Patents

Literature

58results about How to "Effective control generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

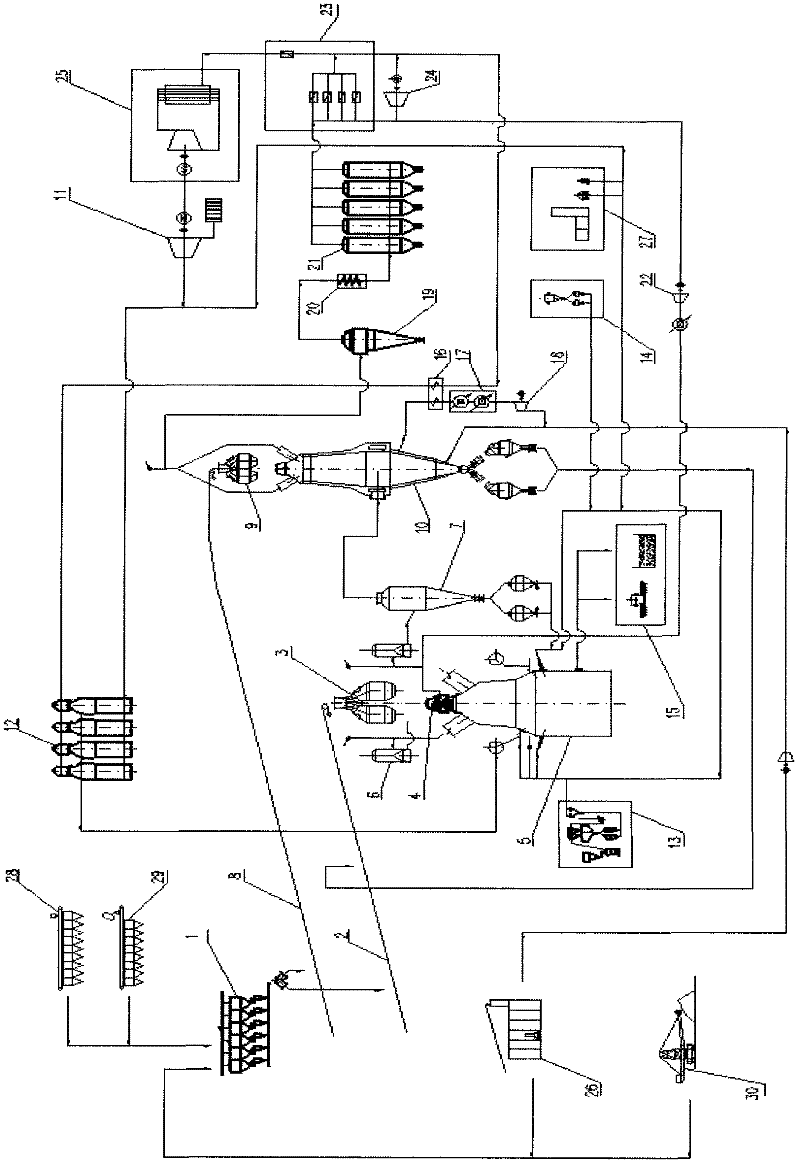

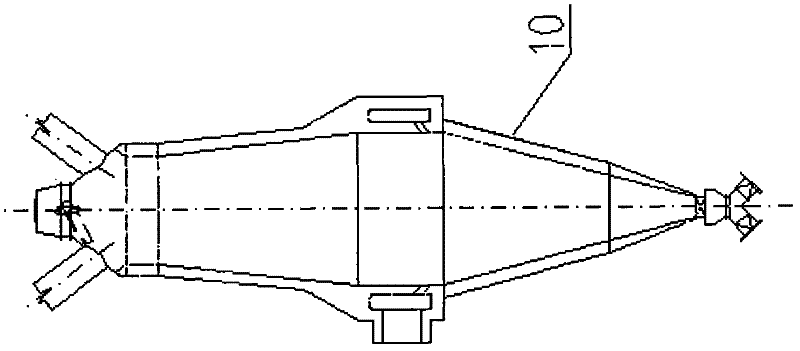

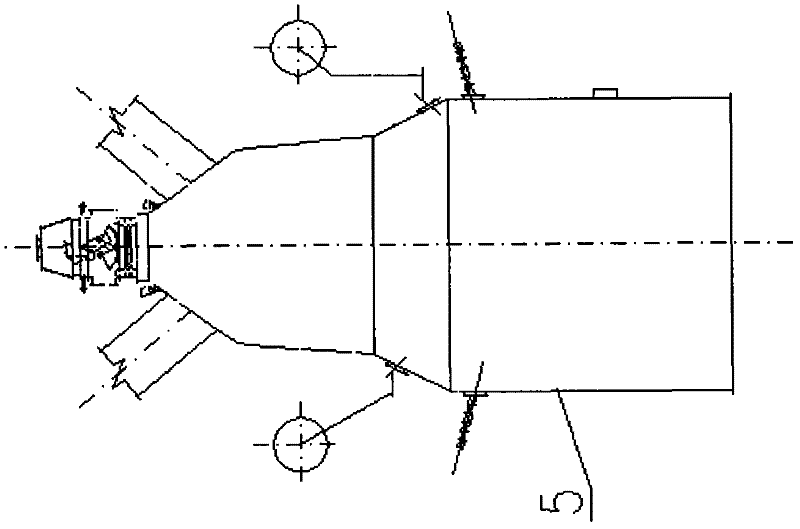

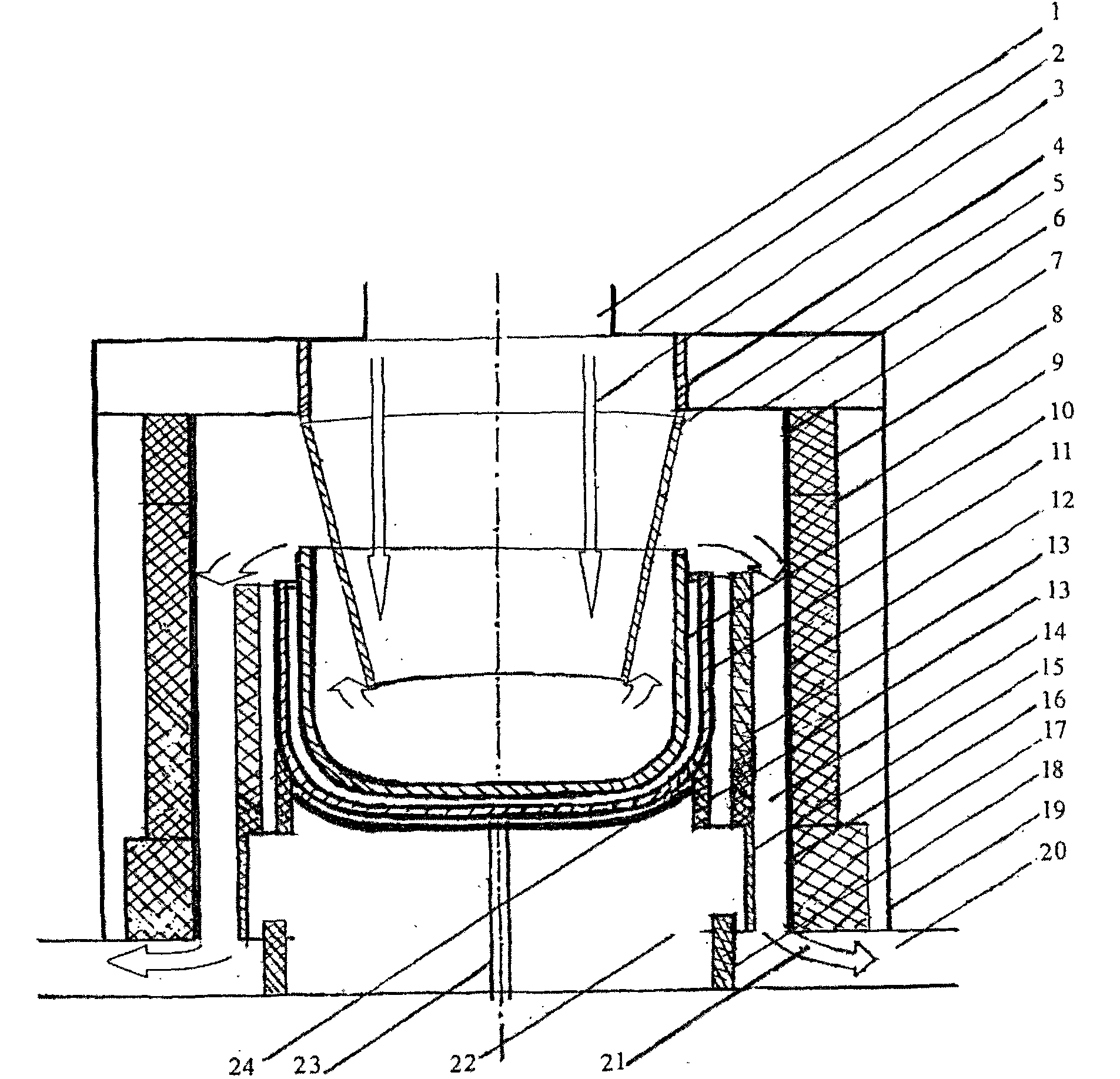

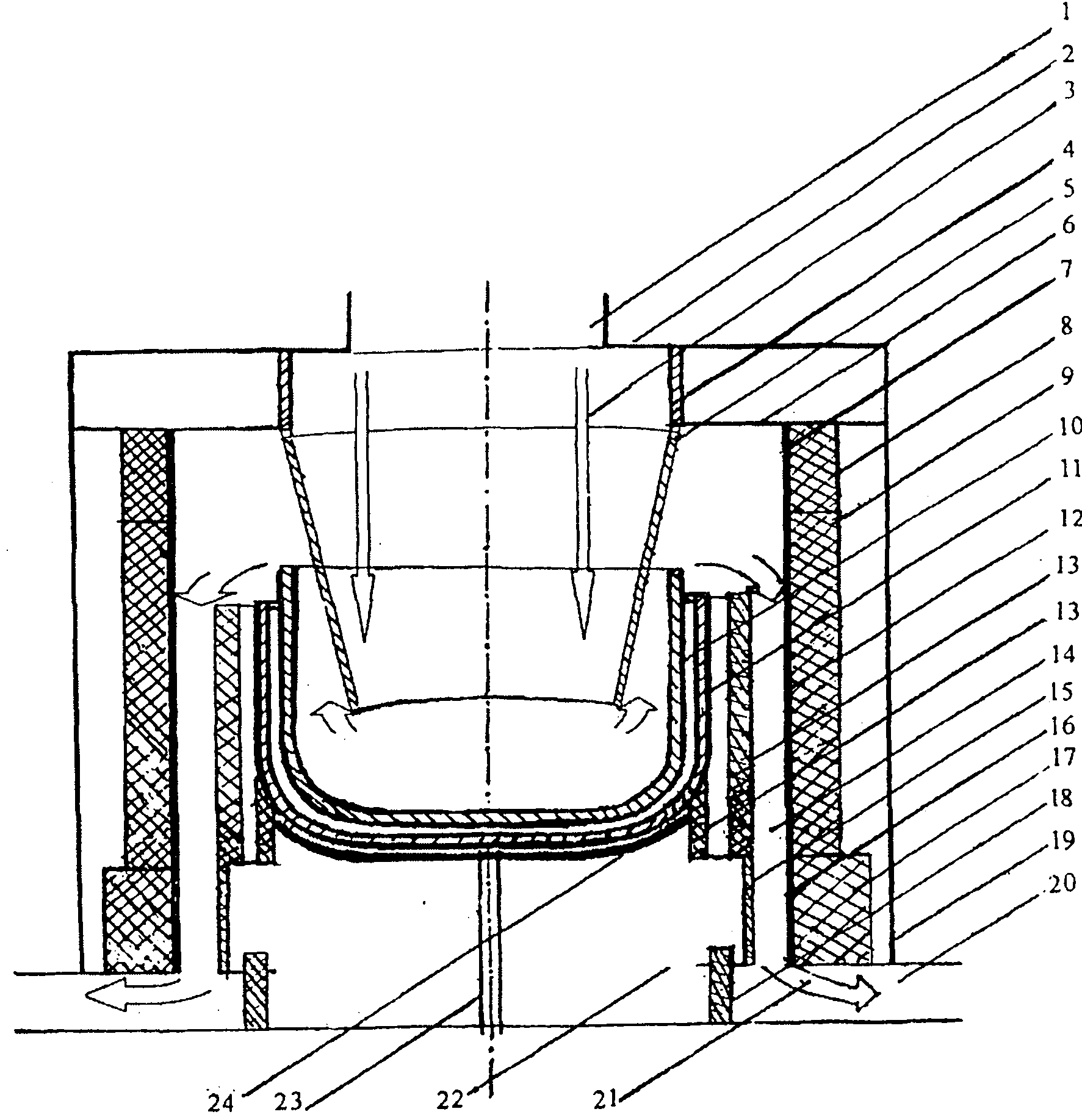

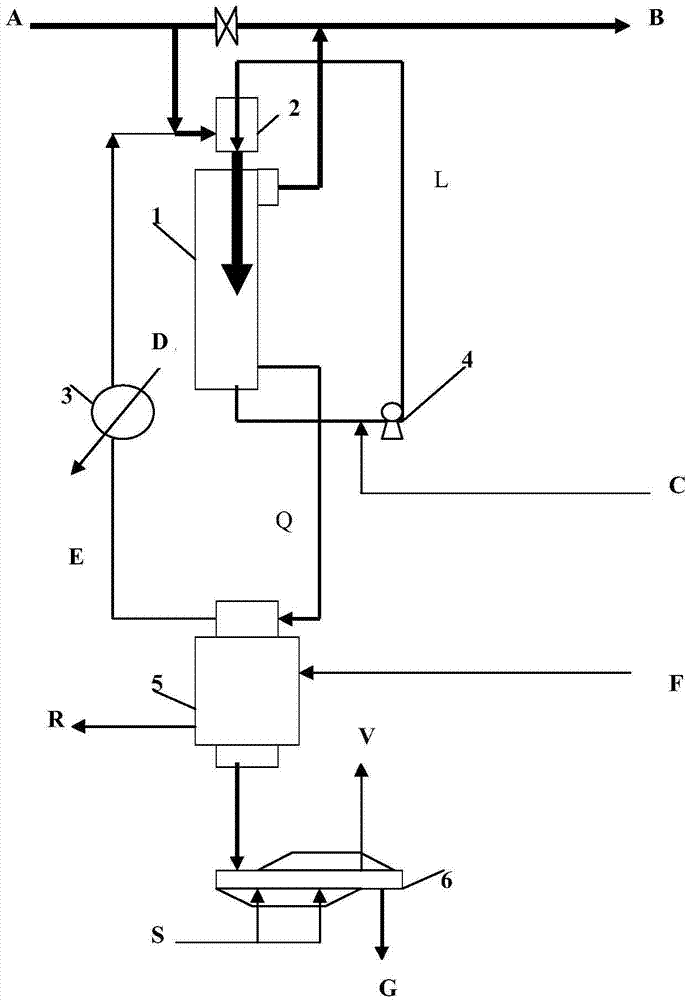

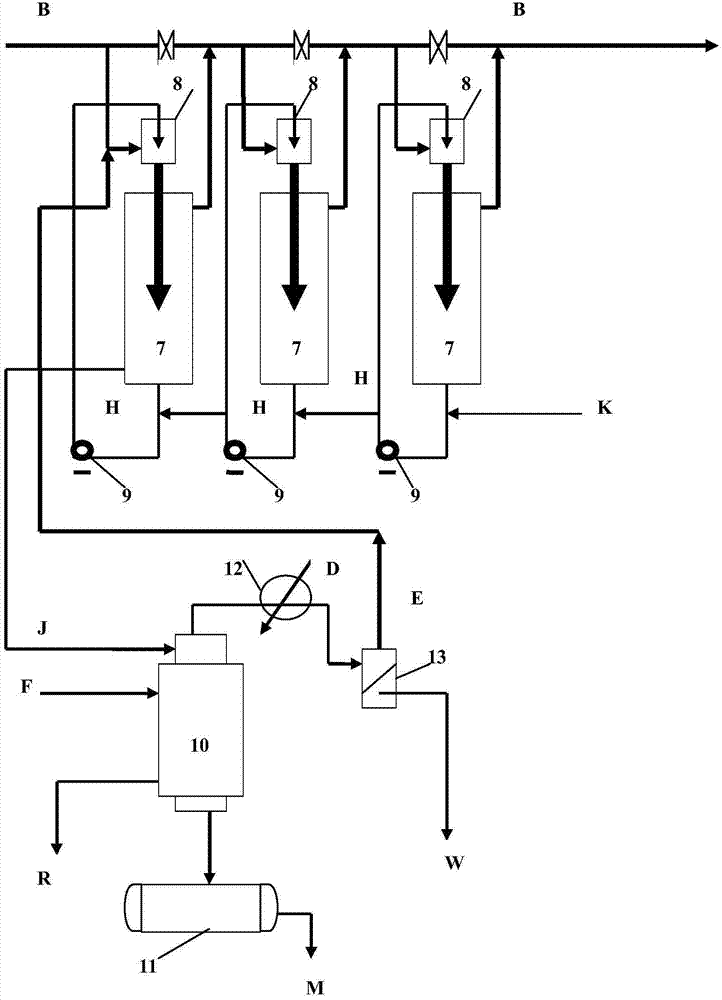

High-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and method

ActiveCN102337369AGood for high pressure operationGood for material level controlShaft furnaceMetallurgyCogeneration

The invention discloses a high-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and a method, which belong to the technical field of melting reduction. The device comprises a raw material system, a furnace top material charging and distributing system, a melting reduction furnace, a furnace top high-temperature gas system, a prereduction furnace, a semicoke gas recycling system, a coal dust preparing and spraying system, a molten iron desulfurizing agent preparing and jetting device, an oxygen and nitrogen supplying system, a residual iron treating system, a high-wind-temperature hot blast furnace, a melting reduction furnace blower, a furnace top gas dedusting and recycling system and a gas cogeneration device. The method comprises the following steps of: introducing high-temperature gas which is generated in a high-wind-temperature rotational flow injection disturbance melting reduction furnace into the prereduction furnace; directly reducing an iron-containing raw material in a solid phase state into a prereduction furnace material with a certain metallization rate; cooling, and then adding the cooled material and semicoke which serve as the furnace material and a fuel respectively into the melting reduction furnace; and finally producing molten iron by reduction. The device and the method have the advantages of high production efficiency and low energy consumption, are easy to operate and make industrialization easily realized.

Owner:BEIJING SHOUGANG INT ENG TECH

Production technology of lotus seed wine

A production technology of lotus seed wine comprises the steps: crushing dry lotus seeds with or without husks into 1 mesh to 8 meshes, adding 40 Kg-70 Kg of water and mixing to moisten the crushed dry lotus seeds; putting into a container or wrapping with cloth, compacting and pilling up to make water uniformly fully absorbed, then stirring to a fluffy state, steaming until the lotus seeds are thoroughly cooked, spreading and cooling to 26 DEG C-34 DEG C; stirring and mixing with 0.8%-2% of a medicinal liquor, 0.2%-0.6% of glucoamylase and 0.08%-0.15% of dry yeast which are calculated by dry weight of dry lotus seeds; putting in a tank and sealing the mouth of the tank with thin cloth for about 16 h-24 h, then removing the thin cloth and sealing with a thin film, controlling the temperature at 24 DEG C-38 DEG C and fermenting for 25 days -40 days; taking out the wine original blank, squeezing, placing the squeezing liquid at the lower layer of a distiller, introducing steam to make the boiling squeezing liquid evaporated and pass through the squeezed blank to obtain original wine with alcohol degree of 40 degrees to 60 degrees; and filtering the original wine with diatomite to obtain the wine. According to the production technology, pure fruit lotus seeds with or without husks are employed for production of the wine, and the wine is not added with sugar, is not colored and is not perfumed; the production technology is easy to control, special raw material pretreatment and slaking technology is employed; and fermentation is performed at a low temperature, the use amount of the medicinal liquor is reduced, the generation of methanol is reduced, and the quality is improved.

