Patents

Literature

40results about How to "Convenient and efficient transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

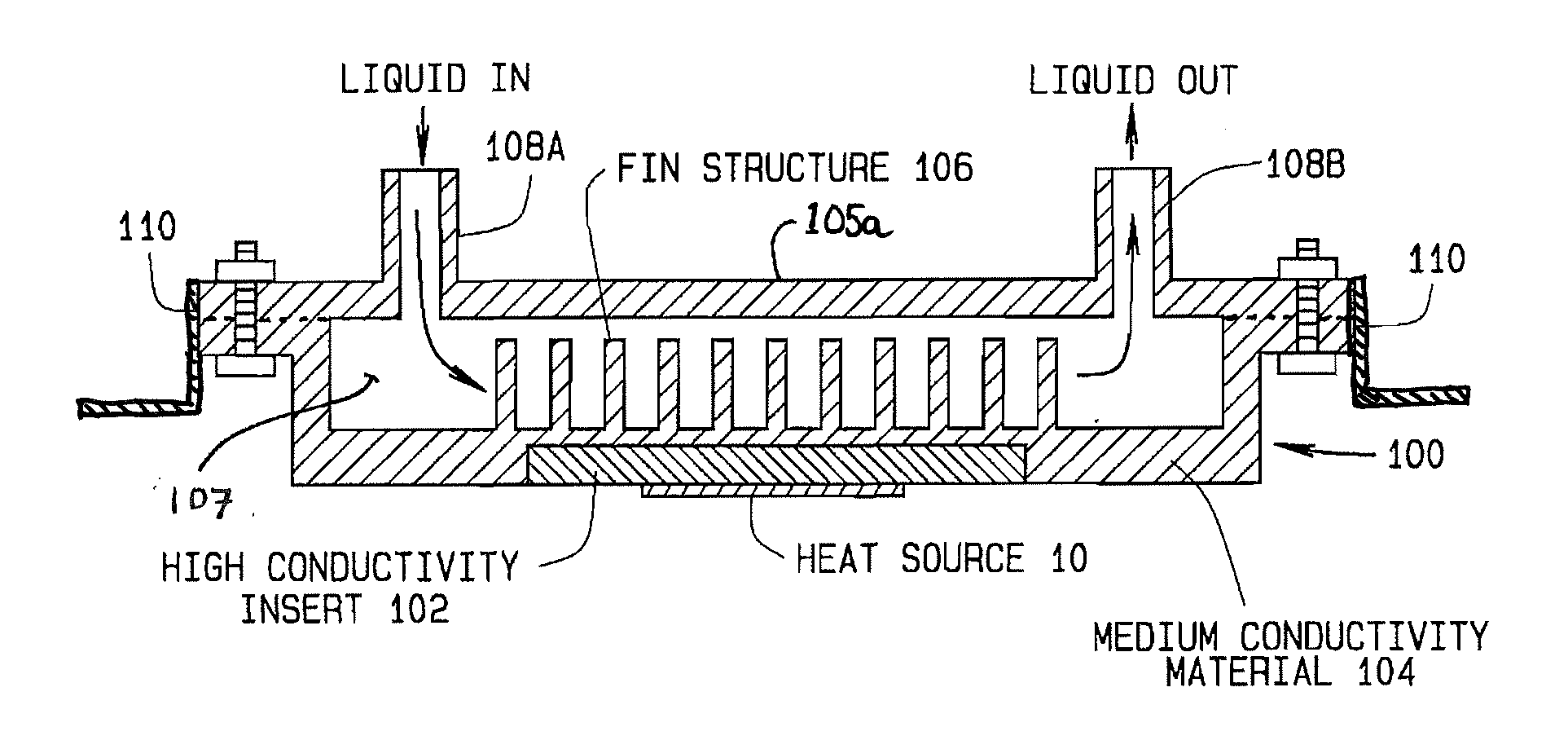

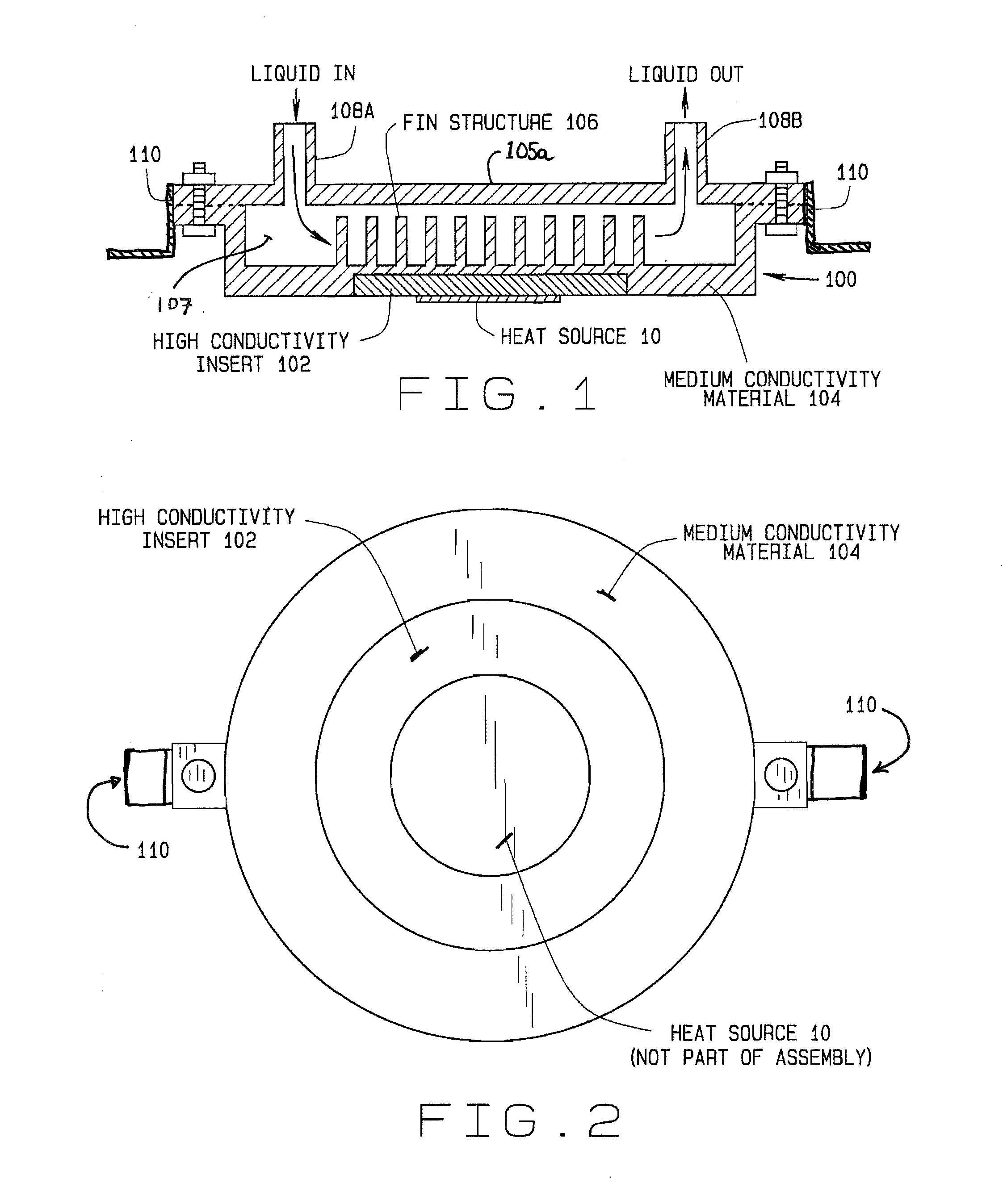

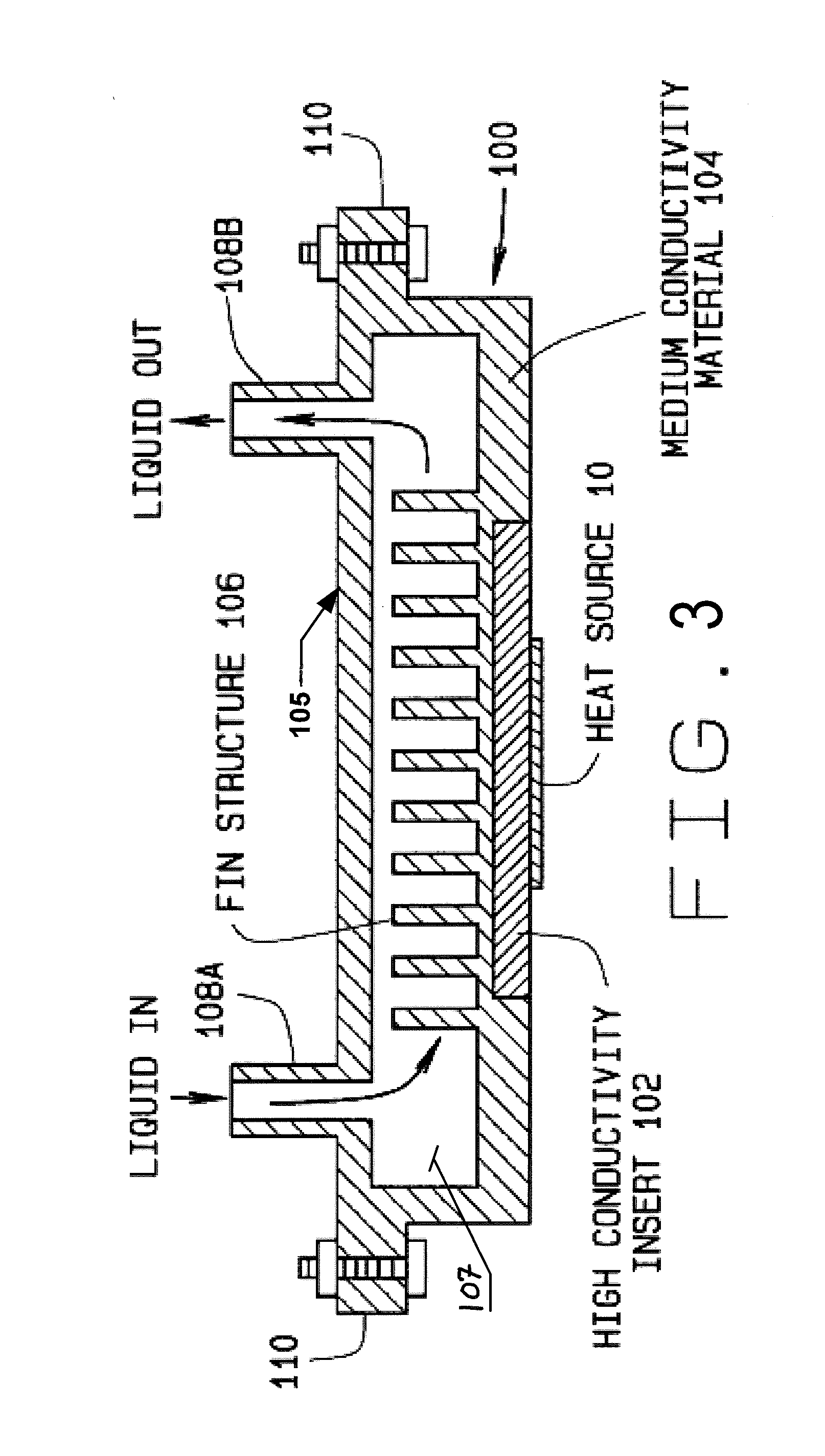

Liquid Cooling System Cold Plate Assembly

InactiveUS20120175094A1Convenient and efficient transferSemiconductor/solid-state device detailsSolid-state devicesThermal energyLiquid cooling system

A cold plate assembly consisting of a thermally conductive base component with an insert having a high thermal transfer characteristic adapted for contacting the surface of a heat source on one side. The surface of the base component opposite from the insert is surrounding by a housing defining an enclosed volume through with a flow of liquid coolant is directed. Inlet baffles adjacent to a fluid inlet in the housing direct the incoming flow of liquid coolant towards the surface of the base component in proximity to the insert, facilitating an efficient transfer of thermal energy from the heat source to the liquid coolant through the insert and base component. Optional extensions or fins extending into the liquid coolant contained in the enclosed volume from the surface of the base component further facilitate the transfer of thermal energy from the heat source.

Owner:ASETEK DANMARK

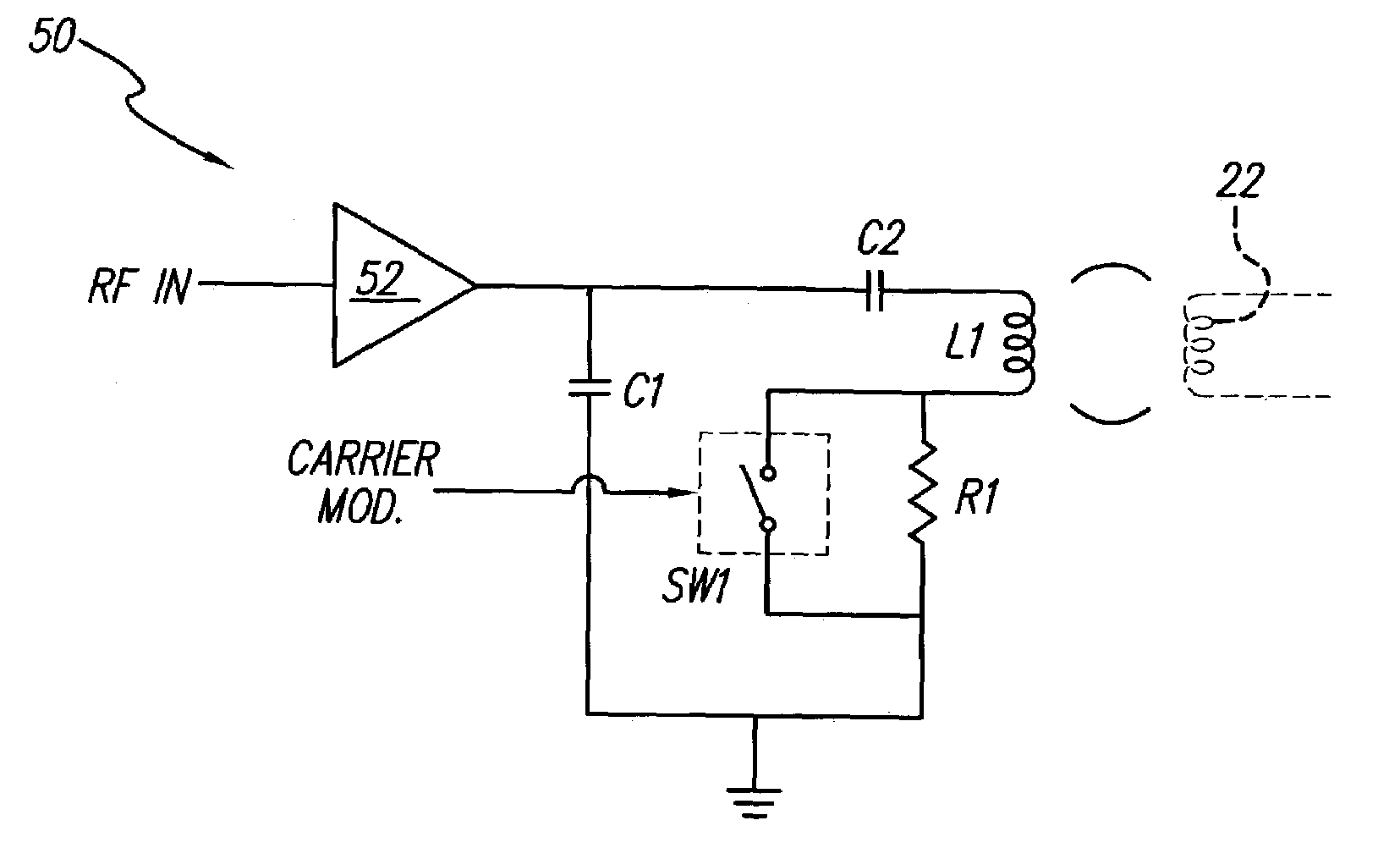

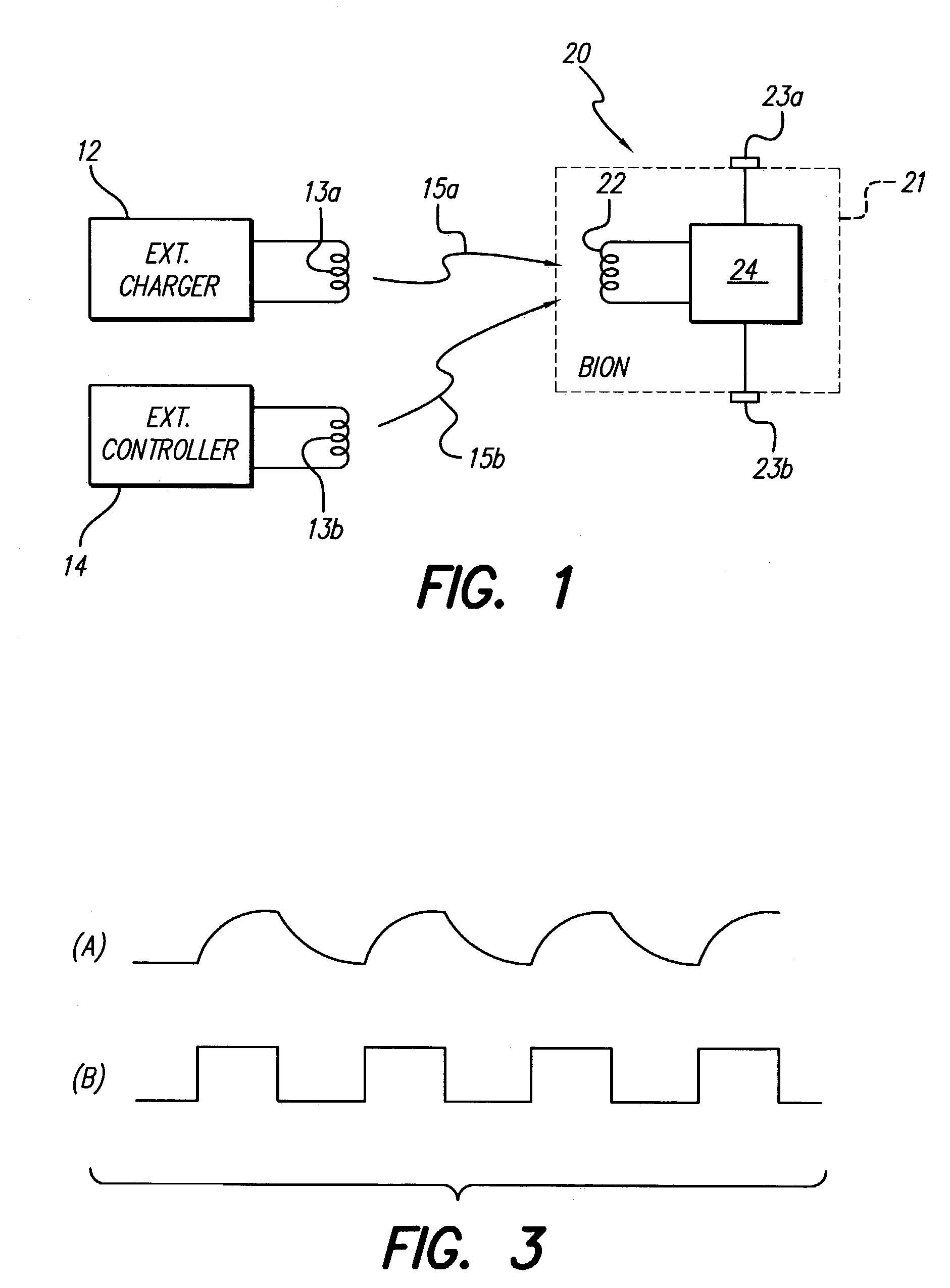

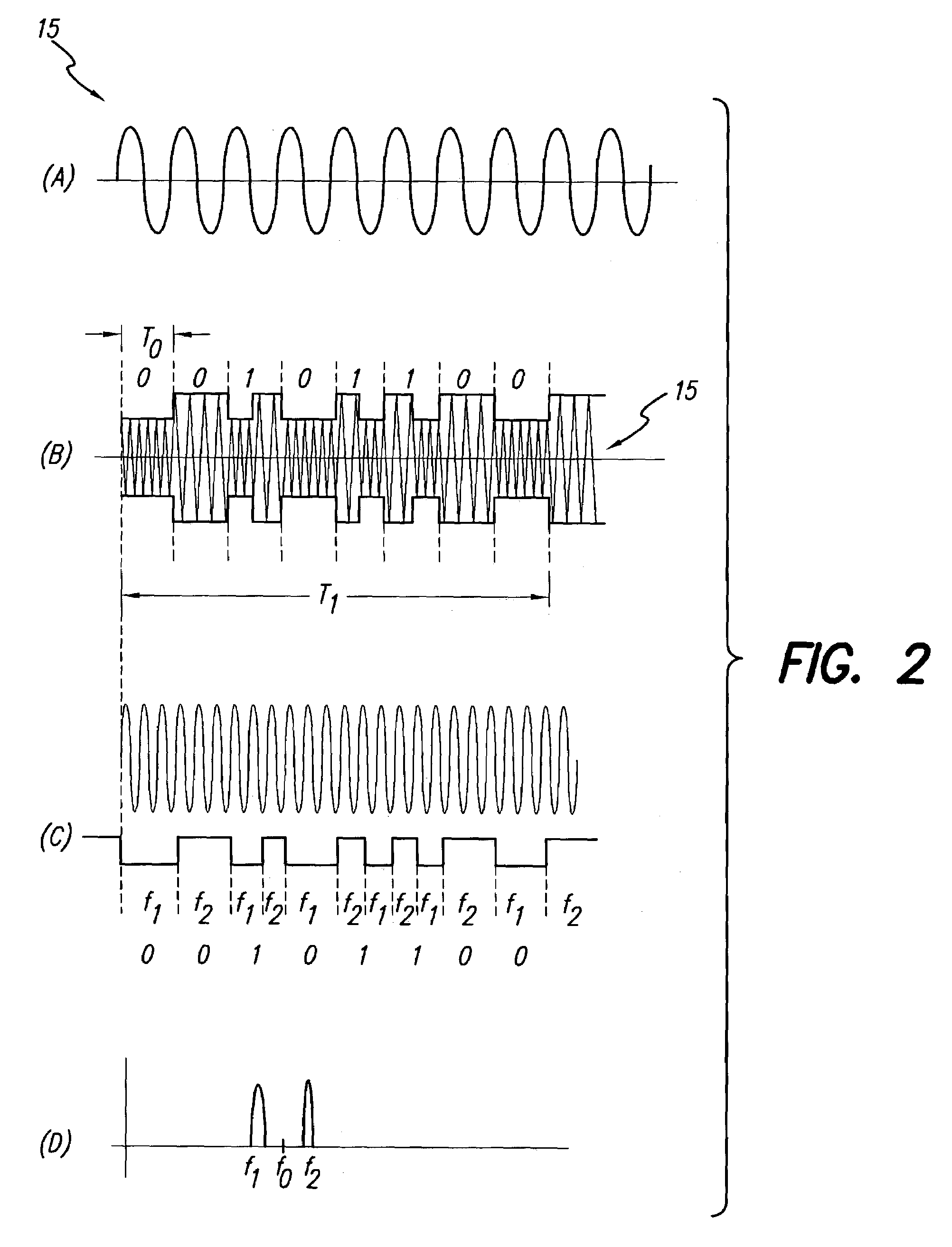

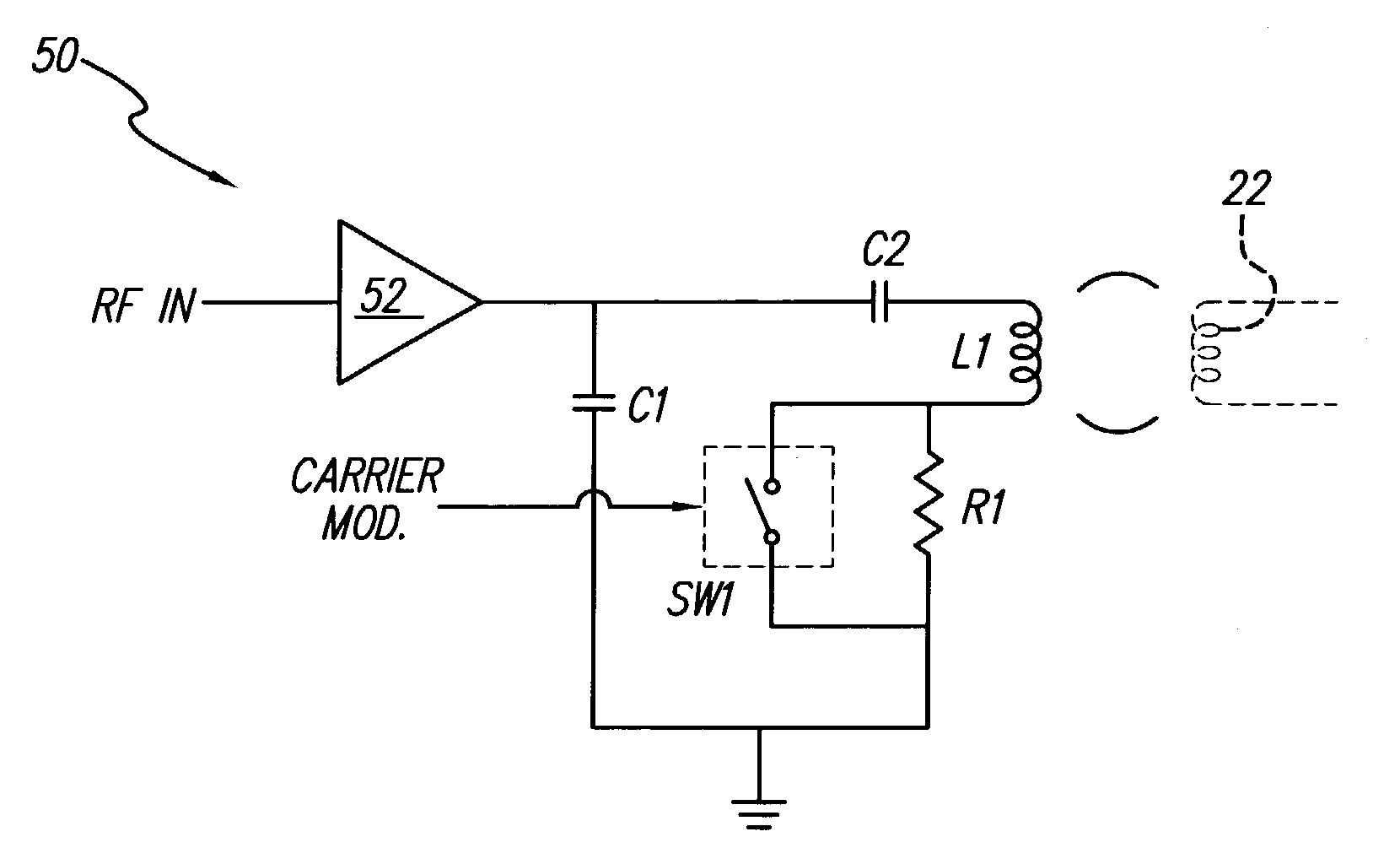

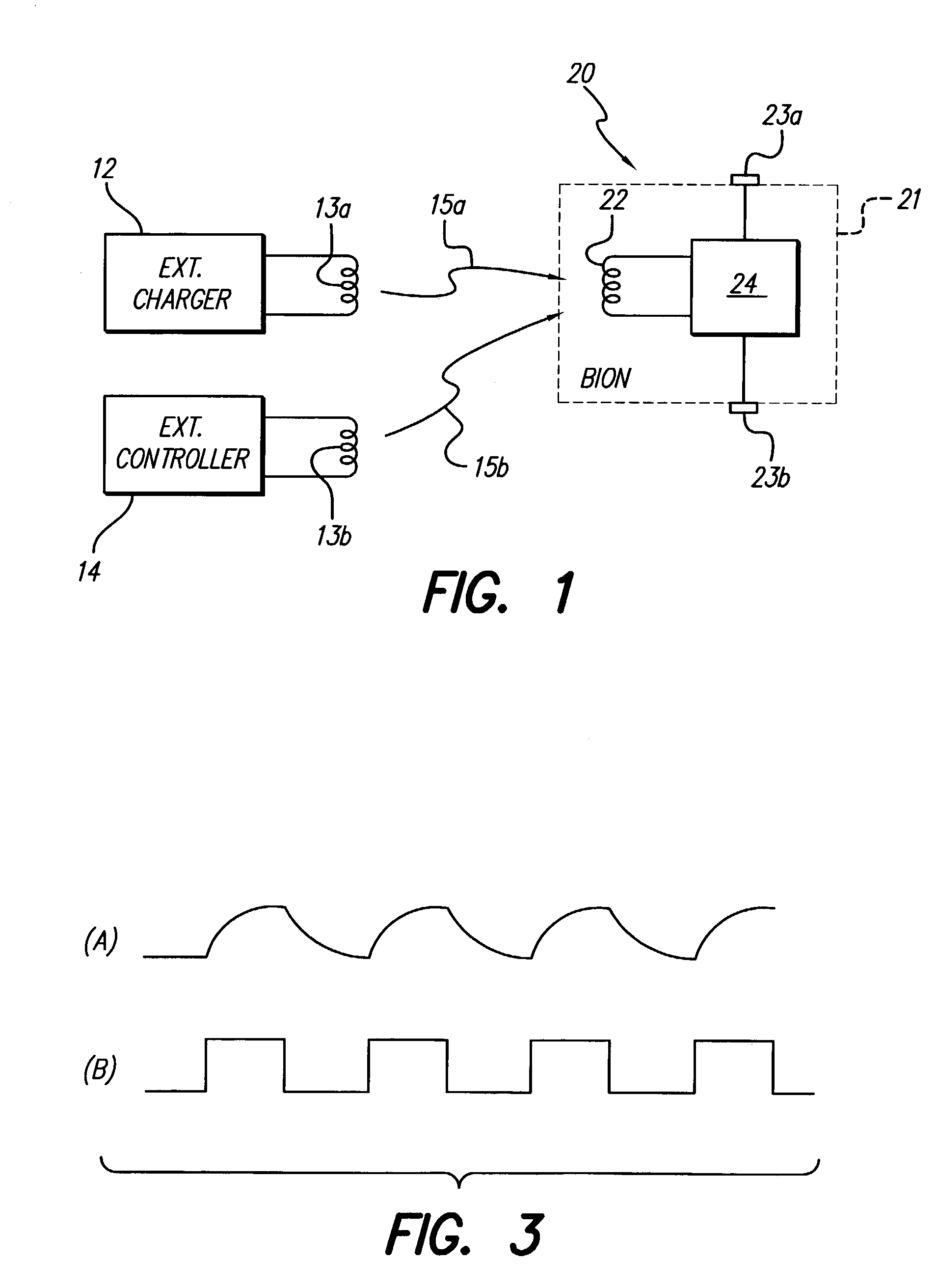

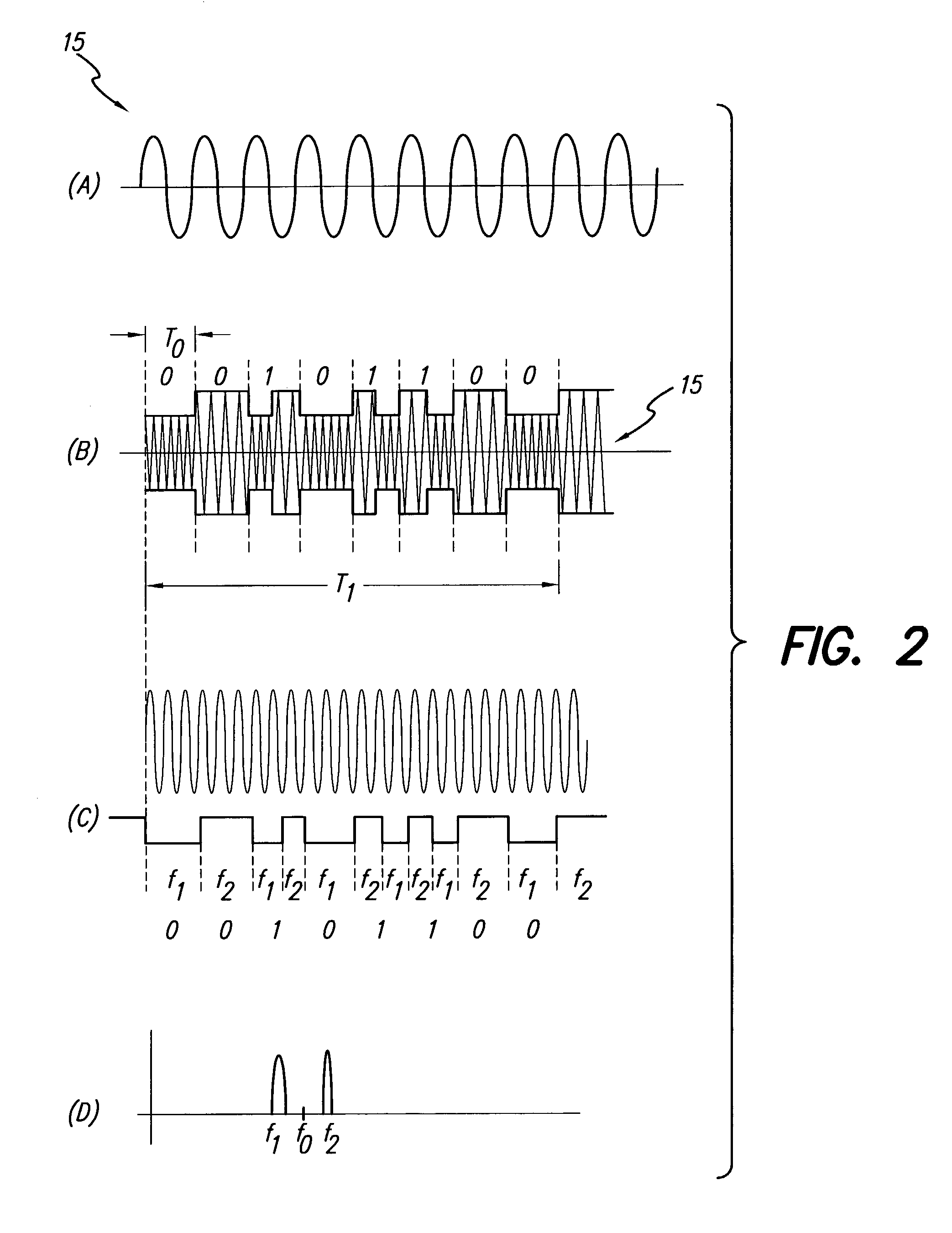

Low-power, high-modulation-index amplifier for use in battery-powered device

InactiveUS7079901B1Reliably efficiently transmittingEfficient power consumptionNear-field transmissionElectrotherapyElectrical batteryCarrier signal

An external transmitter circuit drives an implantable neural stimulator having an implanted coil from a primary coil driven by a power amplifier. For efficient power consumption, the transmitter output circuit (which includes the primary coil driven by the power amplifier inductively coupled with the implanted coil) operates as a tuned resonant circuit. When operating as a tuned resonant circuit, it is difficult to modulate the carrier signal with data having sharp rise and fall times without using a high power modulation amplifier. Sharp rise and fall times are needed in order to ensure reliable data transmission. To overcome this difficulty, the present invention includes an output switch that selectively inserts a resistor in the transmitter output coil circuit in order to de-tune the resonant circuit only during those times when data modulation is needed. Such de-tuning allows sharp rise and fall times in the data modulation without the need for using a high power modulation amplifier. Because data modulation is typically needed for only a small percent of the time that a carrier signal is present, it is thus possible using the present invention to achieve reliable data modulation, transmission and reception without having to use a high power modulation amplifier in the transmitter.

