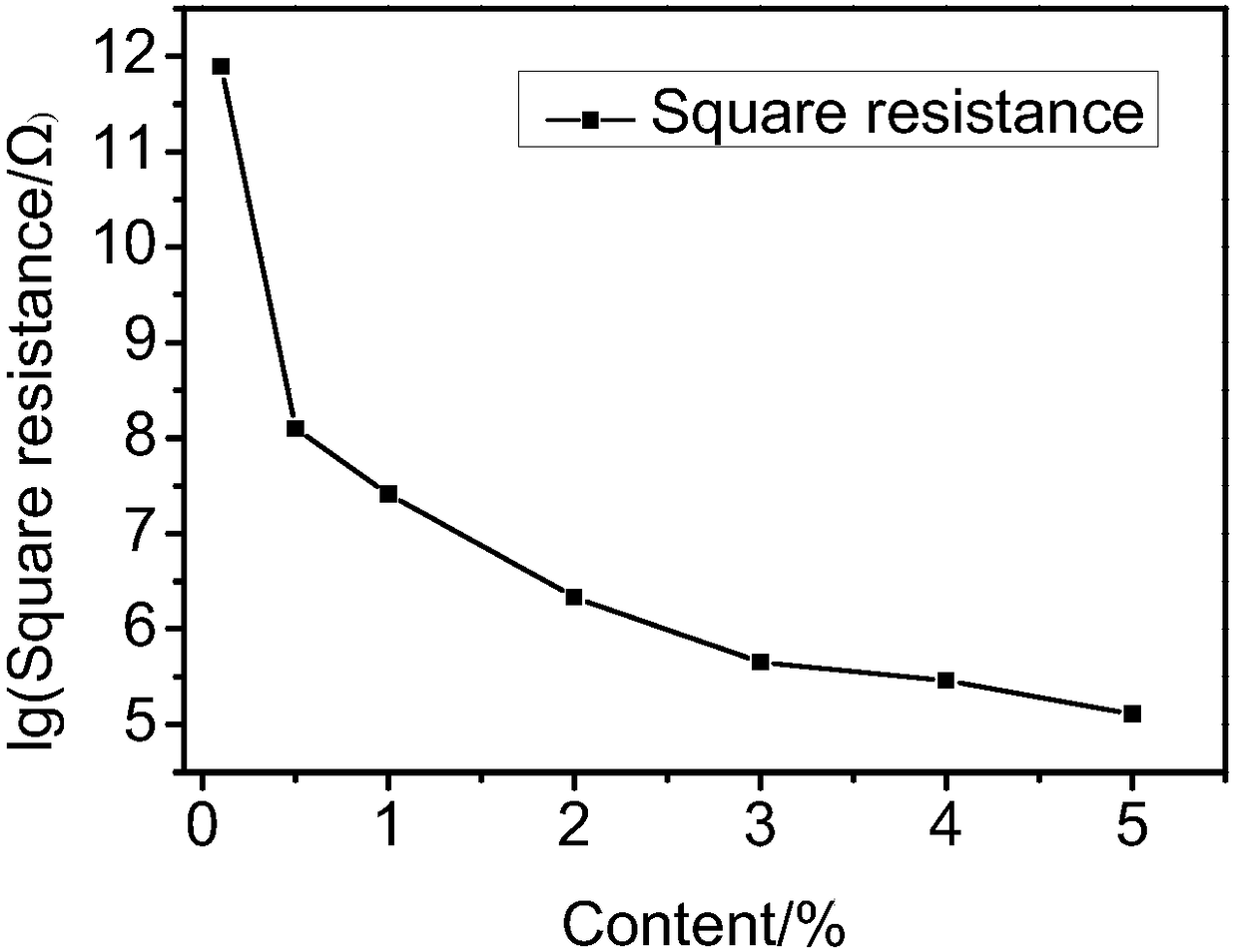

Preparation method of multifunctional regenerated cellulose composite fiber

ActiveCN108277545AHigh strengthImprove antistatic performanceArtificial filaments from cellulose derivativesWet spinning methodsPolymer scienceFar infrared