Owner:杨起根

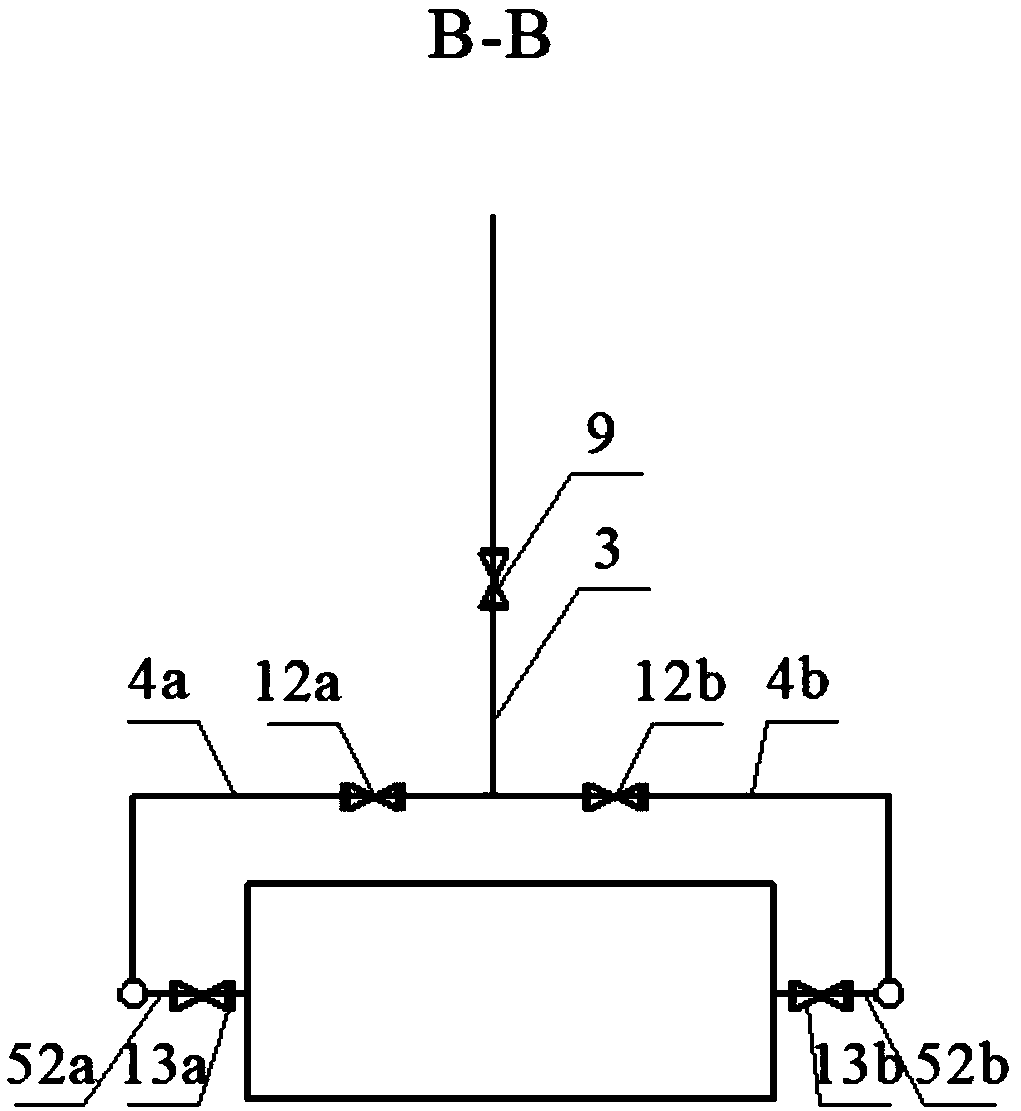

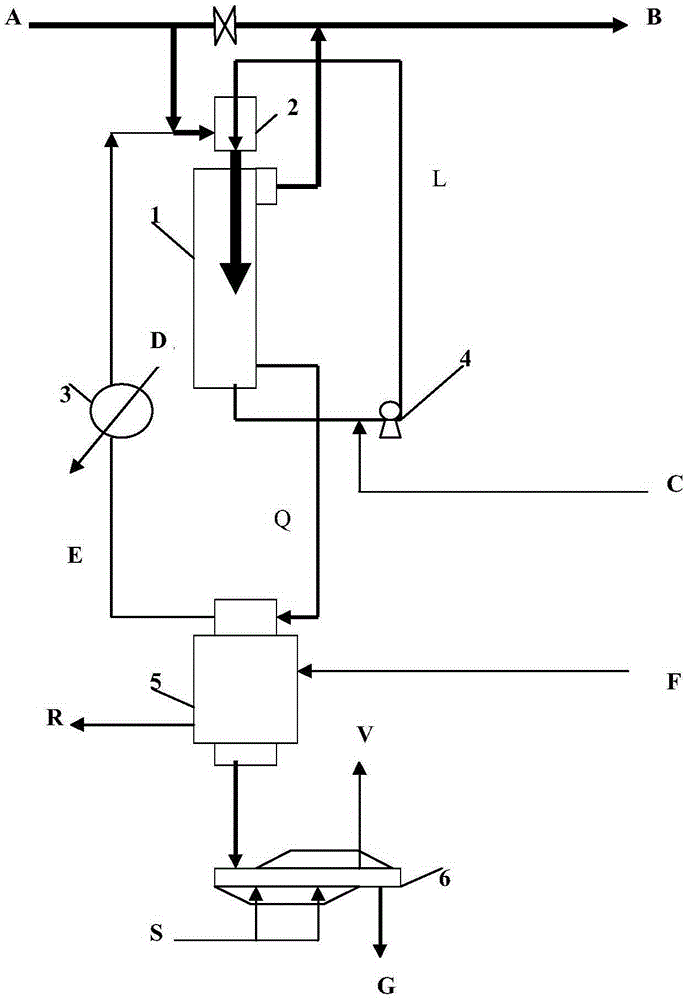

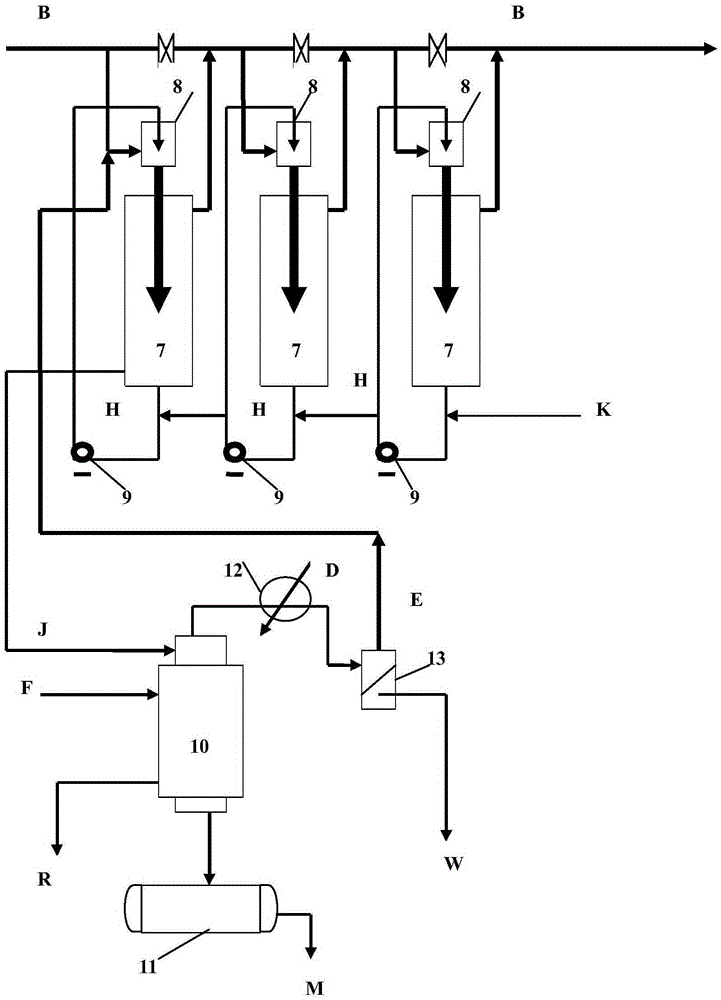

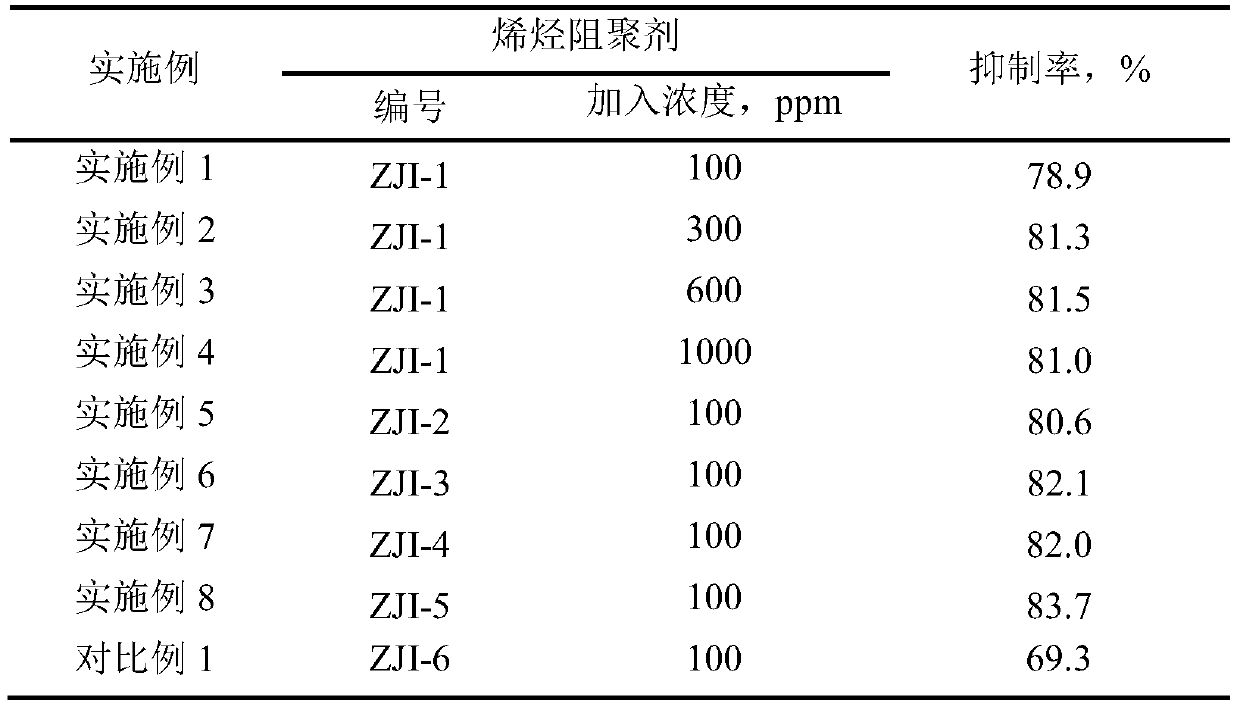

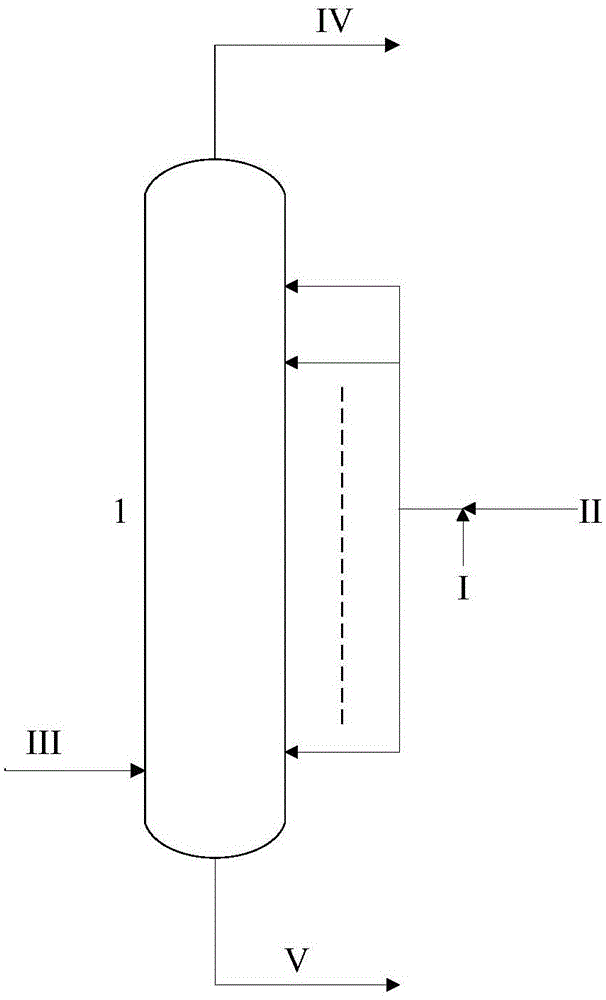

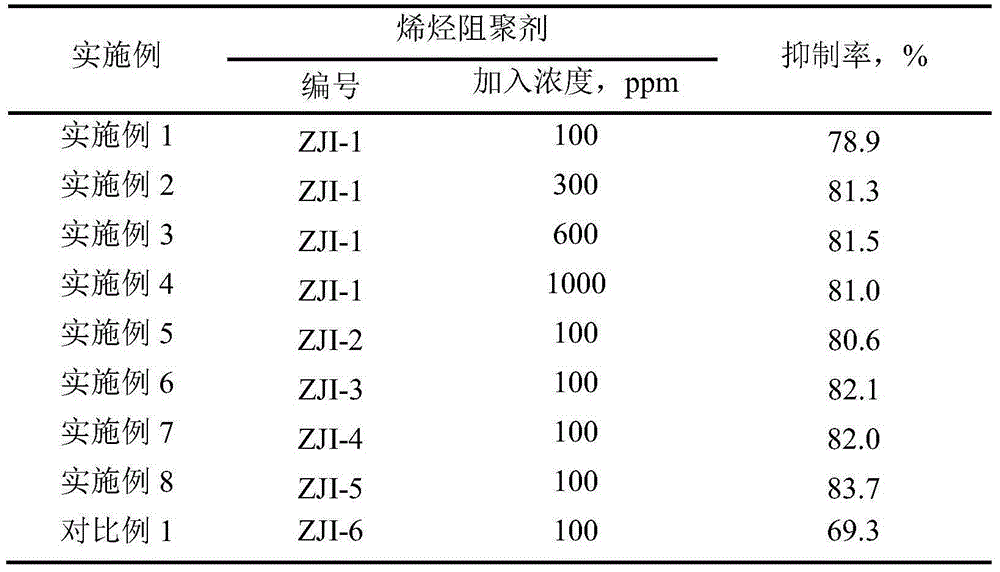

Method of inhibiting olefin polymerization in alkaline washing column of methanol-to-olefin (MTO) device

InactiveCN106467447AReduce pollutionInhibit aggregationHydrocarbon purification/separationHydrocarbonsOrganic chemistryPoor control

The invention relates to a method of inhibiting olefin polymerization in an alkaline washing column of a methanol-to-olefin device and mainly solves the technical problems of poor control effect on olefin polymerization, poor targeted applications, instability, complex operations, high toxicity and high cost in an alkaline wash column of an MTO apparatus in the prior art. In the technical scheme, a) an olefin polymerization inhibitor (I) is employed and includes, by weight, 0-20 parts of an amine compound and 0-10 parts of an alcohol compound; and b) the olefin polymerization inhibitor (I) is injected to the alkaline wash column (1) along with an alkaline solution (II) in an online continuous injection manner through an alkaline solution injection line on the alkaline wash column. The method solves the technical difficult problems and can be used for controlling and preventing the olefin polymerization in the MTO apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

