Patents

Literature

74results about How to "Facilitate the combustion reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

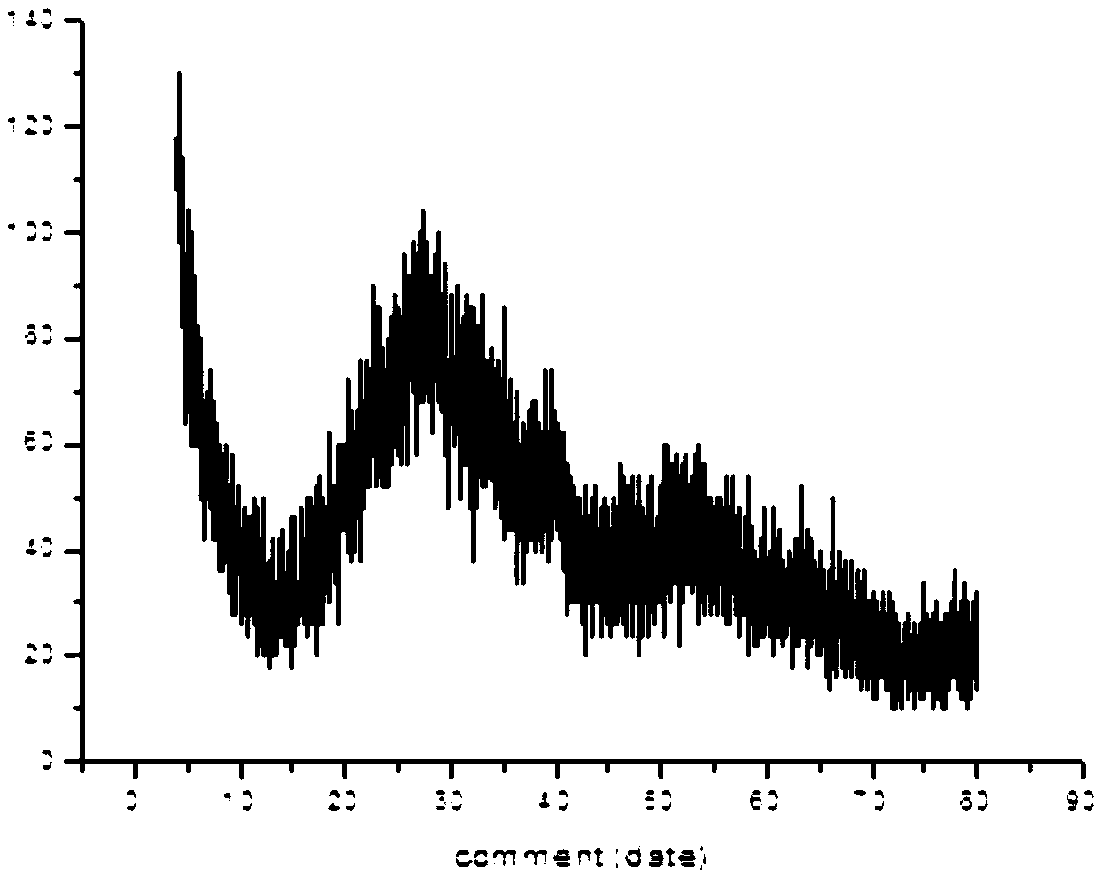

Application Year

Inventor

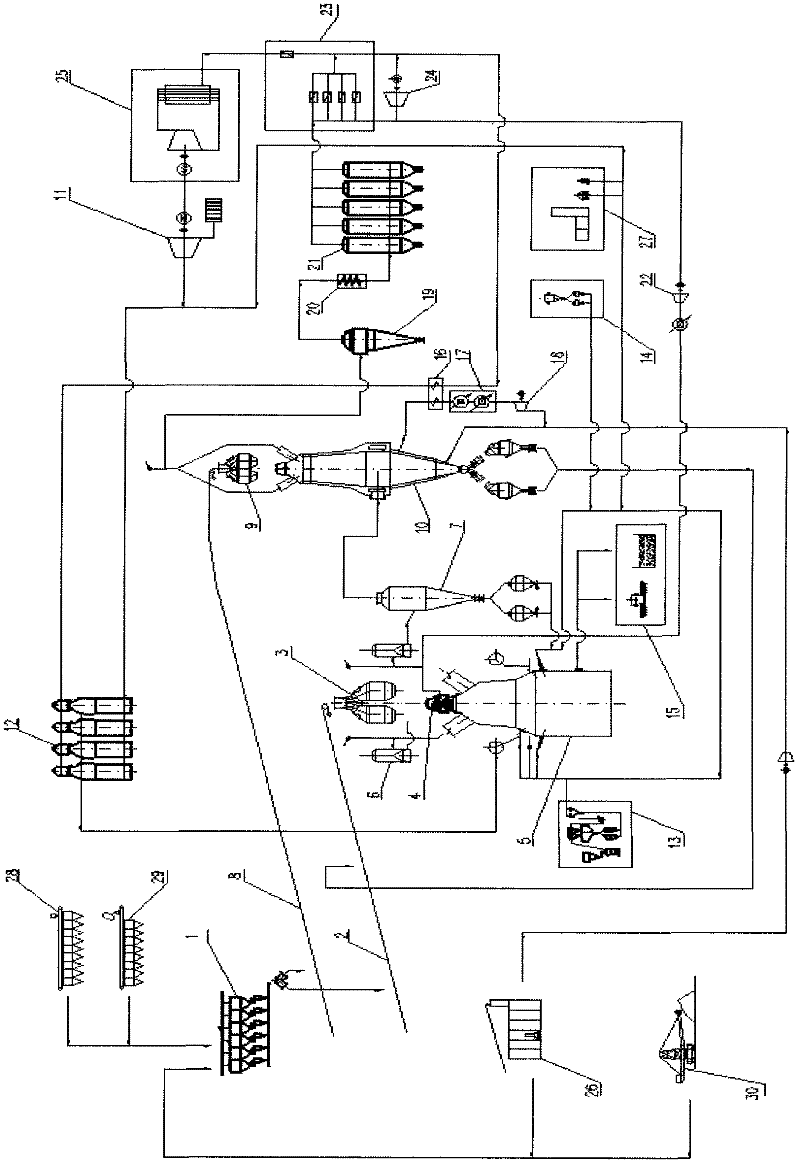

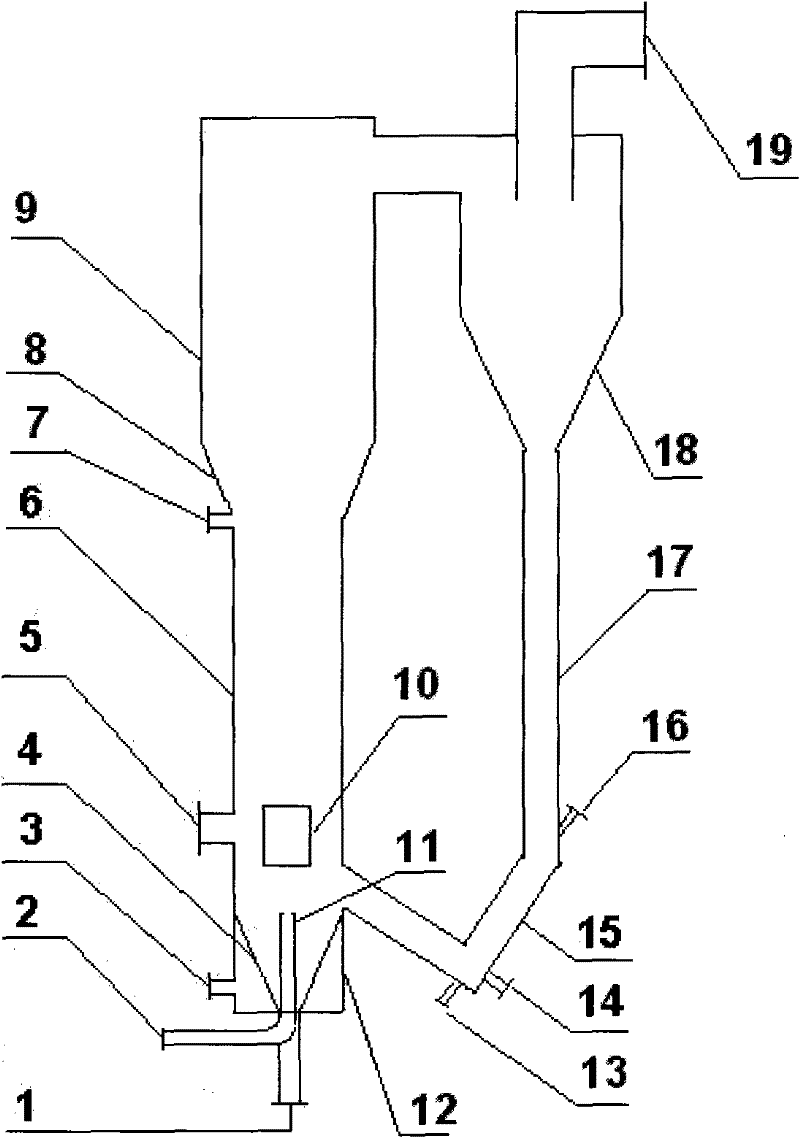

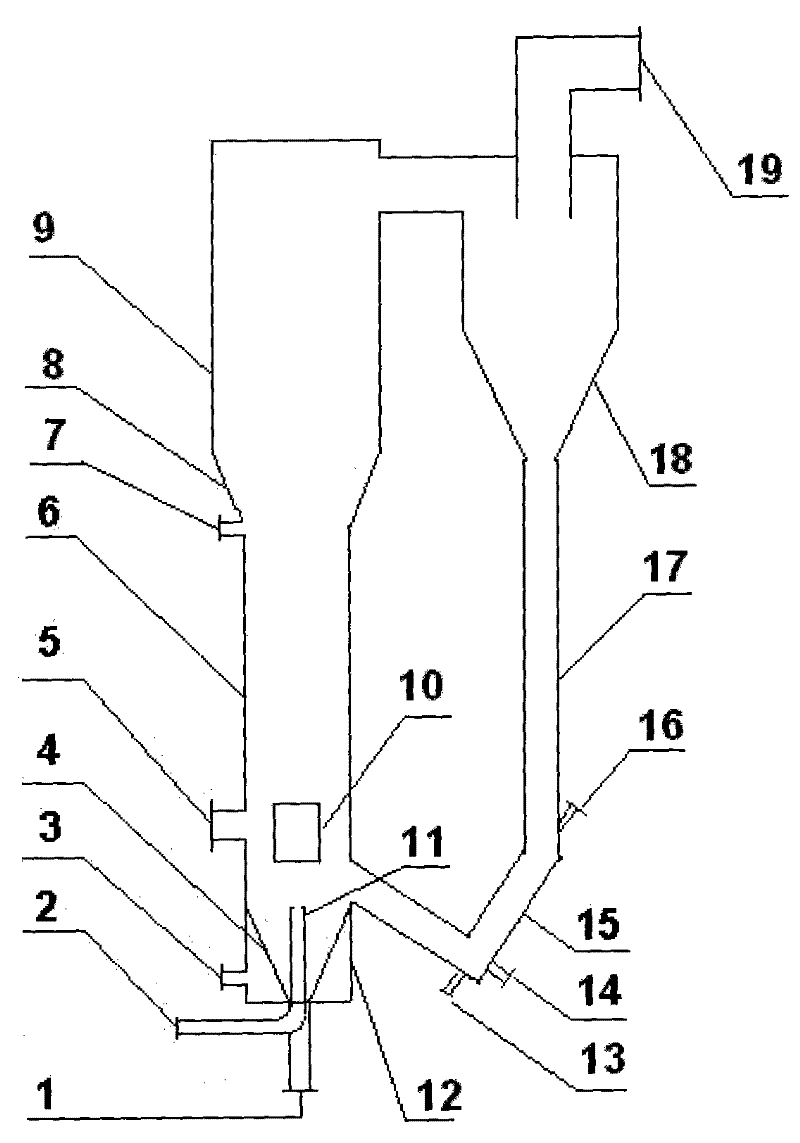

High-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and method

ActiveCN102337369AGood for high pressure operationGood for material level controlShaft furnaceMetallurgyCogeneration

The invention discloses a high-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and a method, which belong to the technical field of melting reduction. The device comprises a raw material system, a furnace top material charging and distributing system, a melting reduction furnace, a furnace top high-temperature gas system, a prereduction furnace, a semicoke gas recycling system, a coal dust preparing and spraying system, a molten iron desulfurizing agent preparing and jetting device, an oxygen and nitrogen supplying system, a residual iron treating system, a high-wind-temperature hot blast furnace, a melting reduction furnace blower, a furnace top gas dedusting and recycling system and a gas cogeneration device. The method comprises the following steps of: introducing high-temperature gas which is generated in a high-wind-temperature rotational flow injection disturbance melting reduction furnace into the prereduction furnace; directly reducing an iron-containing raw material in a solid phase state into a prereduction furnace material with a certain metallization rate; cooling, and then adding the cooled material and semicoke which serve as the furnace material and a fuel respectively into the melting reduction furnace; and finally producing molten iron by reduction. The device and the method have the advantages of high production efficiency and low energy consumption, are easy to operate and make industrialization easily realized.