The invention relates to a preparation method of multifunctional regenerated cellulose composite fiber. The preparation method comprises the following steps: mixing regenerated cellulose with oxidizedgraphene to prepare a spinning solution, spinning in a mixed coagulating bath, and then preparing the regenerated cellulose / oxidized graphene composite fiber through multi-stage washing and high-temperature steam stretching. The method is simple and extremely easy to industrialize; cellulose raw materials are wide in source and low in cost. The anti-static property of the prepared regenerated cellulose / oxidized graphene composite fiber is obviously improved; the anti-static property has designability; the multifunctional regenerated cellulose composite fiber is excellent in mechanical property, sterilization performance and anti-ultraviolet far infrared performance; meanwhile, the multifunctional regenerated cellulose composite fiber has the advantages of softness, breathability, high hygroscopicity, easiness in dyeing and the like of cellulose, and can be widely applied to the textile industry.

Owner:HANGZHOU GAOXI TECH CO LTD

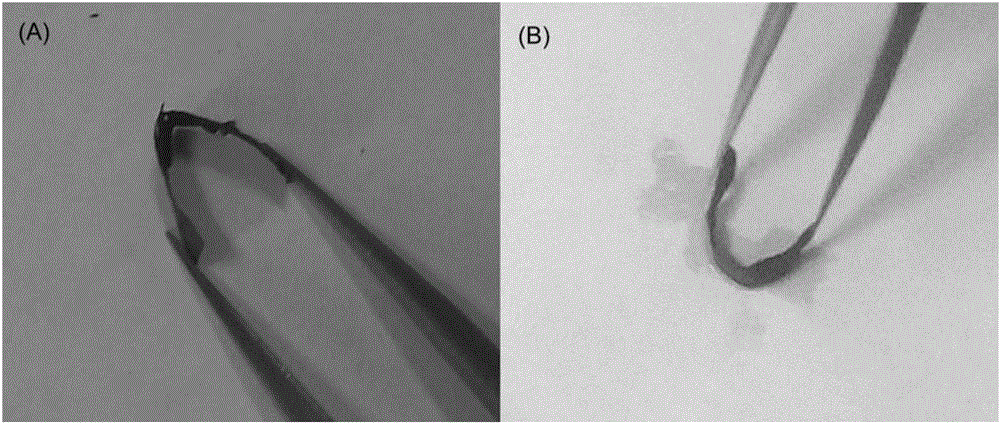

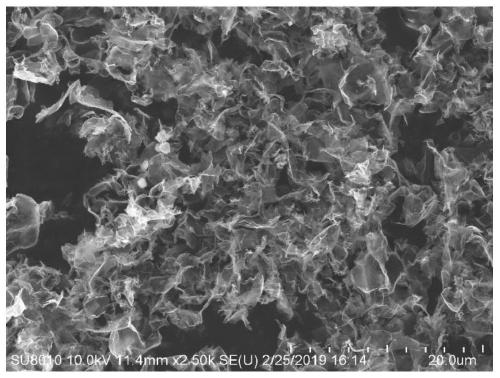

Preparation method for highly-dispersed few-layer graphene

InactiveCN110117002AIncrease production capacityNo stackingSingle layer grapheneNitrogen gasFew layer graphene

The invention provides a preparation method for highly-dispersed few-layer graphene. The preparation method comprises the following steps that firstly, a graphene oxide dispersion liquid and a tea polyphenol material are mixed to obtain a mixed liquid; secondly, auxiliary gas is introduced into the mixed liquid obtained in the previous step for a reaction to obtain a reaction liquid, wherein the auxiliary gas includes one or more of hydrogen, nitrogen and inert gas; finally, the reaction liquid obtained in the previous step is post-treated to obtain the graphene. According to the preparation method, an environment-friendly reduction mode combining the auxiliary gas and the tea polyphenol material is adopted, a pi-pi stacking function among sheet layers of the graphene is greatly hindered,and interlayer stacking of the graphene in the reduction process is effectively prevented while graphene oxide is reduced. The functionalized single-layer or few-layer graphene prepared by means of the method has the thin sheet layers, no obvious stacking phenomenon occurs among the sheet layers of the graphene, the preparation process is simple, the condition is mild, the time is short, the preparation method is environmentally friendly and free of pollution, and the application, popularization and later large-scale production of the graphene are facilitated.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Epoxy resin composite material granulating device