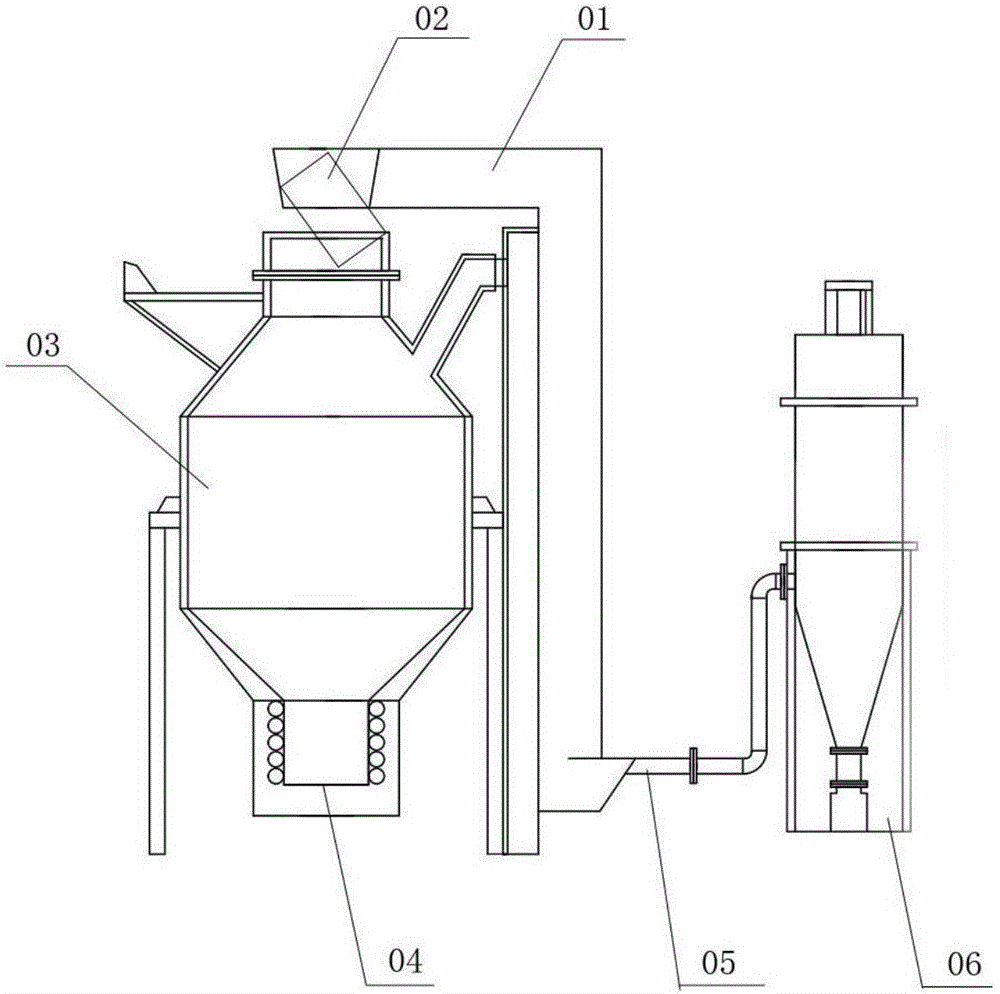

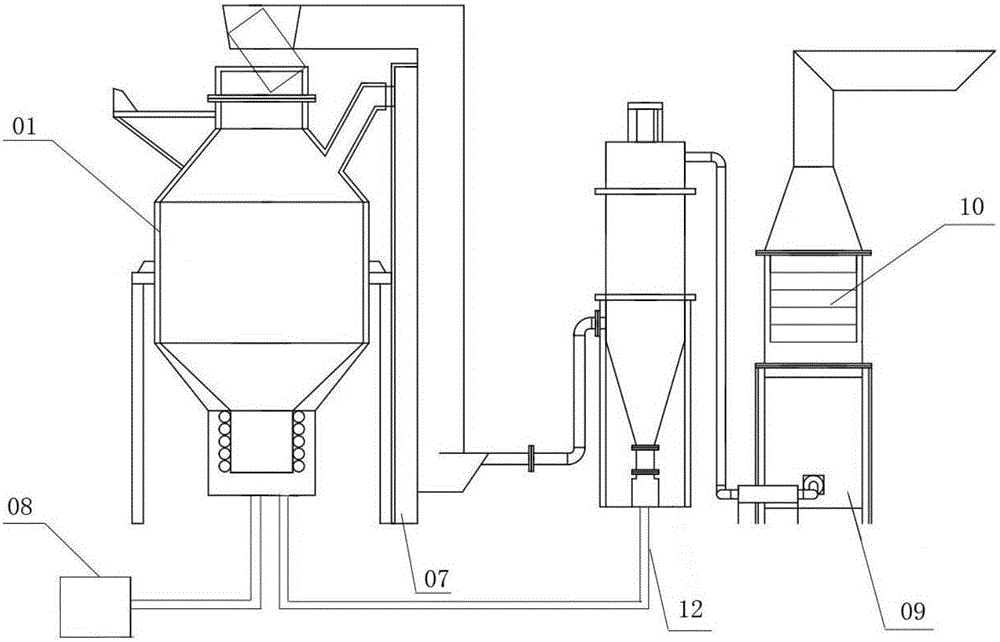

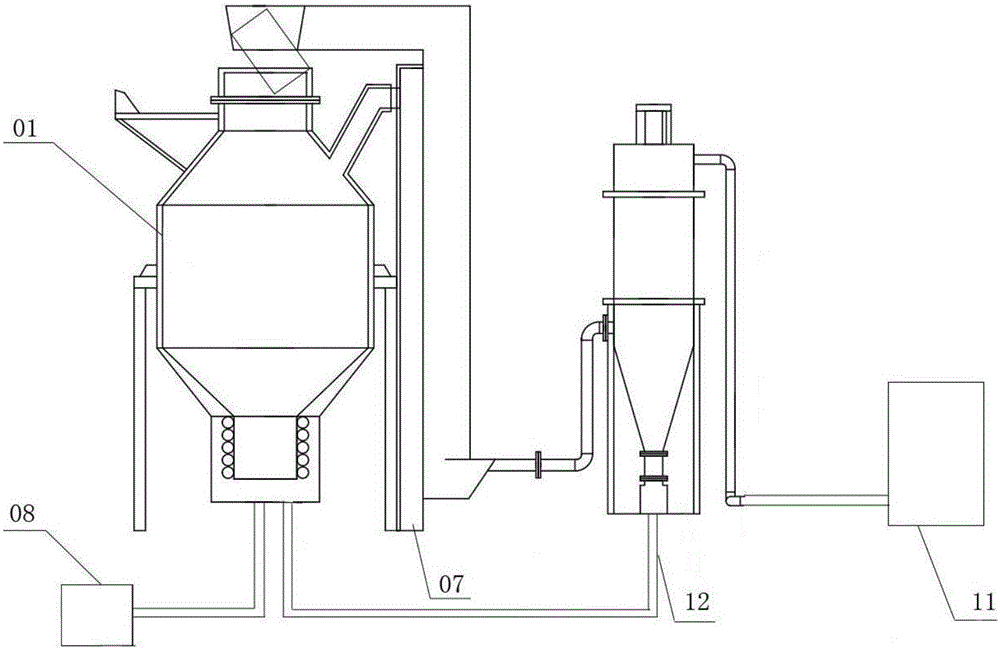

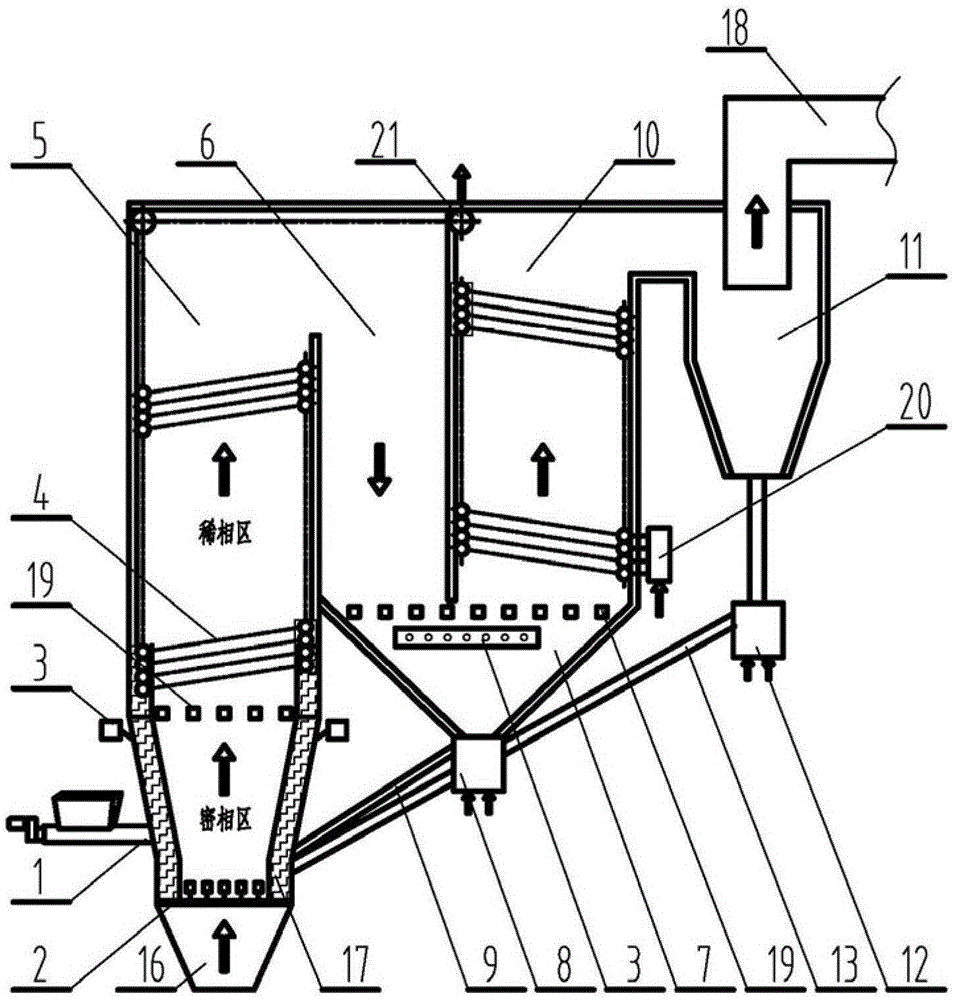

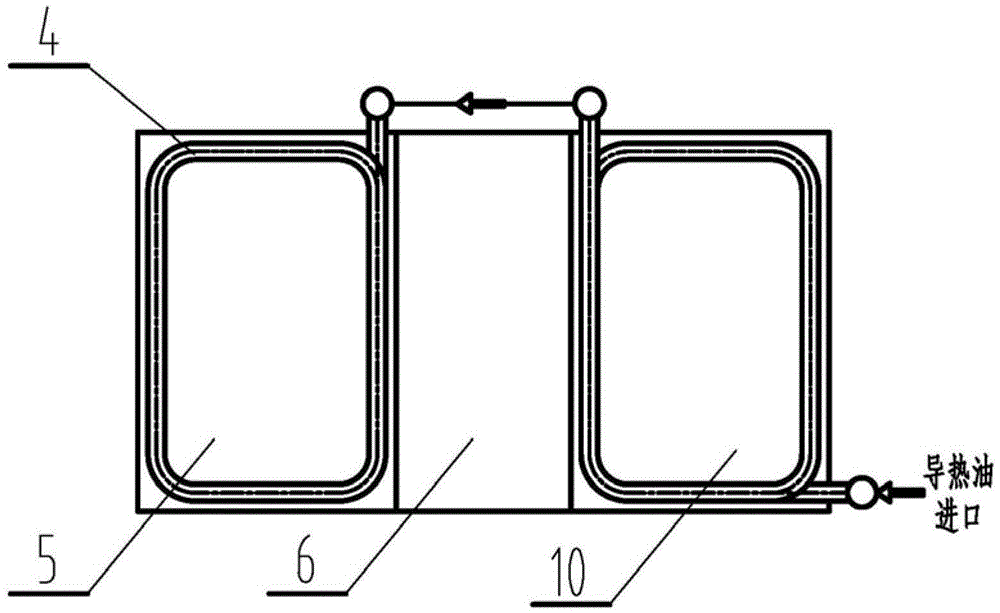

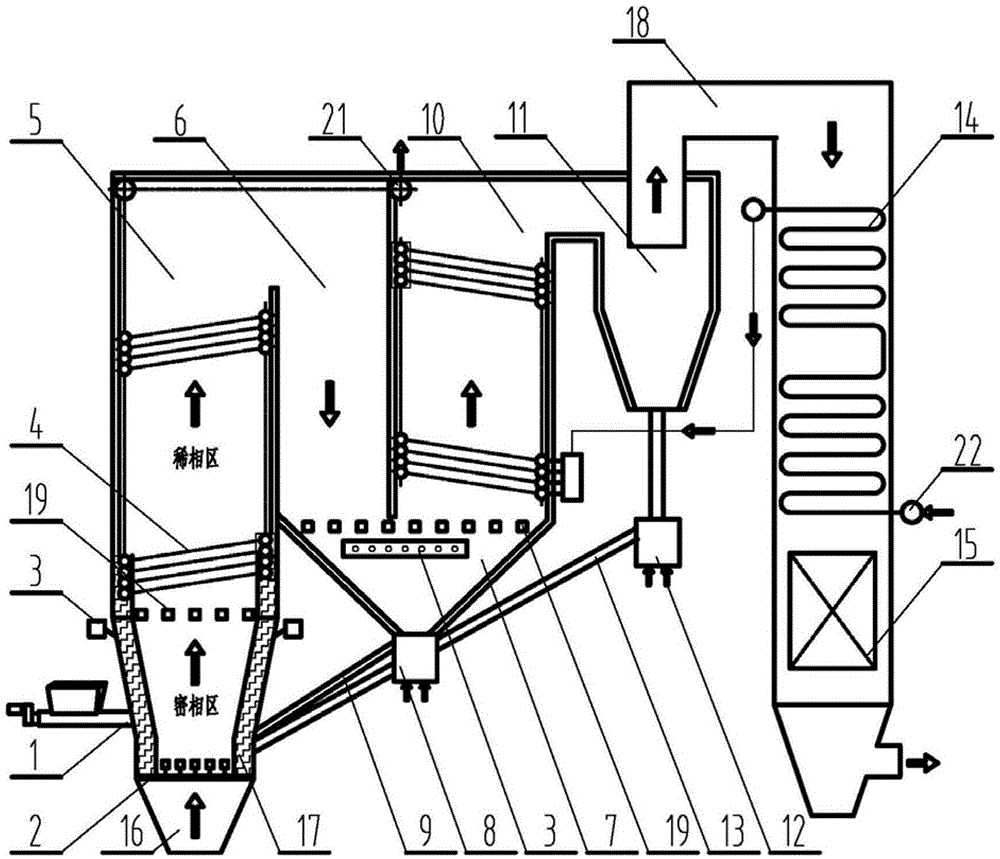

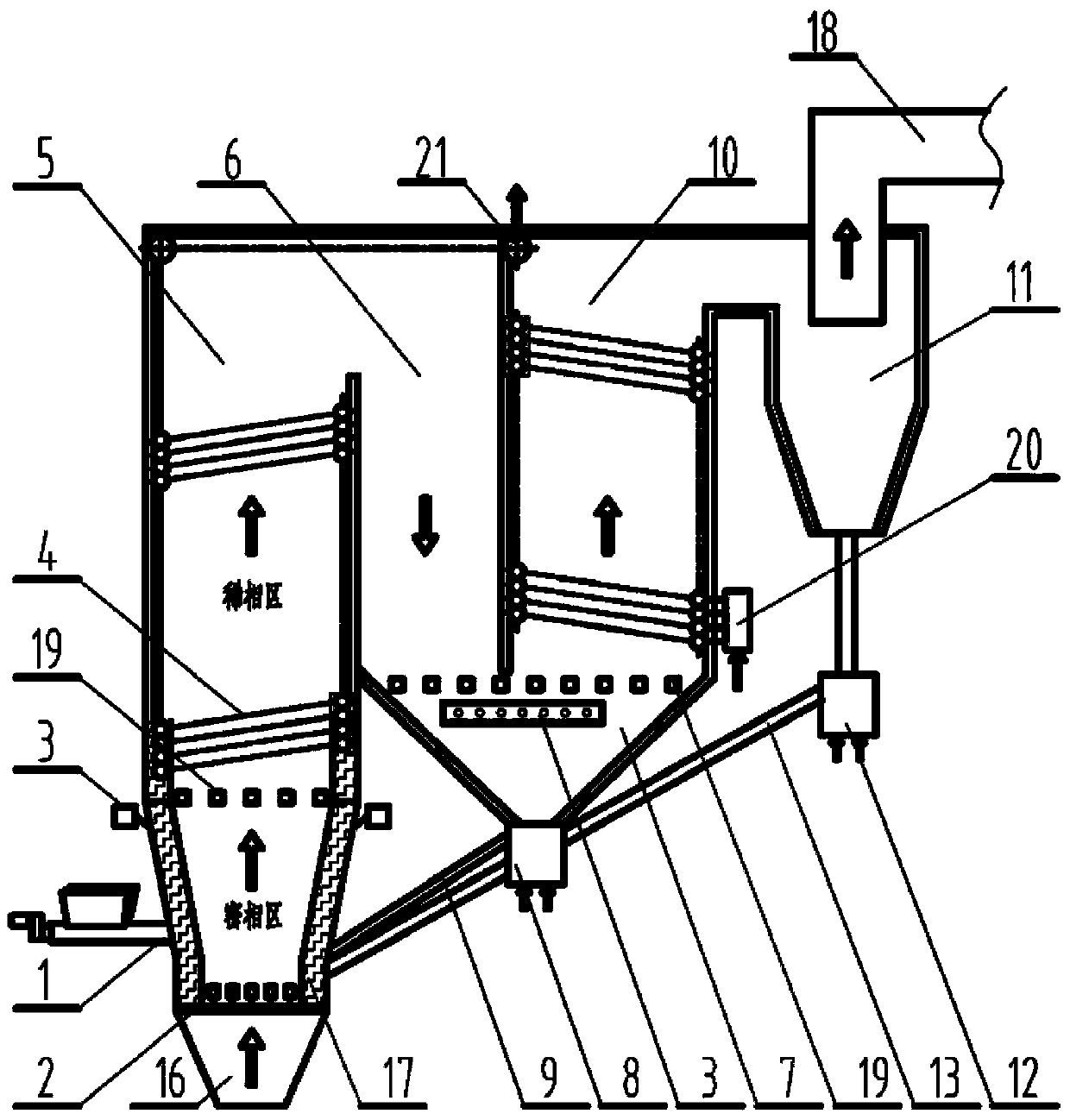

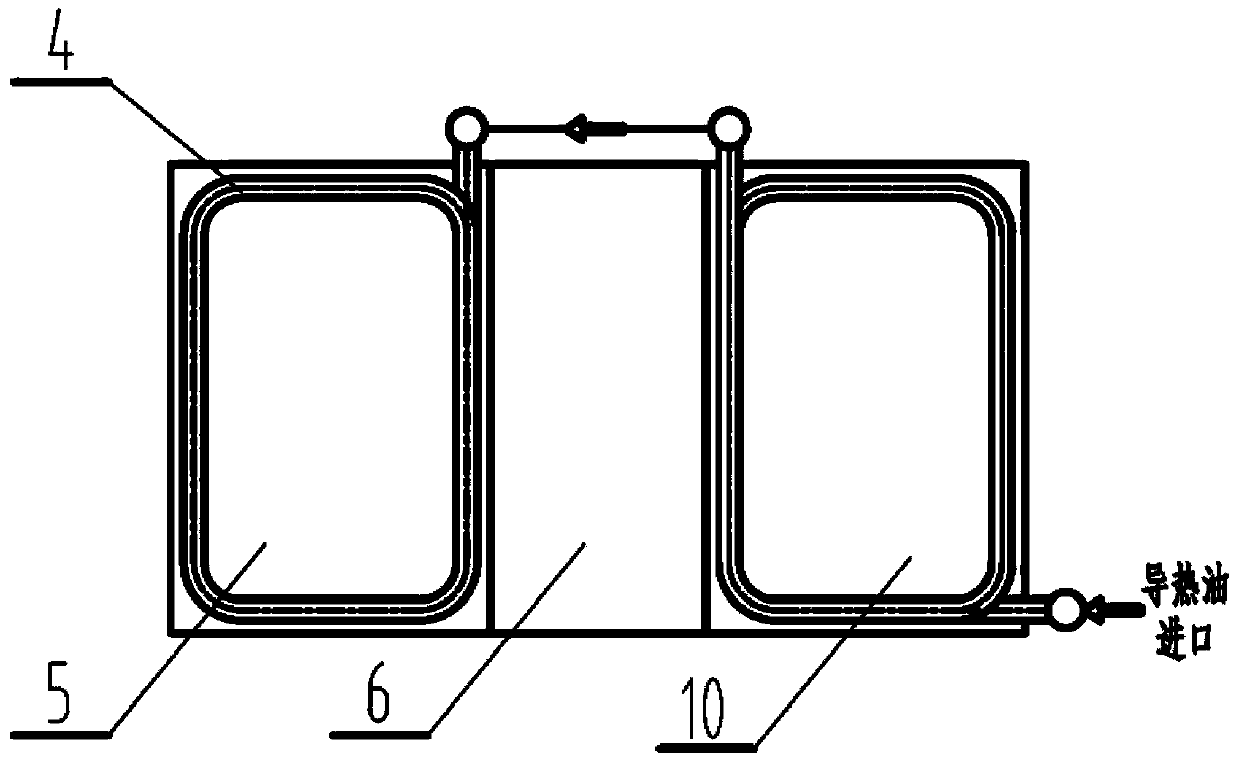

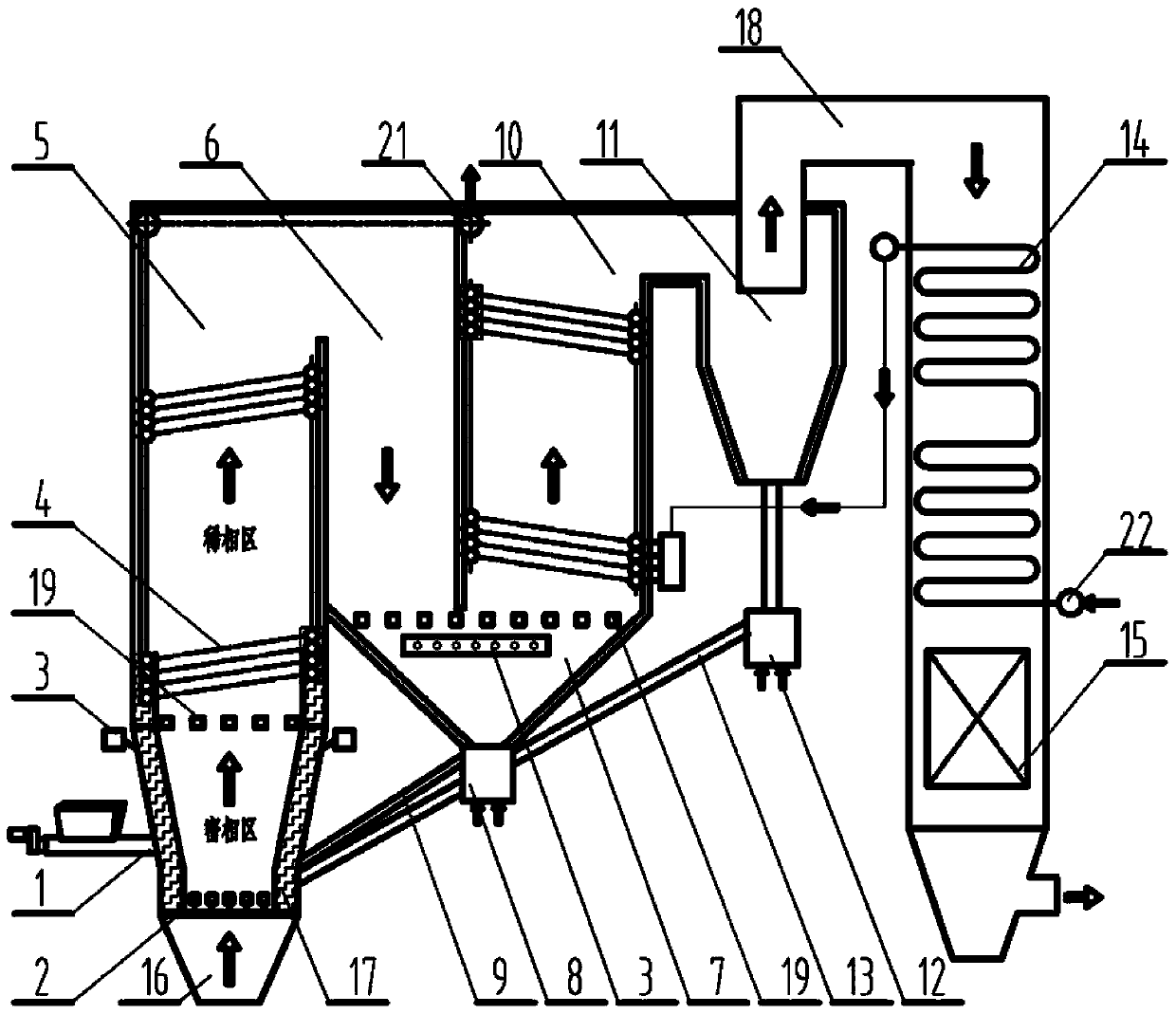

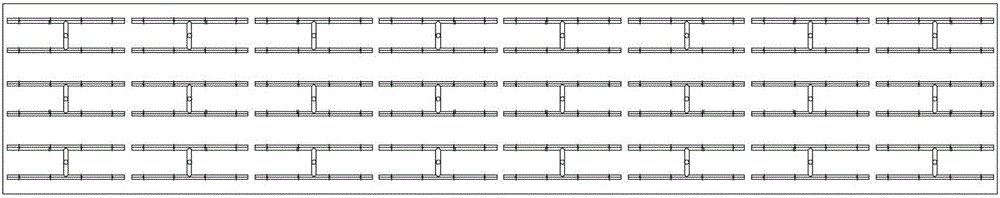

Heat-conduction oil furnace of horizontal circulating fluidized bed

ActiveCN103423869AWide fuel adaptabilityHigh temperature flue gas process is longFluidized bed combustionStorage heatersCirculating fluidized bed boilerCombustion chamber

The invention discloses a heat-conduction oil furnace of a horizontal circulating fluidized bed, and relaters to combustion equipment of the circulating fluidized bed for inferior coal, solid wastes, urban and industrial sludge and biomass fuels, in particular to a heat-conduction oil heating device. The heat-conduction oil furnace is mainly composed of a feeding device, a main combustion chamber, an auxiliary combustion chamber, an after-combustion chamber and a cyclone separator, wherein heat-conduction oil coils are arranged in the main combustion chamber and the after-combustion chamber, an economizer and an air pre-heater can be arranged behind the cyclone separator, and a waste heat boiler can also be arranged behind the cyclone separator. The heat-conduction oil heating device adopts a horizontal circulating fluidized bed technology, changes the traditional structural style adopting a chain grate furnace to heat, changes the single-stage and vertical circulating structure of the traditional fluidized bed boiler, effectively reduces the height of the boiler, and reduces the requirement on the construction height of plants. Through reasonable structural layout, the problem that the circulating fluidized bed boiler is easily abraded is effectively solved, and the heat-conduction oil heating device has wide adaptability to fuels, has high combustion efficiency, and has lower pollutant discharging quantity.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

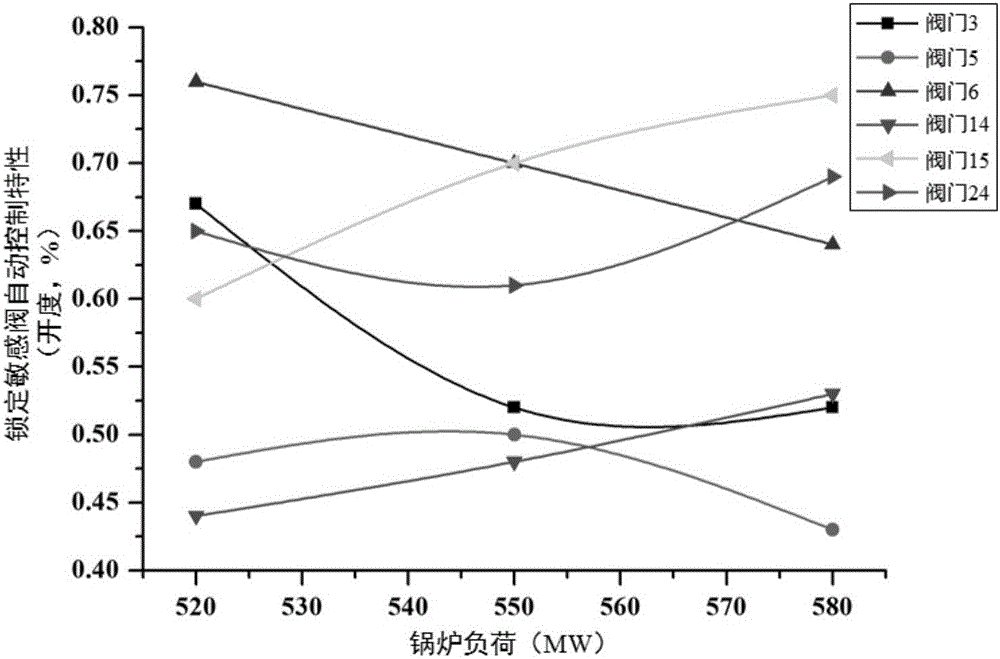

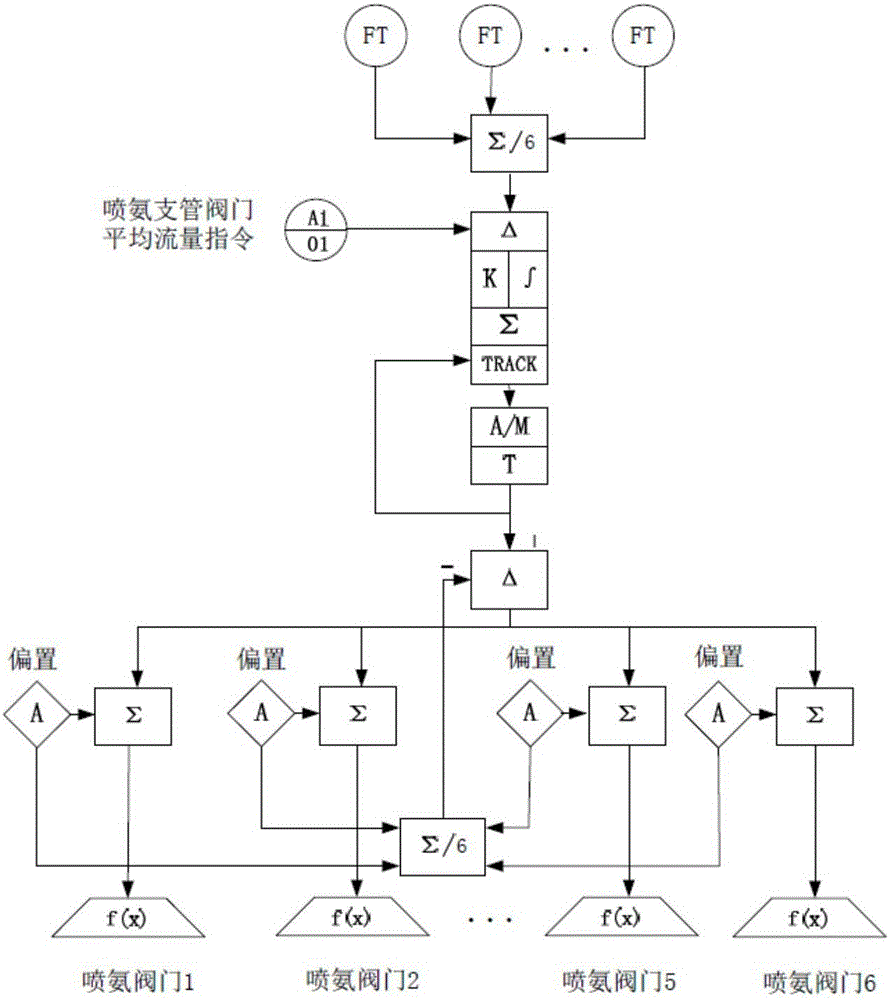

SCR system automatic control method based on ammonia spraying sensitive valve locking

ActiveCN105700504AImprove reaction efficiencySave ammonia consumptionGas treatmentDispersed particle separationAutomatic controlField tests

The present invention discloses a SCR system automatic control method based on ammonia spraying sensitive valve locking. The method comprises three steps: firstly, performing comprehensive analysis of varying load condition operation characteristics of the SCR system based on a field test and a CFD numerical simulation technology to obtain flue gas 'NOx flow' regional continuous distribution characteristics matching an AIG type; then determining the weight of each ammonia spraying branch pipe valve, locking a certain number of sensitive valves according to a preset sensitive valve locking principle, and installing an automatic regulating valve at a corresponding ammonia spraying region; finally, developing an ammonia spraying logic controller and corresponding main control and sub-control logics, realizing multistage optimization setting of parameters of the control system, and realizing the accurate automatic control of the main ammonia spraying regulating valve of the SCR system and the locking sensitive valves. The SCR system automatic control method based on ammonia spraying sensitive valve locking is able to overcome the problems of characteristics of the SCR system such as nonlinearity, large delay and the like so as to realize the accurate automatic control of the ammonia spraying of the SCR system, substantially enhance the SCR denitration reaction efficiency, save the dosage of ammonia, reduce the ammonia escape and effectively inhibit the generation of ABS.

