Shield tunneling machine continuous belt rack material lifting and storage device

A technology for storage devices and material storage boxes, applied in transportation and packaging, cranes, underground transportation, etc., can solve the problem that the continuous belt frame of the trailer cannot be quickly and conveniently extended and assembled, so as to improve convenience and efficiency and avoid heavy operations , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

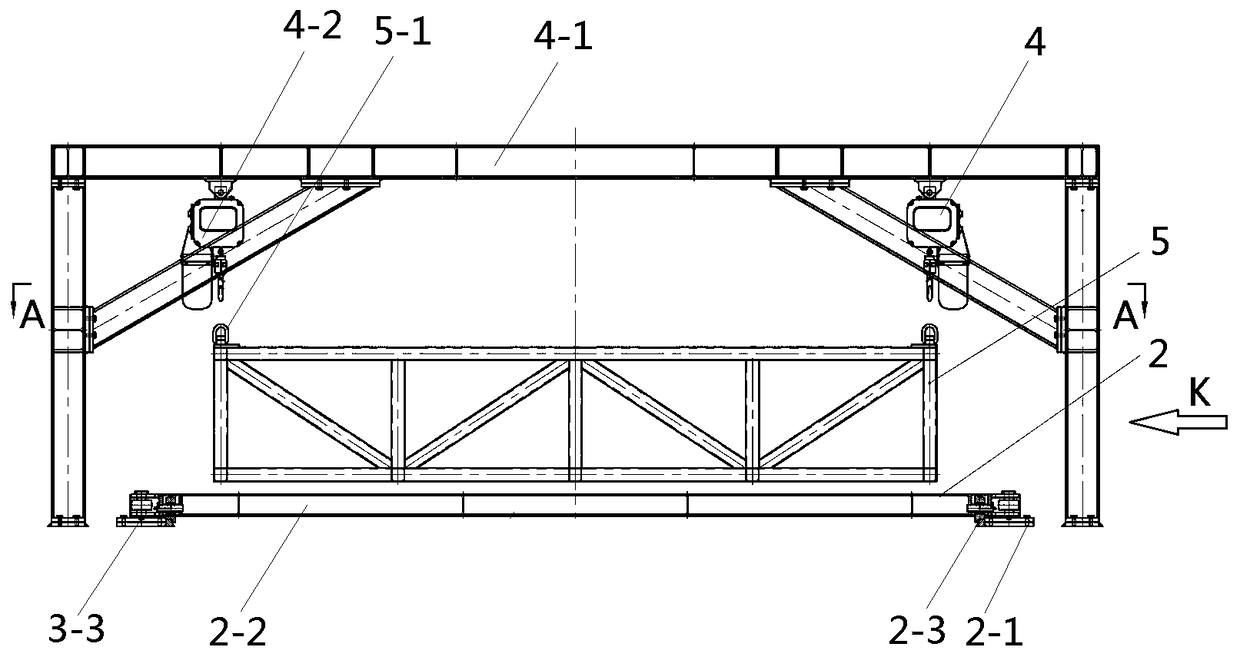

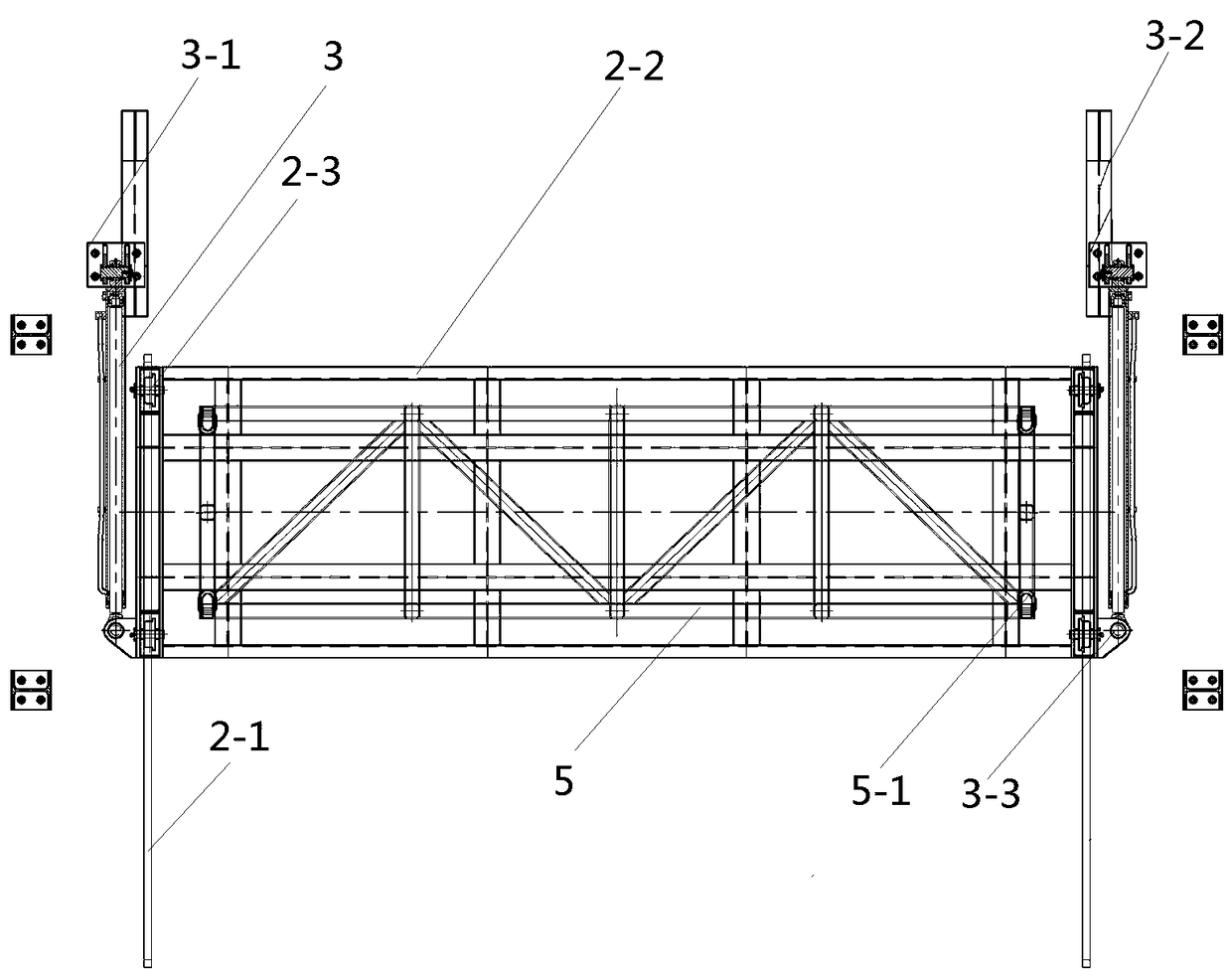

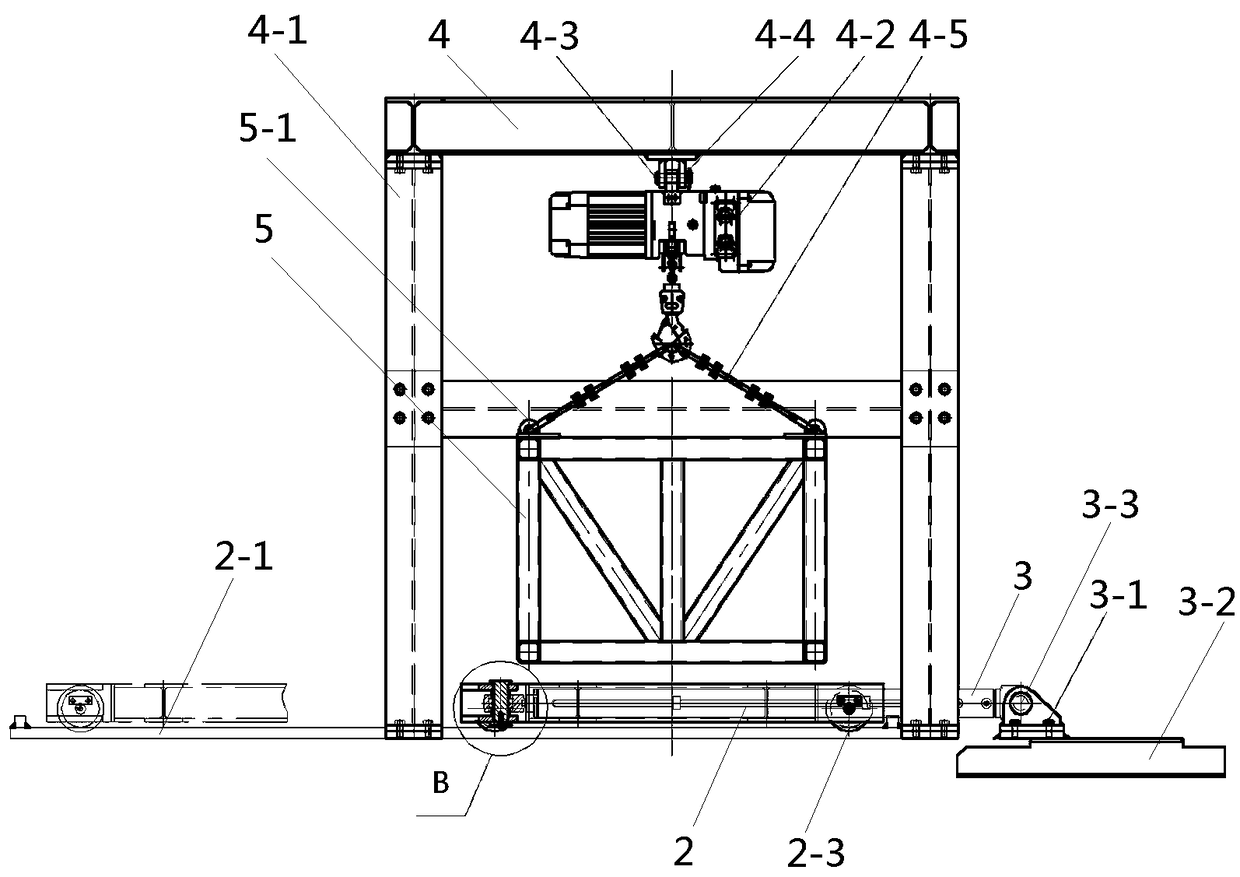

[0021] Embodiment 1, the material hoisting and storage device of the continuous belt frame of the shield machine, including the trailer 1 of the shield machine, and the top of the trailer 1 is provided with a hoisting opening, such as Figure 1-3 As shown, a mobile platform 2 for controlling the closing of the hoisting mouth is arranged above the hoisting mouth, and a hoisting device 4 corresponding to the upper and lower sides of