Boiler smoke recirculation system and method

A recirculation system and boiler flue gas technology, applied in the boiler flue gas recirculation system and combustion field, can solve the problems of difficult nitrogen oxide concentration, increase boiler operating cost, pollution, etc., to reduce emissions and improve pollution. Problems, the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0024] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

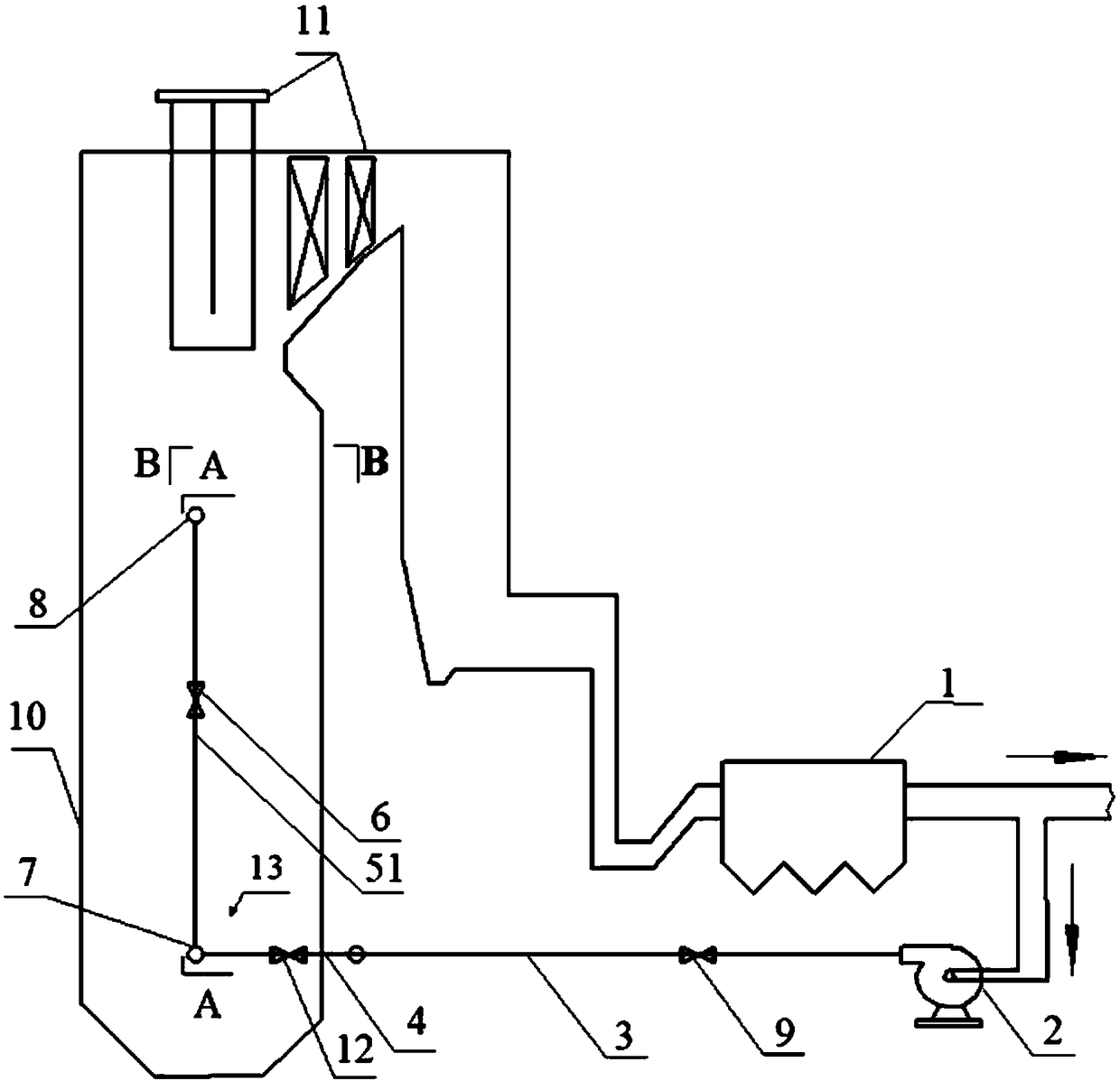

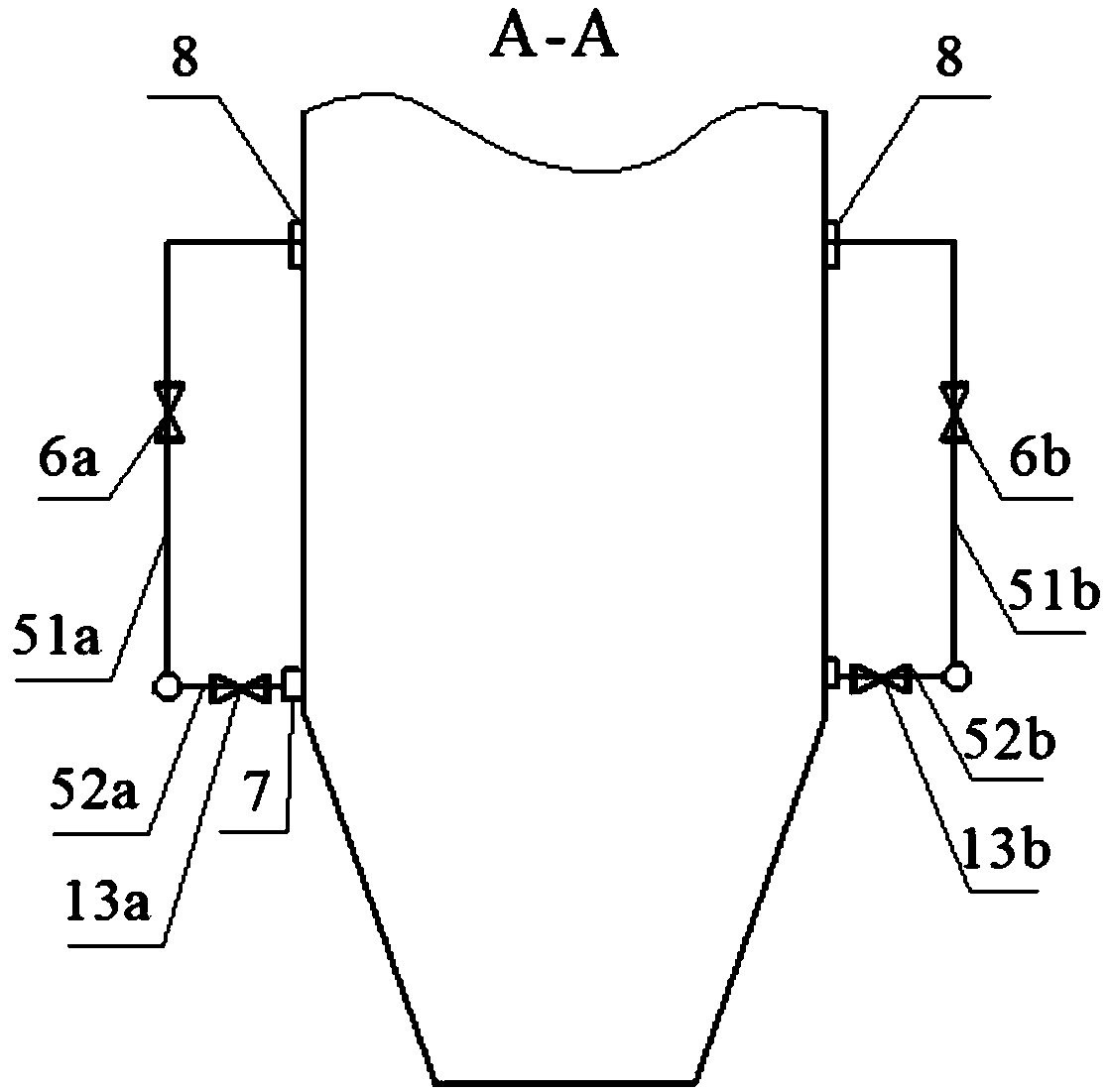

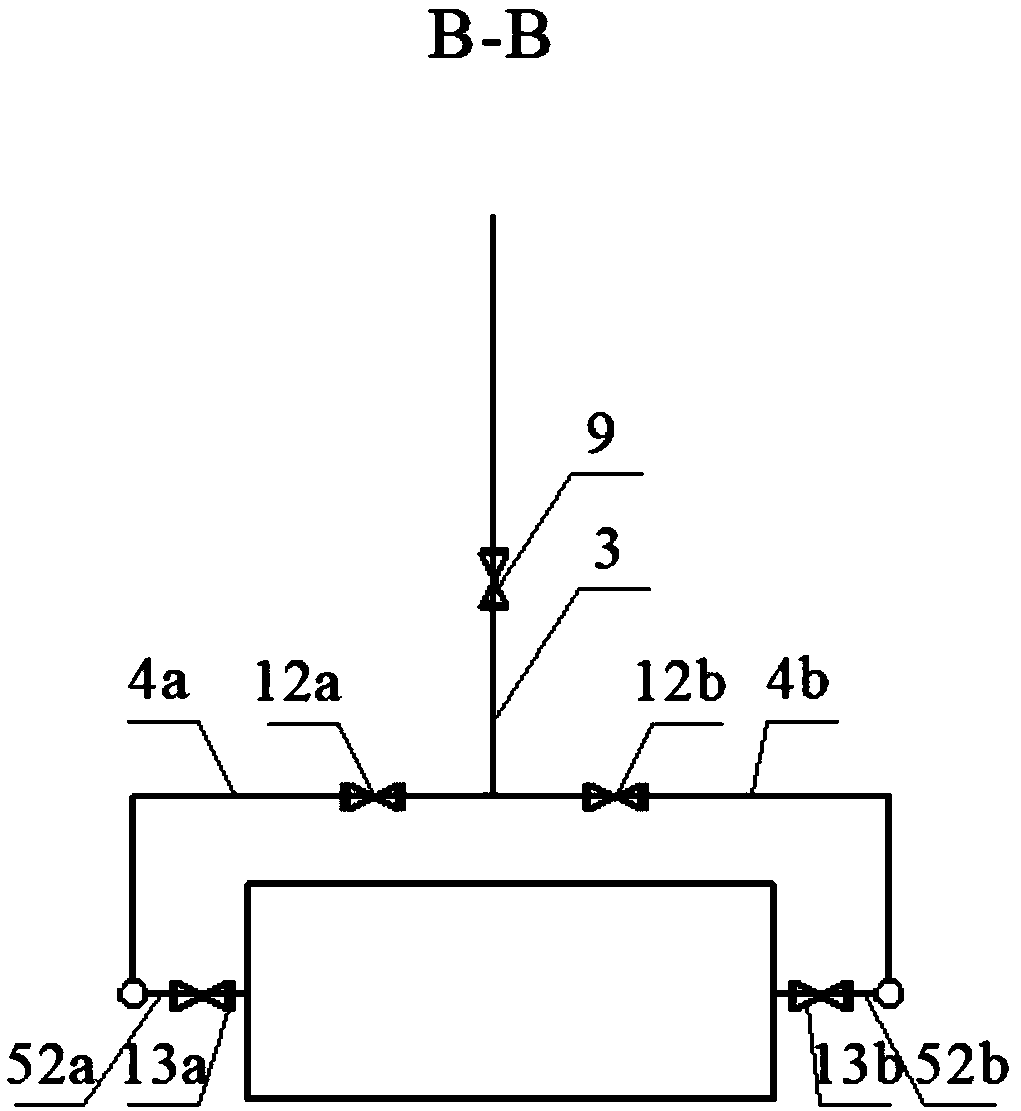

[0025] Such as figure 1 As shown, a boiler flue gas recirculation system includes a fan 2, a main air duct 3, a sub-air duct 4, and a nozzle group 5, etc. The system can be used to return flue gas from the boiler dust collector 1 outlet to the boiler furnace 10 . The last-stage burn-out air outlet on the upper part of the furnace 10 is the OFA air supply port 8, and the last-stage burn-out air usually refers to the burn-out air or secondary air at the highest part of the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com