Owner:BEIJING SHOUGANG INT ENG TECH

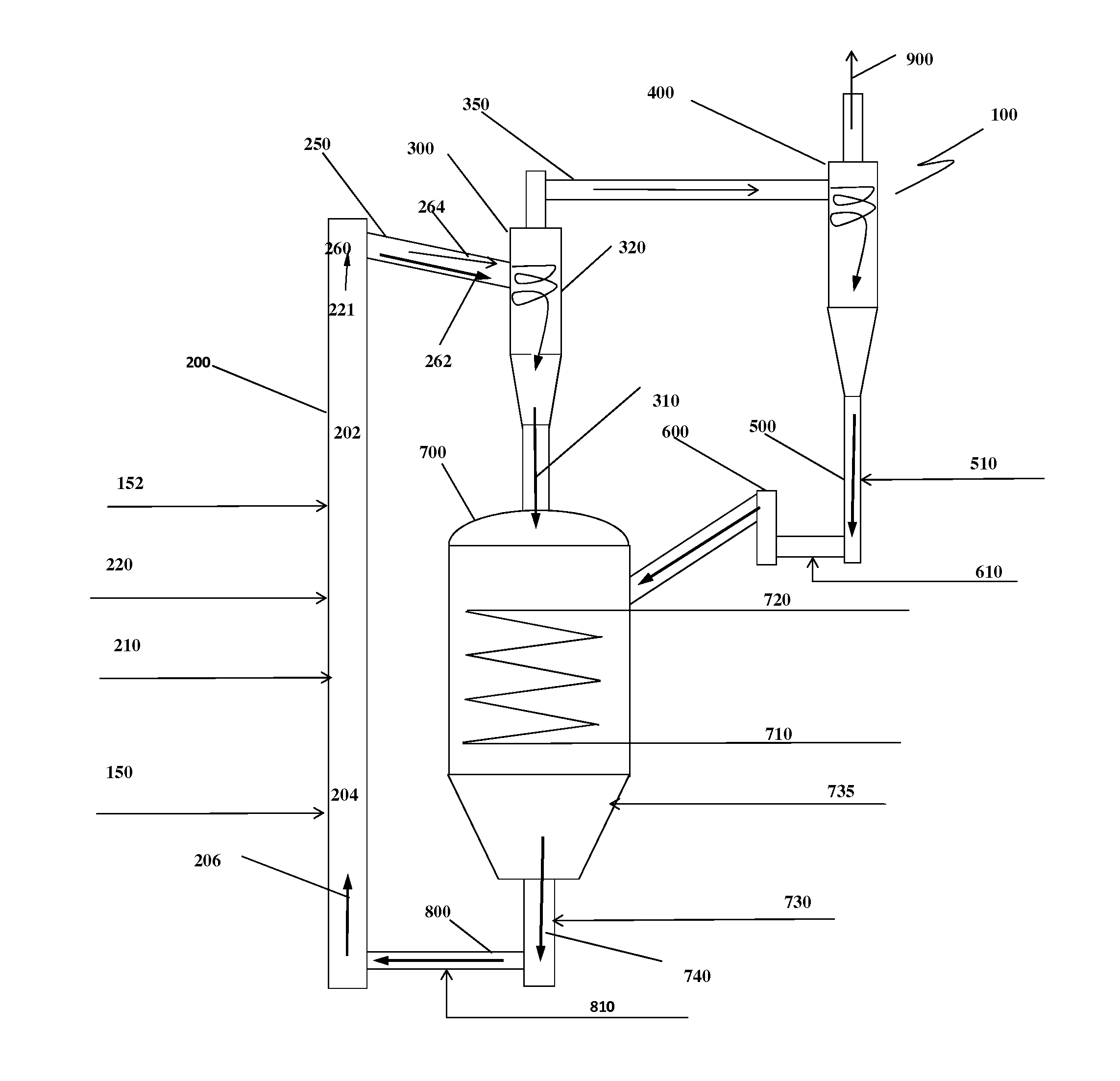

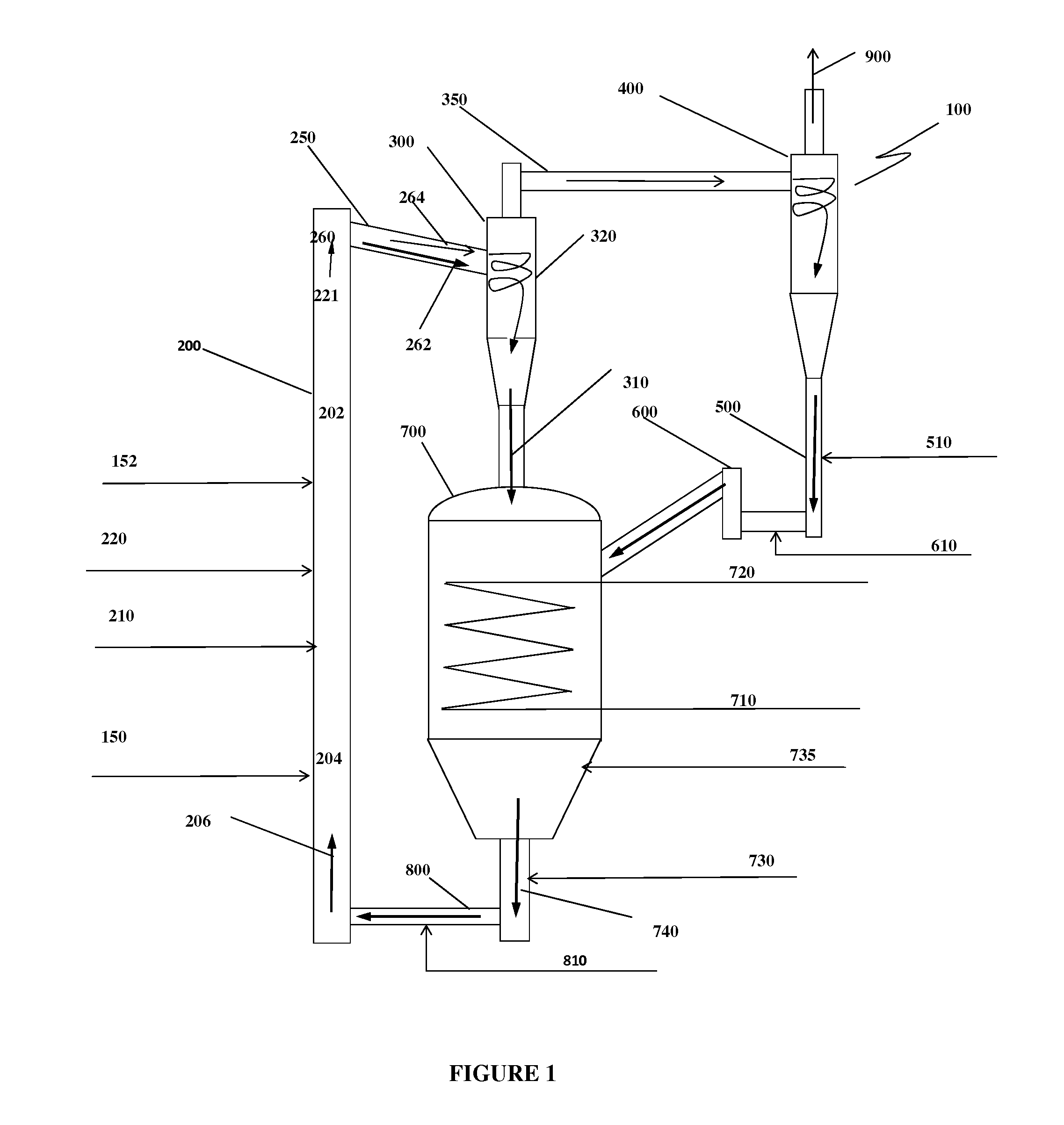

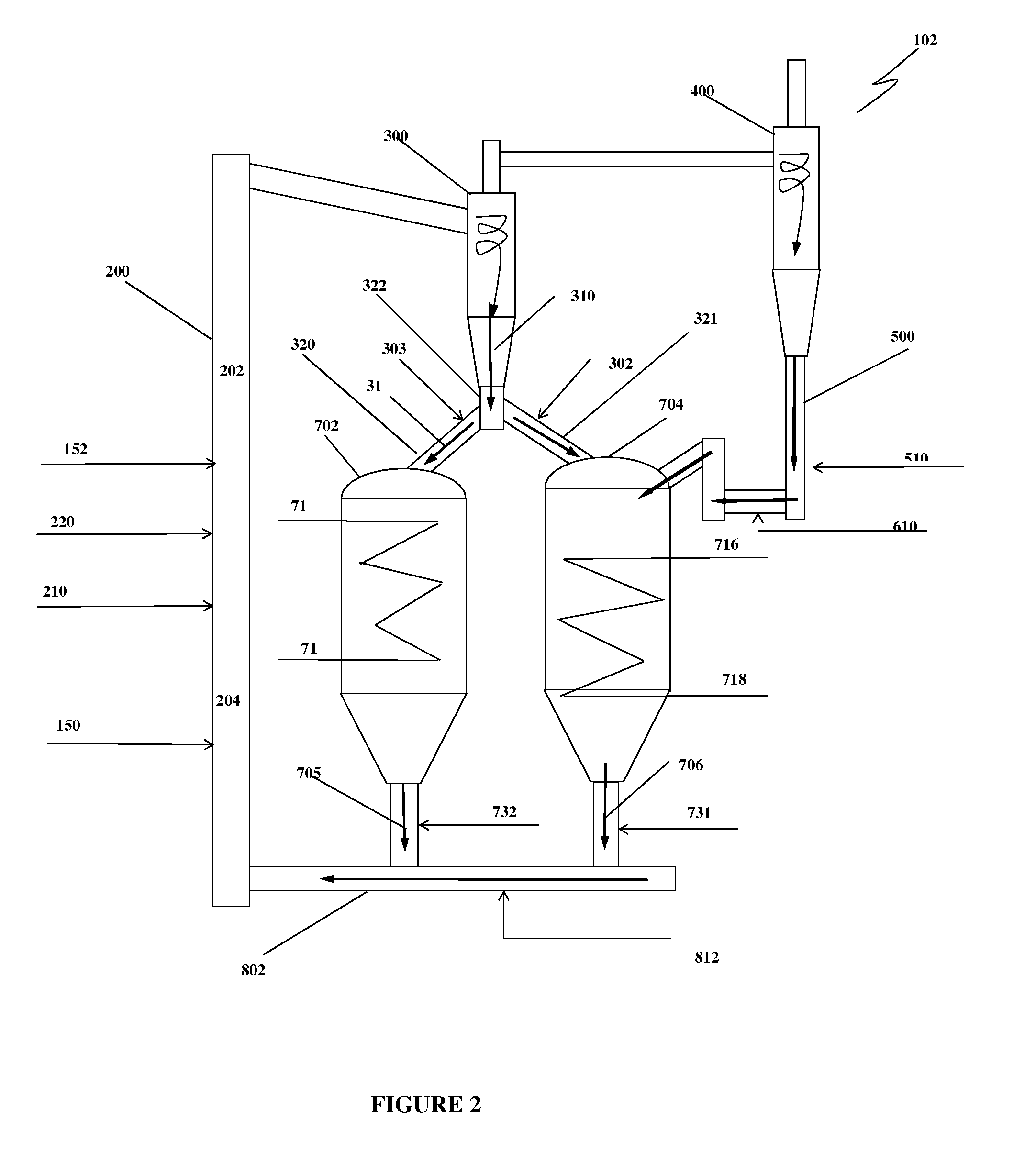

Oxycombustion In Transport Oxy-Combustor

ActiveUS20130055936A1Efficient removalReduce operating costsFluidized bed combustionSteam generation using pressureFlue gasMoisture condensation