The invention discloses an epoxy resin composite material granulating device, which comprises a transmission unit; the transmission unit includes a supporting frame; a conveying belt is mounted on the supporting frame; the driving shaft of the conveying belt is connected with a speed controlling box; the granulating device also comprises a material feeding unit, a heating unit and a material cutting unit; the heating unit and the material cutting unit are mounted on the supporting frame; the heating unit includes a front heating unit and a rear heating unit; and the material cutting unit is positioned between the front heating unit and the rear heating unit. The granulating device disclosed by the invention is used for changing the epoxy resin composite material from viscous liquid state into solid granule state, can perform the functions of heating, shaping and cutting simultaneously, therefore, achieves a high production efficiency, can realize continuous production, can obtain products having compact microstructure, stable performance and high quality, solves the problem that the epoxy resin composite material is liable to adhere to a granulating device, and reduces the abrasion to a machine.

Owner:CHANGAN UNIV

Hoisting type pipeline transportation cart

InactiveCN110949473AConvenient and efficient transferNo crush collisionsHand carts with multiple axesHand cart accessoriesVehicle framePipeline transport

The invention relates to the field of pipeline machining, in particular to a hoisting type pipeline transportation cart which comprises a cart frame, telescopic devices, universal wheels and lifting appliances. The frame is square, the telescopic devices are located at the four corners of the frame, the top ends of the telescopic devices are fixedly connected with the frame, and the telescopic devices are used for adjusting the height of the frame. The universal wheels are fixedly connected to the bottom ends of the telescopic devices; the lifting appliances are detachably connected to the lower surface of the frame, the multiple lifting appliances are arranged in the vertical direction, and the lifting appliances are used for lifting pipelines. The hoisting type pipeline transportation cart has the beneficial effects that the frame is lifted through the telescopic devices, so that the lifting appliances and the pipelines are located at the same height, and the pipelines can be conveniently and efficiently transferred to a transportation cart; each pipeline is hoisted by the corresponding independent lifting appliance, so that the adjacent pipelines are prevented from being extruded and collided; due to the fact that the pipelines are hoisted below the frame, the pipelines cannot be stacked, and the pipelines located at the bottom cannot be extruded to deform.

Owner:福建恒杰塑业新材料有限公司

A kind of preparation method of sandwich structure composite graphene oxide paper electrode material

ActiveCN105845456BIntegrity guaranteedImprove integrityHybrid capacitor electrodesHybrid/EDL manufactureComposite electrodeFiltration

The invention belongs to the field of composite electrode material preparation, and in particular relates to the preparation of a composite graphene oxide paper electrode material with a sandwich structure. A sandwich structure composite graphene oxide paper electrode material is prepared by a one-step method. The specific steps are: ultrasonically disperse graphite oxide in a solvent, then add a transition metal salt and keep stirring to make the system evenly mixed, adjust the pH to alkaline and then adjust the pH to 80-150 After reacting at ℃ for 8-12h, suction filtration, washing and drying at low temperature, a sandwich structure composite graphene oxide paper electrode material was obtained. In order to improve the electrochemical properties of the electrode material, it was calcined and soaked in the electrolyte after calcining. The raw materials of the prepared material are cheap and easy to obtain, the process is simple and easy to operate, the production cost is low, and it is suitable for industrial production, and the prepared electrode material shows excellent electrochemical performance.