Owner:SOUTHEAST UNIV +1

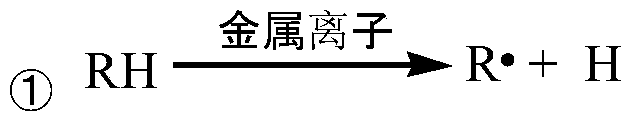

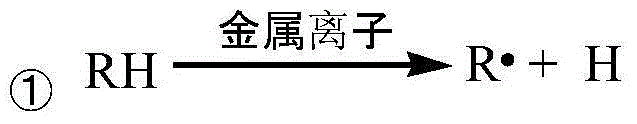

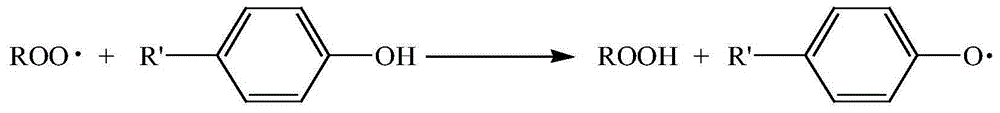

Olefin polymerization inhibitor for alkali-washing tower of methanol-to-olefin production device

ActiveCN106467448ANot targetedEffective control generationHydrocarbon purification/separationHydrocarbonsOlefin polymerizationToxicity

The invention relates to an olefin polymerization inhibitor for an alkali-washing tower of a methanol-to-olefin production device. The olefin polymerization inhibitor mainly solves the problem that the conventional olefin polymerization inhibitor has poor specificity in an alkali-washing tower, has poor effect, is unstable, is operated through complex processes, has high toxicity and a high cost. The olefin polymerization inhibitor comprises, by weight, 0 to 20 parts of an amine compound and 0 to 10 parts of an alcohol compound. The olefin polymerization inhibitor solves the above technical problem and can be used for controlling and preventing the polymerization of olefins in the alkali-washing tower of the methanol-to-olefin production device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device of oxygen control growth in single crystal furnace

InactiveCN101922040AImprove insulation effectReduce generationPolycrystalline material growthBy pulling from meltEngineeringInsulation system

The invention belongs to the technical field of semiconductor separation and particularly relates to a device of oxygen control growth in processes of producing and separating single crystal silicon. The device is formed by improving a heater, a guiding cylinder and a lower insulation system in a single crystal furnace, the height of a blade of the heater is reduced, the hot source area at the bottom of a crucible is decreased, the bottom of the quartz crucible is heated little and less oxygen in the production process is generated; a sealing guide system is reconstructed, an encryption type guiding cylinder is additionally arranged on an upper cover plate, and can accelerate the cooling speed; and a lower insulation system in the furnace is reconstructed, therefore, the insulation effect of a lower insulation cylinder is reinforced, more oxygen from a crystal and melt interface can be taken away, the oxygen content is reduced and generated boroxol complex is decreased. The invention can effectively reduce generation and retention of the oxygen in the production process and control generation and transportation of the oxygen, reduces the process and the quantity of the oxygen entering a single crystal, and has the advantages of simple structure, low cost and convenient installation, use and operation.

Owner:江国庆

Method for preparing sodium hydrosulfide from hydrogen sulfide acid gas containing carbon dioxide

ActiveCN103693626AInhibition and delayed absorptionBenefit its solubilityProductsReagentsSodium bicarbonateSodium hydrosulfide

The invention discloses a method for preparing sodium hydrosulfide from hydrogen sulfide acid gas containing carbon dioxide, which belongs to the technical field of decarburization. The method comprises the following steps of firstly, mixing buffer solution containing sodium hydroxide and sodium bicarbonate with non-decarburized hydrogen sulfide acid gas to react and absorb carbon dioxide and hydrogen sulfide in the acid gas, so as to obtain decarburized pregnant solution, and then, heating the decarburized pregnant solution to make the sodium hydrosulfide in the decarburized pregnant solution hydrolyze and change into sodium hydroxide, wherein the sodium hydroxide generated by hydrolysis reaction reacts with free alkali and sodium bicarbonate in the decarburized pregnant solution to generate sodium carbonate; conveying the hydrogen sulfide acid gas without carbon dioxide into a tubular mixing reactor, performing reverse absorption with circulated alkali liquor to obtain pregnant solution containing sodium hydrosulfide, evaporating and concentrating the pregnant solution containing sodium hydrosulfide to obtain sodium hydrosulfide products of different levels. The method provided by the invention can remove carbon dioxide from hydrogen sulfide acid gas, and quality of the sodium hydrosulfide product prepared from the decarburized acid gas is controllable and adjustable.

Owner:武穴融泰医药科技有限公司

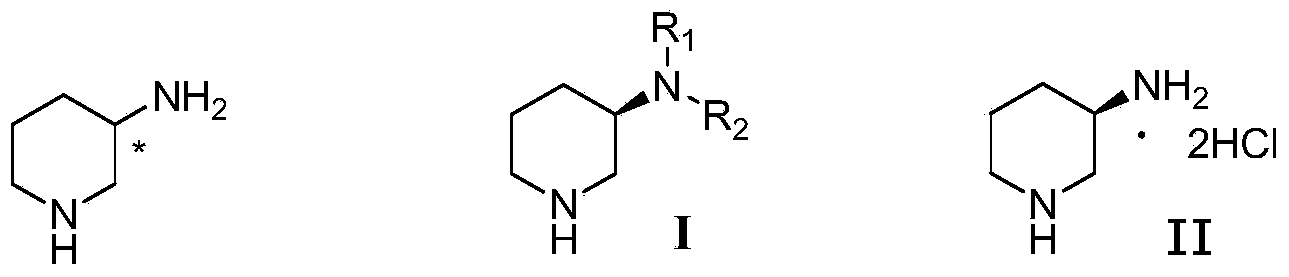

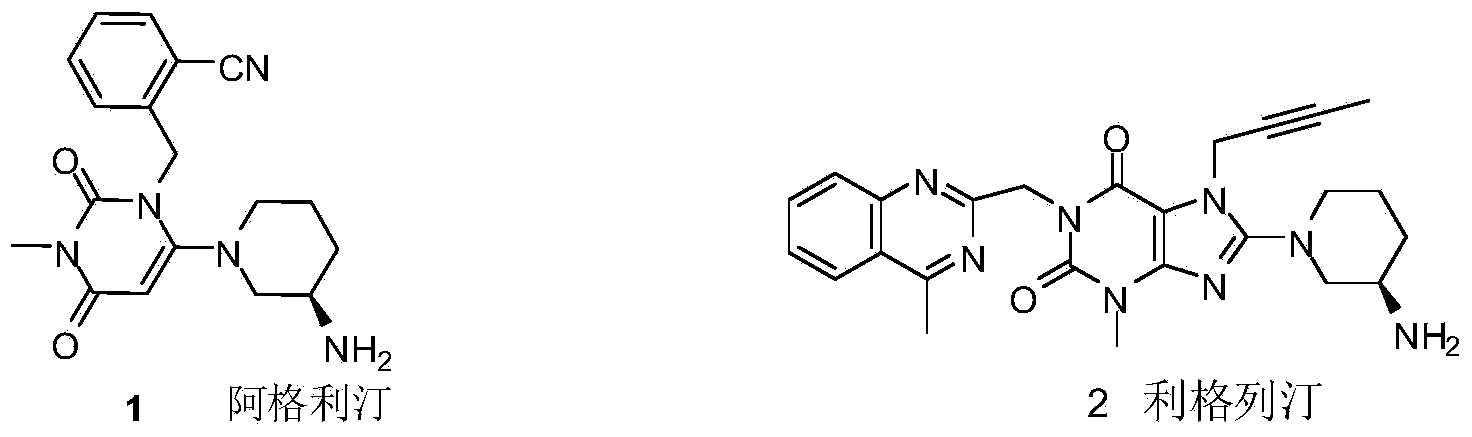

Compound I and (R)-3-aminopiperidine hydrochloride II, preparation method and application in Linagliptin synthesis

ActiveCN104387315AHigh optical purityHigh process reproducibilityOptically-active compound separationOrganic racemisationDipeptidyl peptidase3-Aminopyridine

The invention discloses a preparation method of 3-aminopiperidine and its derivative with optical activity and an application of the compound and its derivative in synthesis of a dipeptidyl peptidase-IV inhibitor Linagliptin. According to the preparation method, 3-aminopyridine is used as a raw material to prepare a compound I by 3- amino protection, catalytic hydrogenation reduction of pyridine ring and chiral reagent resolution, and deprotection is then carried out to obtain (R)-3-aminopiperidine hydrochloride II. In the application, a compound III prepared from the compound I is an important intermediate for synthesis of Linagliptin, and (R)-3-aminopiperidine hydrochloride II also can directly be used for synthesis of high-purity Linagliptin. The raw material used in the invention is low-cost and is easily-available in the market; each step is simple to operate; requirements on equipment are low; safety is high; and the preparation method is easy for industrial production.

Owner:2Y CHEM

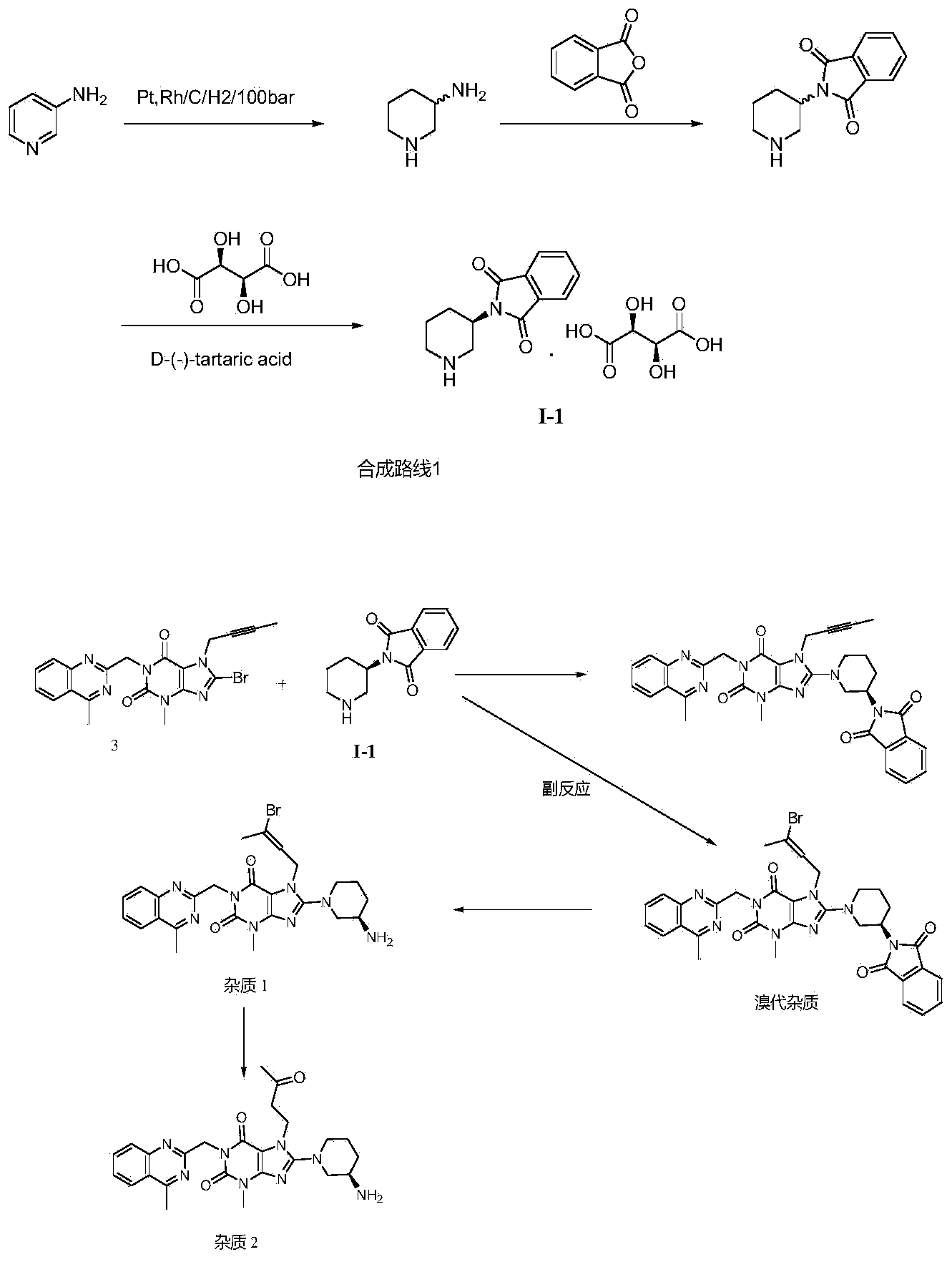

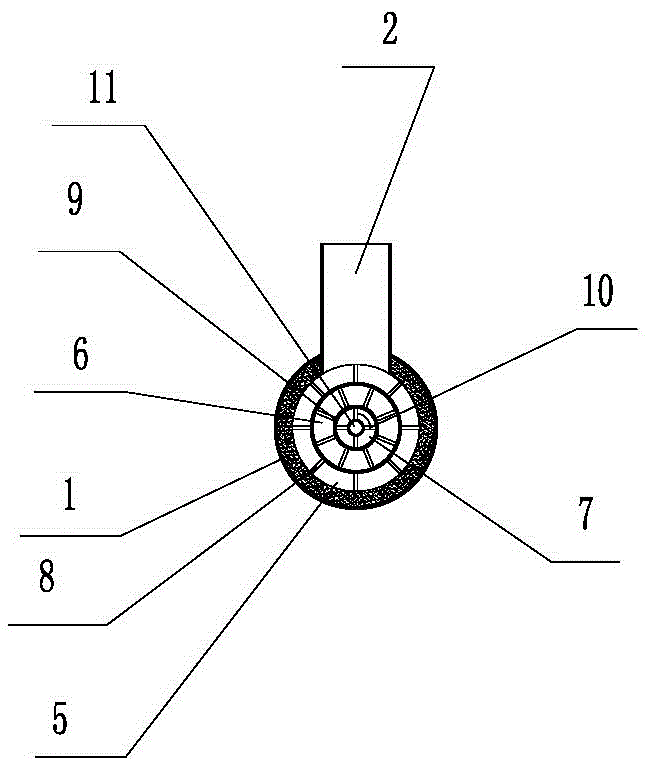

Combusting device for low nitrogen combustion of classification pre-mixed swirling flow

ActiveCN105737152AStable combustionEffective control generationGaseous fuel burnerCombustion chambersLow nitrogenPre combustion

The invention relates to a combusting device for low nitrogen combustion of a classification pre-mixed swirling flow, and effectively realizes the combustion purposes of classification pre-mixed combustion, flame stabilization combustion and temperature control combustion among coal gas, air, auxiliary air, and steam. Four pipe bodies are mounted in a stepped sleeving manner; an air inlet pipe is arranged at the closed end of an outer layer air annular passage; an auxiliary air inlet pipe is arranged at the closed end of an inner layer auxiliary air annular passage; a coal gas annular passage is arranged at the middle, and a coal gas inlet pipe is arranged at the closed end of the coal gas annular passage; swirling flow supporting pieces are separately arranged in outlet sections of the passages; centers of the four pipe bodies are steam passages; a pre-mixed pre-combustion chamber communicating with a combustion gas flow outlet is arranged in the outer pipe body; a conic bluff body with a contracted duct in the center is arranged at the outlet of the auxiliary air annular passage. According to the combustion device disclosed by the invention, the generation of nitrogen oxides during the combustion process is effectively controlled, the combustion temperature is reasonably controlled, and the emission capacity of the nitrogen oxides is effectively reduced; therefore, the fuel is saved, the investments are saved, and pollution to atmospheric environment is reduced.

Owner:陈维汉

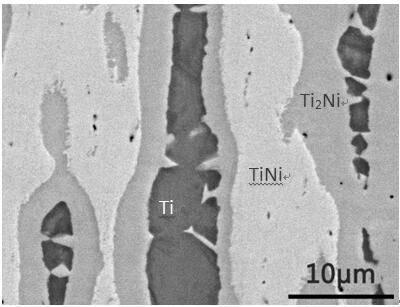

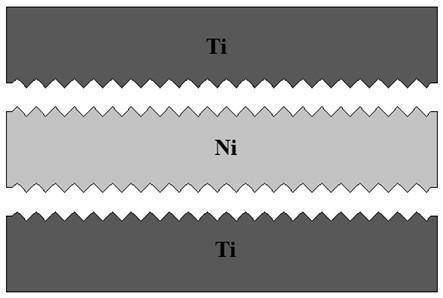

Enhanced TiNi layered composite material and preparation method thereof

ActiveCN110293717AEffective control generationGood mechanical propertiesLamination ancillary operationsLaminationTitaniumPre treatment

The invention discloses an enhanced TiNi layered composite material and a preparation method thereof, and belongs to the field of processing of special material composite technology. By aiming at theproblems of poor mechanical properties of the existing Ti / Ni layered composite material, pure titanium and pure nickel are used as raw materials; titanium plates and pure nickel plates are respectively subjected to surface pretreatment; then, the placement is performed in an alternate laminated sequence in a mode of Ti / Ni / Ti; through the subsequent rolling compounding and heat treatment processes,the Ti / Ni layered composite material with excellent mechanical property is prepared. The preparation process is simple; the cost is low; the mechanical property is excellent.