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

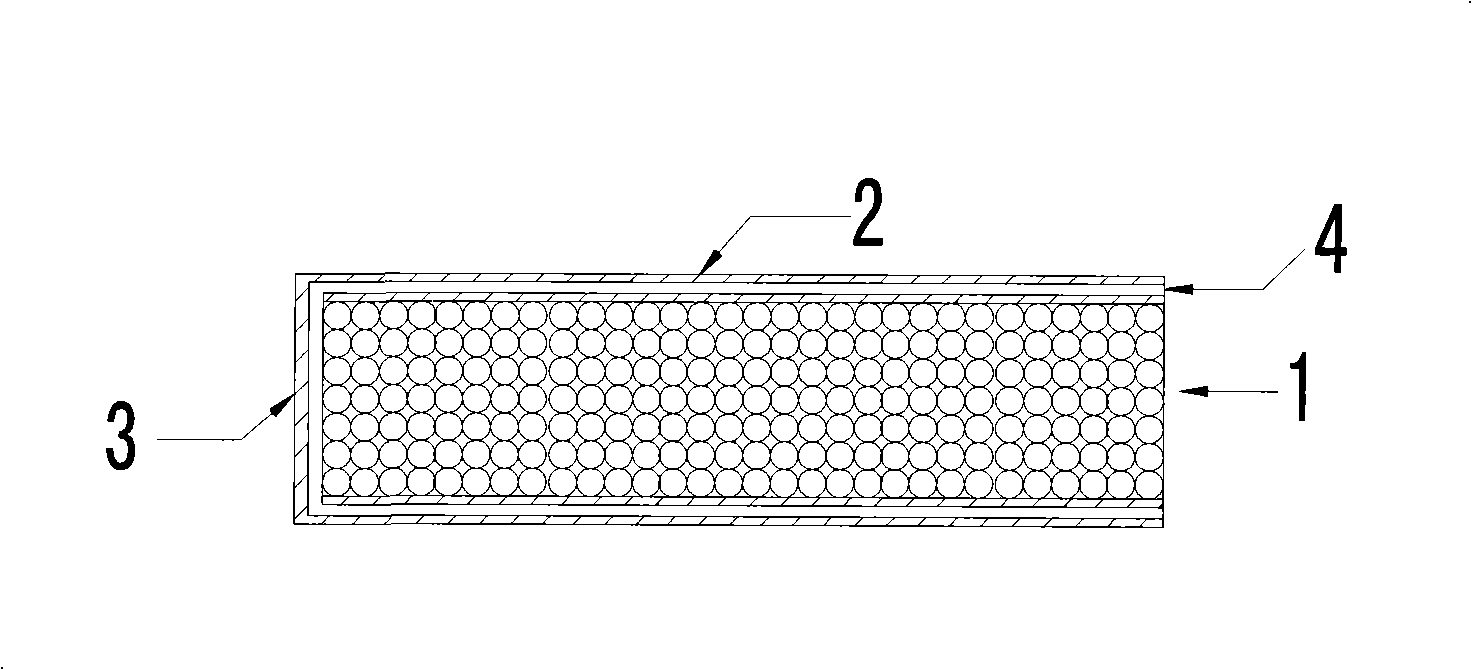

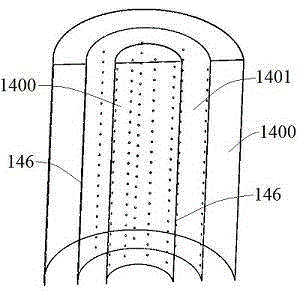

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

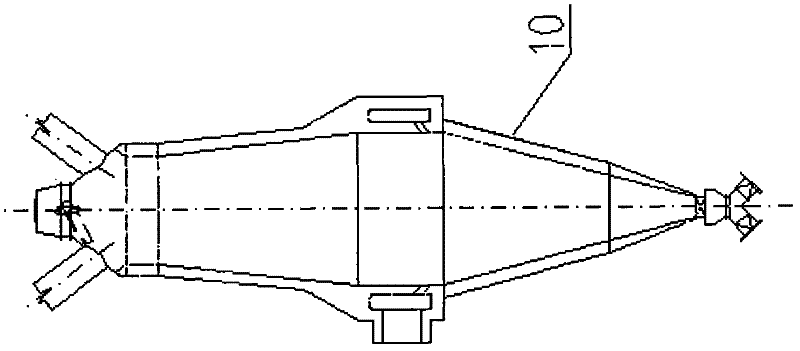

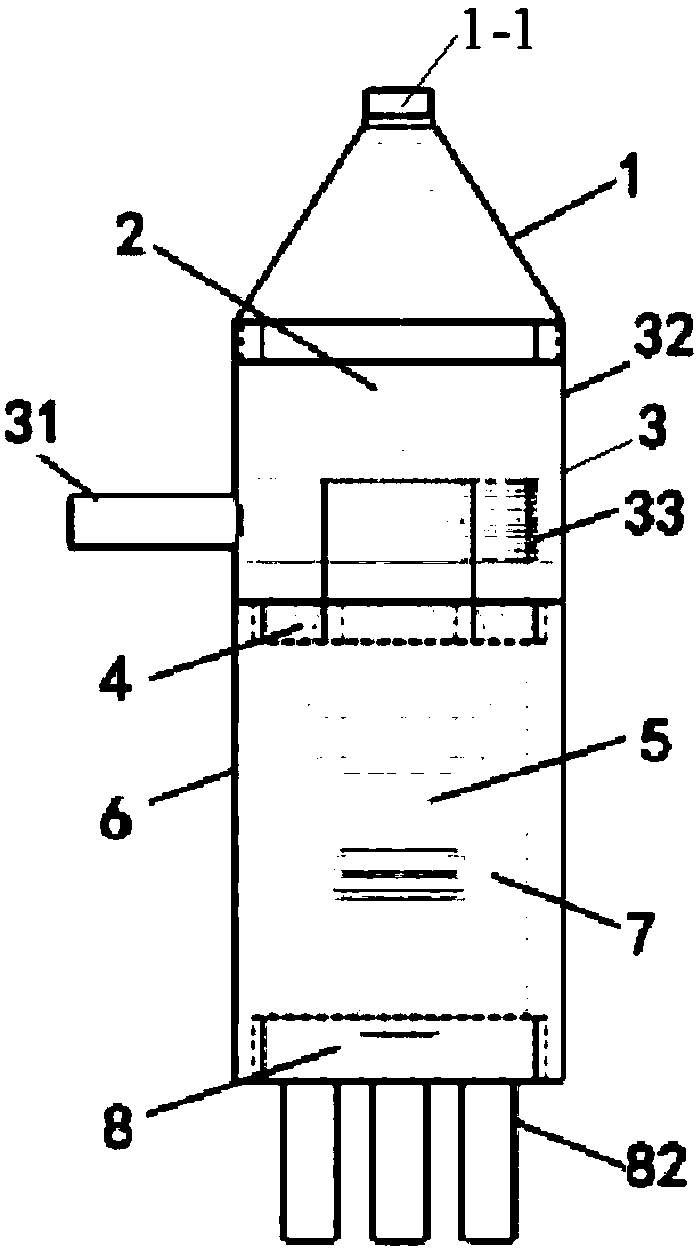

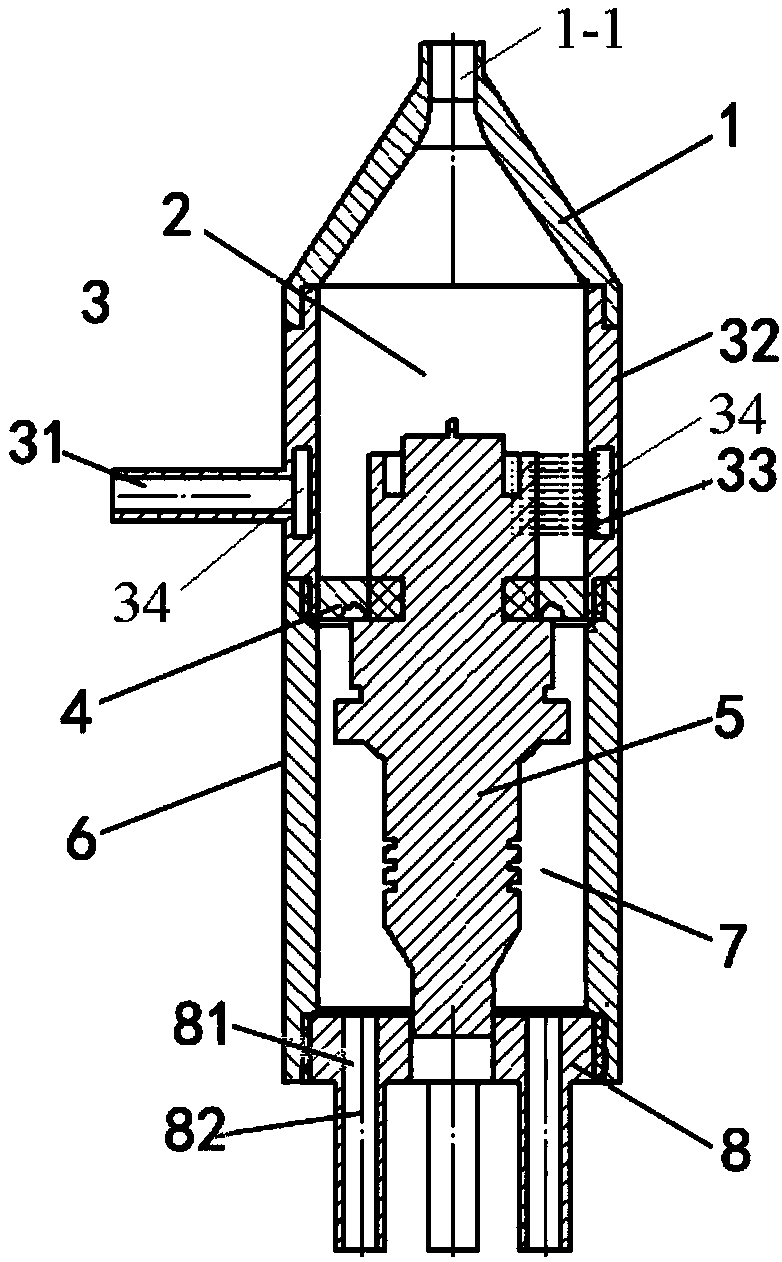

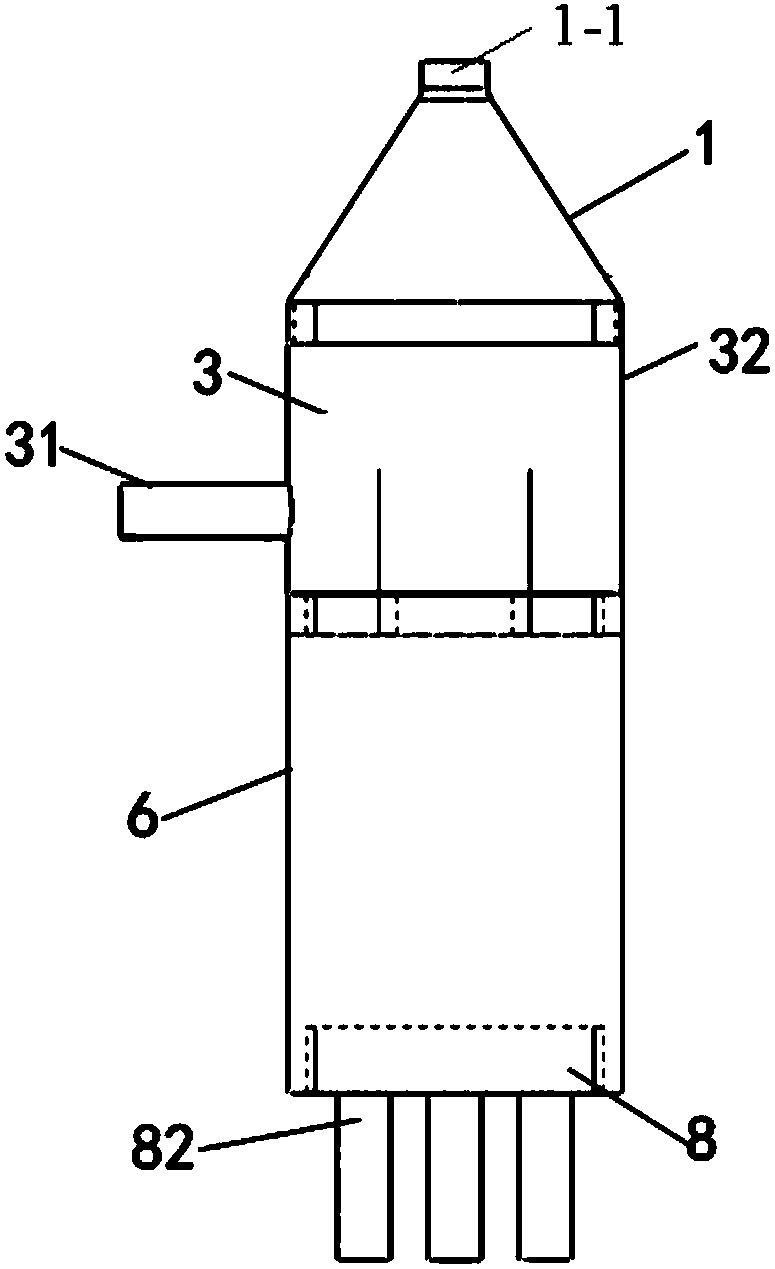

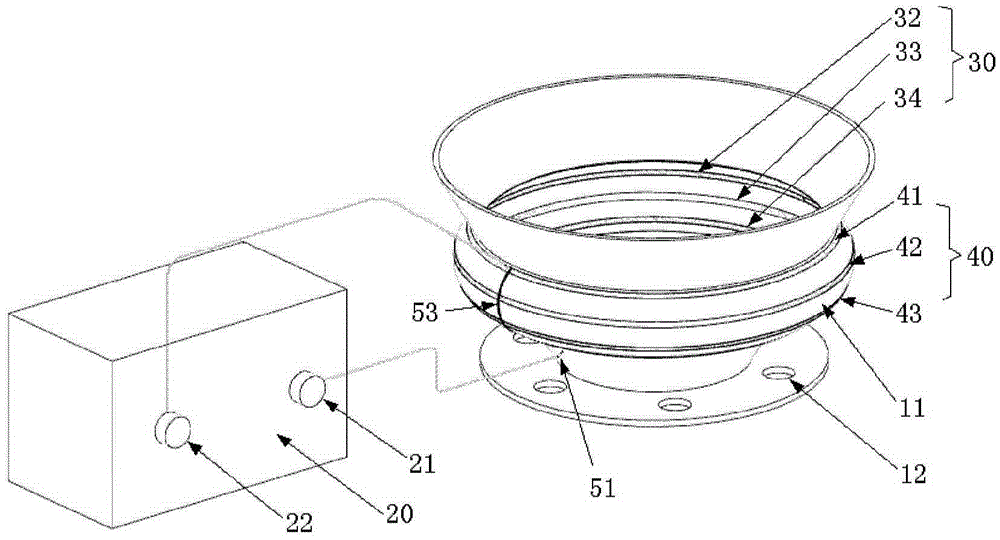

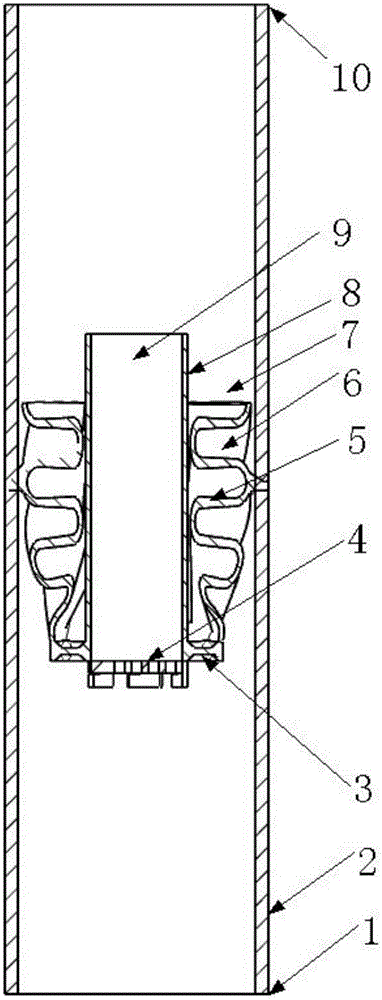

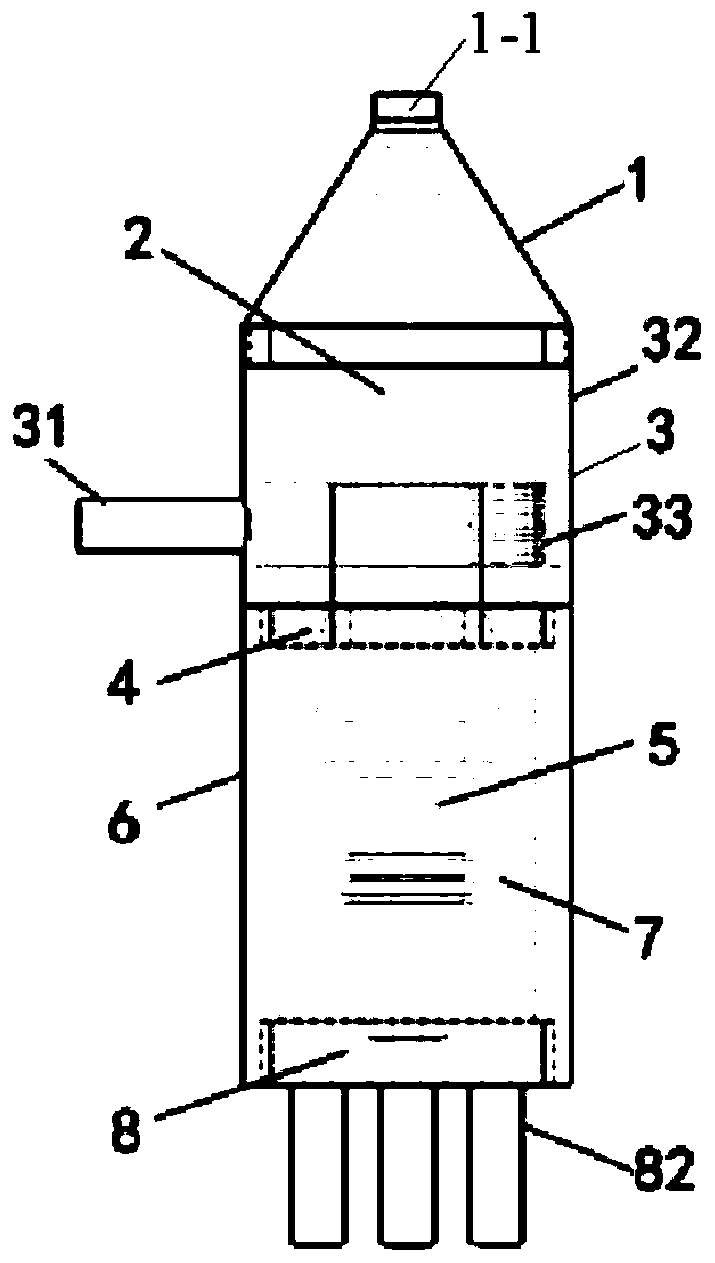

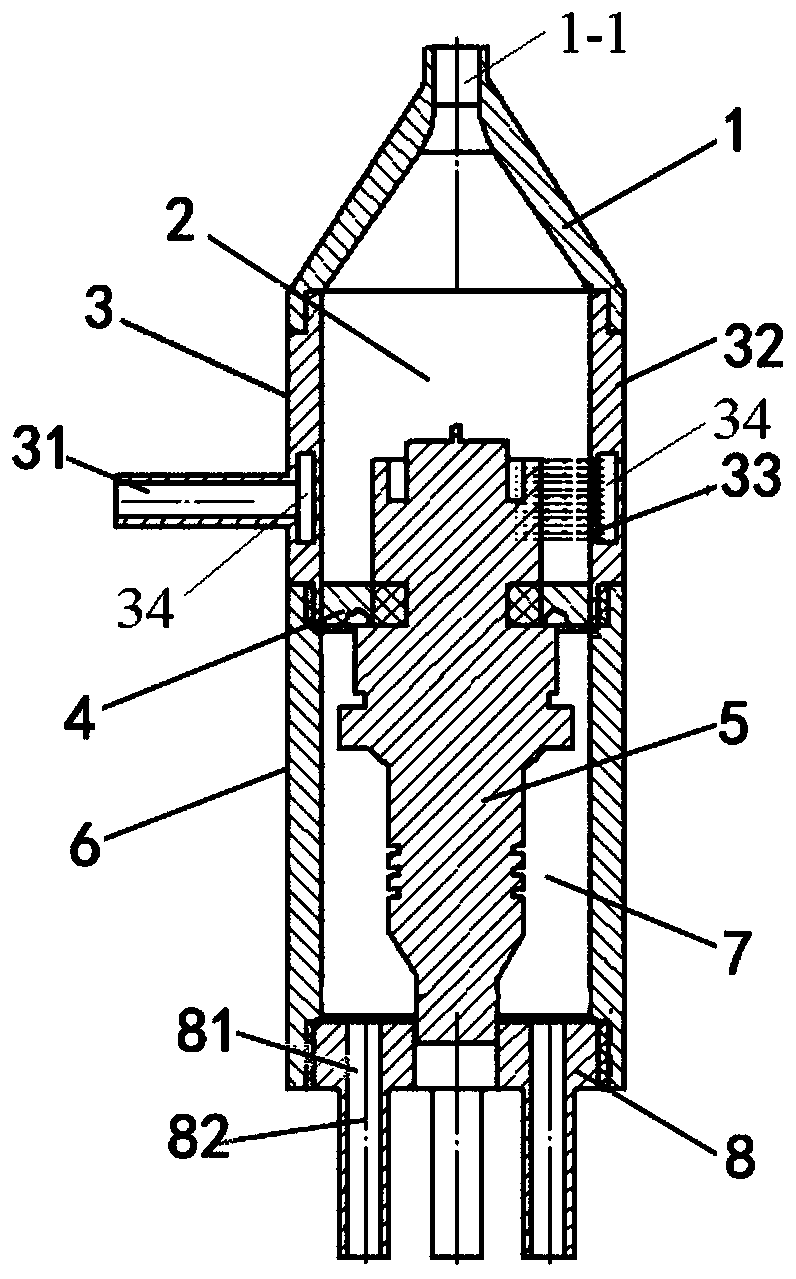

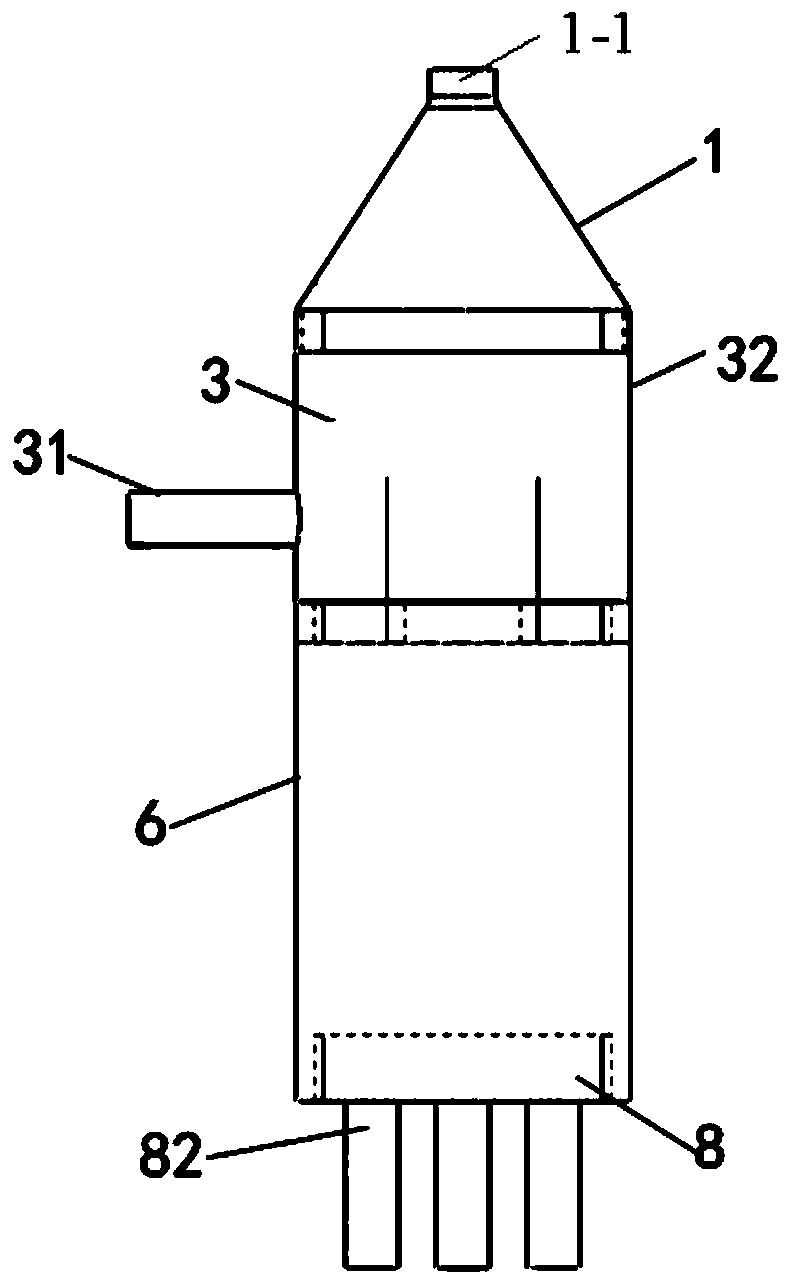

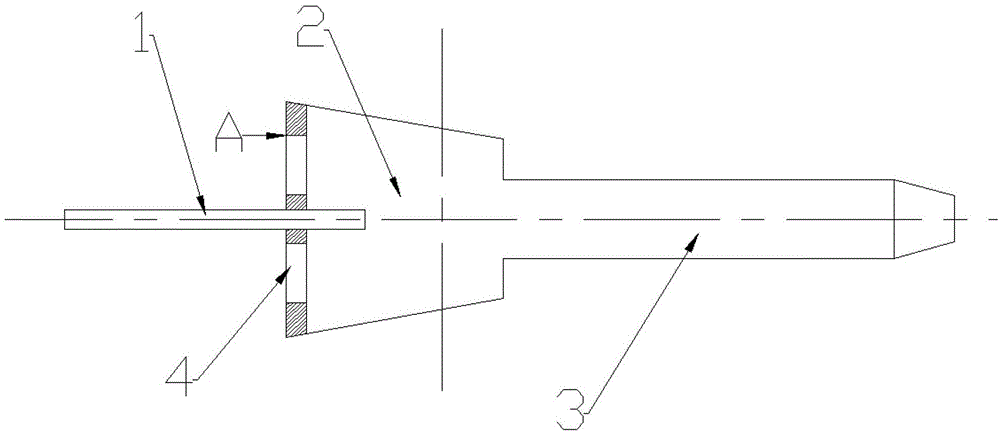

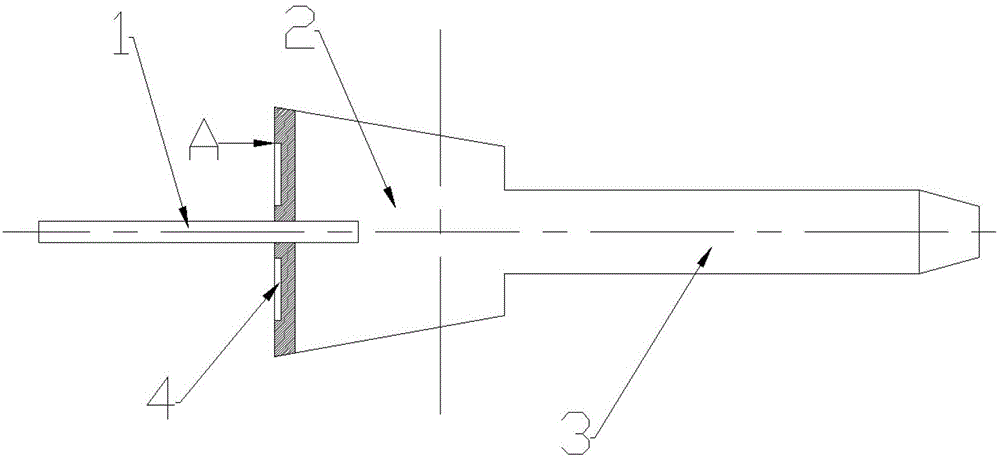

Pre-combustion type plasma igniter and ignition method

ActiveCN107842427AEasy to assembleIncrease production capacityTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

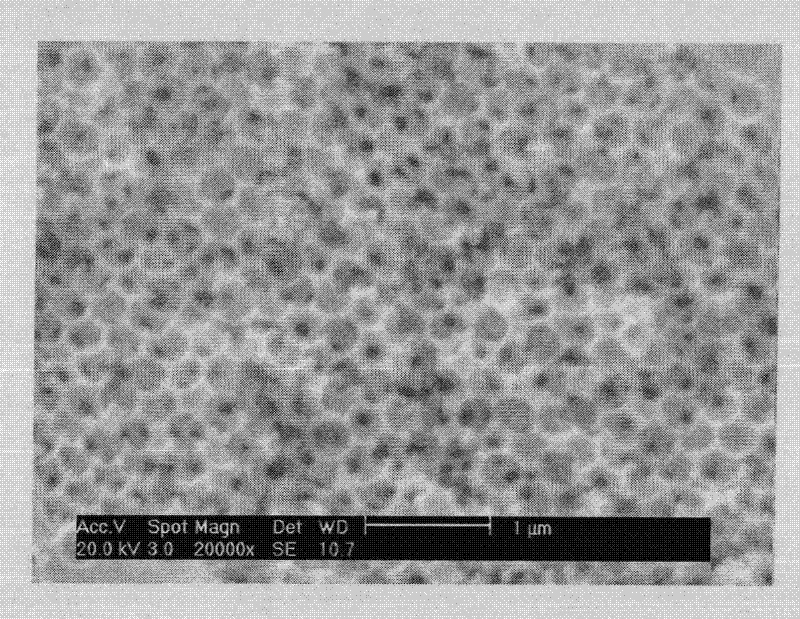

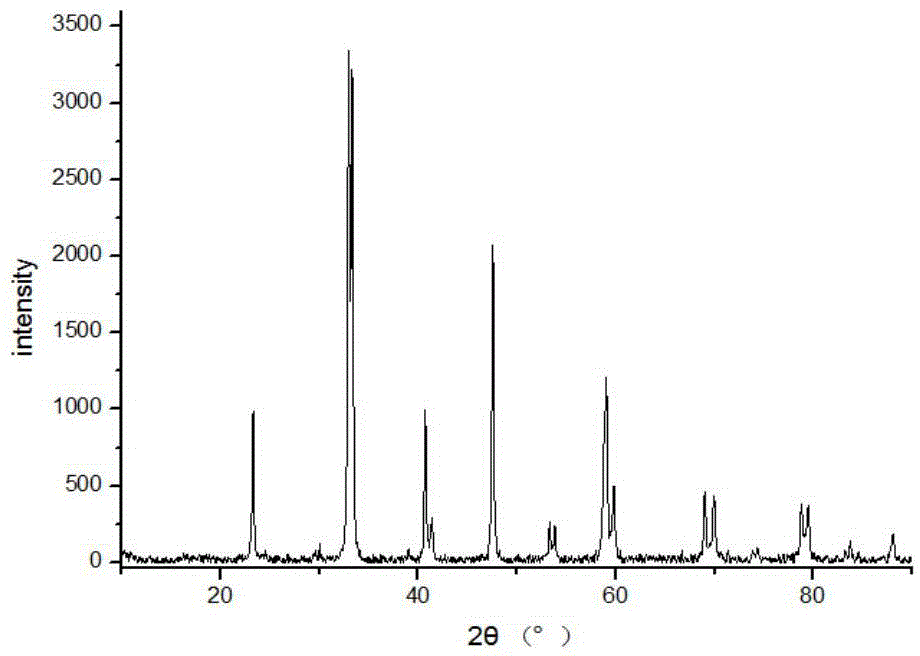

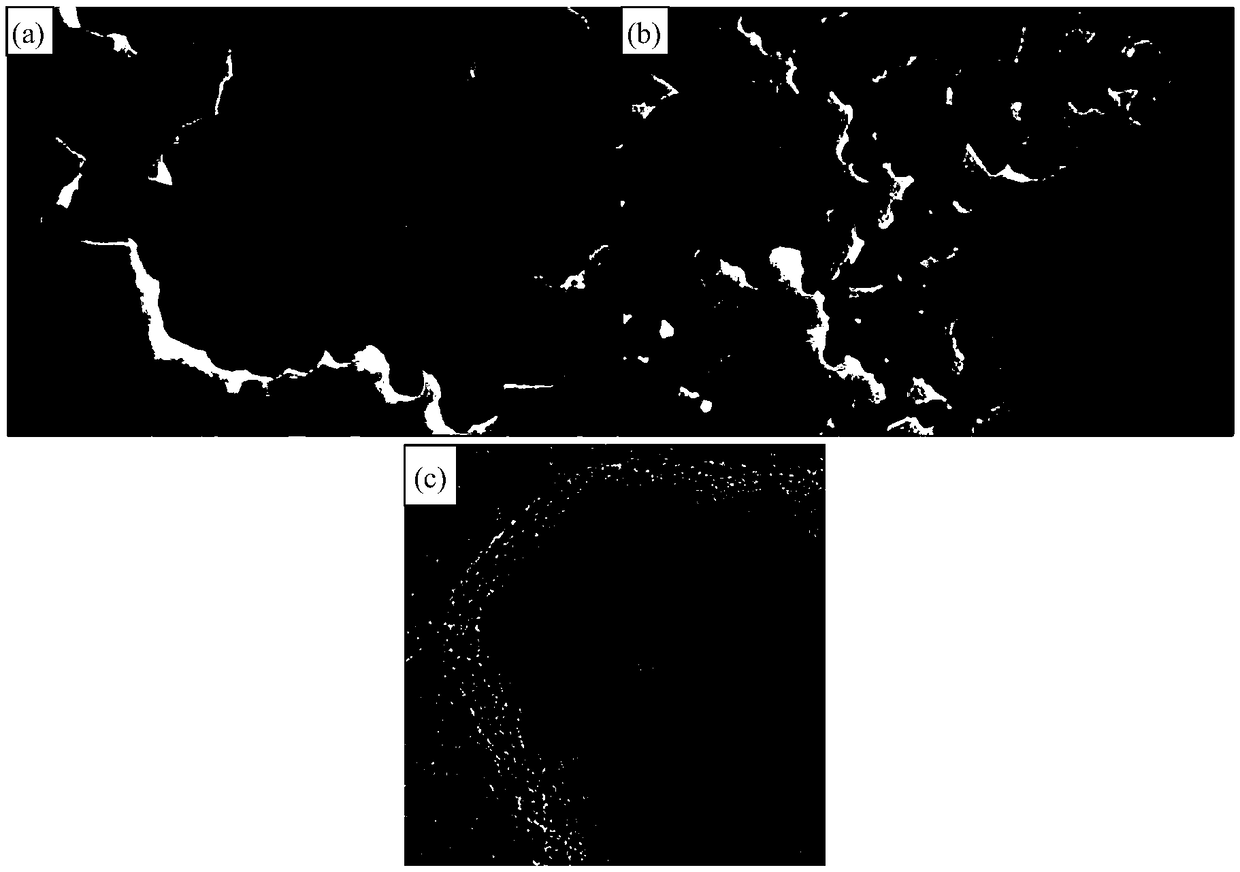

Oxygen carrier of chemical-looping combustion and preparation method and application thereof