Owner:CHANGZHOU UNIV +1

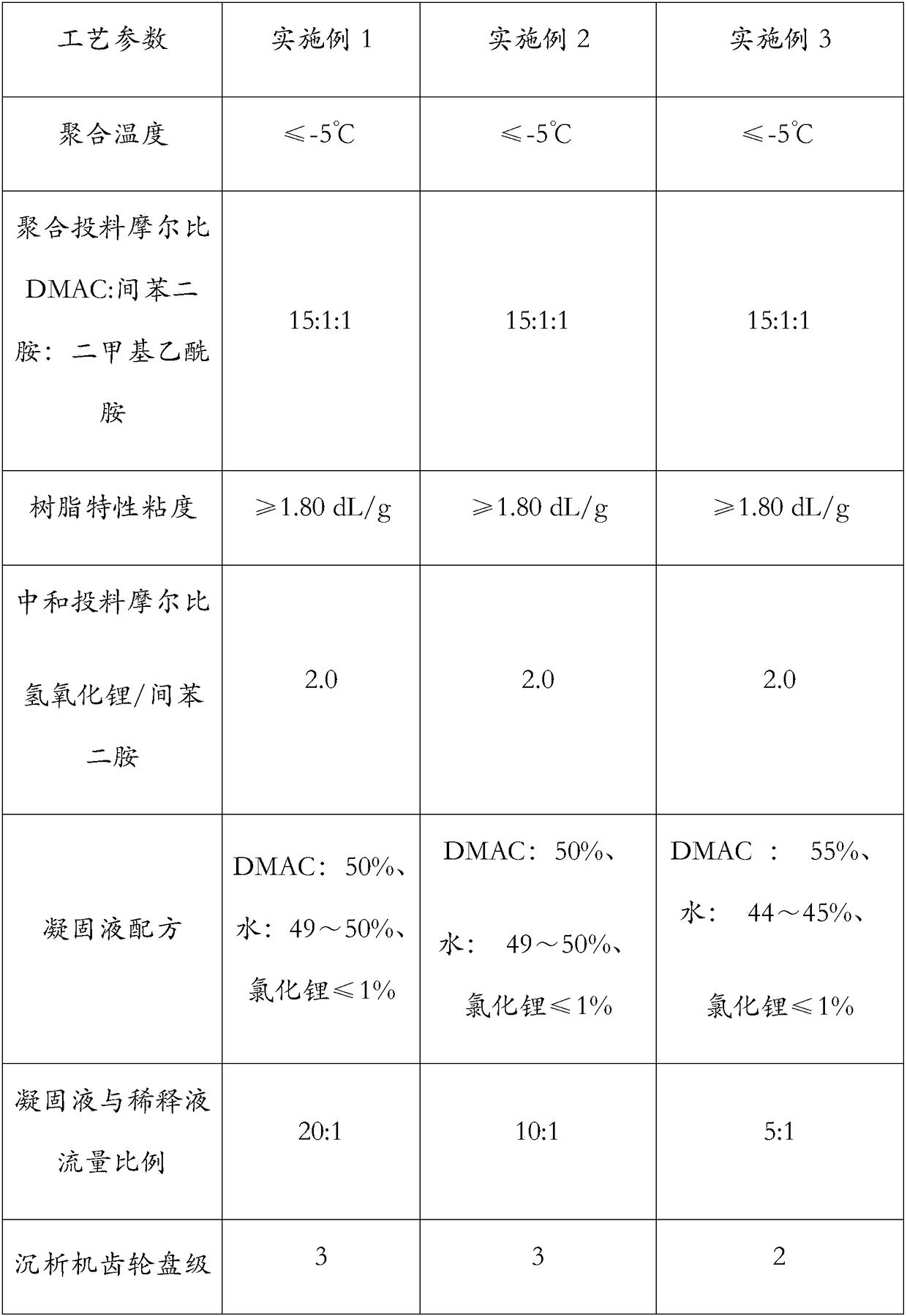

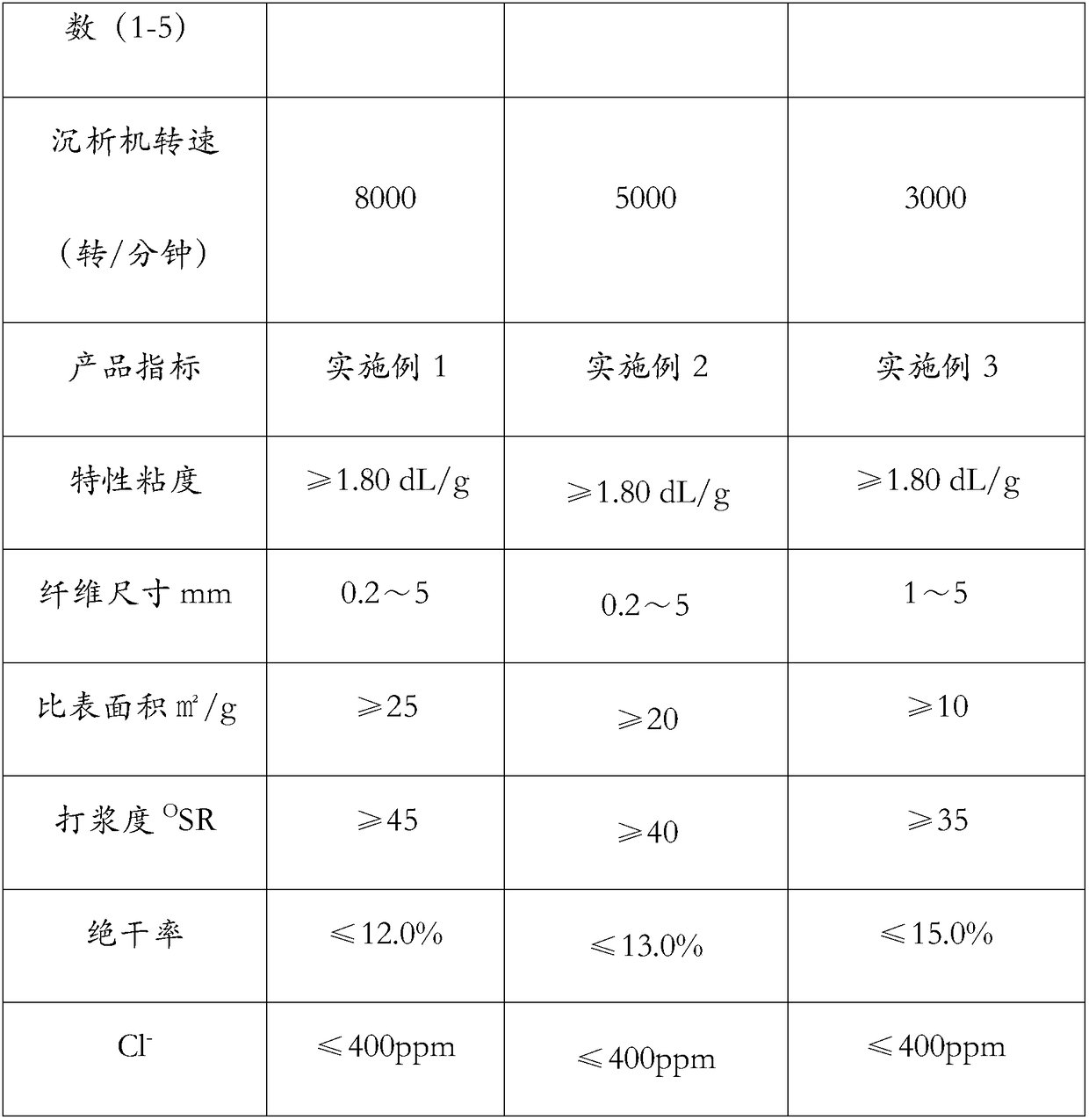

A method for environmentally friendly production of meta-aramid precipitated fibers

ActiveCN106637473BHigh economic valueStrong market digestionMonocomponent copolyamides artificial filamentWet spinning methodsLithium chlorideLithium hydroxide