Owner:BOSTON SCI NEUROMODULATION CORP

Low-power, high-modulation-index amplifier for use in battery-powered device

InactiveUS7092762B1Efficient power consumptionSharp rise and fall timeNear-field transmissionElectrotherapyElectrical batteryCarrier signal

Owner:BOSTON SCI NEUROMODULATION CORP

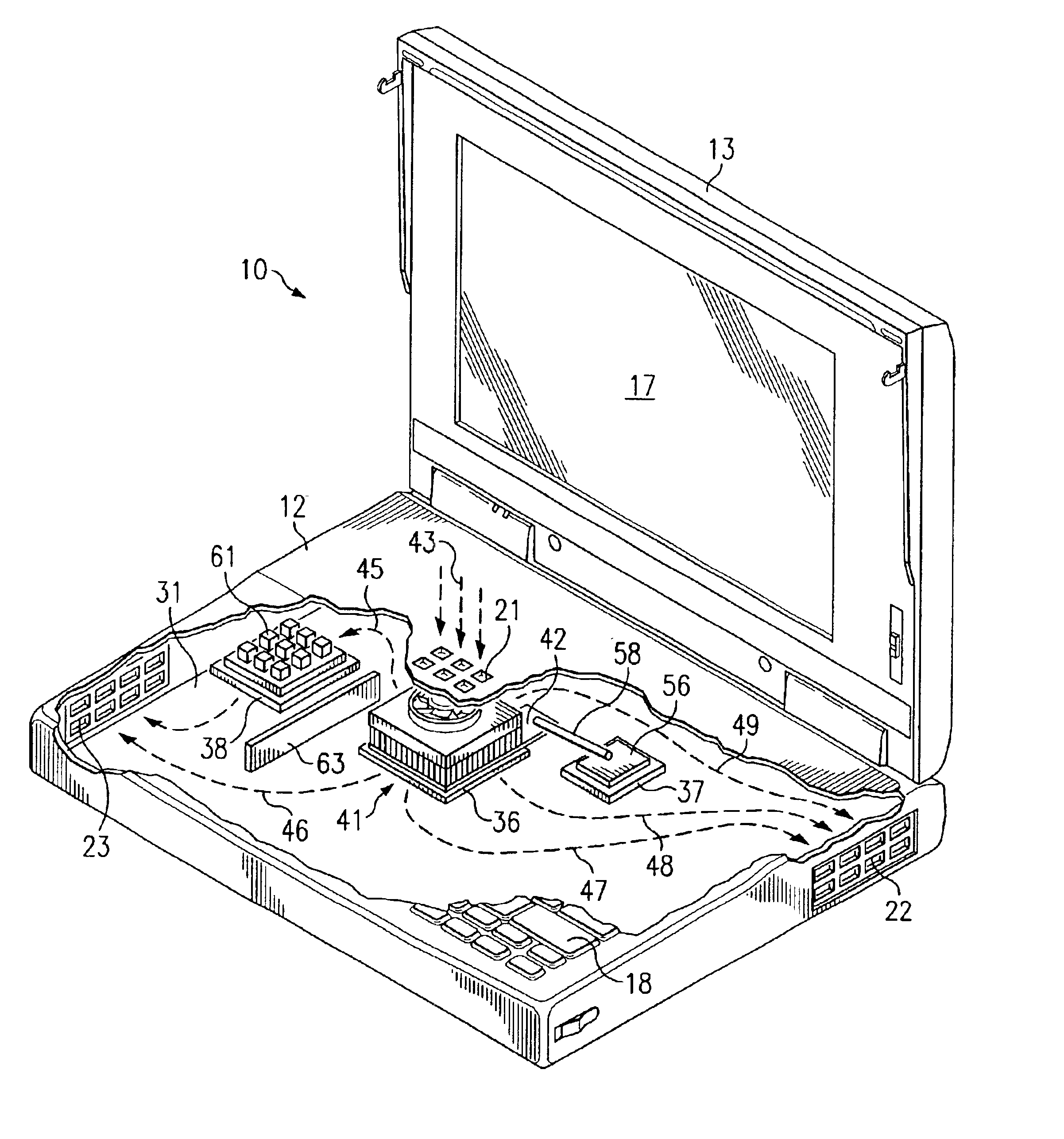

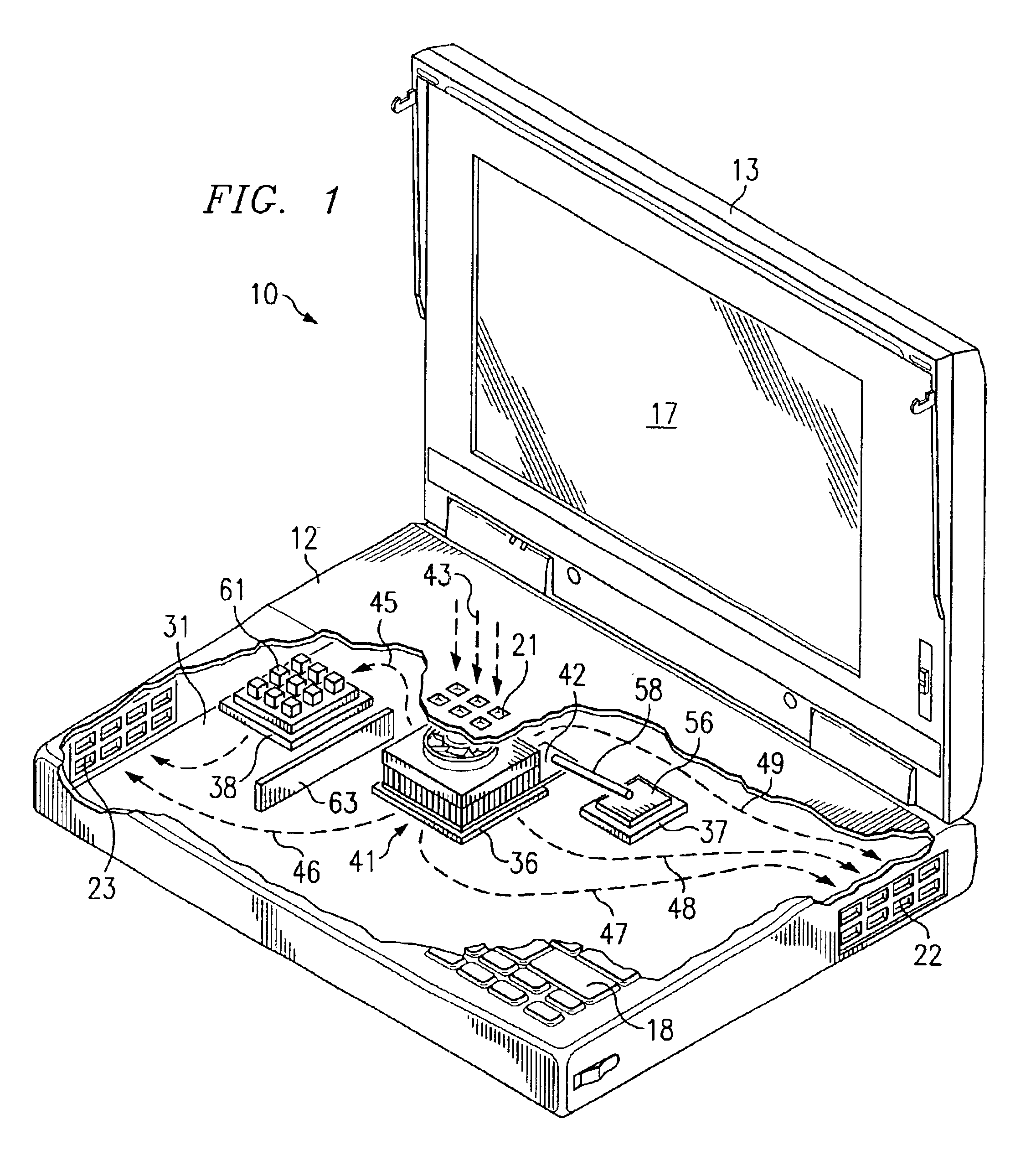

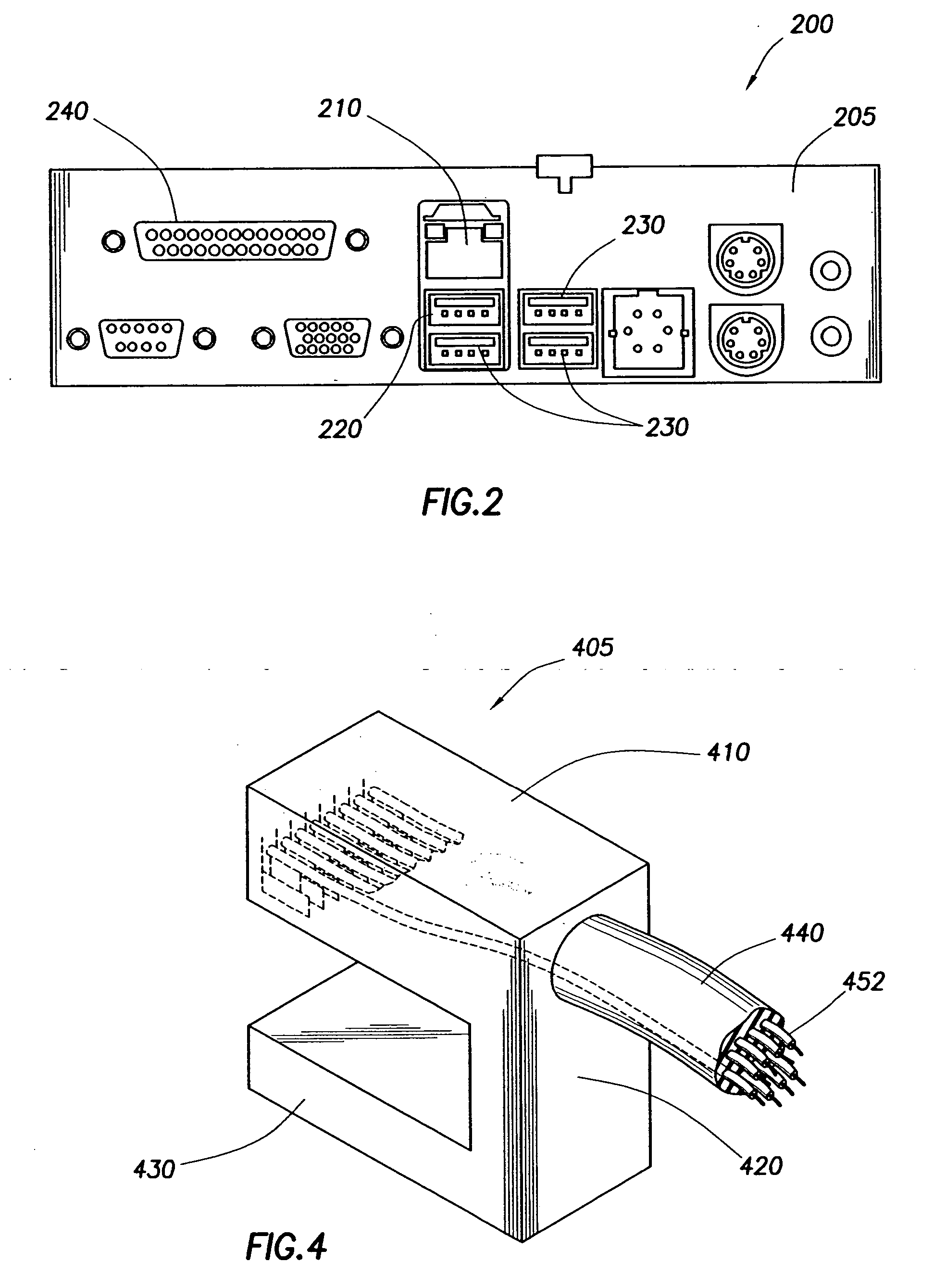

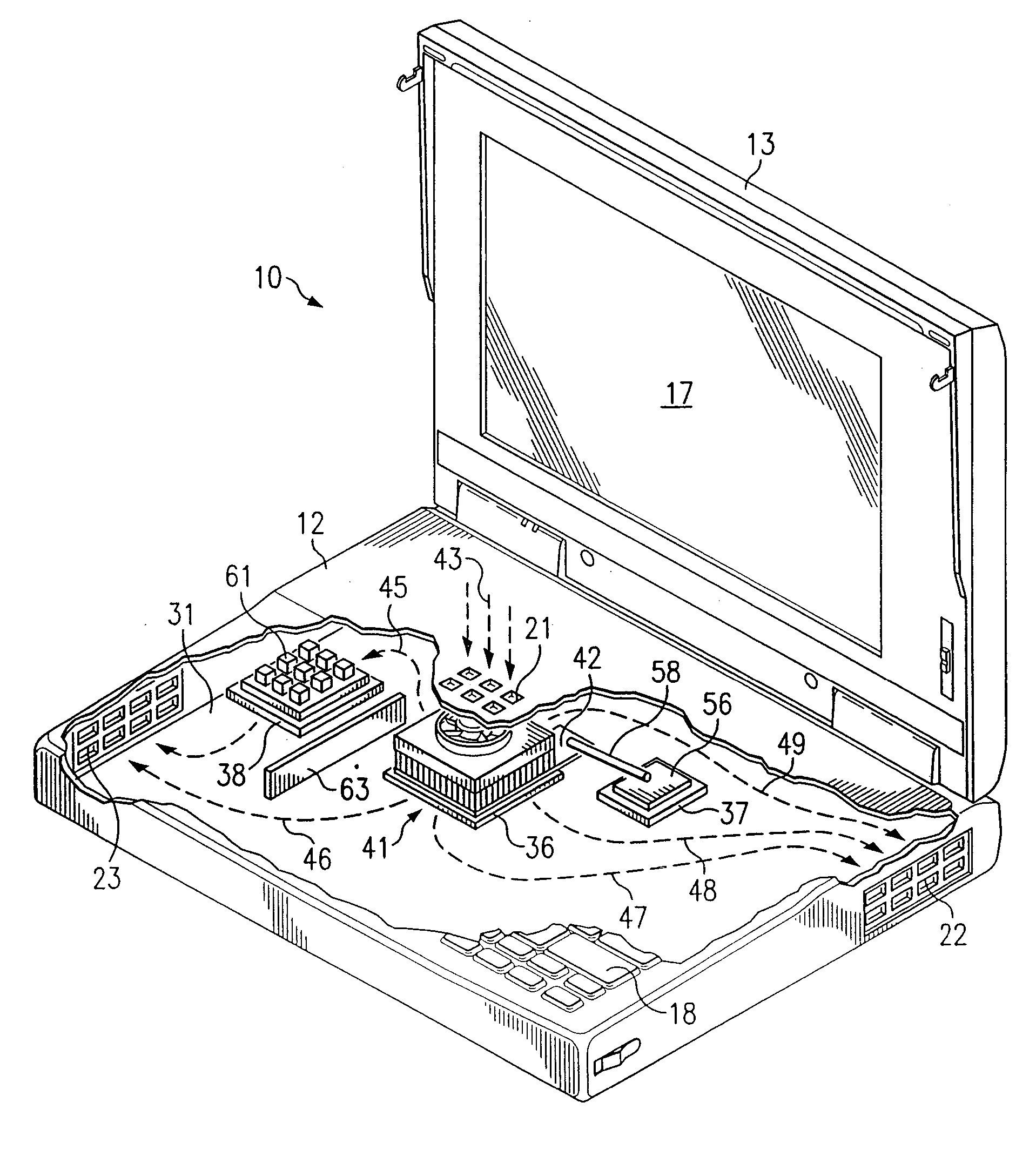

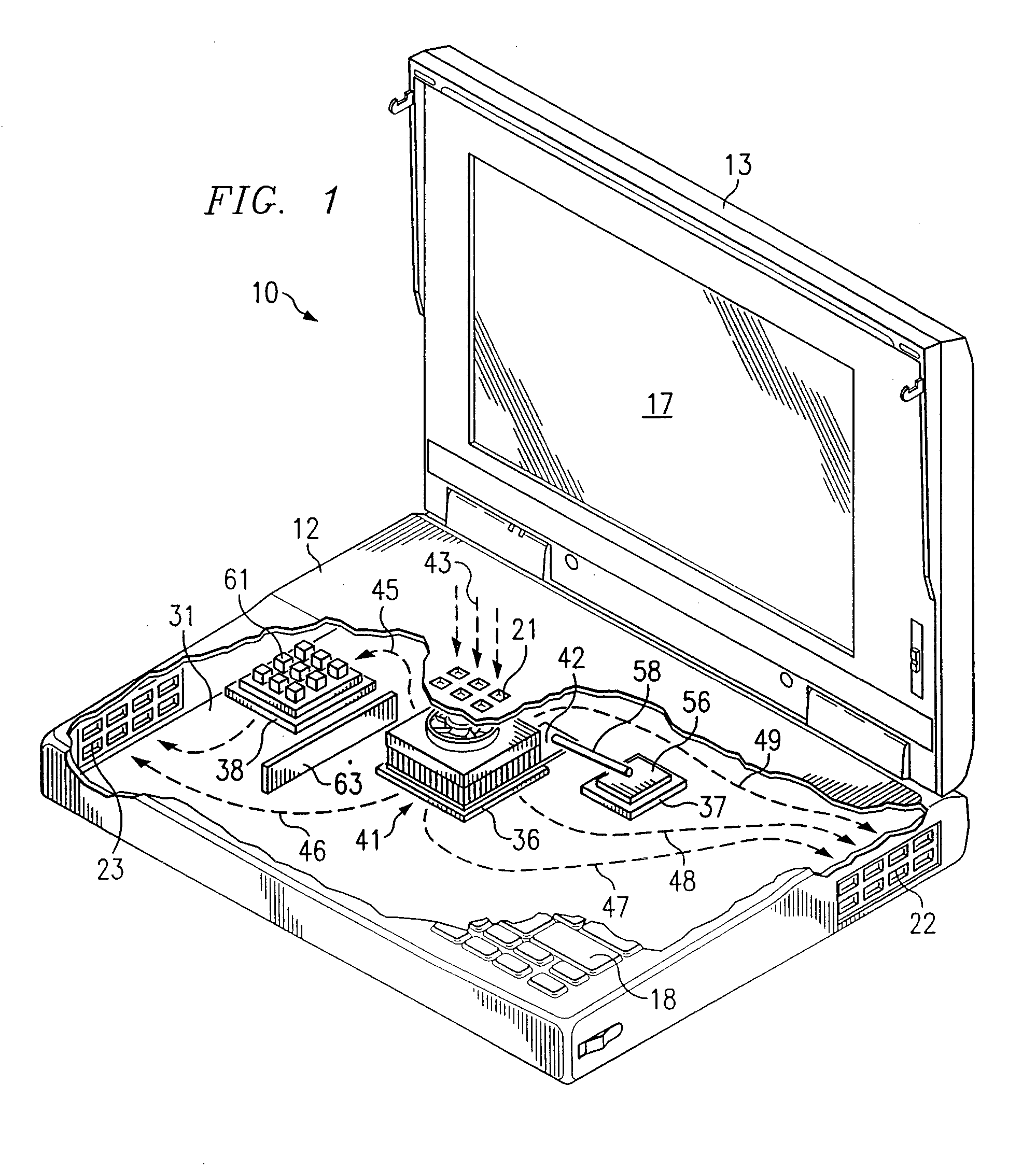

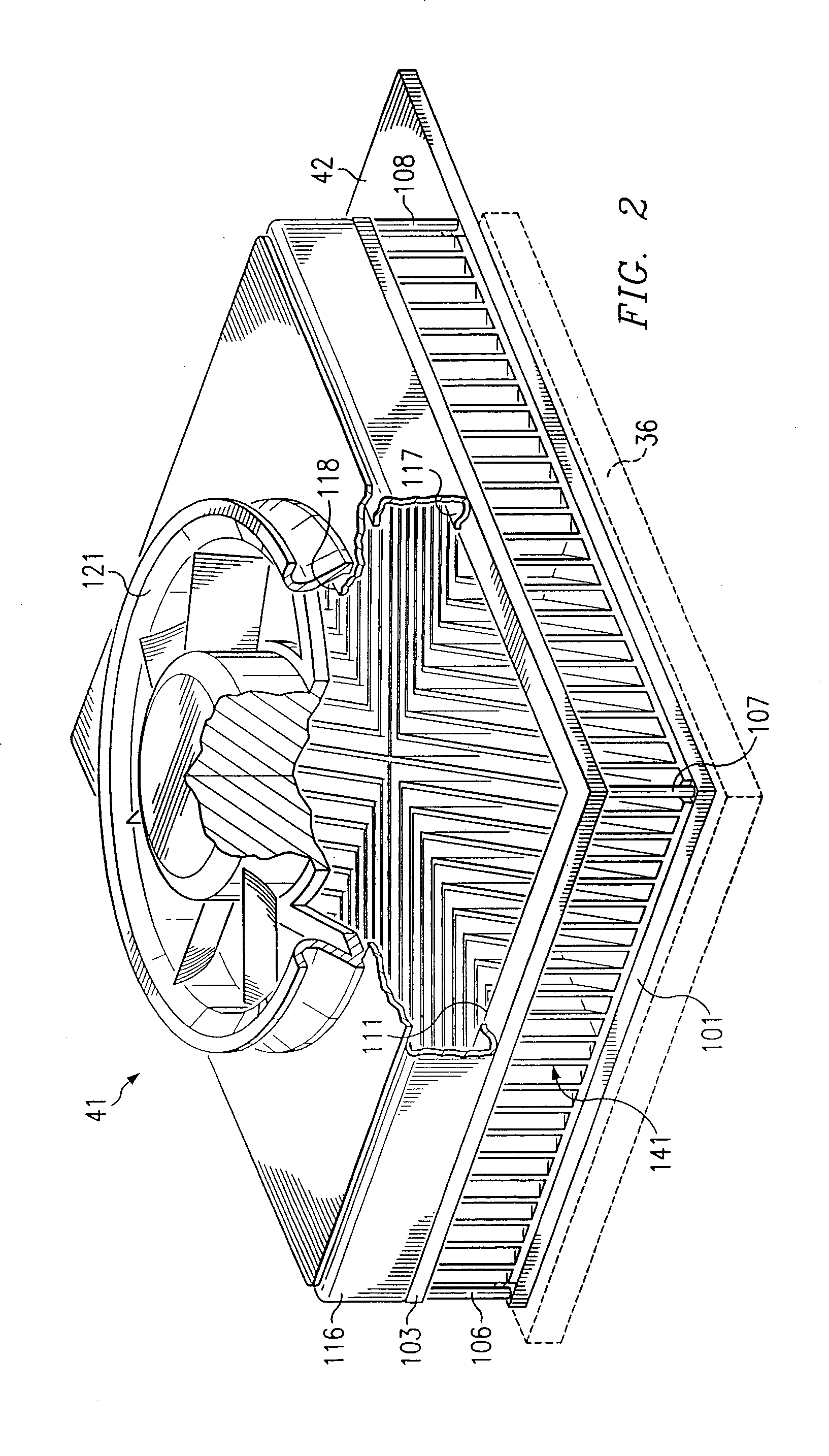

Method and apparatus for cooling a portable computer

InactiveUS6972950B1Improve cooling effectIncrease air circulationPump componentsDomestic cooling apparatusEngineeringFluid supply

A portable computer includes a housing containing a circuit component, and a temperature adjusting arrangement which has a thermally conductive section with a side facing approximately along an axis and thermally coupled to the component. A fluid supply section directs a fluid flow along the axis and the thermally conductive section splits the fluid flow into a plurality of flow portions which each flow through the thermally conductive section in a direction approximately parallel to a plane perpendicular to the axis, the flow portions exiting the thermally conductive section at a plurality of respective locations disposed along a substantial portion of the periphery of the thermally conductive section.

Owner:PC COMA LLC

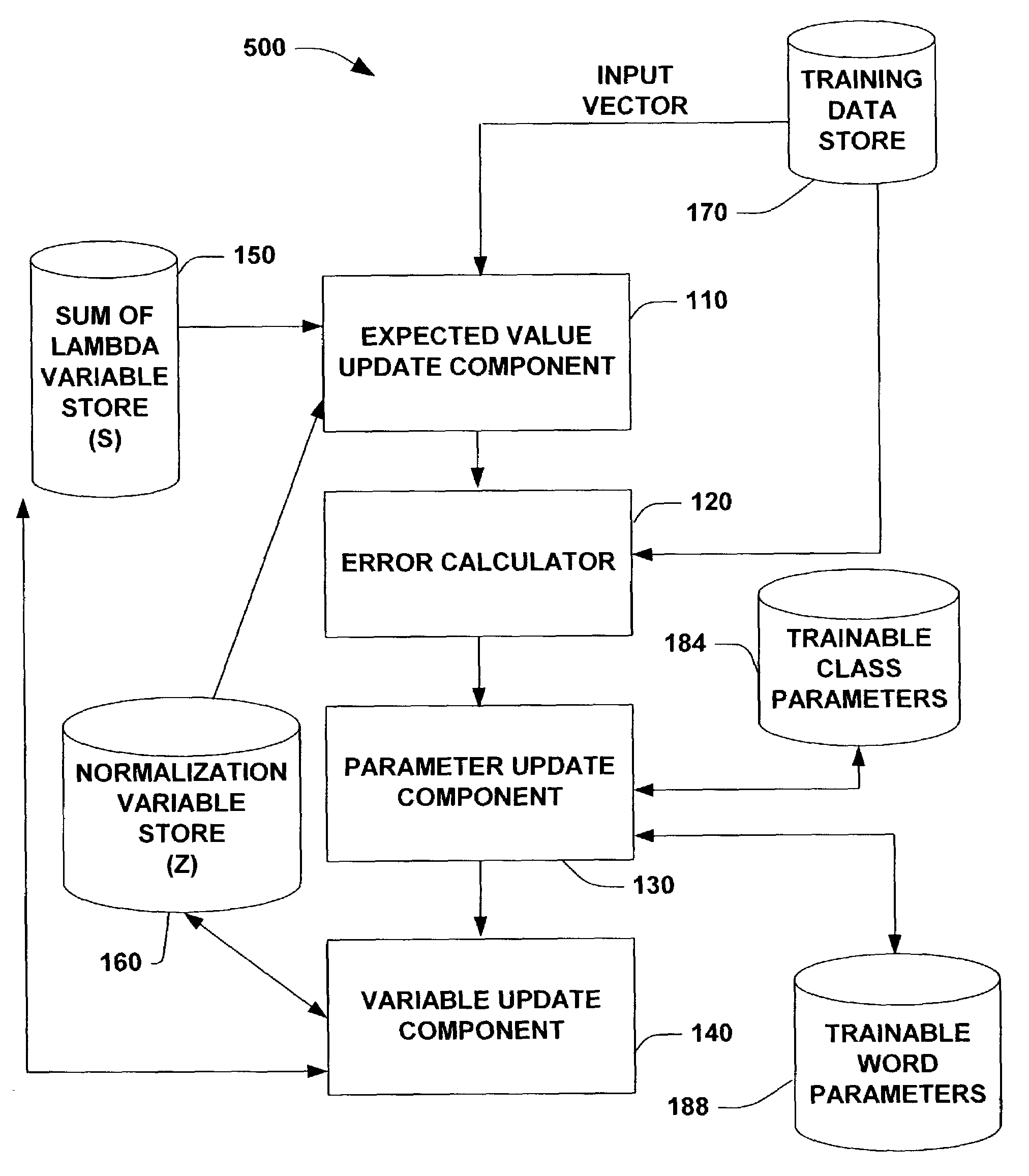

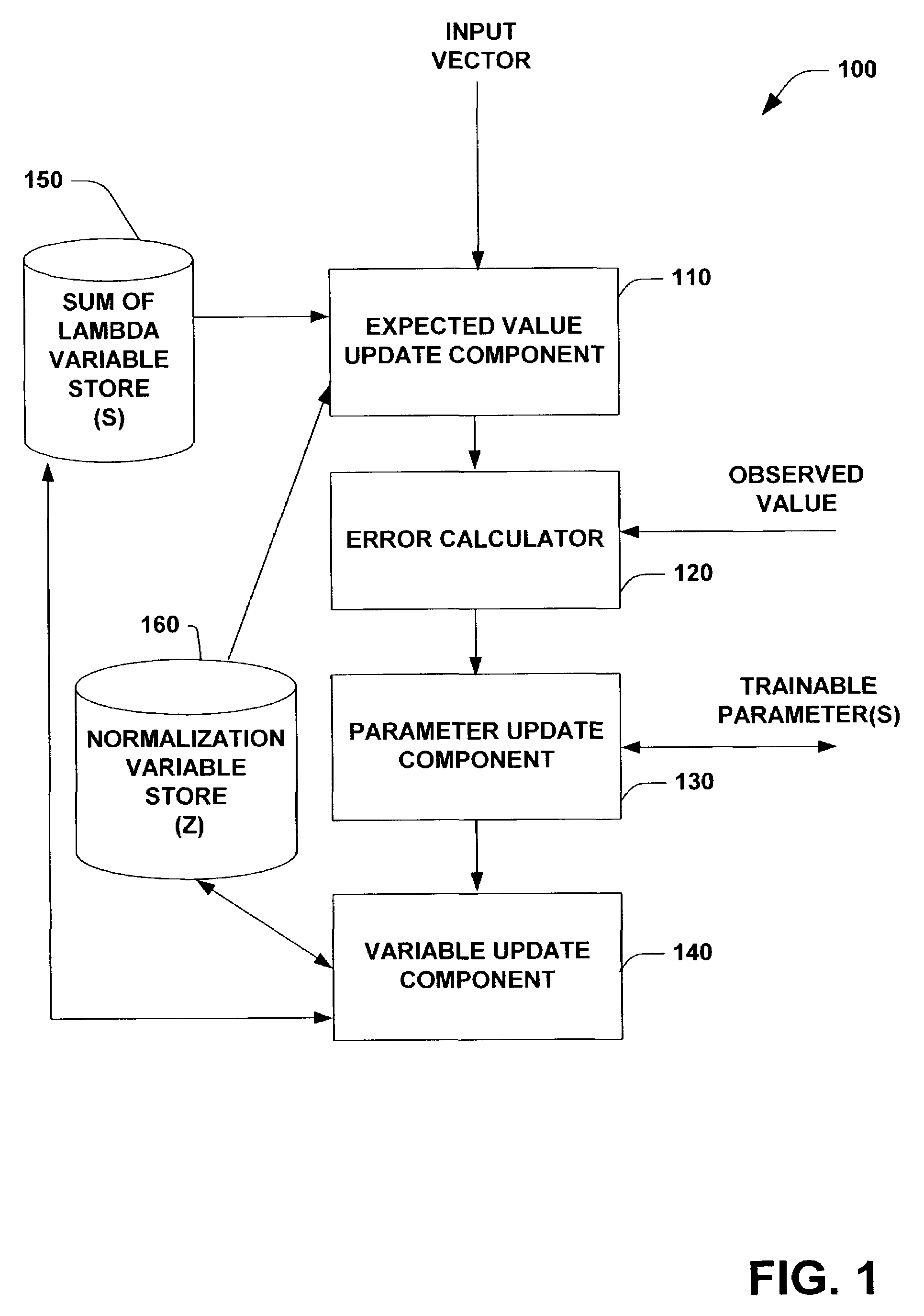

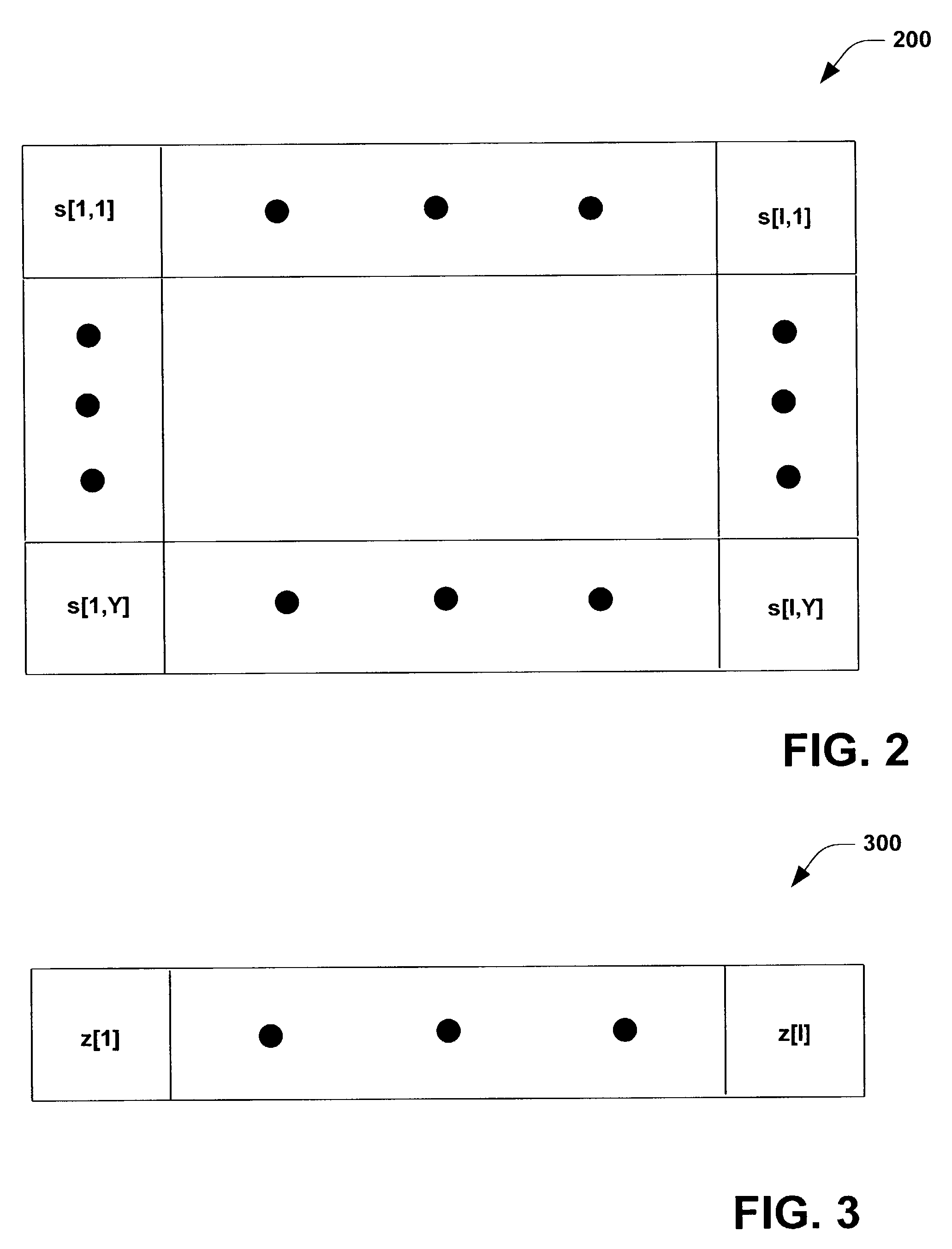

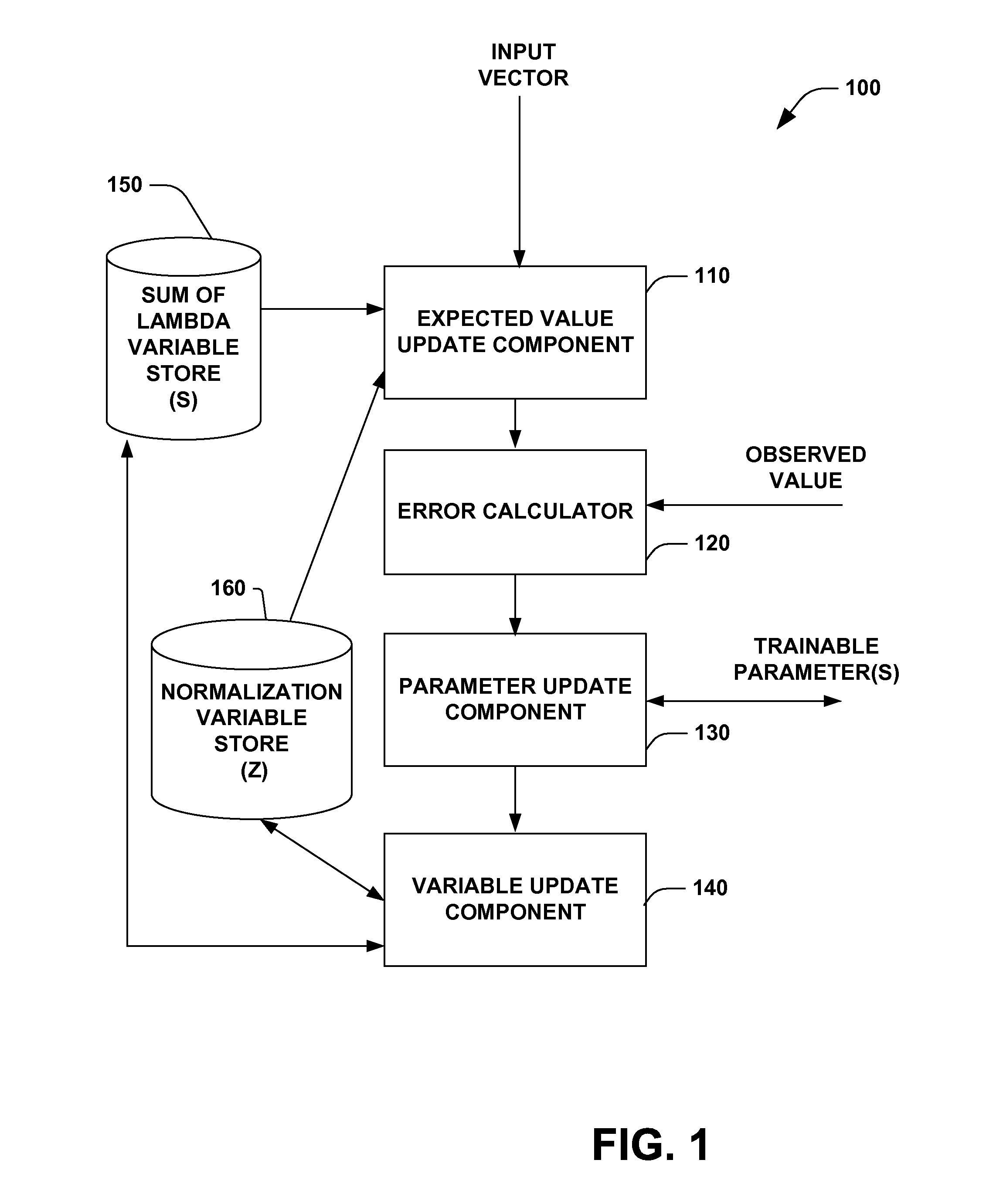

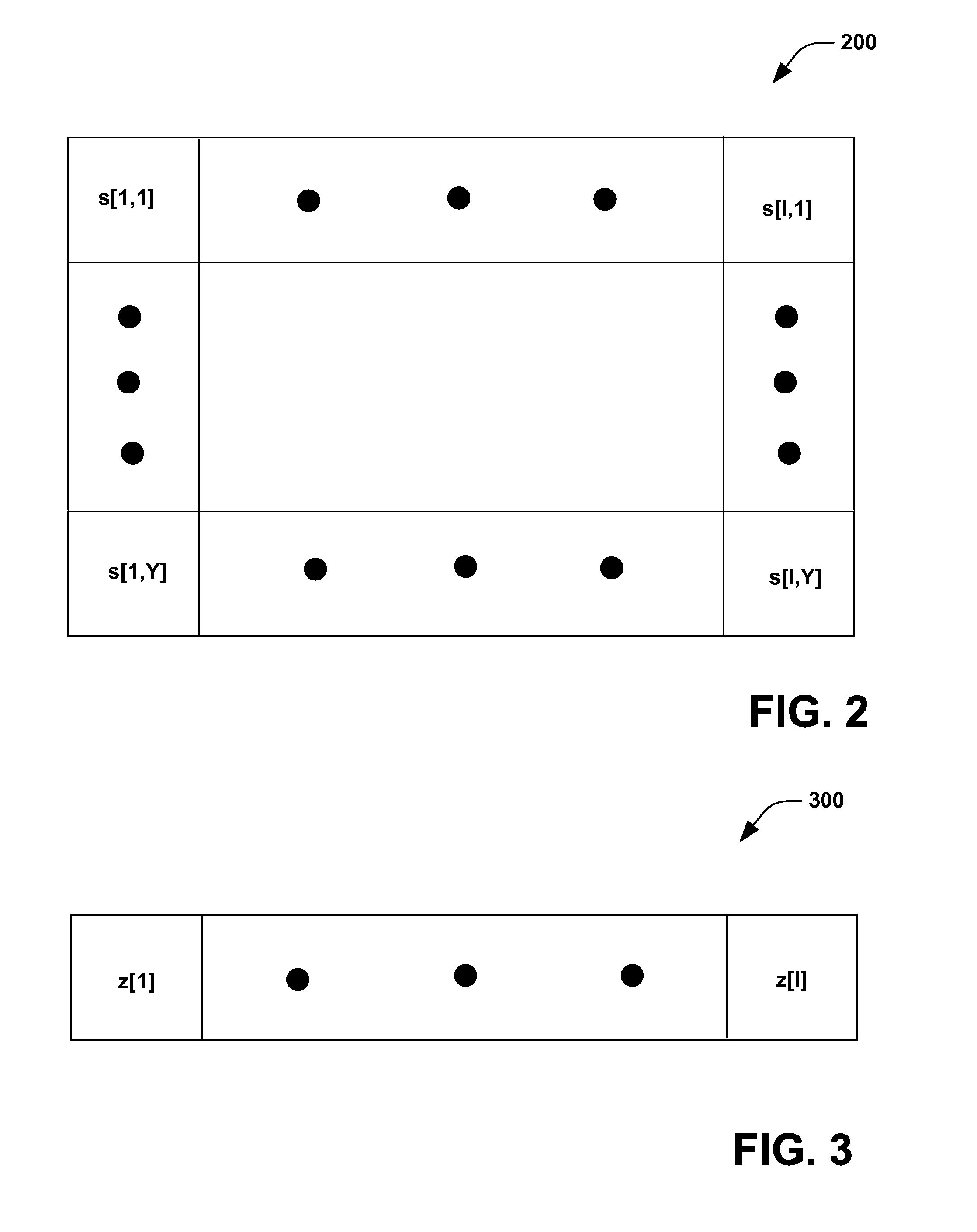

Training machine learning by sequential conditional generalized iterative scaling

InactiveUS7107207B2Raise the possibilityIncrease speedSpeech recognitionMachine learningGeneralized iterative scalingMachine learning

A system and method facilitating training machine learning systems utilizing sequential conditional generalized iterative scaling is provided. The invention includes an expected value update component that modifies an expected value based, at least in part, upon a feature function of an input vector and an output value, a sum of lambda variable and a normalization variable. The invention further includes an error calculator that calculates an error based, at least in part, upon the expected value and an observed value. The invention also includes a parameter update component that modifies a trainable parameter based, at least in part, upon the error. A variable update component that updates at least one of the sum of lambda variable and the normalization variable based, at least in part, upon the error is also provided.