ActiveCN102443454AImprove stabilityFacilitated DiffusionFuel additivesActive componentEmulsion polymerization

The invention discloses an oxygen carrier of chemical-looping combustion and preparation method and application thereof; the oxygen carrier uses CeO2 as carrier and Fe2O3 as active component; the weight percentage of the active component Fe2O3 in the oxygen carrier is 5-30%; and the aperture of the oxygen carrier is 500nm-50um. The preparation method of the oxygen carrier comprises the following processes of: preparing template by emulsion polymerization method, preparing the macroporous CeO2 and loading the active component and the like. The oxygen carrier is applied to the chemical-looping combustion, wherein the reaction temperature in the air reactor is 500-1000 DEG C, the reaction temperature of the fuel reactor is 500-1000 DEG C, and the reaction pressure is constant pressure. The oxygen carrier of the invention has three-dimension ordered macroporous structure, uniform distribution of the active component and simple preparation method; and the oxygen carrier in the chemical-looping combustion has the advantages that the lamination of the reaction bed is reduced, the activity of the reaction bed is high and the diffusion effect of the reaction bed is good and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

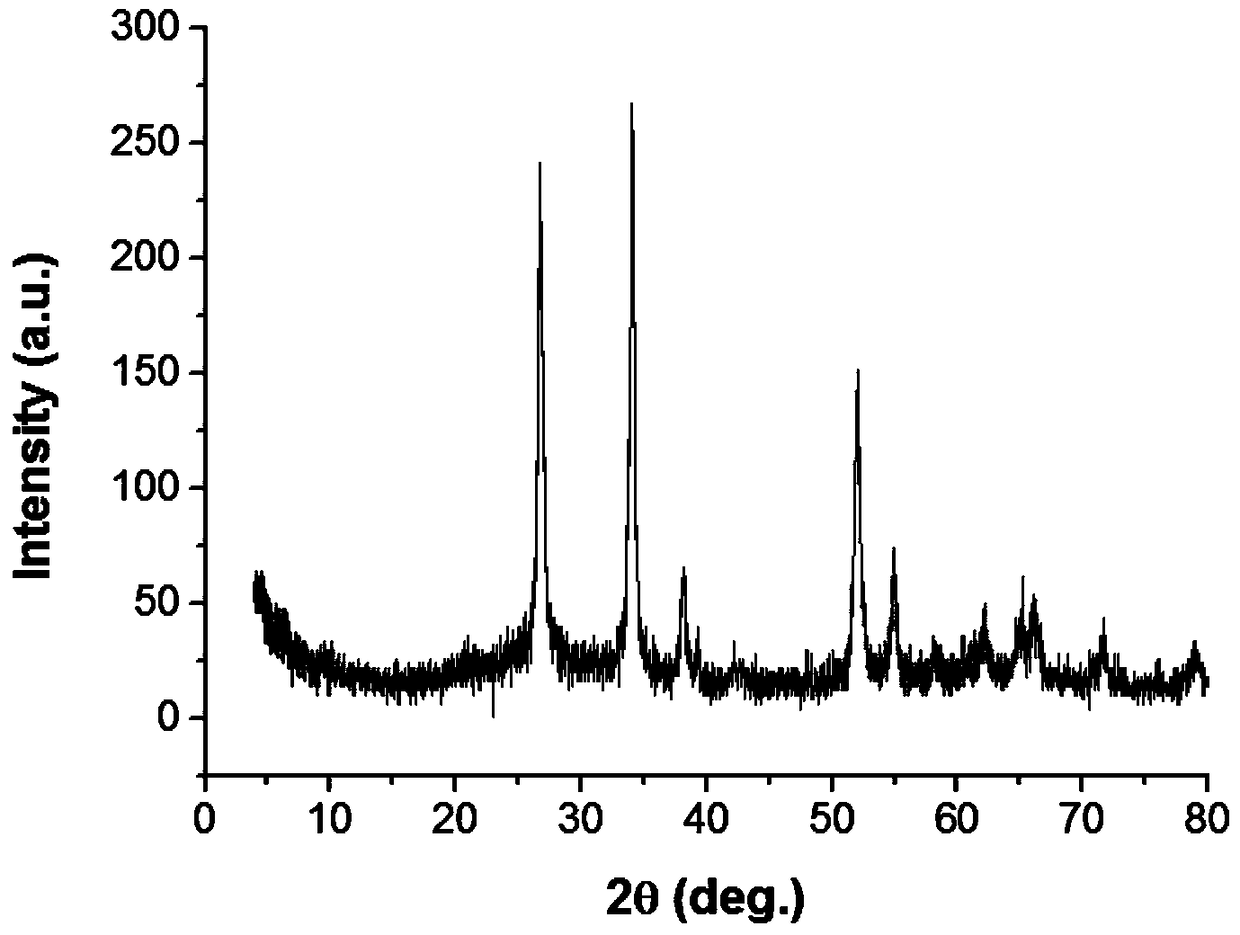

Graphene oxide rare earth compound catalytic material and preparation method thereof

ActiveCN104307530AUnique Surface Interface StructureHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCombustionHydrazine compound

The invention discloses a graphene oxide rare earth compound catalytic material and a preparation method thereof. The catalytic material comprises the following raw materials in percentage by mass: 0.47-1.48% of graphene oxide, 11.71-28.25% of perovskite type rare earth oxide and 70.62-87.82% of an additive. The catalytic material is prepared from graphene oxide, perovskite type rare earth oxide and the additive by using a hydrothermal method; the perovskite type rare earth oxide is ABO3 oxide; the additives are ethanediamine, hydrazine hydrate or urea. The catalyst disclosed by the invention is excellent in methane combustion catalytic activity, the initial combustion temperature is 300 DEG C, complete conversion can be achieved at 405 DEG C, the activity effect is relatively good, the initial combustion temperature is identical, and the complete conversion temperature is reduced by 85 DEG C.

Owner:HEBEI UNIV OF TECH

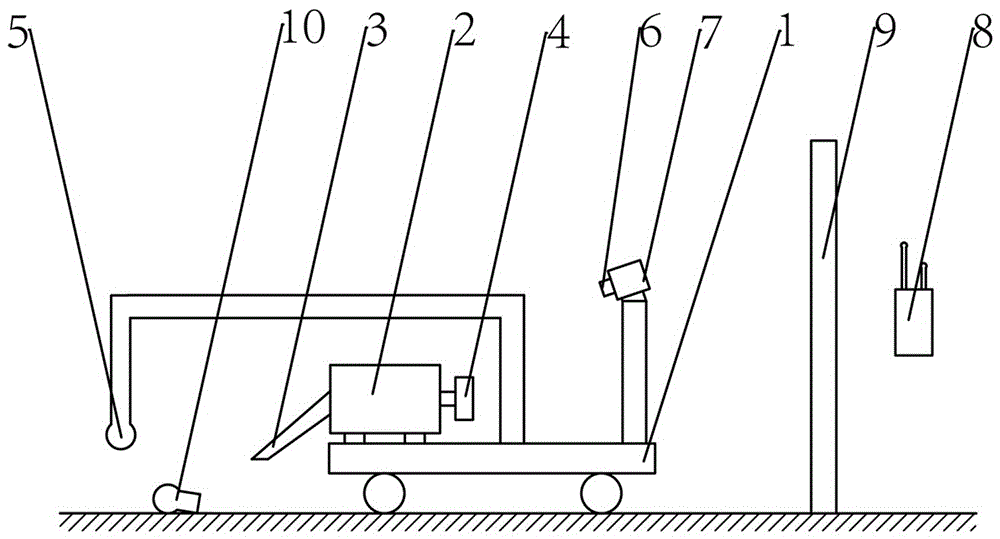

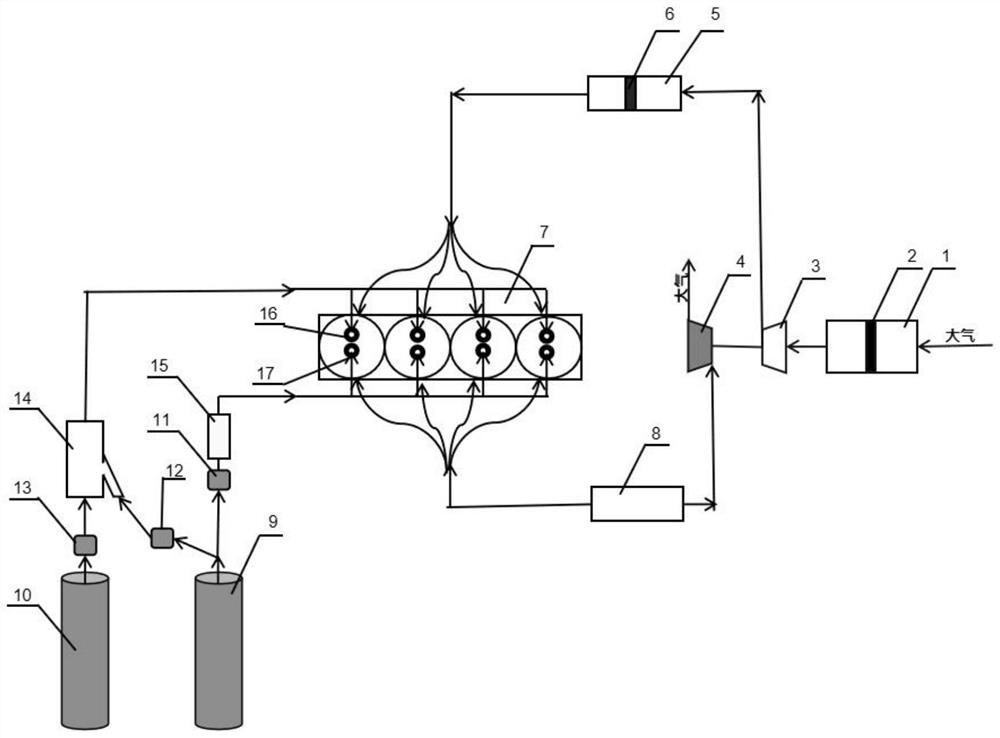

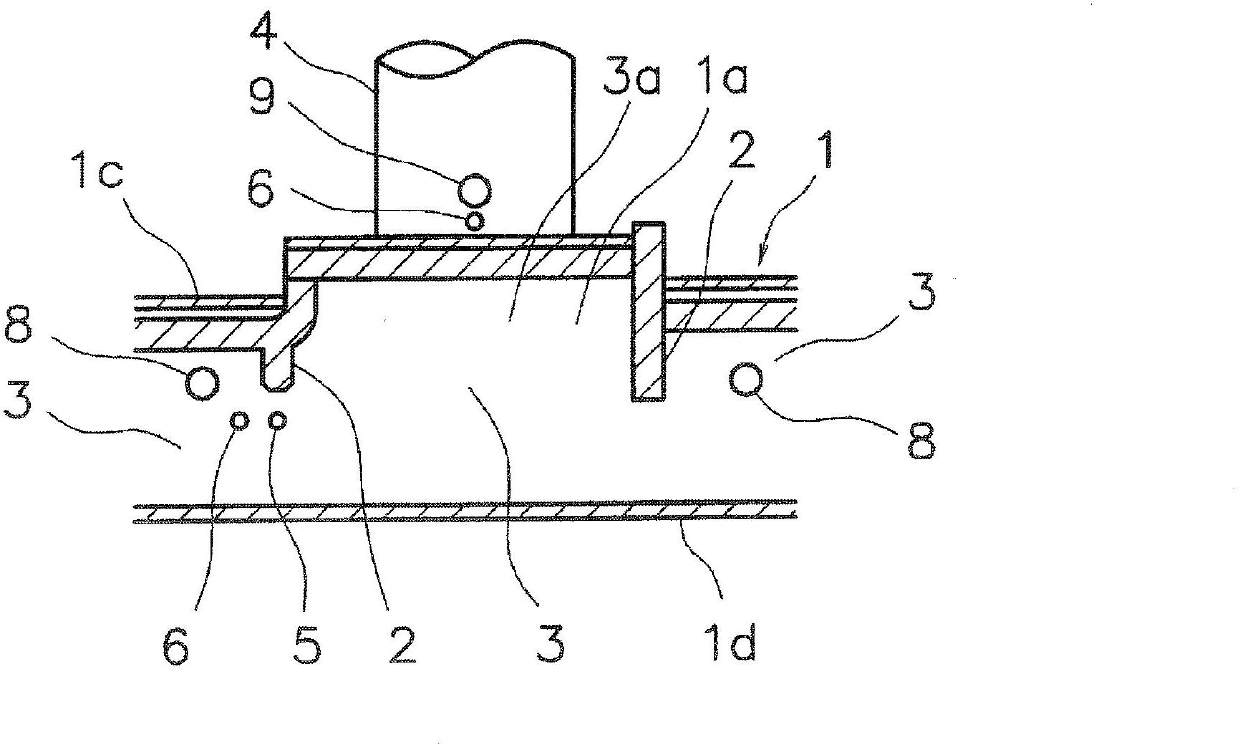

A co-combustion device for biomass and coal circulating fluidized bed controlled by jet flow

ActiveCN102278742AWell mixedFacilitate the combustion reactionFluidized bed combustionIndirect carbon-dioxide mitigationCombustionFluidized bed

A biomass and coal composite burner is composed of a fluidized bed (7), a biomass jet inlet pipe (2), an oxygen-rich air inlet (3), a gas distributor (4), a feed coal inlet (5), a fluidized bed heat conduction pipe (6), a heat exchanger (9), a heat exchanger heat conduction pipe (10), a cyclone separator (8), an ash outlet (1), an oxygen-poor air outlet (11) and an ash discharge outlet (12), and is characterized in that the bottom of the fluidized bed (7) is equipped with the ash outlet (1), the jet inlet pipe (2) and the gas distributor (4), the lower portion is equipped with the heat conduction pipe (6), the side surface is provided with the feed coal inlet (5), and the upper portion is equipped with the cyclone separator (8); the bottom of the heat exchanger (9) is provided with the ash discharge outlet (12), the lower portion is equipped with the oxygen-poor air outlet (11), and the heat conduction pipe (10) is disposed inside heat exchanger. After biomass is transferred by oxygen-rich air into the fluidized bed (7), biomass and coal are rapidly mixed under the action of jet and then combust, thus greatly minimizing the generation of biomass tar.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

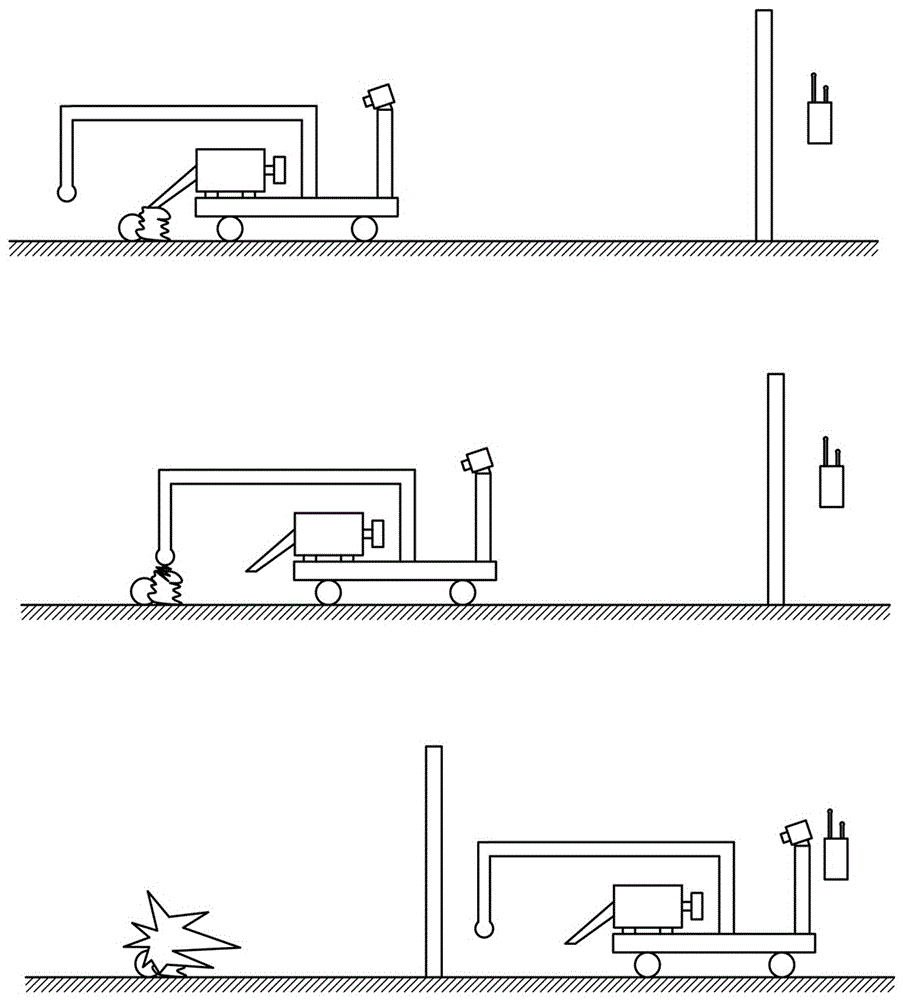

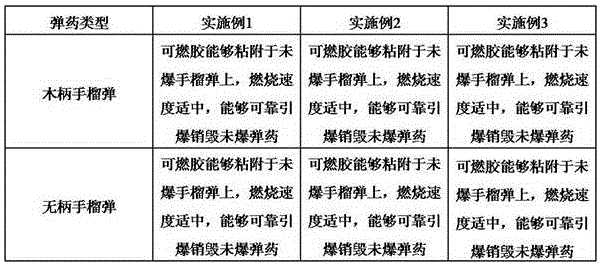

Combustible glue used for destroying unexploded ordnance and preparation method and application thereof

The invention provides combustible glue used for destroying unexploded ordnance and a preparation method and application thereof. The combustible glue is prepared through the following steps that Al powder and Fe3O4 powder are evenly mixed to obtain Al / Fe3O4 mixed powder; lac is dissolved in absolute ethyl alcohol to obtain a lac absolute ethyl alcohol solution with the mass concentration being 5%-6%; the Al / Fe3O4 mixed powder is added into the lac absolute ethyl alcohol solution, and the Al / Fe3O4 mixed powder and the absolute ethyl alcohol solution are stirred to be evenly mixed; glass fiber powder is added and stirred to be evenly mixed; and expandable graphite is added and stirred to be evenly mixed to obtain the combustible glue. The mass ratio of the Al powder to the Fe3O4 powder is 7-8 to 15. The massic volume ratio of the Al / Fe3O4 mixed powder to the lac absolute ethyl alcohol solution is 1g to 2-3 mL. The adding amount of the glass fiber powder is 1%-3% of the Al / Fe3O4 mixed powder by mass. The adding amount of the expandable graphite is 1%-3% of the Al / Fe3O4 mixed powder by mass. The combustible glue is low in combustion speed, large in combustion heat output and long in combustion duration, and can heat explosives in the unexploded ordnance once being ignited, and it can be ensured that the explosives in the unexploded ordnance are reliably detonated.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