Owner:JINCHUAN GROUP LIMITED

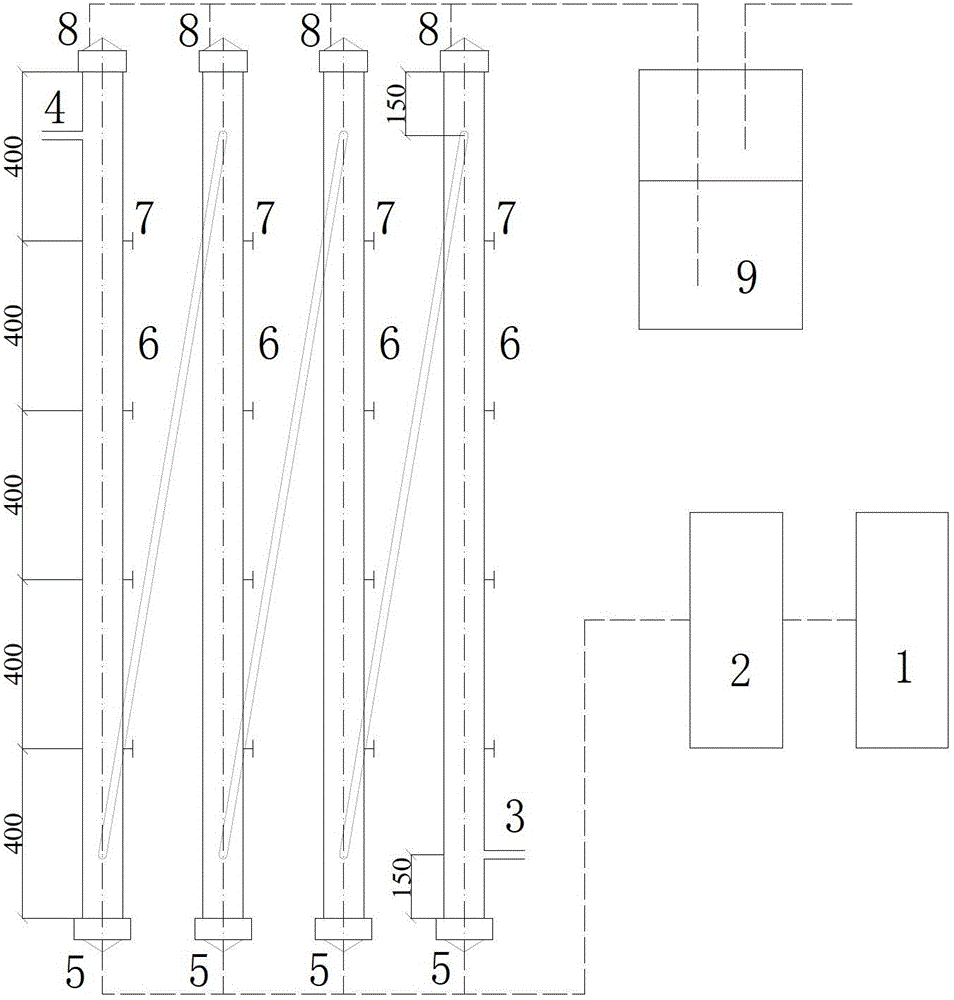

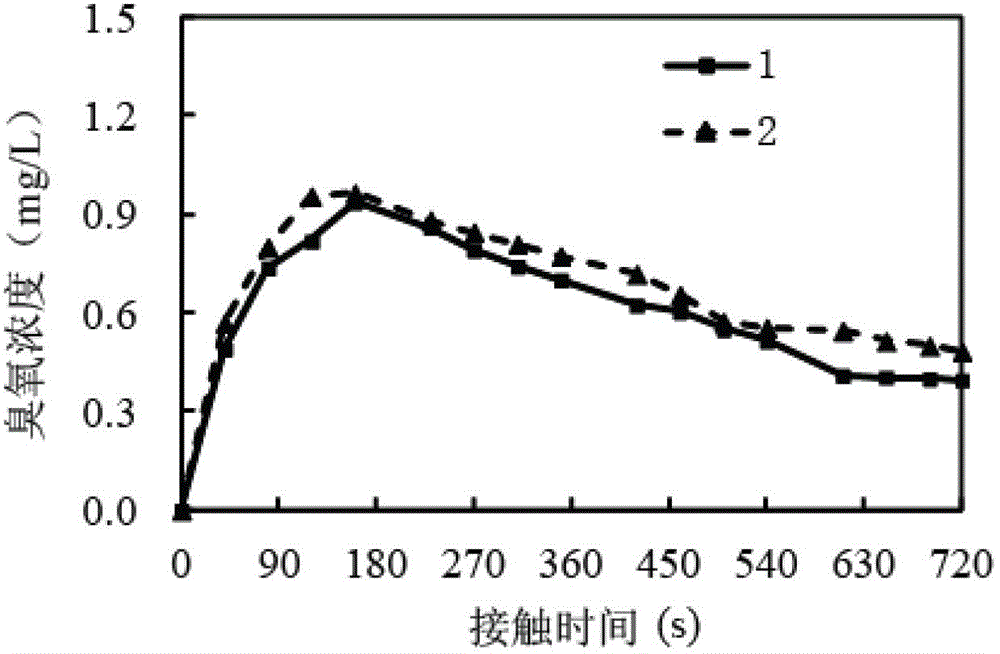

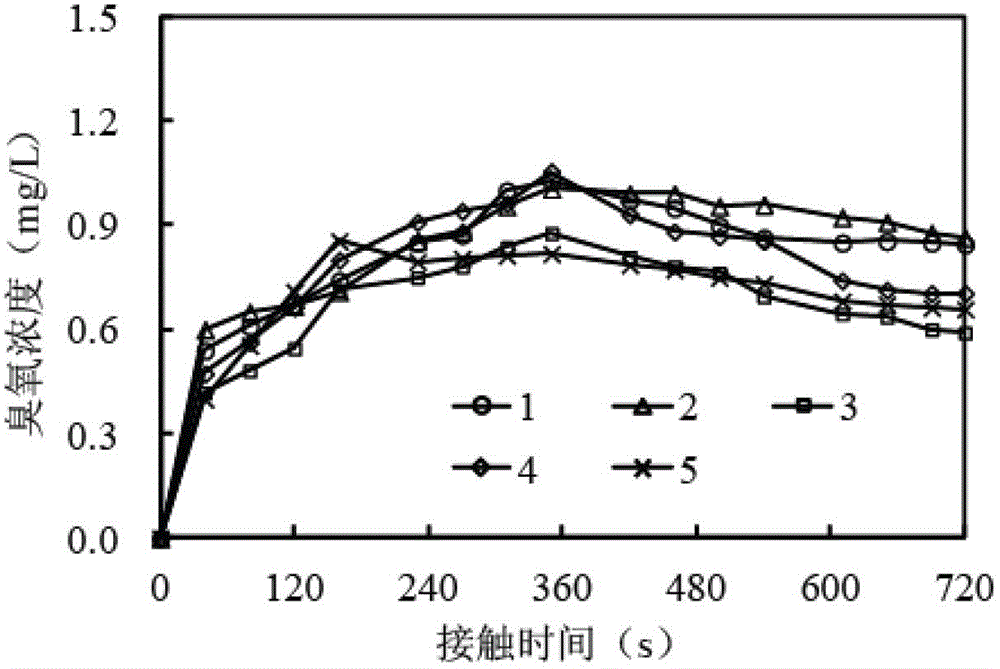

Ozone contact optimal dosing method in drinking water treatment and device thereof

InactiveCN103145229AHigh removal rateImprove ozone mass transfer efficiencyComponent separationMaterial analysis by observing effect on chemical indicatorBiological activated carbonBromate

The invention discloses an ozone contact optimal dosing method in a drinking water treatment and a device thereof. The optimal ozone dosing method is determined by changing the number of the dosing points and a dosing ratio of ozone, and investigating the effects of ozone concentration changes along the way, ozone mass transfer efficiency, CT (Captive Test) values and a pollutant removal rate. Researches show that when aeration is generated at three points, and the dosing ratio of the ozone is 3:3:1, the ozone mass transfer efficiency reaches 86.8%, the UV (Ultraviolet) 254 removal rate is 52.9%, the effluent ozone concentration is 0.39mg / L, after KBr (potassium bromide) is added, bromate has the lowest production amount, and is the optimal ozone dosing ratio. The ozone contact optimal dosing method in the drinking water treatment and the device thereof have the advantages of obviously improving the ozone mass transfer efficiency and the pollutant removal rate by optimizing the ozone dosing method, effectively controlling the production of the bromate without increasing the total ozone dosing quantity, having no impact on a subsequent biological activated carbon process, and having safety and economy.

Owner:UNIV OF SCI & TECH BEIJING

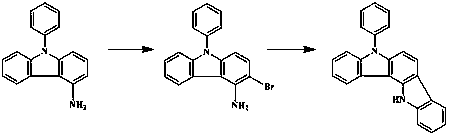

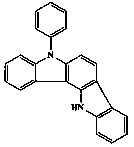

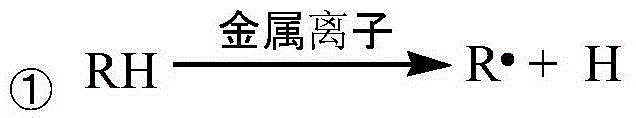

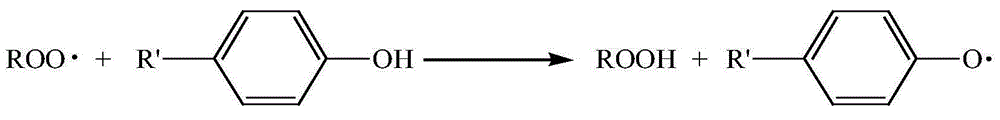

Synthesis method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole

ActiveCN108148065AEffective control generationControl generationOrganic chemistryChemical synthesisHydrogen

The invention discloses a production method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole. The method belongs to the field of organic chemical synthesis, and comprises the steps of adopting 1-amino-N-phenylcarbazole as a starting material, and carrying out bromination reaction, Suzuki coupling reaction and Buchwald coupling reaction to synthesize the 11,12-dihydro-11-phenylindole [2,3-a]carbazole. During the reaction process, the method is less in side reaction, simple to operate and high in yield. The synthesized 11,12-dihydro-11-phenylindole [2,3-a]carbazole can be applied to the fieldssuch as organic optoelectronic materials and medicines, and is an important intermediate for carbazole photoelectric materials, medicines and pesticides.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL

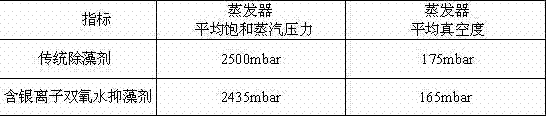

Efficient algae-inhibiting method for water circulation system of cooling tower

InactiveCN103588265AReduce the chance of infectionGood effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationCooling towerWater cycling

The invention provides an efficient algae-inhibiting method for a water circulation system of a cooling tower. Silver ion-containing hydrogen peroxide is used as an algae inhibitor. When the cooling tower starts running, 3.5-4.5 g of silver ion-containing hydrogen peroxide is added in every liter of circulation water; and the silver ion-containing hydrogen peroxide is supplemented one time every 7-10 days. A stable sanitizer (the silver ion-containing hydrogen peroxide) is used as an algae inhibitor to replace conventional sanitizer, algaecide and biocide. The algae inhibitor is long in action time and obvious in effect, and can inhibit growth of the algae in the circulation water and effectively control production of biological membranes. The silver ion-containing hydrogen peroxide is colorless and has no smell, is mutually soluble with water, can be decomposed into water and oxygen, is safe and environment-friendly, is harmless to human, is not influenced by temperature and pH value, has a broad spectrum bactericidal effect, and can achieve an object of energy conservation and cost consumption.

Owner:YANTAI NORTH ANDRE JUICE

5,12-dihydro-5-phenyl indole (3,2-a)carbazole synthesizing method

The invention discloses a 5,12-dihydro-5-phenyl indole (3,2-a)carbazole production method and belongs to the field of organic chemical synthesis. The 5,12-dihydro-5-phenyl indole (3,2-a)carbazole is synthesized by the following steps of utilizing 4-amino-N-phenyl carbazole as a beginning raw material, brominating and Suzuki and Buchwald coupling. The synthesizing method ahs the advantages of little side reaction in a reaction process, simpleness in operation and high yield. The synthesizing 5,12-dihydro-5-phenyl indole (3,2-a)carbazole can be applied to the fields of organic photoelectric materials, medicine and the like and is an important intermediate of carbazole photoelectric materials, medicine and pesticides.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Method for treating solid waste through incineration

InactiveCN106051776AEffective control generationControl generationIncinerator apparatusLiquid metalInduction furnace

The invention discloses a method for treating solid waste through incineration, and relates to the technical field of environment protection. The method comprises the steps that the solid waste is fully combusted in a furnace body of an ultrahigh-temperature pyrolysis gasification and melting furnace; metal including Fe, Zn and Pb is gathered in an induction furnace located at the bottom of the furnace body in a simple substance state to form a liquid metal alloy; and due to the large specific gravity, after the liquid metal alloy and other liquid inorganic matter are obviously layered, reserved hole positions are formed in preset positions of the induction furnace in advance so that liquid metal alloy slag can be independently discharged out of the induction furnace. According to the method, dioxin generation can be effectively controlled; the yield of fly ash and waste gas is low; the amount of needed air is low during operation; the dust content in smoke is low; little acid gas is generated; a garbage pretreatment process is not needed; a pretreatment plant and equipment are omitted; the initial cost can be reduced; all products generated by combustion are liquid slag; and inorganic nonmetal and metal liquid slag can be independently discharged correspondingly.

Owner:北京保利洁科技发展有限公司

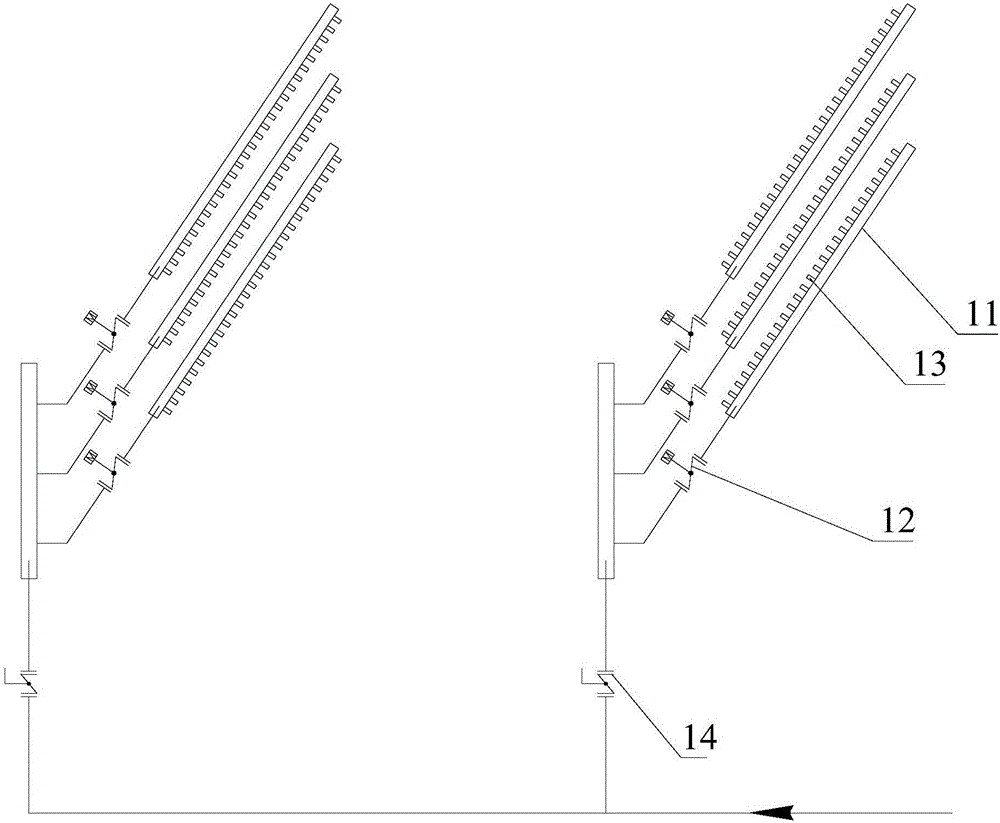

Boiler smoke recirculation system and method

PendingCN108592015AEffective control generationEmission reductionCombustion apparatusCombustionNitrogen oxides

A boiler smoke recirculation system comprises a draught fan, a main air pipe, auxiliary air pipes, spray pipe groups and the like. The draught fan is arranged on the main air pipe. The start end of the main air pipe is connected with an outlet of a dust collector. The tail end of the main air pipe is located outside the lower portion of a hearth of a boiler. The auxiliary air pipes are connected to the tail end of the main air pipe. The spray pipe groups are connected to the tail ends of the auxiliary air pipes and each comprise an upper spray pipe and a lower spray pipe. An opening of each upper spray pipe is arranged at an OFA supply opening of the upper portion of the hearth of the boiler. An opening of each lower spray pipe is arranged at a primary air opening of the hearth of the boiler. The flow of recirculation smoke is adjusted through a main air valve. The recirculation rate of the recirculation smoke is made to be 10-30%. The recirculation smoke is adjusted and distributed byan upper air valve and / or a lower air valve so that the ratio between the amount of the smoke entering the hearth via the upper spray pipes and the amount of the smoke entering the hearth via the lower spray pipes is 2:8-8:2. By the adoption of the boiler smoke recirculation system, through adjustment of the recirculation rate of the smoke and adjustment of the flow ratio between upper smoke andlower smoke of the hearth, the flame temperature and the outlet temperature of the hearth are effectively adjusted, and operation is flexible and easy; and emission of nitrogen oxides is reduced, andthe contamination problem caused by combustion of high-alkali metal fuel is relieved.

Owner:TSINGHUA UNIV

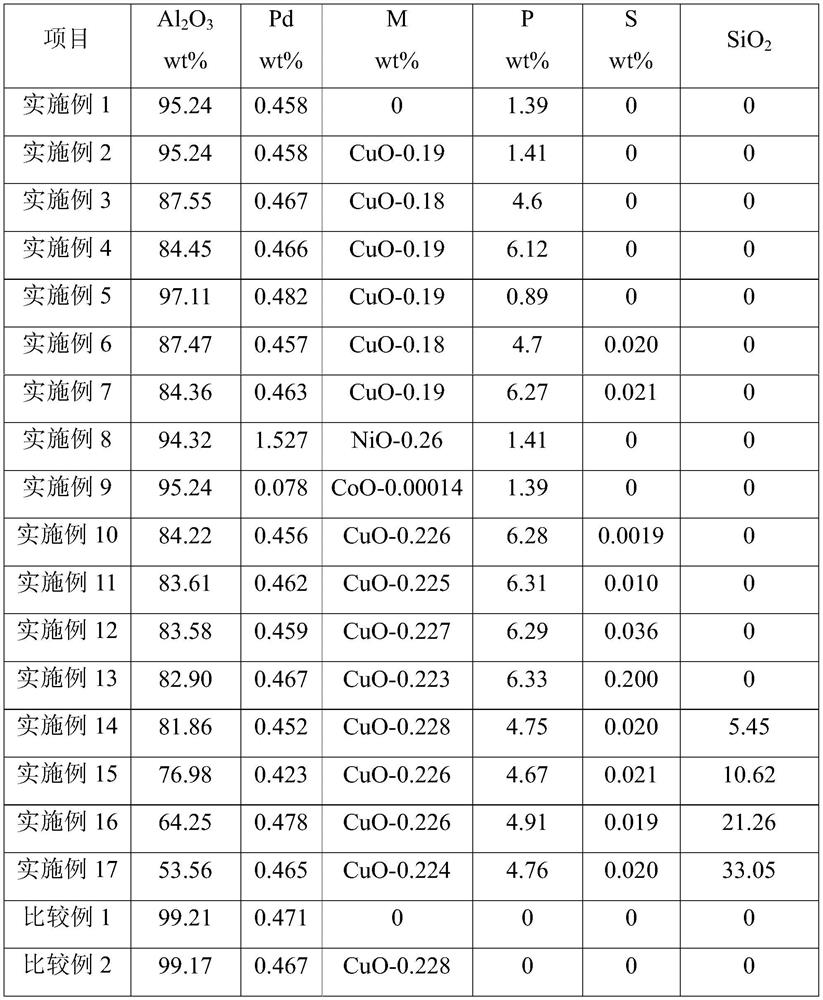

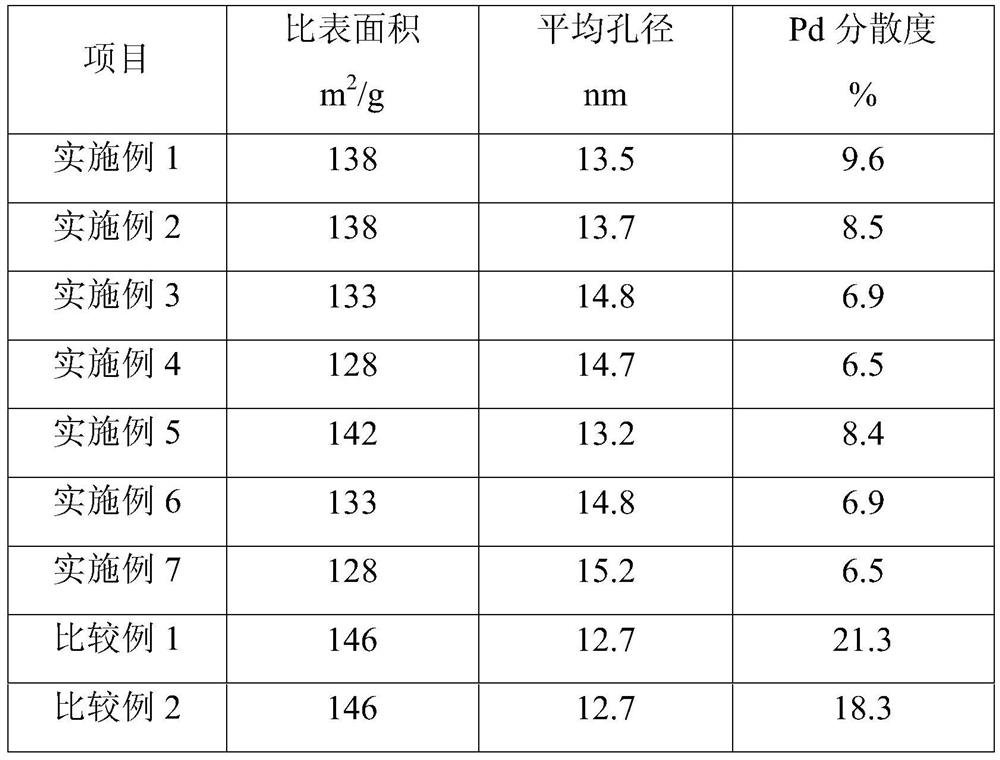

Catalyst for preparing isopropylbenzene as well as preparation and application of catalyst

ActiveCN112569972AImprove hydrogenation activityImprove stabilityCatalystsHydrocarbon preparation catalystsIsopropylcyclohexanePtru catalyst

The invention provides a catalyst for preparing isopropylbenzene as well as preparation and application of the catalyst. The catalyst comprises a carrier and an active component loaded on the carrier,the carrier comprises a carrier matrix and a modification auxiliary component loaded on the carrier matrix, the active component comprises metal palladium and / or oxide thereof, and the modification auxiliary component is phosphorus and / or an oxide thereof; and optionally, the active component further comprises metal copper and / or oxide thereof, and the catalyst further comprises a sulfur-containing compound. When the catalyst is used for preparing isopropylbenzene, local overheating of the catalyst caused by high initial activity of the catalyst can be well inhibited, metal crystal grain growth and excessive hydrogenation of isopropylbenzene to isopropylcyclohexane are avoided, generation of isopropylbenzene is effectively controlled, the operation stability of the catalyst is obviously improved, and meanwhile, the isopropylbenzene selectivity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

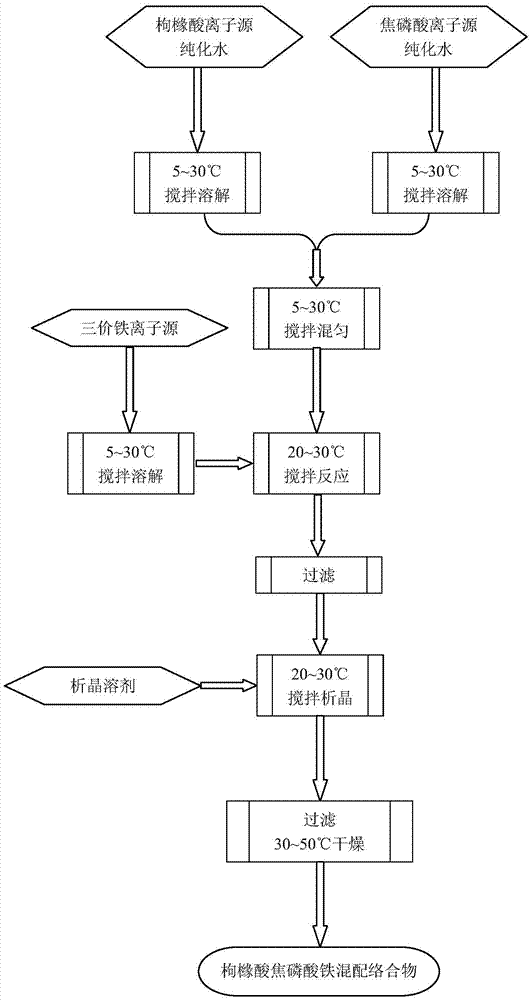

Ferric pyrophosphate citrate mixed complex preparation method

ActiveCN106977552AAvoid decompositionAvoid destructionIron organic compoundsPhosphateIron pyrophosphate

The invention discloses a ferric pyrophosphate citrate mixed complex preparation method, which comprises: (1) preparing an aqueous solution containing trivalent iron cations; (2) respectively preparing an aqueous solution containing citric acid anions and an aqueous solution containing pyrophosphoric acid anions, slowly adding the aqueous solution containing pyrophosphoric acid anions into the aqueous solution containing citric acid anions in a dropwise manner, and uniformly stirring and mixing to obtain a mixed aqueous solution; (3) slowly adding the aqueous solution prepared in the step (1) into the mixed aqueous solution prepared in the step (2) while stirring, carrying out a stirring reaction for 1-2 h after completing the adding to obtain a dark green solution, filtering out insoluble matters, and taking the filtrate; and (4) adding the filtrate obtained in the step (3) into a crystallization solvent in a dropwise manner, continuously stirring for 1-2 h after completing the adding to obtain a slight green precipitate, filtering, and drying the obtained solid so as to obtain the ferric pyrophosphate citrate mixed complex. According to the present invention, with the preparation method, the high-yield phosphate-radical-free ferric pyrophosphate citrate having the low organic impurity content can be stably obtained.

