Method for catalyzing dimerization-hydrogenation reaction of alpha-pinene by using bifunctional microporous molecular sieve

A microporous molecular sieve and hydrogenation reaction technology, applied in molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve difficult problems, lack of shape-selective properties of mesoporous catalytic materials, affecting low-temperature viscosity of oil products and Freezing point and other issues, to achieve good catalytic performance, easy to separate and reuse, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

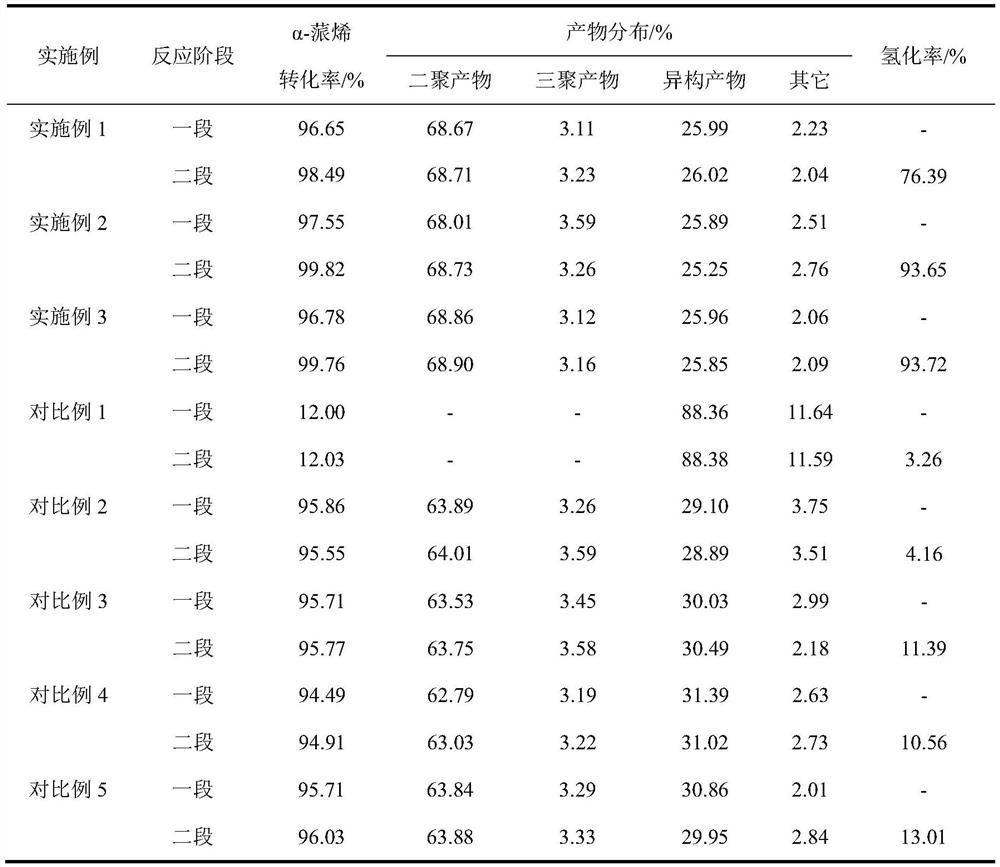

Examples

Embodiment 1

[0016] SiO 2 :Na 2 O: Al 2 o 3 :TEAOH:H 2 O = 1: 0.064: 0.04: 0.43: 10.5 The proportion of substances first NaOH, 25% TEAOH (tetraethylammonium hydroxide) aqueous solution and NaAlO 2 Mix and stir until clear, then slowly add silica, and stir the resulting mixture for 1 h to obtain a transparent viscous gel. After the gel was completely dried in a vacuum oven at 70°C, it was ground and transferred to a 20 mL polytetrafluoroethylene liner, and then the liner containing the precursor was placed in another 100 mL liner with 0.5 mL deionized water at the bottom. The polytetrafluoroethylene lining was transferred to a hydrothermal reaction kettle for crystallization at 150°C for 24h. Wash the obtained solid with water and ethanol, dry it, and heat it up to 550°C at a rate of 1.67°C / min for 4 hours to remove the template agent, and then use 1.0mol / L NH 4 The Cl solution was ion-exchanged at 80° C. for 1 h, filtered, washed and dried, and then calcined in a muffle furnace at 55...