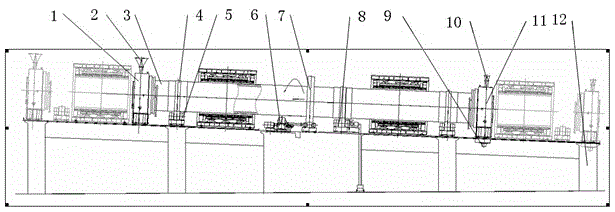

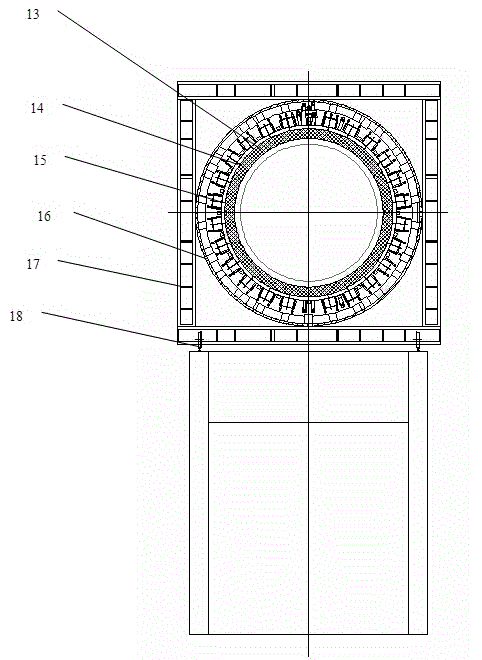

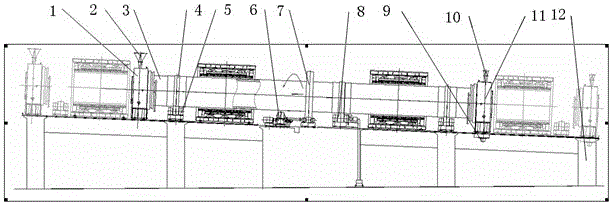

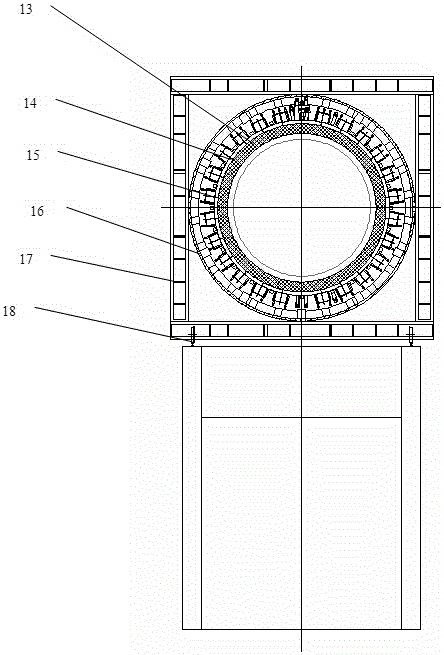

Energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with size of phi 2000*18 meters

ActiveCN104880059ASimplify fuel procurement transportation and security managementAvoid polluting the environmentRotary drum furnacesAutomatic controlElectromagnetic induction

The invention relates to an energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with the size of phi 2000*18 meters. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln comprises a kiln head cover, a mercury ore feeding hopper, a high-temperature alloy steel inner container kiln barrel, a wheel belt, a movable carrier wheel group, a transmission device, a gear pair, a fixed carrier wheel group, a track and cement piles. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the advantages that the energy is clean, and the problems that a mercury metallurgy rotary kiln roasted by a coal furnace is low in production efficiency, severe in environmental pollution, high in energy consumption and the like is solved. The energy is used and distributed conveniently. Compared with a mode of heating by fuel, gas and the like, the heating mode of the energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the characteristics that heat efficiency is high, sensible heat is not taken out by smoke or ash, and a kiln body is simple and compact in structure, small in heat dissipation area, low in heat dissipation loss, easy to control and regulate automatically and high in kiln temperature control precision, and meets requirements of a narrow calcining temperature process. The production efficiency is high, energy consumption is reduced, and emission of environmental pollutants is reduced. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln is an innovation of energy conservation, environmental protection and an equipment technology of a mercury metallurgy kiln.

Owner:朱兴发

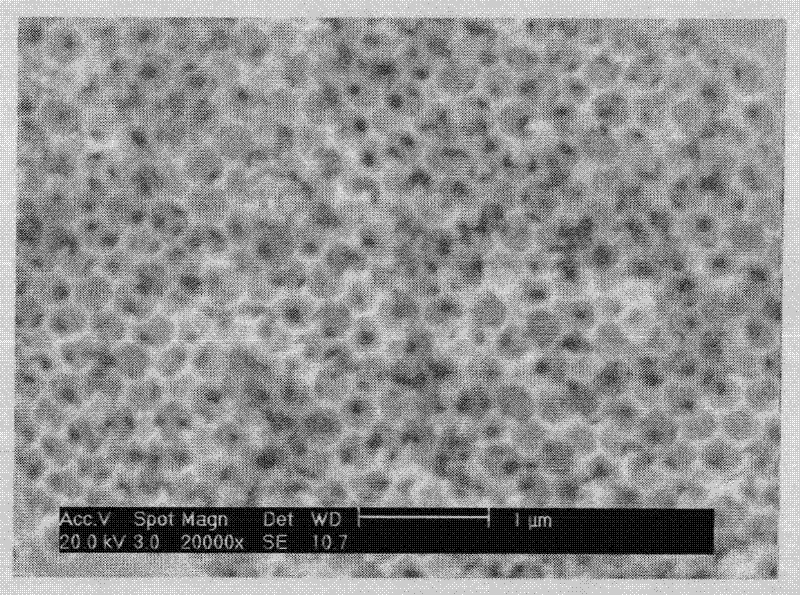

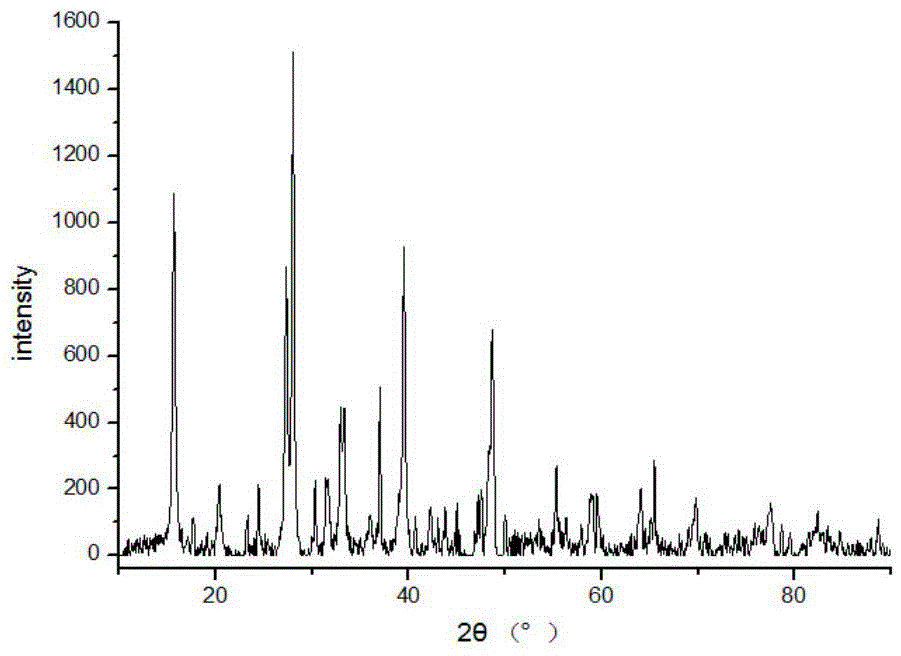

Oxygen carrier, preparation method therefor, and applications thereof

ActiveCN103374431AFacilitated DiffusionSmall pressure dropHydrogen productionFuel additivesActive componentHigh activity

The invention discloses an oxygen carrier. The oxygen carrier employs CeO2-Al2O3 as a carrier and NiO as an active component. CeO2 is coated on the surface of Al2O3 in the carrier CeO2-Al2O3. CeO2 weighs 10-50% of the total weight of the carrier, the preference being 20-40%. According to the final weight content of the oxygen carrier, the content of the active component NiO in the oxygen carrier is 1-20%, the preference being 1-10%. The oxygen carrier has a pore size of 10-100 nm. The oxygen carrier is advantaged by mesoporous structure, and small particle size and homodisperse of the active component. The oxygen carrier has advantages of high activity, good stability and the like during chemical looping combustion and hydrogen production.

Owner:CHINA PETROLEUM & CHEM CORP +1

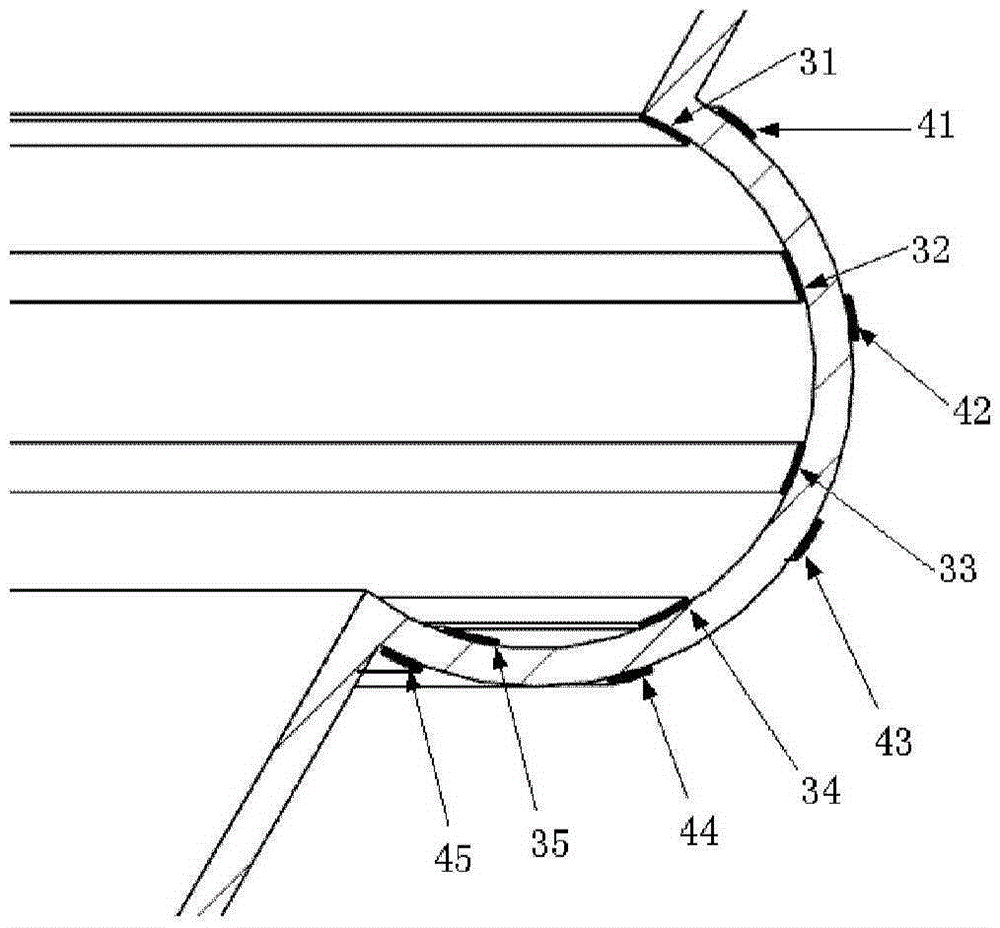

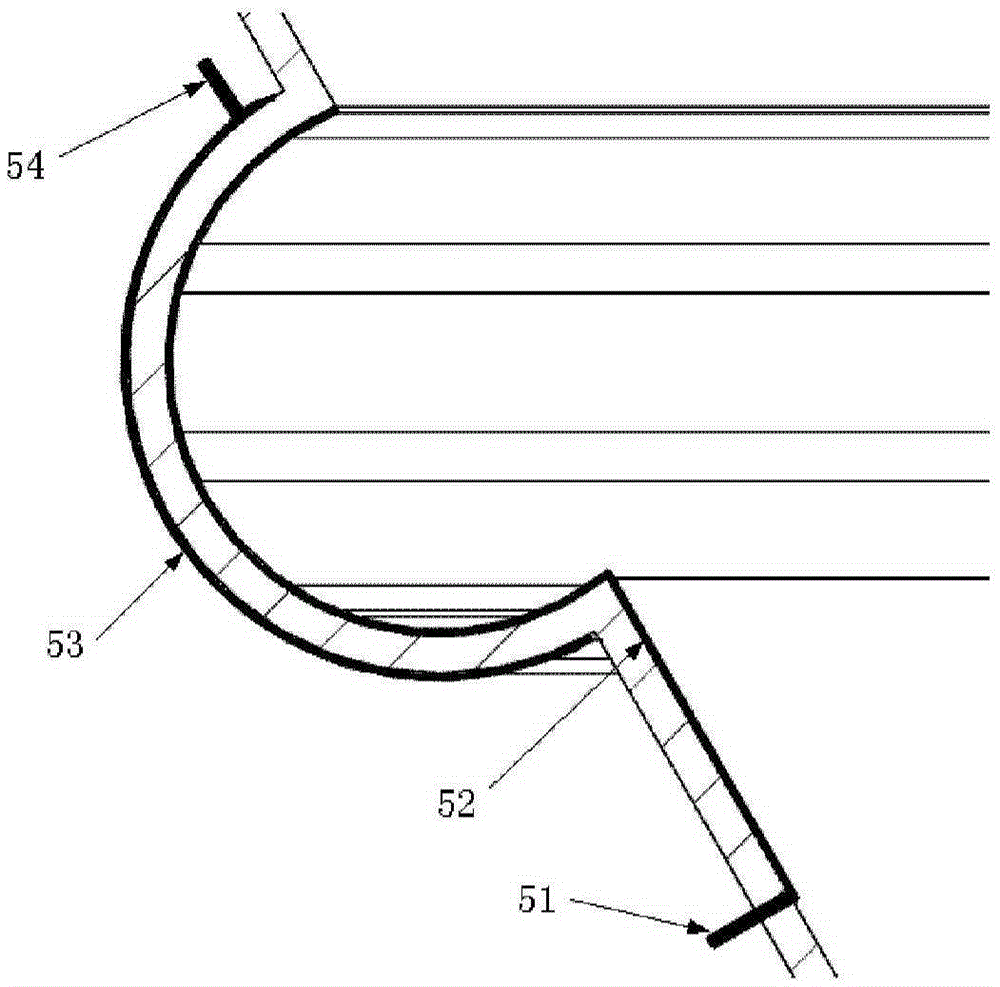

Burner outlet expansion section and burner adopting same

The invention discloses a burner outlet expansion section. A concave cavity is formed in the burner outlet expansion section, a plurality of sets of plasma exciters are arranged in the concave cavity, and plasma can heat fluid, produce active particles, induce flowing and enhance the swirling motion in the concave cavity, and thus fluid mixing in a burning zone can be facilitated, the burning state is improved, the burning stability is enhanced, and the flame length is shortened. The invention also discloses a burner adopting the burner outlet expansion section. According to the burner outlet expansion section, the effects that the stable operation range of the burner is broadened, the burning efficiency is improved and the axial size of a burning chamber is reduced are achieved; the problem of unstable burning of large-angle expansion sections is solved, and the problem of unstable burning caused by burning low-heat value fuel can also be solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Biodiesel with higher water content rate and its use

InactiveCN1891793AReduce manufacturing costFull use of oxygen enrichmentBiofuelsLiquid carbonaceous fuelsManufacturing cost reductionBiodiesel

The invention relates to biological diesel oil with high water content and its application. It belongs to liquid fuel technical field. The constituent weight percentages of the biological diesel oil are follows: fatty acid monoester 75-98%, water 1-20%, and emulsifier 0.1-5% whose hydrophilic oleophilic equilibrium value HLB is 1.0-8.0. And its features at room temperature are that its density is 0.80-0.96g / cm3; viscosity is 1.0-10.0 mm2 / s; heat value is 32.00-42.00MJ / Kg; solution surface tension is 1.0*10-2-8.0*10-2N / m; and dripping diameter is 0.001-10.00um. The invention offers the emulsifying biological diesel oil with high water content which has storage stability. And it can simplify removing water technology, reduce manufacturing cost, and improve the burning performance of the biological diesel oil.

Owner:NANCHANG UNIV

Mixed combustion device and combustion equipment utilizing same

InactiveCN105276583AExtended service lifeReduce volumeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFirewoodSolid fuel

The invention discloses a mixed combustion device and combustion equipment utilizing same, and belongs to the technical field of combustion equipment. The mixed combustion device comprises a to-be-sprayed medium channel and a mixed combustion channel, wherein a reaction space wall for spacing the to-be-sprayed medium and the mixed combustion channel is provided with an orifice; and a combustion medium is sprayed from the to-be-sprayed medium channel to the mixed combustion channel through the orifice. From a combustion initial end of the mixed combustion channel to a combustion exhaustion end of the mixed combustion channel, combustion conditions are optimized along with progress of a combustion process; and different matching proportions of the to-be-sprayed medium are realized according to needs of different combustion stages, mixing uniformity of different media is realized to the greatest extent to facilitate combustion. The mixed combustion device is suitable for combustion of gas fuels, can be applied to combustion of liquid and solid fuels, and is especially suitable for combustion of fuels such as natural gas, coal gas, biogas, biomass cracking fuel gas, fuel oil, methanol, pulverized coal, biomass micro powder, straws, firewood, biomass forming fuels, block-shaped coals and the like.

Owner:庄彦峰

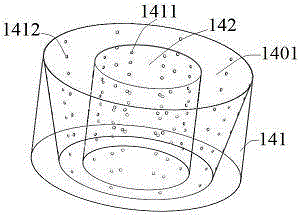

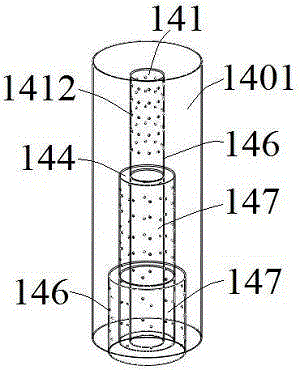

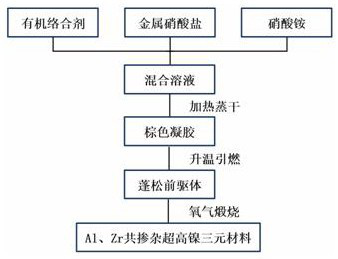

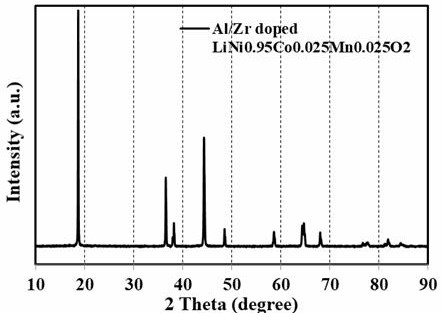

Simple preparation method of Al and Zr co-doped ultrahigh nickel ternary single crystal material

PendingCN114212835AImprove electrochemical performanceAvoid burn-inSecondary cellsPositive electrodesSingle crystalAmmonium nitrate

The invention discloses a simple preparation method of an Al and Zr co-doped ultra-high nickel ternary single crystal material, which realizes preparation of the ultra-high nickel ternary single crystal material and in-situ co-doping of Al and Zr elements through low-temperature combustion reaction of a mixed system of nitrate, an organic complexing agent and ammonium nitrate. Compared with an existing method for preparing the high-nickel layered positive electrode material, the method is easy to operate and low in ignition temperature, a combustion reaction is promoted by using a large amount of oxidizing agent ammonium nitrate, pre-sintering treatment of a precursor in a low-temperature section can be avoided, energy consumption is reduced, and the method is suitable for industrial production. In addition, due to the violent combustion reaction and high-temperature calcination, the crystal growth of the single crystal material is sufficient, the structural stability is high, and the electrochemical performance of the ultrahigh-nickel ternary positive electrode material is comprehensively improved.

