Liquid Cooling System Cold Plate Assembly

a technology of liquid cooling system and cold plate, which is applied in the direction of stationary conduit assembly, lighting and heating apparatus, laminated elements, etc., can solve the problems of degrading system performance, localized heat sources or hot spots within the chassis environment, and motherboard and various auxiliary components consuming power and generating heat, etc., to facilitate efficient thermal energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The following detailed description illustrates the invention by way of example and not by way of limitation. The description enables one skilled in the art to make and use the present disclosure, and describes several embodiments, adaptations, variations, alternatives, and uses of the present disclosure, including what is presently believed to be the best mode of carrying out the present disclosure.

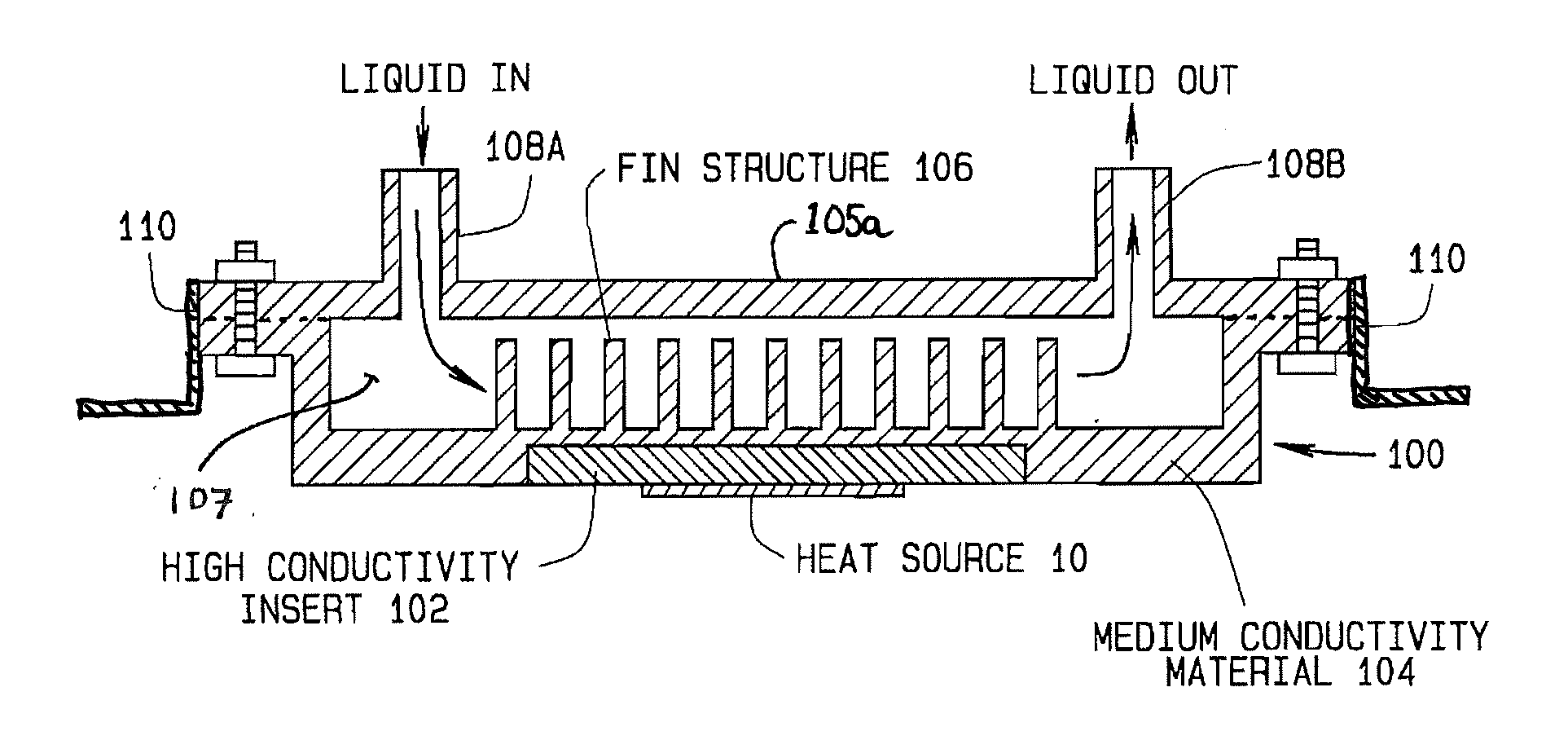

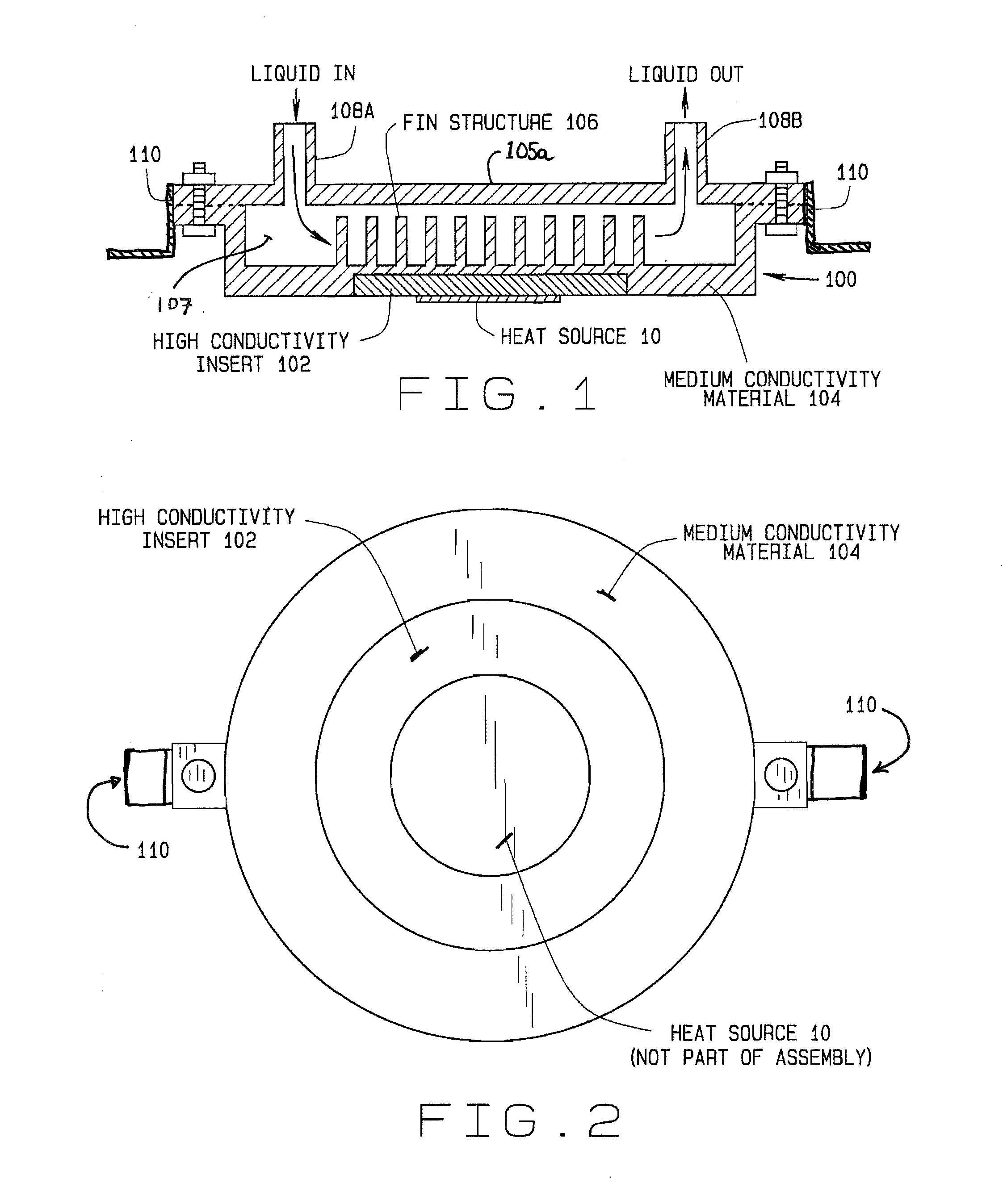

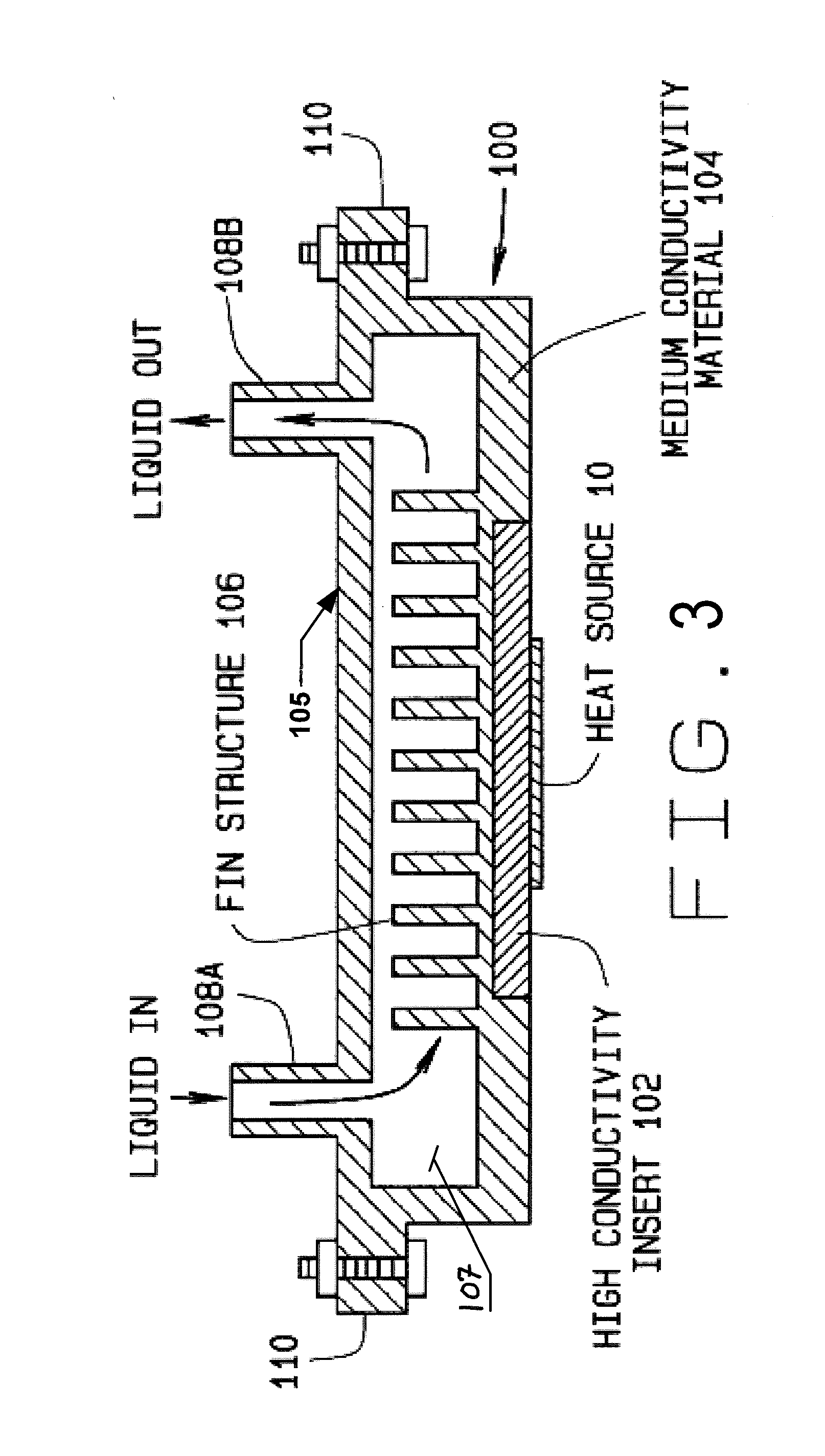

[0024]Turning to the Figures, a cold plate assembly 100 of the present invention adapted for secured over a heat source 10 such as an integrated circuit, video or graphic processing unit is shown configured for connection to an existing liquid cooling circulating flow loop via any suitable liquid pathway. The liquid cooling loop, which is not directly part of the present invention, provides all necessary components for circulating a flow of liquid coolant to and from the cold plate assembly 100 through inlets 108A and outlets 108B, thereby drawing heat away from the various heat-gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com