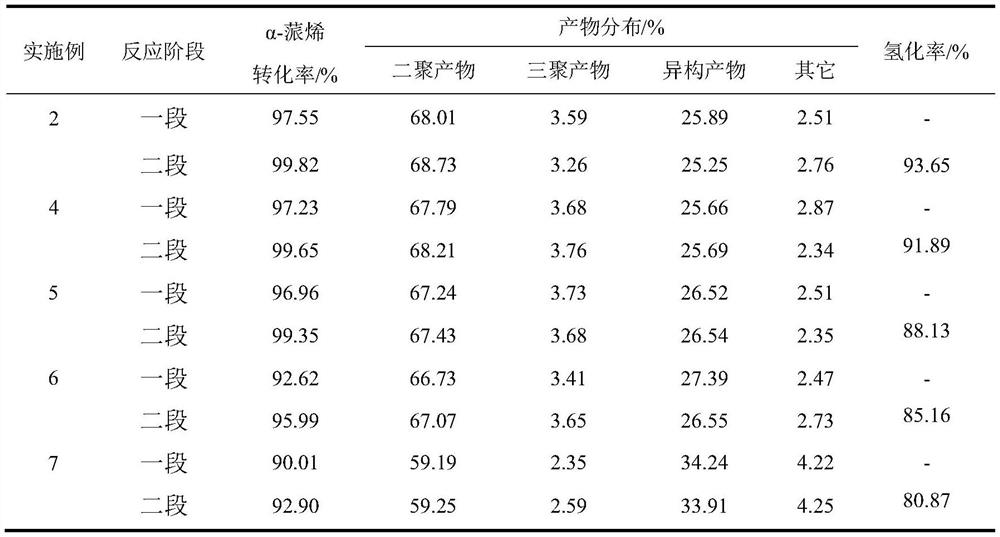

Embodiment 2

[0021] SiO 2 :Na 2 O: Al 2 o 3 :TEAOH:H 2 O = 1: 0.064: 0.04: 0.43: 10.5 The proportion of substances first NaOH, 25% TEAOH (tetraethylammonium hydroxide) aqueous solution and NaAlO 2 Mix and stir until clear, then slowly add silica, and stir the resulting mixture for 1 h to obtain a transparent viscous gel. After the gel was completely dried in a vacuum oven at 70°C, it was ground and transferred to a 20 mL polytetrafluoroethylene liner, and then the liner containing the precursor was placed in another 100 mL liner with 0.5 mL deionized water at the bottom. The polytetrafluoroethylene lining was transferred to a hydrothermal reaction kettle for crystallization at 150°C for 24h. Wash the obtained solid with water and ethanol, dry it, and heat it up to 550°C at a rate of 1.67°C / min for 4 hours to remove the template agent, and then use 1.0mol / L NH 4 The Cl solution was ion-exchanged at 80° C. for 1 h, filtered, washed and dried, and then calcined in a muffle furnace at 55...

Embodiment 3

[0026] SiO 2 :Na 2 O:Al 2 o 3 :TEAOH:H 2 O = 1: 0.064: 0.04: 0.43: 10.5 The proportion of substances first NaOH, 25% TEAOH (tetraethylammonium hydroxide) aqueous solution and NaAlO 2 Mix and stir until clear, then slowly add silica, and stir the resulting mixture for 1 h to obtain a transparent viscous gel. After the gel was completely dried in a vacuum oven at 70°C, it was ground and transferred to a 20 mL polytetrafluoroethylene liner, and then the liner containing the precursor was placed in another 100 mL liner with 0.5 mL deionized water at the bottom. The polytetrafluoroethylene lining was transferred to a hydrothermal reaction kettle for crystallization at 150°C for 24h. Wash the obtained solid with water and ethanol, dry it, and heat it up to 550°C at a rate of 1.67°C / min for 4 hours to remove the template agent, and then use 1.0mol / L NH 4 The Cl solution was ion-exchanged at 80° C. for 1 h, filtered, washed and dried, and then calcined in a muffle furnace at 550...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com