Owner:TIANJIN B&M SCI & TECH

Fuel additive

InactiveCN101955820AFacilitate the combustion reactionBurn completelyLiquid carbonaceous fuelsFuel additivesExhaust gasButanol

The invention relates to a fuel additive which comprises the following components of ethanol, tertiary butanol, benzoic acid, distilled water, molybdenyl dialkyl dithiophosphate, copper diisooctyl dithiophosphate and benzotriazole fatty amine. After the fuel additive is mixed with internal combustion engine fuel in an internal combustion engine, the fuel can react rapidly and can combust completely in combustion, the content of carbon oxide in exhaust tail gas is greatly reduced, the abrasion between cylinders and pistons is reduced, and fuel is saved.

Owner:北京奈特通达科技发展有限责任公司

Hydrogen-ignited ammonia-hydrogen mixed combustion zero-carbon engine and control method

PendingCN114738140AIncrease the speed of flame spreadEliminate ammonia slipElectrical controlInternal combustion piston enginesProcess engineeringOil supply

Owner:HARBIN ENG UNIV

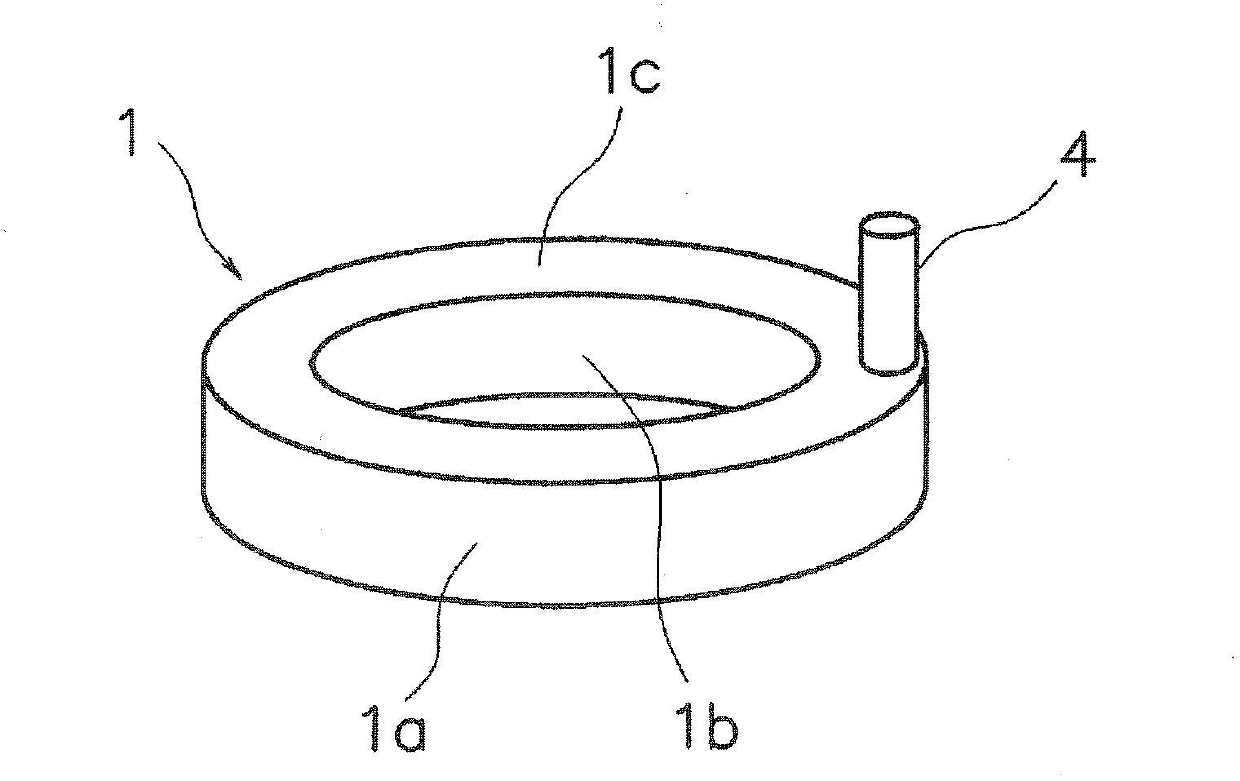

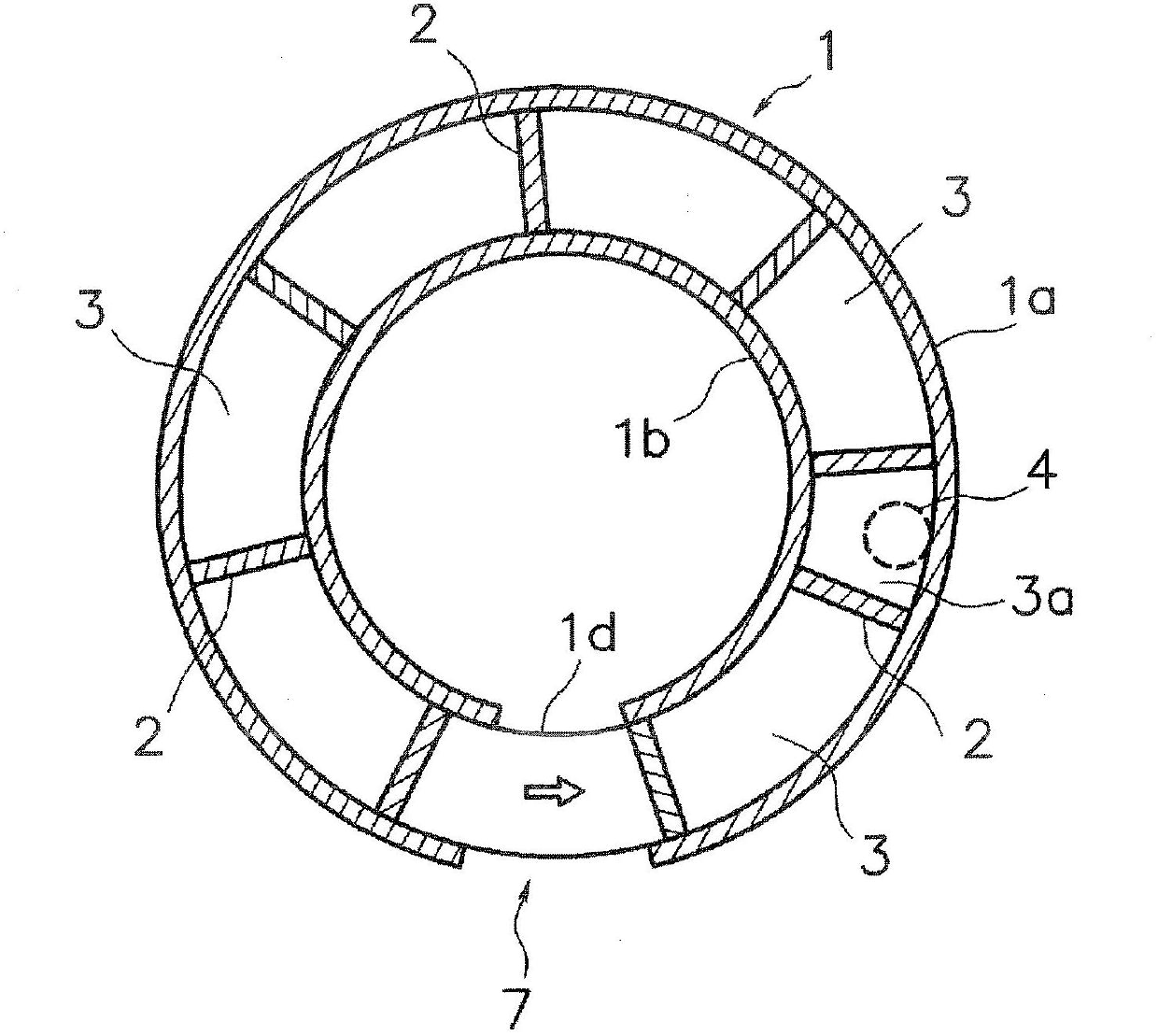

Rotary hearth furnace

InactiveCN102667386AFacilitate the combustion reactionExtended stayFurnace typesProduction rateProduct gas

Owner:KOBE STEEL LTD

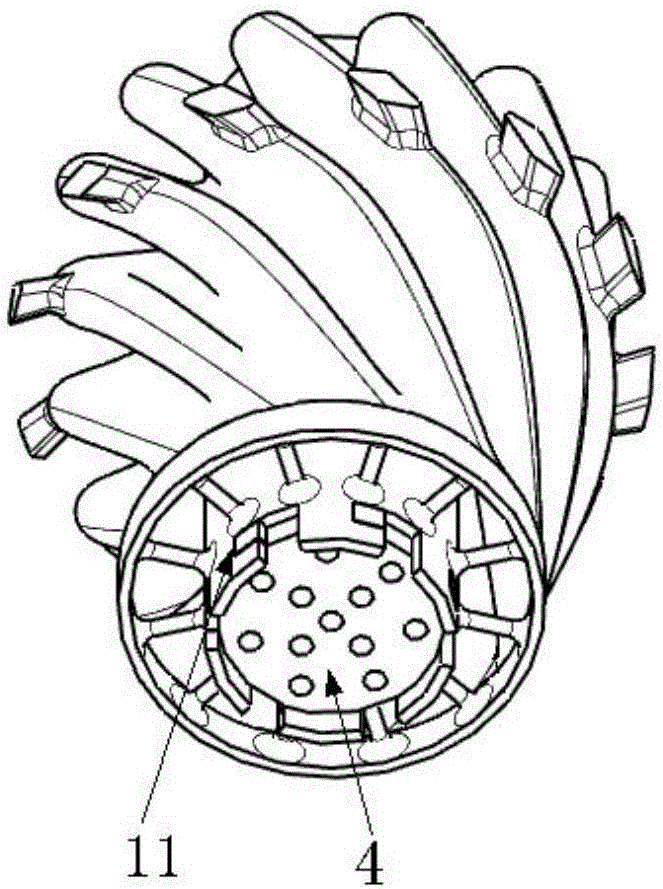

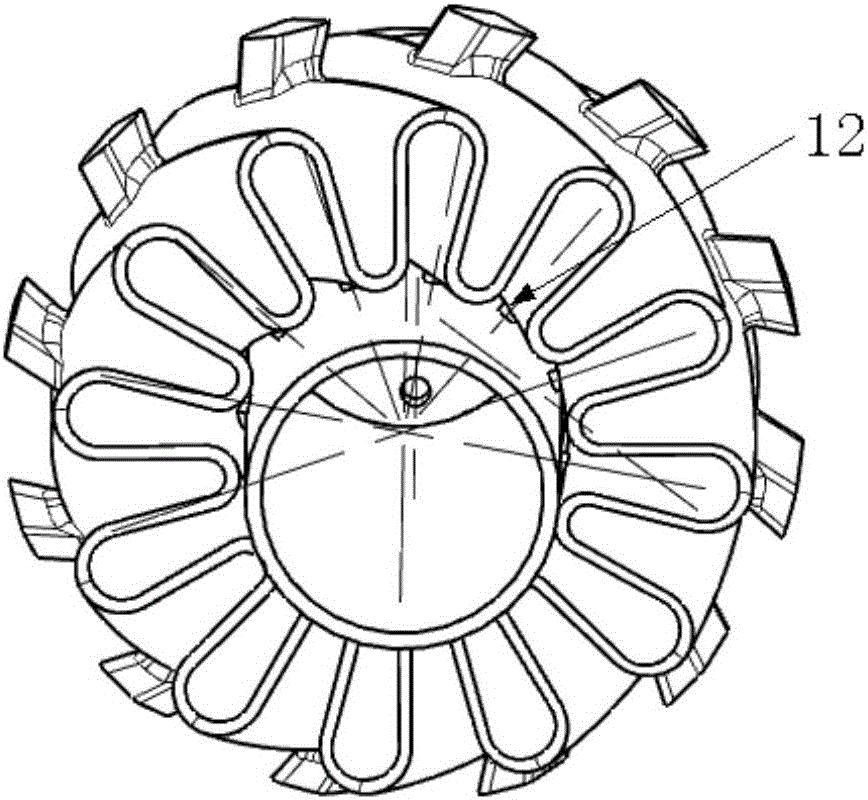

Premixing nozzle for part catalytic combustion, nozzle array and combustor

ActiveCN106642107AIncrease the areaImprove uniformityIndirect carbon-dioxide mitigationGaseous fuel burnerCycloneCombustor

The invention discloses a premixing nozzle for part catalytic combustion, a nozzle array and a combustor. The premixing nozzle comprises a middle cylinder, an outer wall cylinder, a net hole plate, a wave cyclone structure and a catalyst coating layer. The wave cyclone structure is positioned in the outer wall cylinder; and fuels and air are mutually mixed before entering the nozzle. The combustion is performed in two areas; the catalytic combustion is performed on a cyclone; and the flame combustion is performed in an outlet of the combustor. The cyclone is a carrier of a catalyst; the drape surface of the cyclone effectively increases the area of a catalyst coating layer; an inclined flow channel on the cyclone can enable a combustion mixture to generate a rotating motion; and a waveform structure of an outlet and flow surrounding cylinders around a middle channel can increase the turbulent degree, improve the flowing uniformly and accelerate the flame propagation speed to reinforce the combustion stability. The premixing nozzle can lower the combustion temperature, realizes stable combustion of harmful gas and low-heat-value gas, reduces generation of such combustion pollutants as nitric oxides and carbon monoxide, and is harmless in harmful gas to the greatest extent.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

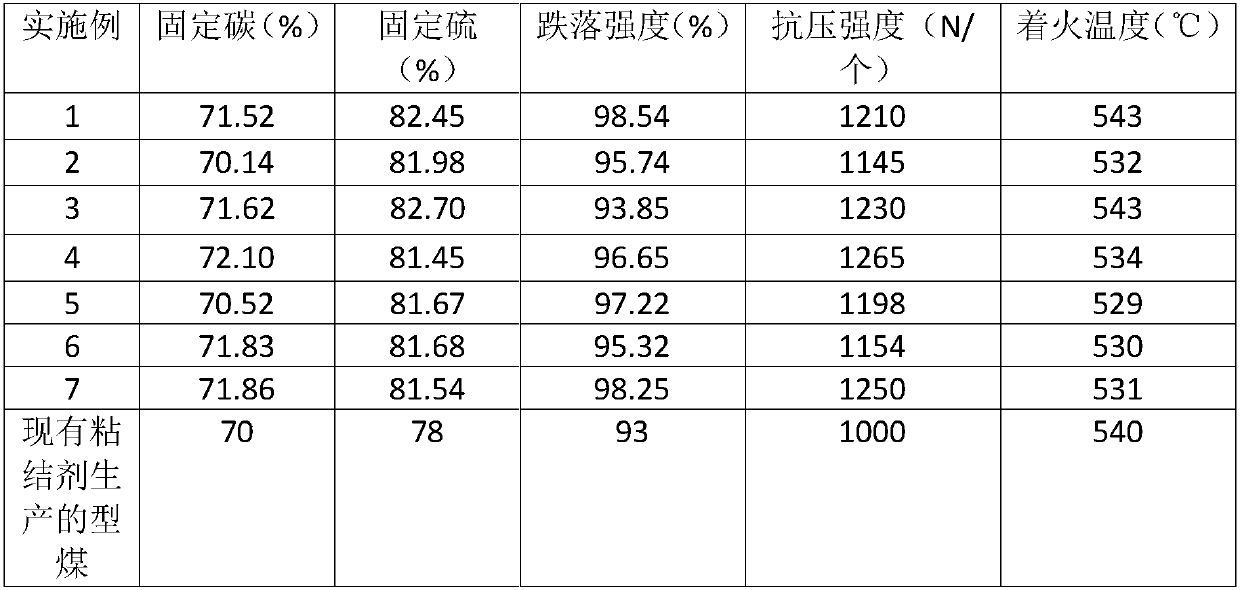

Mould coal binder, and preparation method thereof

The invention discloses a mould coal binder, and a preparation method thereof. The mould coal comprises, by mass, 0.5 to 0.75 parts of esterified swill-cooked dirty oil, 0.1 to 0.5 part of sodium carbonate, 3 to 5.5 parts of smithsonite, 85 to 91 parts of a consolidation agent, 0.3 to 0.5 part of basic zinc carbonate, 1 to 2 parts of potassium chloride, and 1 to 3 parts of polyacrylamide. No largeamount of pollutant is released in combustion of the mould coal binder, no secondary pollution is caused, and cleaning efficiency is high.

Owner:攀枝花市观诚工贸有限公司

Heatproof high oxygen storage denitration catalyst and preparation method thereof

InactiveCN109529803AHigh low temperature activityExtend your lifeHeterogenous catalyst chemical elementsDispersed particle separationCerium nitrateCerium nitrate hexahydrate

The invention provides a heatproof high oxygen storage denitration catalyst and a preparation method thereof. The formula of the catalyst comprises cerium nitrate, lanthanum nitrate, yttrium nitrate,gamma-alumina, nanometer titanium dioxide, a lubricant, a binder, a surfactant, a toughener and pore forming agent. The preparation method comprises the following steps: weighing the gamma-alumina andnanometer titanium dioxide, drying the weighed substances, and cooling the dried substances; adding the cerium nitrate, lanthanum nitrate, yttrium nitrate, the binder, the toughener and the pore forming agent into a pug mill, and performing uniform mixing; placing the obtained pug ball in a muffle furnace, and calcining the pug ball; adding the lubricant and the surfactant, and performing mixingto form a ball; dissolving the remaining cerium nitrate, lanthanum nitrate and yttrium nitrate, and adding a combustible component; and immersing the obtained spherical carrier in a combustion liquid,and performing calcining. The catalyst carrier has a high specific surface area to improve the low-temperature activity and the life of the catalyst; a low-temperature self-propagating combustion coating process is adopted is adopted to achieve uniform distribution of active components in the catalyst; and the spherical catalyst has an improved catalysis efficiency.

