Premixing nozzle for part catalytic combustion, nozzle array and combustor

A technology of catalytic combustion and premixing nozzles, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of complex structure, unstable combustion, and many parts of the burner, and achieve the goal of broadening the flameout limit and stabilizing combustion , the effect of reducing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

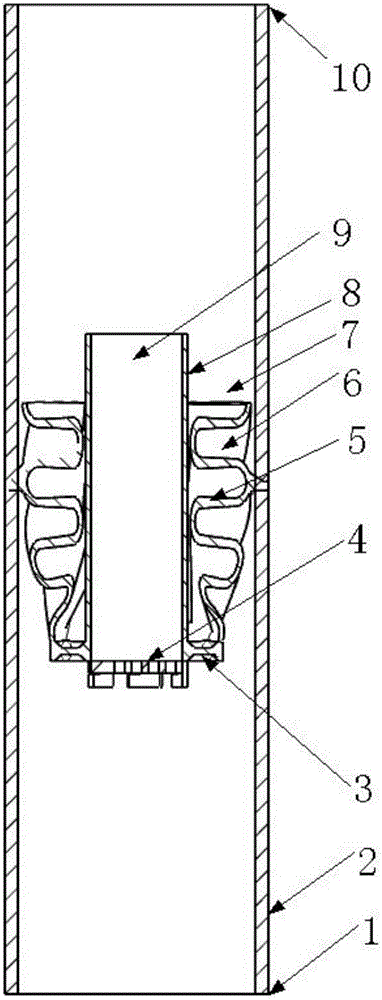

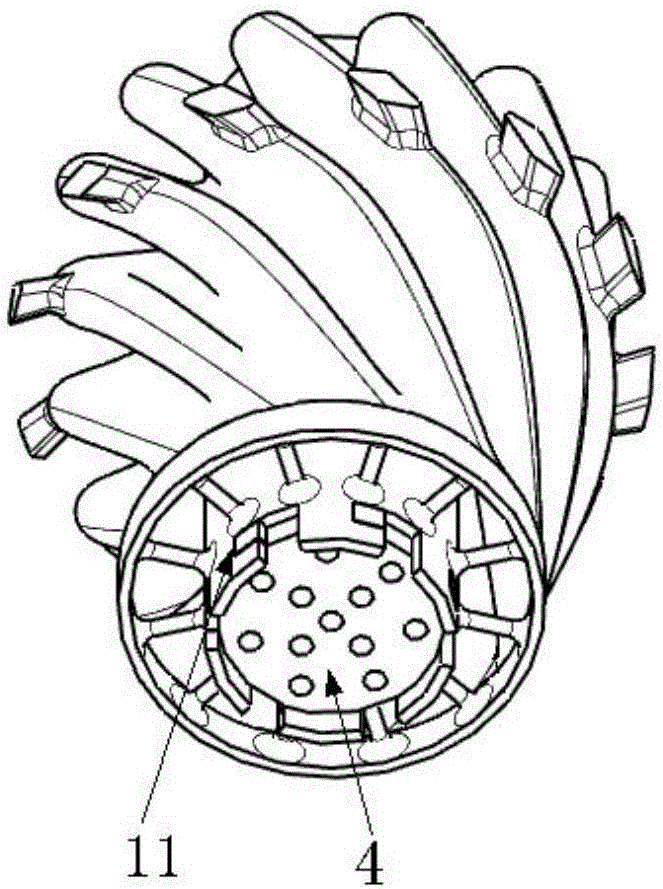

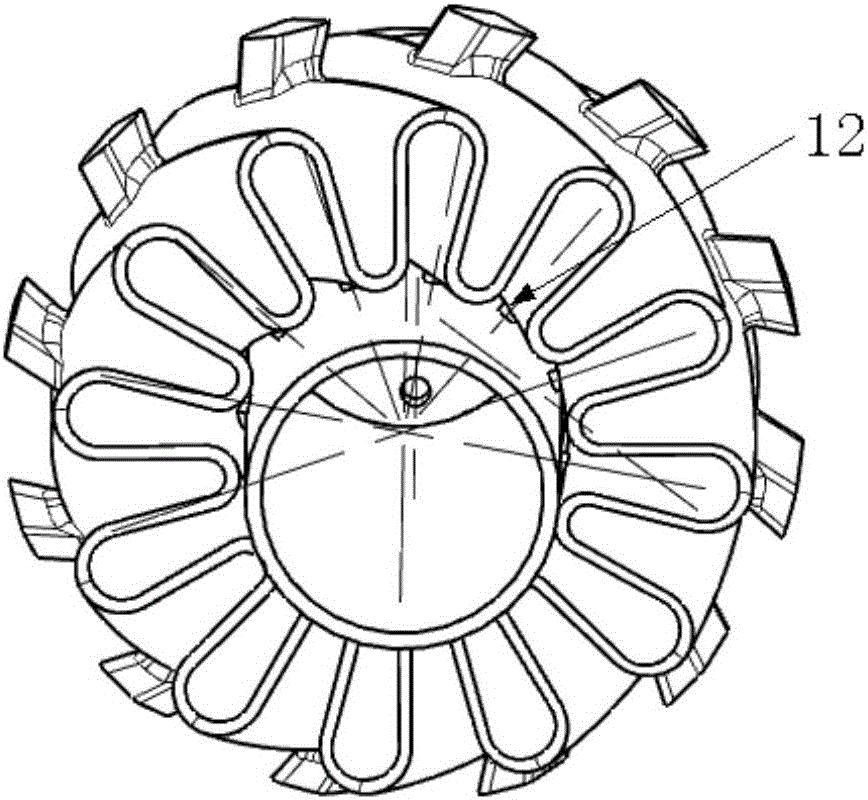

[0029] Please refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a partial catalytic combustion premixing nozzle, including: nozzle outer wall cylinder 2, middle cylinder 8, perforated plate 4, swirler wrinkled blade 5, swirler inlet cylinder 3, swirl Cyclone outlet cylinder 12, cyclone perforated plate installation bayonet 11 and catalyst coating on the cyclone, middle cylinder and perforated plate. The intermediate cylinder 8 is located inside the cyclone 5 in this embodiment. The swirler corrugated vane 5 is located in the flow channel between the nozzle outer wall cylinder 2 and the swirler middle cylinder 8, and the swirler corrugated vane 5 consists of multiple crests and troughs that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com