Owner:MICROSOFT TECH LICENSING LLC

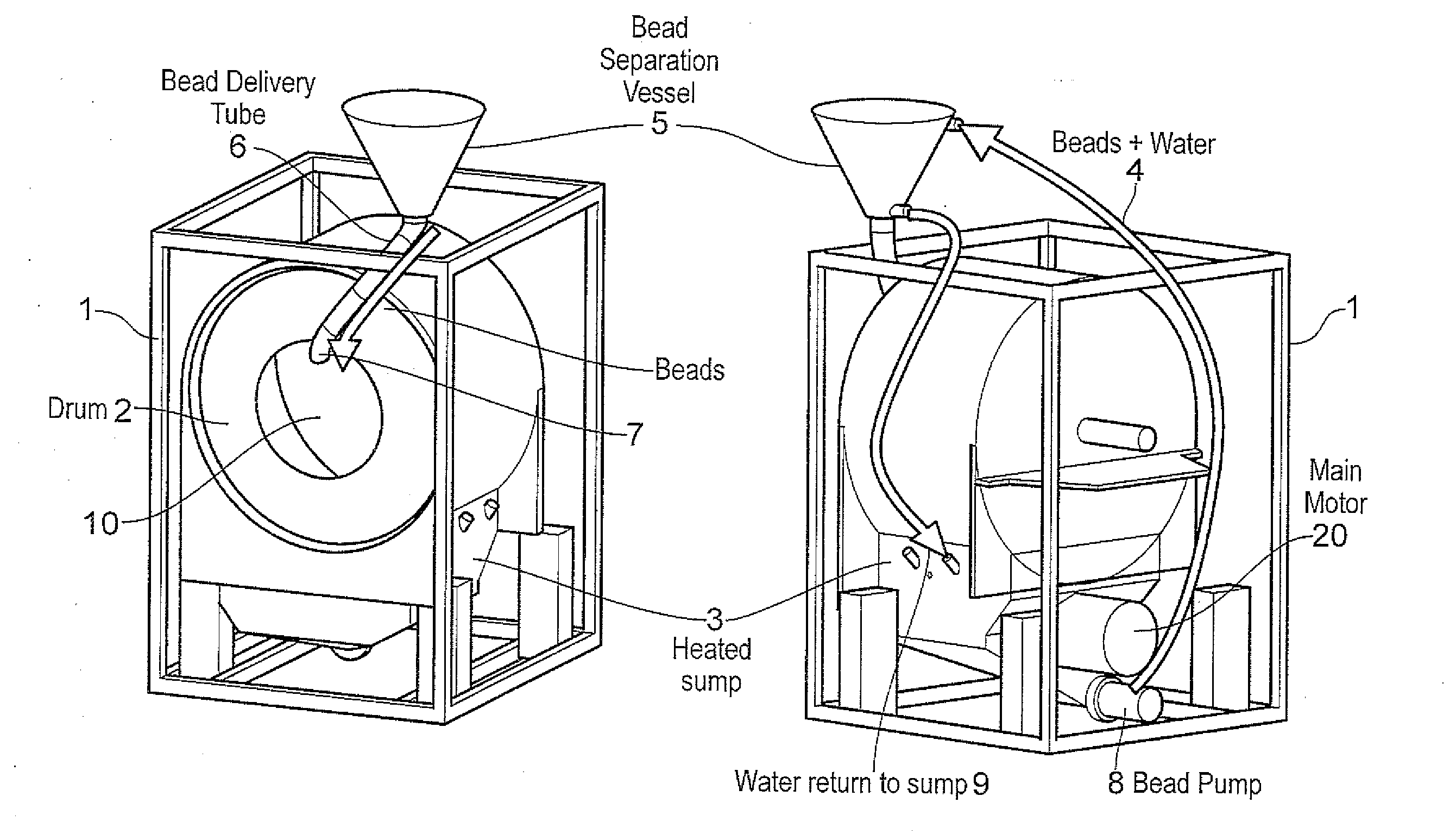

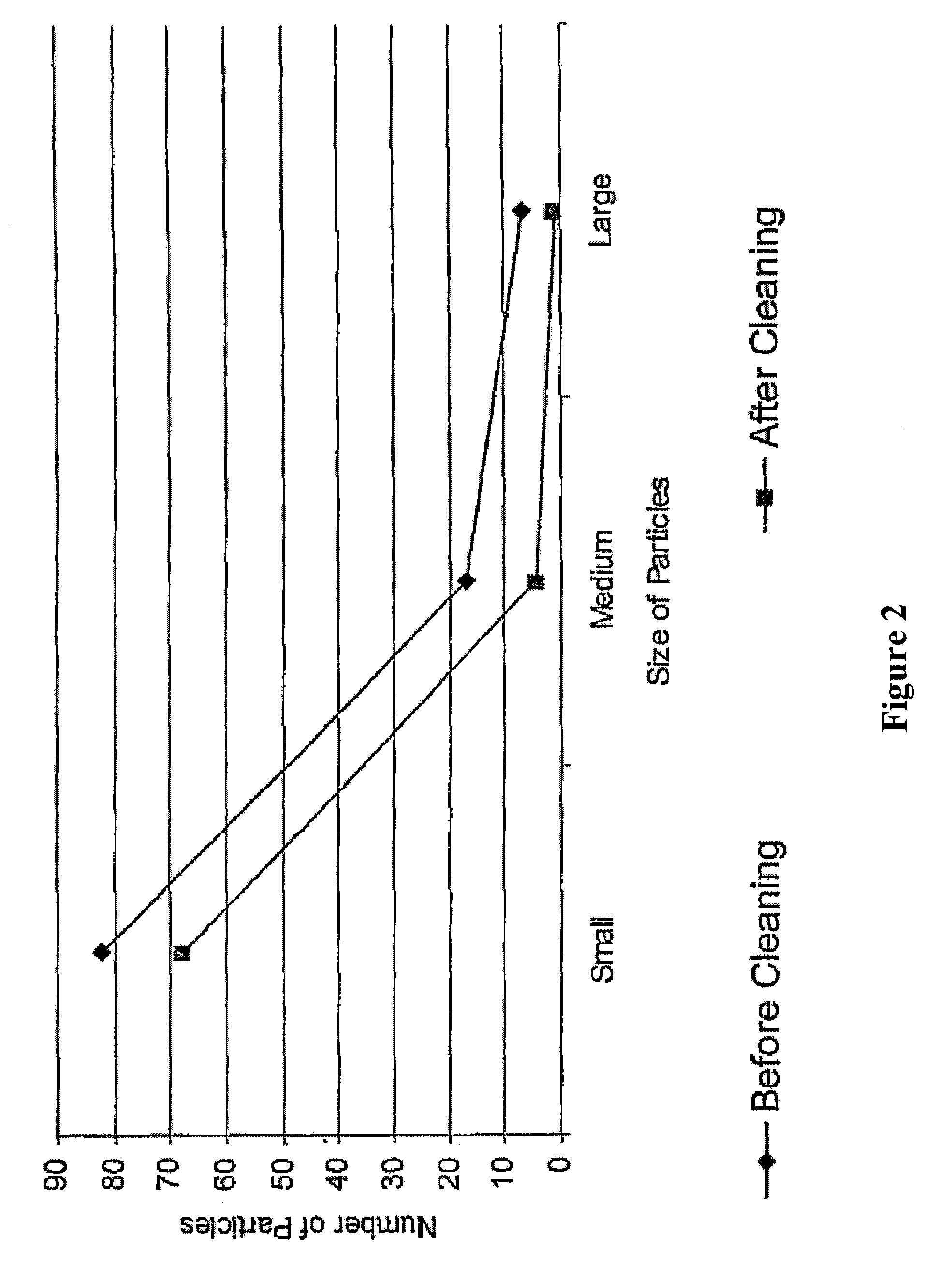

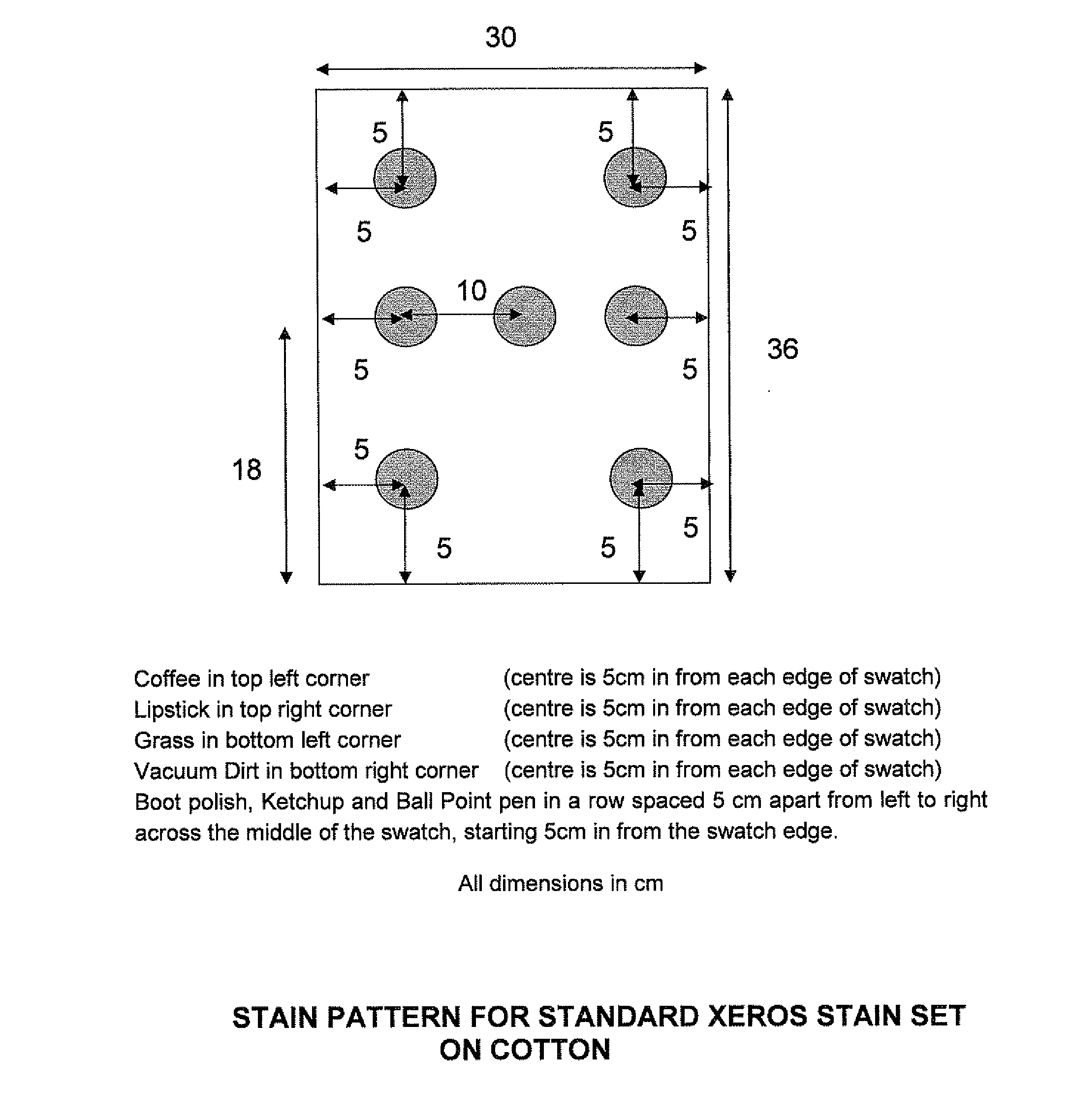

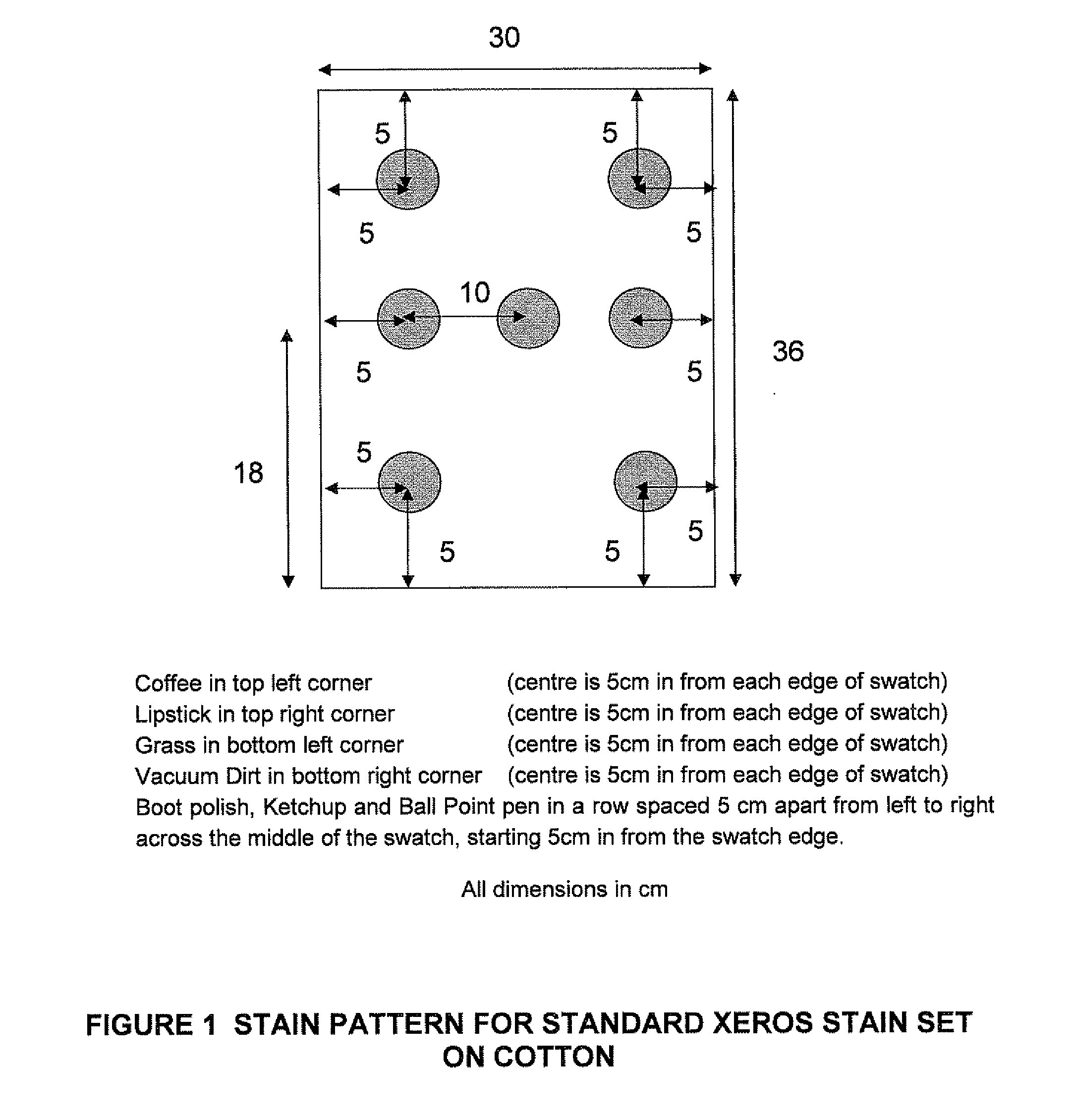

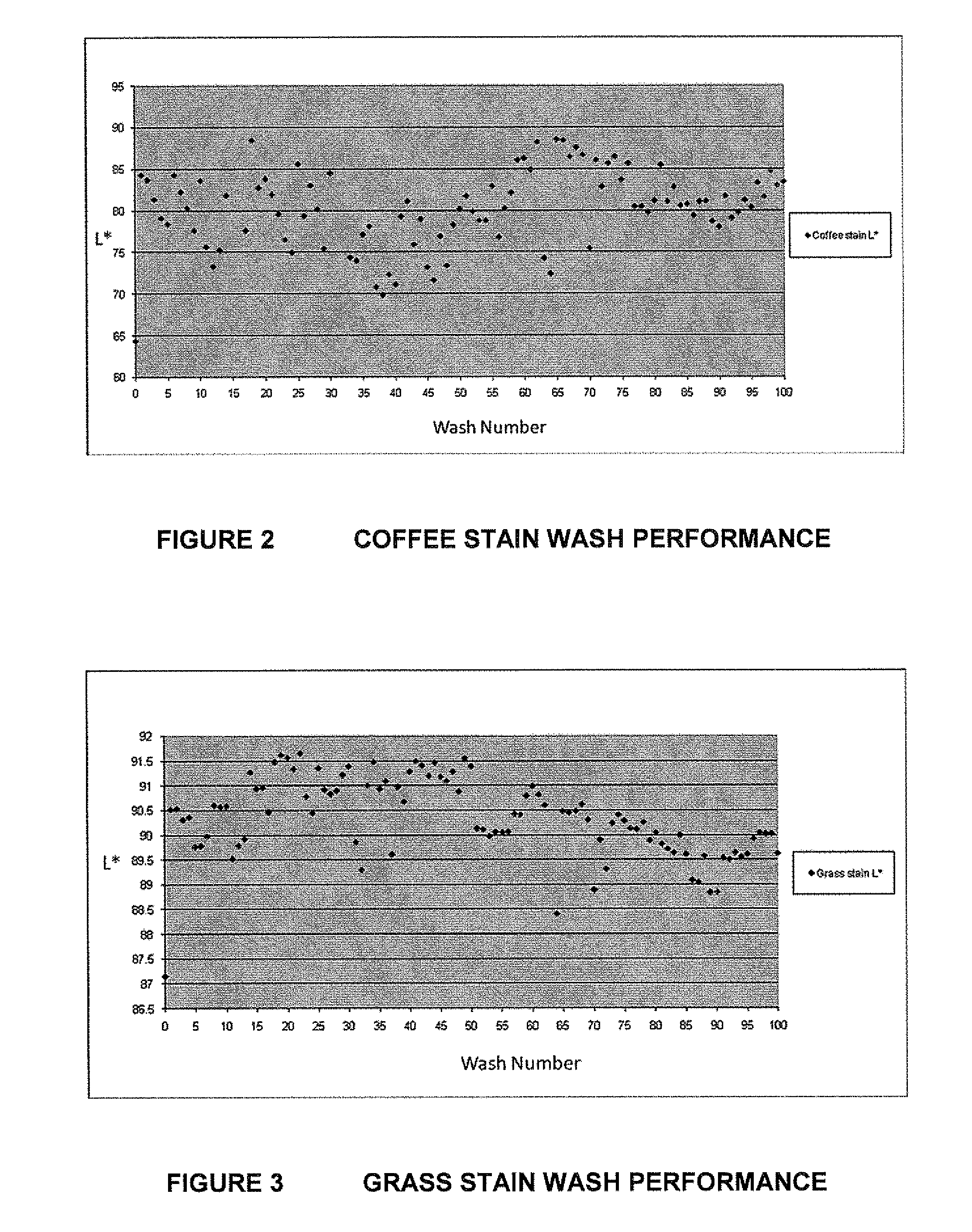

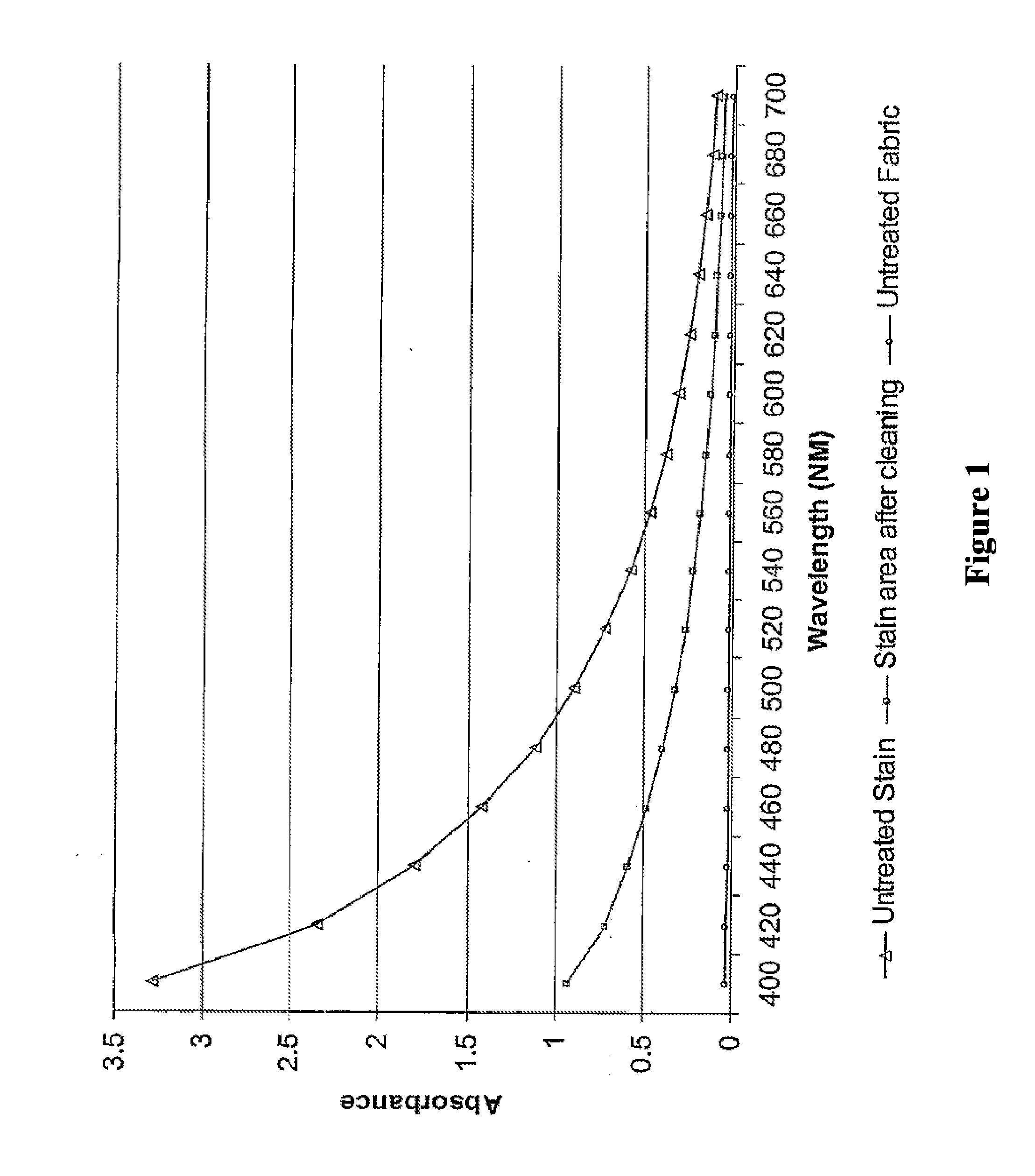

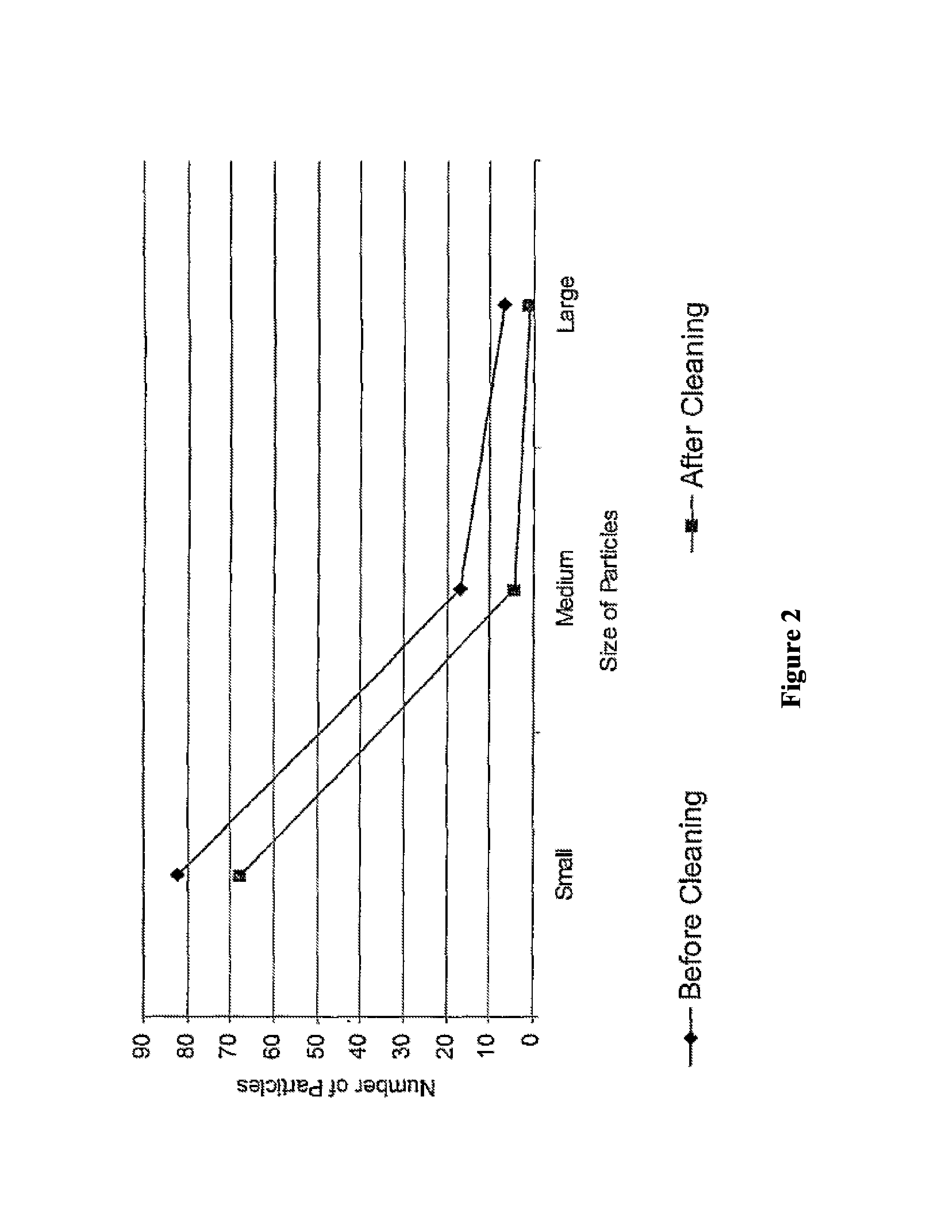

Polymer treatment method

InactiveUS20130167882A1Promote dissolutionImprove stabilityNon-ionic surface-active compoundsDetergent mixture composition preparationFiberPolyester

The invention provides a method for the treatment of polymeric particles recovered after use in cleaning processes for soiled substrates, the method comprising treating the particles with a particle cleaning agent. Preferably, said agent comprises at least one surfactant. Preferably said agent comprises an aqueous medium. Typically, the polymeric particles comprise particles of nylon or polyester. The invention also provides a method for cleaning a soiled substrate, the method comprising the steps of: (a) treating polymeric particles with a particle cleaning agent; and (b) treating a moistened substrate with a formulation comprising a multiplicity of said treated polymeric particles. Most preferably, the substrate comprises a textile fibre or fabric. The results obtained are very much in line with those observed when carrying out conventional aqueous cleaning processes and the method provides the significant advantages that the useable lifetime of the polymeric particles is maximised and the economic and environmental burden generated by the polymeric particle cleaning process is minimised.

Owner:XEROS LTD

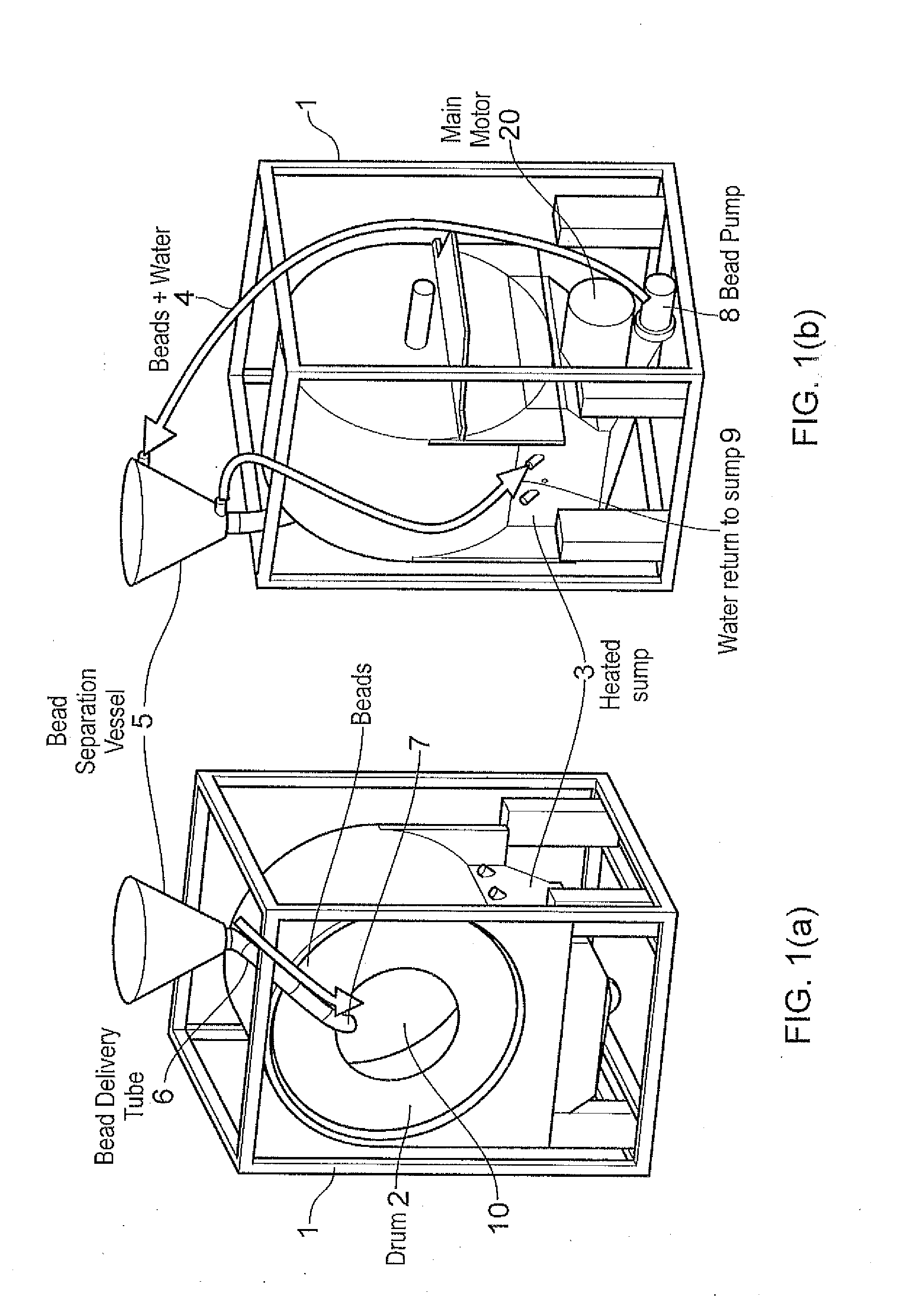

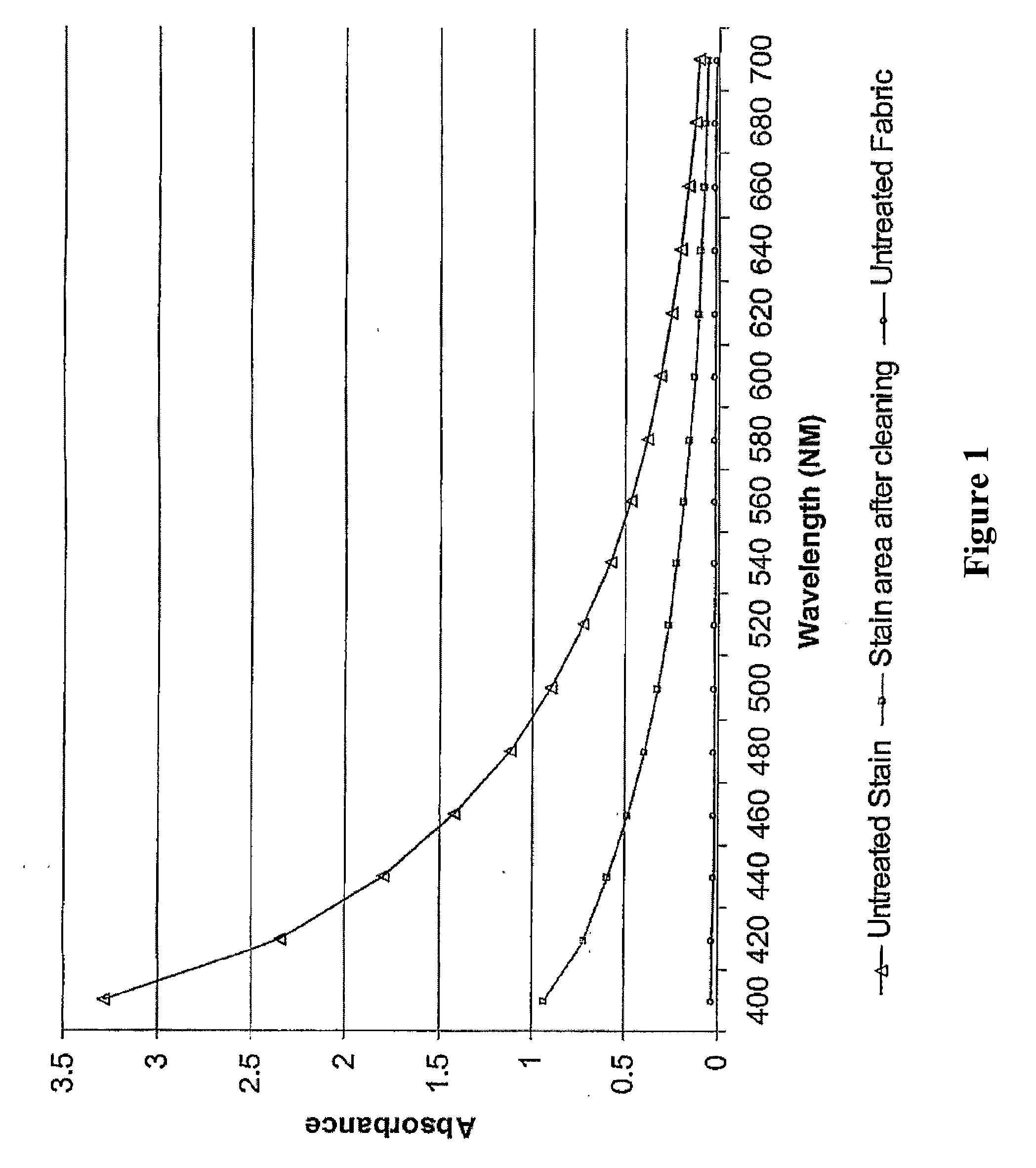

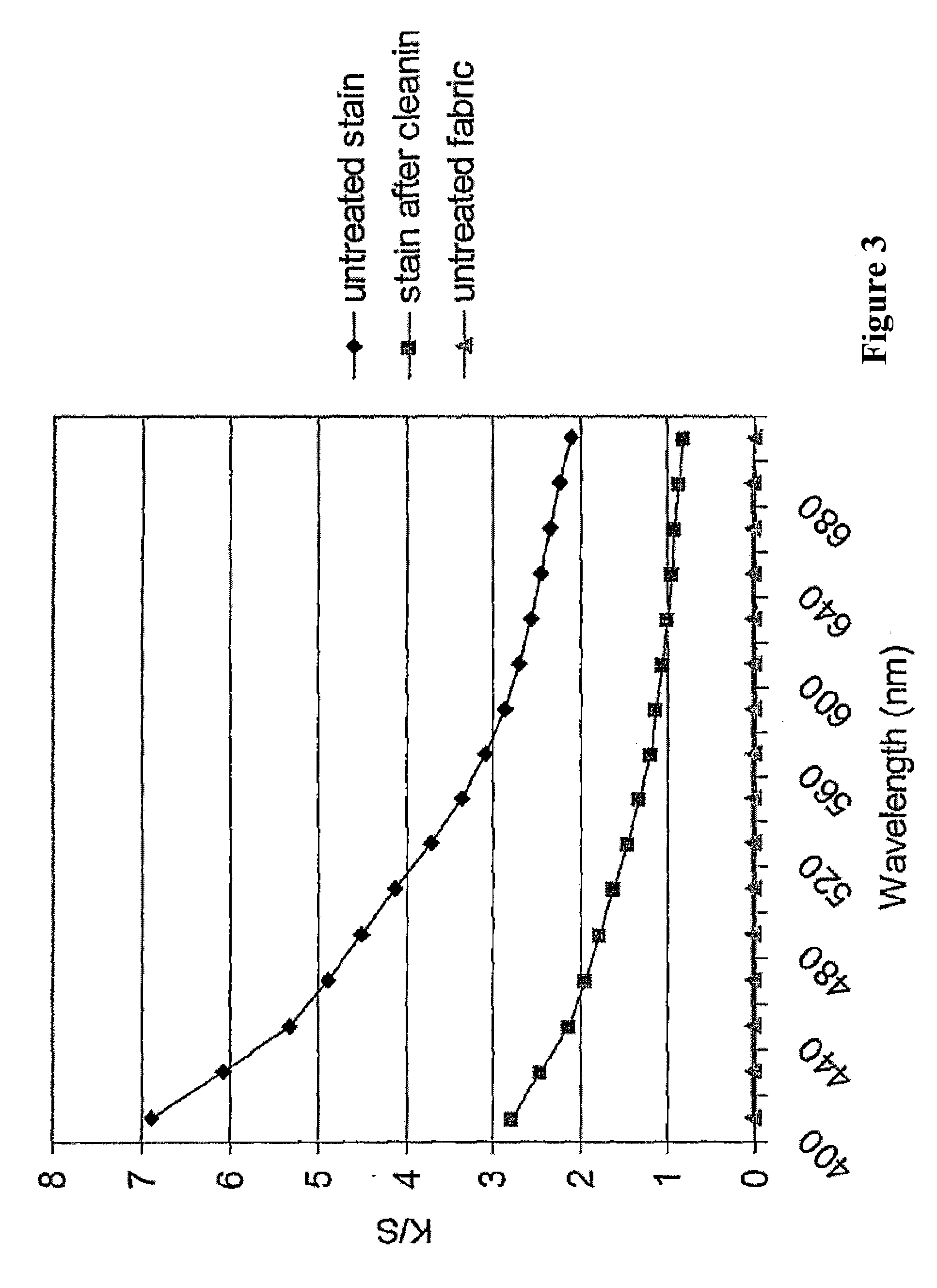

Novel cleaning method

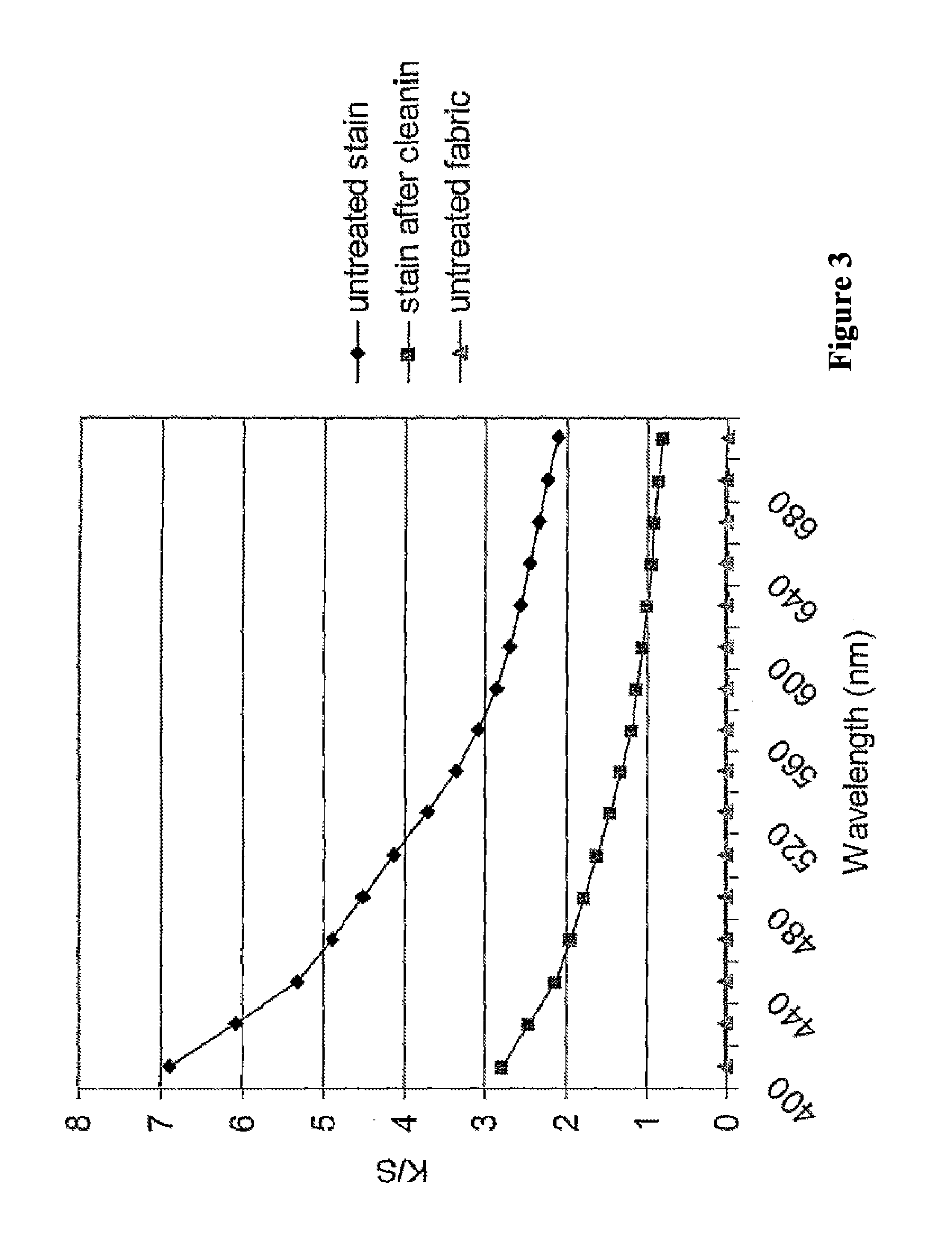

ActiveUS20090217461A1Improve propertyFacilitate efficient transferOrganic detergent compounding agentsDetergent mixture composition preparationSolventChemistry

The invention provides a method and formulation for cleaning a soiled substrate, the method comprising the treatment of the moistened substrate with a formulation comprising a multiplicity of polymeric particles, wherein the formulation is free of organic solvents. Preferably, the substrate is wetted so as to achieve a substrate to water ratio of between 1:0.1 to 1:5 w / w. Optionally, the formulation additionally comprises at least one cleaning material and, in this embodiment, it is preferred that the polymeric particles are coated with the at least one cleaning material. Preferably, the cleaning material comprises a surfactant, which most preferably has detergent properties. Most preferably, the substrate comprises a textile fibre. Typically, the polymeric particles comprise particles of nylon, most preferably in the form of nylon chips. The results obtained are very much in line with those observed when carrying out conventional dry cleaning processes and the method provides the significant advantage that the use of solvents, with all the attendant drawbacks in terms of cost and environmental considerations, can be avoided.