the hoisting mouth is arranged above the trailer. A hoisting opening is provided on the top of the trailer 1, and the continuous belt rack material can be directly transported from the marshalling trolley at the lower part of the trailer 1 to the top of the trailer 1, and the material operation can be completed by cleverly utilizing the structure of the trailer 1 itself, and the hoisting equipment can be convenient And complete the transfer of materials efficiently; the mobile platform 2 can not only seal the hoisting opening, but also transport the c...

Embodiment 2

[0024] Embodiment 2, shield machine continuous belt rack material hoisting and storage device, such as figure 2 , image 3 As shown, the moving direction of the mobile platform 2 is perpendicular to the forward direction of the trailer 1, so that the mobile platform 2 can carry materials to move to one side of the top of the trailer, which is convenient for the extended installation of the continuous belt rack.

[0025] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0026] Embodiment 3, shield machine continuous belt frame material hoisting and storage device, such as Figure 1-6 As shown, a material storage box 5 is arranged in cooperation with the size of the hoisting opening, and a lifting ring 5-1 is arranged above the material storage box 5, and the electric hoist 4-2 connects with the material storage box 5 above the lifting rope 4-5. Ring 5-1 links to each other. Setting the material storage box can hoist and transport a large amount of continuous belt rack materials at one time, which further improves the efficiency of continuous belt rack extension splicing, and can also be used for material storage.

[0027] Other structures of this embodiment are the same as those of Embodiment 2.

[0028] The working process of the present invention is as Figure 5 and Image 6 As shown, the assembly part 8 of the continuous belt frame is placed in the material storage box 5, and is transported by the marshalling trolley in the shield machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com