Owner:天津浩创节能环保设备有限公司

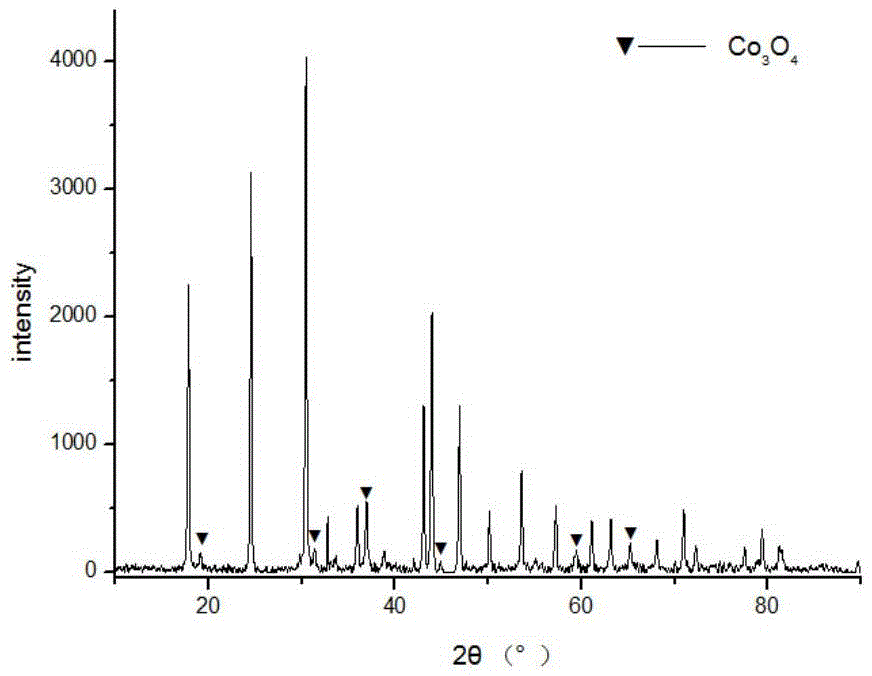

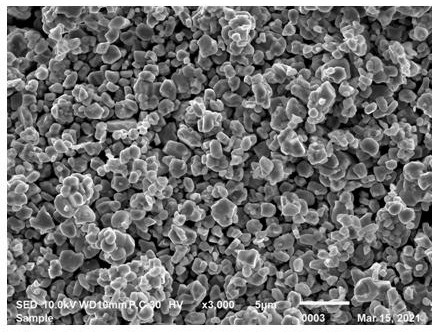

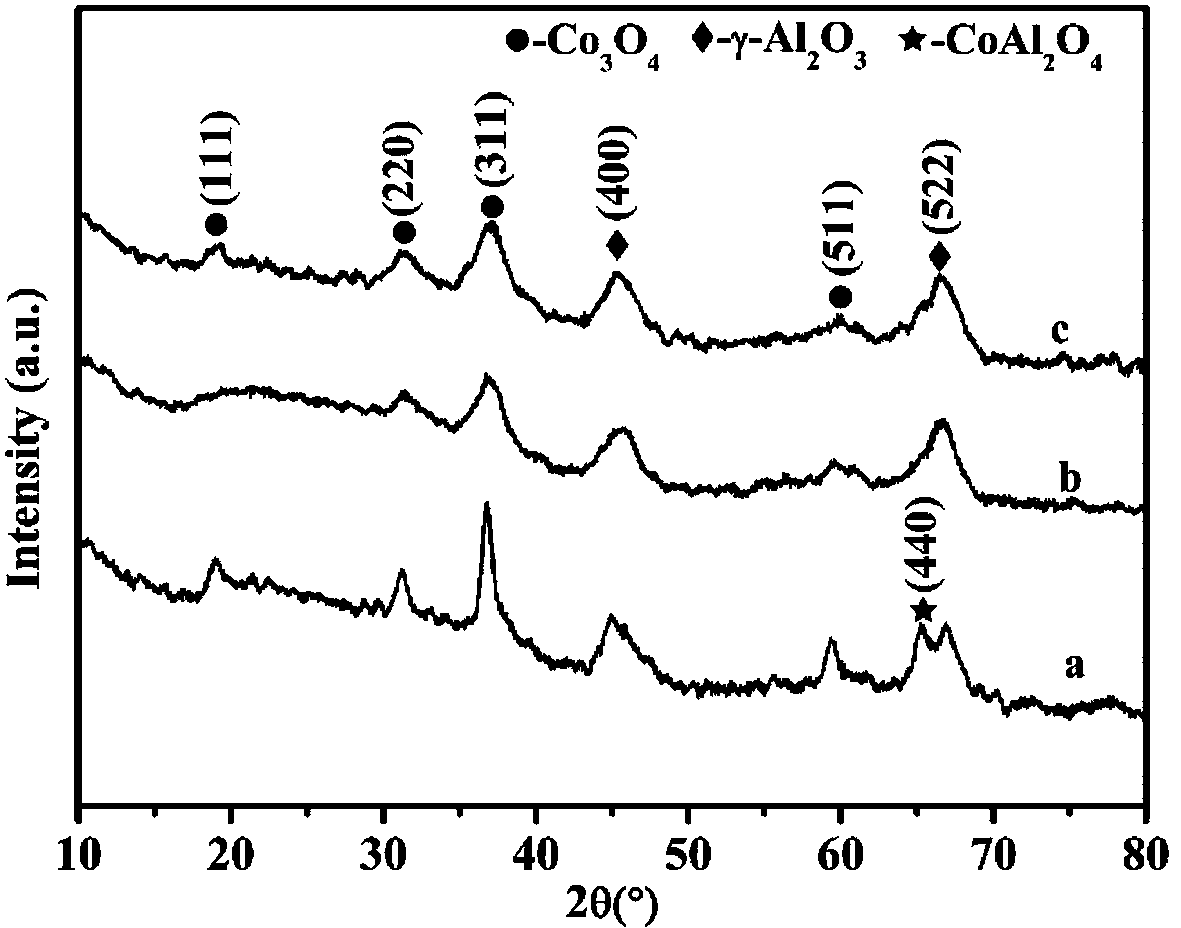

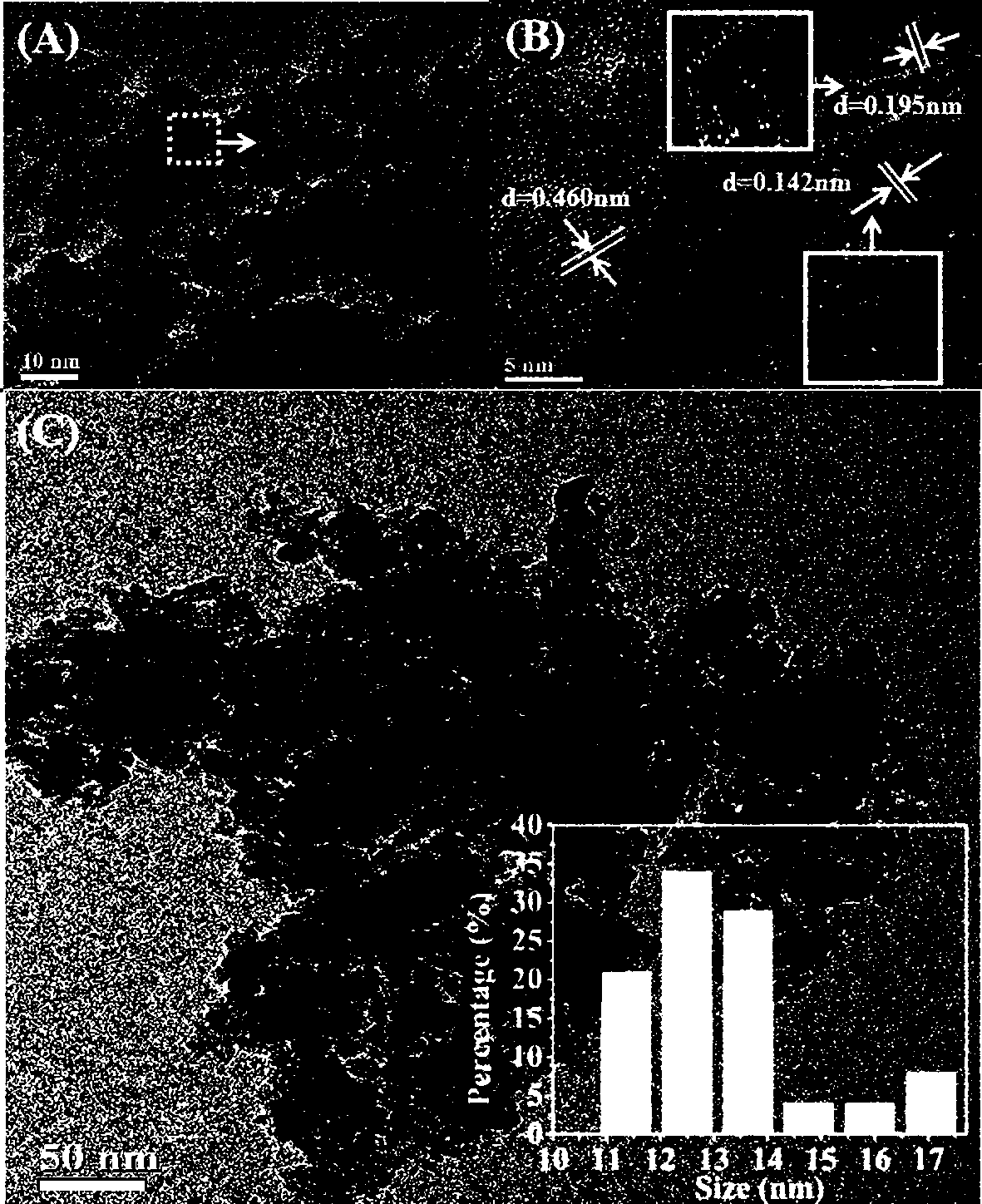

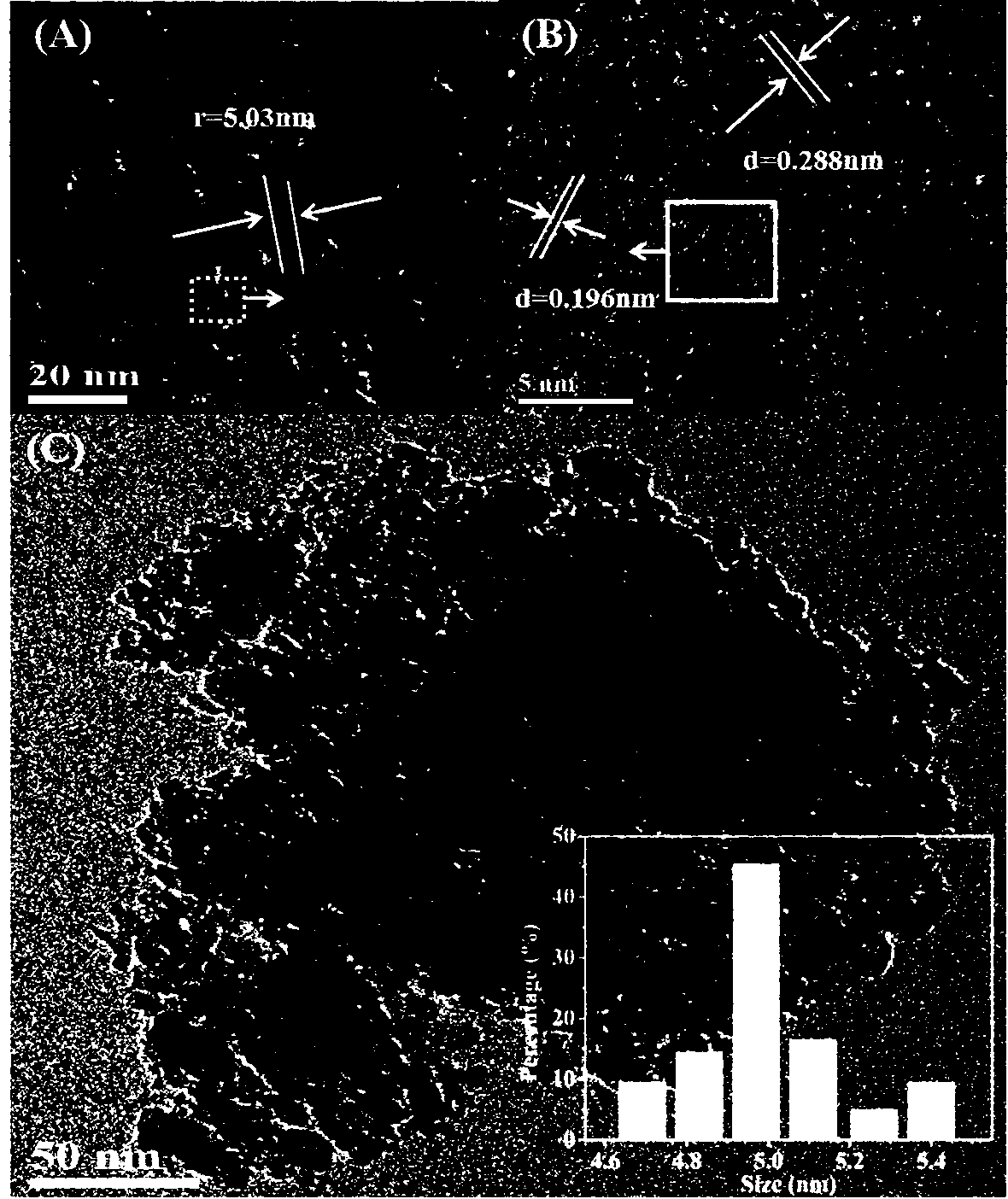

Preparation method of small-grain-size cobalt-based aluminum oxide catalyst

InactiveCN109647405AEasy to operateLow costMaterial nanotechnologyCatalyst activation/preparationUreaCOBALTOUS ACETATE

The invention discloses a preparation method of a small-grain-size cobalt-based aluminum oxide catalyst. The method comprises the steps that by adopting a sol-gel method, hydrochloric acid is adoptedas an acidity regulator, acetic acid is adopted as an interface protective agent to synthesize an alumna supporter, then, cobaltous acetate is adopted as a cobalt source, diglycol is adopted as a complexing agent, and a dipping method is adopted for manufacturing the small-grain-size cobalt-based aluminum oxide catalyst. Compared with existing cobalt-based aluminum oxide synthesized by adopting glycine and urea as complexing agents, the grain size of cobaltosic oxide in synthesized cobalt-based aluminum oxide is smaller, the number of catalyst surface active loci is increased, and the interaction strength between the supporter and active ingredients is enhanced. In addition, the cobalt-based aluminum oxide is good in thermal stability, generation of a CoAl2O4 non-active phase can be restrained within the certain temperature range, and the activity of the catalyst in the methane catalyst combustion reaction is improved. The method is easy to implement, the synthesized cobalt-based aluminum oxide can be adopted as a catalyst carrier and can also be adopted as a catalyst obtained after a methane catalysis combustion reaction, and the good application prospect is achieved.

Owner:FUJIAN NORMAL UNIV

Noble metal catalyst and preparation method and application thereof

ActiveCN108636403AHigh activityHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystLattice oxygen

The invention provides a noble metal catalyst, which employs noble metal as a first active component and stannic oxide as a second active component, and a methane combustion catalyst having high catalytic activity and sintering-resistant performance is obtained. The stannic oxide can protect the noble metal component from sintering, contains abundant and active surface oxygen vacancy, the latticeoxygen in a body phase has certain activity, at the same time, the surface of the stannic oxide has Lewis acid center, realizes effective catalysis, and is in favor of a catalytic combustion reactionof methane. A part of the noble metal is introduced into lattice of stannic oxide to substitute the divalent tin ions, and can increase the cavity concentration, so that the free electron concentration is reduced, adsorbed oxygen ions can be formed at the surface of the catalyst, the noble metal catalyst is in favor of generation of an oxidation reaction by the reductibility gas methane at the surface of the catalyst through oxygen ion adsorption, and the activity of the catalyst is increased.

Owner:吉林晟航科技发展有限公司

Environment protection and quality increasing process for coal and water-coal fluid

ActiveCN100372916CImprove combustion efficiencyImprove surface activityLiquid carbonaceous fuelsEngineeringCoal particle

A process to treat coal for decreasing its environmental pollution and improving its quality includes such steps as superfine pulverizing to obtain submicron-class coal particles, and mixing them with desulfurizing assistant. A water-coal slurry is prepared from micron-class coal particles and micron-class desulfurizing assistant. Its advantages are high combustion efficiency, low pollution and not blocking to nozzle.

Owner:毕舒

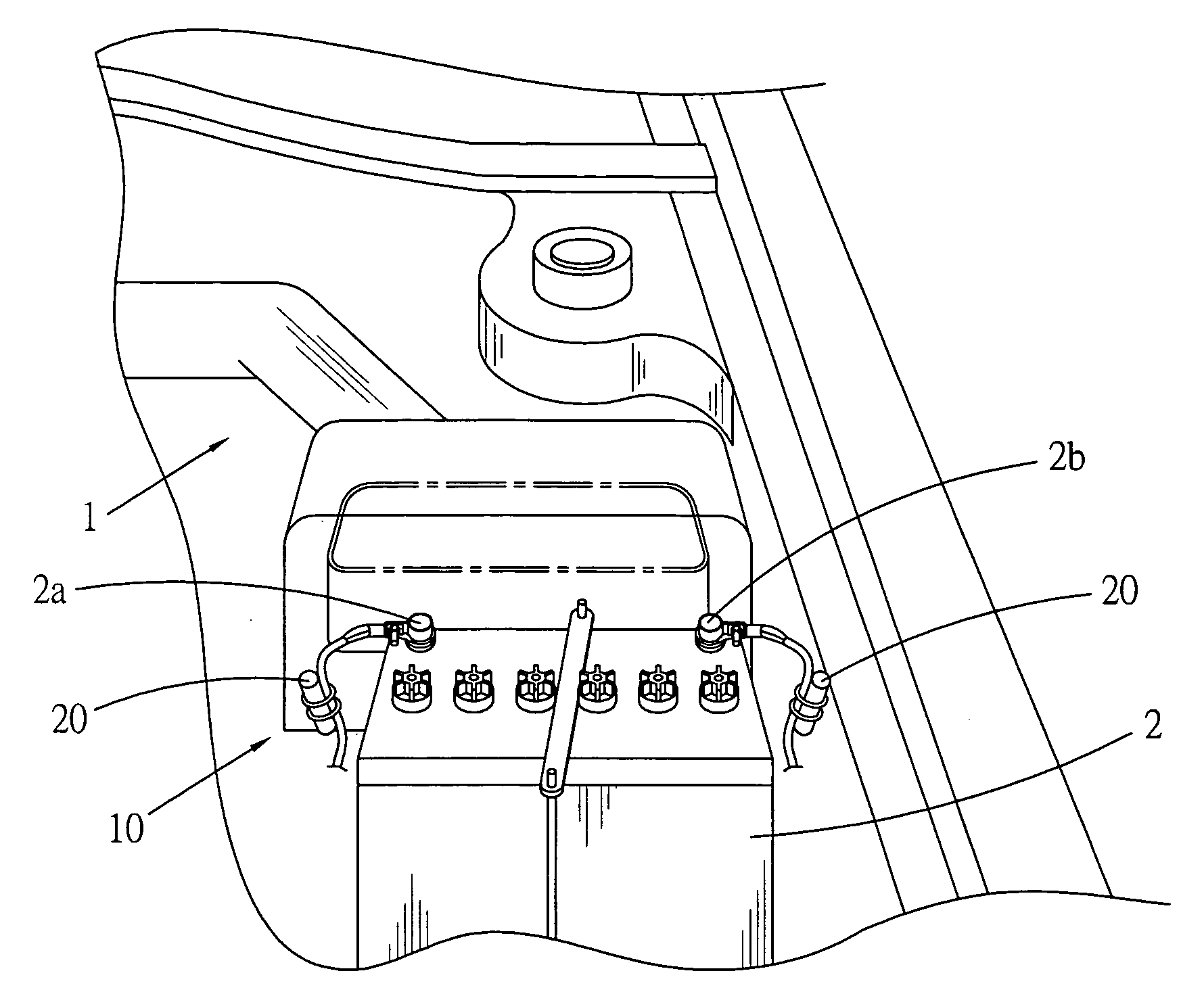

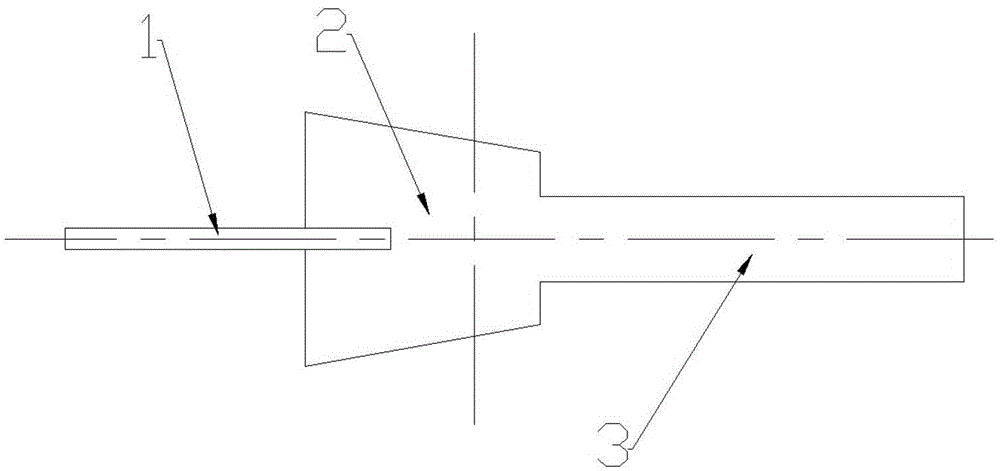

Energy-releasing apparatus for energizing and covibrating fuel molecules and arranging reactant molecules