Owner:XEROS LTD

Novel cleaning method

InactiveUS20120048299A1Improve propertiesConvenient and efficient transferOrganic detergent compounding agentsDetergent mixture composition preparationFiberParticulates

The invention provides a method for cleaning a soiled substrate, the method comprising the treatment of the moistened substrate with a formulation comprising a solid particulate cleaning material wherein the formulation is free of organic solvents, the treatment comprising agitation of the substrate and the formulation in at least one sealed container. Preferably the sealed container comprises a metal container or a container formed from a rigid or flexible plastic material. Preferably, the at least one container is agitated in a rotating device such as a tumble dryer. Preferably, the substrate is wetted and the solid particulate cleaning material comprises a multiplicity of polymeric particles which comprise at least one additional cleaning agent, which preferably comprises a surfactant. Most preferably, the substrate comprises a textile fibre. Typically, the polymeric particles comprise particles of nylon or polyester. The results obtained are in line with those observed when carrying out conventional cleaning processes and the method provides the significant advantage that the use of solvents, with all the attendant drawbacks in terms of cost and environmental considerations, can be avoided.

Owner:XEROS LTD

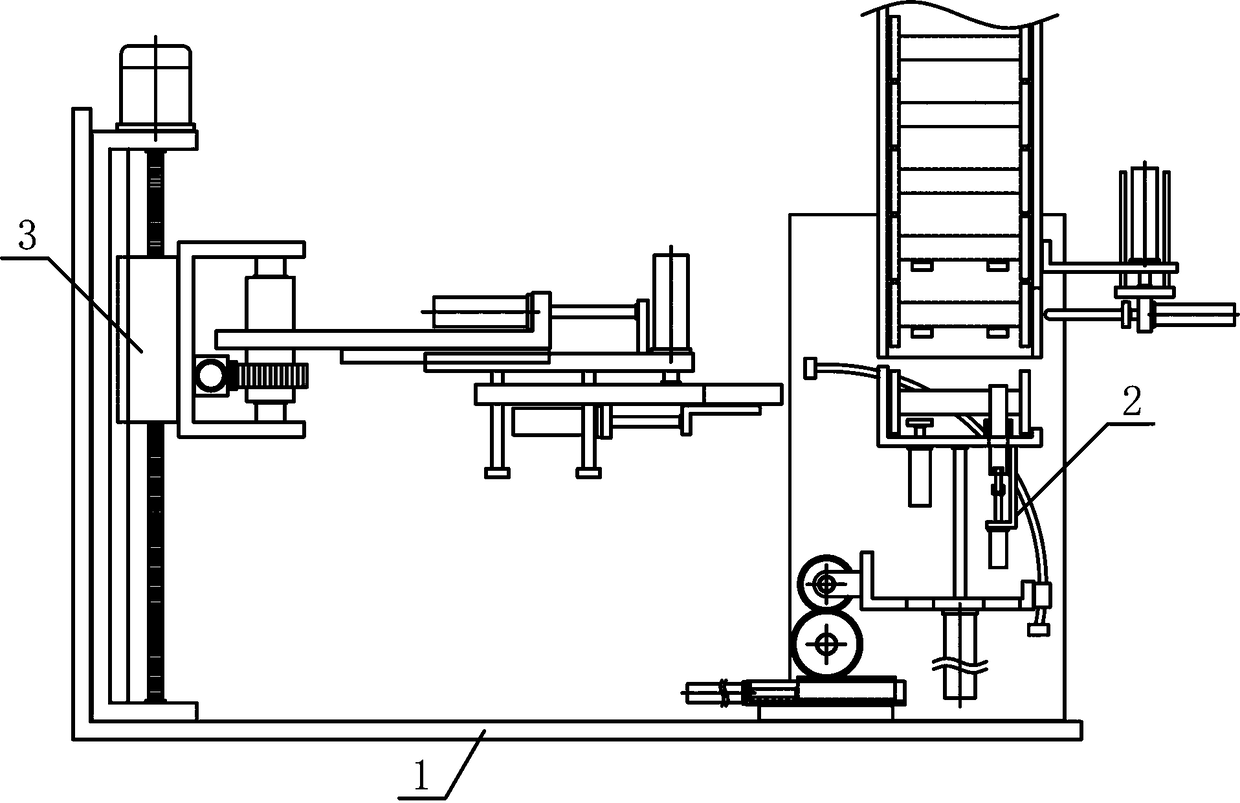

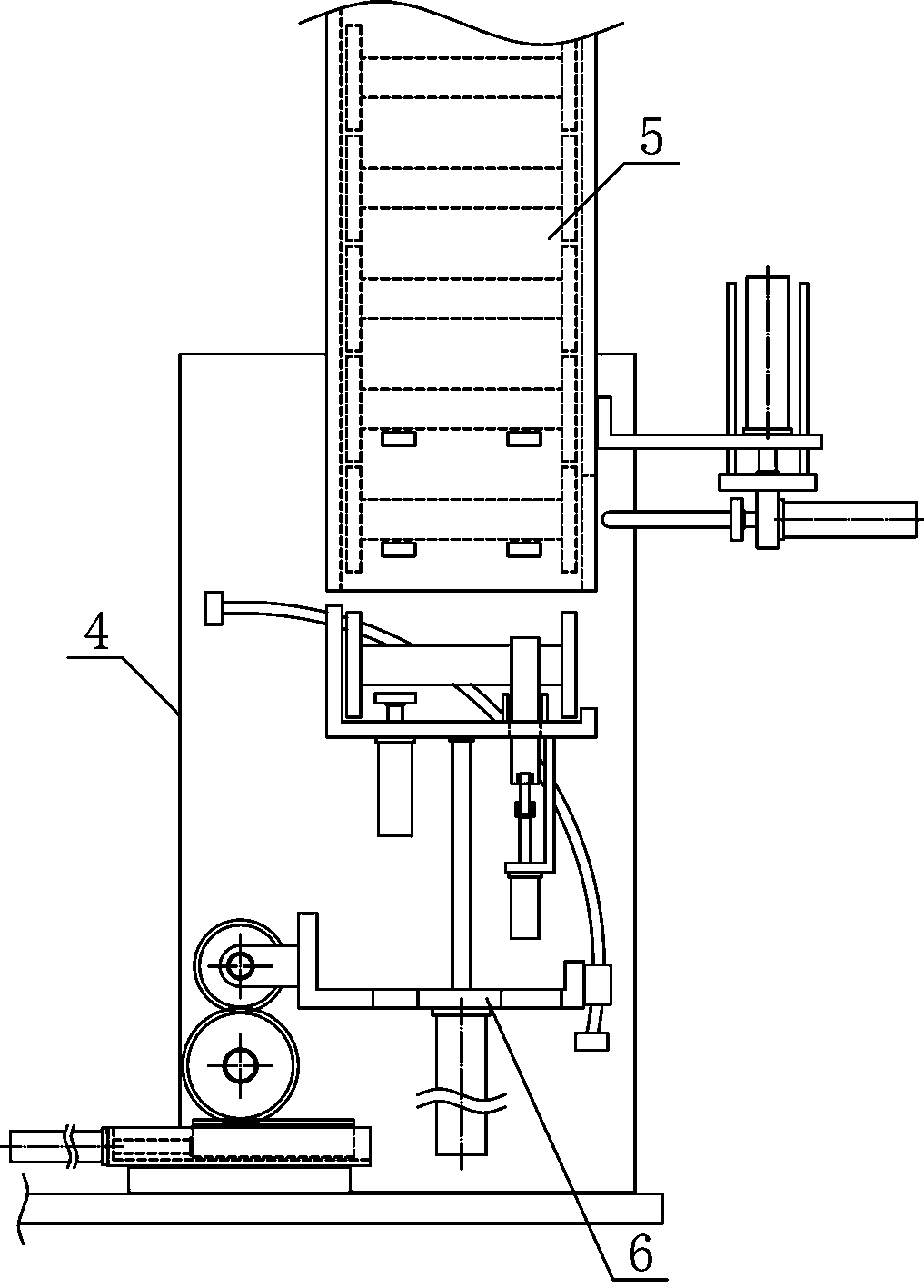

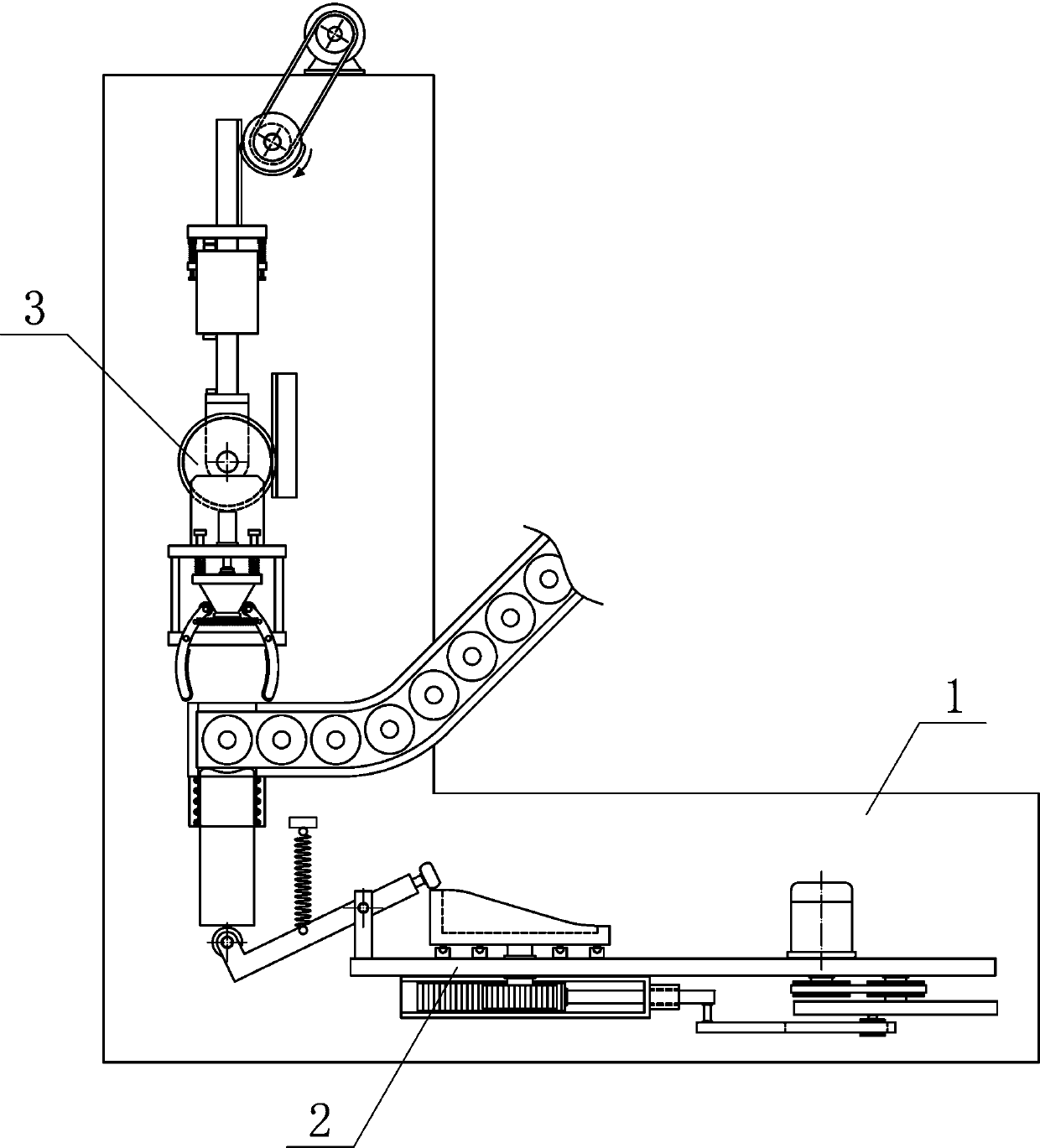

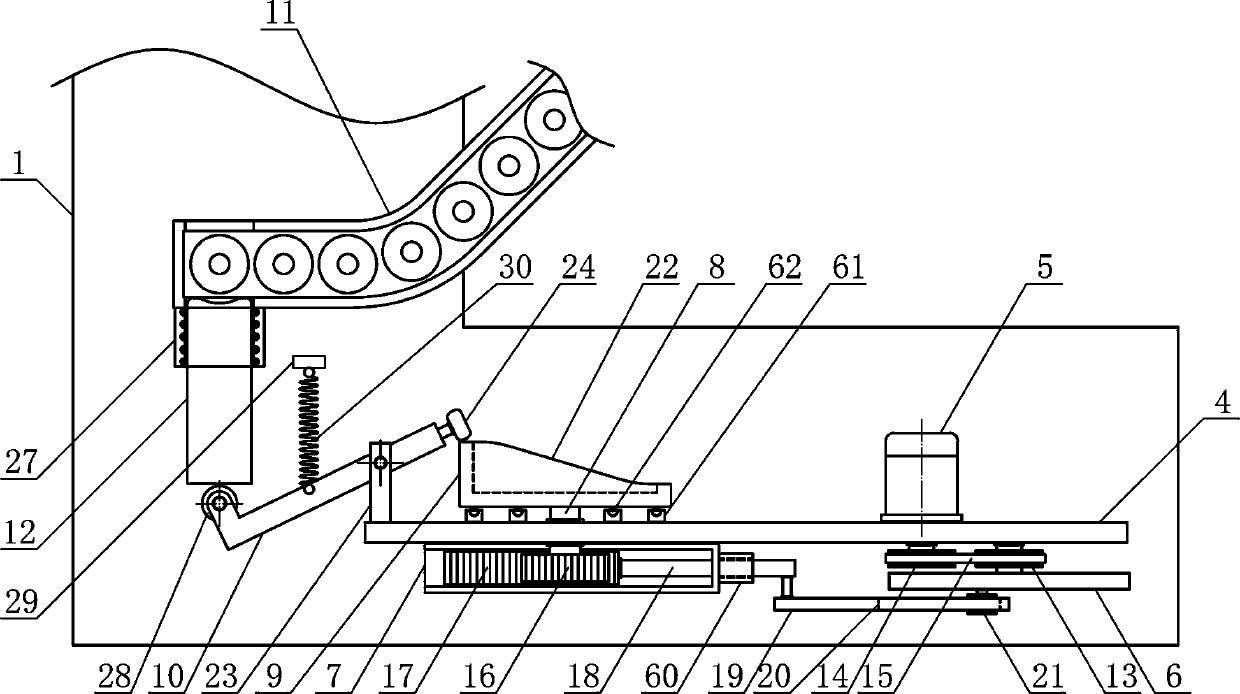

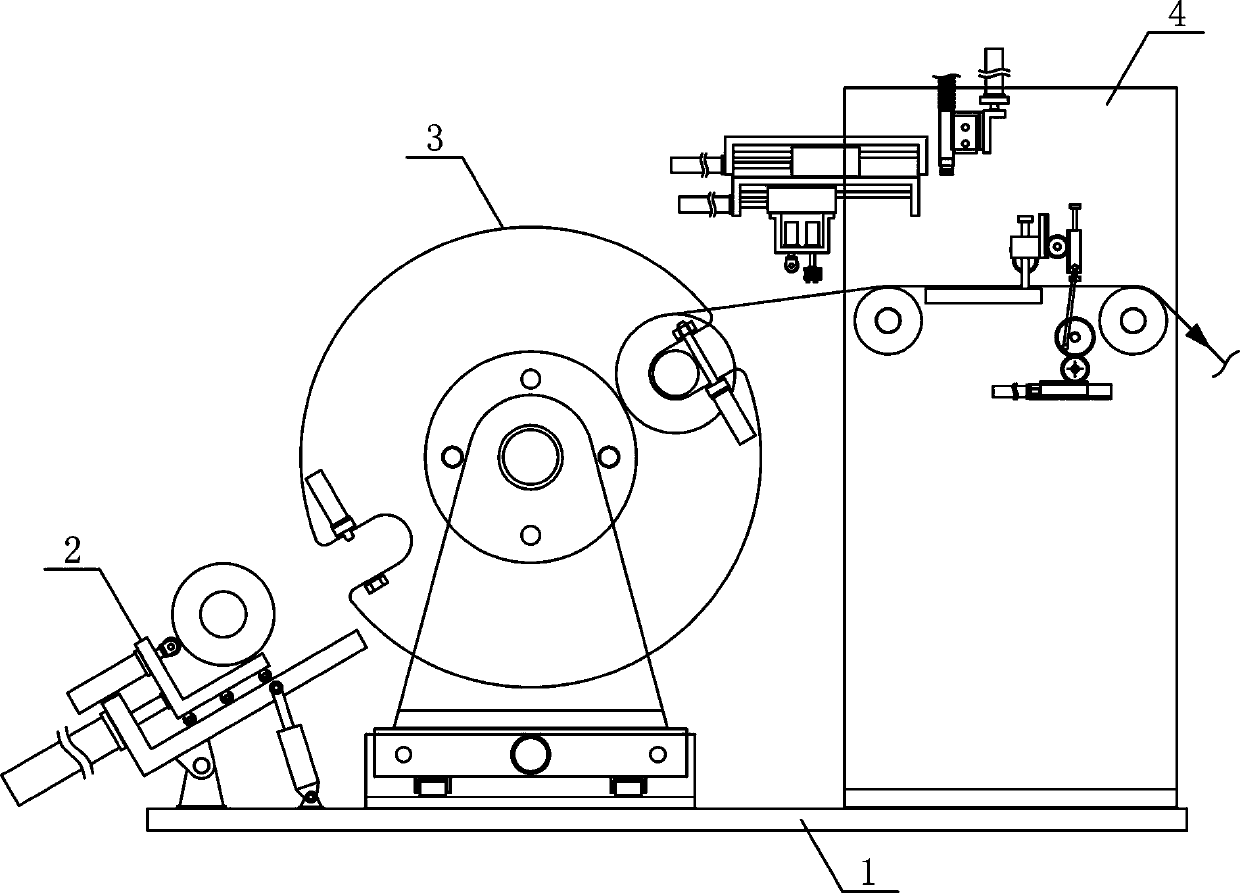

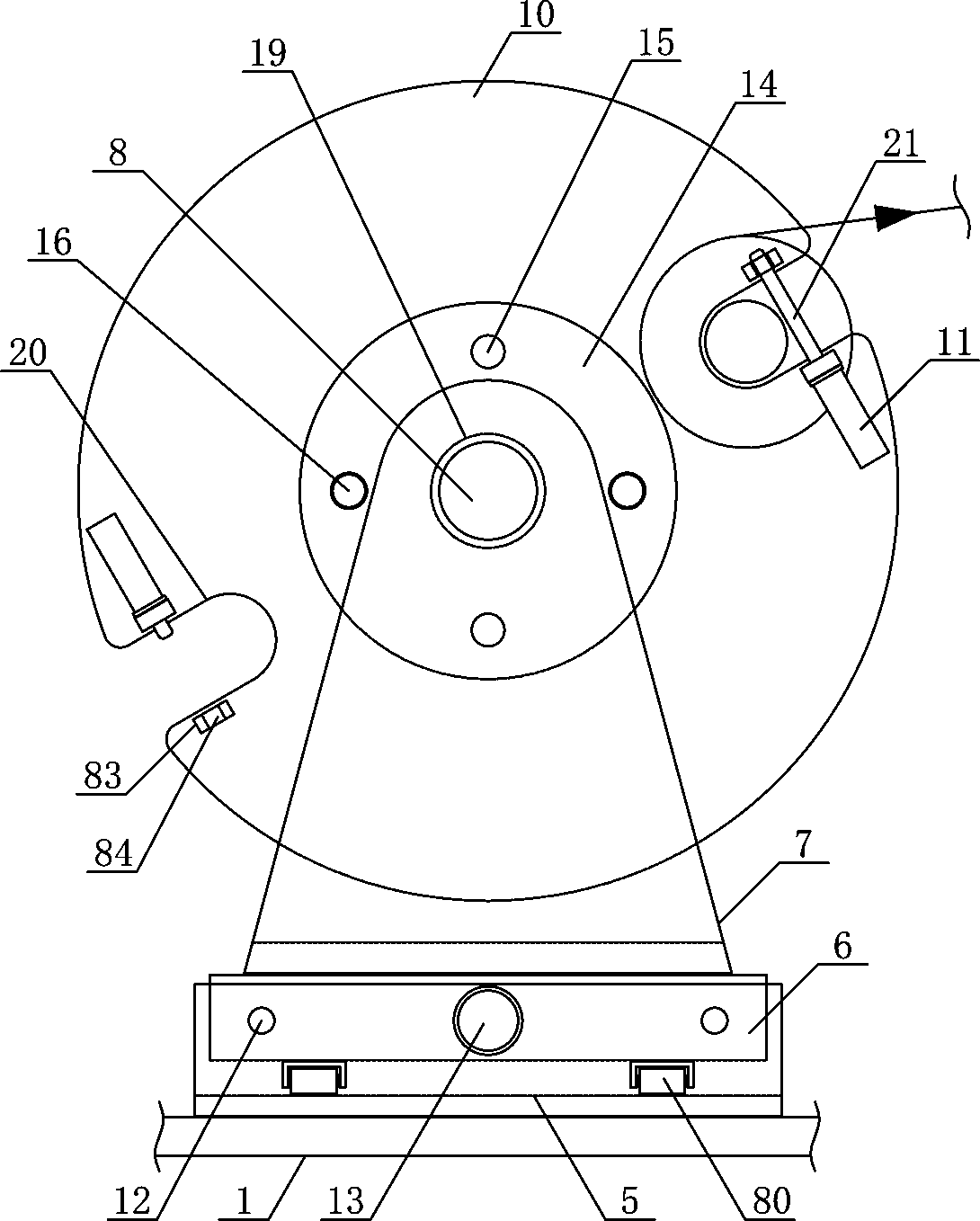

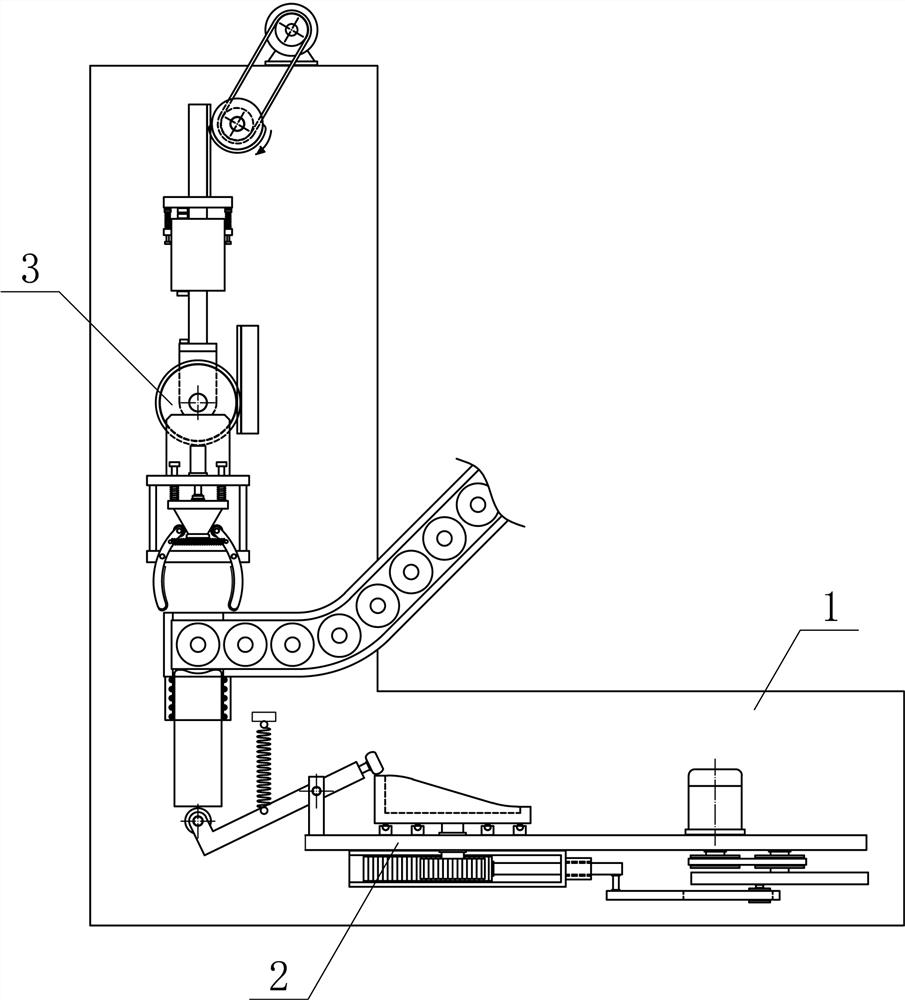

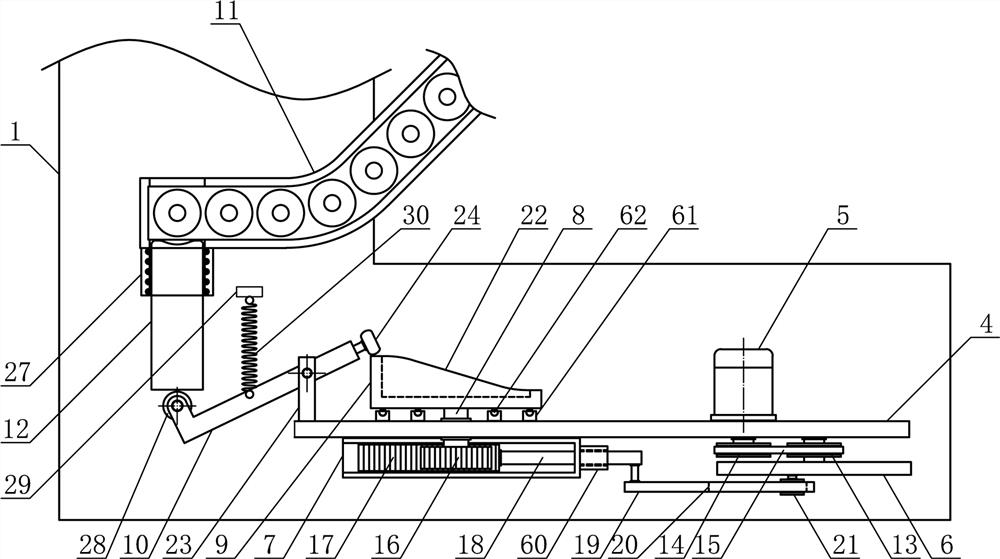

Automatic feeding mechanism for yarn winding drums

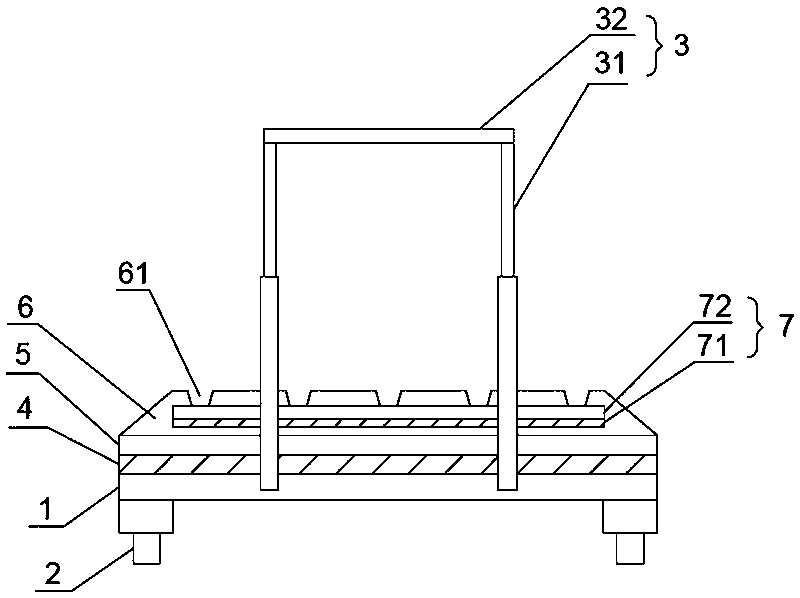

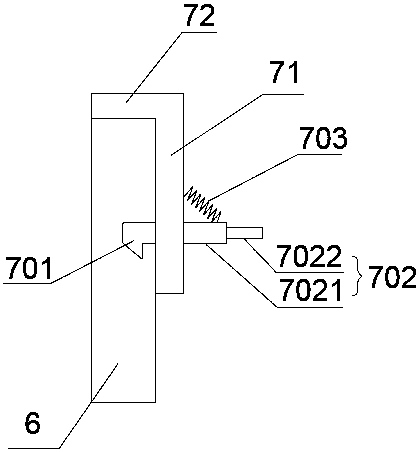

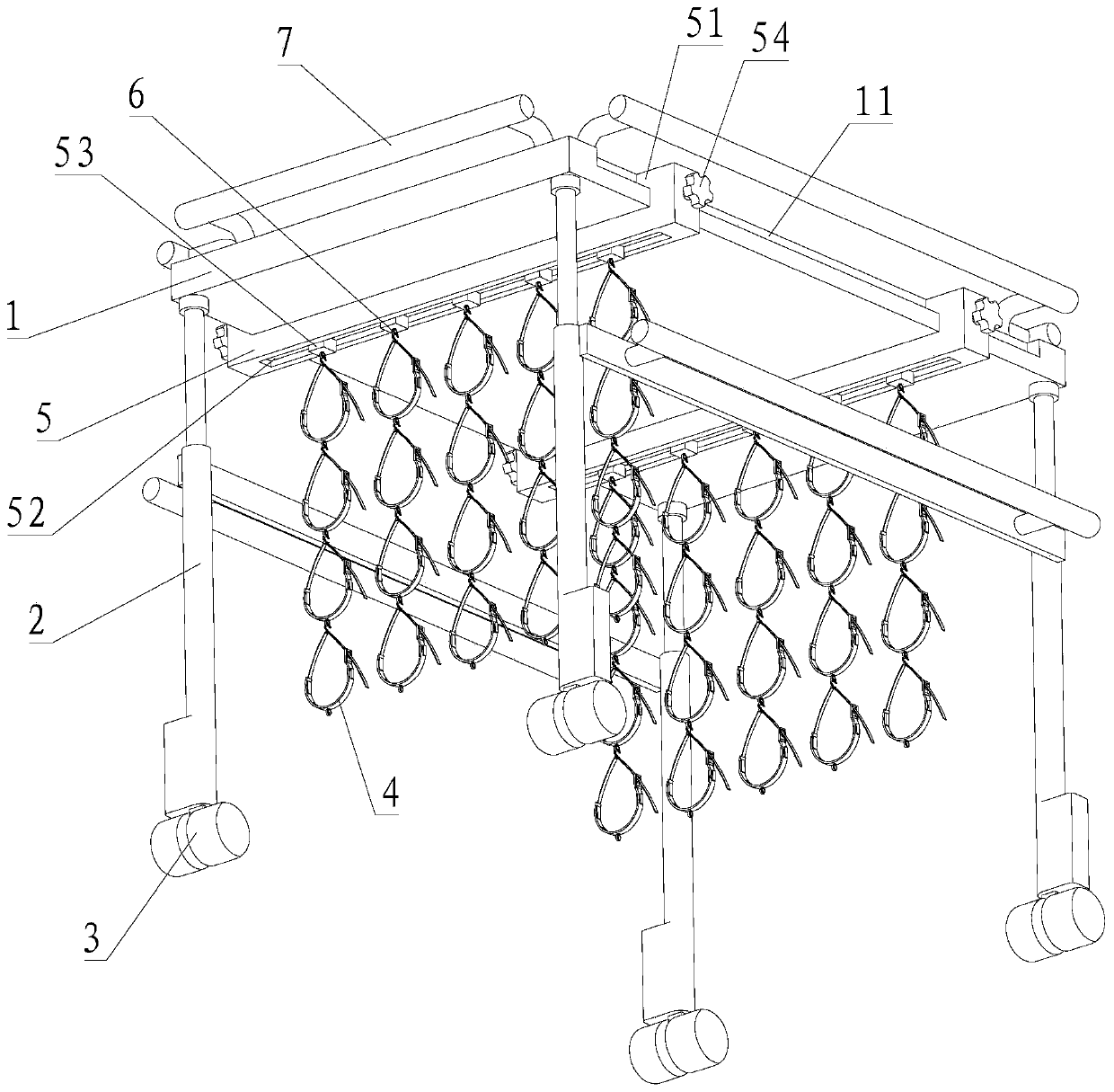

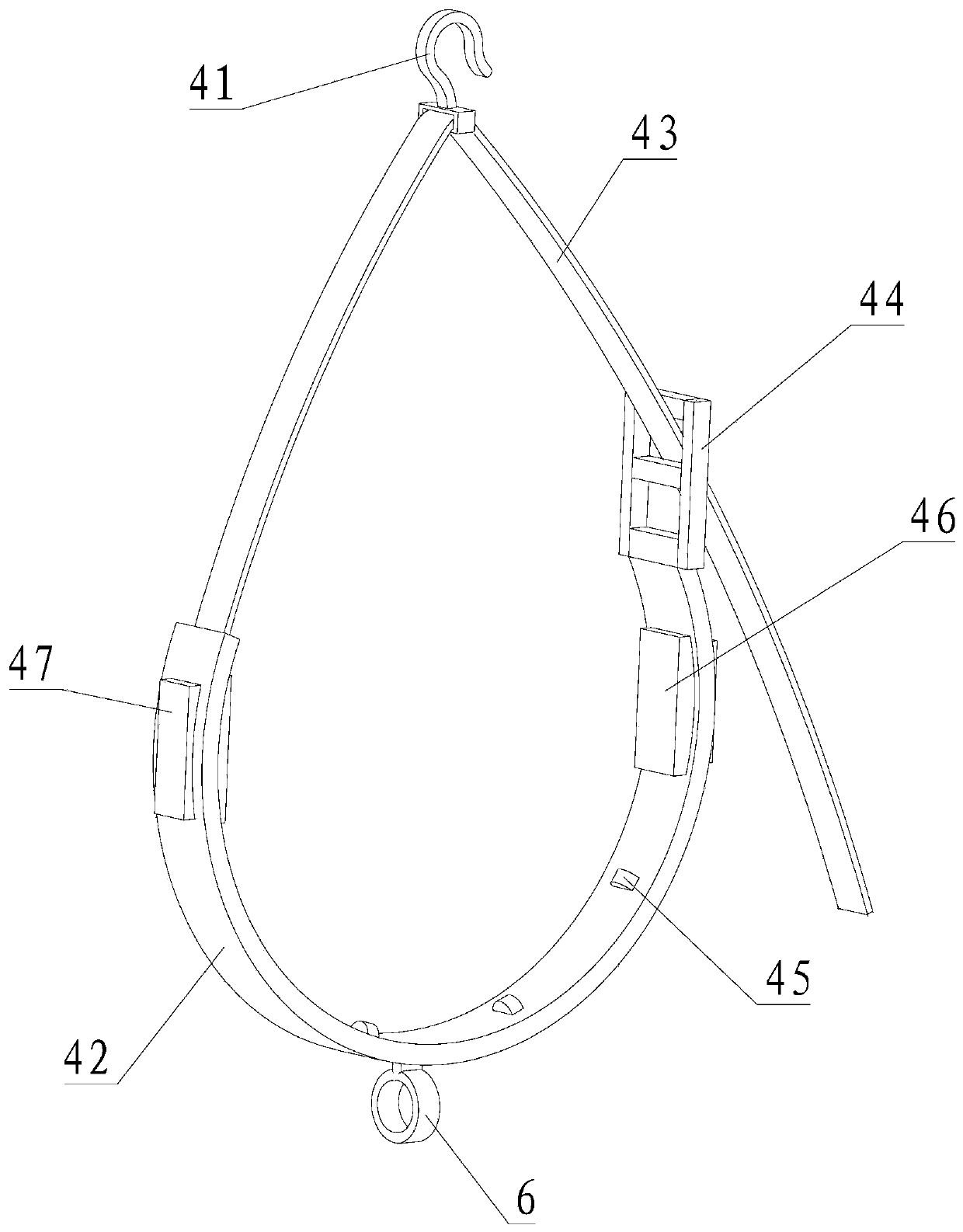

InactiveCN109292541AHigh degree of automationSmooth vertical flip loadingFilament handlingYarnEngineering

The invention discloses an automatic feeding mechanism for yarn winding drums, and belongs to the field of fabric production and processing machinery and equipment. A transfer mechanism and barrel moving mechanism of the automatic feeding mechanism are sequentially, vertically and fixedly arranged on the two sides of the upper portion of a feeding base in the horizontal direction. A barrel guidingmechanism and a barrel turning mechanism are sequentially, vertically and fixedly arranged on one side of a transfer bracket from top to bottom. A barrel guiding material pipe is vertically and fixedly arranged on one side of the transfer bracket. A barrel placing bracket is horizontally and fixedly arranged at the output end of a barrel bearing cylinder in the middle of the lower side of a reciprocating bracket. A rotating bracket is horizontally and fixedly arranged on the middle portion of a rotating sleeve of a barrel moving bracket. A barrel moving connecting plate is horizontally arranged at the lower side of a translation connecting plate, and a barrel bearing clamping plate is horizontally and fixedly arranged at the output end of a clamping plate cylinder. The automatic feeding mechanism is reasonable in structural design, can smoothly transfer and feed the yarn winding drums one by one and smoothly transfer and place the yarn winding drums to required positions, improves theautomation degree of feeding the yarn winding drums, and meets the requirements of production and use.