The invention relates to the technical field of special synthetic fiber manufacture, in particular to a method for environment-friendly production of meta-position aramid fiber fibrid. The method comprises the following steps that 1, a meta-position aramid fiber resin solution is prepared; 2, meta-position aramid fiber resin is neutralized; 3, the meta-position aramid fiber resin is subjected to fiber precipitation; 4, a precipitation fiber product is separated and washed; 5, a solvent DMC and lithium chloride are recovered. The method adopts the lithium hydroxide to serve as a neutralizer of a polymerization resin solution, and calcium hydroxide low in price and non-environment-friendly in operating interface and a neutralizing product calcium chloride high in environment-friendly disposal cost are not adopted. Customized production of physical and chemical indicators of a product can be achieved through selective control of process parameters in the fiber precipitation process. A newly increased solvent preparation kettle is optimized through a process, and the production capacity of the polymerization reaction kettle is improved for more than one time. The reaction kettle and a solvent recovery device of an existing aramid fiber production line can be concurrently used for producing the meta-position aramid fiber fibrid, and the investment cost can be remarkably reduced.

Owner:四川辉腾科技股份有限公司

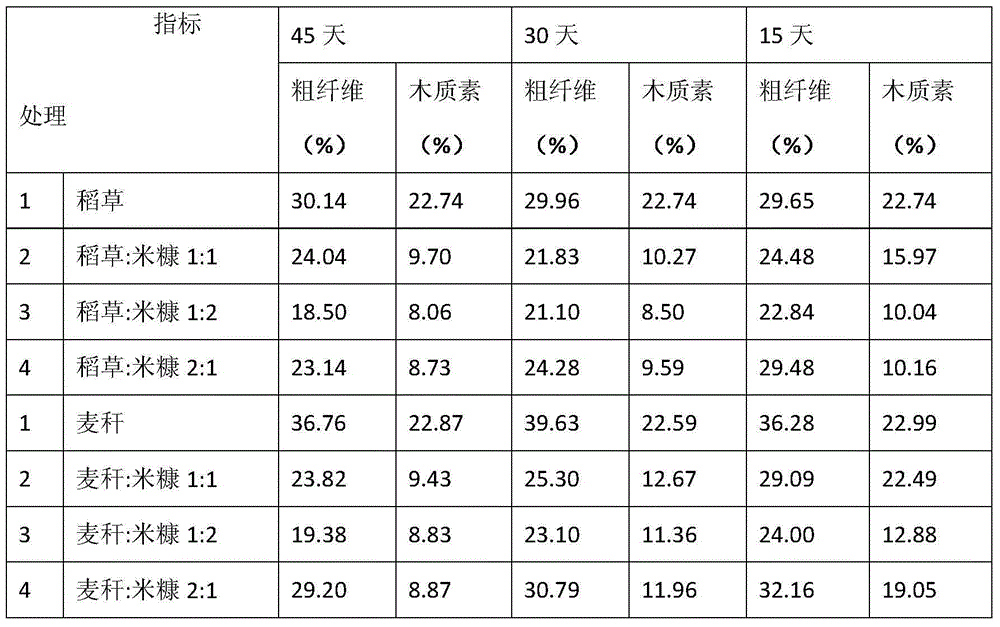

Technology for rapidly decaying rice and wheat straws

The invention discloses a technology for rapidly decaying rice and wheat straws. The technology comprises a step of evenly spraying rice bran on the rice and wheat straws so as to utilize the fermentation of the rice bran to decay the rice and wheat straws under the actions of the natural temperature and dews in the night. The technology has the following advantages that the rice bran is easily available in villages and is very cheap, the mixed rice bran and rice and wheat straws can be decayed under a natural temperature condition, no other auxiliary condition is required, and moreover the operation is very convenient. The technology uses agricultural waste (rice bran) to process waste (straws), is environment-friendly, is harmless for human and livestock, and is accord with the ecological circulation requirements of agricultural production.

Owner:万华禾香生态科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com