Owner:SHANDONG CHENGCHUANG BLUE OCEAN PHARM TECH CO LTD

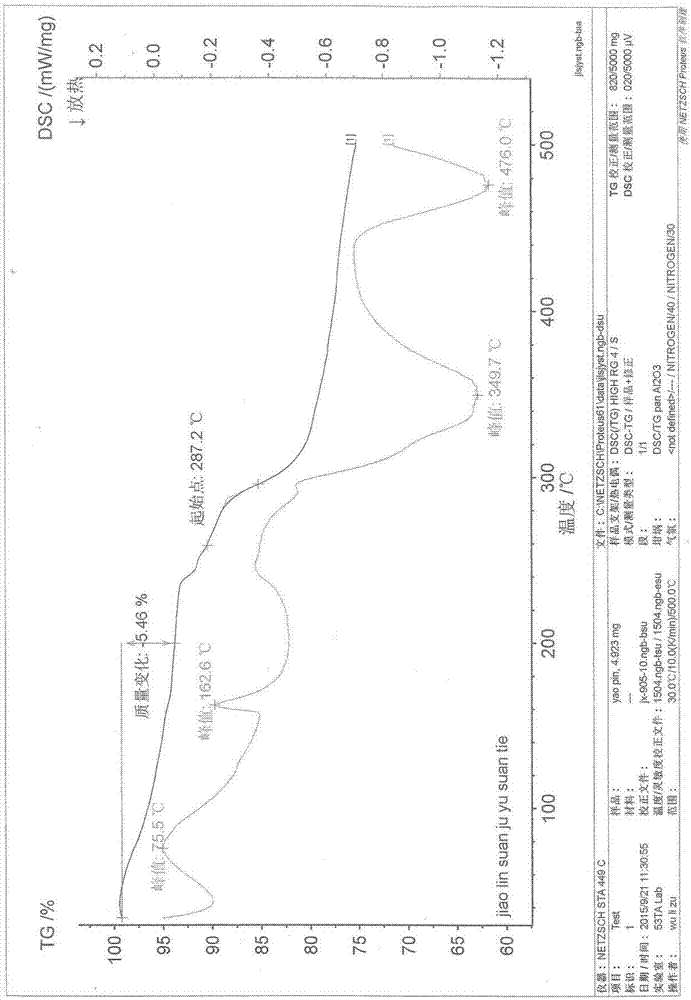

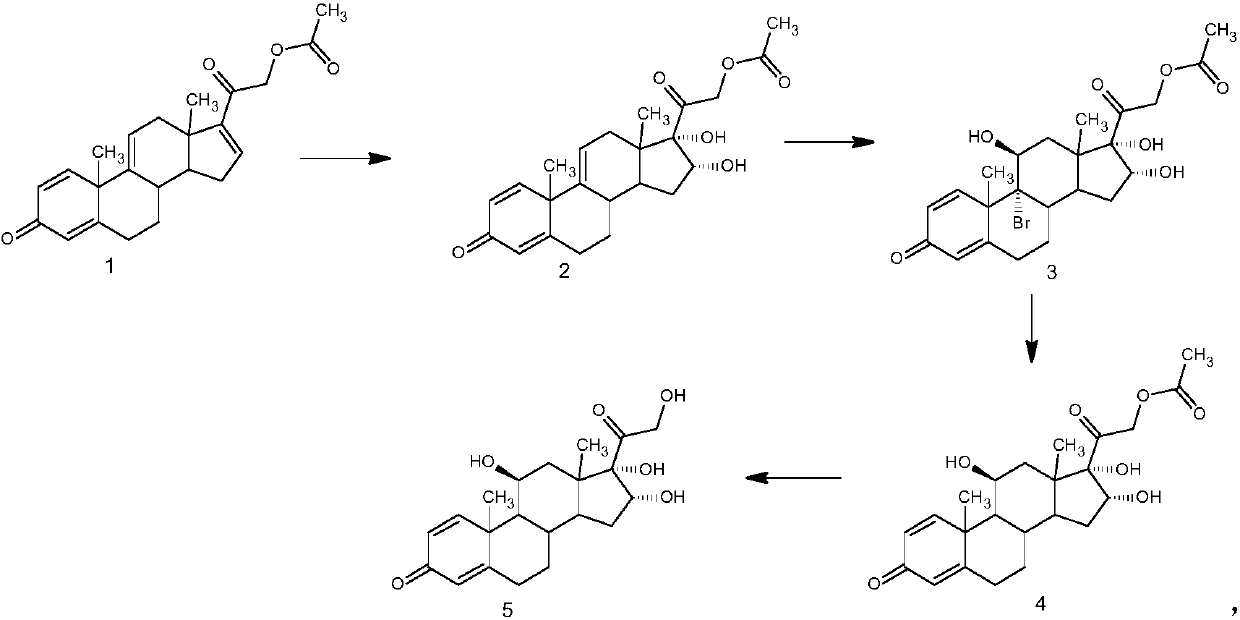

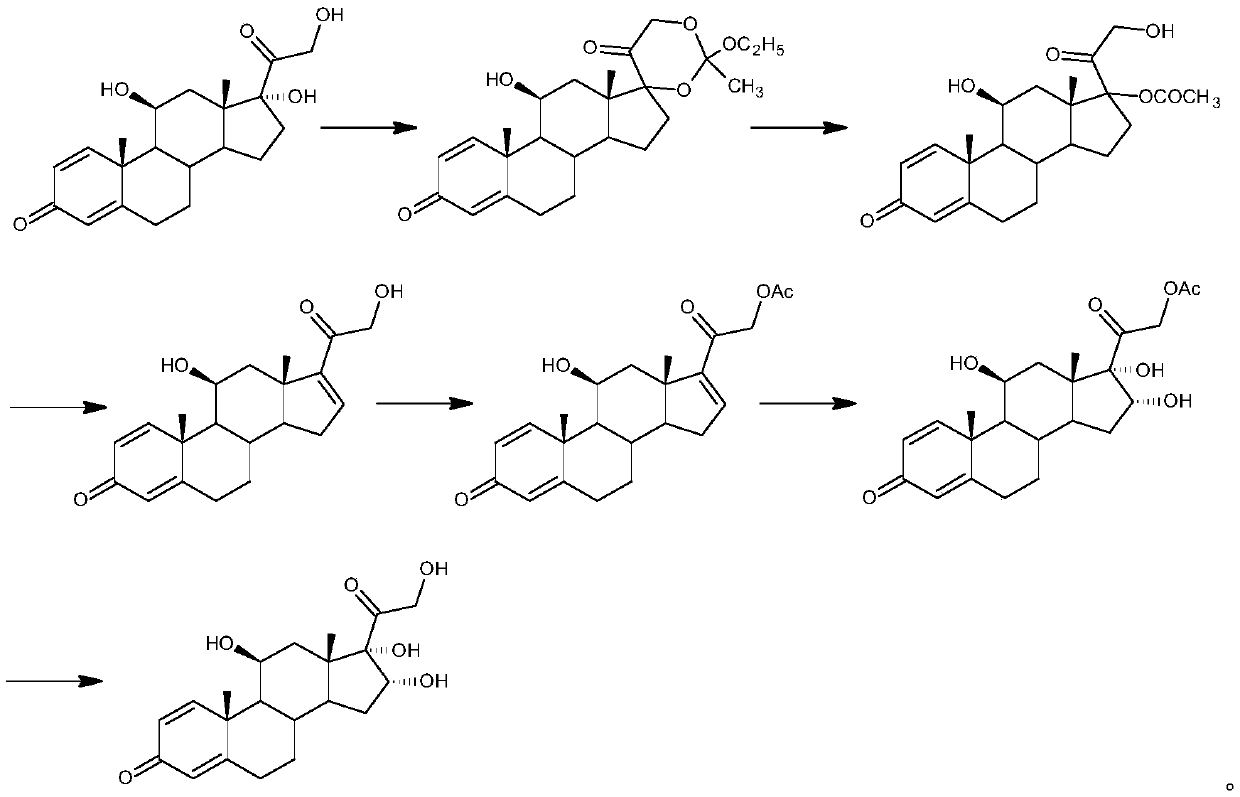

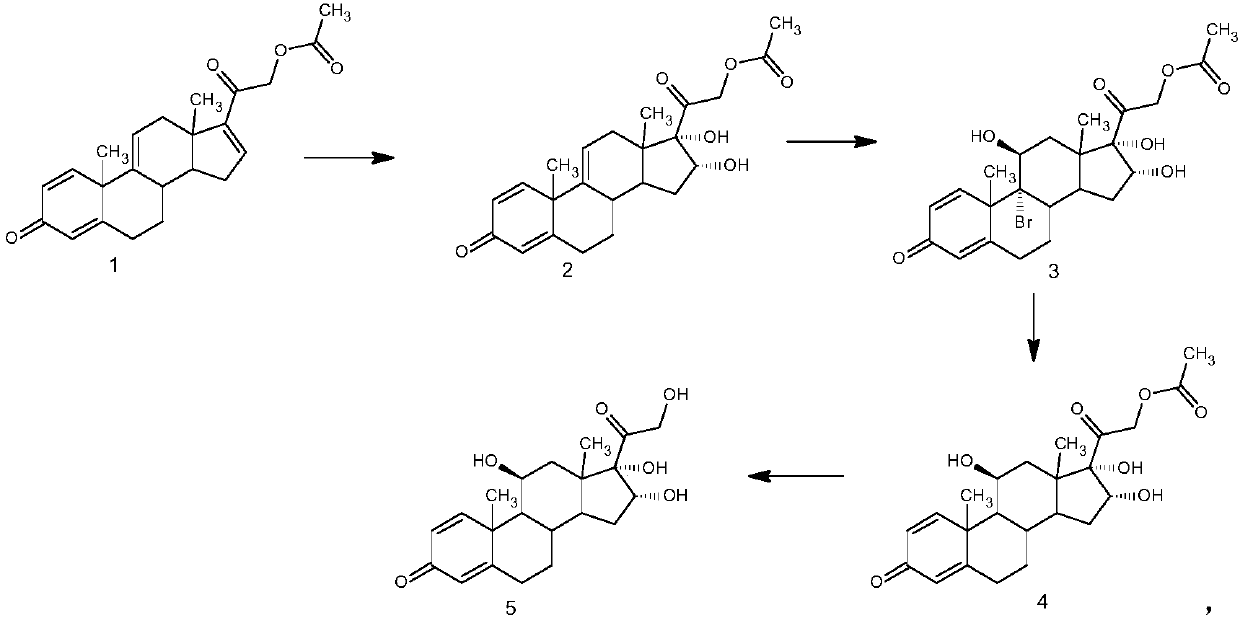

Method for preparing 16 alpha-hydroxyprednisolone

ActiveCN111253457ATo avoidImprove reaction efficiencyOrganic decompositionSteroidsPrednisoloneBiochemical engineering

The invention discloses a method for preparing 16 alpha-hydroxyprednisolone, belonging to the technical field of medicine preparation and processing. According to the method, 21-hydroxypregna-1,4,9(11),16-tetraene-3,20-dione 21-acetate is used as an initial raw material and subjected to oxidation, bromo-hydroxylation, debromination and alcoholysis to prepare 16 alpha-hydroxyprednisolone. Accordingto the method for preparing 16 alpha-hydroxyprednisolone, generation of impurities in the reaction process can be effectively controlled by improving the defects of a traditional process, reaction process is mild, and an overall conversion rate is high; and the method disclosed by the invention has the advantages of low requirements on a reaction device, low operation cost, simplicity and convenience in operation, suitability for industrial production and higher market prospects.

Owner:ZHEJIANG SHENZHOU PHARMA

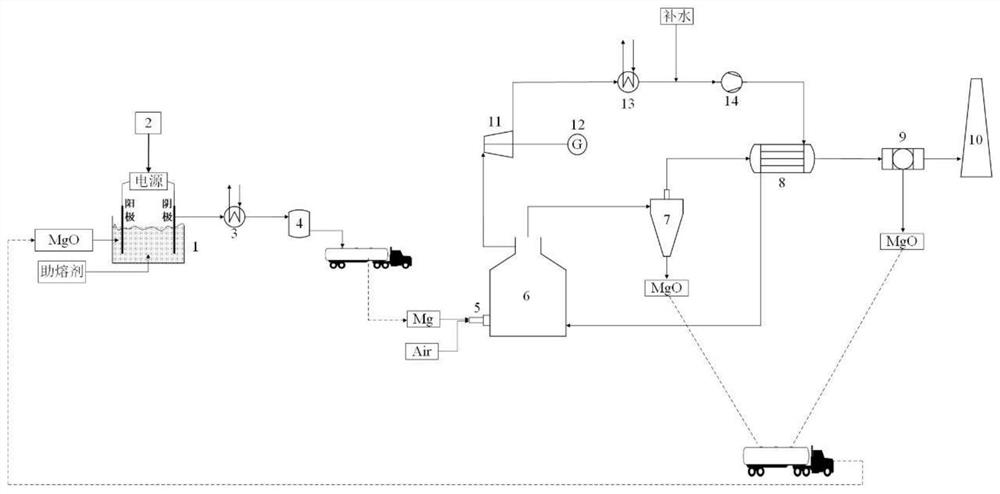

Power generation system taking magnesium as fuel and working method thereof

PendingCN112282878AIncrease energy densityEffective control generationElectrolysis componentsSteam generation plantsElectrolysisHigh energy

The invention discloses a power generation system taking magnesium as fuel and a working method thereof. The power generation system comprises a magnesium fuel electrolysis preparation subsystem, a magnesium combustion and combustion product collection subsystem and a steam Rankine cycle power generation subsystem. By effectively coupling magnesium fuel energy storage, magnesium combustion power generation, steam Rankine cycle, magnesium oxide electrolysis regeneration and the like, the power generation system has the advantages of high energy storage density, long energy storage period, permanent storage, no consumption in fuel circulation regeneration, convenience in development of global energy trade and the like.