Owner:桐乡市富利来针织股份有限公司

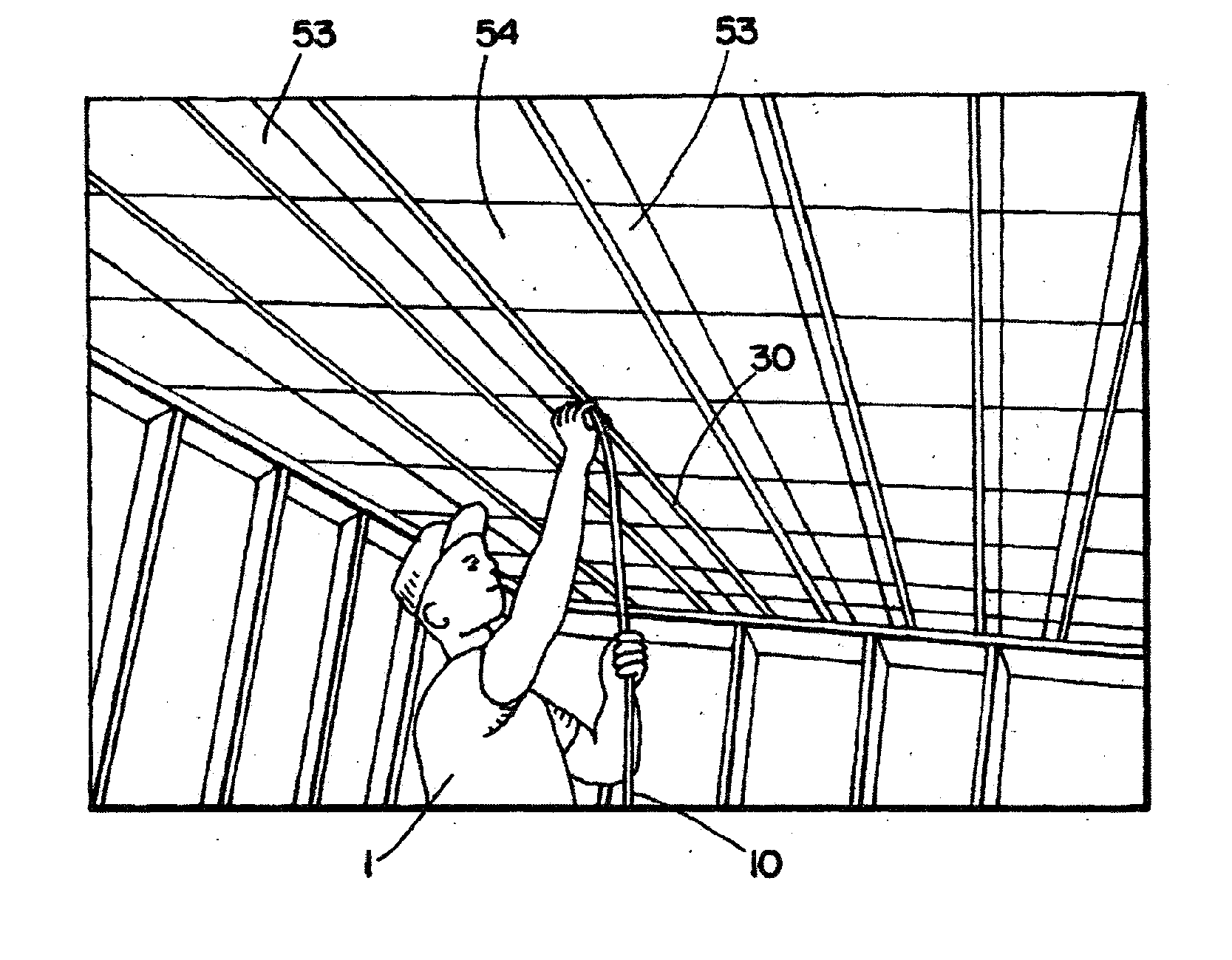

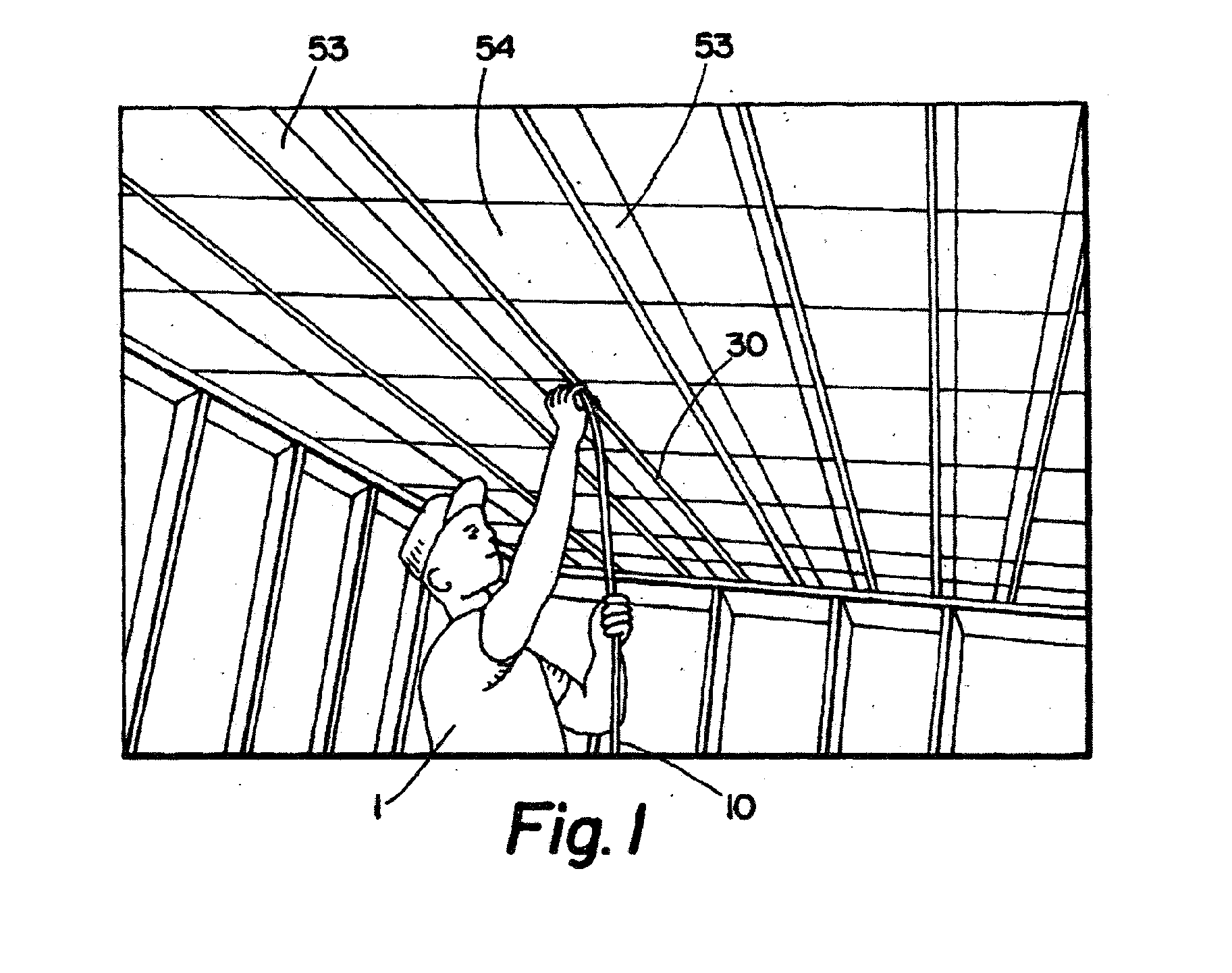

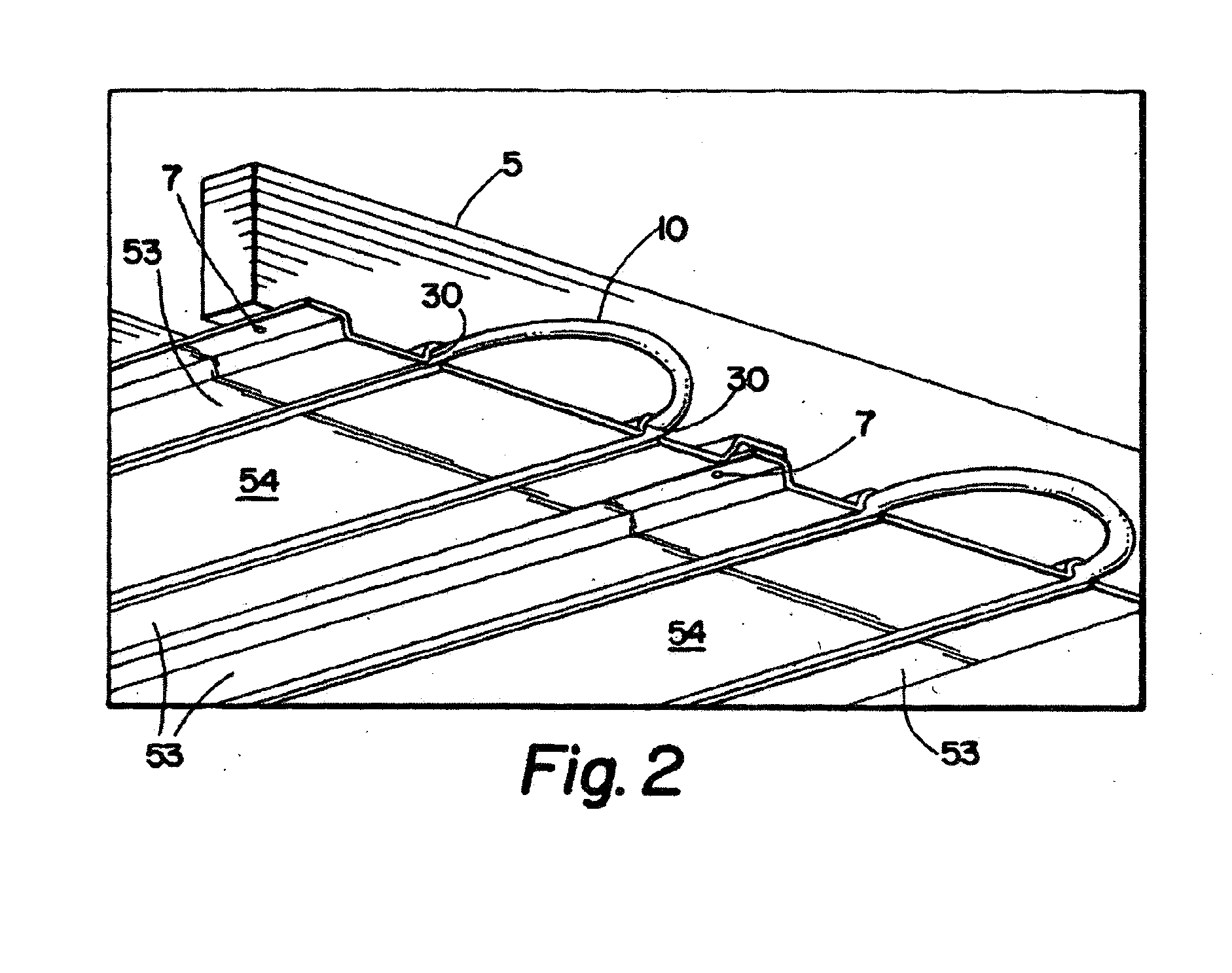

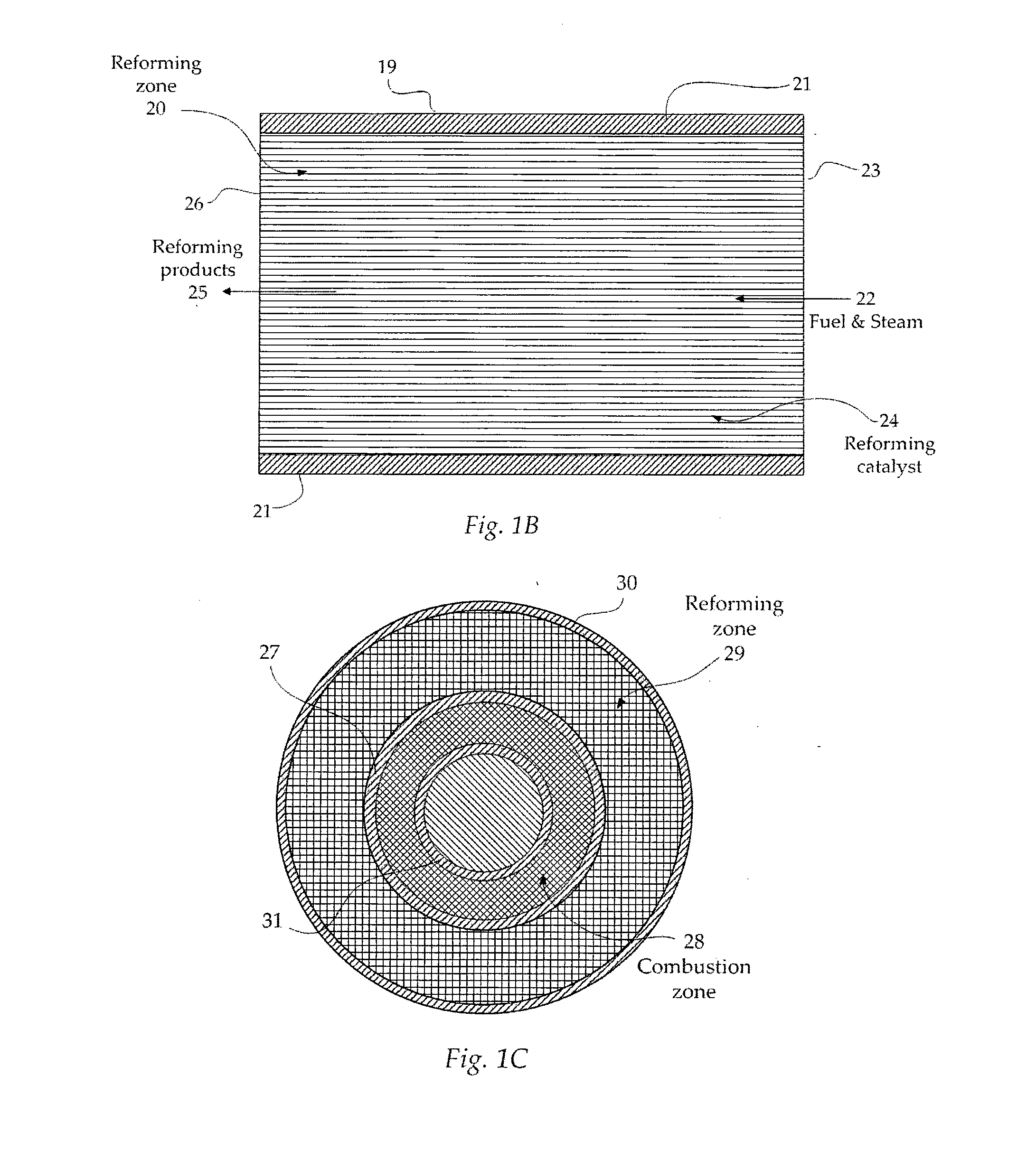

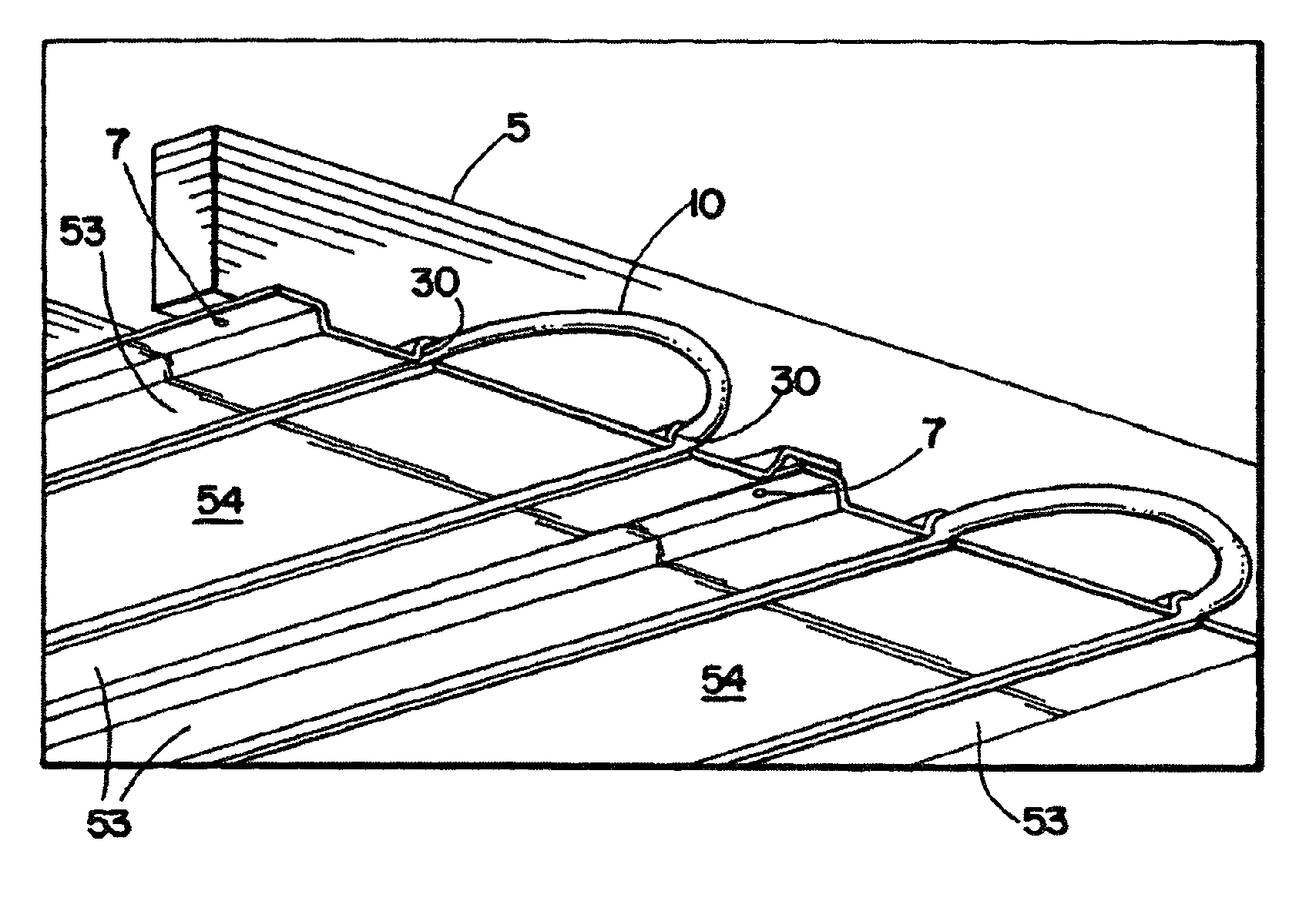

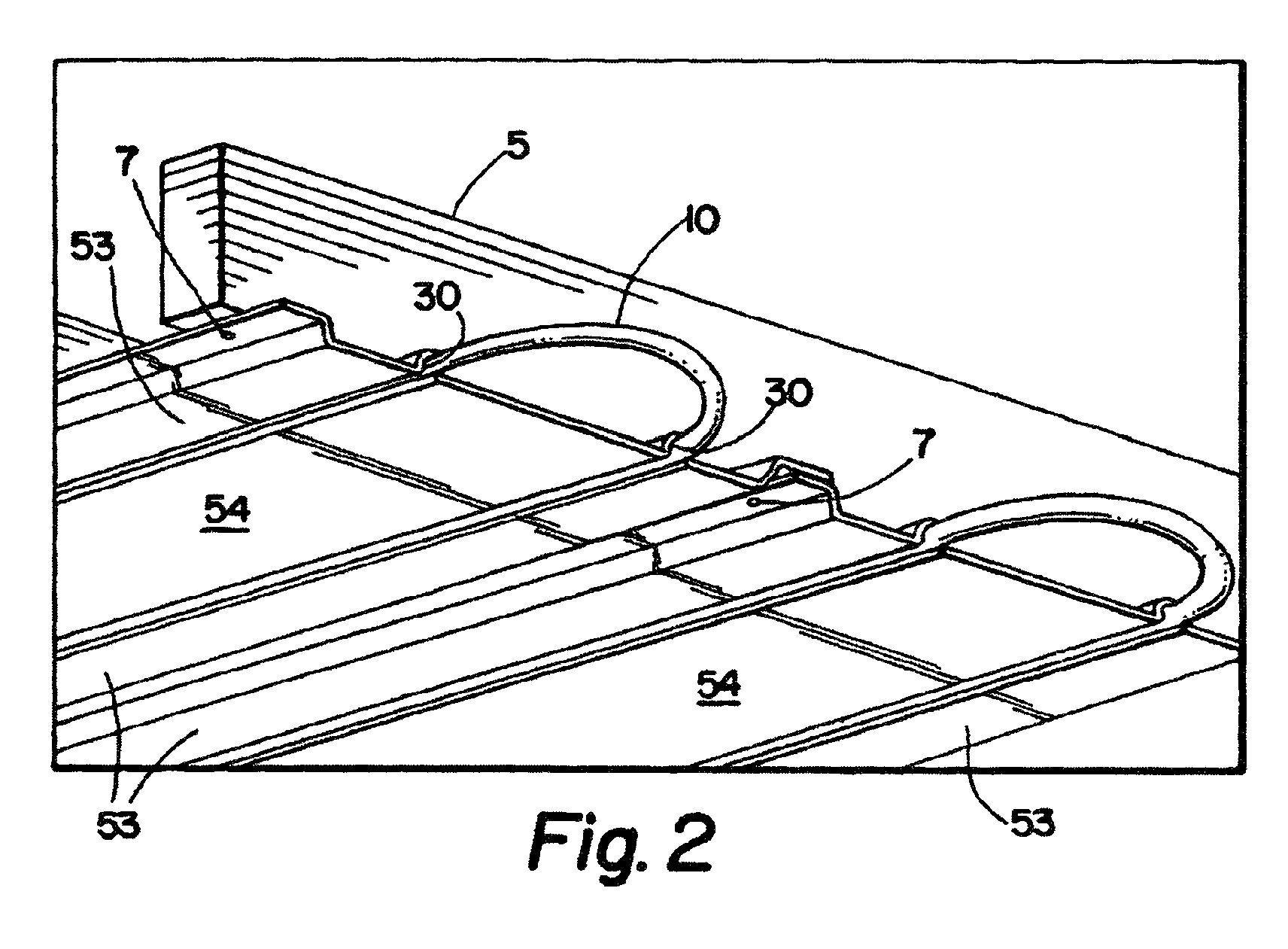

Radiant heating and cooling panel

InactiveUS20080264602A1Convenient and efficient transferImprove sound insulationCombustible gas coke oven heatingHot-air central heatingEmissivityJoist

A radiant panel for use in radiant heating and cooling systems that provides numerous benefits over conventional panels currently in use. The radiant panel comprises an offset hydronic radiant tube channel in which is nested a hydronic radiant tube that obviates the need to thread the hydronic tubes through the joists in a ceiling installation or the studs in a wall installation. In an alternative embodiment, specific emissivity coatings on each side of the radiant panel further promote the efficient transfer of heat. The system provides increased sound isolation and is robust enough to withstand the crushing forces associated with a floor installation.

Owner:TALBOTT SOLAR & RADIANT HOMES

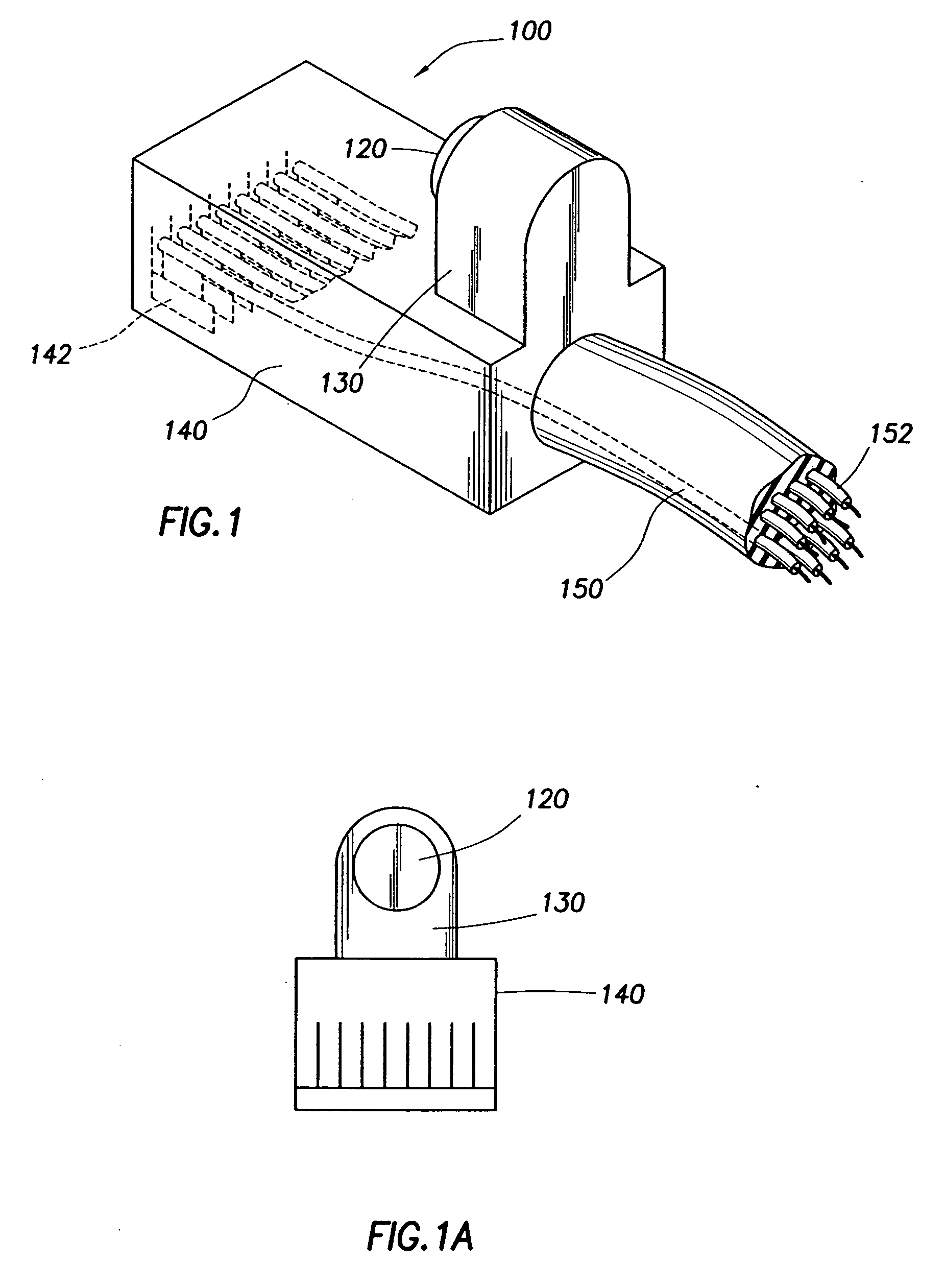

Method for transmitting data using a releasable connector

InactiveUS20060035480A1Reduce usageEasy to useEngagement/disengagement of coupling partsTwo-part coupling devicesInformation processingCoupling

A method and system for releasing a reusable breakaway media connection is disclosed. The connector includes a coupling element that may be released via an automated process. The connector may be used to efficiently convey data to and from an information handling system.