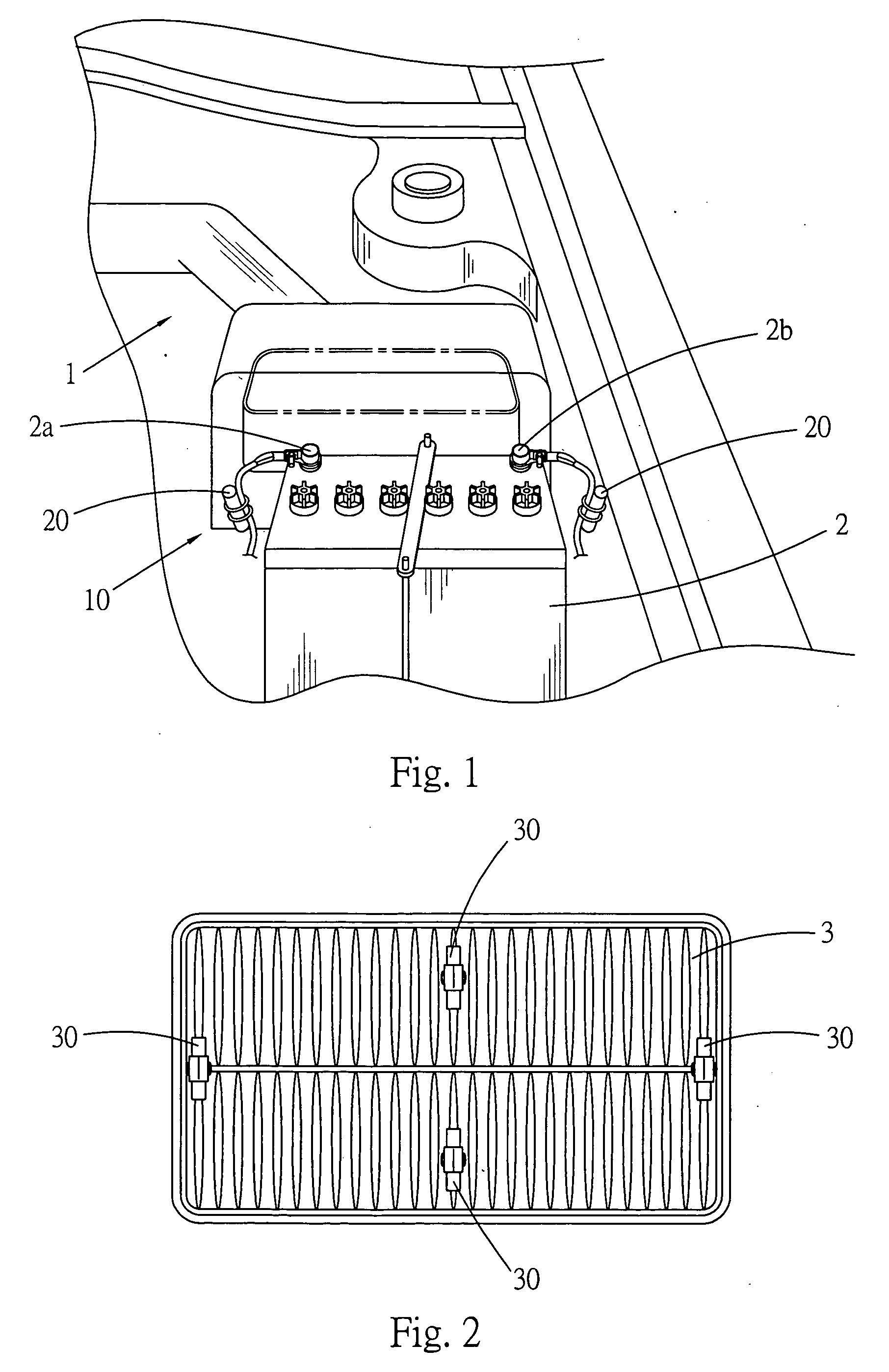

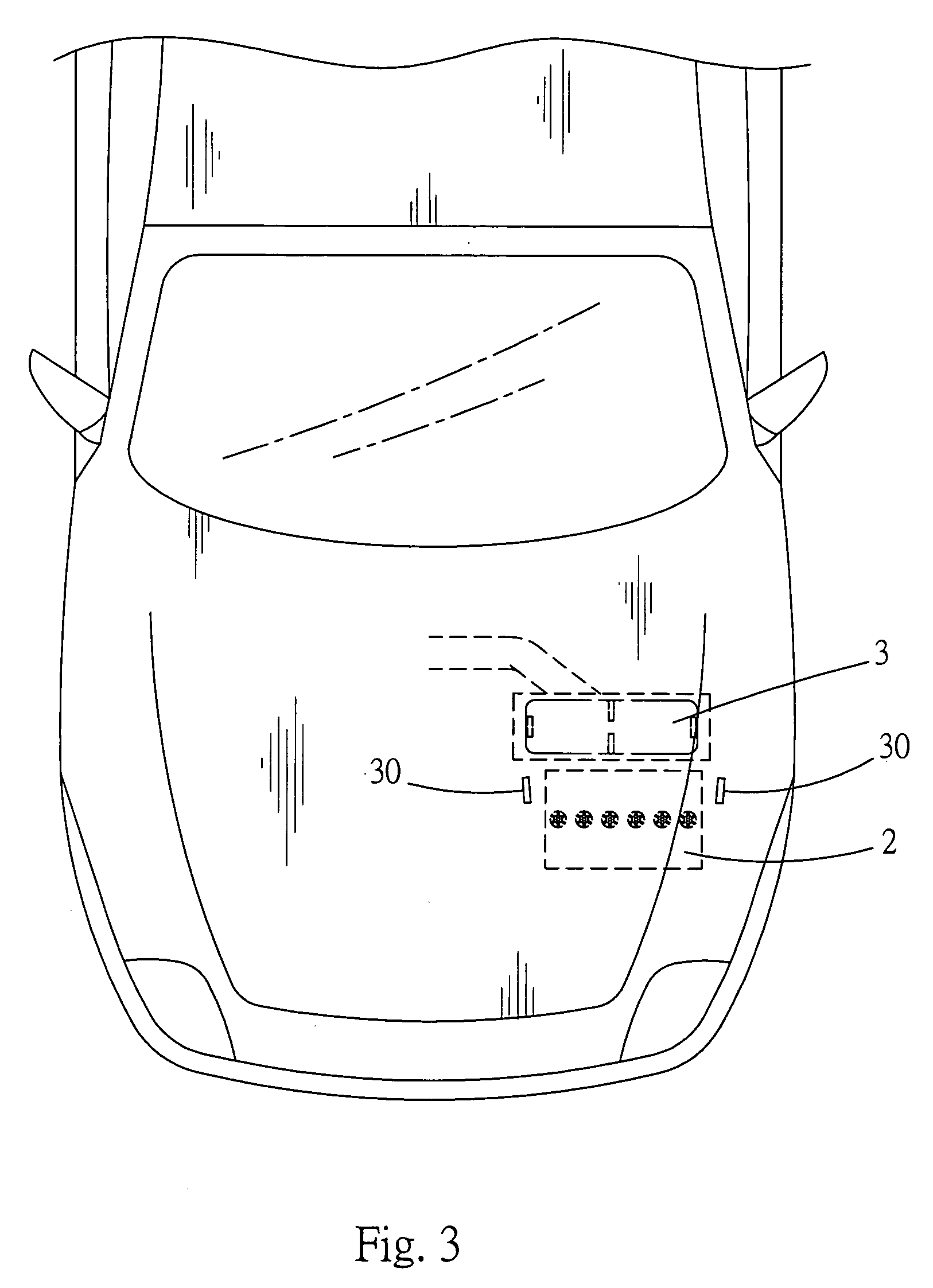

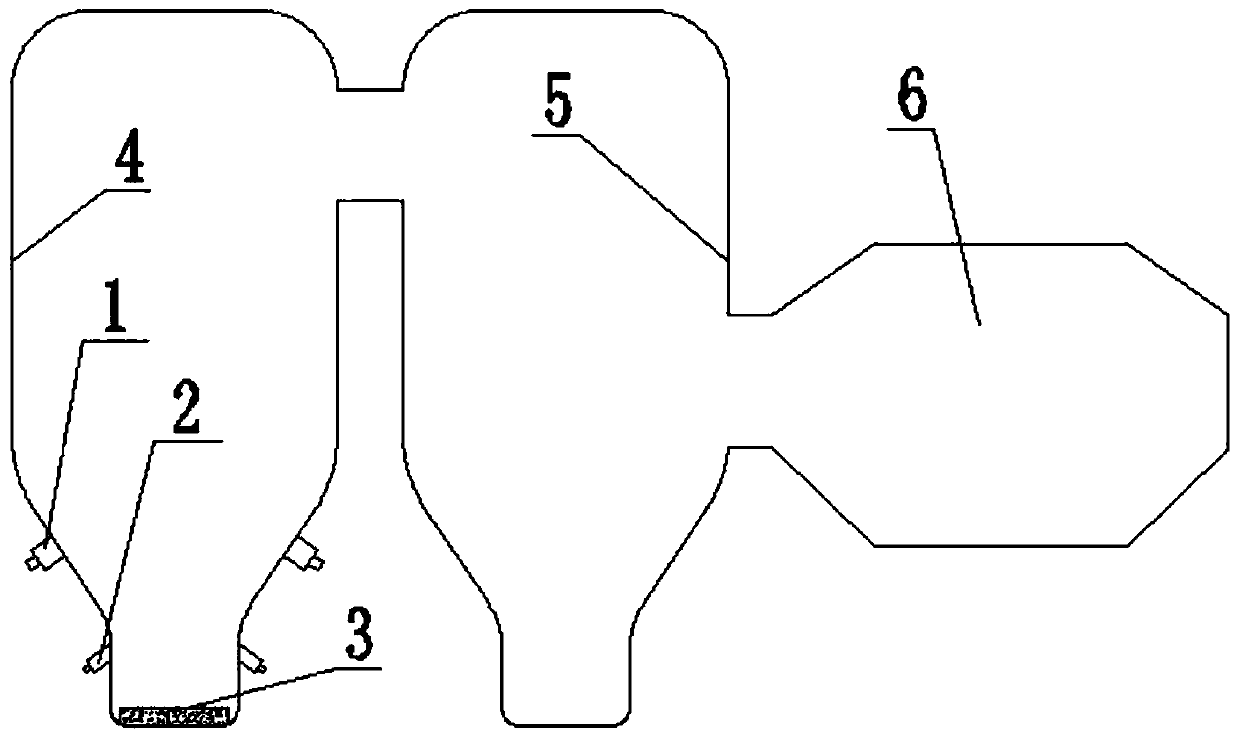

InactiveUS20050247293A1Facilitate the combustion reactionMaximum output powerInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberEngineering

An energy-releasing apparatus for energizing and covibrating fuel molecules and arranging reactant molecules. The energy-releasing apparatus is installed in a predetermined position in an engine compartment of a vehicle. The energy-releasing apparatus includes at least one first energy-releasing section disposed beside the electrodes of the battery in the engine compartment chamber and at least one second energy-releasing section disposed in the engine compartment beside the intake duct of the combustion chamber. The first and second energy-releasing sections generate left-handed force field to arrange the electrons or the battery and the gas molecules in the intake duct. The left-handed force field further energizes the alkylate molecules of the fuel entering the combustion, whereby the molecules of all the reactants participating in the burning reaction are uniformly arranged and activated so as to achieve a complete reaction.

Owner:JEWEL JAR INT

Integrated incineration device capable of treating yellow phosphorus exhaust gas without pollution and recovering energy

The invention discloses an integrated incineration device capable of treating yellow phosphorus exhaust gas without pollution and recovering energy. The integrated incineration device consists of a device body; the device body comprises a first combustion tower and a second combustion tower; a fluidizer is arranged on the bottom side of the first combustion tower; a first ejector positioned on theupper side of the fluidizer is arranged on the outer wall of the first combustion tower; a second ejector is arranged on the outer wall of the first combustion tower on the upper side of the first ejector; and the second combustion tower communicates with an exhaust gas absorption tower. The invention aims to provide the incineration device that solves the problems of low treatment efficiency andhigh operating cost in the existing yellow phosphorus exhaust gas treatment, treats the yellow phosphorus exhaust gas, simultaneously performs energy recovering and reducing the operating cost.

Owner:SINOMA ENERGY CONSERVATION

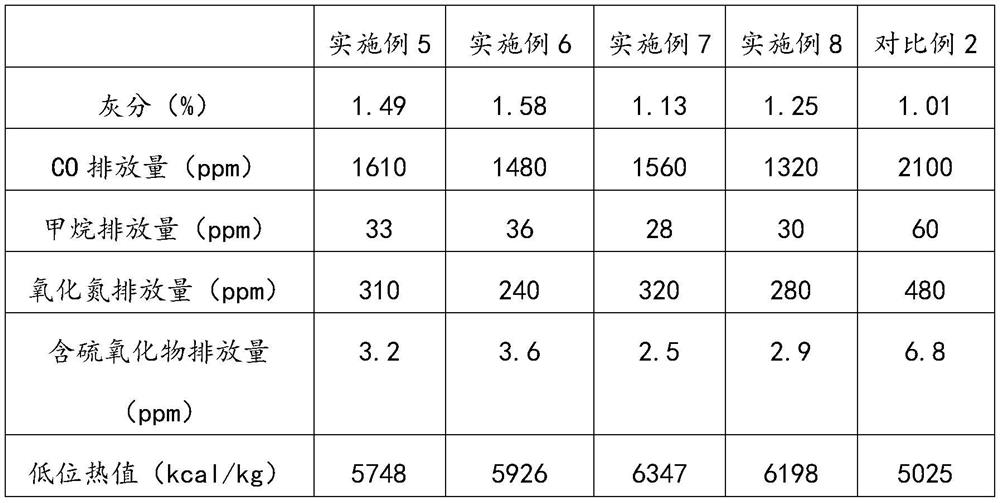

Biomass granular fuel and preparation method thereof

InactiveCN112111311AReduce porosityImprove molding rateBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a biomass granular fuel and a preparation method thereof, and relates to the field of development and utilization of waste biomass resources. The biomass granular fuel disclosed by the invention is prepared by the following steps: drying and crushing a biomass raw material to obtain powder, adding the lignin-based binder and the additive into the powder, uniformly stirringby virtue of a stirrer, mechanically compressing, granulating and cooling, thereby obtaining the biomass granular fuel. The lignin-based binder is obtained by adding a polyacrylic acid / urea polymer into a suspension containing lignin particles, adjusting the pH value, stirring, filtering, drying and crushing. According to the biomass granular fuel provided by the invention, by adding the lignin-based binder, the forming rate of the biomass granular fuel is increased, the biomass granular fuel is not easy to break in the transportation process, the combustion speed is stable, slag bonding is not liable to generate in the combustion process, the combustion efficiency is improved, the service life of a combustion device is prolonged, and the environmental pollution is reduced.

Owner:桃江县新辉生物质颗粒有限公司

Biomass granular fuel and preparation method thereof

ActiveCN108641773AIncrease the softening temperature of ash accumulationFully contactedBiofuelsSolid fuelsOxygenAlkali metal

The invention discloses a biomass granular fuel. The fuel comprises a biomass raw material and an additive, wherein the additive is a mixture of chitosan, calcium oxide and urea, and a weight of the additive is 0.5-4.8% of a weight of the biomass raw material. According to the fuel disclosed by the invention, a certain amount of chitosan, calcium oxide and urea are added into the biomass raw material as the additive, so that alkali metal elements in the biomass granular fuel can be fixed, and the problems of dust accumulation and slagging caused by alkali metals contained in the biomass granular fuel can be effectively improved; and addition of the chitosan, the calcium oxide and the urea can increase a contact area of the biomass granular fuel and oxygen, make a combustion reaction more sufficient, and prolong burning time, thereby improving burning efficiency. The invention also provides a preparation method of the biomass granular fuel.

Owner:湖北和泰生物能源有限公司

A kind of pre-combustion type plasma igniter and ignition method

ActiveCN107842427BRegion size increasesChemically activeTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

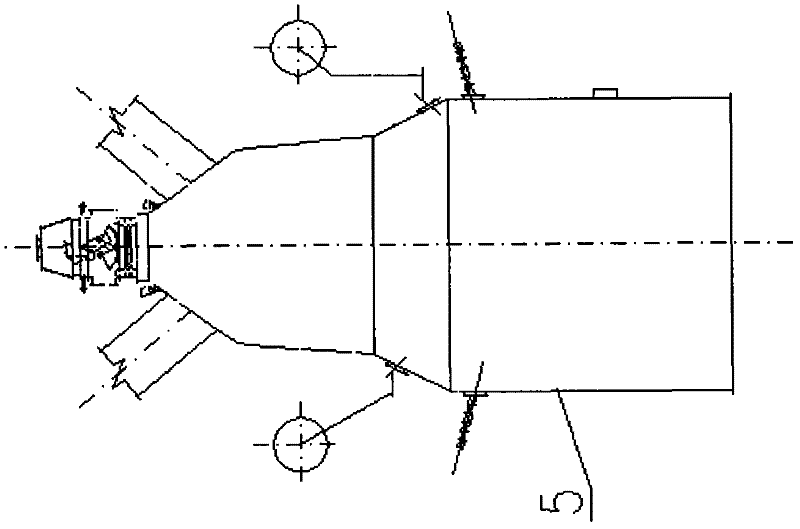

A pre-ignition pulse burner

InactiveCN103206710BAchieve flameless combustionFacilitate the combustion reactionGaseous fuel burnerCombustorSpray nozzle

The invention provides a pre-burning type pulsating burner which comprises a nozzle, a pre-burning chamber and a tail pipe. Grooves with b equal to 0 degree to 70 degrees are washed at the front end of the pre-burning chamber and are evenly distributed in a right-handed rotation or left-handed rotation mode, air entering is guaranteed, rotational flow effect is achieved, and the rear end of the pre-burning chamber is connected with the tail pipe so as to discharge burning products. Fuel enters the pre-burning chamber through the nozzle to be mixed with air. Due to the fact that air flow pulsation and the burning process have coupling effect, the pulsating burner can perform self-absorption of air and the fuel from the position of an inlet and gas is discharged towards an outlet at a certain pressure. Due to the fact that a pulsation technology is adopted to enable hot air and the fuel to be absorbed into the pre-burning chamber under pressure changes of the pre-burning chamber, the burning products are sprayed into a hearth through the tail pipe so as to be burned in a flameless mode within a large area simultaneously, an excess air coefficient is reduced, and burning efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

A φ2000×18m energy-saving and environment-friendly mercury smelting electromagnetic induction roasting rotary kiln

ActiveCN104880059BNo take away sensible heatCompact structureRotary drum furnacesAutomatic controlEngineering

The invention relates to an energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with the size of phi 2000*18 meters. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln comprises a kiln head cover, a mercury ore feeding hopper, a high-temperature alloy steel inner container kiln barrel, a wheel belt, a movable carrier wheel group, a transmission device, a gear pair, a fixed carrier wheel group, a track and cement piles. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the advantages that the energy is clean, and the problems that a mercury metallurgy rotary kiln roasted by a coal furnace is low in production efficiency, severe in environmental pollution, high in energy consumption and the like is solved. The energy is used and distributed conveniently. Compared with a mode of heating by fuel, gas and the like, the heating mode of the energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the characteristics that heat efficiency is high, sensible heat is not taken out by smoke or ash, and a kiln body is simple and compact in structure, small in heat dissipation area, low in heat dissipation loss, easy to control and regulate automatically and high in kiln temperature control precision, and meets requirements of a narrow calcining temperature process. The production efficiency is high, energy consumption is reduced, and emission of environmental pollutants is reduced. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln is an innovation of energy conservation, environmental protection and an equipment technology of a mercury metallurgy kiln.

Owner:朱兴发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com