Owner:XIAN THERMAL POWER RES INST CO LTD

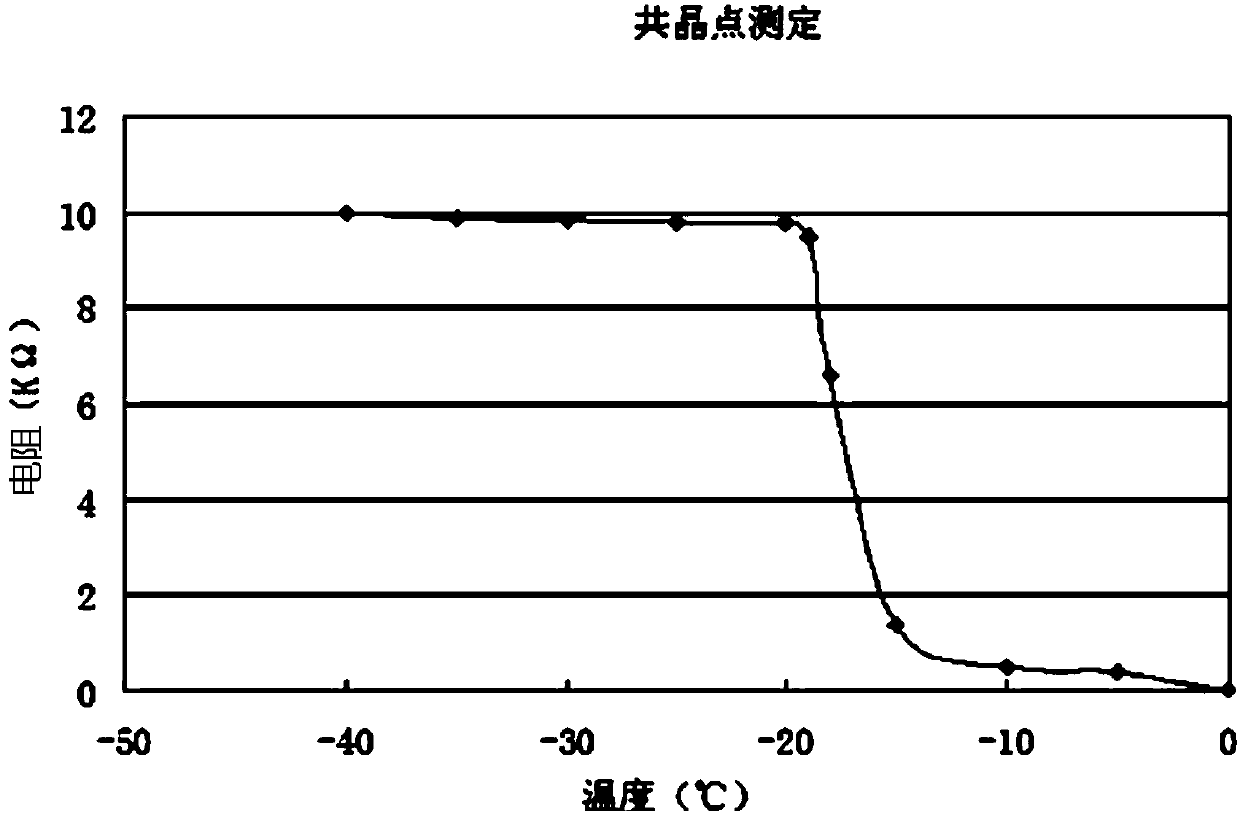

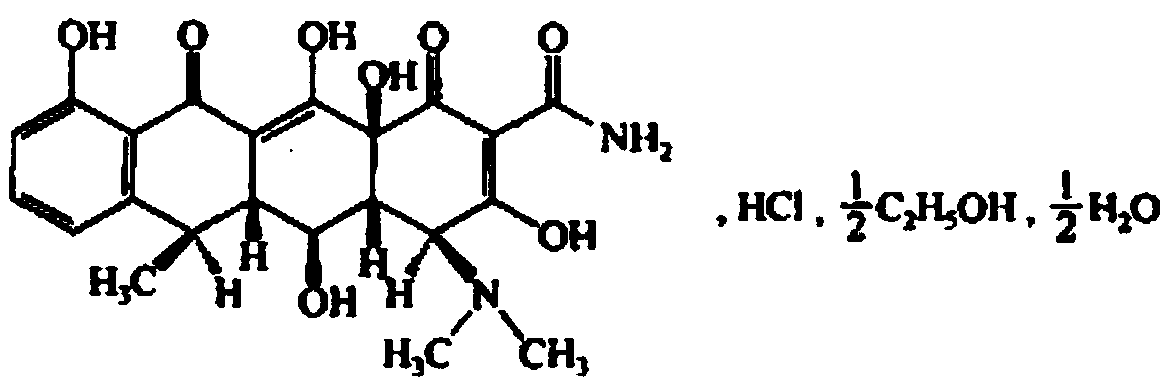

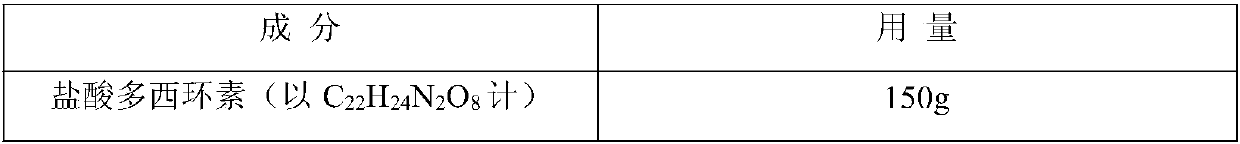

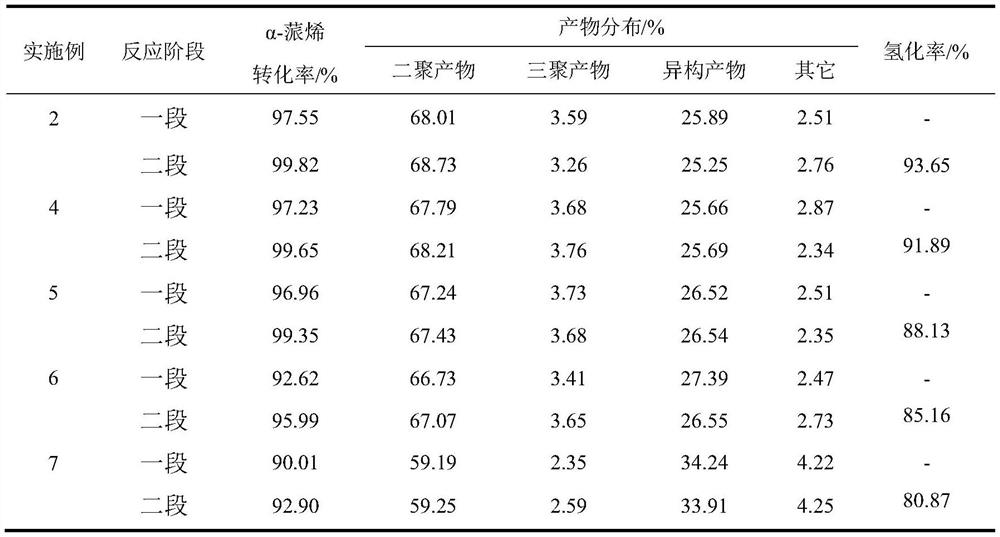

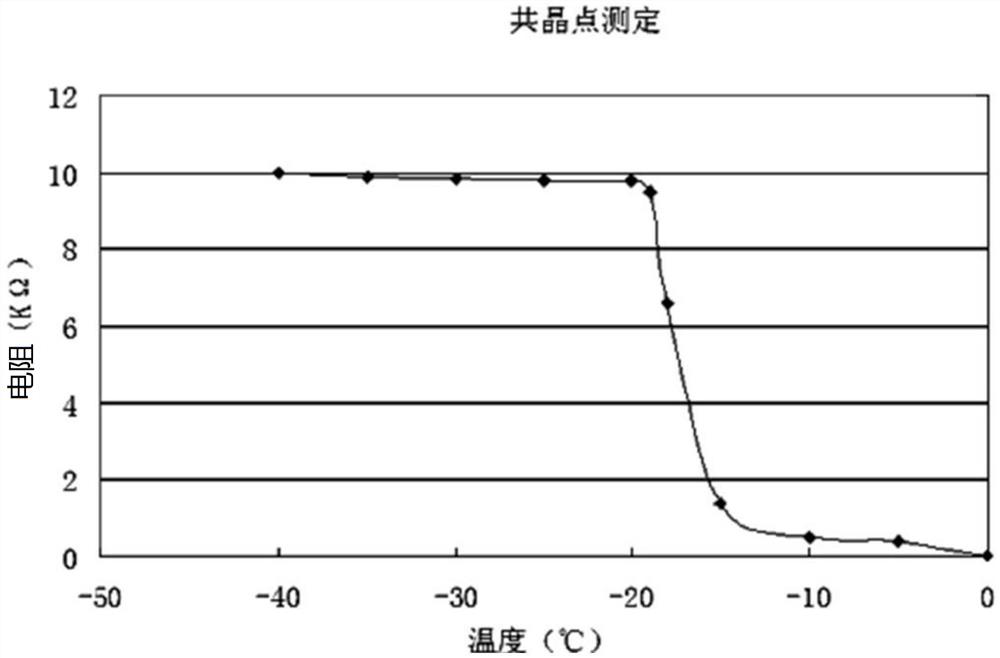

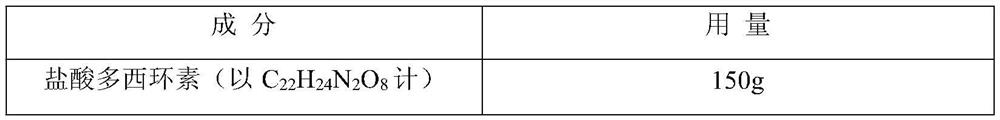

Injection doxycycline hyclate freeze-drying powder and preparation method thereof

ActiveCN107638395AEffective control generationImprove stabilityAntibacterial agentsPowder deliveryPharmaceutical preservativesFreeze dry

The invention relates to injection doxycycline hyclate freeze-drying powder and a preparation method thereof. The freeze-dry powder comprises active components, namely doxycycline hyclate, a stabilizer, an excipient and injection water, wherein the stabilizer is vitamin C and cysteine hydrochloride; the excipient is lactose; the weight ratio of doxycycline hyclate, vitamin C, cysteine hydrochloride to the lactose is (10-20):(40-60):(0.5-1):(30-40). A good eutectic compound is prepared from the doxycycline hyclate, the vitamin C, the cysteine hydrochloride and the lactose. According to the preparation method of the freeze-drying powder, a repeated heating and cooling mode is adopted in pre-freezing, and the analysis drying temperature is appropriately increased. By adopting the technical scheme, the freeze-drying powder is good in shape, full in appearance, loosened and porous and good in redissolubility, controllable in moisture limit and stable in quality, and the storage life of themedicine can be effectively prolonged.

Owner:JINAN KANGHE MEDICAL TECH

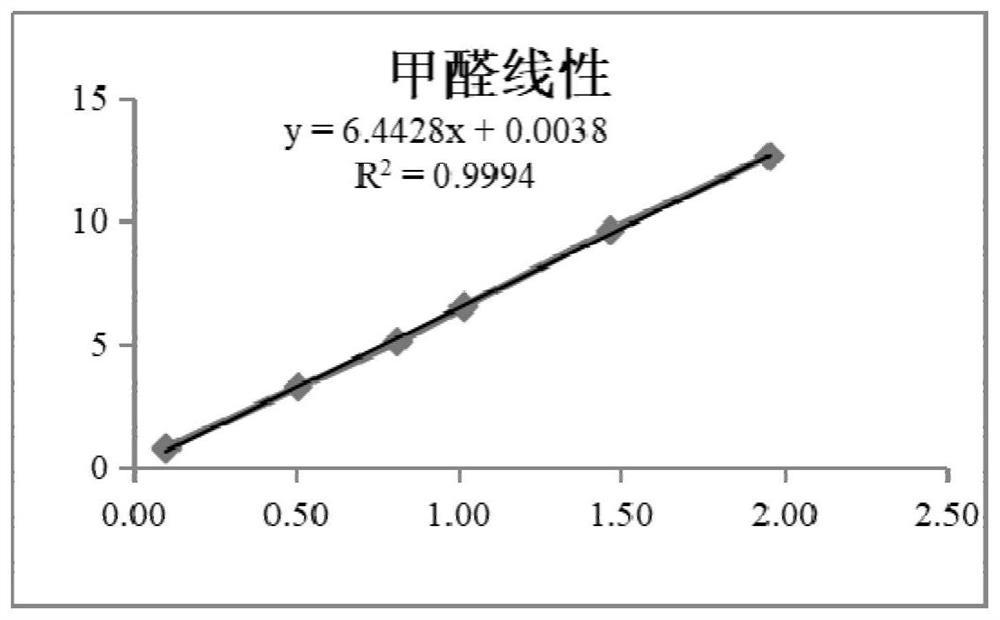

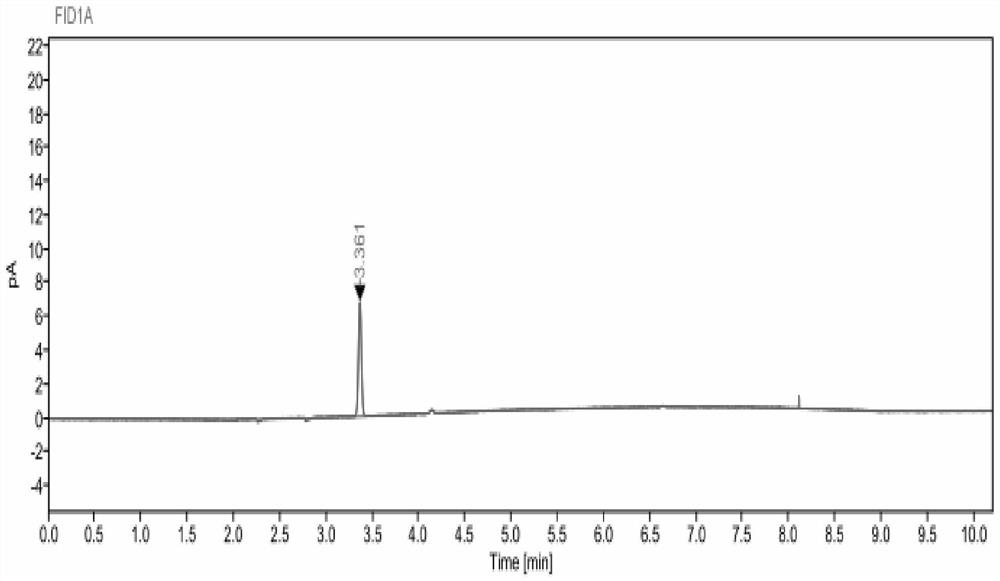

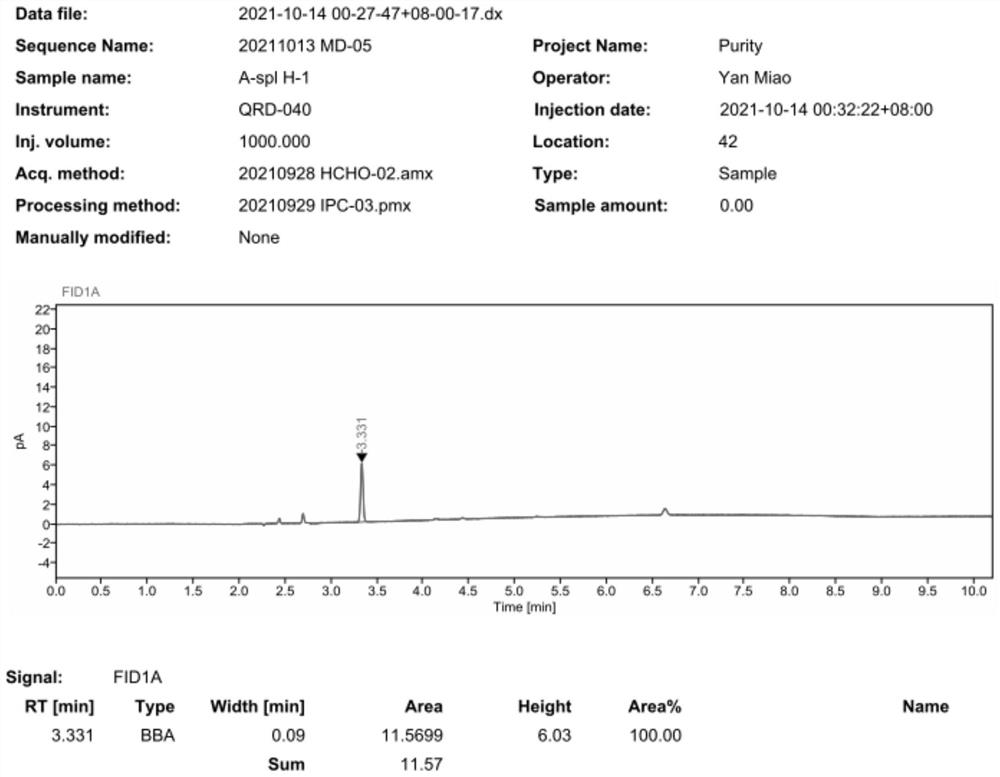

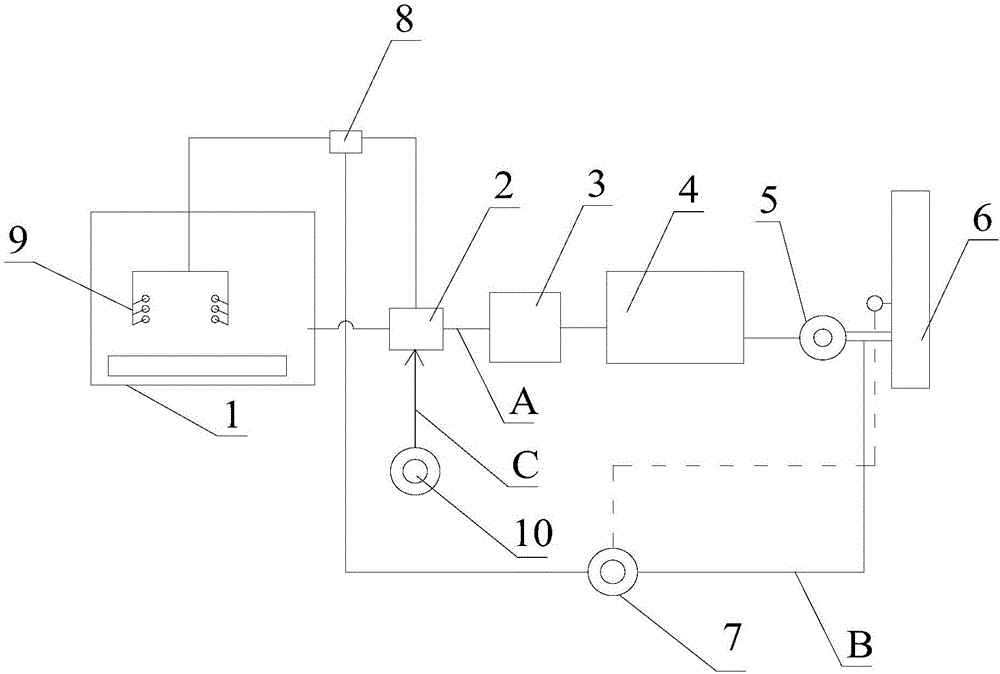

Indirect determination method for impurity content in torasemide injection

PendingCN114487155AEffective control generationLower control costsComponent separationPolyethylene glycolPhysical chemistry

The invention provides an indirect determination method for impurity content in a torasemide injection, which is characterized in that the amount of impurity F is determined by directly determining the reduction amount of polyethylene glycol 400 and the content of formaldehyde in the torasemide injection through headspace gas chromatography. Through analysis, generation of PEG400 and formaldehyde in the technological process is effectively monitored in the production of the torasemide injection. According to the method, the content of formaldehyde in the polyethylene glycol 400 and torasemide injection is detected by headspace gas chromatography; the headspace gas chromatography is adopted, derivatization is not needed, a quartz capillary column, temperature programming, nitrogen serving as carrier gas and a flame ionization detector are used, and the method is easy to operate, high in specificity, high in sensitivity, low in control cost and capable of being used for quantitative analysis.

Owner:江苏睿实生物科技有限公司

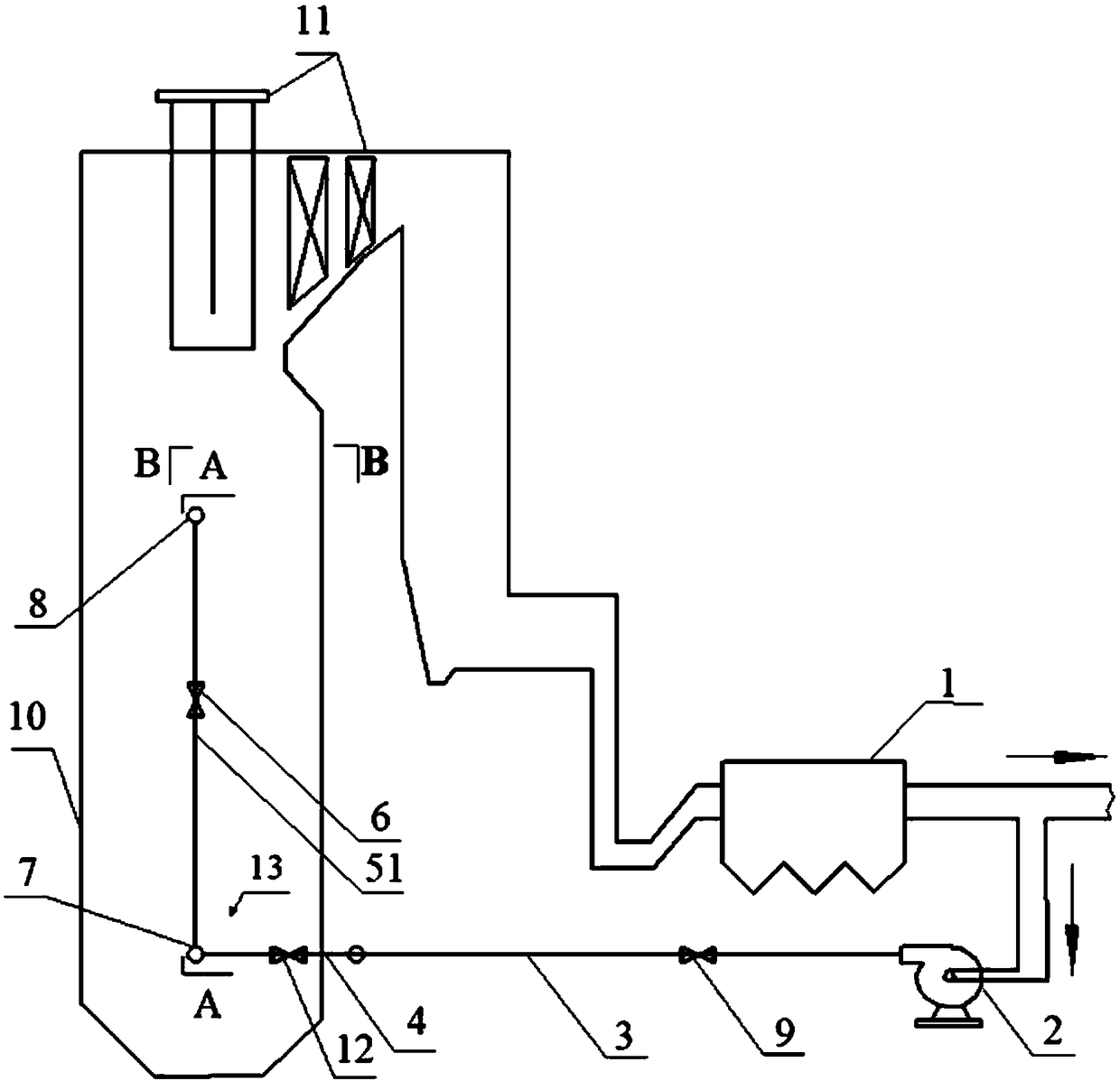

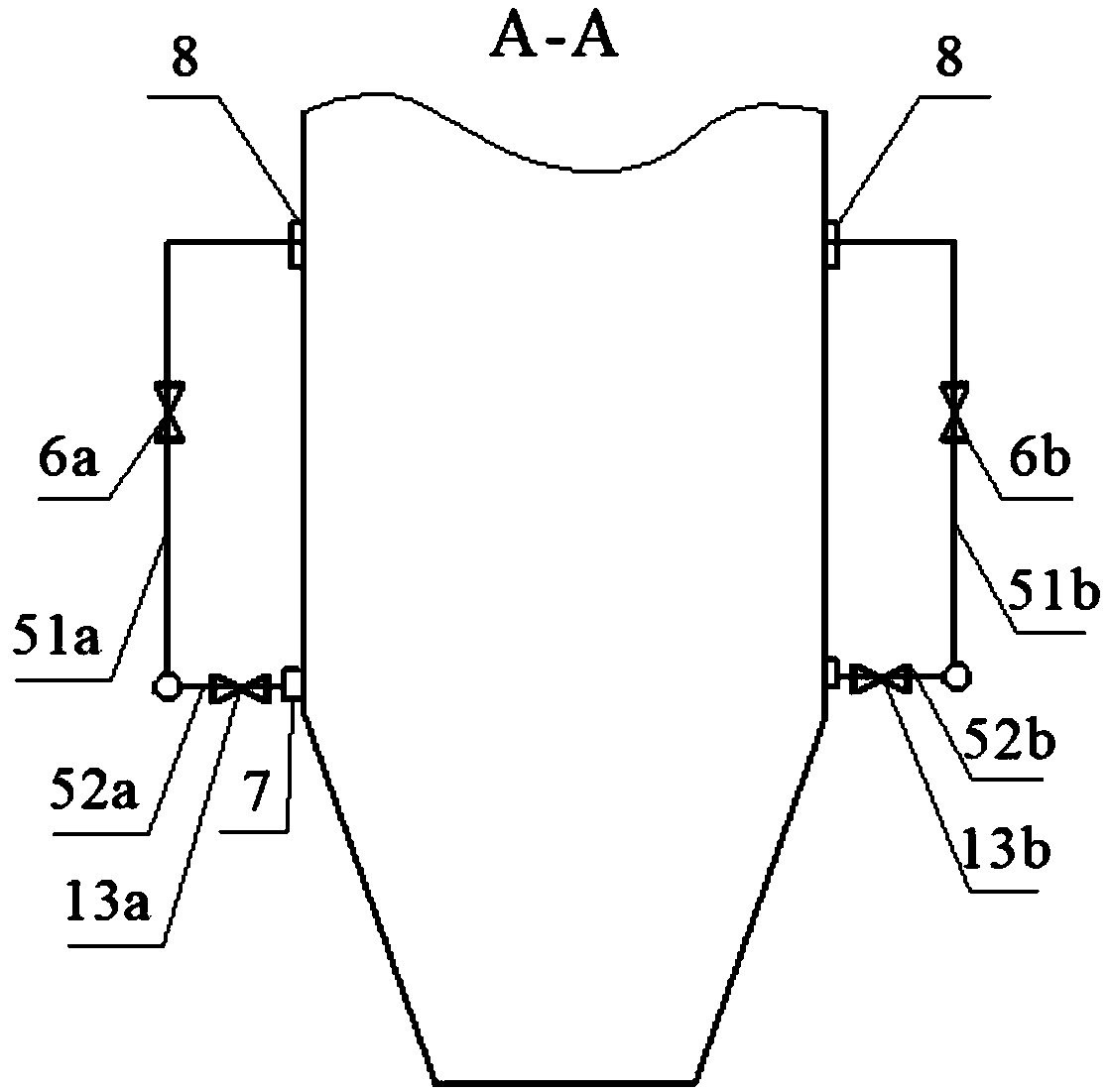

Biomass boiler system with three-gear mixed-air nozzles

ActiveCN106224938AAchieving temperature regulationAchieving regulation of oxygen concentrationSolid fuel combustionIndirect carbon-dioxide mitigationBaghouseEngineering

The invention discloses a biomass boiler system with three-gear mixed-air nozzles. The biomass boiler system comprises a boiler, an air pre-heater, a multi-tube dust remover, a bag-type dust remover, an induced draft fan, a funnel, a backflow draft fan, a mixer, mixed-air nozzle devices and a secondary air fan. A flue gas exhaust opening of the boiler sequentially communicates with the flue gas side of the air pre-heater, the multi-tube dust remover, the bag-type dust remover, the induced draft fan and the funnel through a flue. A flue gas backflow pipe sequentially communicates with the backflow draft fan, the mixer and the mixed-air nozzle devices in the boiler. The two mixed-air nozzle devices each specifically comprises three mixed-air blowing tubes which are arranged in sequence from top to bottom, valves and the corresponding nozzles, wherein each valve and the corresponding nozzle are arranged on the corresponding mixed-air blowing tube. The biomass boiler system with the three-gear mixed-air nozzles is provided with the three-gear mixed-air nozzle devices including the high-gear, the middle-gear and the low-gear; the functions that the flue gas temperature, the oxygen concentration and the like can be adjusted can be achieved; and the biomass boiler system is better in adaptability and greater in operability.