Owner:DELL PROD LP

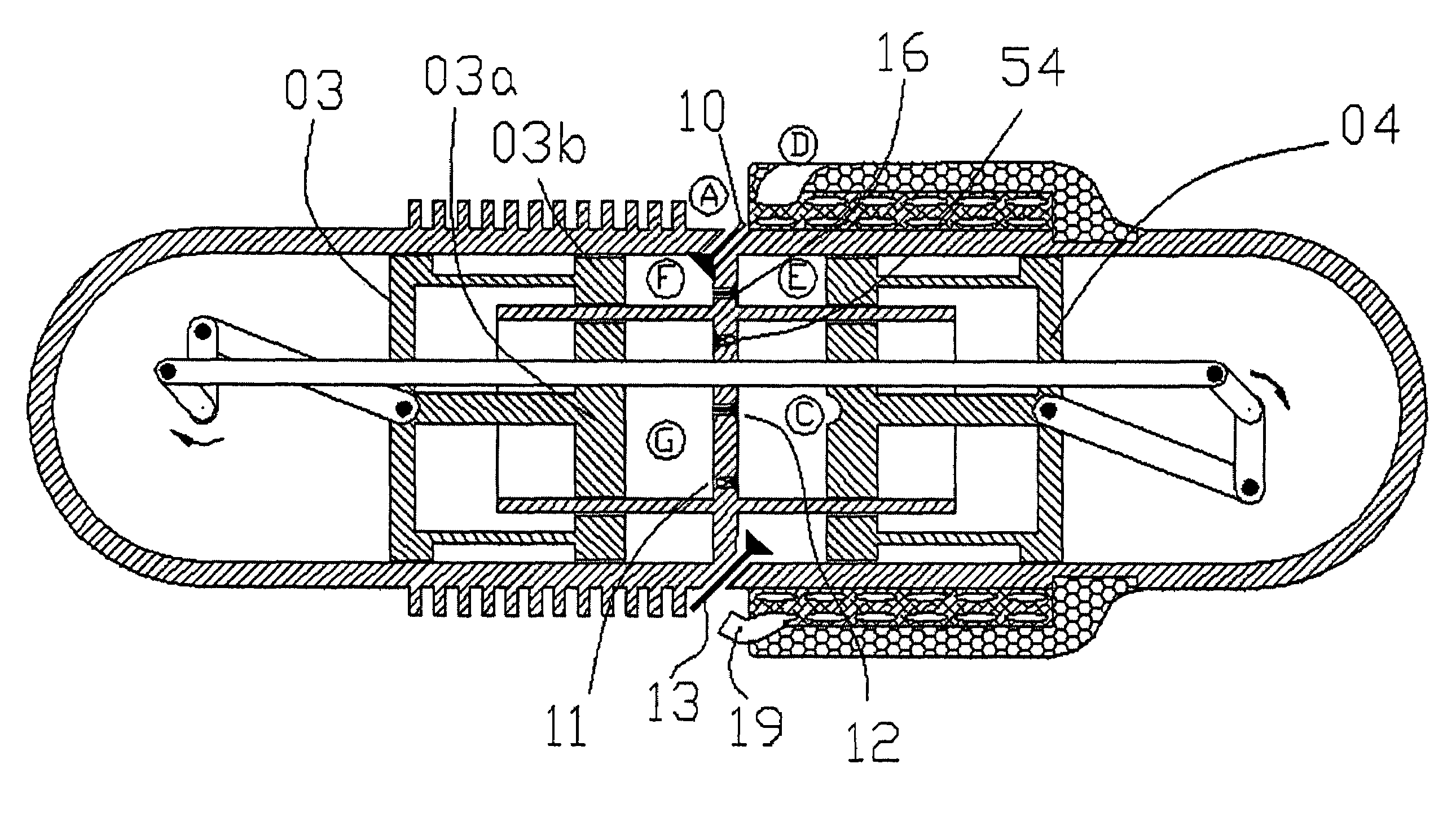

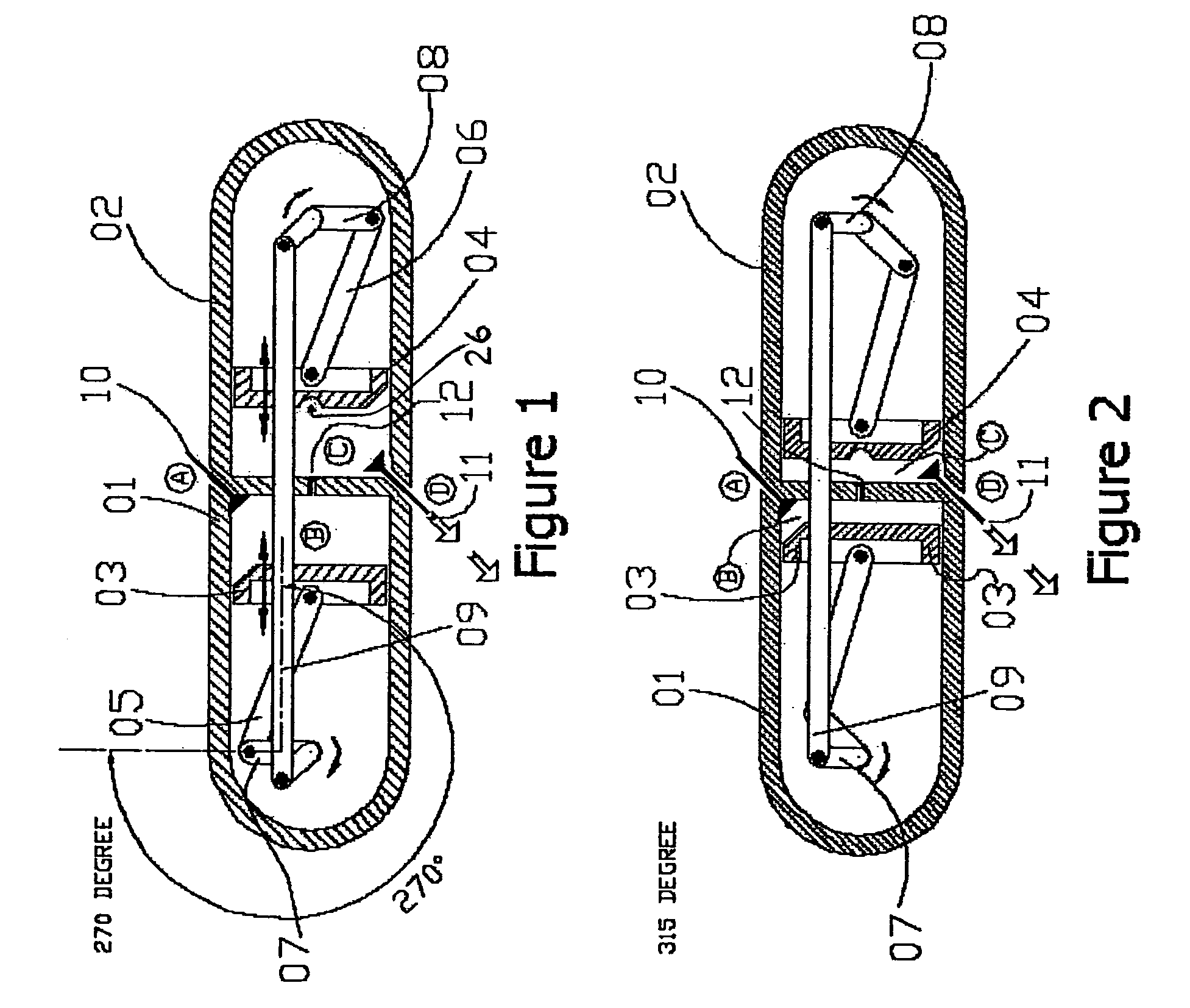

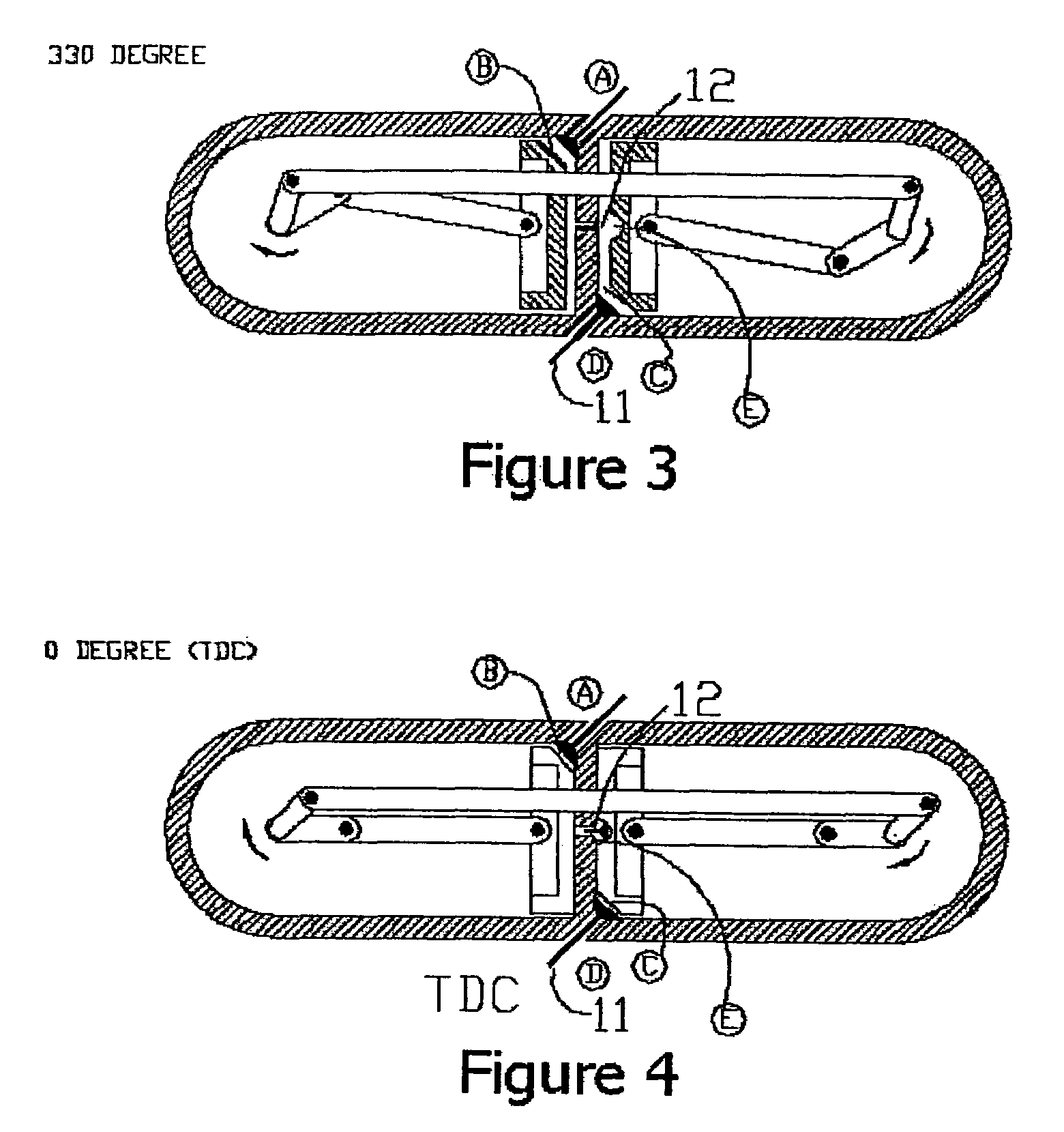

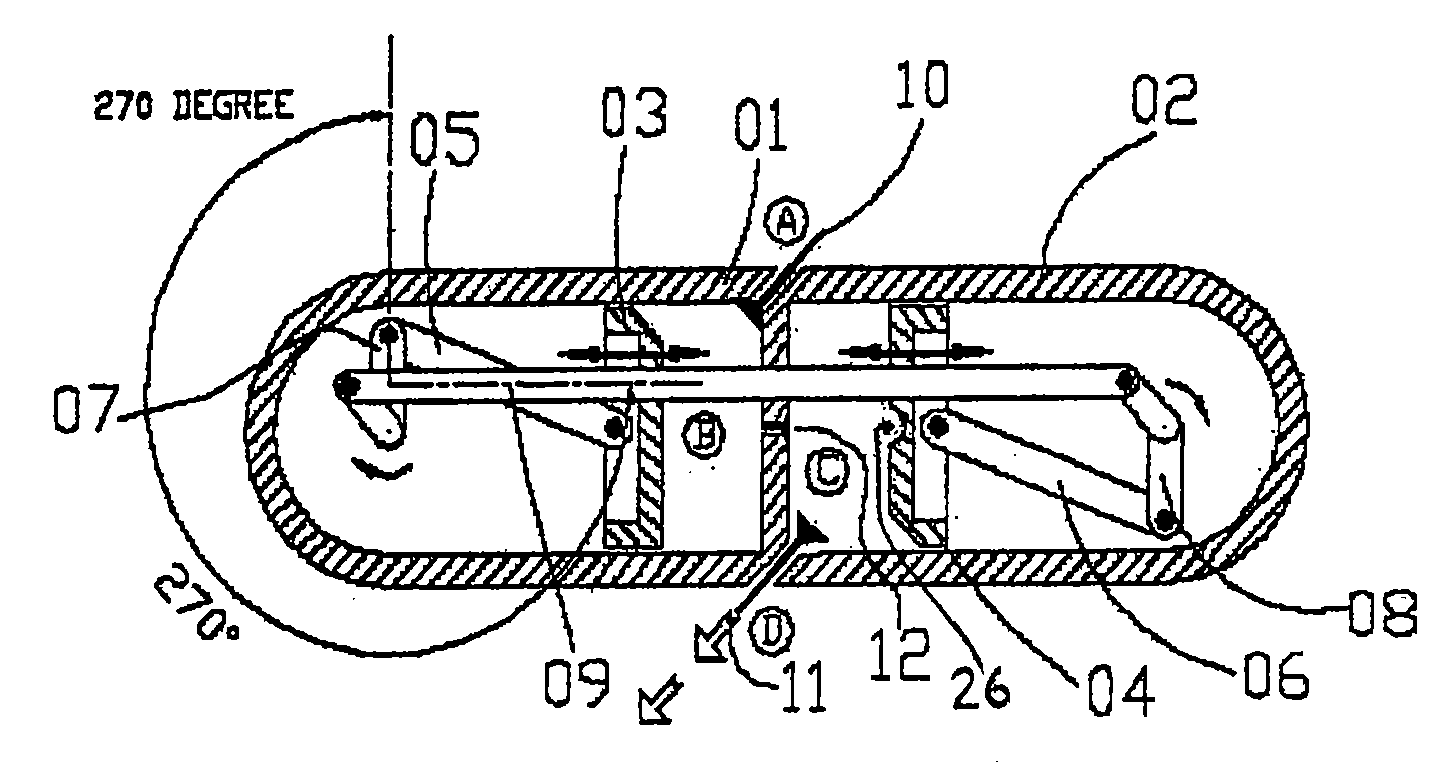

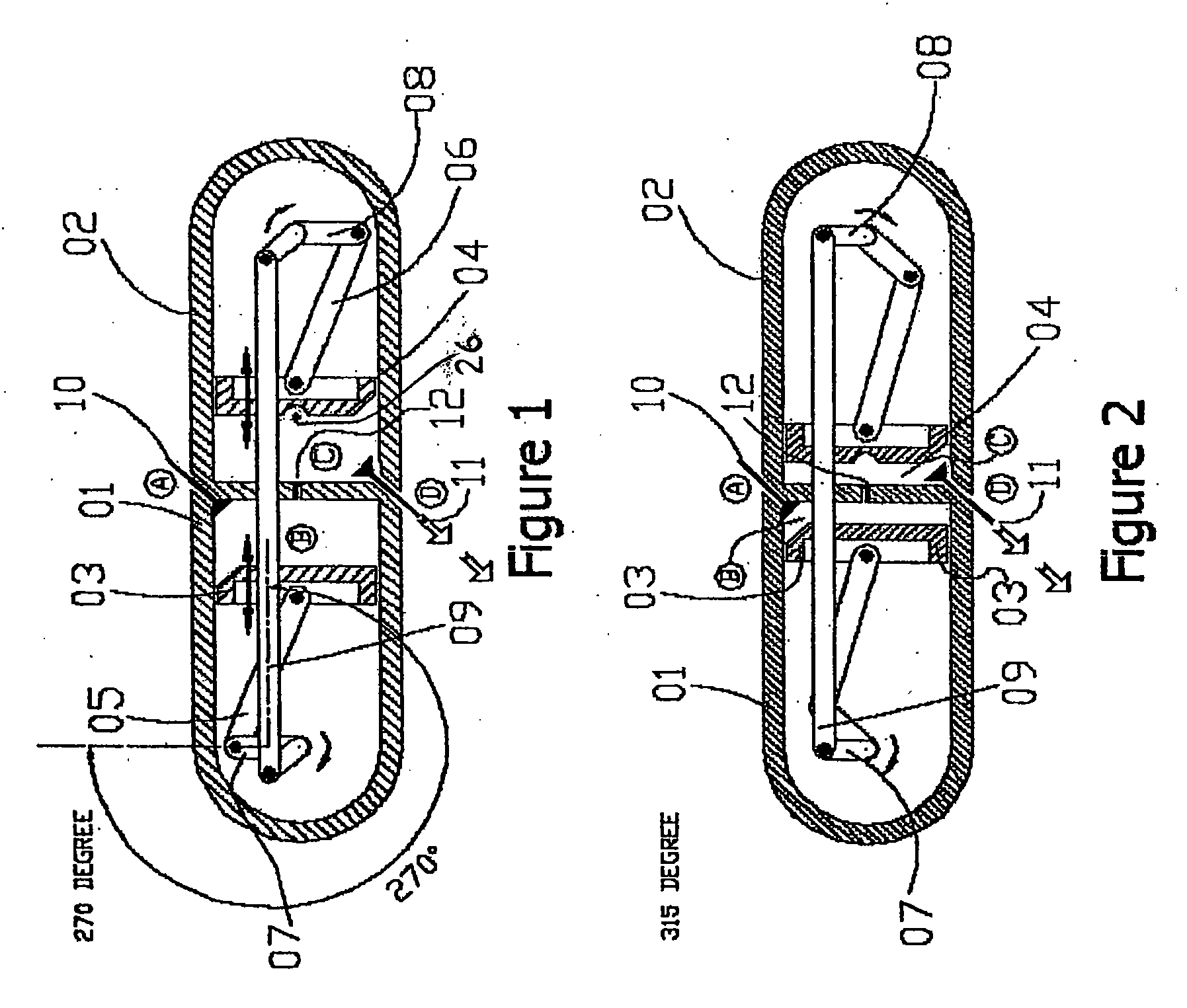

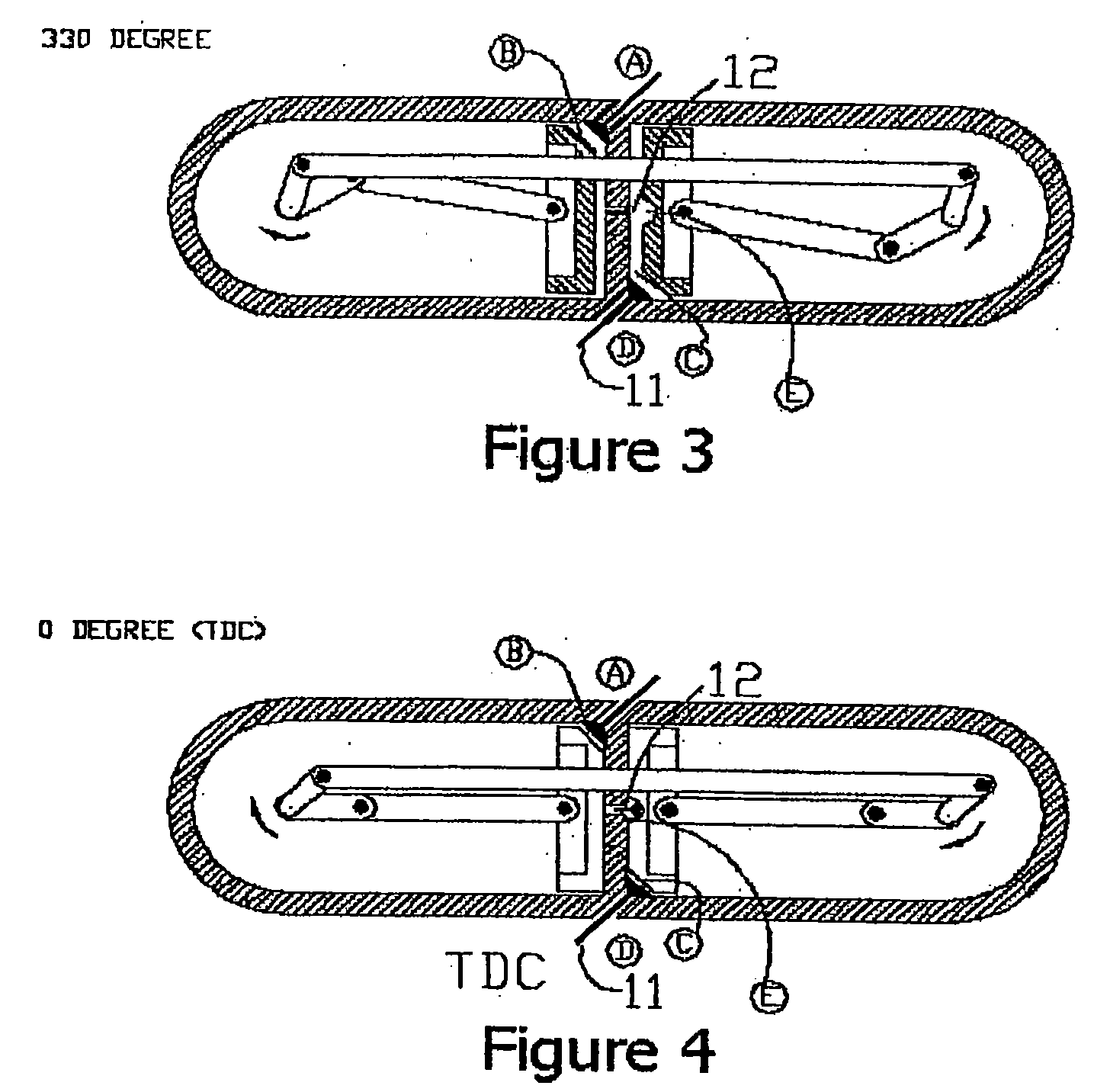

Steam enhanced double piston cycle engine

ActiveUS7273023B2Improve engine efficiencyReduce the temperatureInternal combustion piston enginesGas pressure propulsion mountingEngineeringPiston

A steam enhanced dual piston cycle engine utilizes a unique dual piston apparatus that includes: a first cylinder housing a first piston therein, wherein the first piston performs only intake and compression strokes; a second cylinder housing an inner power piston that forms an inner internal chamber of the second cylinder, and either a ring-shaped outer power piston surrounding the inner power piston, wherein the outer power piston forms an outer internal chamber of the second cylinder and is configured to convert engine heat into additional work, and / or an outer boiler which is configured to produce steam to be converted into additional work.

Owner:TOUR ENGINE INC

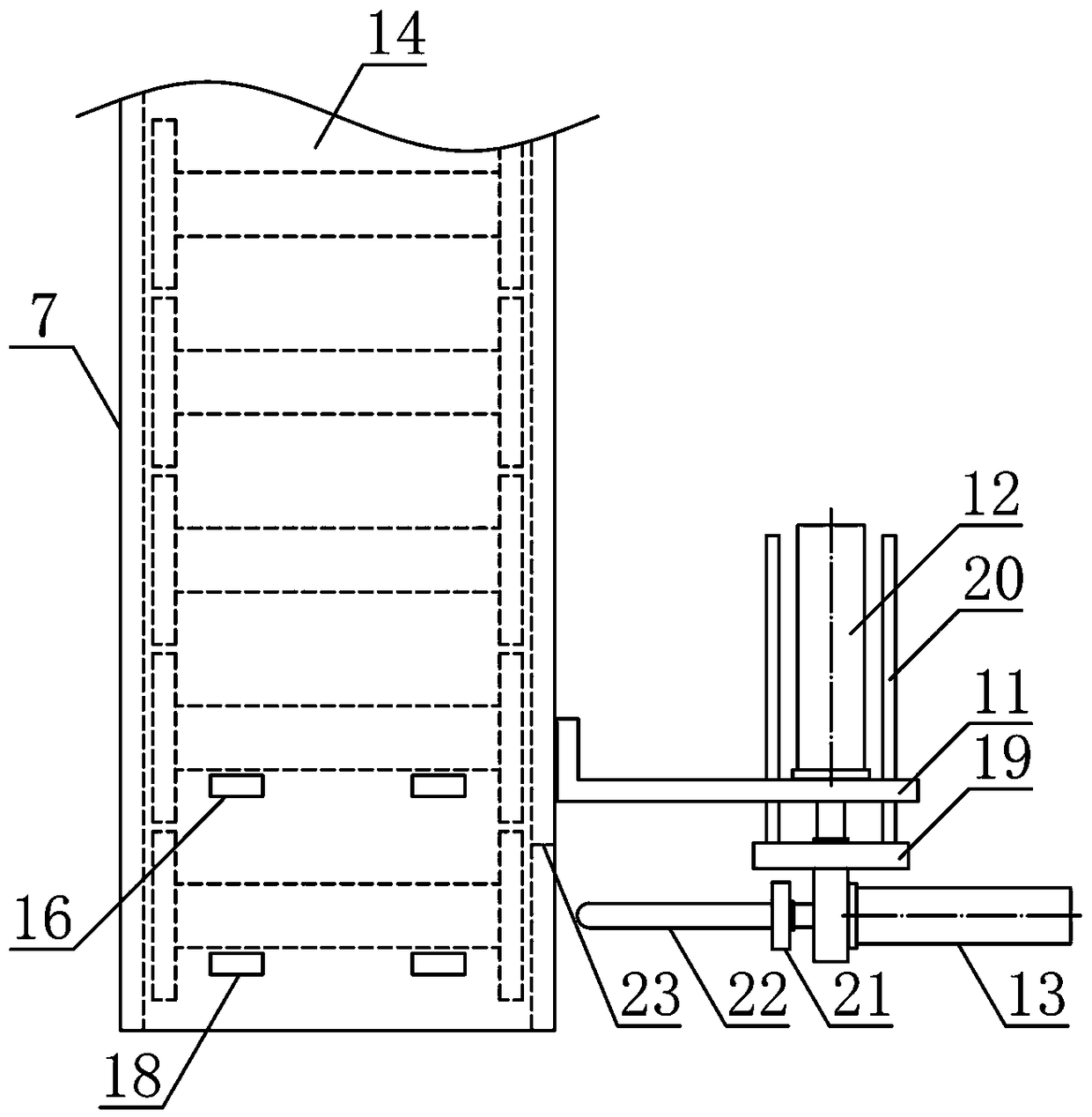

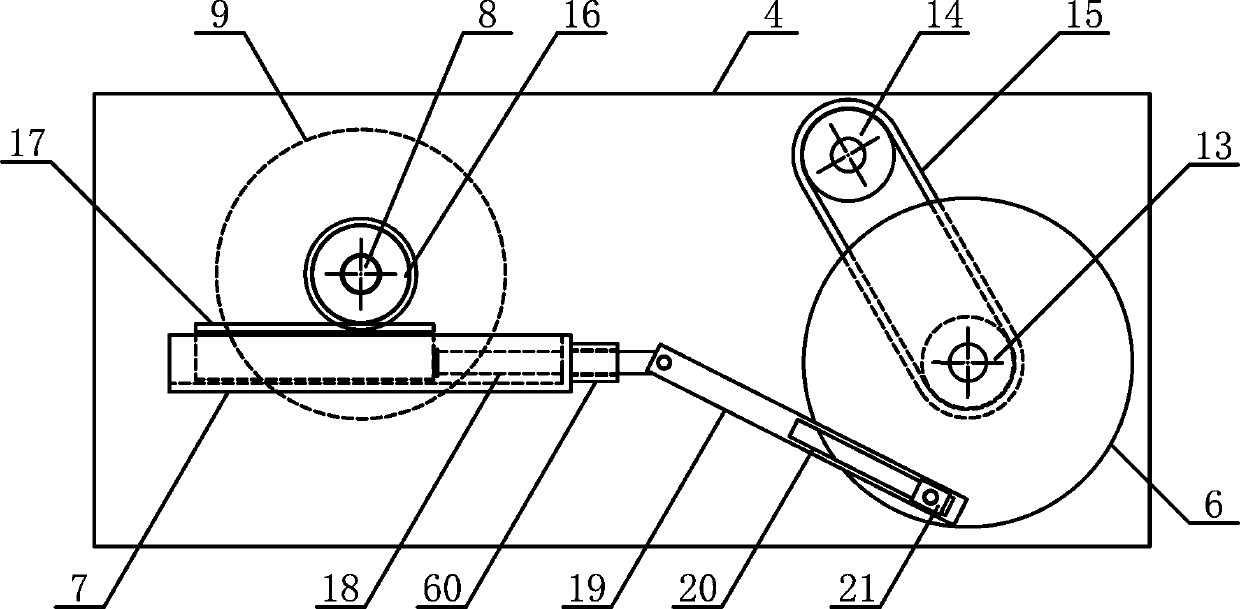

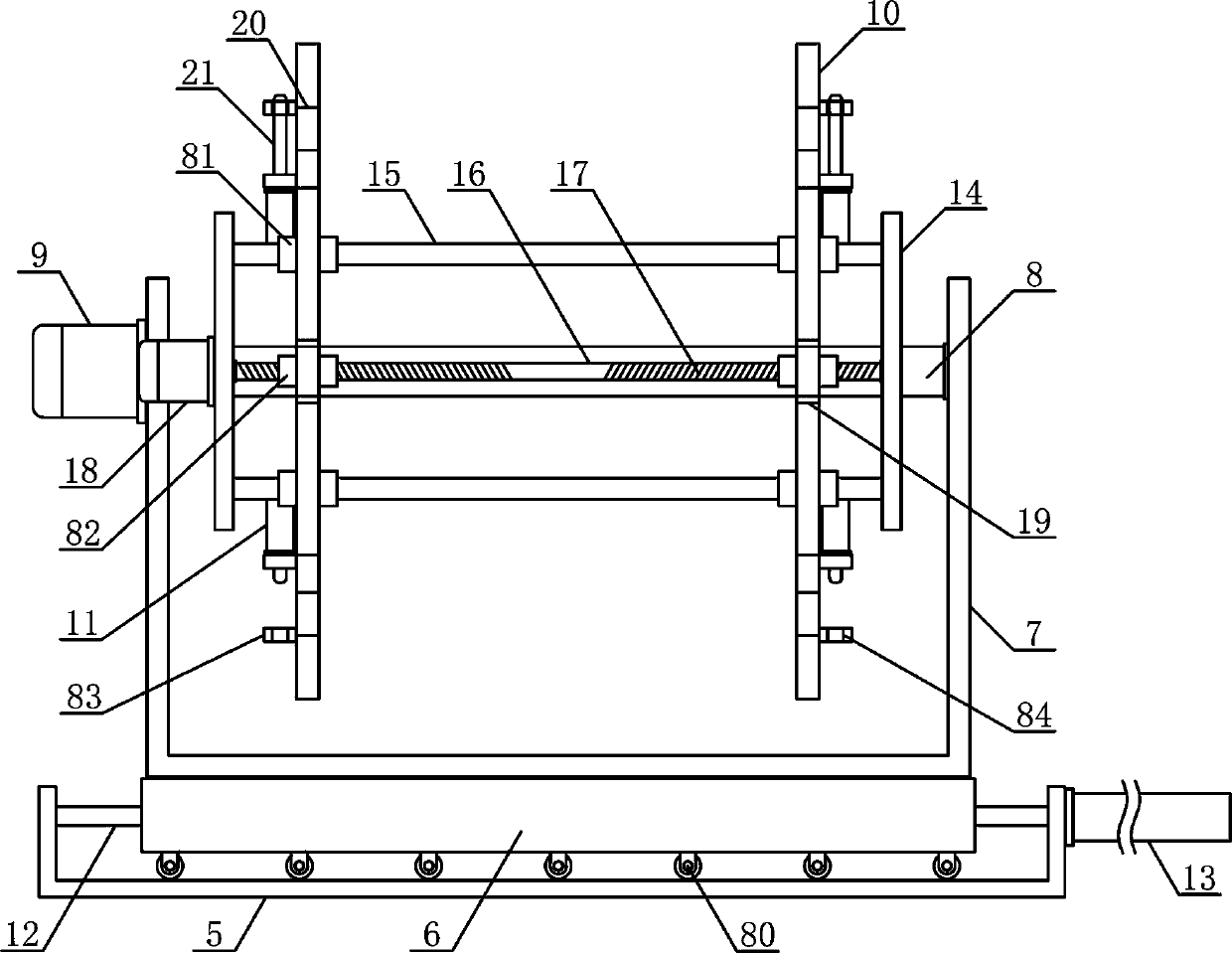

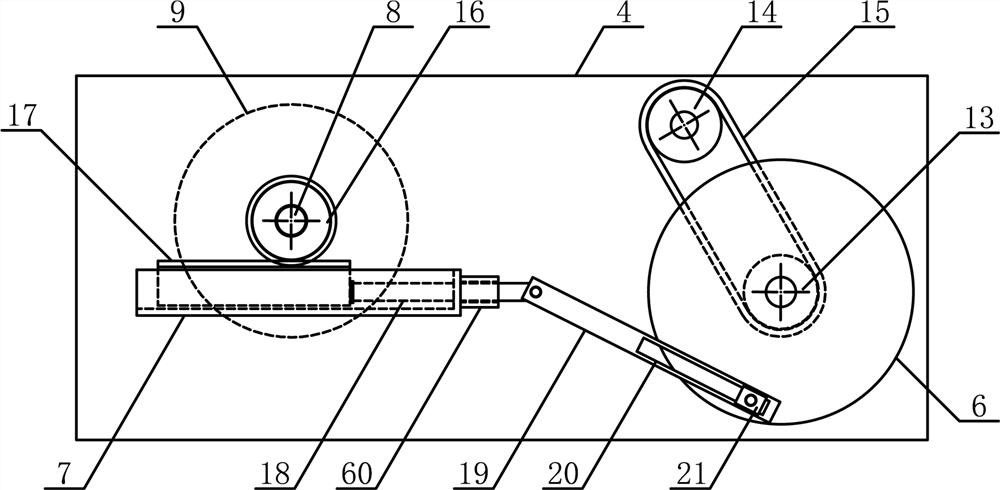

Chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing

ActiveCN111039094AHigh degree of automationSmooth and accurate reciprocating translational movementFilament handlingFiberGear wheel

The invention discloses a chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing and belongs to the field of textile processing mechanical equipment. Accordingto the chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing of the invention, a bobbin feeding mechanism is horizontally and fixedly arranged at the lower side of a bobbin guiding support; a bobbin transferring mechanism above one side of the bobbin feeding mechanism is vertically arranged on the bobbin guiding support; a push rod rotating slope is arranged on the upper side of a reciprocating rotating cam; the middle of a reciprocating rotating rod is hinged to the upper side of a rotating rod supporting seat; a bobbin guiding and feeding pipe locatedabove the reciprocating rotating rod is fixedly arranged on the bobbin guiding support; a lifting transferring guide plate is slidably arranged on a lifting fixing sleeve in a vertical direction; a gear rotating support at the lower end of the lifting transferring guide plate is vertically and rotationally connected with a lifting rotating gear; and a bobbin clamping mechanism is fixedly arrangedon one side of the lifting rotating gear in the radial direction of the lifting rotating gear. The chemical fiber bobbin continuous transferring and feeding device is reasonable in structural design,can efficiently, stably and sequentially feed and machine chemical fiber bobbins one by one, is high in automation degree, and meets processing and using requirements.

Owner:桐乡市富昌化纤股份有限公司

Novel cleaning method

ActiveUS20140137340A1Improve propertiesConvenient and efficient transferDetergent mixture composition preparationOther washing machinesFiberOrganic solvent

The invention provides a method and formulation for cleaning a soiled substrate, the method comprising the treatment of the moistened substrate with a formulation comprising a multiplicity of polymeric particles, wherein the formulation is free of organic solvents. Preferably, the substrate is wetted so as to achieve a substrate to water ratio of between 1:0.1 to 1:5 w / w. Optionally, the formulation additionally comprises at least one cleaning material and, in this embodiment, it is preferred that the polymeric particles are coated with the at least one cleaning material. Preferably, the cleaning material comprises a surfactant, which most preferably has detergent properties. Most preferably, the substrate comprises a textile fibre. Typically, the polymeric particles comprise particles of nylon, most preferably in the form of nylon chips. The results obtained are very much in line with those observed when carrying out conventional dry cleaning processes and the method provides the significant advantage that the use of solvents, with all the attendant drawbacks in terms of cost and environmental considerations, can be avoided.

Owner:XEROS LTD

Method and apparatus for cooling a portable computer

InactiveUS20050280988A1Improve cooling effectIncrease air circulationDigital data processing detailsSemiconductor/solid-state device detailsEngineeringFluid supply

Owner:PC COMA LLC

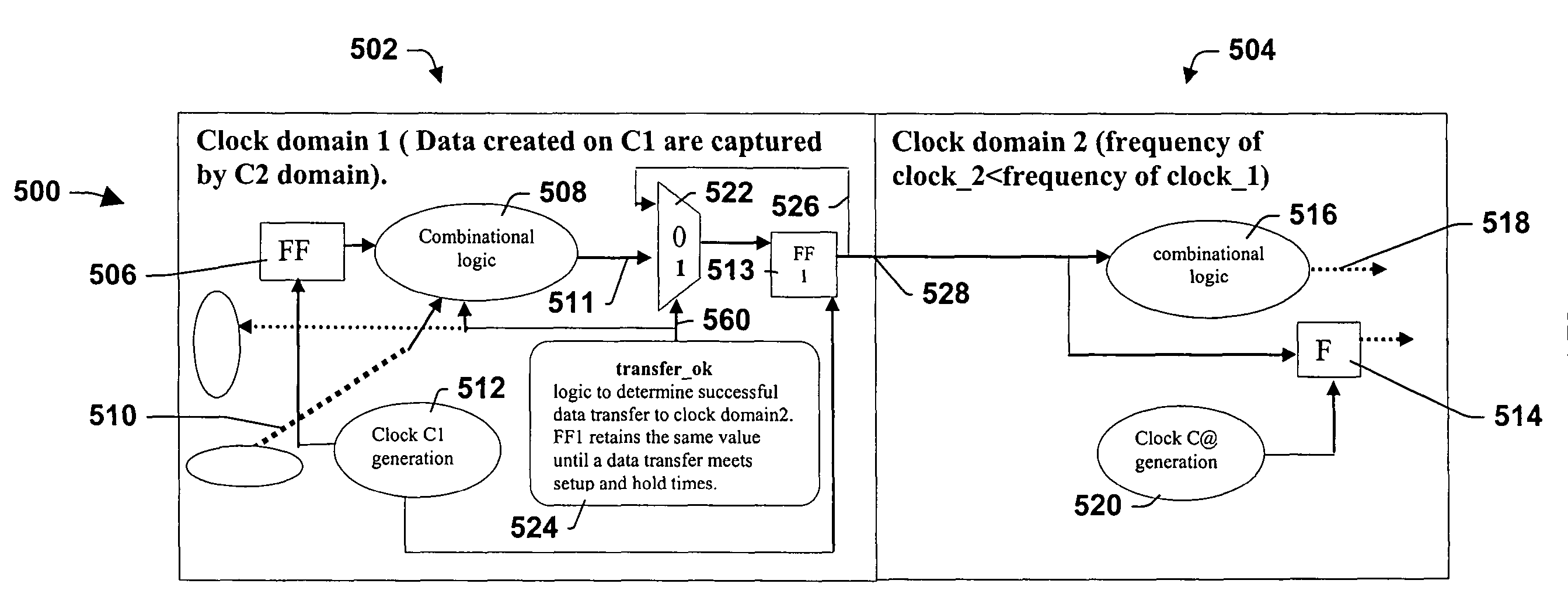

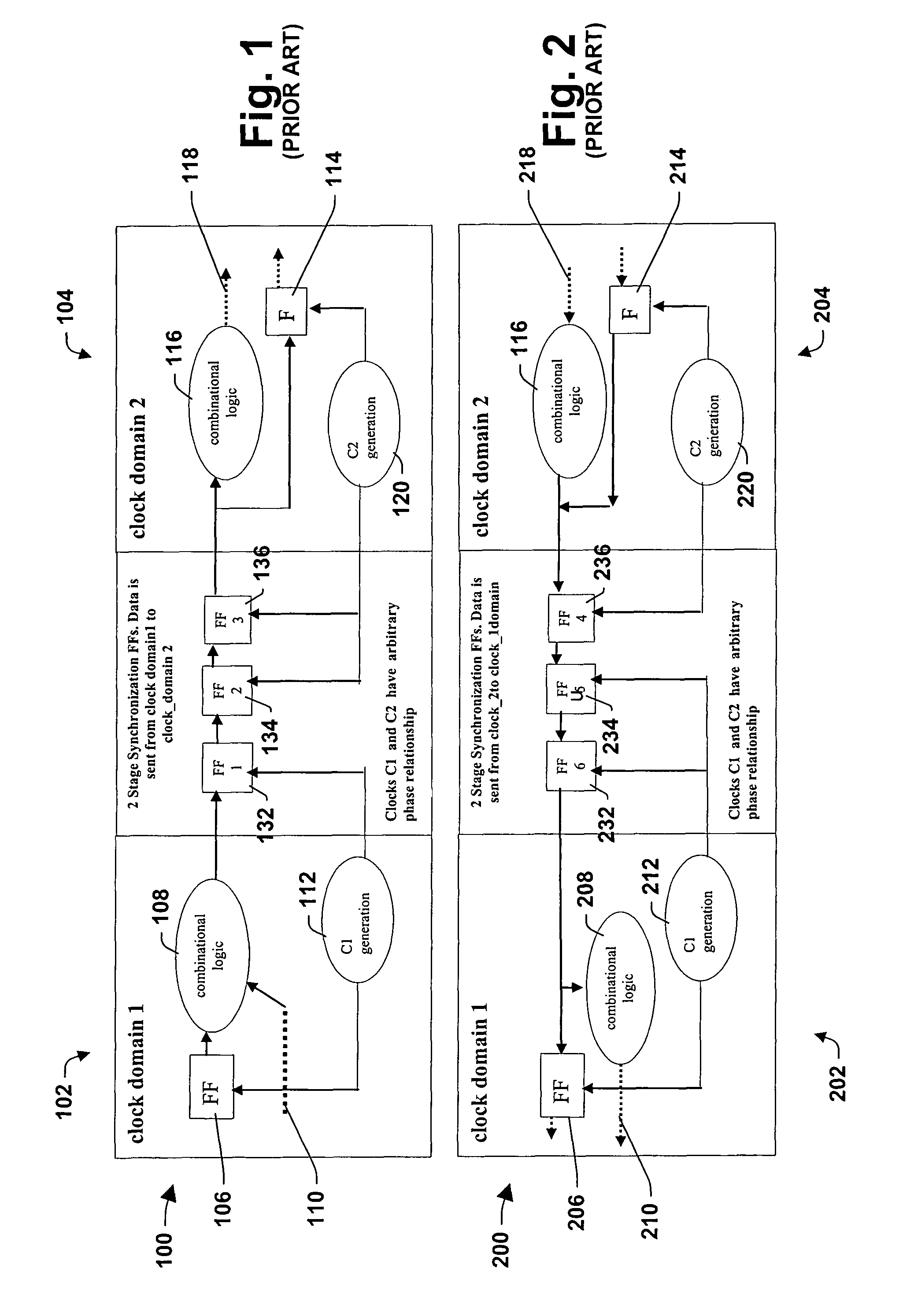

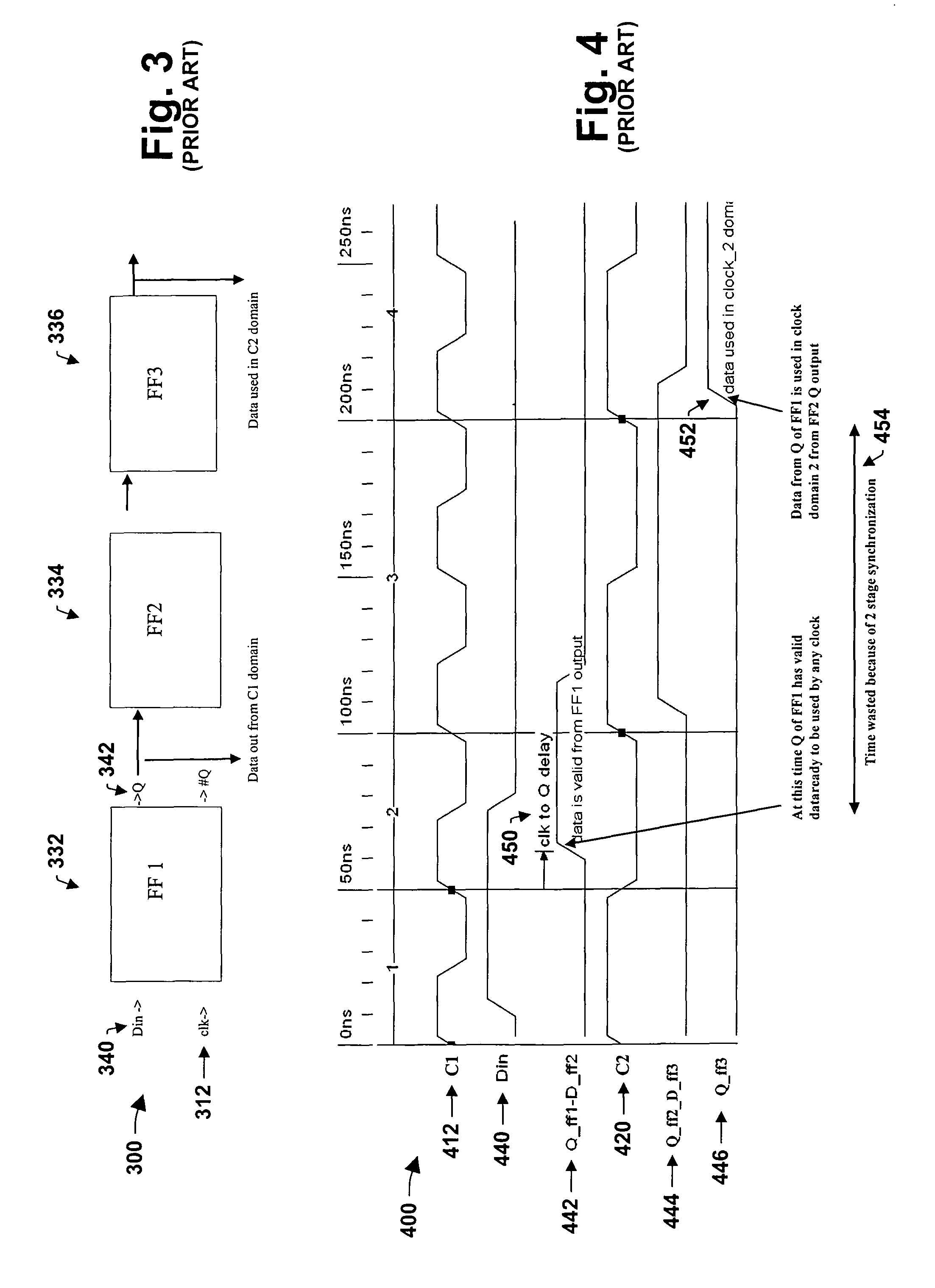

Digital data transfer between different clock domains

ActiveUS7813459B2Convenient and efficient transferReduce delaysSynchronisation information channelsDigital dataComputer science

One or more aspects of the present invention pertain to transferring digital data between first and second domains, where a first clock of the first domain operates at a first frequency and a second clock of the second domain operates at a second frequency, where the first frequency is higher than the second frequency, and where the first and second clocks have arbitrary phase relationships relative to one another. Techniques employed facilitate efficient digital data transfer between the first and second domains while conserving valuable semiconductor real estate.

Owner:CYPRESS SEMICON CORP

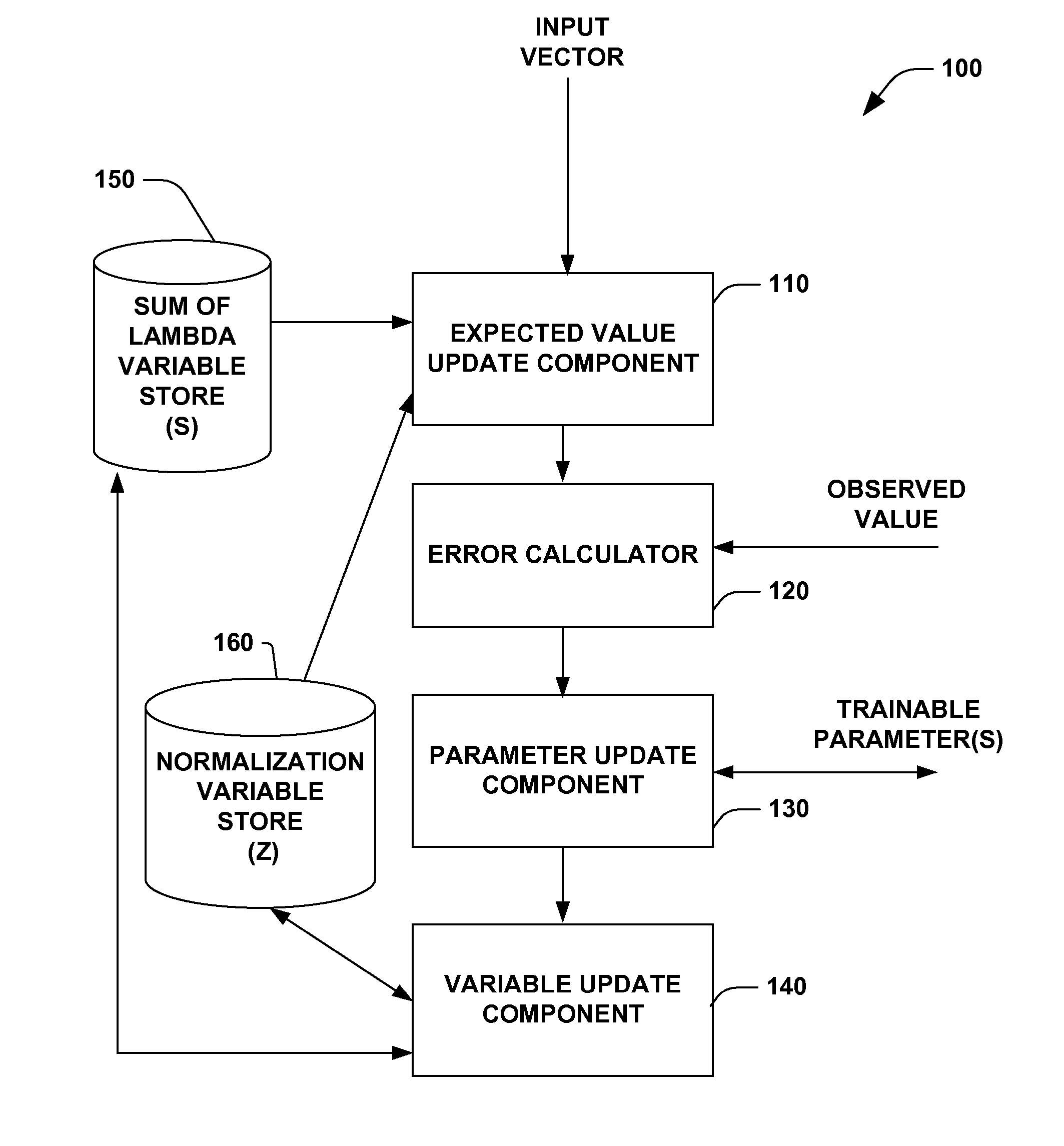

Sequential conditional generalized iterative scaling

InactiveUS20070022069A1Raise the possibilityIncrease speedDigital computer detailsSpeech recognitionGeneralized iterative scalingCalculation error

A system and method facilitating training machine learning systems utilizing sequential conditional generalized iterative scaling is provided. The invention includes an expected value update component that modifies an expected value based, at least in part, upon a feature function of an input vector and an output value, a sum of lambda variable and a normalization variable. The invention further includes an error calculator that calculates an error based, at least in part, upon the expected value and an observed value. The invention also includes a parameter update component that modifies a trainable parameter based, at least in part, upon the error. A variable update component that updates at least one of the sum of lambda variable and the normalization variable based, at least in part, upon the error is also provided.

Owner:MICROSOFT TECH LICENSING LLC

Thin film coil-changing conveying device

ActiveCN110937441AConvenient and efficient transferRealize automatic roll change transmissionWebs handlingThin membraneMechanical equipment

The invention discloses a thin film coil-changing conveying device, and belongs to the field of thin film conveying mechanical equipment. According to the thin film coil-changing conveying device, a film coil feeding mechanism, a thin film unwinding mechanism and a thin film bonding mechanism are sequentially and fixedly arranged on the upper side of a thin film conveying base in the horizontal direction, unwinding clamp grooves are correspondingly formed in the two sides of a coil bearing circular plate above an unwinding fixed support, a rotary adjusting air cylinder is arranged between a rotary adjusting support and the thin film conveying base in an inclined upward mode, an unwinding feed support is arranged on the upper side of the rotary adjusting support, the thin film bonding mechanism comprises a thin film bonding support, a film pressing mechanism, a glue feeding mechanism and a film pulling and pressing mechanism, and a thin film bonding and bearing plate is horizontally andfixedly arranged between a film inlet guiding roller and a film outlet guiding roller of the thin film bonding support. According to the thin film coil-changing conveying device, the structural design is reasonable, automatic coil-changing can be conducted on thin films, the ends of two coils of the thin films which are sequentially conveyed can be quickly and efficiently bonded, the stable and smooth continuous conveying of the thin films is achieved, the automation degree of the thin film conveying is improved, and the needs of production and use are met.

Owner:浙江耀阳新材料科技有限公司

Steam enhanced double piston cycle engine

InactiveUS20080034755A1Improve engine efficiencyReduce the temperatureInternal combustion piston enginesEngine componentsEngineeringPiston

A steam enhanced dual piston cycle engine utilizes a unique dual piston apparatus that includes: a first cylinder housing a first piston therein, wherein the first piston performs only intake and compression strokes; a second cylinder housing an inner power piston that forms an inner internal chamber of the second cylinder, and either a ring-shaped outer power piston surrounding the inner power piston, wherein the outer power piston forms an outer internal chamber of the second cylinder and is configured to convert engine heat into additional work, and / or an outer boiler which is configured to produce steam to be converted into additional work.

Owner:TOUR BENJAMIN H +1

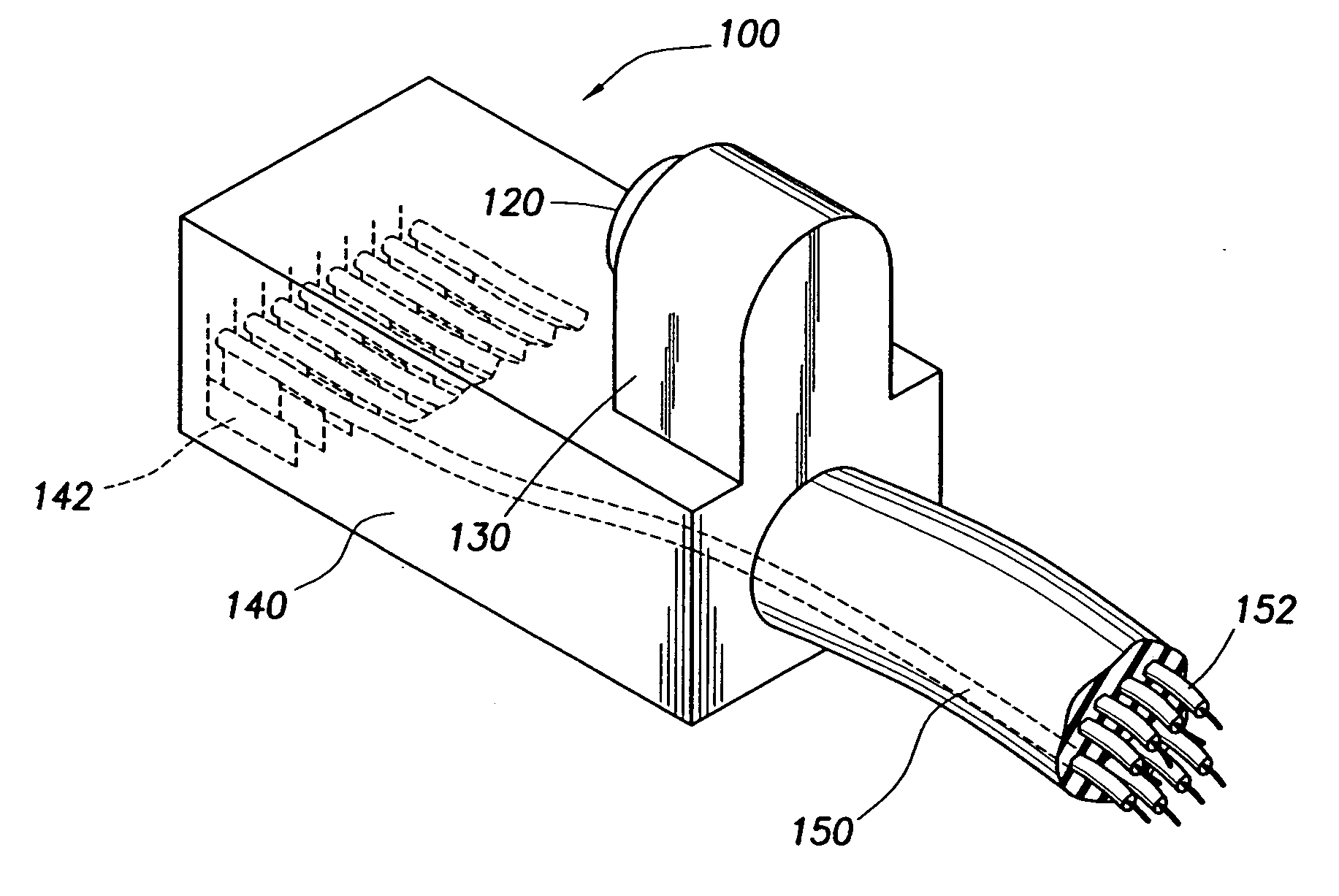

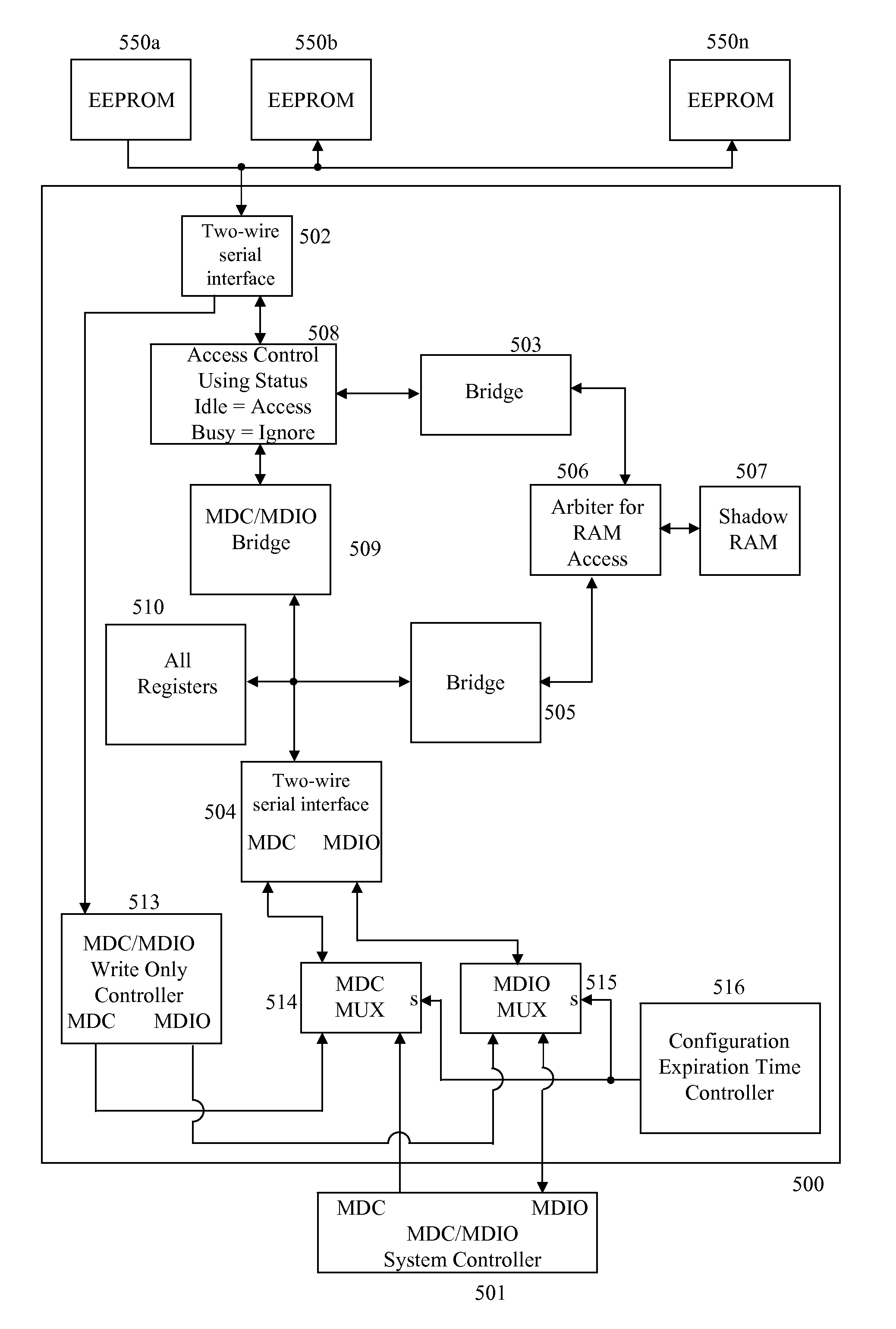

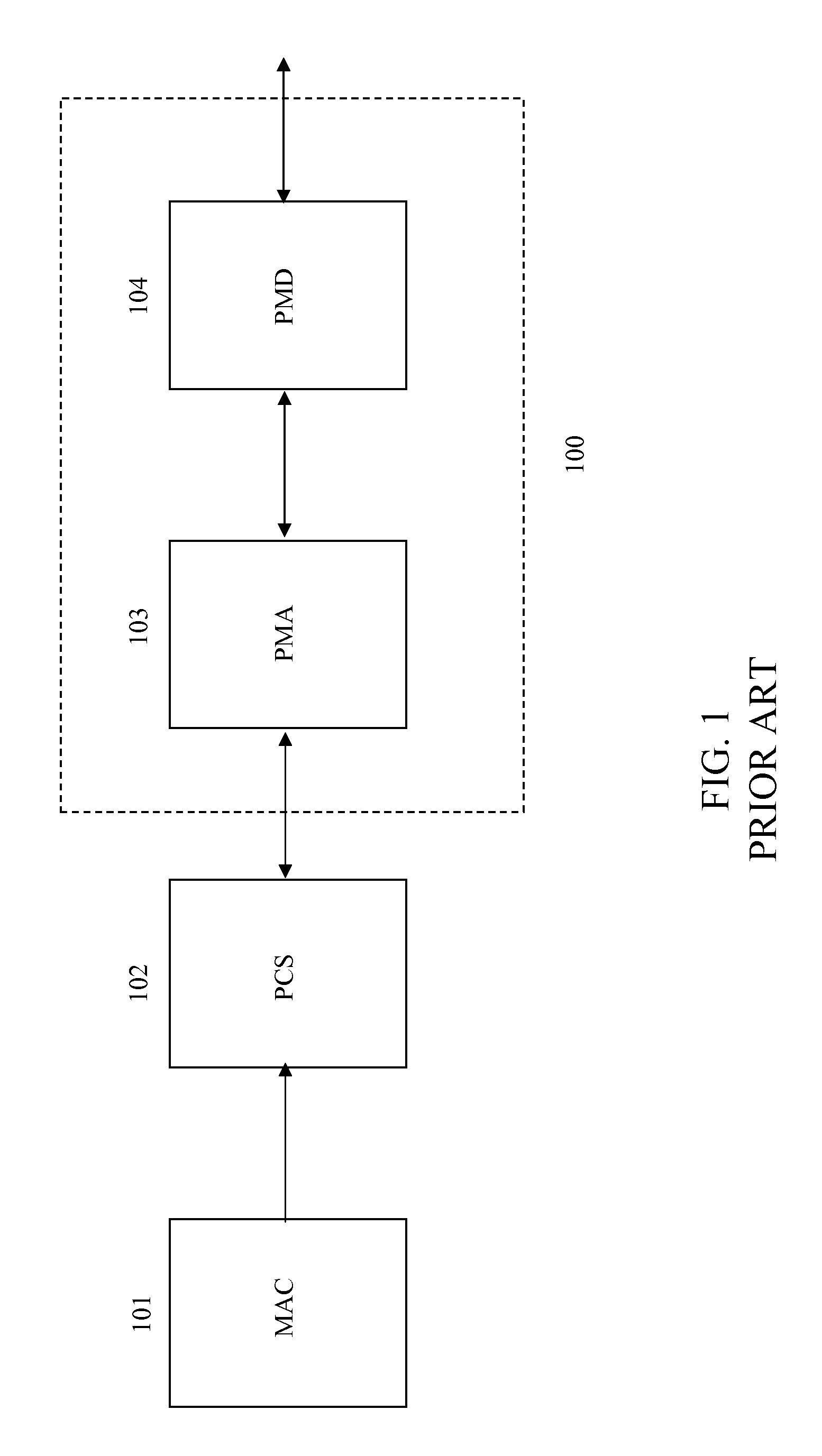

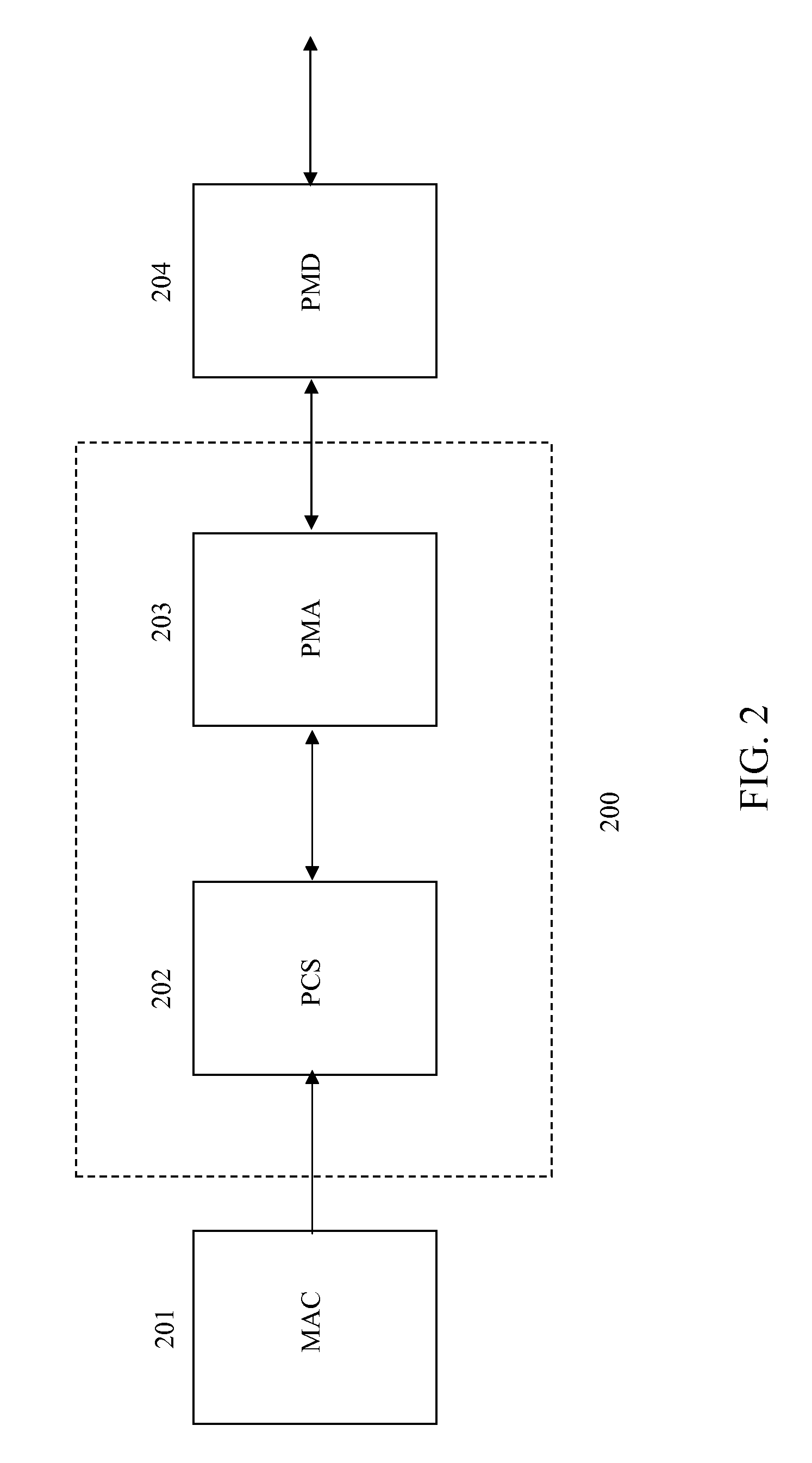

Method and apparatus for controlling data transfer between EEPROM and a physical layer device

ActiveUS7640370B1Efficiently locatedFacilitate controlDigital computer detailsNetwork connectionsData transmissionEEPROM

An IEEE 802.3 compliant physical layer device provides efficient loading of configuration information of the physical layer device. The configuration information is written into a volatile memory in the physical layer device, and then uploaded to at least one EEPROM. The configuration information is downloaded to the volatile memory during startup of the physical layer device. The system controller can also directly access the EEPROMs, bypassing the volatile memory. By providing a bridge between the system controller and the EEPROMs and providing additional bits in the volatile memory of the physical layer device, the system controller can read and write the EEPROMs one byte at a time. During reset time, the content of the EERPOMs is written to registers in the physical layer device to configure the physical layer device.

Owner:MARVELL ASIA PTE LTD

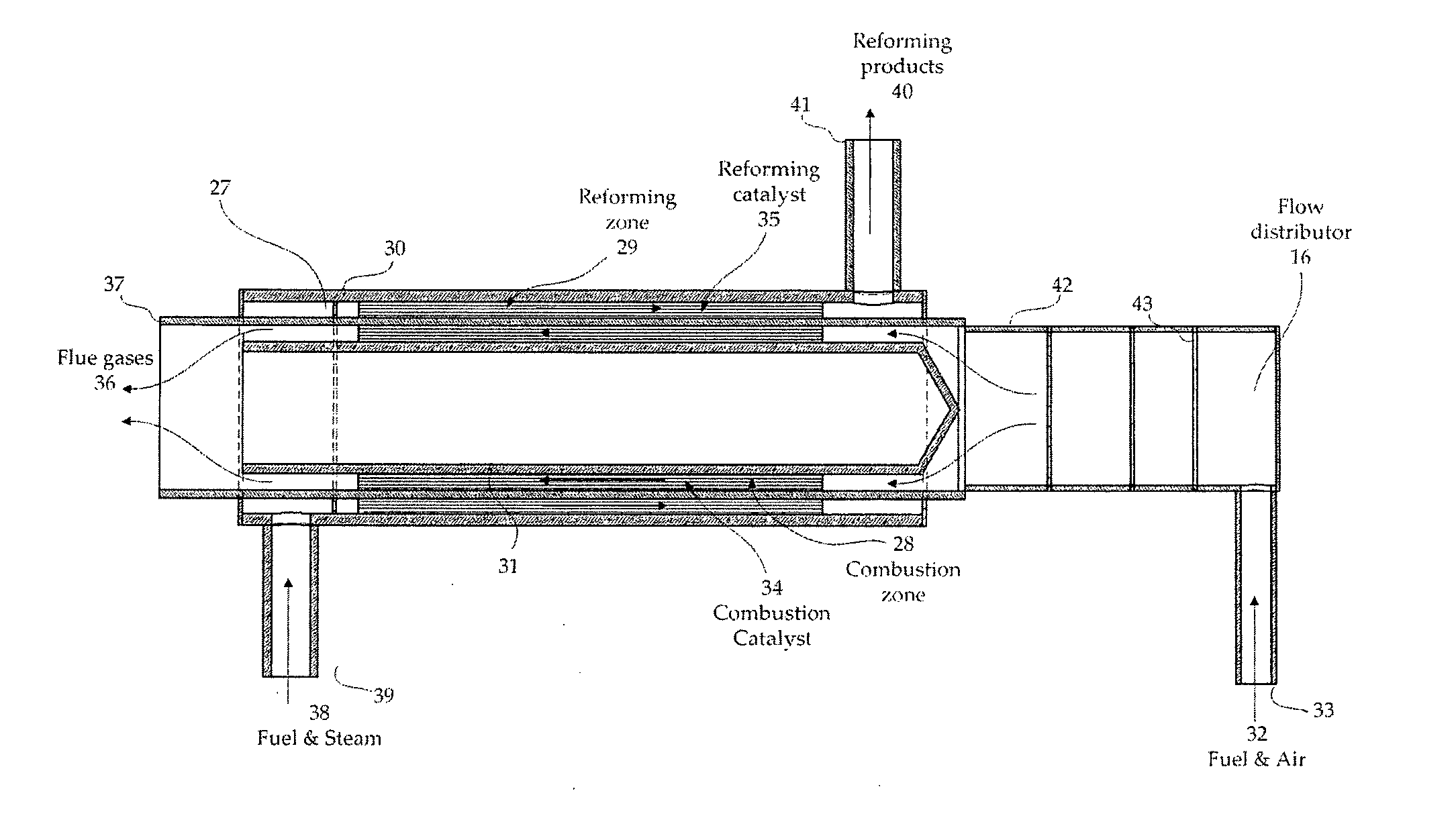

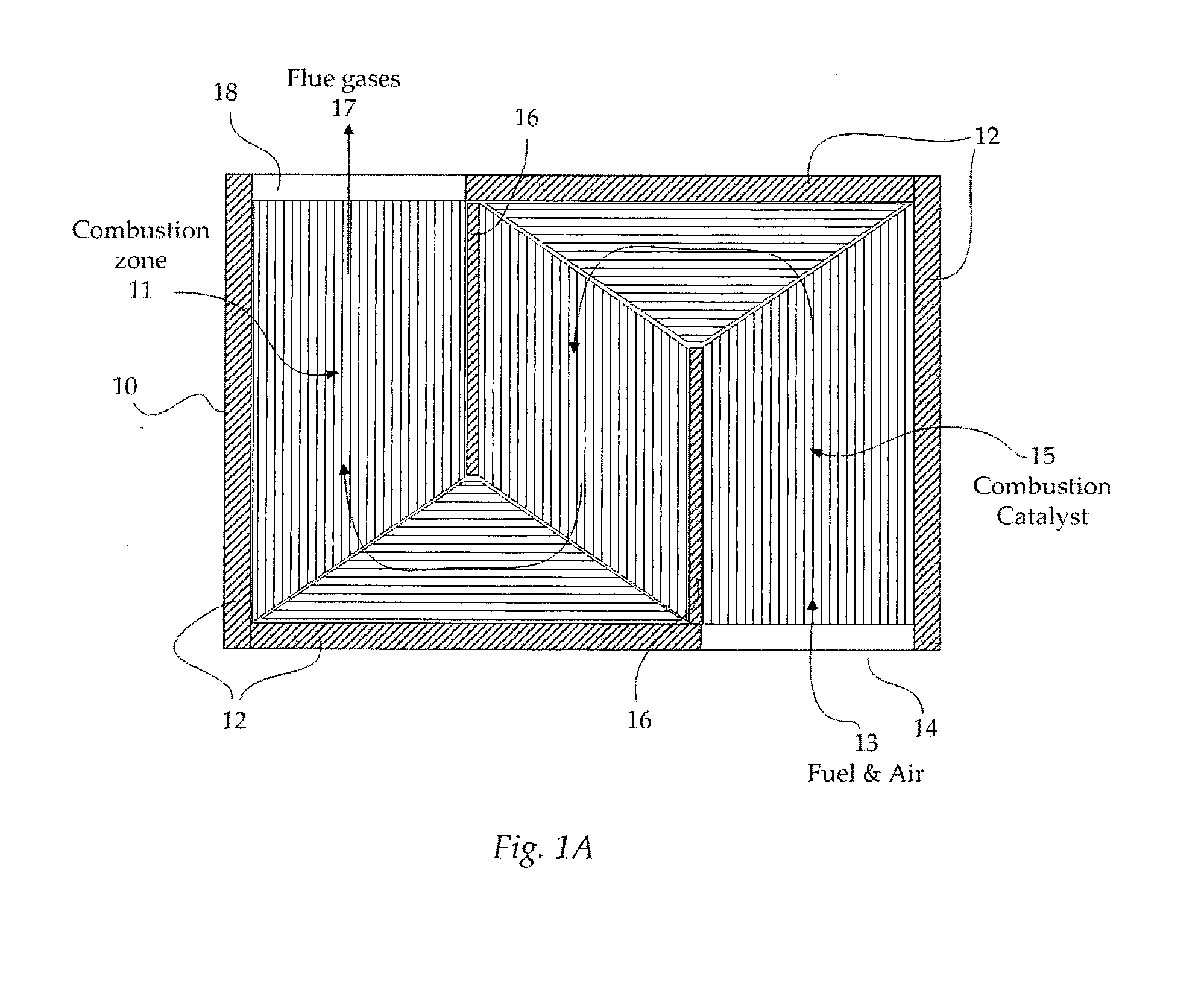

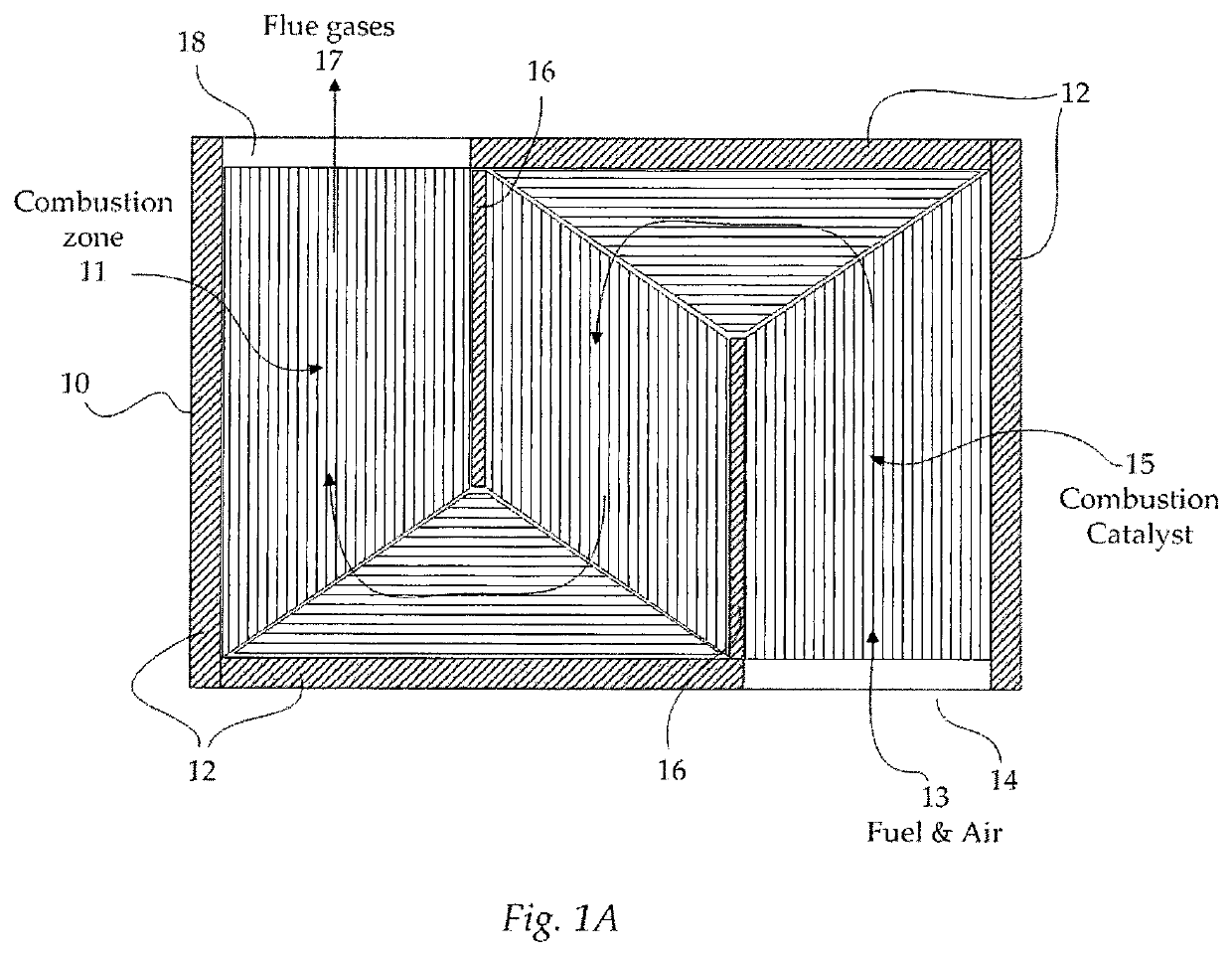

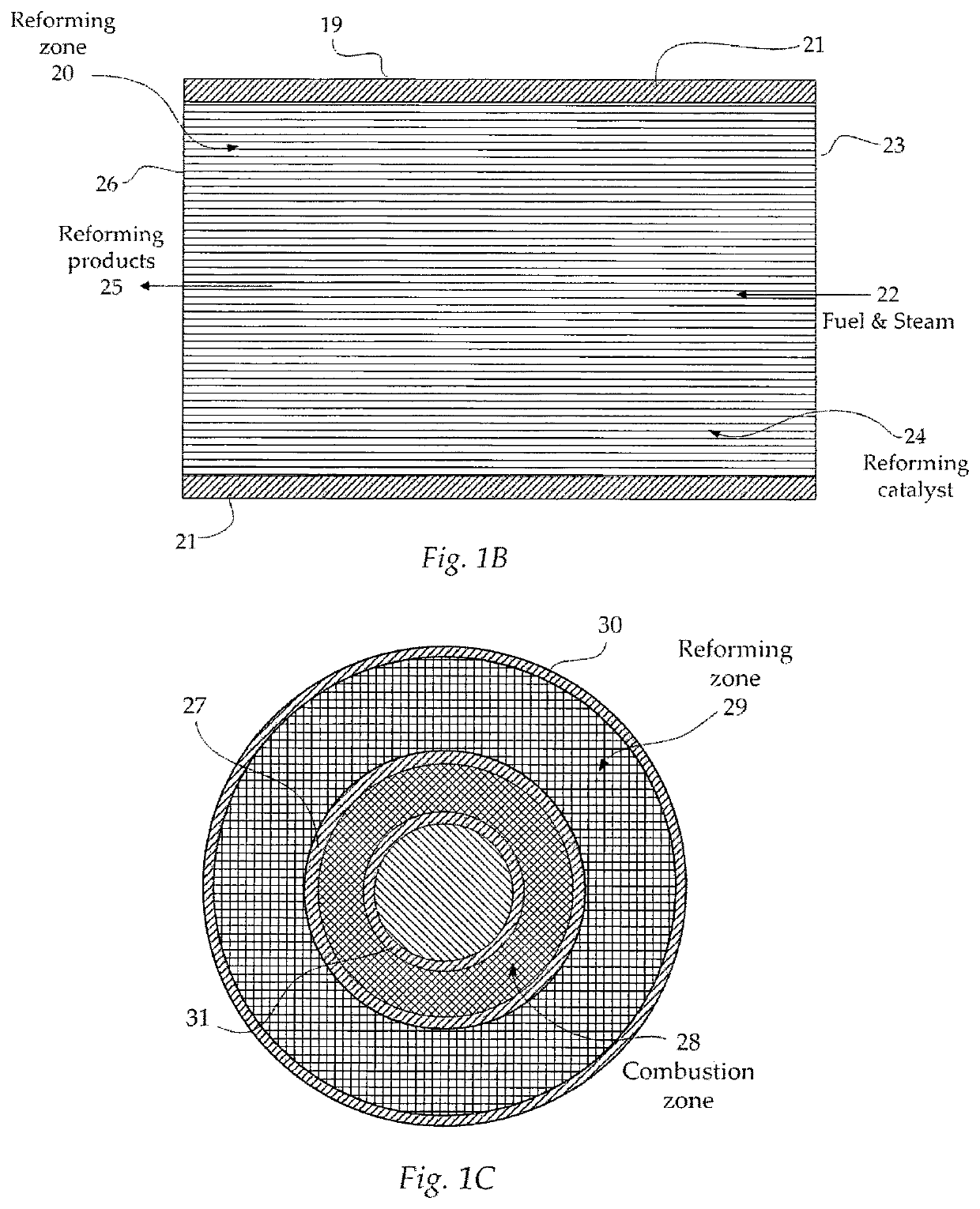

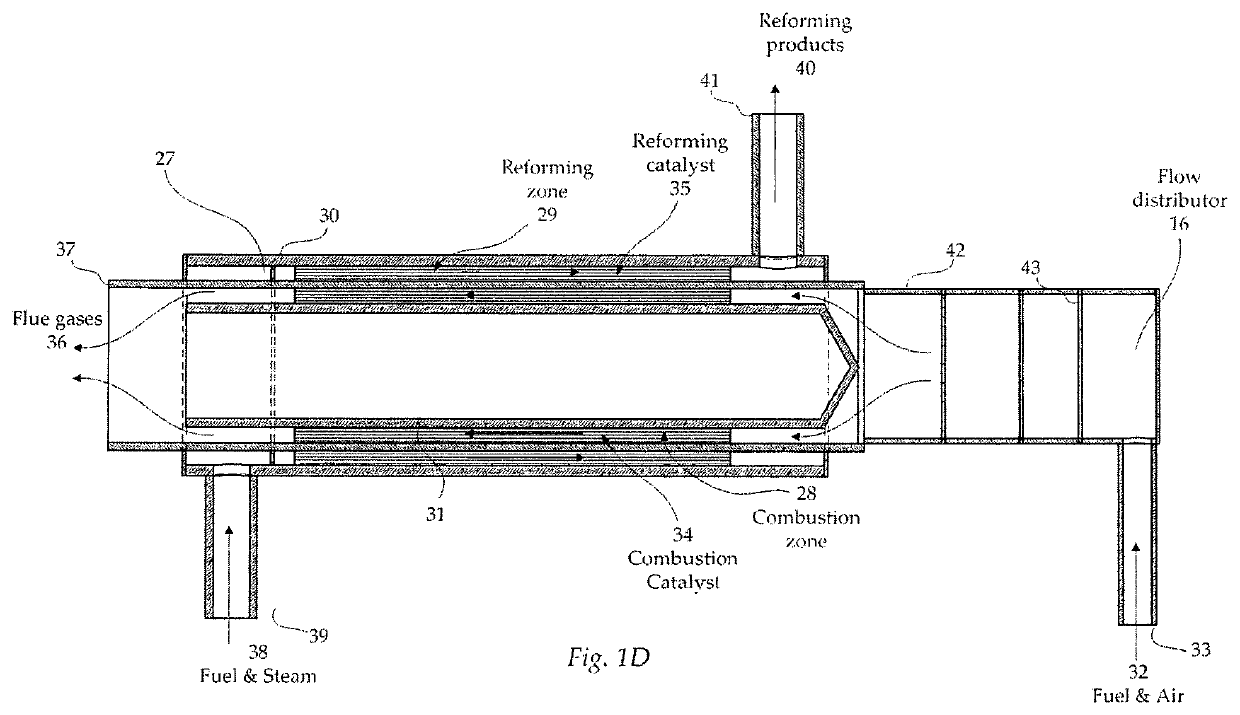

Catalytically heated fuel processor with replaceable structured supports bearing catalyst for fuel cell

ActiveUS20150118123A1Facilitate the combustion reactionImprove distributionHydrogenIndirect heat exchangersCatalytic reformingFuel cells

A highly compact heat integrated fuel processor, which can be used for the production of hydrogen from a fuel source, suitable to feed a fuel cell, is described. The fuel processor assembly comprises a catalytic reforming zone (29) and a catalytic combustion zone (28), separated by a wall (27). Catalyst able to induce the reforming reactions is placed in the reforming zone and catalyst able to induce the combustion reaction is placed in the combustion zone, both in the form of coating on a suitable structured substrate, in the form of a metal monolith. Fe—Cr—Al—Y steel foils, in corrugated form so as to enhance the available area for reaction, can be used as suitable substrates. The reforming and the combustion zones can be either in rectangular shape, forming a stack with alternating combustion / reforming zones or in cylindrical shape forming annular sections with alternating combustion / reforming zones, in close contact to each other. The close placement of the combustion and reforming catalyst facilitate efficient heat transfer through the wall which separates the reforming and combustion chambers.

Owner:HELBIO

Radiant heating and cooling panel

InactiveUS8256690B2Convenient and efficient transferIncrease contactCombustible gas coke oven heatingHot-air central heatingEngineeringRadiative heating

A radiant panel for use in radiant heating and cooling systems that provides numerous benefits over conventional panels currently in use. The radiant panel comprises an offset hydronic radiant tube channel in which is nested a hydronic radiant tube that obviates the need to thread the hydronic tubes through the joists in a ceiling installation or the studs in a wall installation. In an alternative embodiment, specific emissivity coatings on each side of the radiant panel further promote the efficient transfer of heat. The system provides increased sound isolation and is robust enough to withstand the crushing forces associated with a floor installation.