Owner:GUANGZHOU DEVOTION HOME ENVIRONMENT TECH CO LTD

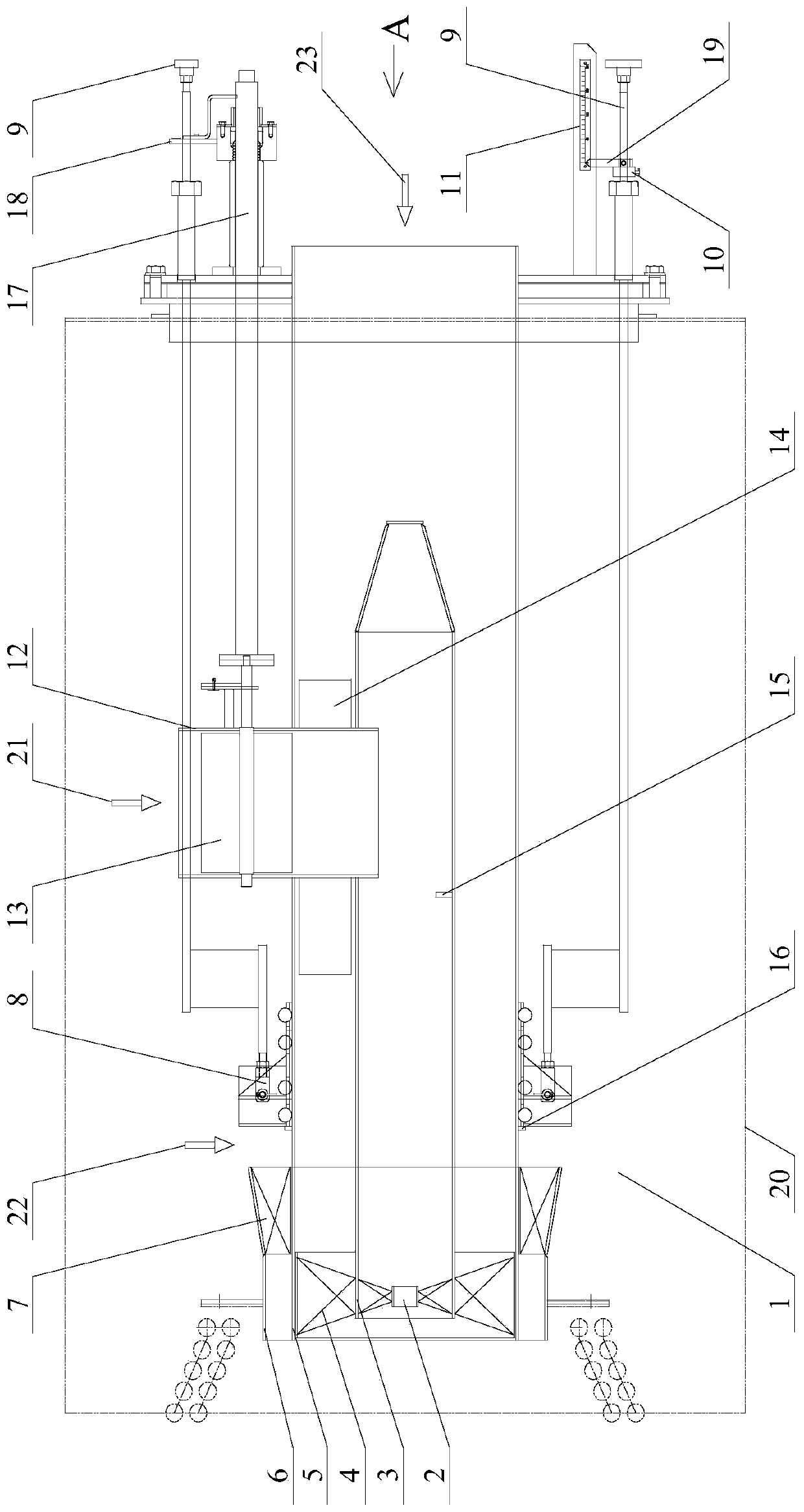

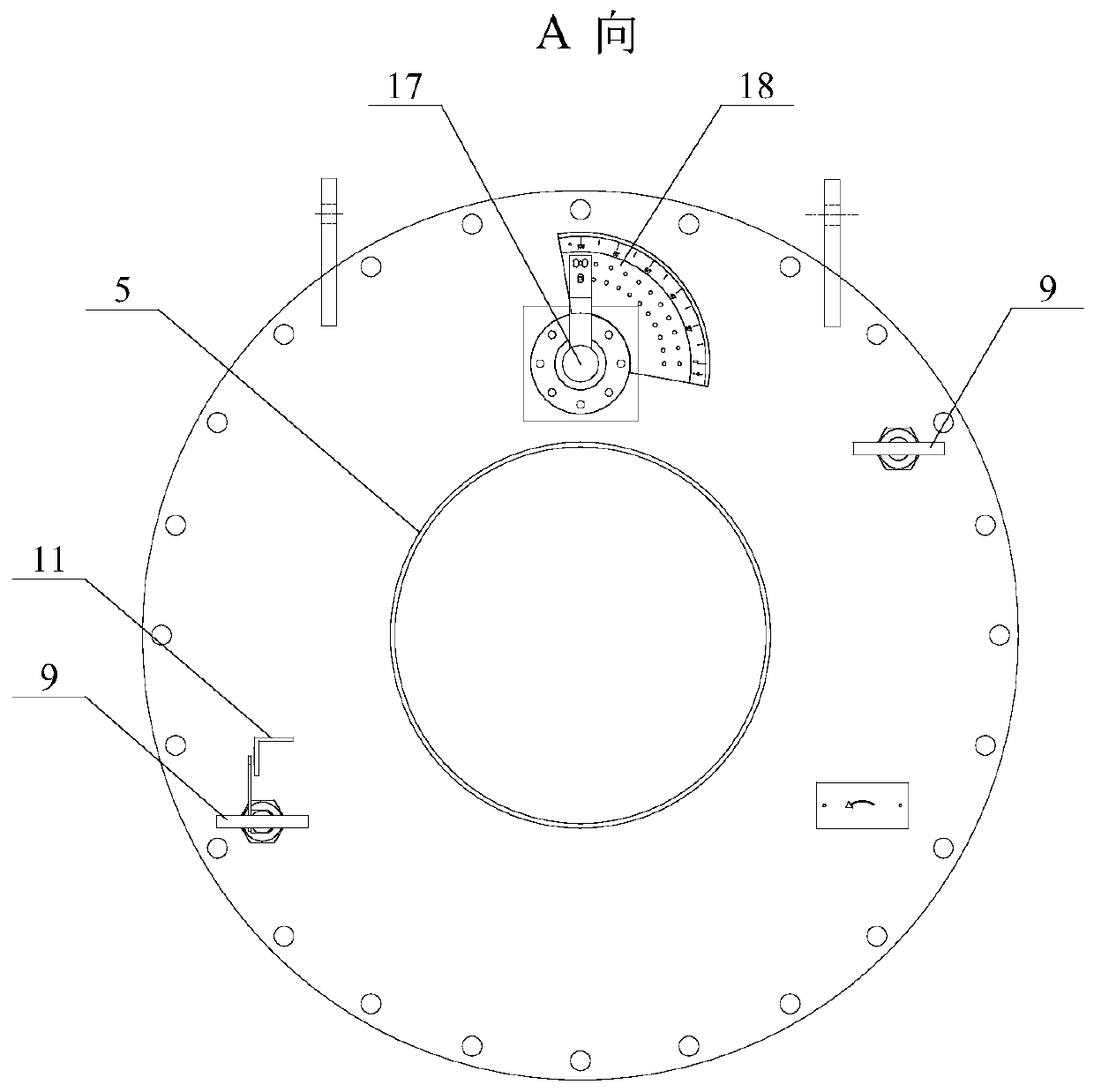

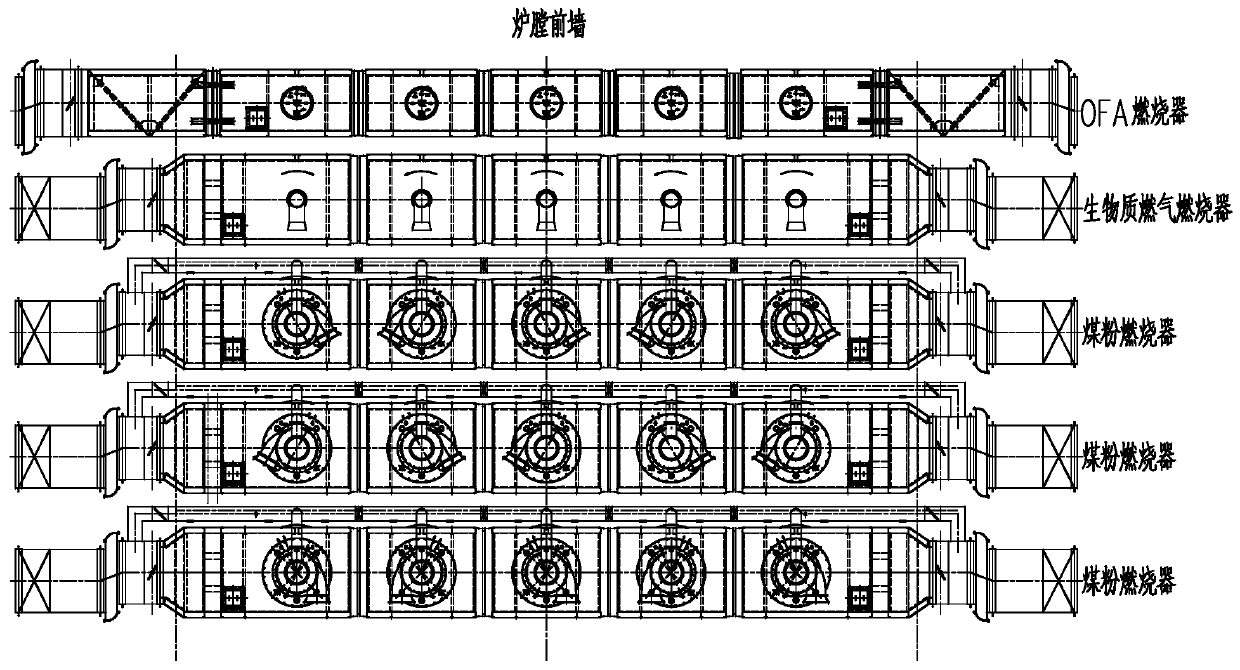

Coal-burning boiler coupling biomass fuel gas combustion device and combustion system arrangement method using same

PendingCN110701604AGuaranteed efficiencyGuaranteed emission concentrationCombustion using gaseous and pulverulent fuelAir supply regulationCombustion systemThermodynamics

The invention provides a coal-burning boiler coupling biomass fuel gas combustion device and a combustion system arrangement method using the coal-burning boiler coupling biomass fuel gas combustion device, and belongs to the technical field of boiler combustion devices and the combustion system arrangement methods of the coal-burning boiler coupling biomass fuel gas combustion devices. A biomassfuel gas combustion device is arranged inside a bellow. A central ventilator is fixed inside a fuel gas channel. The central ventilator and the fuel gas channel are concentrically arranged. A secondary air duct is fixed on the outside of the back end of the fuel gas channel. The secondary air duct and the fuel gas channel are concentrically arranged. A secondary wind swirl device is fixed on an air inlet end of the secondary air duct. A central wind swirl device is installed at the back end inside the central ventilator. A fuel gas swirl device is arranged between the back end of the fuel gaschannel and the back end of the central ventilator. A central wind inlet channel is fixed in the center of the fuel gas channel in forward and backward direction and communicates with the central ventilator. According to the combustion system arrangement method using the coal-burning boiler coupling biomass fuel gas combustion device, the biomass fuel gas combustion device is arranged between an upper pulverized coal burner and an OFA burner.

Owner:HARBIN BOILER

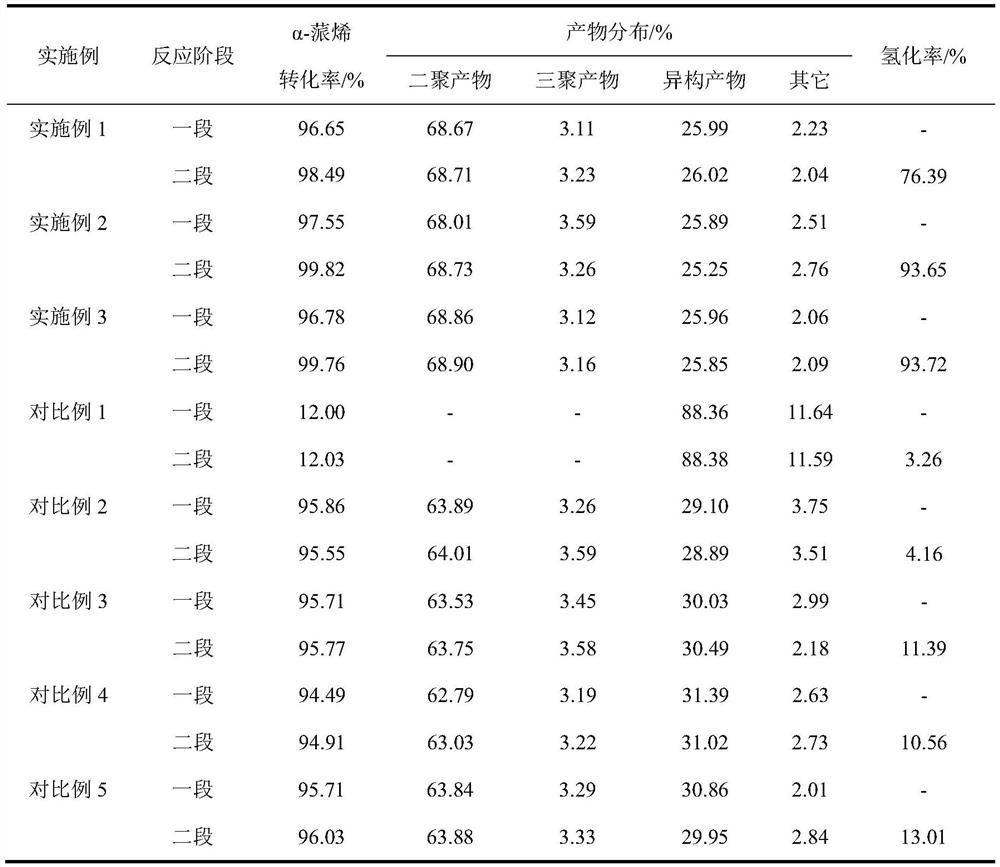

Method for catalyzing dimerization-hydrogenation reaction of alpha-pinene by using bifunctional microporous molecular sieve

ActiveCN112979406AReduce usageHigh activityMolecular sieve catalystsHydrocarbons from unsaturated hydrocarbon additionMolecular sievePtru catalyst

The invention discloses a method for catalyzing a dimerization-hydrogenation two-stage one-pot reaction of alpha-pinene in an intermittent autoclave reactor by adopting Ru metal nanoparticle coupled SOT-Hbeta zeolite as a bifunctional microporous molecular sieve catalyst. The method is characterized in that a seed crystal-organic template method is adopted to construct an Hbeta zeolite skeleton with proper acidity and shape selectivity so as to reduce the use of an organic template; the metal nanoparticles are introduced by adopting an isopyknic alcohol solution impregnation method and a hydrogen reduction method so as to ensure that the catalyst has high activity of both a metal component and a zeolite acid component. The one-pot reaction catalysis method is simple in process operation and excellent in reaction performance, the catalyst is easy to separate and reuse, and a clean and efficient new method is provided for preparation of the turpentine-based biomass high-energy-density fuel.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of doxycycline hydrochloride freeze-dried powder for injection and preparation method thereof

ActiveCN107638395BEffective control generationImprove stabilityAntibacterial agentsPowder deliveryVitamin CDoxycycline hydrochloride

The invention relates to a doxycycline hydrochloride freeze-dried powder for injection and a preparation method thereof. The freeze-dried powder comprises an active ingredient doxycycline hydrochloride, a stabilizer, an excipient and water for injection. The stabilizer is vitamin C, cysteine hydrochloride; the excipient is lactose. The weight ratio of doxycycline hydrochloride: vitamin C: cysteine hydrochloride: lactose is 10-20: 40-60: 0.5-1: 30-40. Doxycycline hydrochloride, vitamin C, cysteine hydrochloride, and lactose can form a good co-crystal compound. In the preparation method of the freeze-dried powder, the pre-freezing adopts the method of repeated heating and cooling, and the analytical drying temperature is appropriately increased. The freeze-dried powder prepared by the technical scheme is well formed, has a plump appearance, is loose and porous, and has good resolubility. The moisture limit of the freeze-dried preparation is controllable, the quality is stable, and the storage period of the medicine can be effectively extended.

Owner:JINAN KANGHE MEDICAL TECH

A horizontal circulating fluidized bed heat conduction oil furnace

ActiveCN103423869BEasy to useEmission reductionFluidized bed combustionStorage heatersCombustion chamberSingle stage

The invention discloses a heat-conduction oil furnace of a horizontal circulating fluidized bed, and relaters to combustion equipment of the circulating fluidized bed for inferior coal, solid wastes, urban and industrial sludge and biomass fuels, in particular to a heat-conduction oil heating device. The heat-conduction oil furnace is mainly composed of a feeding device, a main combustion chamber, an auxiliary combustion chamber, an after-combustion chamber and a cyclone separator, wherein heat-conduction oil coils are arranged in the main combustion chamber and the after-combustion chamber, an economizer and an air pre-heater can be arranged behind the cyclone separator, and a waste heat boiler can also be arranged behind the cyclone separator. The heat-conduction oil heating device adopts a horizontal circulating fluidized bed technology, changes the traditional structural style adopting a chain grate furnace to heat, changes the single-stage and vertical circulating structure of the traditional fluidized bed boiler, effectively reduces the height of the boiler, and reduces the requirement on the construction height of plants. Through reasonable structural layout, the problem that the circulating fluidized bed boiler is easily abraded is effectively solved, and the heat-conduction oil heating device has wide adaptability to fuels, has high combustion efficiency, and has lower pollutant discharging quantity.

Owner:TSINGHUA UNIV +1

A kind of method that utilizes hydrogen sulfide acid gas containing carbon dioxide to prepare sodium hydrosulfide

ActiveCN103693626BEffective control generationEffective control of residuesProductsReagentsSodium bicarbonateSodium hydrosulfide

The invention discloses a method for preparing sodium hydrosulfide from hydrogen sulfide acid gas containing carbon dioxide, which belongs to the technical field of decarburization. The method comprises the following steps of firstly, mixing buffer solution containing sodium hydroxide and sodium bicarbonate with non-decarburized hydrogen sulfide acid gas to react and absorb carbon dioxide and hydrogen sulfide in the acid gas, so as to obtain decarburized pregnant solution, and then, heating the decarburized pregnant solution to make the sodium hydrosulfide in the decarburized pregnant solution hydrolyze and change into sodium hydroxide, wherein the sodium hydroxide generated by hydrolysis reaction reacts with free alkali and sodium bicarbonate in the decarburized pregnant solution to generate sodium carbonate; conveying the hydrogen sulfide acid gas without carbon dioxide into a tubular mixing reactor, performing reverse absorption with circulated alkali liquor to obtain pregnant solution containing sodium hydrosulfide, evaporating and concentrating the pregnant solution containing sodium hydrosulfide to obtain sodium hydrosulfide products of different levels. The method provided by the invention can remove carbon dioxide from hydrogen sulfide acid gas, and quality of the sodium hydrosulfide product prepared from the decarburized acid gas is controllable and adjustable.

Owner:武穴融泰医药科技有限公司

Olefin polymerization inhibitor used in the alkali washing tower of methanol to olefin unit

ActiveCN106467448BNot targetedEffective control generationHydrocarbon purification/separationHydrocarbonsAlcoholTower

The invention relates to an olefin polymerization inhibitor for an alkali-washing tower of a methanol-to-olefin production device. The olefin polymerization inhibitor mainly solves the problem that the conventional olefin polymerization inhibitor has poor specificity in an alkali-washing tower, has poor effect, is unstable, is operated through complex processes, has high toxicity and a high cost. The olefin polymerization inhibitor comprises, by weight, 0 to 20 parts of an amine compound and 0 to 10 parts of an alcohol compound. The olefin polymerization inhibitor solves the above technical problem and can be used for controlling and preventing the polymerization of olefins in the alkali-washing tower of the methanol-to-olefin production device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole Synthesis method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole](https://images-eureka.patsnap.com/patent_img/96a4c6f8-057b-4327-a380-11f32e52be83/248573DEST_PATH_IMAGE001.png)

![Synthesis method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole Synthesis method of 11,12-dihydro-11-phenylindole [2,3-a]carbazole](https://images-eureka.patsnap.com/patent_img/96a4c6f8-057b-4327-a380-11f32e52be83/71035DEST_PATH_IMAGE002.png)