Owner:TALBOTT SOLAR & RADIANT HOMES

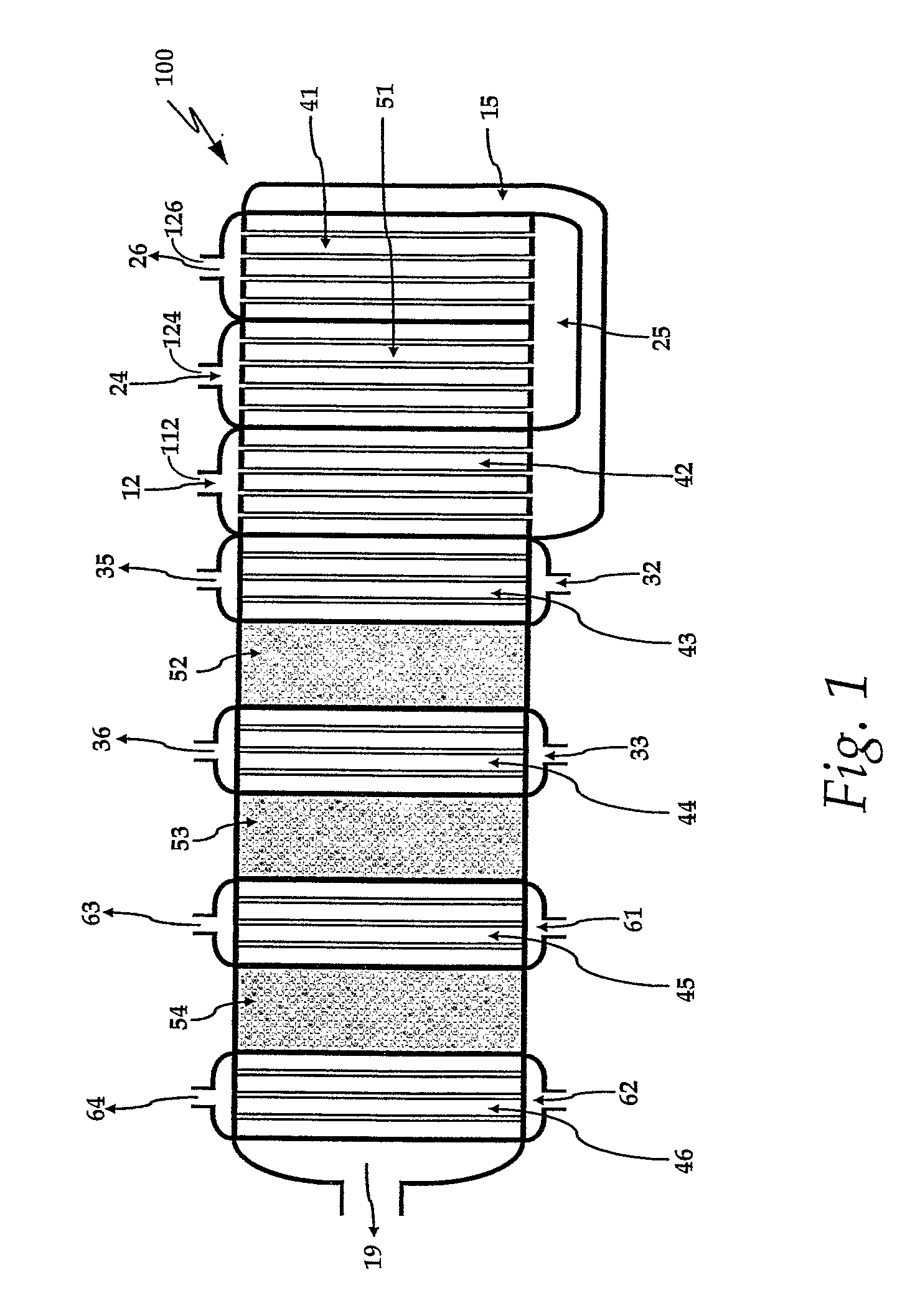

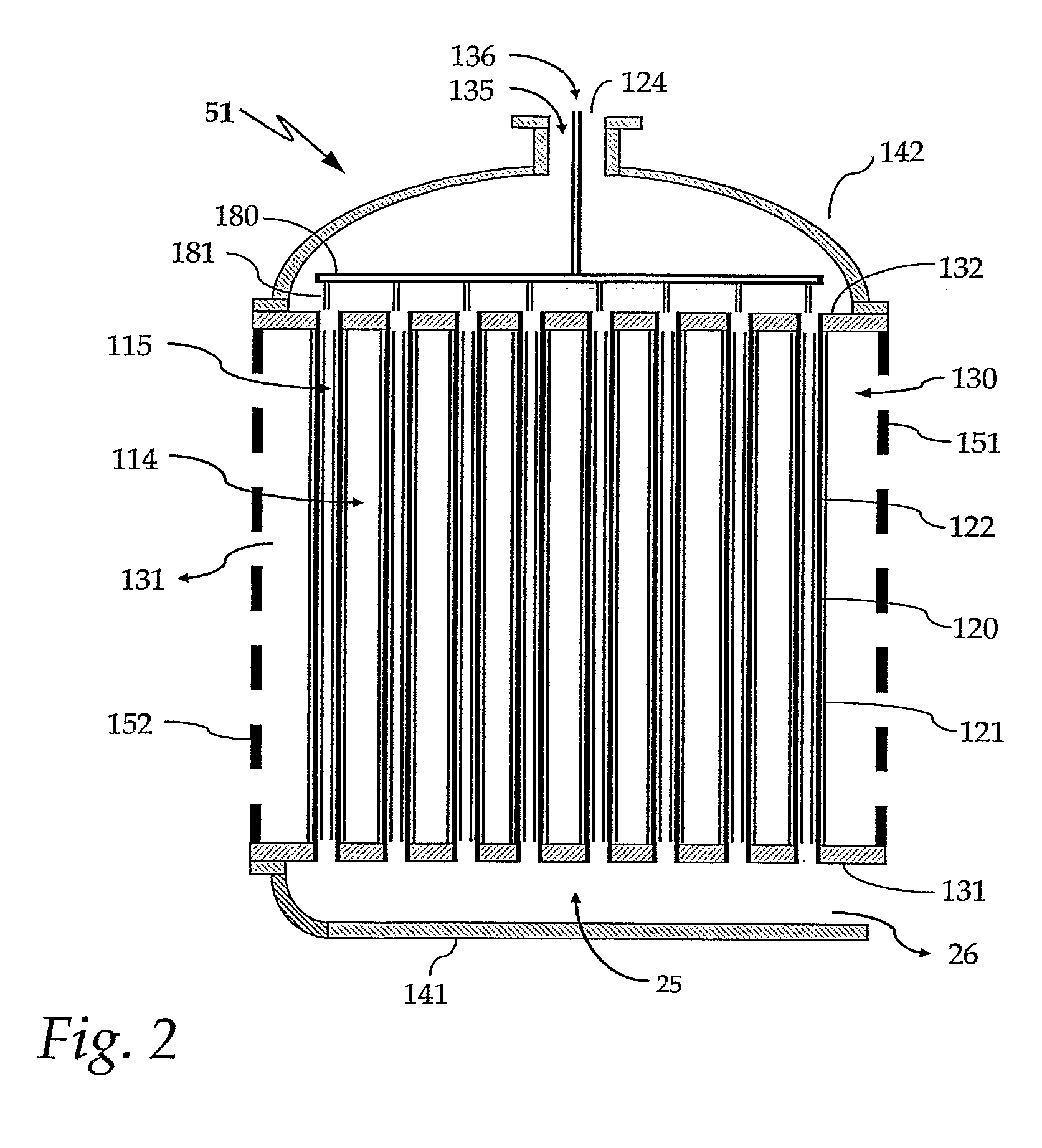

Catalytically heated fuel processor with replaceable structured supports bearing catalyst for fuel cell

ActiveUS10960372B2Convenient and efficient transferEasy to removeHydrogenChemical/physical/physico-chemical stationary reactorsCatalytic reformingThermodynamics

A highly compact heat integrated fuel processor, which can be used for the production of hydrogen from a fuel source, suitable to feed a fuel cell, is described. The fuel processor assembly comprises a catalytic reforming zone (29) and a catalytic combustion zone (28), separated by a wall (27). Catalyst able to induce the reforming reactions is placed in the reforming zone and catalyst able to induce the combustion reaction is placed in the combustion zone, both in the form of coating on a suitable structured substrate, in the form of a metal monolith. Fe—Cr—AI—Y steel foils, in corrugated form so as to enhance the available area for reaction, can be used as suitable substrates. The reforming and the combustion zones can be either in rectangular shape, forming a stack with alternating combustion / reforming zones or in cylindrical shape forming annular sections with alternating combustion / reforming zones, in close contact to each other. The close placement of the combustion and reforming catalyst facilitate efficient heat transfer through the wall which separates the reforming and combustion chambers.

Owner:HELBIO

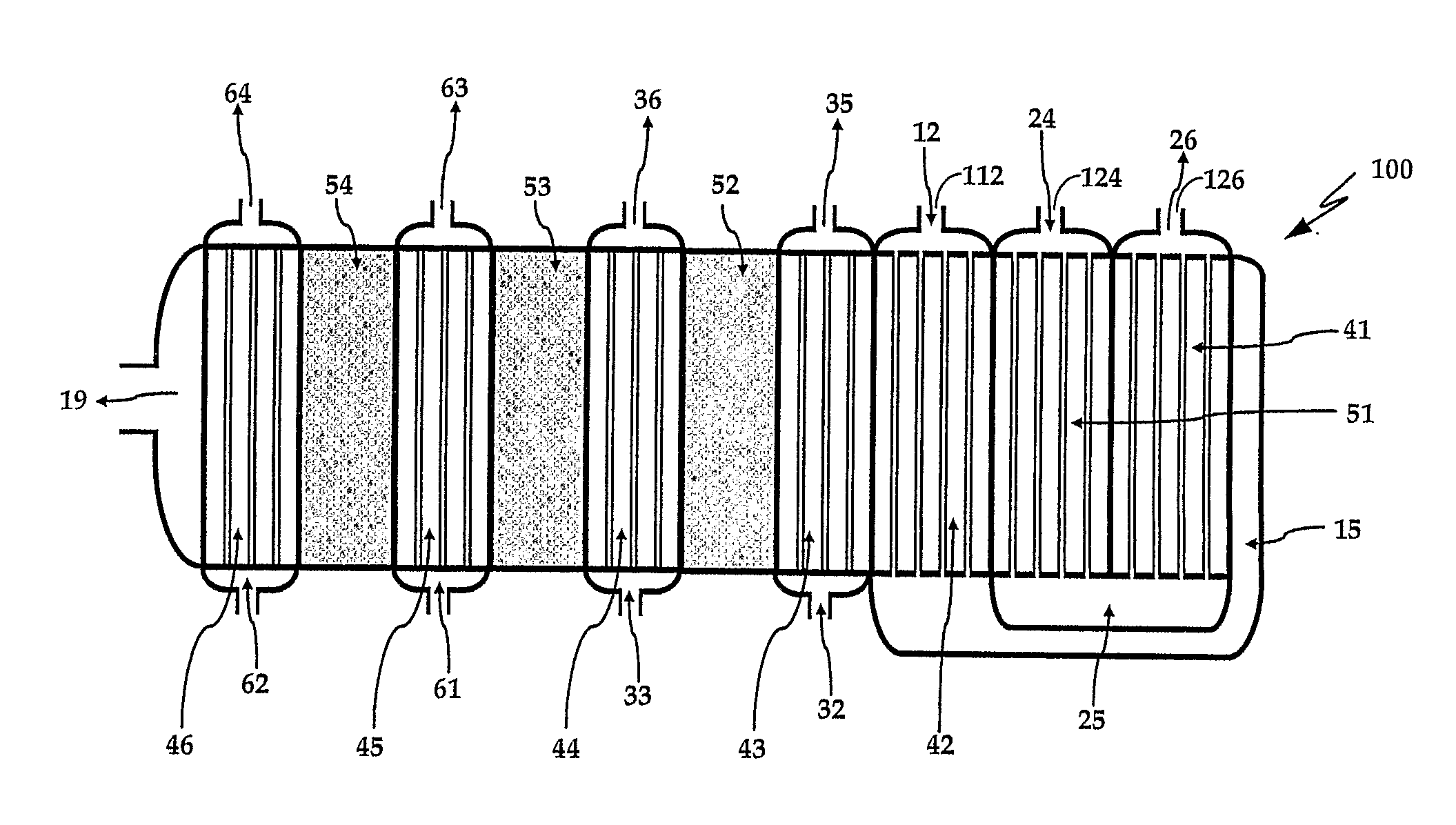

Highly heat integrated fuel processor for hydrogen production

InactiveUS20100183487A1High degree of heat integrationHigh efficiencyCatalytic gas-gas reactionHydrogenProcess engineeringHydrogen production

Described herein is a highly heat integrated fuel processor assembly that can be used for hydrogen production from a fuel source. The assembly comprises a heat exchanger type integrated reformer / combustor sub-assembly 51 also including catalyst able to induce the reforming and the combustion reaction. The fuel processor also comprises a high temperature WGS reactor 52, a low temperature WGS reactor 53 and a selective CO oxidation or methanation reactor 54 so that the train of reactors can maximize hydrogen production and minimize the CO concentration of the product. The fuel processor further comprises a series of steam generators and heat exchangers that enhance the heat integration of the fuel processor. The whole fuel processor assembly or sub-assemblies can be employed for highly efficient distributed hydrogen generation.

Owner:HELBIO HYDROGEN & ENERGY PRODN SYST

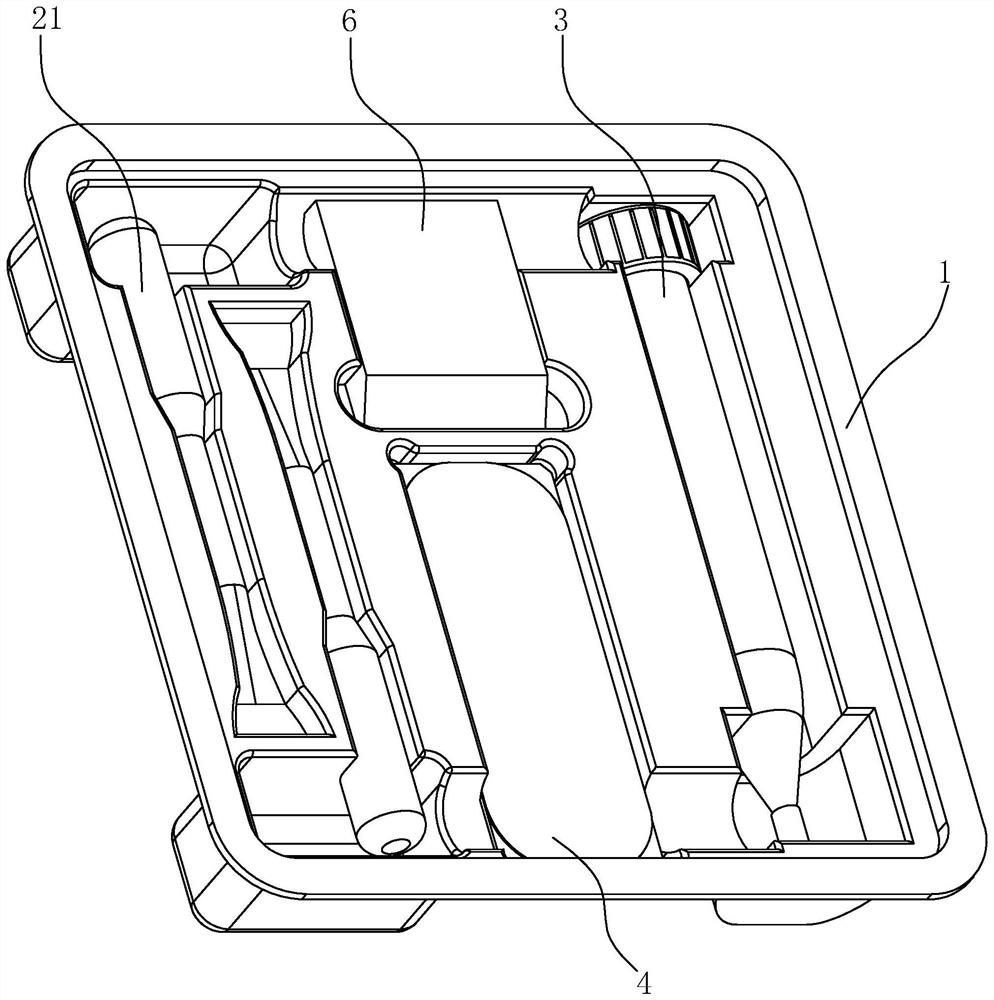

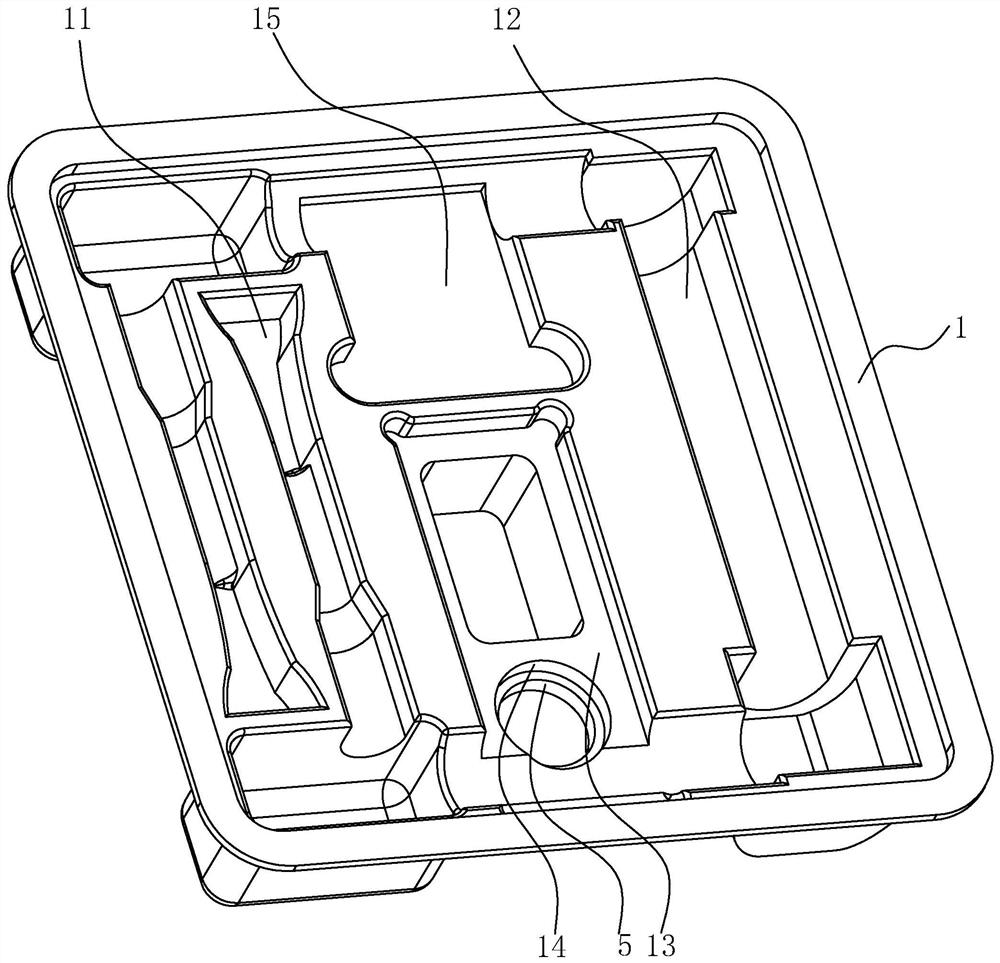

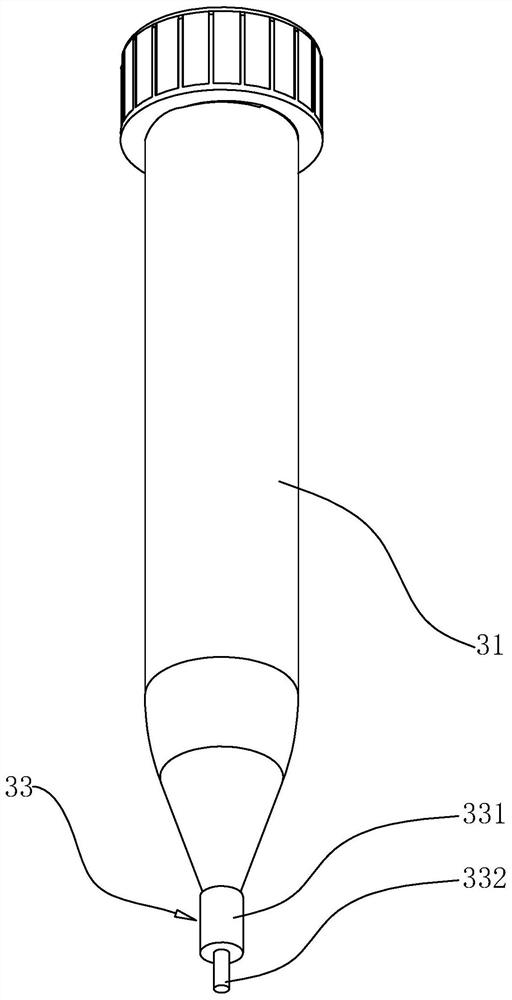

Cell block collection device and cell block collection method

ActiveCN111811901AEfficient collectionEfficient enrichmentPreparing sample for investigationCancer detectionBody fluid

The invention discloses a cell block collection device and a cell block collection method, and belongs to the technical field of collection of cells in body fluid. The technical problem of low detection rate when cancer detection is carried out by adopting cell slices when the content of cancerous cells in the body fluid is relatively low is solved. The cell collection device comprises a supporting plate, a plurality of grooves are formed in the supporting plate, and an auxiliary material tube, a fixed supporting plate, a special centrifugal tube, a tissue embedding box and embedding paper areclamped in the grooves respectively. A use method of the cell collection device comprises the following steps: preparing raw materials; centrifugally filtering exfoliated cell sap; performing cell precipitation hardening; fixing exfoliated cell blocks; and embedding and paraffinizing the exfoliated cell blocks. The cell collection device can be used for collecting and preparing cell blocks of cast-off cells in samples such as pleural effusion, ascites, urine and sputum, has the advantages of efficient enrichment of a small number of cast-off cells and unsupported preparation of the cell blocks, facilitates later cell slicing, and improves the detection rate of later pathological detection.

Owner:郑志森 +1

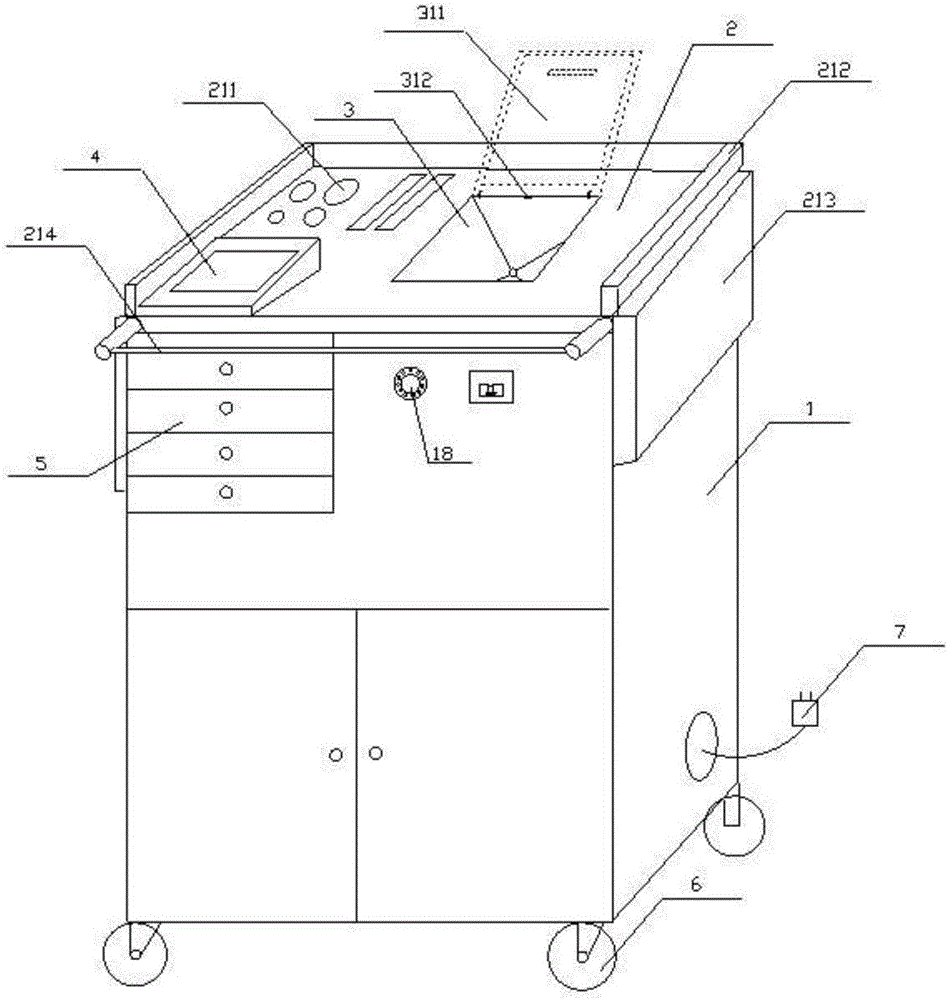

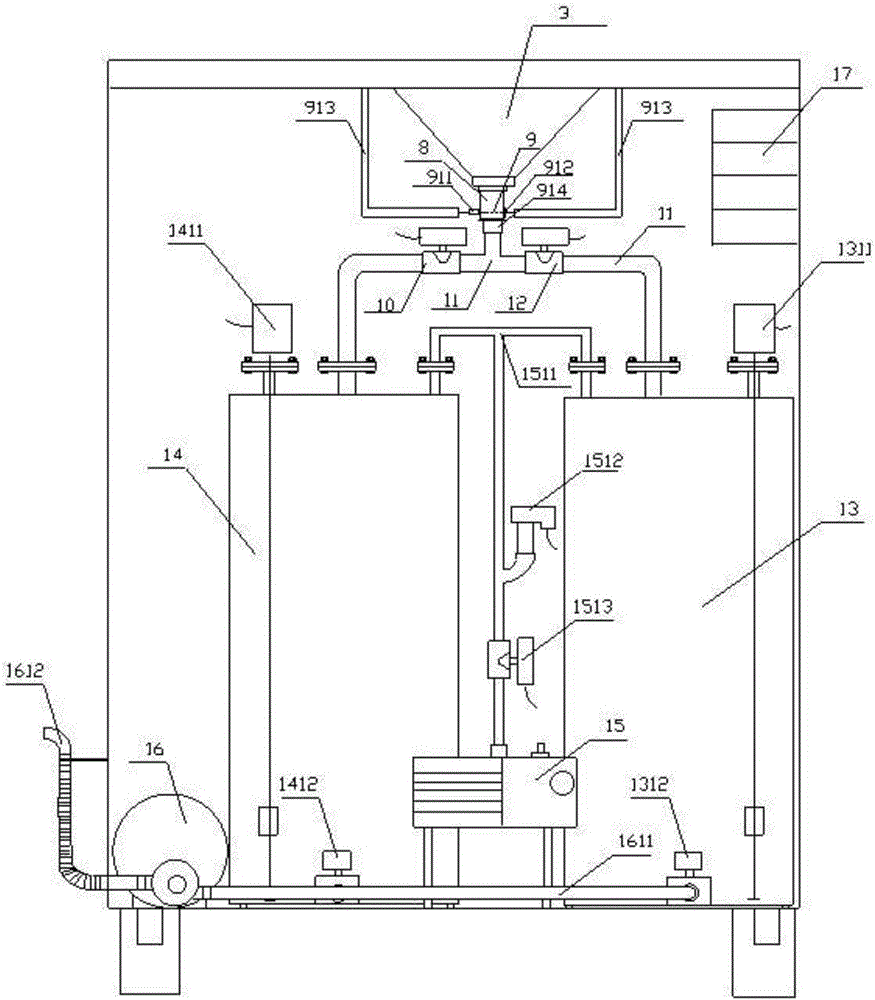

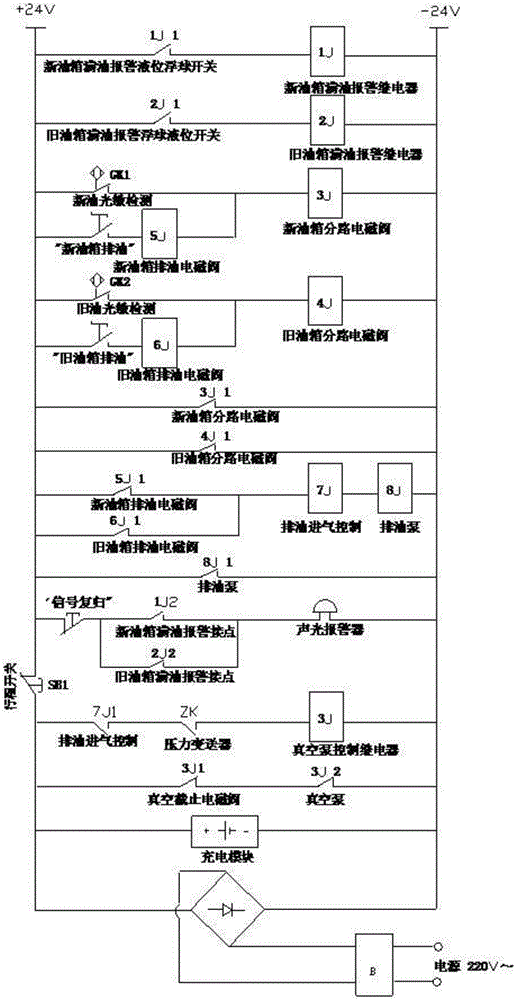

Treating and recycling device for insulating oil sample

InactiveCN106018854AEasy to operateHigh degree of intelligenceMaterial analysisElectricitySolenoid valve

The invention relates to a device for processing and recovering insulating oil samples, which comprises a movable cabinet, the upper end of the cabinet is a test operation table, an oil collection tank is embedded in the middle of the test operation table, and the oil outlet at the lower end of the oil collection tank is It is connected with an oil color detection tube, and the outer wall of the oil color detection tube is equipped with an infrared photosensitive detector. A new oil bypass solenoid valve and an old oil bypass solenoid valve are connected with the new oil and used oil sealed oil storage tanks, and the new oil and used oil sealed oil storage tanks are also connected with the vacuum pump through a T-shaped vacuum tube; there is also a LCD touch control screen, liquid crystal touch control screen, one-way valve, infrared photosensitive detector, new oil shunt solenoid valve, old oil shunt solenoid valve and vacuum pump are all electrically connected with the controller. The beneficial effect of the invention is that it can realize the automatic classification collection, vacuum-sealed storage and quick transfer of the test waste oil.

Owner:韩功篑

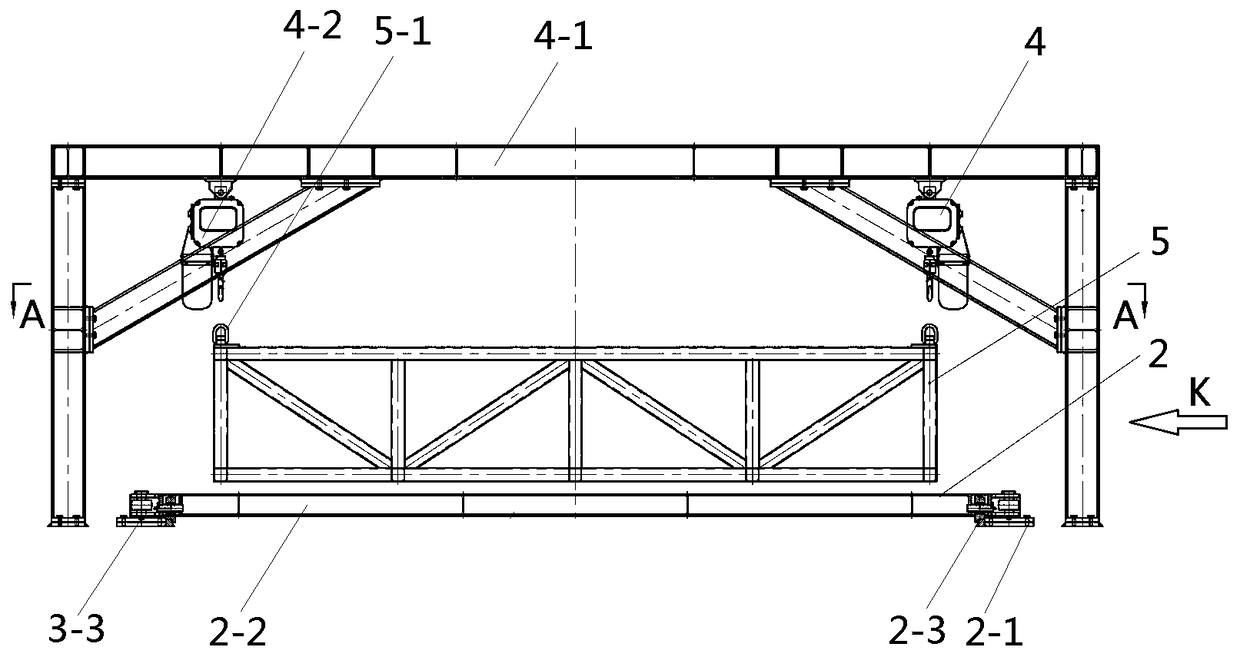

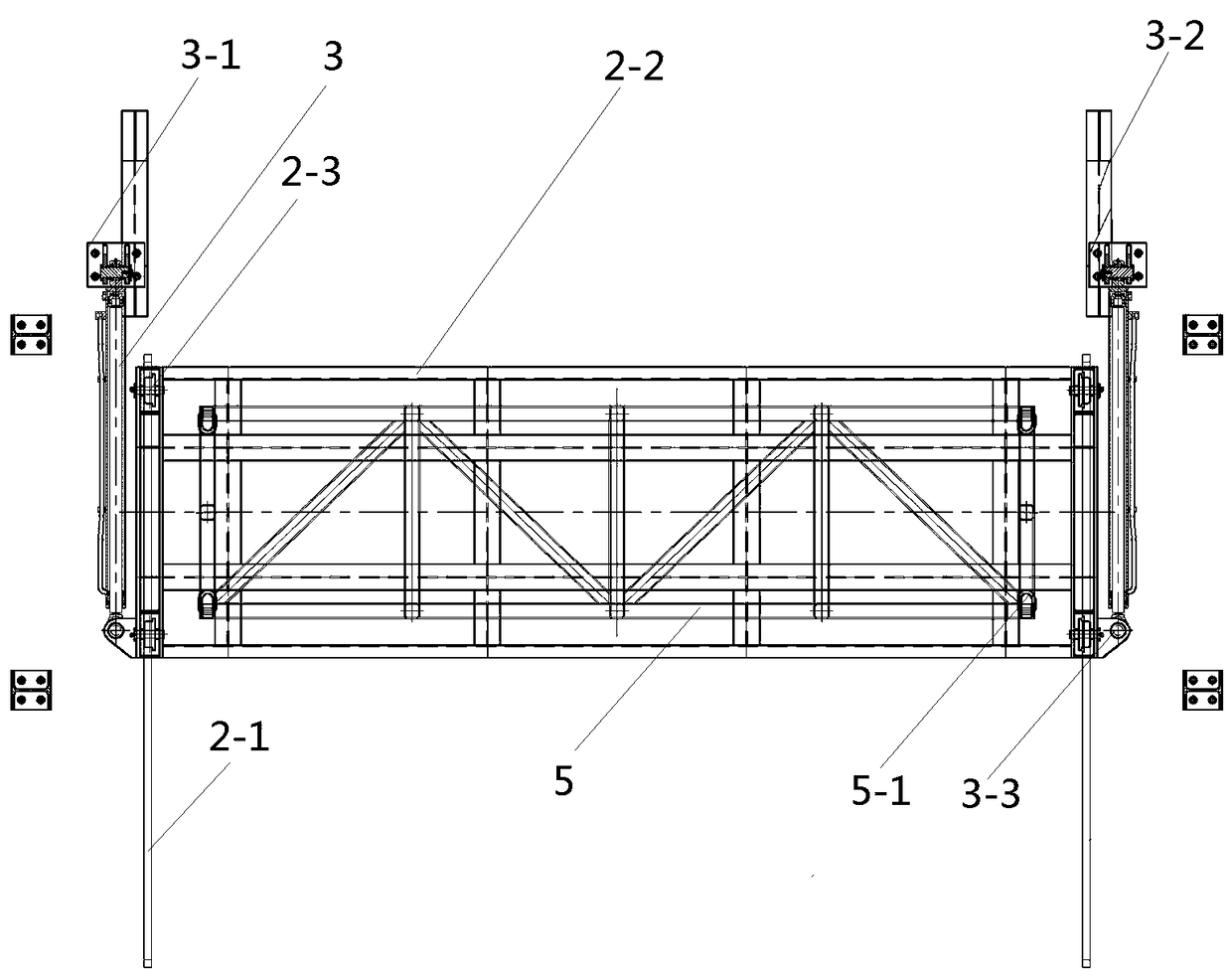

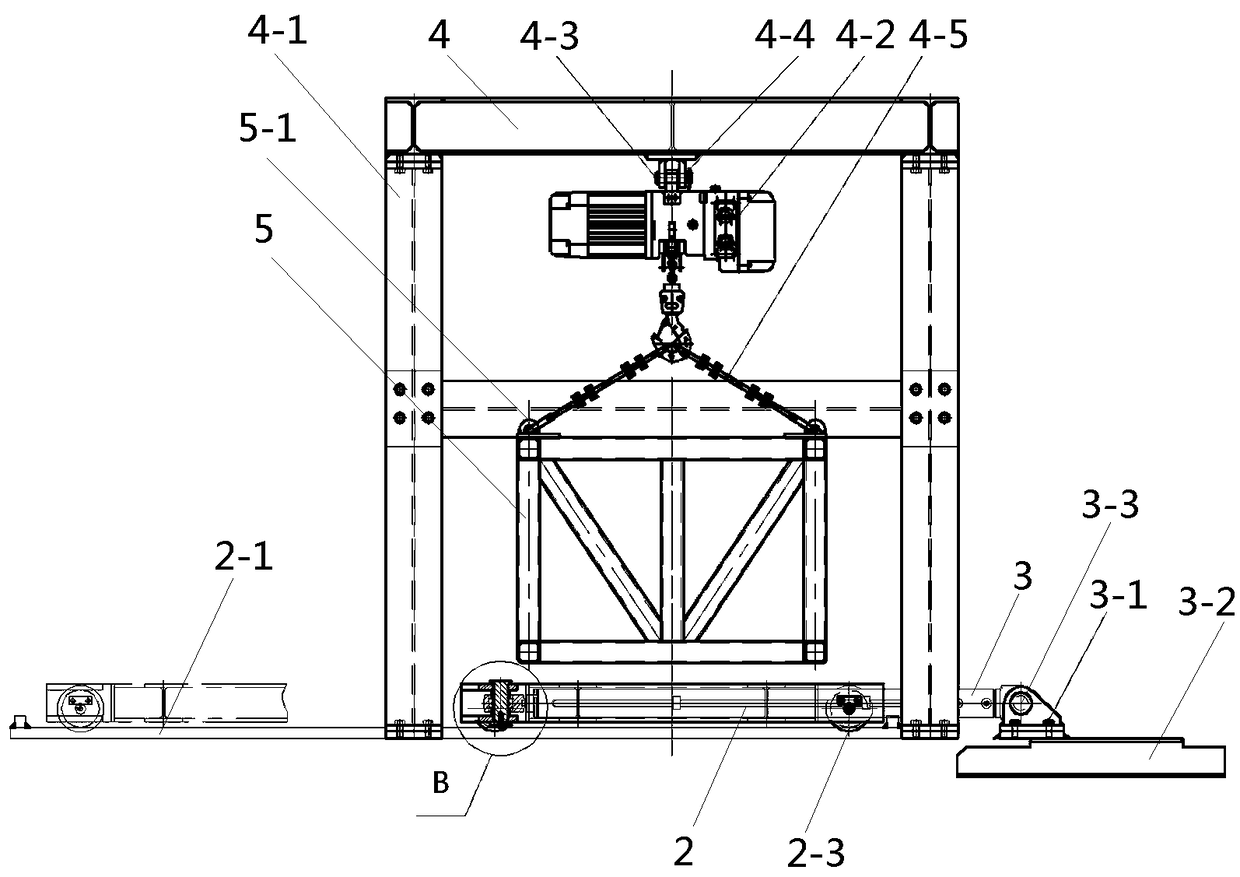

Shield tunneling machine continuous belt rack material lifting and storage device

PendingCN109404040AConvenient and efficient transportationEasy to placeEarth drilling and miningUnderground transportEngineeringShield tunneling

The invention discloses a shield tunneling machine continuous belt rack material lifting and storage device. The technical problem that assemble extending of a trailer continuous belt rack cannot be conducted quickly and conveniently is solved. The shield tunneling machine continuous belt rack material lifting and storage device comprises a trailer of a shield tunneling machine. A lifting port isformed in the top of the trailer, a mobile platform which is used for controlling the lifting port to be closed is arranged on the upper part of the lifting port, and a lifting device which corresponds to the lifting port is arranged on the upper part of the trailer. According to the shield tunneling machine continuous belt rack material lifting and storage device, the structure is simple, operation is reliable, and transportation and storage of continuous belt rack materials can be completed conveniently and efficiently. Due to the lifting port formed in the top of the trailer, the continuousbelt rack materials can be directly conveyed from a grouping trolley on the lower part of the trolley to the top part of the trailer, materials can be transported by cleverly using the structure of the trailer, and the materials can be transported conveniently and efficiently by the lifting device; and the mobile platform can block the lifting port and can also convey the continuous belt rack materials to one side of the top of the trailer to be installed, safety and reliability are achieved, and convenience and efficiency are achieved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Roller transfer device

InactiveCN107719437AConvenient and efficient transferReduce labor intensitySupporting partsHand carts with multiple axesPulp and paper industryCaster

A roller transfer device belongs to the technical field of roller production. The invention includes a supporting plate, a plurality of universal wheels arranged at the bottom of the supporting plate, a push-pull handle arranged at one end of the supporting plate, a shock absorbing pad arranged on the supporting plate, a carrier roller plate arranged on the shock absorbing There are multiple roller grooves on the side of the roller plate, and limiting plates at both ends of the multiple roller grooves; the limiting plate includes guide parts at both ends, and fixed shaft parts between the guide parts on both sides. One end connected to the fixed shaft part is gradually inclined downward toward the other end, and the fixed shaft part is provided with a plurality of fixed shaft openings matching with the roller groove; It includes a flipping plate that can be attached to the side of the limiting plate, and a baffle that is arranged at one end of the flipping plate and can be attached to the end surface of the limiting plate; the flipping plate is provided with a hook bar, and the limiting plate is provided with a hook groove matching the hook bar. The invention can conveniently and efficiently transfer a small amount of rollers, so as to improve the efficiency of transfer and reduce the labor intensity of workers.

Owner:湖州展业物流机械设备有限公司

Hoisting type pipeline transportation cart

InactiveCN110949473AConvenient and efficient transferNo crush collisionsHand carts with multiple axesHand cart accessoriesVehicle framePipeline transport

The invention relates to the field of pipeline machining, in particular to a hoisting type pipeline transportation cart which comprises a cart frame, telescopic devices, universal wheels and lifting appliances. The frame is square, the telescopic devices are located at the four corners of the frame, the top ends of the telescopic devices are fixedly connected with the frame, and the telescopic devices are used for adjusting the height of the frame. The universal wheels are fixedly connected to the bottom ends of the telescopic devices; the lifting appliances are detachably connected to the lower surface of the frame, the multiple lifting appliances are arranged in the vertical direction, and the lifting appliances are used for lifting pipelines. The hoisting type pipeline transportation cart has the beneficial effects that the frame is lifted through the telescopic devices, so that the lifting appliances and the pipelines are located at the same height, and the pipelines can be conveniently and efficiently transferred to a transportation cart; each pipeline is hoisted by the corresponding independent lifting appliance, so that the adjacent pipelines are prevented from being extruded and collided; due to the fact that the pipelines are hoisted below the frame, the pipelines cannot be stacked, and the pipelines located at the bottom cannot be extruded to deform.

Owner:福建恒杰塑业新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com